Top Management, Green Innovations, and the Mediating Effect of Customer Cooperation in Green Supply Chains

Abstract

1. Introduction

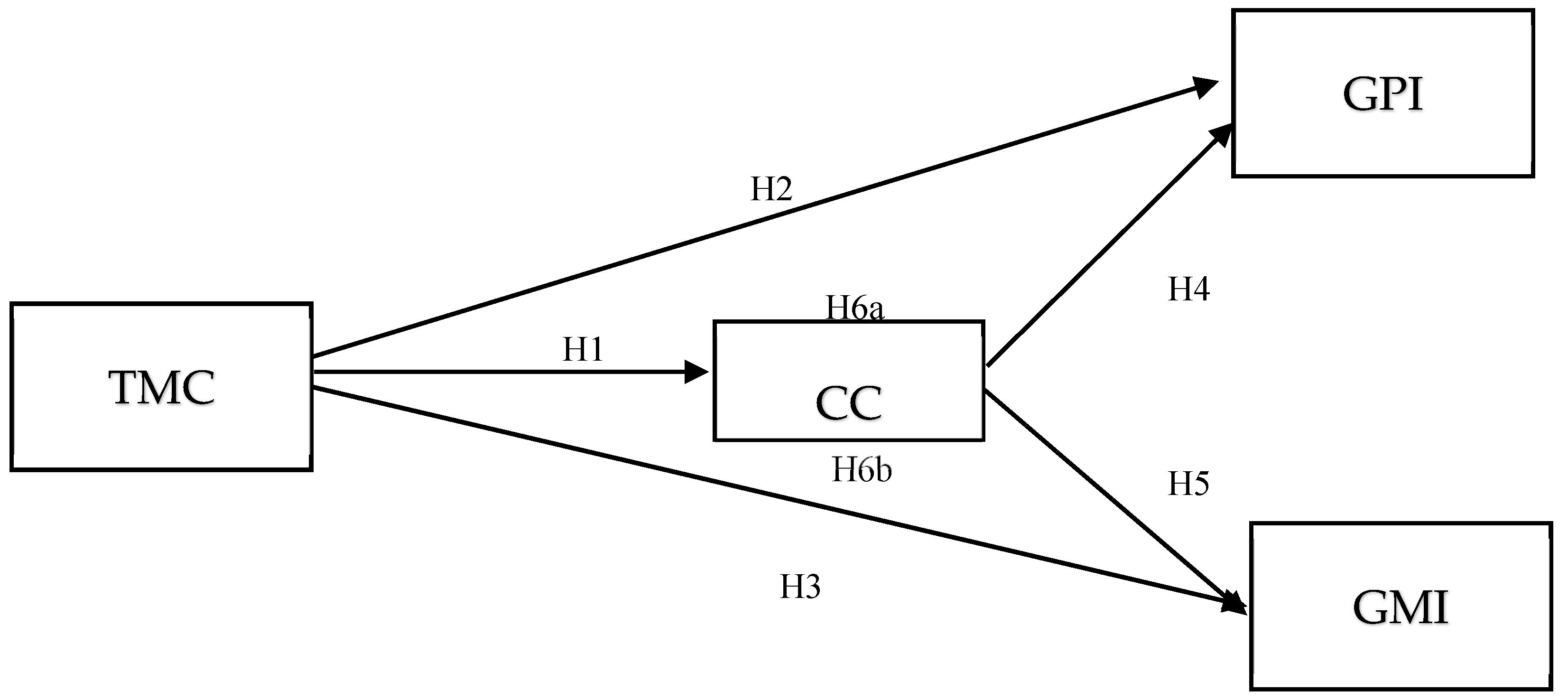

2. Conceptual Model and Hypotheses

2.1. Top Management, Customer Cooperation and Green Innovations

2.2. Customer Cooperation and Green Innovations

2.3. Mediation Effect

3. Empirical Setting and Measurements

3.1. Measurements

3.2. Validation of Constructs

4. Results

4.1. SEM Analysis

4.2. The Mediation Analysis

5. Discussions and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Nanath, K.; Pillai, R.R. The influence of green is practices on competitive advantage: Mediation role of green innovation performance. Inf. Syst. Manag. 2017, 34, 3–19. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green product innovation in manufacturing firms: A sustainability-oriented dynamic capability perspective. Bus. Strategy Environ. 2017, 26, 490–506. [Google Scholar] [CrossRef]

- Wu, W.; Liu, Y.; Chin, T.; Zhu, W. Will Green CSR Enhance Innovation? A Perspective of Public Visibility and Firm Transparency. Int. J. Environ. Res. Public Health 2018, 15, 268. [Google Scholar] [CrossRef] [PubMed]

- Lam, J.S.L.; Van de Voorde, E. Green Port Strategy for Sustainable Growth and Development. In Transport Logistics for Sustainable Growth at a New Level, International Forum on Shipping. Ports and Airports. Available online: http://www.icms.polyu.edu.hk/Proceedings/Proceedings%20of%20IFSPA%202012.pdf (accessed on 15 February 2019).

- Burki, U.; Ersoy, P.; Dahlstrom, R. Achieving triple bottom line performance in manufacturer-customer supply chains: Evidence from an emerging economy. J. Clean. Prod. 2018, 197, 1307–1316. [Google Scholar] [CrossRef]

- Chen, Y.; Lai, S.; Wen, C. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- GEMI. New Paths to Business Value; GEMI: Washington, DC, USA, 2001. [Google Scholar]

- Sancha, C.; Wong, C.W.; Thomsen, C.G. Buyer–supplier relationships on environmental issues: A contingency perspective. J. Clean. Prod. 2016, 112, 1849–1860. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Guoyou, Q.; Saixing, Z.; Chiming, T.; Haitao, Y.; Hailiang, Z. Stakeholders’ influences on corporate green innovation strategy: A case study of manufacturing firms in China. Corp. Soc. Responsib. Environ. Manag. 2013, 20, 1–14. [Google Scholar] [CrossRef]

- Hoejmose, S.; Brammer, S.; Millington, A. “Green” supply chain management: The role of trust and top management in B2B and B2C markets. Ind. Mark. Manag. 2012, 41, 609–620. [Google Scholar] [CrossRef]

- Burki, U.; Dahlstrom, R. Mediating effects of green innovations on interfirm cooperation. Australas. Mark. J. 2017, 25, 149–156. [Google Scholar] [CrossRef]

- Gerstberger, C.; Yaneva, D. Analysis of EU-27 Household Final Consumption Expenditure—Baltic Countries and Greece Still Suffering Most from the Economic and Financial Crisis; Eurostat Statistics in Focus: Brussels, Belgium, 2013. [Google Scholar]

- Gunday, G.; Ulusoy, G.; Kilic, K.; Alpkan, L. Effects of innovation types on firm performance. Int. J. Prod. Econ. 2011, 133, 662–676. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Shankar, K.M. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Chen, Y.S. The driver of green innovation and green image–green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Tseng, M.L.; Wang, R.; Chiu, A.S.; Geng, Y.; Lin, Y.H. Improving performance of green innovation practices under uncertainty. J. Clean. Prod. 2013, 40, 71–82. [Google Scholar] [CrossRef]

- Govindan, K.; Muduli, K.; Devika, K.; Barve, A. Investigation of the influential strength of factors on adoption of green supply chain management practices: An Indian mining scenario. Resour. Conserv. Recycl. 2016, 107, 185–194. [Google Scholar] [CrossRef]

- Bernauer, T.; Engel, S.; Kammerer, D.; Sejas Nogareda, J. Explaining green innovation: Ten years after Porter’s win-win proposition: How to study the effects of regulation on corporate environmental innovation? Work. Pap. 2006, 17, 1–16. [Google Scholar] [CrossRef]

- Solberg Hjorth, S.; Brem, A.M. How to Assess Market Readiness for an Innovative Solution: The Case of Heat Recovery Technologies for SMEs. Sustainability 2016, 8, 1152. [Google Scholar] [CrossRef]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Roy, M.; Khastagir, D. Exploring role of green management in enhancing organizational efficiency in petro-chemical industry in India. J. Clean. Prod. 2016, 121, 109–115. [Google Scholar] [CrossRef]

- Dangelico, R.M. Green product innovation: Where we are and where we are going. Bus. Strategy Environ. 2015, 25, 560–576. [Google Scholar] [CrossRef]

- Pereira de Carvalho, A.; Barbieri, J.C. Innovation and sustainability in the supply chain of a cosmetics company: A case study. J. Technol. Manag. Innov. 2012, 7, 144–156. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, J.W. Integrating suppliers into green product innovation development: An empirical case study in the semiconductor industry. Bus. Strategy Environ. 2011, 20, 527–538. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Institutional-based antecedents and performance of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 108–117. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Modelling cause and effect relationship among enablers of innovation in SMEs. Benchmark. Int. J. 2018, 25, 1597–1622. [Google Scholar] [CrossRef]

- Huang, Y.C.; Ding, H.B.; Kao, M.R. Salient stakeholder voices: Family business and green innovation adoption. J. Manag. Organ. 2009, 15, 309–326. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Chan, R.Y.; He, H.; Chan, H.K.; Wang, W.Y. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Kearns, G.S.; Sabherwal, R. Strategic alignment between business and information technology: A knowledge-based view of behaviors, outcome, and consequences. J. Manag. Inf. Syst. 2006, 23, 129–162. [Google Scholar] [CrossRef]

- Lee, K.H. Why and how to adopt green management into business organizations? The case study of Korean SMEs in manufacturing industry. Manag. Decis. 2009, 47, 1101–1121. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Chung, S.A.; Kim, G.M. Performance effects of partnership between manufacturers and suppliers for new product development: The supplier’s standpoint. Res. Policy 2003, 32, 587–603. [Google Scholar] [CrossRef]

- Arvanitis, S.; Lokshin, B.; Mohnen, P.; Wörter, M. Impact of external knowledge acquisition strategies on innovation: A comparative study based on Dutch and Swiss panel data. Rev. Ind. Organ. 2015, 46, 359–382. [Google Scholar] [CrossRef]

- Mahr, D.; Lievens, A.; Blazevic, V. The value of customer cocreated knowledge during the innovation process. J. Prod. Innov. Manag. 2013, 31, 599–615. [Google Scholar] [CrossRef]

- Gruner, K.E.; Homburg, C. Does customer interaction enhance new product success? J. Bus. Res. 2000, 49, 1–14. [Google Scholar] [CrossRef]

- Belderbos, R.; Carree, M.; Lokshin, B.; Sastre, J.F. Inter-temporal patterns of R&D collaboration and innovative performance. J. Technol. Transf. 2015, 40, 123–137. [Google Scholar] [CrossRef]

- Chuang, S.H.; Lin, H.N. Co-creating e-service innovations: Theory, practice, and impact on firm performance. Int. J. Inf. Manag. 2015, 35, 277–291. [Google Scholar] [CrossRef]

- Cui, A.S.; Wu, F. Utilizing customer knowledge in innovation: Antecedents and impact of customer involvement on new product performance. J. Acad. Mark. Sci. 2016, 44, 516–538. [Google Scholar] [CrossRef]

- Homburg, C.; Droll, M.; Totzek, D. Customer prioritization: Does it pay off, and how should it be implemented? J. Mark. 2008, 72, 110–130. [Google Scholar] [CrossRef]

- Koufteros, X.A.; Cheng, T.E.; Lai, K.H. “Black-box” and “gray-box” supplier integration in product development: Antecedents, consequences and the moderating role of firm size. J. Oper. Manag. 2007, 25, 847–870. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Nevo, S.; Jin, J.; Wang, L.; Chow, W.S. IT capability and organizational performance: The roles of business process agility and environmental factors. Eur. J. Inf. Syst. 2014, 23, 326–342. [Google Scholar] [CrossRef]

- Geffen, C.; Rothenberg, S. Sustainable development across firm boundaries: The critical role of suppliers in environmental innovation. Int. J. Oper. Prod. Manag. 2000, 20, 166–186. [Google Scholar] [CrossRef]

- Wong, C.W.; Lai, K.H.; Cheng, T.C.E. Complementarities and alignment of information systems management and supply chain management. Int. J. Shipp. Transp. Logist. 2009, 1, 156–171. [Google Scholar] [CrossRef]

- Da Silveira, G.J.; Arkader, R. The direct and mediated relationships between supply chain coordination investments and delivery performance. Int. J. Oper. Prod. Manag. 2007, 27, 140–158. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, Y.; Geng, Y.; Fujita, T. A comparison of regulatory awareness and green supply chain management practices among Chinese and Japanese manufacturers. Bus. Strategy Environ. 2017, 26, 18–30. [Google Scholar] [CrossRef]

- Kim, Y.H.; Wemmerlöv, U. Does a supplier’s operational competence translate into financial performance? An empirical analysis of supplier–customer relationships. Decis. Sci. 2015, 46, 101–134. [Google Scholar] [CrossRef]

- Wallenburg, C.M.; Schäffler, T. The interplay of relational governance and formal control in horizontal alliances: A social contract perspective. J. Supply Chain Manag. 2014, 50, 41–58. [Google Scholar] [CrossRef]

- Chang, C.H. The influence of corporate environmental ethics on competitive advantage: The mediation role of green innovation. J. Bus. Ethics 2011, 104, 361–370. [Google Scholar] [CrossRef]

- Johansson, G.; Sundin, E. Lean and green product development: Two sides of the same coin? J. Clean. Prod. 2014, 85, 104–121. [Google Scholar] [CrossRef]

- Heide, J.B.; John, G. Do norms matter in marketing relationships? J. Mark. 1992, 32–44. [Google Scholar] [CrossRef]

- Preacher, K.J.; Hayes, A.F. Asymptotic and resampling strategies for assessing and comparing indirect effects in multiple mediator models. Behav. Res. Methods 2008, 40, 879–891. [Google Scholar] [CrossRef] [PubMed]

- Strizhakova, Y.; Coulter, R.A.; Price, L.L. Branding in a global marketplace: The mediating effects of quality and self-identity brand signals. Int. J. Res. Mark. 2011, 28, 342–351. [Google Scholar] [CrossRef]

- Pacheco, L.; Liboni, L. Dynamic capabilities for green innovations: A systematic literature review and propositions for future studies. In Proceedings of the EnANPAD 2017, São Paulo, Spain, 1–4 October 2017; pp. 1–16. [Google Scholar]

- Ge, B.; Yang, Y.; Jiang, D.; Gao, Y.; Du, X.; Zhou, T. An empirical study on green innovation strategy and sustainable competitive advantages: Path and boundary. Sustainability 2018, 10, 3631. [Google Scholar] [CrossRef]

| Constructs | The Constructs’ Items Measured on 7-Point Likert-Type Scales with Endpoints Indicating Strongly Disagree and Strongly Agree |

|---|---|

| Customer Cooperation CC: 4 items α = 0.82, CR = 0.83 | Our firm cooperates closely work with… …this customer for green packaging. …this customer to achieve green handling procedures. …this customer to evaluate green sustainable practices. …this customer to implement green sustainable practices. |

| Green Process Innovation GPI: 3 items α = 0.92, CR = 0.93 | Our firm has taken measures... ...to lower the consumption of water, electricity, gas, and petrol during the production/disposal process. ...to recycle, reuse and remanufacture materials or parts. ...to achieve savings in the usage of energy, water and waste. |

| Green Managerial Innovation GMI: 2 items α = 0.67, CR = 0.72 | Our firm has redesigned…… …operation and production processes to meet internal environmental efficiency. …and improved products and services to meet new environmental criteria. |

| Top Management Commitment TMC: 4 items α = 0.87, CR = 0.88 | Our firm’s top management… …strongly support efforts to develop sustainable practices. ...consider sustainable practices as a vital part of corporate strategy. …strongly implement sustainable practices during procurement procedures. …strongly support sustainable practices efforts. |

| Size of the firm | Size: The number of employers in the respondent firm (natural logarithm). |

| Relationship duration | Time: The number of years our firm is doing business with this customer (natural logarithm). |

| TMC | CC | PI | MI | Size | Time | |

|---|---|---|---|---|---|---|

| TMC | 1.00 (0.88) | |||||

| CC | 0.367 | 1.00 (0.55) | ||||

| GPI | 0.492 | 0.560 | 1.00 (0.93) | |||

| GMI | 0.160 | 0.153 | 0.204 | 1.00 (0.57) | ||

| Size | 0.267 | 0.317 | 0.321 | 0.230 | 1.000 | |

| Time | 0.261 | 0.136 | 0.211 | −0.029 | 0.305 | |

| Mean | 3.6119 | 2.7196 | 2.8803 | 3.7459 | 3.8855 | |

| S.D. | 1.0499 | 0.9093 | 1.3374 | 1.0443 | 1.3807 | 1.000 |

| N | 181 | 181 | 181 | 181 | 181 | 181 |

| Paths | Direct Effect | Total Effect | Indirect Effect |

|---|---|---|---|

| TMC => CC => GPI | 0.263 (p < 0.001) | 0.359 (p < 0.001) | 0.138 (p < 0.05) |

| TMC => CC => GMI | 0.201 (p > 0.149) | 0.009 (p< 0.090) | −0.035 (p > 0.658) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burki, U.; Ersoy, P.; Najam, U. Top Management, Green Innovations, and the Mediating Effect of Customer Cooperation in Green Supply Chains. Sustainability 2019, 11, 1031. https://doi.org/10.3390/su11041031

Burki U, Ersoy P, Najam U. Top Management, Green Innovations, and the Mediating Effect of Customer Cooperation in Green Supply Chains. Sustainability. 2019; 11(4):1031. https://doi.org/10.3390/su11041031

Chicago/Turabian StyleBurki, Umar, Pervin Ersoy, and Usama Najam. 2019. "Top Management, Green Innovations, and the Mediating Effect of Customer Cooperation in Green Supply Chains" Sustainability 11, no. 4: 1031. https://doi.org/10.3390/su11041031

APA StyleBurki, U., Ersoy, P., & Najam, U. (2019). Top Management, Green Innovations, and the Mediating Effect of Customer Cooperation in Green Supply Chains. Sustainability, 11(4), 1031. https://doi.org/10.3390/su11041031