Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models

Abstract

1. Introduction

1.1. Background: Review of CBM Visualization Tools

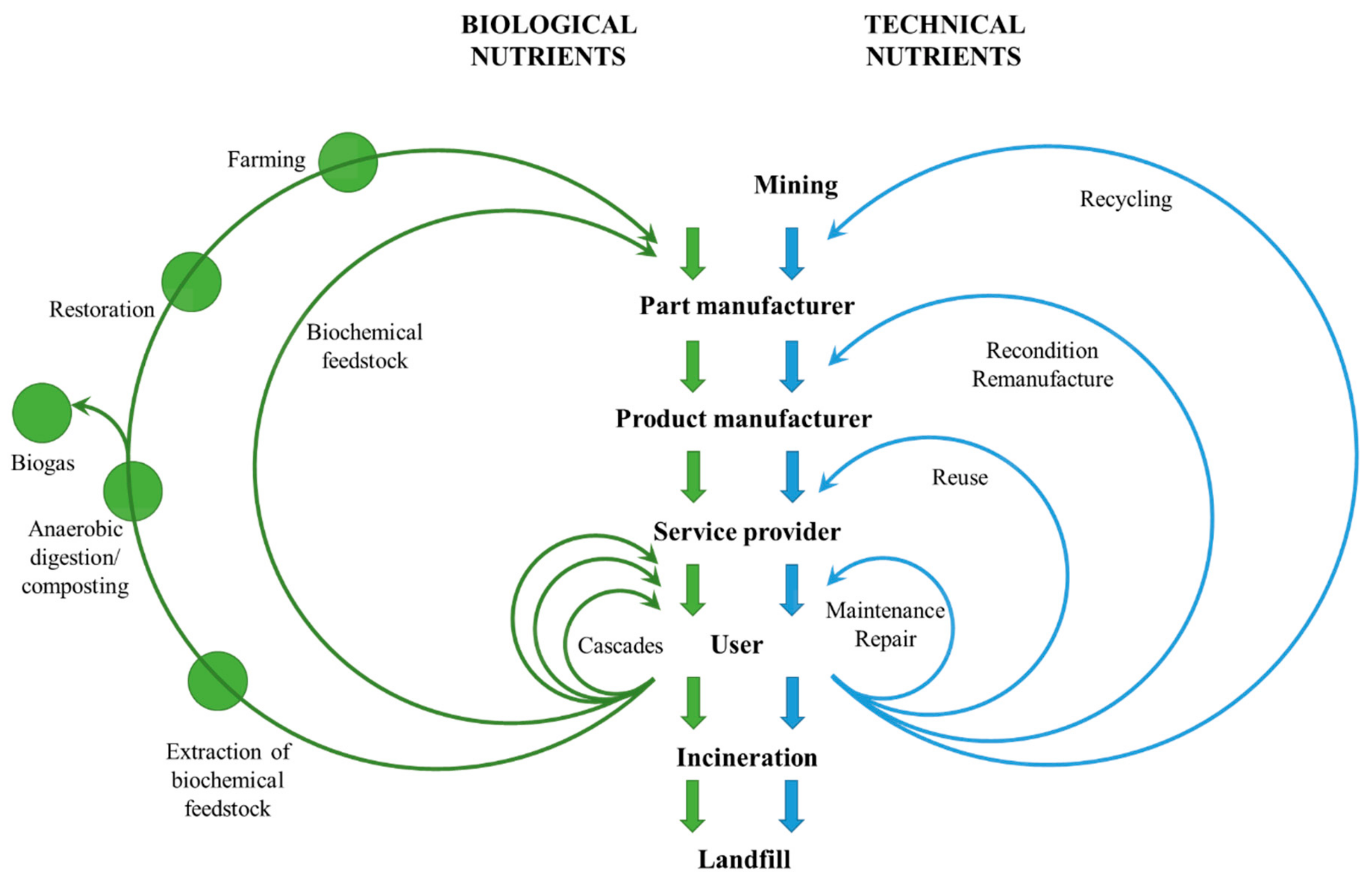

1.1.1. Ellen MacArthur Foundation Model

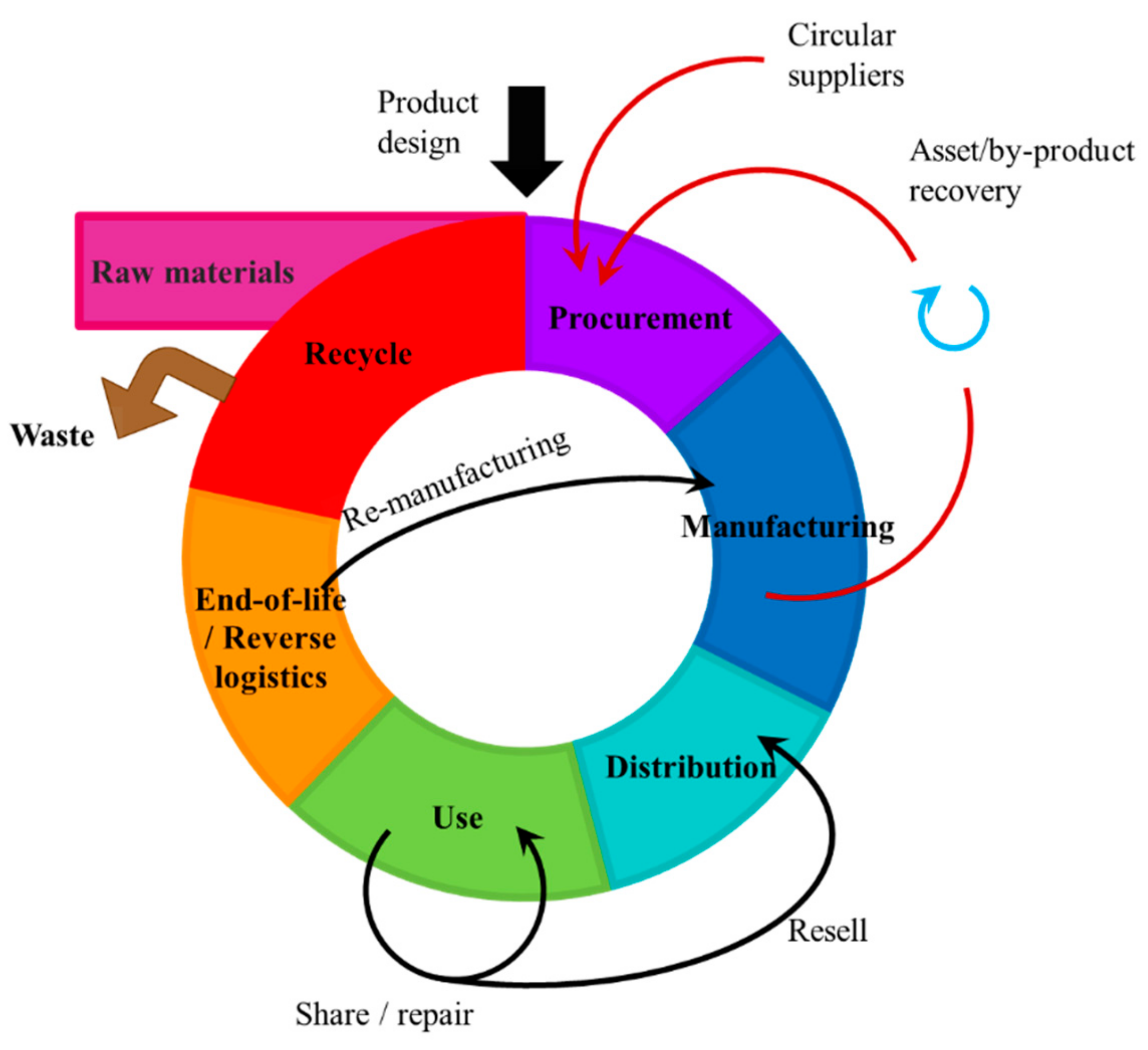

1.1.2. Accenture Model

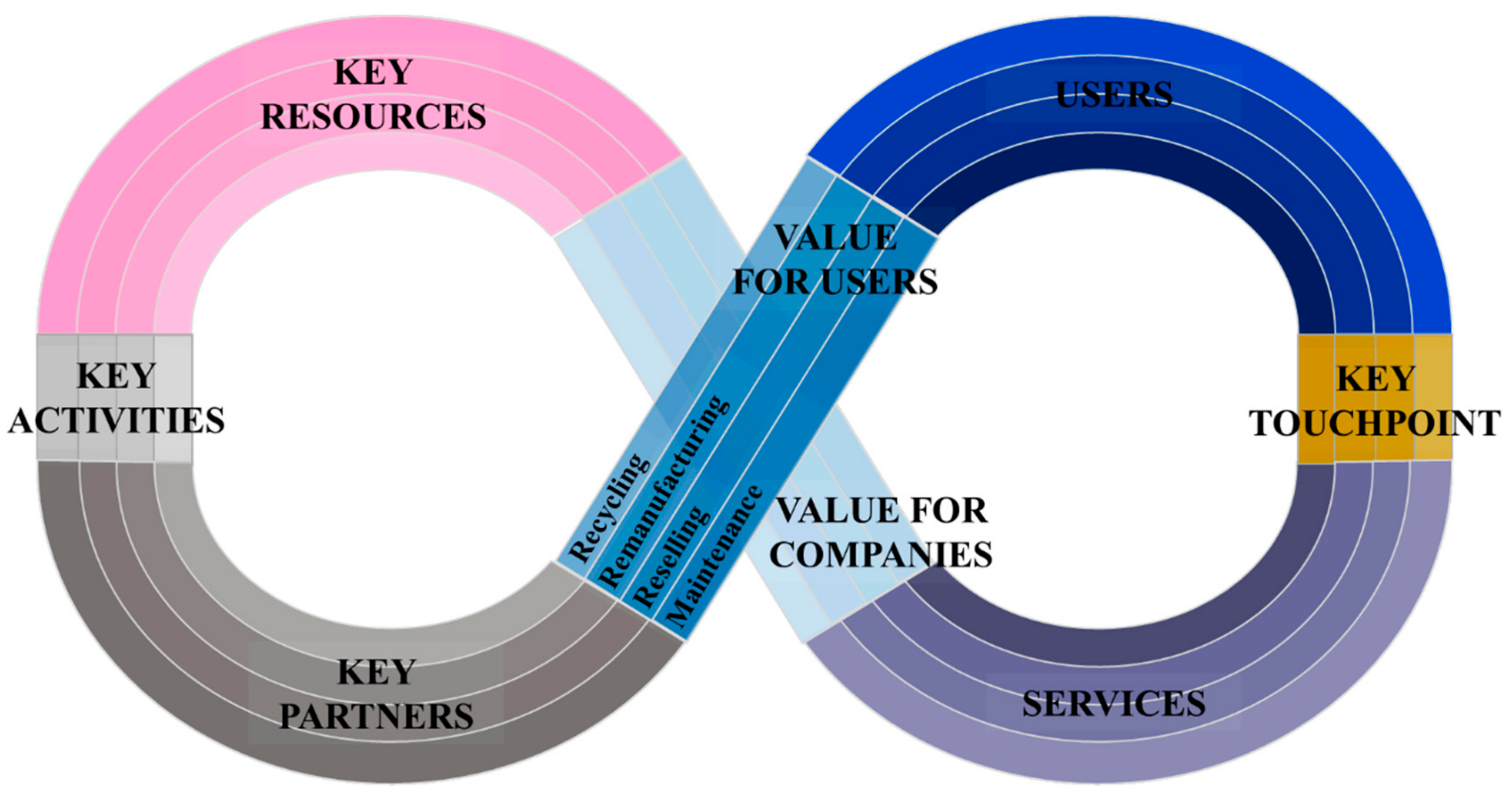

1.1.3. MoonFish Model

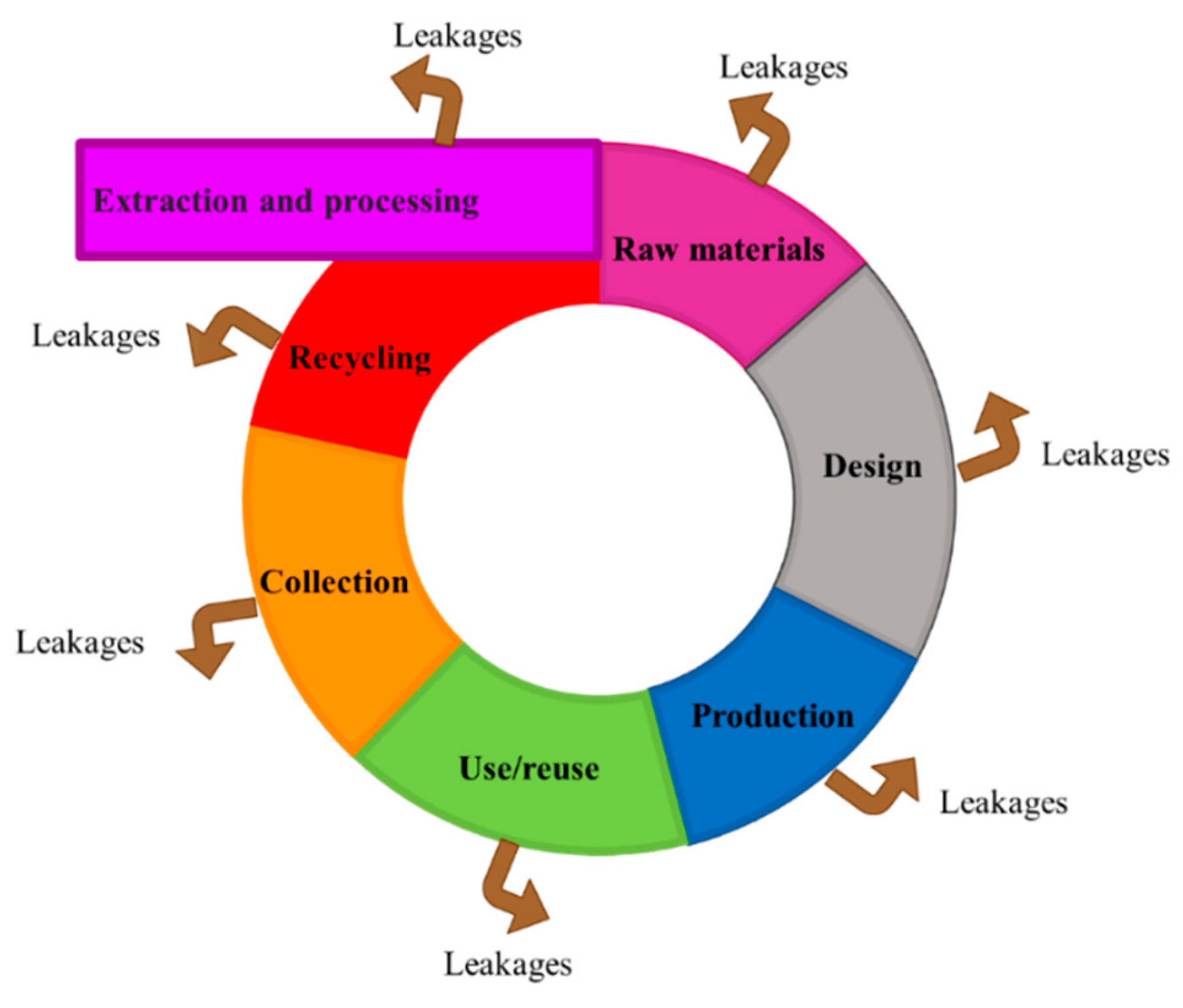

1.1.4. EIT Raw Materials Model

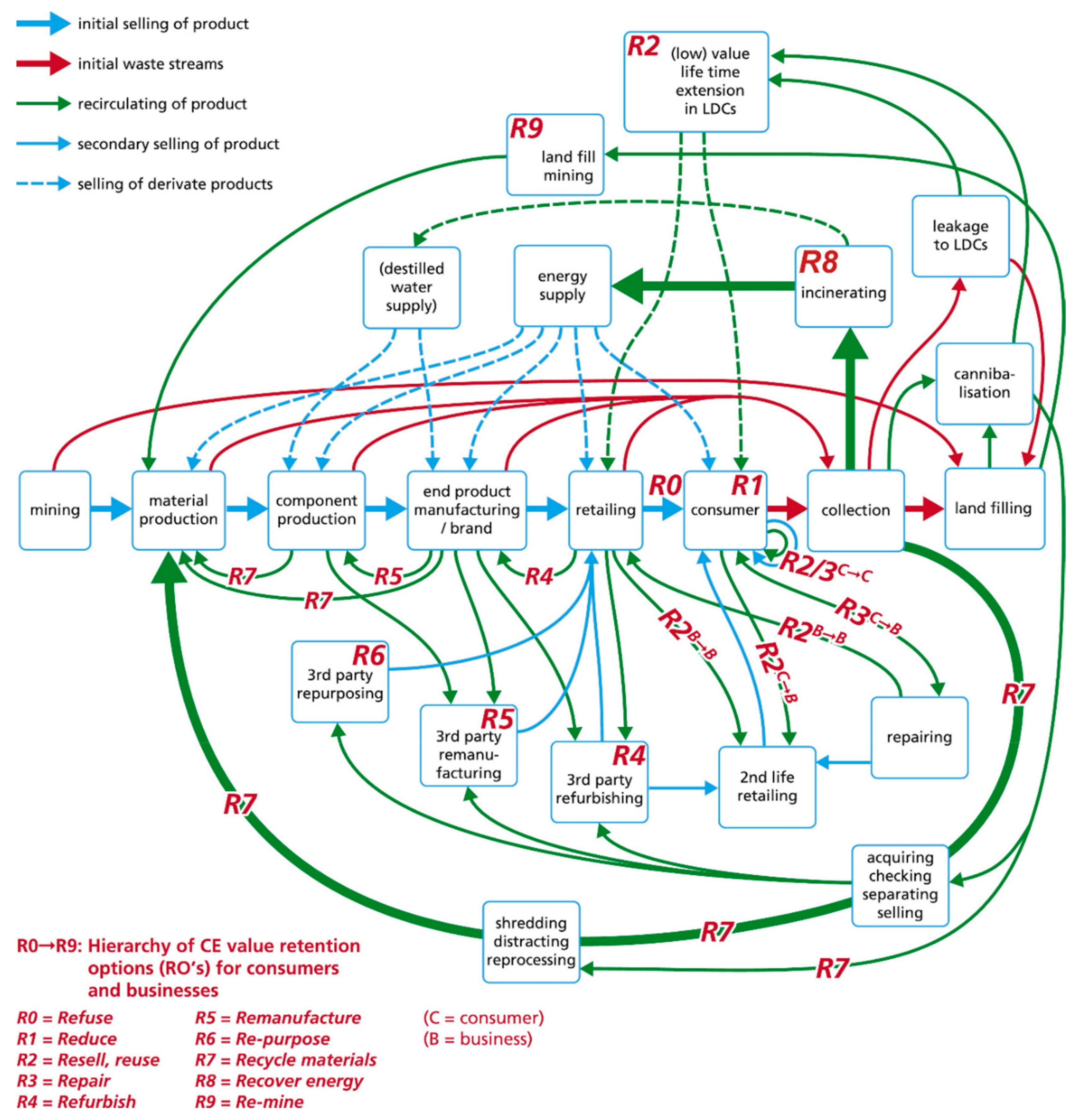

1.1.5. Reike Model

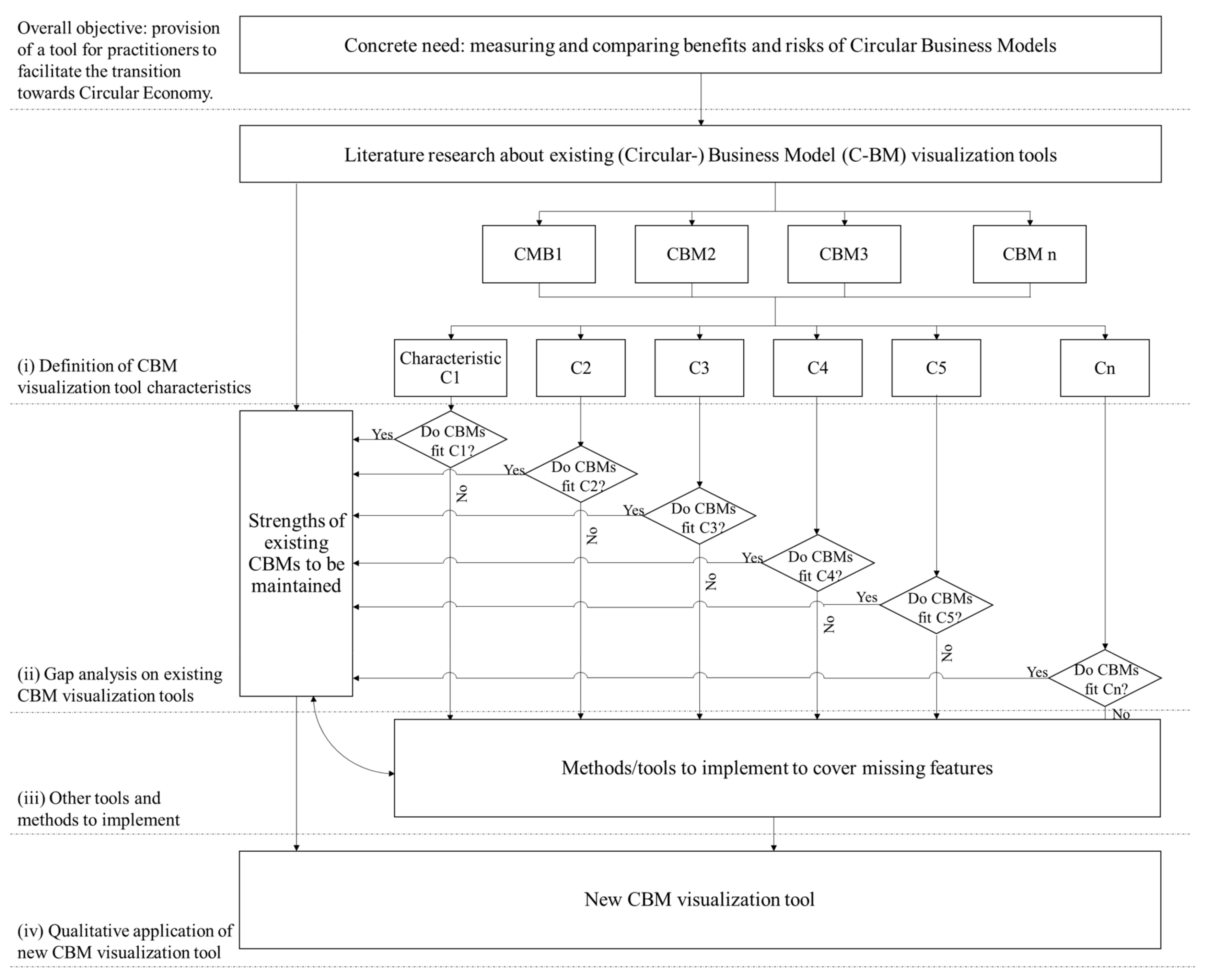

2. Materials and Methods

- (i)

- Definition of the characteristics, selected by literature, which are seen by the authors as fundamental for a CBM visualization tool. This phase responds to the question Q1: what are the fundamental elements that must be visualized in a tool for CBM evaluation?

- (ii)

- Gap analysis on the CBM visualization tool available in the literature. This phase responds to the question Q2: what are the existing tools that fits these characteristics and what are the missing aspects?

- (iii)

- Definition of tools and methods to be inserted to overcome the main drawbacks of the current models. This phase responds to the question Q3: are there methods, techniques, and tools that can be used and integrated to cover previous gaps?

- (iv)

- Qualitative application of the new CBM visualization tool to the supply chain of a generic ‘technical’ product. This phase finally provides all the information to use the developed tool.

2.1. Fundamental Characteristics of a CBM Visualization Tool

2.1.1. C1: Ease of Understanding

2.1.2. C2: Correspondence to Real Situations

2.1.3. C3: Useful Representation of Circular Initiatives

2.1.4. C4: Quantification of the Circularity Grade of the Initiatives

2.1.5. C5: Adaptation of the Model to Every Product and Industrial Sector

2.1.6. C6: Insertion of Maintenance as a Stage of the Product Life-Cycle

2.2. Gap Analysis

2.3. Tools and Methods to Overcome the Main Gaps of the Current Models

2.3.1. Supply Chain Structure

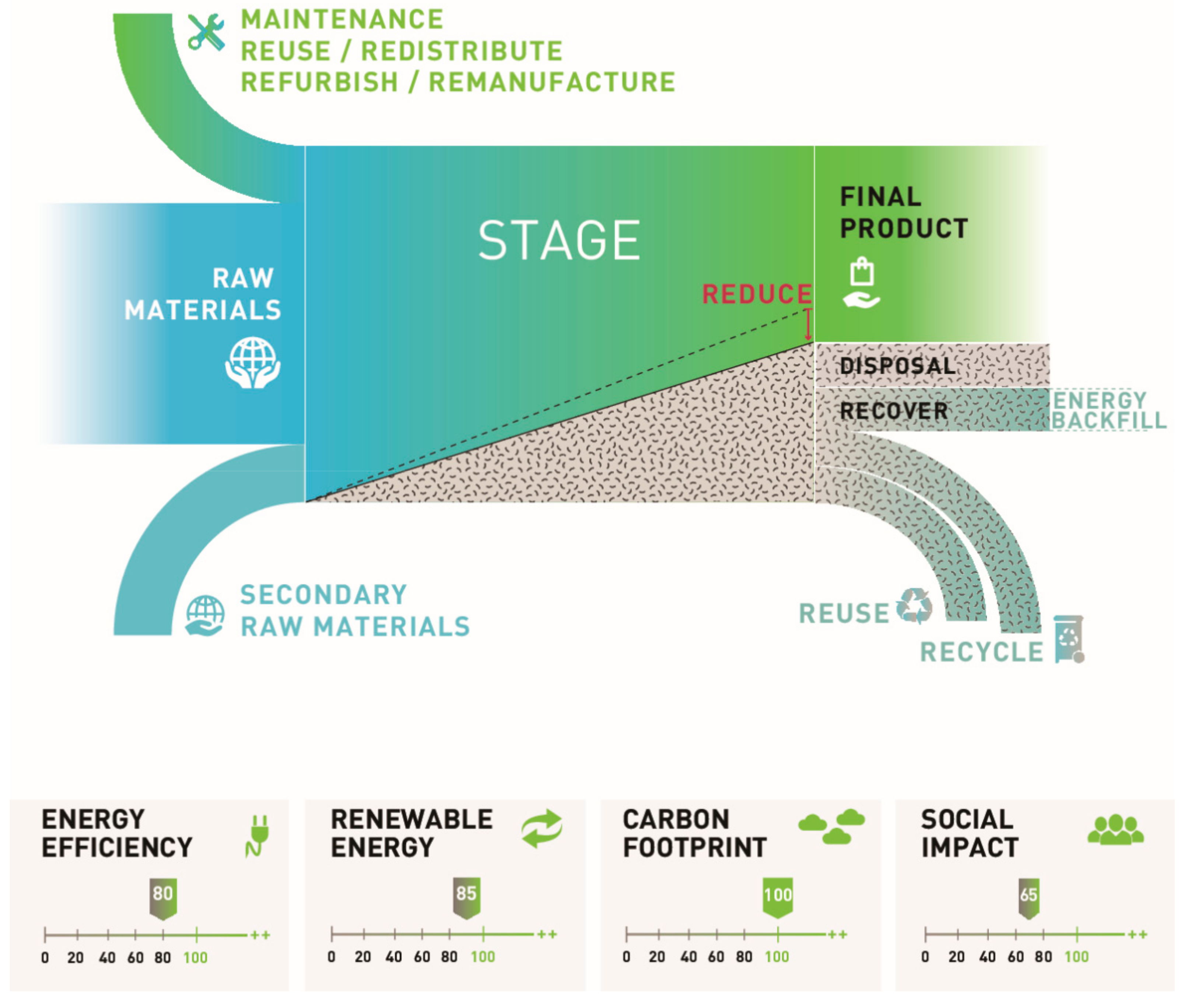

2.3.2. Waste Hierarchy

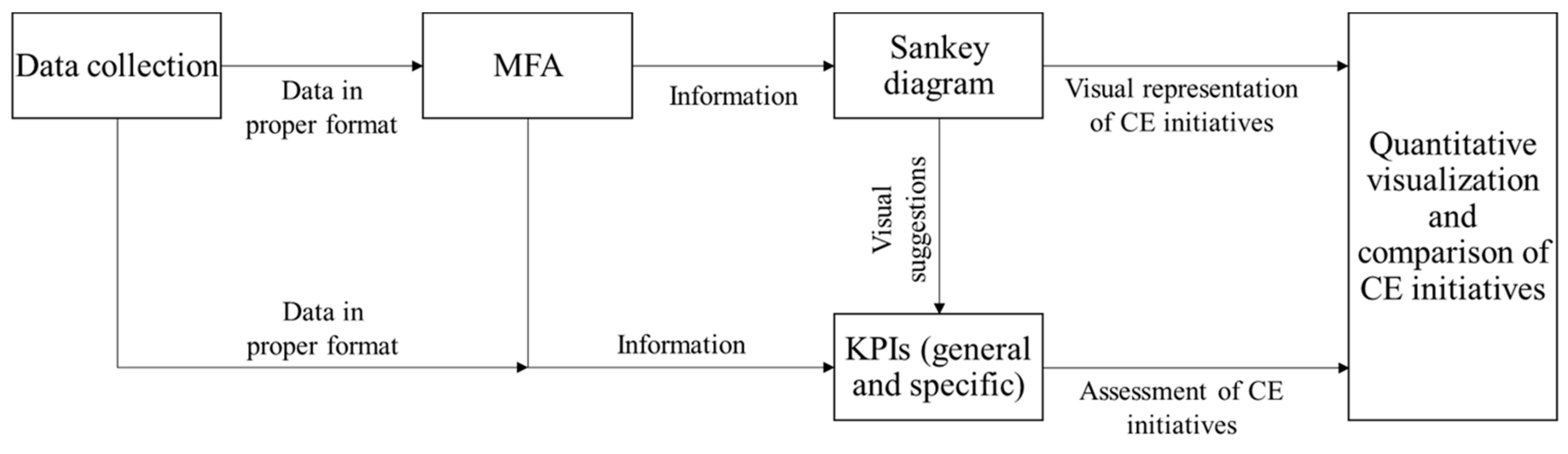

2.3.3. Quantification Methods: Material Flow Analysis, Sankey Diagram and Circular KPIs

2.3.4. Color Code

2.3.5. Design for X

2.3.6. Digitalization and Intelligent Assets

3. Results

3.1. Model of a Single Stage in the Supply Chain

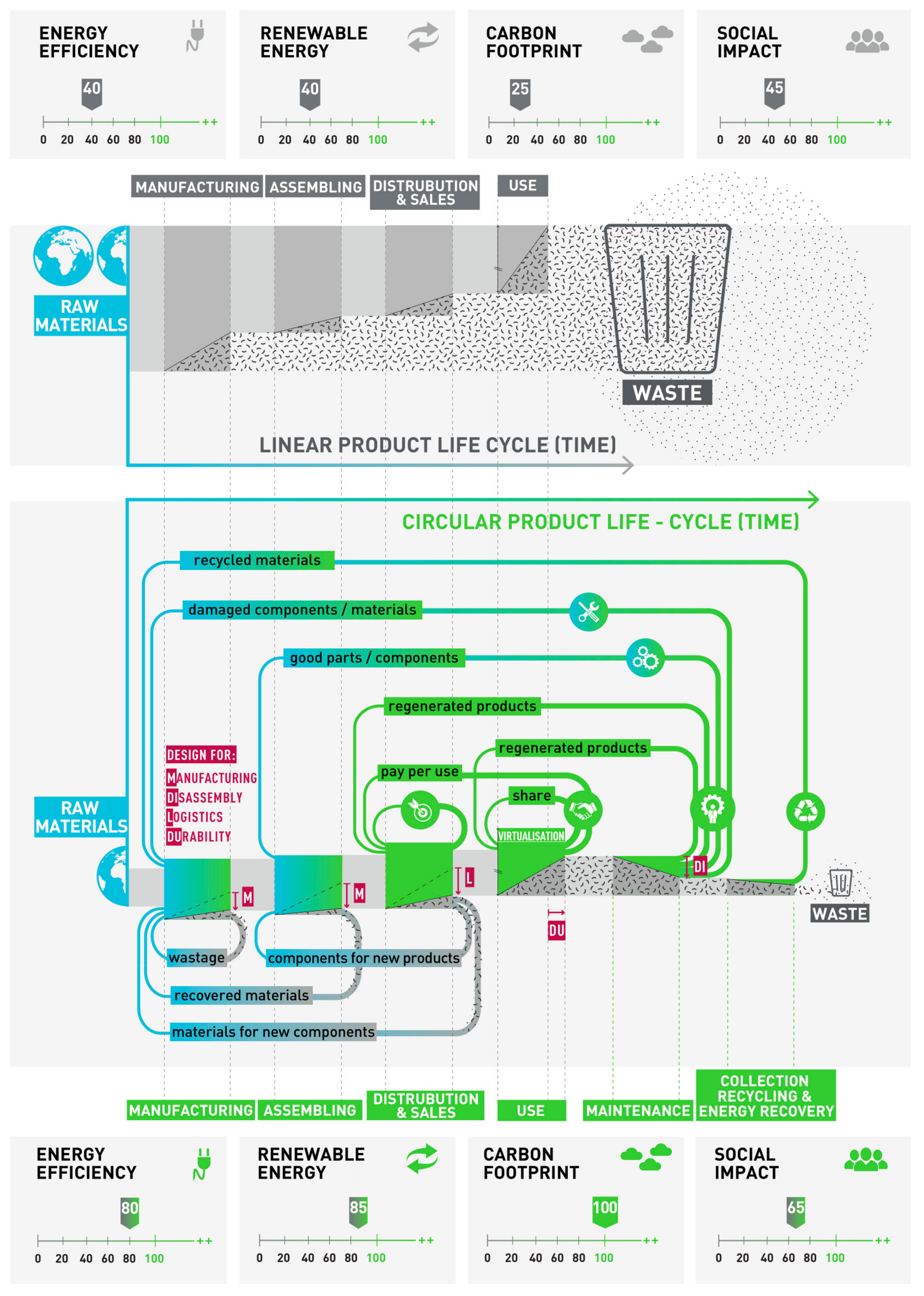

3.2. Model of the Entire Supply Chain

- a significant reduction of primary raw materials derived from the environment;

- a significant reduction of waste sent to landfill;

- the extension of the life-cycle of resources and products (the time expressed in the x-axis is greater in the circular case) and

- the revalorization of resources and products at the end of their life.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Closing the loop-An EU action plan for the Circular Economy. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 21 November 2019).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- De Pádua Pieroni, M.; Pigosso, D.C.A.; McAloone, T.C. Sustainable Qualifying Criteria for Designing Circular Business Models. Procedia CIRP 2018, 69, 799–804. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Mäkinen, S.J. Creating value in the circular economy: A structured multiple-case analysis of business models. J. Clean. Prod. 2018, 201, 988–1000. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Schuit, C.S.C.; Kraaijenhagen, C. Experimenting with a circular business model: Lessons from eight cases. Environ. Innov. Soc. Transit. 2018, 28, 79–95. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.; Dahlbo, H.; Aminoff, A. Do circular economy business models capture intended environmental value propositions? J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Mas-Tur, G.C. The Influence of the Circular Economy: Exploring the Knowledge Base. Sustainability 2019, 11, 4367. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F. Towards a Conceptual Framework of Business Models for Sustainability. In Proceedings of the ERSCP-EMSU conference, Delft, The Netherlands, 25–29 October 2010; p. 28. [Google Scholar]

- Degrowth, Steady State Economics and the Circular Economy: Three Distinct Yet Increasingly Converging Alternative Discourses to Economic Growth for Achieving Environmental Sustainability and Social Equity. In World Economic Association Sustainability Conference 2012. Available online: http://sustainabilityconference2012.worldeconomicsassociation.org/wp-content/uploads/WEASustainabilityConference2012_Charonis_Alternative-Discoursesto-Economic-Growth.pdf (accessed on 1 October 2019).

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 8. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Roome, N.; Louche, C. Journeying Toward Business Models for Sustainability: A Conceptual Model Found Inside the Black Box of Organisational Transformation. Organ. Environ. 2016, 29, 11–35. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Evans, S. The Cambridge Business Model Innovation Process. Procedia Manuf. 2017, 8, 262–269. [Google Scholar] [CrossRef]

- Joyce, A.; Paquin, R.L. The triple layered business model canvas: A tool to design more sustainable business models. J. Clean. Prod. 2016, 135, 1474–1486. [Google Scholar] [CrossRef]

- Haanstra, W.; Toxopeus, M.E.; van Gerrevink, M.R. Product Life Cycle Planning for Sustainable Manufacturing: Translating Theory into Business Opportunities. Procedia CIRP 2017, 61, 46–51. [Google Scholar] [CrossRef]

- Levänen, J.; Lyytinen, T.; Gatica, S. Modelling the Interplay Between Institutions and Circular Economy Business Models: A Case Study of Battery Recycling in Finland and Chile. Ecol. Econ. 2018, 154, 373–382. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Suárez-Eiroa, B.; Fernández, E.; Méndez-Martínez, G.; Soto-Oñate, D. Operational principles of circular economy for sustainable development: Linking theory and practice. J. Clean. Prod. 2019, 214, 952–961. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Cauchick-Miguel, P.A. Exploring the challenges for circular business implementation in manufacturing companies: An empirical investigation of a pay-per-use service provider. Resour. Conserv. Recycl. 2018, 135, 3–13. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- Van Barneveld, J.; van der Veen, G.; Enenkel, K.; Mooren, C.; Talman-Gross, L.; Eckartz, K.; Ostertag, K.; Duque-Ciceri, N.; Fischer, T.; Gama, M.; et al. Regulatory Barriers for the Circular Economy: Lessons from Ten Case Studies; Technopolis Group: Amsterdam, The Netherlands, 2016. [Google Scholar]

- De los Rios, I.C.; Charnley, F.J.S. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122, 174. [Google Scholar] [CrossRef]

- Accenture strategy. Circular Advantage. Innovative Business Models and Technologies to Create Value in a World without Limits to Growth. 2014. Available online: https://www.accenture.com/t20150523T053139__w__/us-en/_acnmedia/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Strategy_6/Accenture-Circular-Advantage-Innovative-Business-Models-Technologies-Value-Growth.pdf (accessed on 21 November 2019).

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Van Buren, N.; Demmers, M.; van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties: Circular Business Model Innovation. Bus. Strat. Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Roos, G. Business Model Innovation to Create and Capture Resource Value in Future Circular Material Chains. Resources 2014, 3, 248–274. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef]

- Bianchini, A.; Benci, A.; Pellegrini, M.; Rossi, J. Supply chain redesign for lead-time reduction through Kraljic purchasing portfolio and AHP integration. Benchmarking 2019, 26, 1194–1209. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential. Ellen MacArthur Found. 2016, 1–74. Available online: https://www.ellenmacarthurfoundation.org/publications/intelligent-assets (accessed on 21 November 2019).

- Bocken, N.; Boons, F.; Baldassarre, B. Sustainable business model experimentation by understanding ecologies of business models. J. Clean. Prod. 2019, 208, 1498–1512. [Google Scholar] [CrossRef]

- De Camargo Fiorini, P.; Jabbour, C.J.C. Information systems and sustainable supply chain management towards a more sustainable society: Where we are and where we are going. Int. J. Inf. Manag. 2017, 37, 241–249. [Google Scholar] [CrossRef]

- Su, C.-J.; Huang, S.-F. Real-time big data analytics for hard disk drive predictive maintenance. Comput. Electr. Eng. 2018, 71, 93–101. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential. Appendix: Selected Case Studies. Ellen MacArthur Found. 2016, 1–25. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/EllenMacArthurFoundation_Intelligent_Assets_Case_Studies_1002016.pdf (accessed on 21 November 2019).

- Baldassarre, F.; Ricciardi, F.; Campo, R. The Advent of Industry 4.0 in Manufacturing Industry: Literature Review and Growth Opportunities. In Proceedings of the Dubrovnik International Economic Meeting (DIEM 2017), Scientific Conference on Managing Business Growth in a Volatile Environment, Dubrovnik, Croatia, 12–14 October 2017. [Google Scholar]

- Mendoza-Fong, J.; García-Alcaraz, J.; Jiménez Macías, E.; Ibarra Hernández, N.; Díaz-Reza, J.; Blanco Fernández, J. Role of Information and Communication Technology in Green Supply Chain Implementation and Companies’ Performance. Sustainability 2018, 10, 1793. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Jagadish, H.V. Big Data and Science: Myths and Reality. Big Data Res. 2015, 2, 49–52. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Jabbour, A.B.L.S.; Sarkis, J.; Filho, M.G. Unlocking the circular economy through new business models based on large-scale data: An integrative framework and research agenda. Technol. Forecast. Soc. Chang. 2019, 144, 546–552. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.-F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Bianchini, A.; Pellegrini, M.; Rossi, J.; Saccani, C. Theoretical model and preliminary design of an innovative wet scrubber for the separation of fine particulate matter produced by biomass combustion in small size boilers. Biomass Bioenergy 2018, 116, 60–71. [Google Scholar] [CrossRef]

- European Commission. Moving towards a circular economy with EMAS—Best practices to implement circular economy strategies (with case study examples); European Union: Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Baden-Fuller, C.; Morgan, M.S. Business Models as Models. Long Range Plan. 2010, 43, 156–171. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.; Rana, P.; Evans, S. A value mapping tool for sustainable business modelling. Corp. Gov. 2013, 13, 482–497. [Google Scholar] [CrossRef]

- Beha, F.; Göritz, A.; Schildhauer, T. Business Model Innovation: The Role of Different Types of Visualizations. In Proceedings of the XXVI ISPIM Conference—Shaping the Frontiers of Innovation Management, Budapest, Hungary, 14–17 June 2015. [Google Scholar]

- Tsolakis, N.; Srai, J.S. Mapping supply dynamics in renewable feedstock enabled industries: A systems theory perspective on ‘green’ pharmaceuticals. Oper Manag Res 2018, 11, 83–104. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. A circular business model mapping tool for creating value from prolonged product lifetime and closed material loops. J. Clean. Prod. 2018, 197, 185–194. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation, Toward the Circular Economy. Opportunities for the consumer goods sector. Ellen MacArthur Found. 2013, 1–112. Available online: https://www.ellenmacarthurfoundation.org/publications/towards-the-circular-economy-vol-2-opportunities-for-the-consumer-goods-sector (accessed on 21 November 2019).

- Ghosh, S.; Eckerle, K.; Morrison, H. Turning Waste into Value with Your Supply Chain. Available online: https://www.accenture.com/nl-en/_acnmedia/pdf-49/accenture-full-circle-pov.pdf (accessed on 7 October 2019).

- Moonfish-Creating Sustainable Value for the Future. Available online: https://strategicvalueofdesign.org/2014/06/17/creating-sustainable-value-for-the-future/ (accessed on 7 October 2019).

- Eit Raw Materials Innovation Themes. Design of Products and Services for the Circular Economy. Available online: https://eitrawmaterials.eu/innovation-themes/ (accessed on 7 October 2019).

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Teng, W.C.; Fong, K.L.; Shenkar, D.; Wilson, J.A.; Foo, D.C.Y. Piper diagram–A novel visualisation tool for process design. Chem. Eng. Res. Des. 2016, 112, 132–145. [Google Scholar] [CrossRef]

- Täuscher, K.; Abdelkafi, N. Visual tools for business model innovation: Recommendations from a cognitive perspective. Creat. Innov. Manag. 2017, 26, 160–174. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y.; Clark, T. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-87641-1. [Google Scholar]

- Joyce, A. Managing Complexity; Springer Proceedings in Business and Economics; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Mentink, B. Circular Business Model Innovation. Master’s Thesis, Delft University of Technology & Leiden University, Leiden, The Netherlands, 2014. [Google Scholar]

- Weetman, C. A Circular Economy Handbook for Business and Supply Chains: Repair, Remake, Redesign, Rethink; Kogan Page Publishers: New York, NY, USA, 2016. [Google Scholar]

- Sustainn, 2017. Circularity Canvas: Methodology to Outline Circular Business Models. Available online: http://www.wearesustainn.com/en/2017/03/circularity-canvasmethodology-circular-business-models/ (accessed on 7 October 2019).

- Achterberg, E.; Hinfelaar, J.; Bocken, N. Master Circular Business with the Value Hill. Circle Economy. 2016. Available online: https://www.circle-economy.com/wp-content/uploads/2016/09/finance-white-paper-20160923.pdf (accessed on 7 October 2019).

- Parajuly, K.; Wenzel, H. Potential for circular economy in household WEEE management. J. Clean. Prod. 2017, 151, 272–285. [Google Scholar] [CrossRef]

- Van Renswoude, K.; Wolde, A.; Joustra, D.J. Circular Business Models–Part 1: An Introduction to IMSA’s Circular Business Model Scan; IMSA: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Aminoff, A.; Valkokari, K.; Kettunen, O. Mapping Multidimensional Value(s) for Co-creation Networks in a Circular Economy. In Collaboration in a Hyperconnected World. PRO-VE 2016; Afsarmanesh, H., Camarinha-Matos, L., Lucas Soares, A., Eds.; IFIP Advances in Information and Communication Technology, 480; Springer: Cham, Switzerland, 2016; pp. 629–638. [Google Scholar] [CrossRef]

- O’Dea, K. How Packaging Plays in the Circular Economy. 2015. Available online: https://www.greenbiz.com/article/how-circular-economy-plays-out-packaging (accessed on 7 October 2019).

- Geisendorf, S.; Wolf, P. The Circular Economy: Building an Economy on the Template of Nature. 2019. Available online: https://theconversation.com/the-circular-economy-building-an-economy-on-the-template-of-nature-115663 (accessed on 7 October 2019).

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Li, Y. Comparative study on the pathways of industrial parks towards sustainable development between China and Canada. Resour. Conserv. Recycl. 2016, 128, 417–425. [Google Scholar] [CrossRef]

- Sauter, E.M.; Witjes, M. Linked Spatial Data for a Circular Economy. Exploring its potential through a Textile Use Case, 1–6. 2017. Available online: http://ceur-ws.org/Vol-2044/paper10/paper10.html (accessed on 7 October 2019).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Vuong, J.; Kaur, S.; Heinrich, J.; Ho, B.K.; Hammang, C.J.; Baldi, B.F.; O’Donoghue, S.I. Versus—A tool for evaluating visualizations and image quality using a 2AFC methodology. Vis. Inform. 2018, 2, 225–234. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Kravchenko, M.; McAloone, T.C.; Pigosso, D.C.A. Implications of developing a tool for sustainability screening of circular economy initiatives. Procedia CIRP 2019, 80, 625–630. [Google Scholar] [CrossRef]

- Svensson, N.; Funck, E.K. Management control in circular economy. Exploring and theorizing the adaptation of management control to circular business models. J. Clean. Prod. 2019, 233, 390–398. [Google Scholar] [CrossRef]

- Sehnem, S.; Chiappetta Jabbour, C.J.; Farias Pereira, S.C.; de Sousa Jabbour, A.B.L. Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Bianchini, A.; Pellegrini, M.; Rossi, J.; Saccani, C. A new productive model of circular economy enhanced by digital transformation in the Fourth Industrial Revolution-An integrated framework and real case studies. In Proceedings of the 23rd Summer School Francesco Turco, Palermo, Italy, 12–14 September 2018; pp. 221–227. [Google Scholar]

- Bianchini, A.; Rossi, J.; Antipodi, L. A procedure for condition-based maintenance and diagnostics of submersible well pumps through vibration monitoring. Int. J. Syst. Assur. Eng. Manag. 2018, 9, 999–1013. [Google Scholar] [CrossRef]

- Bianchini, A.; Pellegrini, M.; Rossi, J. Maintenance scheduling optimization for industrial centrifugal pumps. Int. J. Syst. Assur. Eng. Manag. 2019, 10, 848–860. [Google Scholar] [CrossRef]

- Snihur, Y.; Tarzijan, J. Managing complexity in a multi-business-model organization. Long Range Plan. 2018, 51, 50–63. [Google Scholar] [CrossRef]

- Guyader, H.; Piscicelli, L. Business model diversification in the sharing economy: The case of GoMore. J. Clean. Prod. 2019, 215, 1059–1069. [Google Scholar] [CrossRef]

- Fielt, D.E. Conceptualising Business Models: Definitions, Frameworks and Classifications. J. Bus. Models 2013, 1, 21. [Google Scholar]

- Havemo, E. A visual perspective on value creation: Exploring patterns in business model diagrams. Eur. Manag. J. 2018, 36, 441–452. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Chaudhary, K.; Vrat, P. Circular economy model of gold recovery from cell phones using system dynamics approach: A case study of India. Environ. Dev. Sustain. Accepted. [CrossRef]

- Guzzo, D.; Trevisan, A.H.; Echeveste, M.; Costa, J.M.H. Circular Innovation Framework: Verifying Conceptual to Practical Decisions in Sustainability-Oriented Product-Service System Cases. Sustainability 2019, 11, 3248. [Google Scholar] [CrossRef]

- Guldmann, E. Best Practice Examples of Circular Business Models; The Danish Environmental Protection Agency: Copenhagen, Denmark, 2016; pp. 1–56. [Google Scholar]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Rechberger, H. Measuring the circular economy-A Multiple Correspondence Analysis of 63 metrics. J. Clean. Prod. 2019, 210, 200–216. [Google Scholar] [CrossRef]

- Mesa, J.; Esparragoza, I.; Maury, H. Developing a set of sustainability indicators for product families based on the circular economy model. J. Clean. Prod. 2018, 196, 1429–1442. [Google Scholar] [CrossRef]

- Busu, M.; Trica, C.L. Sustainability of Circular Economy Indicators and Their Impact on Economic Growth of the European Union. Sustainability 2019, 11, 5481. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recycl. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Huysman, S.; De Schaepmeester, J.; Ragaert, K.; Dewulf, J.; De Meester, S. Performance indicators for a circular economy: A case study on post-industrial plastic waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- European Environmental Agency. The Circular Economy and the Bioeconomy Partners in Sustainability; European Environmental Agency: Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Leipold, S.; Petit-Boix, A. The circular economy and the bio-based sector—Perspectives of European and German stakeholders. J. Clean. Prod. 2018, 201, 1125–1137. [Google Scholar] [CrossRef]

- Chilamkurti, N.; Torabi, T.; Elhdad, R. Ontology-based framework for maintenance activity analysis and support: A case study for petroleum plant. Int. J. Syst. Assur. Eng. Manag. 2014, 5, 84–98. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G. Waste hierarchy index for circular economy in waste management. Waste Manag. 2019, 95, 298–305. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Nogueira, A.; Ashton, W.S.; Teixeira, C. Expanding perceptions of the circular economy through design: Eight capitals as innovation lenses. Resour. Conserv. Recycl. 2019, 149, 566–576. [Google Scholar] [CrossRef]

- Silva, S.; Sousa Santos, B.; Madeira, J. Using color in visualization: A survey. Comput. Graph. 2011, 35, 320–333. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Hasanaj, M.; Jansson, A. Supply Chain Management–A Way to Achieve Circular Economy. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2018. [Google Scholar]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Hugos, M. Essentials of Supply Chain Management, 4th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2018. [Google Scholar]

- Taghikhah, F.; Voinov, A.; Shukla, N. Extending the supply chain to address sustainability. J. Clean. Prod. 2019, 229, 652–666. [Google Scholar] [CrossRef]

- Mensah, A.O.; Peprah, J.; Nduro, K. Significance of actors in the maize supply chain for senior high schools in Kumasi. Eur. J. Logist. Purch. Suppl. Chain Manag. 2015, 3, 1–17. [Google Scholar]

- Hollins, O.; Lee, P.; Sims, E.; Bertham, O.; Symington, H.; Bell, B.; Pfaltzgraff, L.; Sjögren, P. Towards a Circular Economy–Waste Management in the EU; European Union: Brussels, Belgium, 2017. [Google Scholar]

- Ferrari, K.; Gamberini, R.; Rimini, B. The waste hierarchy: A strategic, tactical and operational approach for developing countries. the case study of mozambique. Int. J. SDP 2016, 11, 759–770. [Google Scholar] [CrossRef]

- DEFRA. Guidance on Applying the Waste Hierarchy. 2011. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/69403/pb13530-waste-hierarchy-guidance.pdf (accessed on 21 November 2019).

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- European Commission. 2011/753/EU: Commission Decision of 18 November 2011 establishing rules and calculation methods for verifying compliance with the targets set in Article 11(2) of Directive 2008/98/EC of the European Parliament and of the Council (notified under document C (2011) 8165). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32011D0753&from=EN (accessed on 21 November 2019).

- García-Barragán, J.F.; Eyckmans, J.; Rousseau, S. Defining and Measuring the Circular Economy: A Mathematical Approach. Ecol. Econ. 2019, 157, 369–372. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular economy and the matter of integrated resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Ong, B.H.Y.; Klemeš, J.J.; Tan, R.R.; Varbanov, P.S. Circular Integration of processes, industries, and economies. Renew. Sustain. Energy Rev. 2019, 107, 507–515. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis; Advanced methods in resource and waste management; CRC/Lewis: Boca Raton, FL, USA, 2004; ISBN 978-1-56670-604-9. [Google Scholar]

- De Wit, M.; Hoogzaad, J.; Ramkumar, S.; Friedl, H.; Douma, A. The Circularity Gap Report: An analysis of the circular state of the global economy. Circle Economy. Available online: https://www.greengrowthknowledge.org/resource/circularity-gap-report-analysis-circular-state-global-economy (accessed on 21 November 2019).

- Mayer, A.; Haas, W.; Wiedenhofer, D.; Krausmann, F.; Nuss, P.; Blengini, G.A. Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy-wide Material Loop Closing in the EU28: Progress towards a Circular Economy in the EU28. J. Ind. Ecol. 2019, 23, 62–76. [Google Scholar] [CrossRef] [PubMed]

- Steinmann, Z.J.N.; Huijbregts, M.A.J.; Reijnders, L. How to define the quality of materials in a circular economy? Resour. Conserv. Recycl. 2019, 141, 362–363. [Google Scholar] [CrossRef]

- Velte, C.J.; Wilfahrt, A.; Müller, R.; Steinhilper, R. Complexity in a Life Cycle Perspective. Procedia CIRP 2017, 61, 104–109. [Google Scholar] [CrossRef]

- Deloitte. Global Manufacturing Competitiveness Index. Deloitte 2016. Available online: https://www.fastenernewsdesk.com/11142/global-manufacturing-competitiveness-index/ (accessed on 21 November 2019).

- Barragán-Escandón, A.; Terrados-Cepeda, J.; Zalamea-León, E. The Role of Renewable Energy in the Promotion of Circular Urban Metabolism. Sustainability 2017, 9, 2341. [Google Scholar] [CrossRef]

- PostEurop. GHG inventory standard for the postal sector. PostEurop 2010, 1–91. [Google Scholar]

- Robinson, S. Social circular economy. Oppor. People Planet Profit 2017, 1–44. [Google Scholar]

- Silva, S.; Madeira, J.; Santos, B.S. There is More to Color Scales than Meets the Eye: A Review on the Use of Color in Visualization. In Proceedings of the 11th International Conference Information Visualization (IV ’07), Zurich, Switzerland, 4–6 July 2007; pp. 943–950. [Google Scholar]

- Bovea, M.D.; Pérez-Belis, V. Identifying design guidelines to meet the circular economy principles: A case study on electric and electronic equipment. J. Environ. Manag. 2018, 228, 483–494. [Google Scholar] [CrossRef]

- De Jabbour, A.B.L.S.; Luiz, J.V.R.; Rojas, O.; Luiz, R.C.; Jabbour, C.J.C.; Ndubisi, N.O.; De Oliveira, J.H.C.; Junior, H.F. Circular economy business models and operations management. J. Clean. Prod. 2019, 235, 1525–1539. [Google Scholar]

- Halstenberg, F.A.; Lindow, K.; Stark, R. Leveraging Circular Economy through a Methodology for Smart Service Systems Engineering. Sustainability 2019, 11, 3517. [Google Scholar] [CrossRef]

- Baptista, A.J.; Peixoto, D.; Ferreira, A.D.; Pereira, J.P. Lean Design-for-X Methodology: Integrating Modular Design, Structural Optimization and Ecodesign in a Machine Tool Case Study. Procedia CIRP 2018, 69, 722–727. [Google Scholar] [CrossRef]

- Arnette, A.N.; Brewer, B.L.; Choal, T. Design for sustainability (DFS): The intersection of supply chain and environment. J. Clean. Prod. 2014, 83, 374–390. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Design for manufacturing to design for Additive Manufacturing: Analysis of implications for design optimality and product sustainability. Procedia Manuf. 2017, 13, 724–731. [Google Scholar] [CrossRef]

- Pålsson, H.; Pettersson, F.; Winslott Hiselius, L. Energy consumption in e-commerce versus conventional trade channels - Insights into packaging, the last mile, unsold products and product returns. J. Clean. Prod. 2017, 164, 765–778. [Google Scholar] [CrossRef]

- Smidfelt Rosqvist, L.; Winslott Hiselius, L. Online shopping habits and the potential for reductions in carbon dioxide emissions from passenger transport. J. Clean. Prod. 2016, 131, 163–169. [Google Scholar] [CrossRef]

- Todeschini, B.V.; Cortimiglia, M.N.; Callegaro-de-Menezes, D.; Ghezzi, A. Innovative and sustainable business models in the fashion industry: Entrepreneurial drivers, opportunities, and challenges. Bus. Horiz. 2017, 60, 759–770. [Google Scholar] [CrossRef]

- Schaefer, D.; Cheung, W.M. Smart Packaging: Opportunities and Challenges. Procedia CIRP 2018, 72, 1022–1027. [Google Scholar] [CrossRef]

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. User acceptance and adoption of circular offerings in the fashion sector: Insights from user-generated online reviews. J. Clean. Prod. 2019, 231, 928–939. [Google Scholar] [CrossRef]

- Romero, D.; Noran, O. Towards Green Sensing Virtual Enterprises: Interconnected Sensing Enterprises, Intelligent Assets and Smart Products in the Cyber-Physical Circular Economy. IFAC-Pap. 2017, 50, 11719–11724. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Global Footprint Network. Global Footprint Network annual report 2013. Glob. Footpr. Netw. 2013, 1–276. Available online: https://www.footprintnetwork.org/content/images/article_uploads/GFN_AR_2013_final.pdf (accessed on 21 November 2019).

- Farjana, S.H.; Huda, N.; Parvez Mahmud, M.A.; Saidur, R. A review on the impact of mining and mineral processing industries through life cycle assessment. J. Clean. Prod. 2019, 231, 1200–1217. [Google Scholar] [CrossRef]

- Turner, C.; Moreno, M.; Mondini, L.; Salonitis, K.; Charnley, F.; Tiwari, A.; Hutabarat, W. Sustainable Production in a Circular Economy: A Business Model for Re-Distributed Manufacturing. Sustainability 2019, 11, 4291. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Toletti, G. Managing the Introduction of Circular Products: Evidence from the Beverage Industry. Sustainability 2019, 11, 3650. [Google Scholar] [CrossRef]

| Barrier Category | Challenges |

|---|---|

| Internal Process [23,27,28] |

|

| Technical [24,29,30,31,32,33] |

|

| Market [21,29,34,35] |

|

| Institutional, regulatory and social [32] |

|

| Economic and financial [29,31] |

|

| Principle | Description |

|---|---|

| Design out waste | Biological and technical materials must be designed by intention to be returned to the ecosystem (biological) or recovered, refreshed and upgraded (technical) → no waste. |

| Build resilience through diversity | Production systems must be flexible thanks to some characteristics such as modularity, versatility and adaptivity for the use of several different inputs. |

| Shift to renewable energy sources | Renewable energies will be able to feed all the systems since the threshold energy levels will be reduced by a restorative, circular economy. |

| Think in system | Effectiveness of the global system overcome the efficiency optimization of a single part, in order to make the elements less vulnerable to unpredictable changing circumstances. |

| Think in cascades | Extracting values from resources to use them in other applications at a different level. |

| Underlying Business Model | Description |

|---|---|

| Circular supplies | Replacement of single-life and scarce inputs with renewable, bio-based or fully recyclable resources./Removal of inefficiencies with an increased cutting of waste. |

| Resource recovery | Recovery of the value of products and by-products to supply other cycles: recycling and new technologies to transform waste in new resources, with the same or greater value. |

| Product life extension | The value of waste is maintained and improved by repairing, upgrading, remanufacturing or remarketing products. |

| Sharing platforms | Collaboration among consumers (individuals or organizations) to share products, reducing their underutilization and improving their productivity. |

| Product-as-a-service | This is an alternative to the classic product purchase: the products are paid for according to their use and can be used by several consumers. |

| Cycle | Description |

|---|---|

| Maintenance | It is a service offered by the producers to implement the inner cycle. |

| Re-selling | It acts when a product can be used again for the same purpose, limiting its enhancement or change. |

| Refurbishing/Remanufacturing | It is applied to a non-working product to restore its good operating conditions. It is applied in components in good conditions to build new products. |

| Recycling | It consists of the reincorporation of used-up products into the cycle in the form of input material. |

| Tool | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| Supply chain structure | X | X | X | X | ||

| Waste hierarchy | X | X | X | X | ||

| Quantification methods: MFA + Sankey Model + circular KPIs | X | X | ||||

| Color code | X | X | ||||

| Design for X | X | |||||

| Digitalization and intelligent assets | X |

| Supply Chain Stage | Core Activities | Input Flow | Output Flow | Leakages |

|---|---|---|---|---|

| Manufacturing | Transformation process | Raw materials | Components/parts; bio-based product | Rejects; non-compliance |

| Assembling | Assembling of n parts into a final product | Components/parts | Final products; waste/wastage | Damaged/wrong parts |

| Distribution & Sales | Storing inventory | Final products; bio-based products | Sold final products (including bio-based) | Unsold, damaged, waste products |

| Use | Use and consumption of final products | Final products; bio-based products | End-of-life final products and waste | Unexploited or not consumed products |

| Maintenance | Restoring initial conditions of products | End-of-life products | Restored products, parts and materials | Unrecoverable/damaged products and materials |

| Collection, Recycling and Energy recovery | Reprocessed materials with low properties | End-of-life products and waste | Materials and energy | Unrecoverable waste/wastage |

| Output Flows | Description |

|---|---|

| Final product | It derives from the transformation process of the input resources for its sale. It is the greatest flow and can improve with process optimization, which corresponds to the waste management option of reduction. |

| Reused resource | Part of resources discarded during production process and directly reused for its original purpose with the smallest efforts (checking and cleaning). It corresponds to the inner circle. |

| Recycled resource | Part of waste that cannot be reused maintaining its primary purpose, but still has a value that can be converted through a recycling process, with fewer properties than the initial materials. |

| Recovered resource | It corresponds to the part of the waste that can be used for: (i) energy production; (ii) backfilling operations. These options do not exploit the entire value of the waste. |

| Disposal | The least valuable flow is the part of waste that is sent to landfill or to incinerators. It consists of the unavoidable leakages, which necessarily require the introduction of new raw materials. |

| Input Flows | Description |

|---|---|

| Raw materials | It corresponds to the flow derived directly from the production of primary resources, which encompasses the extraction of natural resources from the environment. This flow involves the use of new resources and great efforts (costs, labor, energy and resources). |

| Secondary raw material | It includes the resources deriving from the reuse and recycling of ‘waste’ flows and typically require regeneration or re-processing. Secondary raw materials require fewer efforts than the corresponding extraction of primary raw materials. |

| Flow from maintenance, reuse/redistribution and refurbishing/remanufacturing | It consists of flow derived from downstream stages after the restoring of the initial conditions. The original purpose is maintained without further transformation process and additional efforts. This flow is the most valuable. |

| Design for X | Description | Effect |

|---|---|---|

| Manufacturing (and/or assembling) |

| Avoiding errors in advance, reducing damages during transformation, minimizing wastage → Reduction of waste to landfill |

| Logistics |

| Reduction in number of components ordered, shipped and stored and of emissions associated with transports. Reusing of the same packaging material. |

| Durability |

| Extension of product life-cycle. Avoiding the replacement of old components with new parts. |

| Disassembly |

| Greater effectiveness of maintenance; maximizing of resource recovery; replacement of only faulty parts. |

| Digital/Intelligent Asset | Description | Effect |

|---|---|---|

| Virtualization of products and processes | Replacement of physical products with virtual services: e.g., digital books, documents (manuals, industry reports), courses and professional service. | Dematerialization, reduction of resources necessary to manufacture the corresponding physical products and reduction of travel. |

| E-commerce | It avoids time and travel to search for the desired products and/or to compare price; it centralizes order processing, reducing overproduction. | It dematerializes travel and emissions and avoid efforts (costs, resources, time, energy) for unsold products. |

| Smart and active packaging | Smart packaging: information to preserve/use products. Active packaging: monitoring of internal conditions (oxygen, temperature) to extend product duration. | Complete traceability of materials and products, before and after sales (location, condition and availability of resources). |

| Software for process optimization | Sophisticated algorithms to control process parameters in real-time, balance quantity and quality of raw materials. | Process productivity improvement and reduction in consumption and waste. |

| 3D-printing/Rapid Prototyping | Complex geometries and/or with light-weight and high-level properties. Very small batches of production and a high level of customization for products and services. | Reduction of material underutilization and wastage and energy consumption typical of traditional shaving removal technologies. |

| Predictive maintenance | Evaluation of actual condition of assets, failures and remaining life-time estimation, downtime reduction, productivity and product quality improvement. | Extension of asset life, acting only when needed, replacing only faulty components at the end of their life. |

| Stage | Tool | |||

|---|---|---|---|---|

| Circular Initiatives | Design for X | Digitalization and Intelligent Assets | ||

| Input Flows | Output Flows | |||

| Use |

|

| Durability |

|

| Distribution & sales |

|

| Logistics |

|

| Manufacturing |

|

| Manufacturing |

|

| Assembling |

|

| Assembling |

|

| Maintenance |

| Disassembly | Predictive maintenance with artificial intelligence. | |

| Recycling and energy recovery |

| Advanced technology (e.g., robots) for waste sorting. | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchini, A.; Rossi, J.; Pellegrini, M. Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models. Sustainability 2019, 11, 6614. https://doi.org/10.3390/su11236614

Bianchini A, Rossi J, Pellegrini M. Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models. Sustainability. 2019; 11(23):6614. https://doi.org/10.3390/su11236614

Chicago/Turabian StyleBianchini, Augusto, Jessica Rossi, and Marco Pellegrini. 2019. "Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models" Sustainability 11, no. 23: 6614. https://doi.org/10.3390/su11236614

APA StyleBianchini, A., Rossi, J., & Pellegrini, M. (2019). Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models. Sustainability, 11(23), 6614. https://doi.org/10.3390/su11236614