Approaches to Reduce Food Losses in German Fruit and Vegetable Production

Abstract

:1. Introduction

- estimating food losses on farm level,

- identifying and understanding the main reasons along the value chain for these losses, and

- developing and assessing effective measures for the reduction of these losses based on case studies of selected fruits and vegetables.

2. Materials and Methods

- farm specific activities such as cultivation, storage and marketing of the selected crops,

- kind and level of food losses in their company,

- the reasons for these losses and

- their current measures to reduce these losses.

- In addition, they were invited to suggest additional countermeasures.

3. Results

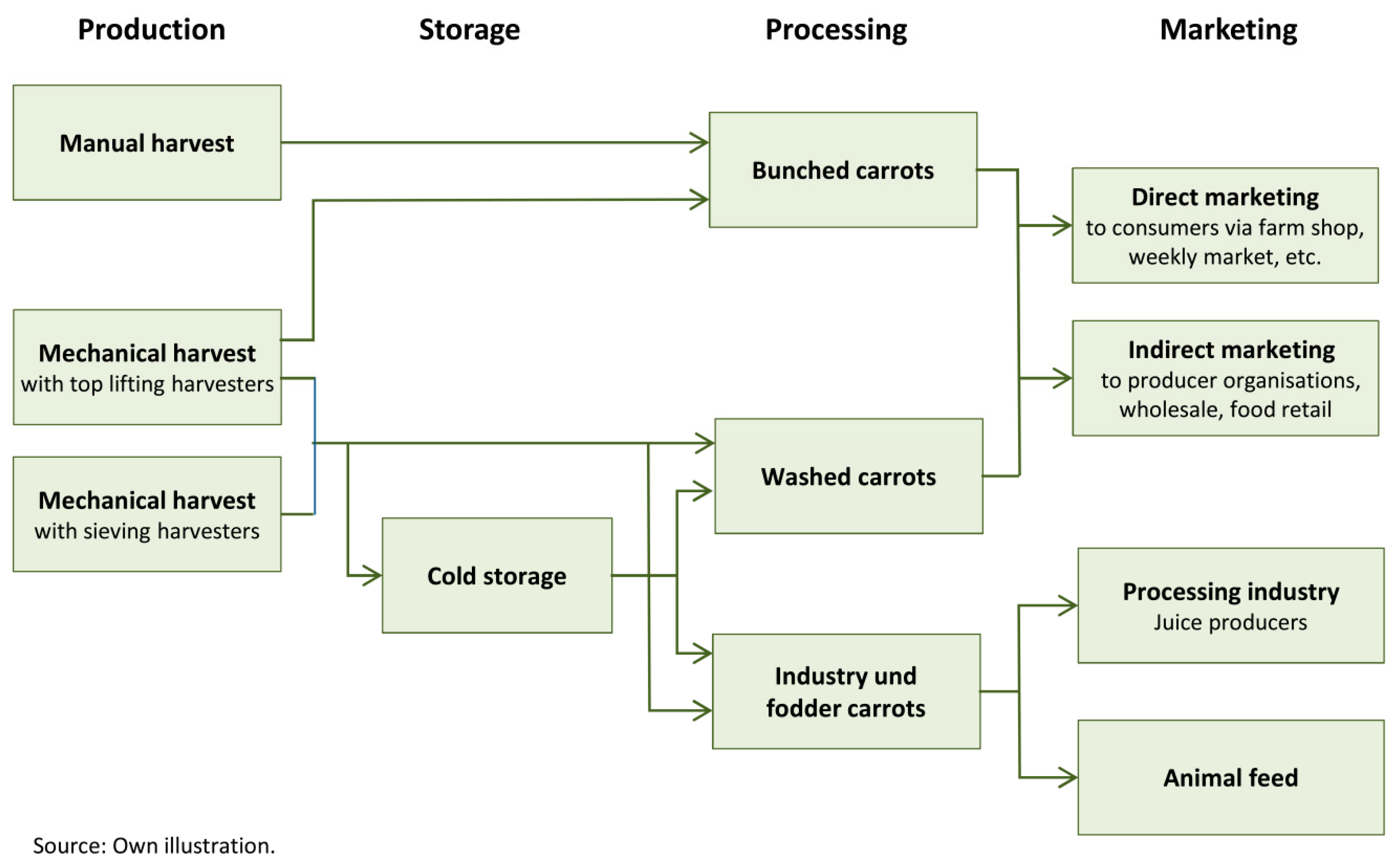

3.1. Brief Description of Sample and Value Chains

- Most of the lettuce producers and half of the carrot producers cultivate comparatively large growing areas, as compared to the statistical averages of 16.3 ha iceberg lettuce per farm in Lower Saxony or 15.5 ha carrots per farm in Rhineland-Palatinate [29]. For fruits, there are fewer producers with larger than average growing areas involved. The statistical averages are 12.7 ha strawberries and 32 ha apples per farm in Lower Saxony [30].

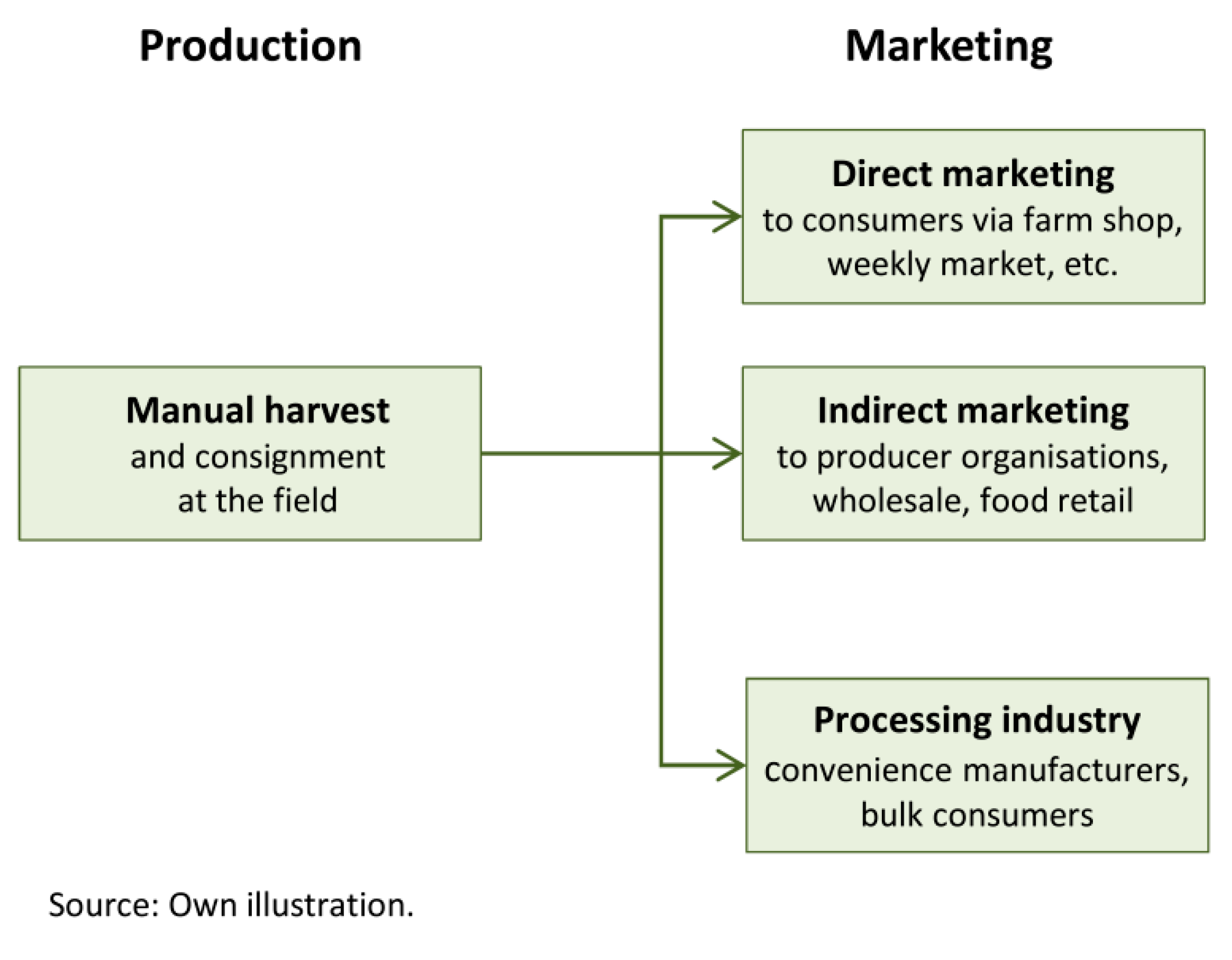

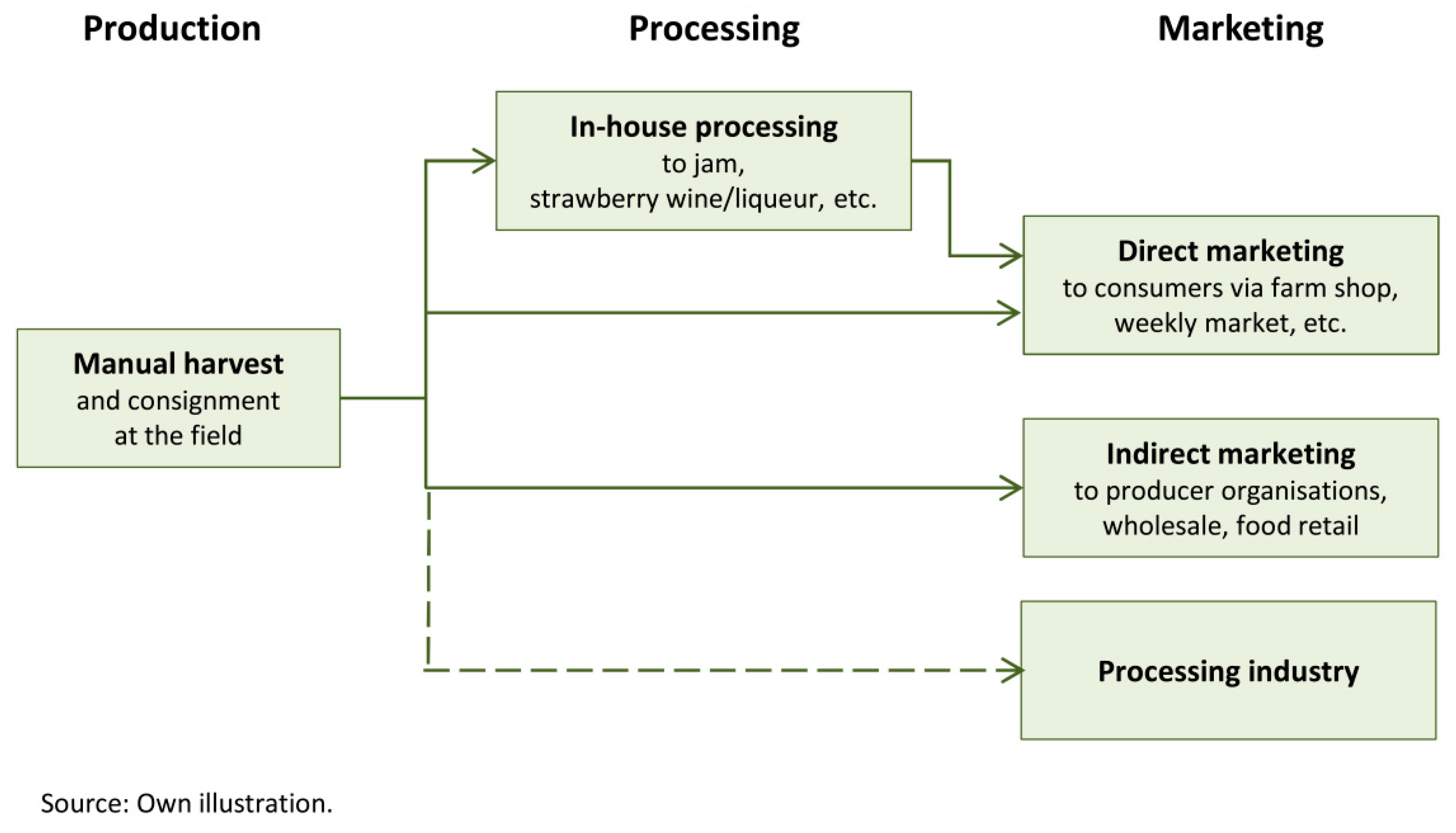

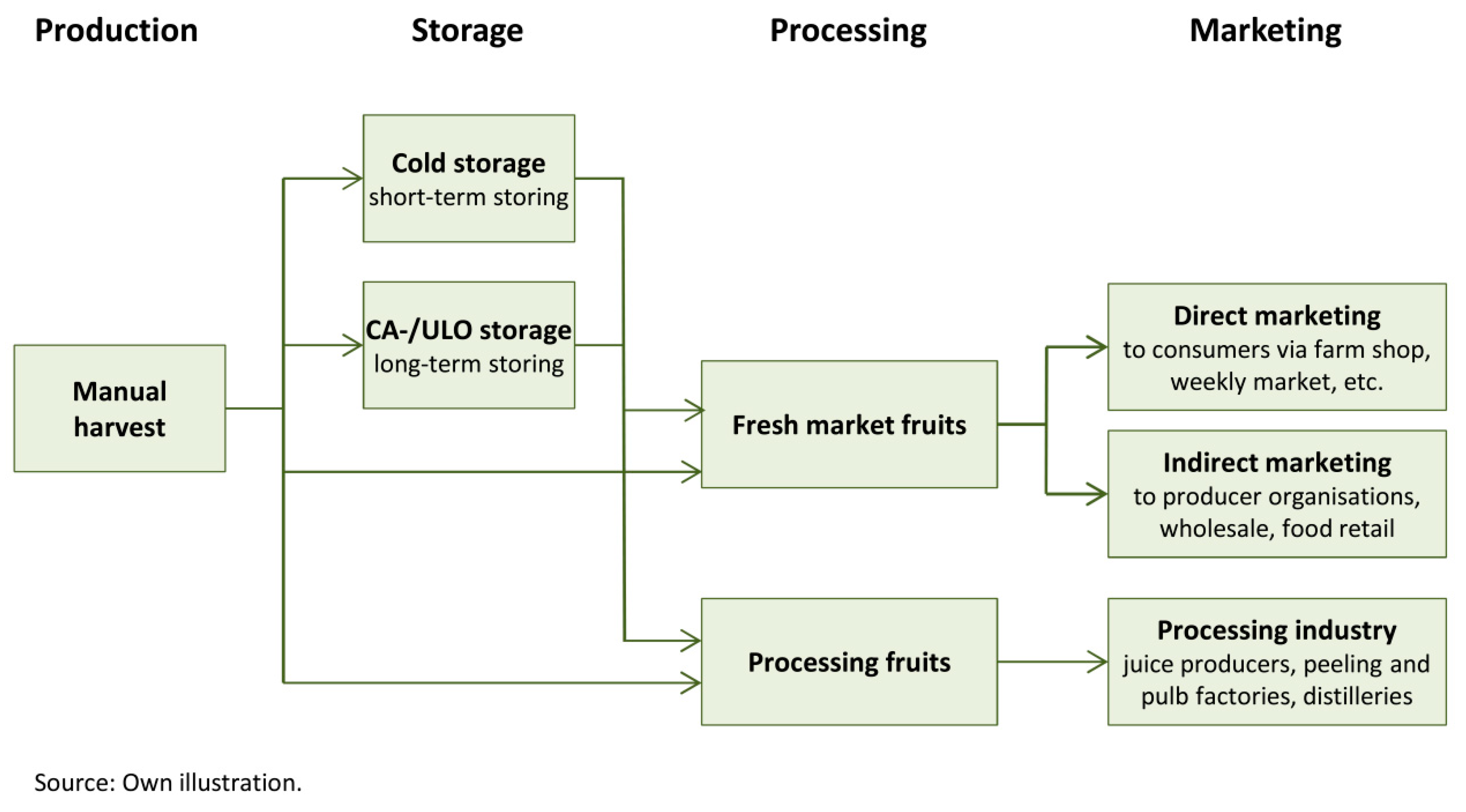

- For the fruit growers, direct marketing to consumers is more important than for the vegetable growers, who are more focused on indirect marketing to producer organisations, wholesalers or food retailers.

- Nearly all apple producers supply the food processing industry. This is the market outlet for apples which do not fulfil the quality requirements of the retail sector but do meet those of the processing industry. For the other products in this survey, the processing industry is less important, as either the quality requirements differ between fresh market and industry produce (carrots) or market volumes for processing are comparatively small (lettuce).

- Some vegetable farms, both lettuce and carrot producers, are engaged in trading additional purchases in order to use sorting and packaging machinery to capacity.

3.2. Quantification of Food Losses at Farm Level

3.3. Reasons for Farm Level Food Losses

Weather Conditions

Market Situation

Farm Management

Quality Standards of the Food Retail Sector

Lack of Marketing Opportunities

3.4. Measures to Reduce Food Losses at Farm Level

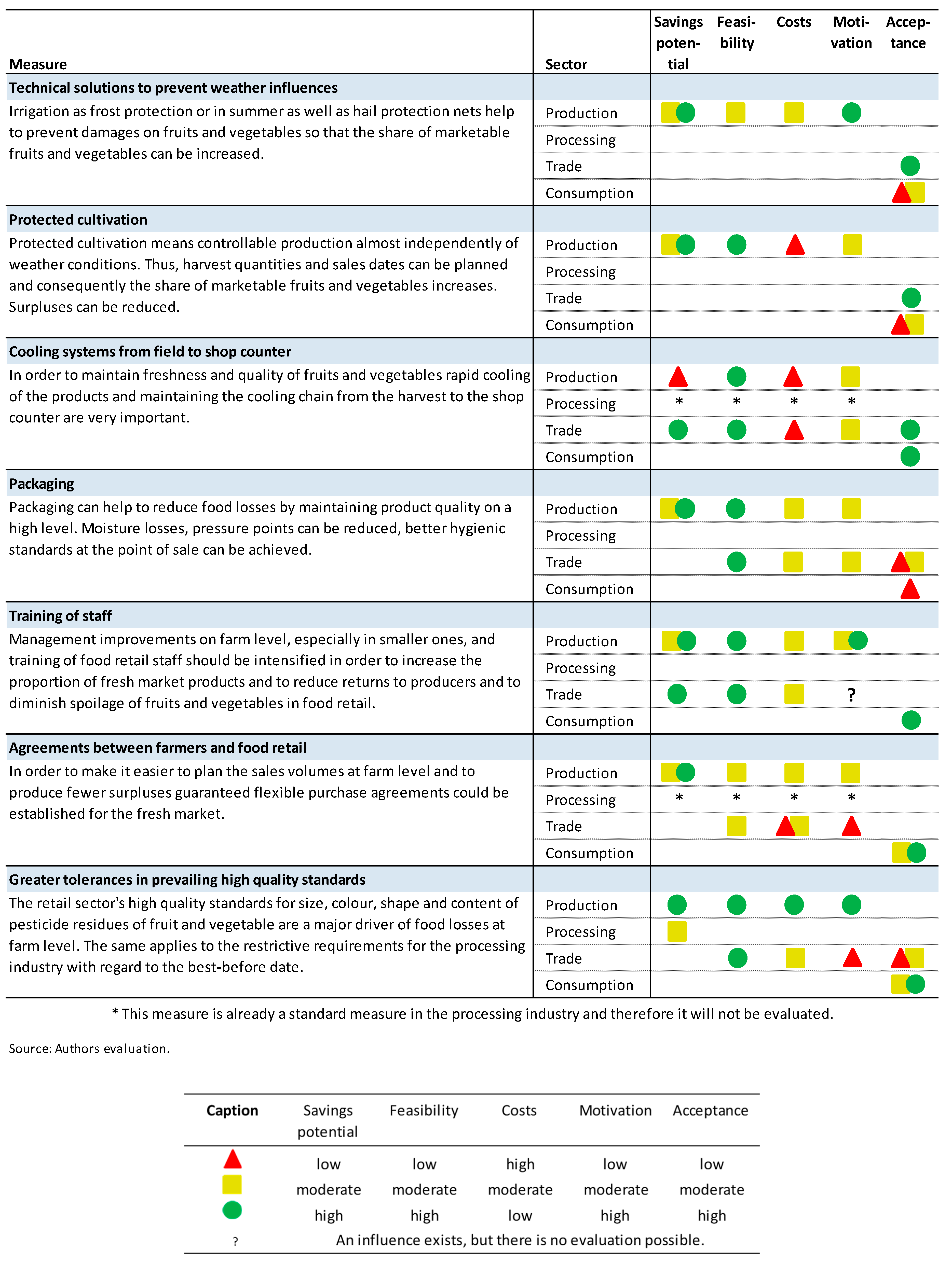

Technical Solutions to Prevent Weather Influences

Protected Cultivation

Cooling Systems from Field to Point of Sale

Packaging

Training of Staff

Agreements between Farmers and Food Retail

Greater Tolerances in Prevailing High-Quality Standards

4. Discussion and Conclusions

- Savings potential: degree of reduction of food losses compared to the status quo.

- Feasibility: degree of technical challenges, organisational changes and/or lack of legal certainty that may be associated with a measure.

- Costs: level of fixed and variable costs associated with the implementation of a measure.

- Motivation: willingness of management and stakeholder to implement the measure, for example, due to expected obstacles or with regard to image gains.

- Acceptance: degree of acceptance of products, production measures or technological changes by other value chain actors and consumers.

Author Contributions

Funding

Conflicts of Interest

Appendix A

- 1.

- Basic Information about the Farm

- 2.

- On Farm Processing and Marketing

- 3.

- Losses along the Value Chain and Reasons for Losses

- 4.

- Statements, Perceptions

- 5.

- Measures to Reduce Losses and Associated Costs

Appendix B

References

- UN (United Nations). Resolution Adopted by the General Assembly on 25 September 2015. Transforming Our World: The 2030 Agenda for Sustainable Development. UN Doc. A/RES/70/1. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 26 September 2019).

- Schmidt, T.; Schneider, F.; Leverenz, D.; Hafner, G. Lebensmittelabfälle in Deutschland—Baseline 2015; Johann Heinrich von Thünen-Institut, Ed.; Thünen Report 71; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2019. [Google Scholar] [CrossRef]

- Kranert, M.; Hafner, G.; Barabosz, J.; Schuller, H.; Leverenz, D.; Kölbig, A.; Schneider, F.; Lebersorger, S.; Scherhaufer, S. Ermittlung der weggeworfenen Lebensmittelmengen und Vorschläge zur Verminderung der Wegwerfrate bei Lebensmitteln in Deutschland; Federal Ministry of Food, Agriculture and Consumer: Protection, Germany, 2012. [Google Scholar]

- Buzby, J.C.; Wells, H.F.; Hyman, J. The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States; United States Department of Agriculture, Ed.; Economic Information Bulletin; United States Department of Agriculture: Washington, DC, USA, 2014; Volume 121.

- Lebersorger, S.; Schneider, F. Food loss rates at the food retail, influencing factors and reasons as a basis for waste prevention measures. Waste Manag. 2014, 34, 1911–1919. [Google Scholar] [CrossRef] [PubMed]

- Filimonau, V.; Gherbin, A. An exploratory study on food waste management practices in the UK grocery retail sector. J. Clean. Prod. 2017, 167, 1184–1194. [Google Scholar] [CrossRef]

- Mattsson, L.; Williams, H.; Berghel, J. Waste of fresh fruit and vegetables at retailers in Sweden—Measuring and calculation of mass, economic cost and climate impact. Resour. Conserv. Recycl. 2018, 130, 118–126. [Google Scholar] [CrossRef]

- WRAP. Quantification of Food Surplus, Waste and Related Materials in the Grocery; WRAP: Banbury, UK, 2016; Available online: https://www.farminguk.com/content/knowledge/Quantification-of-food-surplus-waste-and-related-materials-in-the-grocery-supply-chain(4040-684-286-3476).pdf (accessed on 22 October 2019).

- Richter, B.; Bokelmann, W. Approaches of the German food industry for addressing the issue of food losses. Waste Manag. 2016, 48, 423–429. [Google Scholar] [CrossRef] [PubMed]

- WRAP. Food Waste in Primary Production in the UK; WRAP: Banbury, UK, 2019; Available online: http://www.wrap.org.uk/sites/files/wrap/Food_waste_in_primary_production_in_the_UK_0.pdf (accessed on 22 October 2019).

- Beausang, C.; Hall, C.; Toma, L. Food waste and losses in primary production: Qualitative insights from horticulture. Resour. Conserv. Recycl. 2017, 126, 177–185. [Google Scholar] [CrossRef]

- WRAP. Food Waste in Primary Production—A Preliminary Study on Strawberries and Lettuce; WRAP: Banbury, UK, 2017; Available online: http://www.wrap.org.uk/sites/files/wrap/Food_waste_in_primary_production_report.pdf (accessed on 22 October 2019).

- Meyer, C.H.; Hamer, M.; Frieling, D.; Oertzen, G. Lebensmittelverluste von Obst, Gemüse, Kartoffeln Zwischen Feld und Ladentheke—Ergebnisse Einer Studie in Nordrhein-Westfalen; Landesamt für Natur, Umwelt und Verbraucherschutz Nordrhein-Westfalen (LANUV): Recklinghausen, Germany, 2018; Fachbericht 85. [Google Scholar]

- Johnson, L.K.; Dunning, R.D.; Gunter, C.C.; Bloom, J.D.; Boyette, M.D.; Creamer, N.G. Estimating on-farm food loss at the field level: A methodology and applied case study on a North Carolina farm. Resour. Conserv. Recycl. 2018, 137, 243–250. [Google Scholar] [CrossRef]

- Schmied, E.; Mayerhofer, J.; Schwödt, S.; Obersteiner, G. Gleaning activities as contribution to food waste reduction. In Proceedings of the Sardinia 2017, 16th International Waste Management and Landfill Symposium, Cagliari, Italy, 2–6 October 2017. [Google Scholar]

- Schneider, F.; Part, F.; Göbel, C.; Langen, N.; Gerhards, C.; Kraus, G.F.; Ritter, G. A methodological approach for the on-site quantification of food losses in primary production: Austrian and German case studies using example of potato harvest. Waste Manag. 2019, 86, 106–113. [Google Scholar] [CrossRef] [PubMed]

- Leibetseder, M. Lebensmittelabfälle in der landwirtschaftlichen Produktion—Abschätzung des Verlusts von Obst und Gemüse in der Landwirtschaft und während des Transportes zum Händler. Master’s Thesis, Institute of Waste Management, University of Natural Resources and Life Sciences, Vienna, Austria, 2012. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations (FAO): Rom, Italy, 2011. [Google Scholar]

- Hafner, G.; Barabosz, J.; Leverenz, D.; Maurer, C.; Kranert, M.; Göbel, C.; Friedrich, S.; Ritter, G.; Teitscheid, P.; Wetter, C. Analyse, Bewertung und Optimierung von Systemen zur Lebensmittelbewirtschaftung, Teil I: Definition der Begriffe “Lebensmittelverluste” und “Lebensmittelabfälle”. Müll Abfall—Fachzeitschrift Abfall Ressourcenwirtschaft 2013, 11, 601–609. [Google Scholar]

- European Commission Delegated Decision (EU) of 3 May 2019 Supplementing Directive 2008/98/EC of the European Parliament and of the Council as Regards a Common Methodology and Minimum Quality Requirements for the Uniform Measurement of Levels of Food Waste. Available online: https://ec.europa.eu/transparency/regdoc/rep/3/2019/EN/C-2019-3211-F1-EN-MAIN-PART-1.PDF (accessed on 26 September 2019).

- European Parliament Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety. Available online: https://mobil.bfr.bund.de/cm/343/2002_178_en_efsa.pdf (accessed on 26 September 2019).

- Johnson, L.K.; Bloom, J.D.; Dunning, R.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Farmer harvest decisions and vegetable loss in primary production. Agric. Syst. 2019, 176, 102672. [Google Scholar] [CrossRef]

- Göthlich, S.E. Fallstudien als Forschungsmethode: Plädoyer für einen Methodenpluralismus in der Deutschen Betriebswirtschaftlichen Forschung; No 578; Manuskripte aus den Instituten für Betriebswirtschaftslehre der Universität Kiel: Kiel, Germany, 2003. [Google Scholar]

- Borchardt, A.; Göthlich, S.E. Erkenntnisgewinnung durch Fallstudien. In Methoden der Empirischen Forschung, 3rd ed.; Albers, S., Klapper, D., Konradt, U., Walter, A., Wolf, J., Eds.; Gabler: Wiesbaden, Germany, 2009; pp. 33–48. [Google Scholar]

- AMI—Agrarmarkt Informations-Gesellschaft mbH. AMI Markt Bilanz Obst 2019; AMI—Agrarmarkt Informations-Gesellschaft mbH: Bonn, Germany, 2019. [Google Scholar]

- AMI—Agrarmarkt Informations-Gesellschaft mbH. AMI Markt Bilanz Gemüse 2019; AMI—Agrarmarkt Informations-Gesellschaft mbH: Bonn, Germany, 2019. [Google Scholar]

- Schmidt, T.; Baumgardt, S.; Blumenthal, A.; Burdick, B.; Claupein, E.; Dirksmeyer, W.; Hafner, G.; Klockgether, K.; Koch, F.; Leverenz, D.; et al. Wege zur Reduzierung von Lebensmittelabfällen—Pathways to Reduce Food Waste (REFOWAS): Maßnahmen, Bewertungsrahmen und Analysewerkzeuge Sowie Zukunftsfähige Ansätze für Einen Nachhaltigen Umgang mit Lebensmitteln unter Einbindung Sozio-Ökologischer Innovationen; Johann Heinrich von Thünen-Institut, Ed.; Thünen Report 73; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2019; Volume 2, Available online: https://www.thuenen.de/media/publikationen/thuenen-report/Thuenen-Report_73_Vol2.pdf (accessed on 22 October 2019). [CrossRef]

- Ludwig-Ohm, S.; Dirksmeyer, W. REFOWAS-Fallstudie Obst und Gemüse: Lebensmittelverluste in Verarbeitungsindustrie und Lebensmitteleinzelhandel (LEH); DGG-Proceedings; Deutsche Gartenbauwissenschaftliche Gesellschaft (DGG): Berlin, Germany, 2019; (Under Review). [Google Scholar]

- Strohm, K.; Garming, H.; Dirksmeyer, W. Entwicklung des Gemüsebaus in Deutschland von 2000 bis 2015: Anbauregionen, Betriebsstrukturen, Gemüsearten und Handel; Johann Heinrich von Thünen-Institut, Ed.; Thünen Working Paper 56; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2016; Available online: https://www.thuenen.de/media/publikationen/thuenen-workingpaper/ThuenenWorkingPaper_56.pdf (accessed on 22 October 2019).

- Garming, H.; Dirksmeyer, W.; Bork, L. Entwicklungen des Obstbaus in Deutschland von 2005 bis 2017: Obstarten, Anbauregionen, Betriebsstrukturen und Handel; Johann Heinrich von Thünen-Institut, Ed.; Thünen Working Paper 100; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2018; Available online: https://www.thuenen.de/media/publikationen/thuenen-workingpaper/ThuenenWorkingPaper_100.pdf (accessed on 22 October 2019).

- European Commission Implementing Regulation (EU) No 543/2011 of 7 June 2011. Available online: www.eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R0543 (accessed on 26 September 2019).

- UNECE (United Nations Economic Commission for Europe) Standard FFV-10 Concerning the Marketing and Commercial Quality Control of Carrots. 2017 Edition. Available online: https://www.unece.org/fileadmin/DAM/trade/agr/standard/standard/fresh/FFV-Std/English/10_Carrots.pdf (accessed on 26 September 2019).

- Holthusen, H.H.F. Pflanzenschutz im Deutschen Obstbau: Herausforderungen aus Sicht des Alten Landes. Presented at the 15th Swiss Growing Day, St. Gallen, Switzerland, 24 February 2017; Available online: https://www.agroscope.admin.ch/agroscope/de/home/aktuell/veranstaltungen/schweizer-obstkulturtag.html (accessed on 24 May 2018).

- Frieling, D.; Stricks, V.; Wildenberg, M.; Schneider, F. The beauty and the beast—How quality management criteria at supermarkets create food waste. In Proceedings of the Perspectives on Managing Life Cycles—6th International Conference on Life Cycle Management, Gothenburg, Sweden, 25–28 August 2013. [Google Scholar]

- Runge, F.; Lang, H. Lebensmittelverluste in der Landwirtschaft durch Ästhetik-Ansprüche an Obst und Gemüse—Gründe, Ausmaß und Verbleib. Berichte Landwirtschaft 2016, 94. [Google Scholar] [CrossRef]

- De Hooge, I.E.; van Dulm, E.; van Trijp, H.C.M. Cosmetic specifications in the food waste issue: Supply chain considerations and practices concerning suboptimal food products. J. Clean. Prod. 2018, 183, 698–709. [Google Scholar] [CrossRef]

- Porat, R.; Lichter, A.; Terry, L.A.; Harker, R.; Buzby, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef]

- CORDIS—EU Research Results. Waste Reduction and Quality Improvements of Fruits and Vegetables via an Innovative and Energy-Efficient Humidification/Disinfection Technology. Available online: https://cordis.europa.eu/project/rcn/193303/factsheet/en (accessed on 22 October 2019).

- Eriksson, M.; Ghosh, R.; Mattsson, L.; Ismatov, A. Take-back agreements in the perspective of food waste generation at the supplier-retailer interface. Resour. Conserv. Recycl. 2017, 122, 83–93. [Google Scholar] [CrossRef]

- Goosens, Y.; Wegner, A.; Schmidt, T. Sustainability Assessment of Food Waste Prevention Measures: Review of Existing Evaluation Practices. Front. Sustain. Food Syst. 2019, 3, 90. [Google Scholar] [CrossRef]

| Case Study | Crop | Lower Saxony | North Rhine-Westphalia | Rhineland- Palatinate | Lake Constance |

|---|---|---|---|---|---|

| Vegetable | Lettuce | 9 | 10 | ||

| Carrots | 10 | 11 | |||

| Fruit | Strawberries | 11 | 10 | ||

| Apples | 10 | 10 |

| Crop | All Crops | ||||

|---|---|---|---|---|---|

| Lettuce | Carrot | Strawberry | Apple | ||

| Coordinators 1 | 4 | 4 | 2 | 7 | 4 |

| Processing industry 2 | 5 | ||||

| Food retail | 3 | ||||

| Case Study | Total Number of Farms | Number of Farms with | ||||

|---|---|---|---|---|---|---|

| Growing Area * ≥ 30 ha | Sales to | Trading Additional Purchases | ||||

| Consumers Directly | Producer Organisations, Wholesales, Food Retailers | Industrial Bulk Consumers, Convenience or Food Processing Industry | ||||

| Lettuce | 19 | 15 | 5 | 17 | 8 | 3 |

| Washed carrots | 18 | 9 | 5 | 16 | 3 | 4 |

| Strawberries | 21 | 6 | 17 | 12 | 1 | - |

| Apples | 19 | 5 | 11 | 19 | 18 | - |

| Good Years | Average | Bad Years | ||

|---|---|---|---|---|

| Lettuce | 10–15% | 25–30% | 35–40% | |

| Washed carrots | 10–15% | 25–40% | >50% | |

| Strawberries | LS 2 NW 2 | 5–10% ca. 10% | 15–20% | up to 40% 40–50% |

| Apples | 6–16% |

| Minimum Requirements for Marketable Products | |||

|---|---|---|---|

| All products have to be - intact, - fresh in appearance, - sound, free from rotting, - clean, - practically free from pests, - practically free from damage caused by pests, - free of abnormal external moisture, - free of any foreign smell and/or taste, and - sufficiently developed, but not over-developed/over-ripened | |||

| In addition, there are additional product-specific requirements: | |||

| Lettuce | Carrots | Strawberries | Apples |

| - turgescent - not running to seed - practically free from all earth or other growing medium | - firm - not woody - not running to seed - not forked | - with the calyx | - free from damage caused by pests affecting the flesh |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ludwig-Ohm, S.; Dirksmeyer, W.; Klockgether, K. Approaches to Reduce Food Losses in German Fruit and Vegetable Production. Sustainability 2019, 11, 6576. https://doi.org/10.3390/su11236576

Ludwig-Ohm S, Dirksmeyer W, Klockgether K. Approaches to Reduce Food Losses in German Fruit and Vegetable Production. Sustainability. 2019; 11(23):6576. https://doi.org/10.3390/su11236576

Chicago/Turabian StyleLudwig-Ohm, Sabine, Walter Dirksmeyer, and Kathrin Klockgether. 2019. "Approaches to Reduce Food Losses in German Fruit and Vegetable Production" Sustainability 11, no. 23: 6576. https://doi.org/10.3390/su11236576

APA StyleLudwig-Ohm, S., Dirksmeyer, W., & Klockgether, K. (2019). Approaches to Reduce Food Losses in German Fruit and Vegetable Production. Sustainability, 11(23), 6576. https://doi.org/10.3390/su11236576