Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis

Abstract

1. Introduction

2. Methodology

2.1. Literature Search

2.2. Inclusion Criteria

2.3. Data Extraction and Processing

2.4. Effect Size Calculation and Estimation of Overall Effect Size

2.5. Subgroup Analysis and Meta-Regression

3. Results

3.1. Study Descriptions

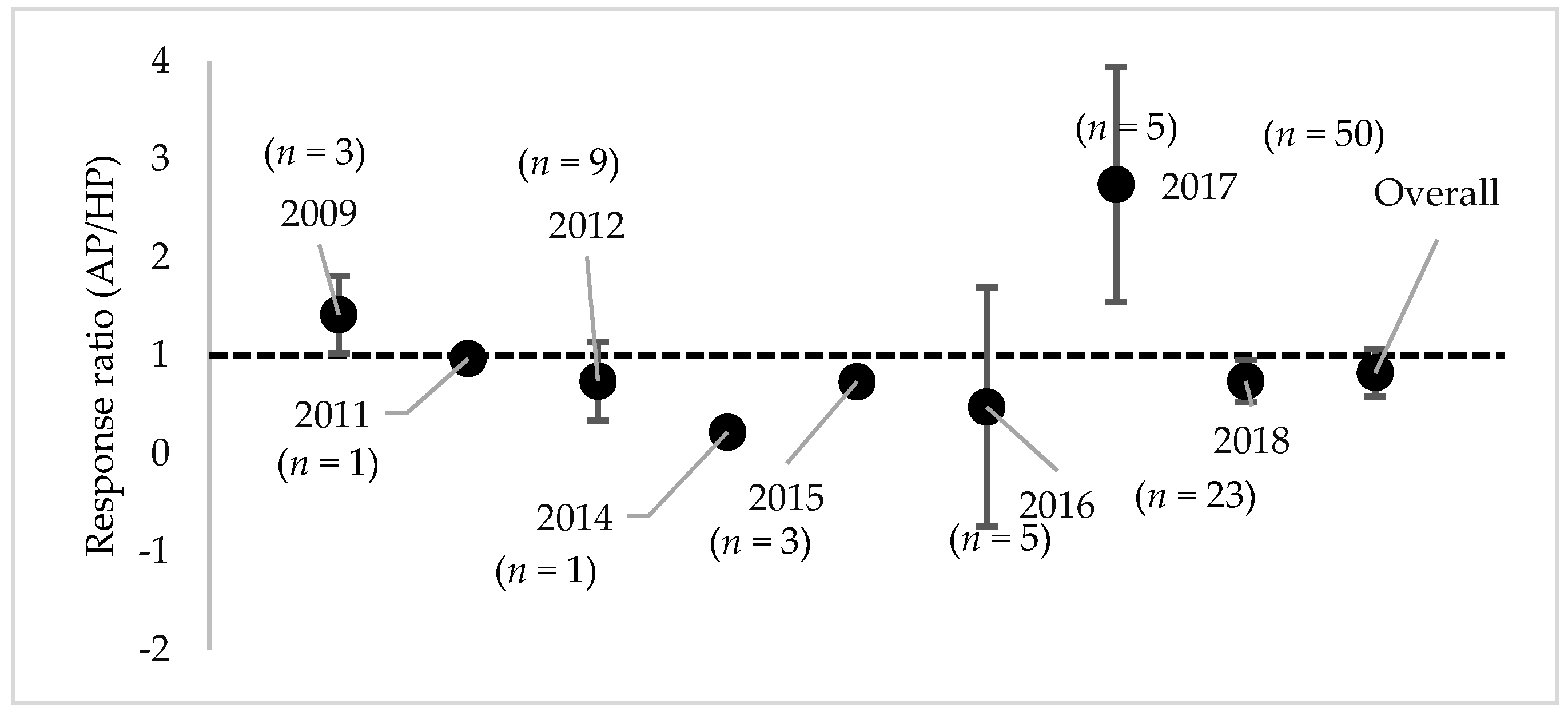

3.2. Crop Yield across Studies

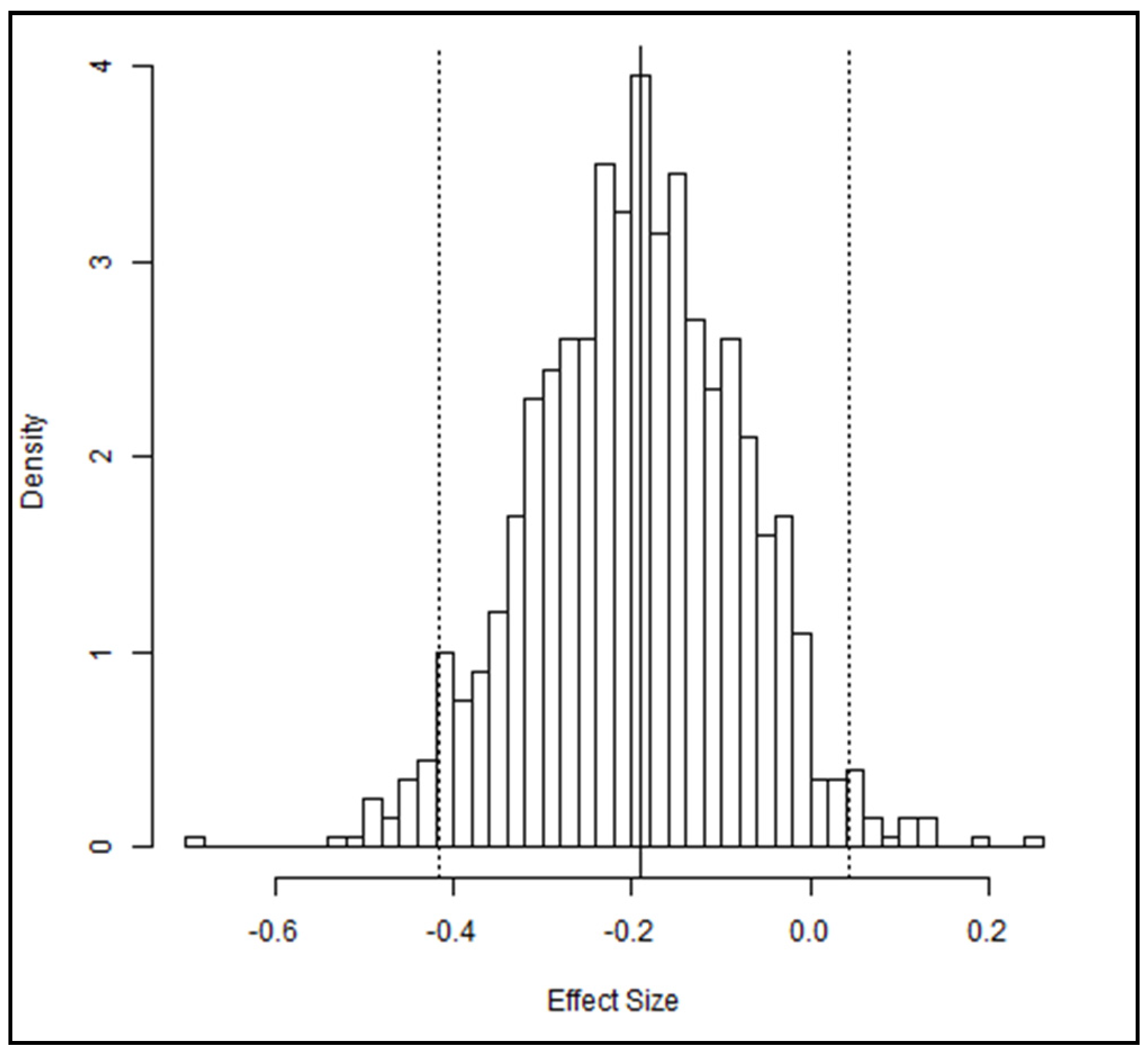

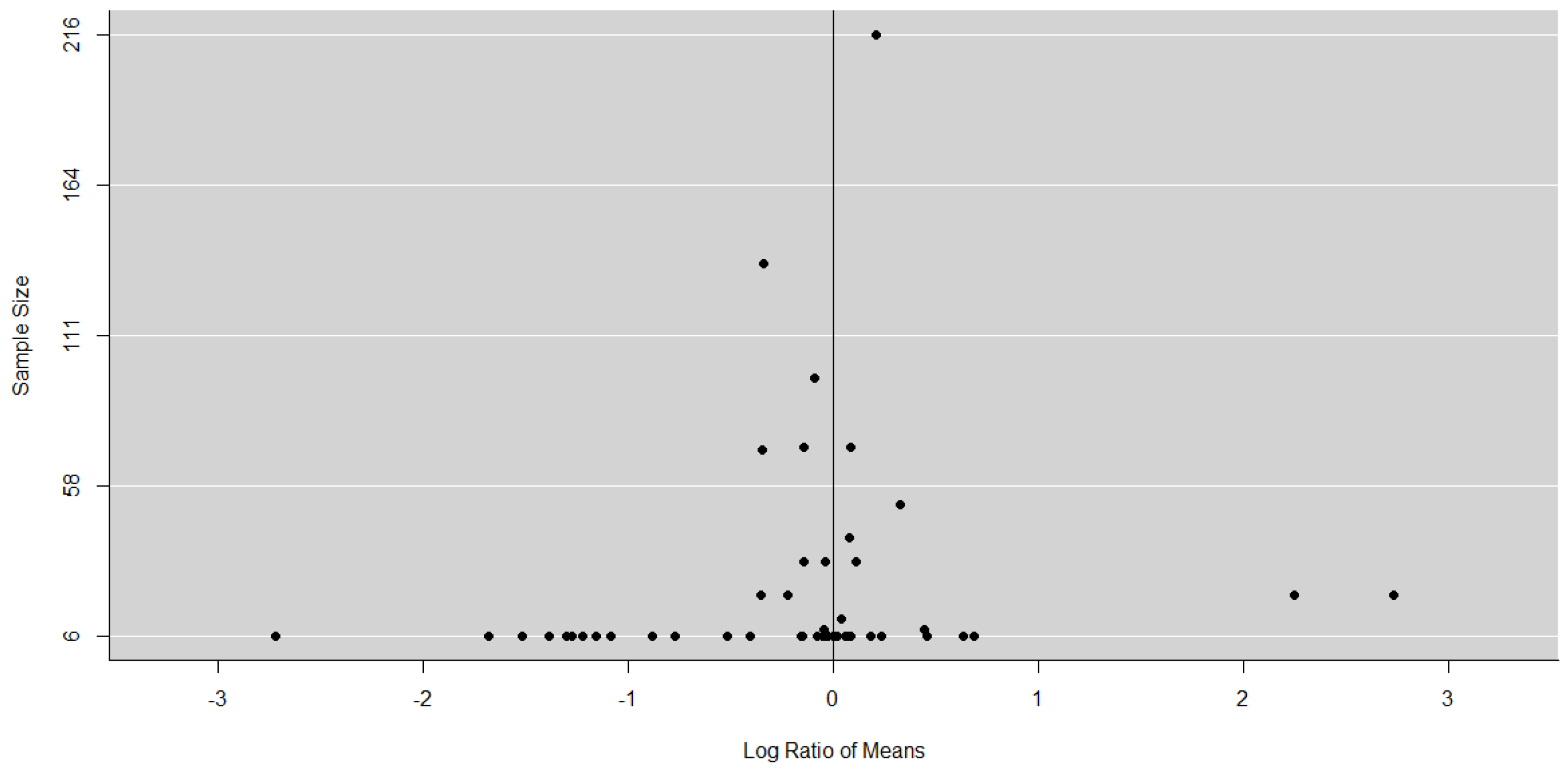

3.3. Publication Bias

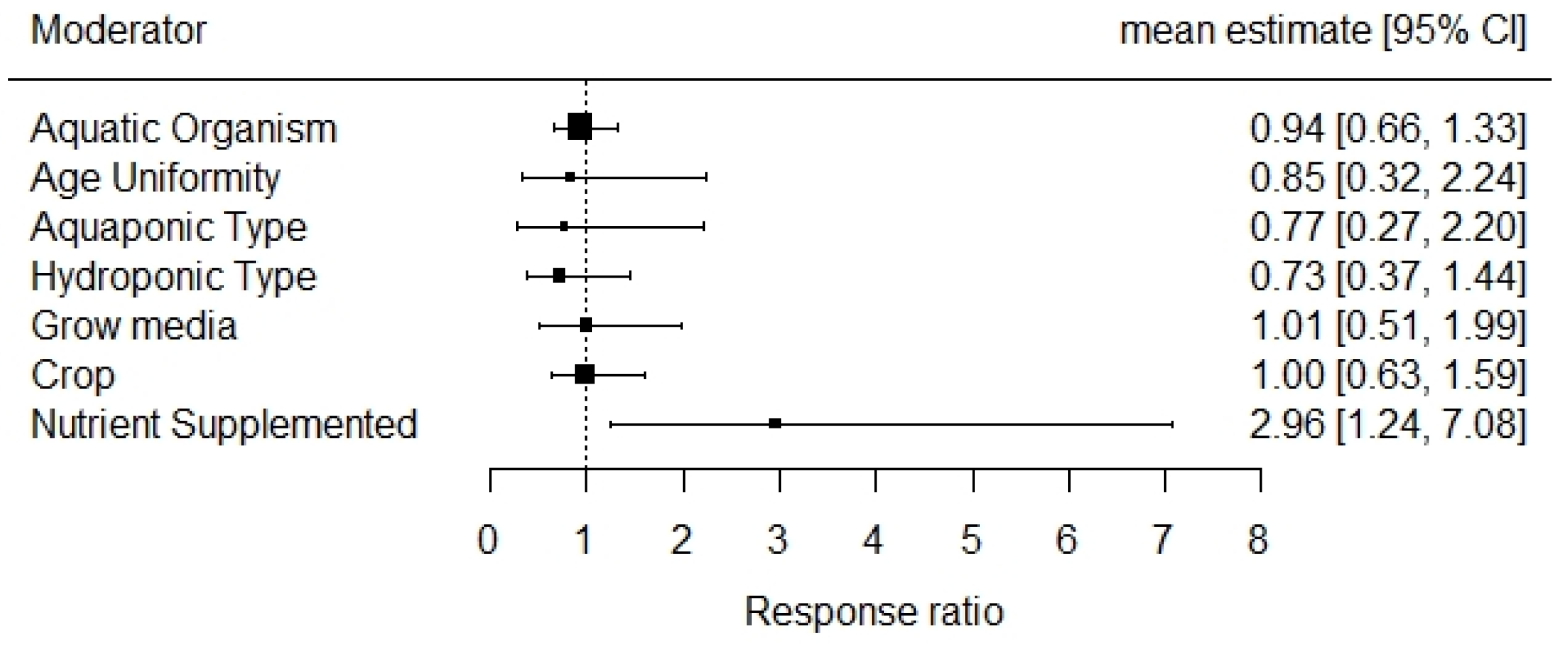

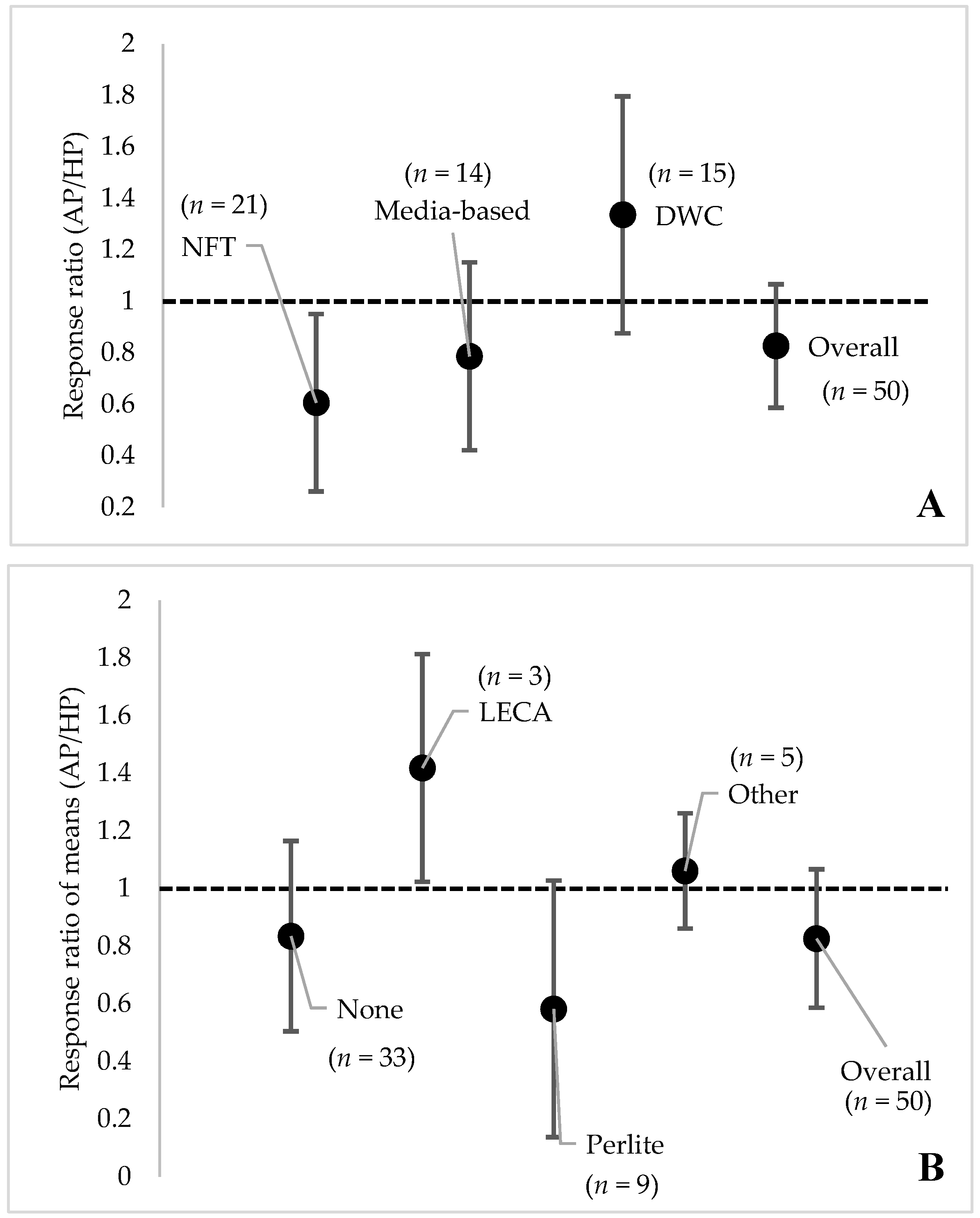

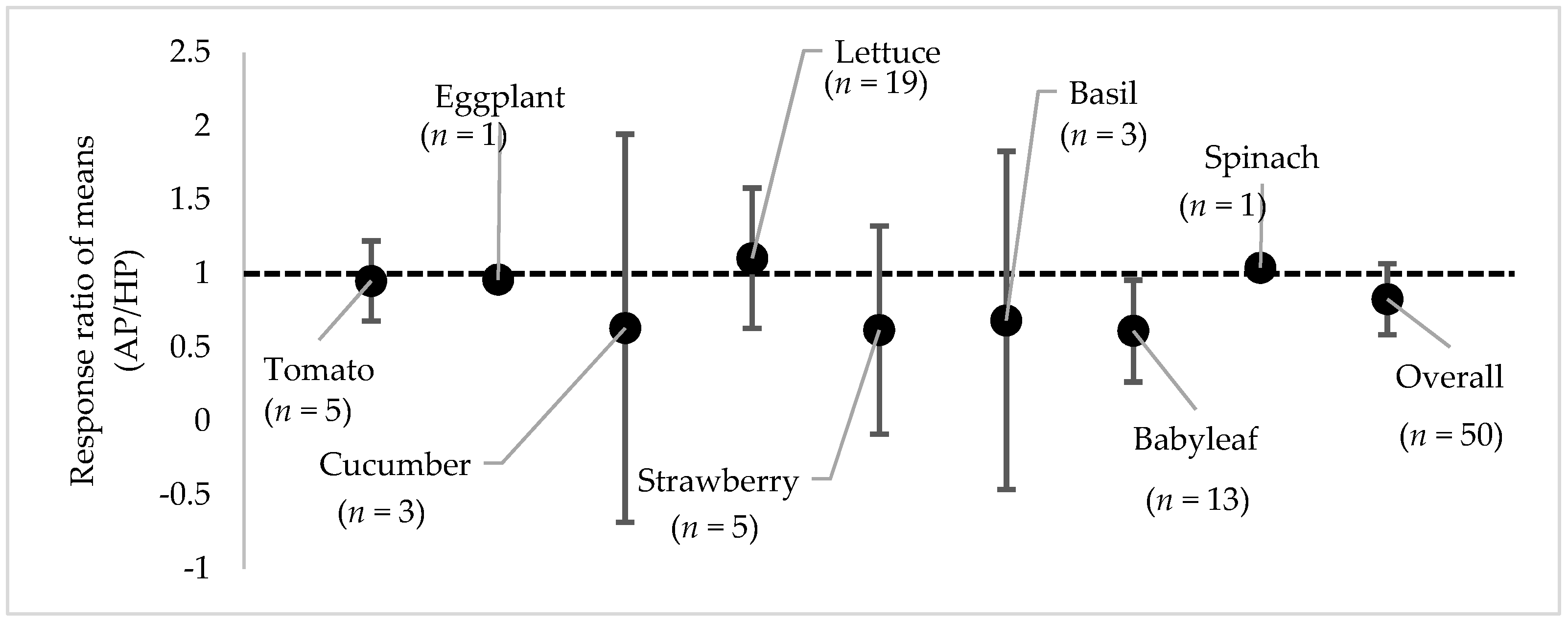

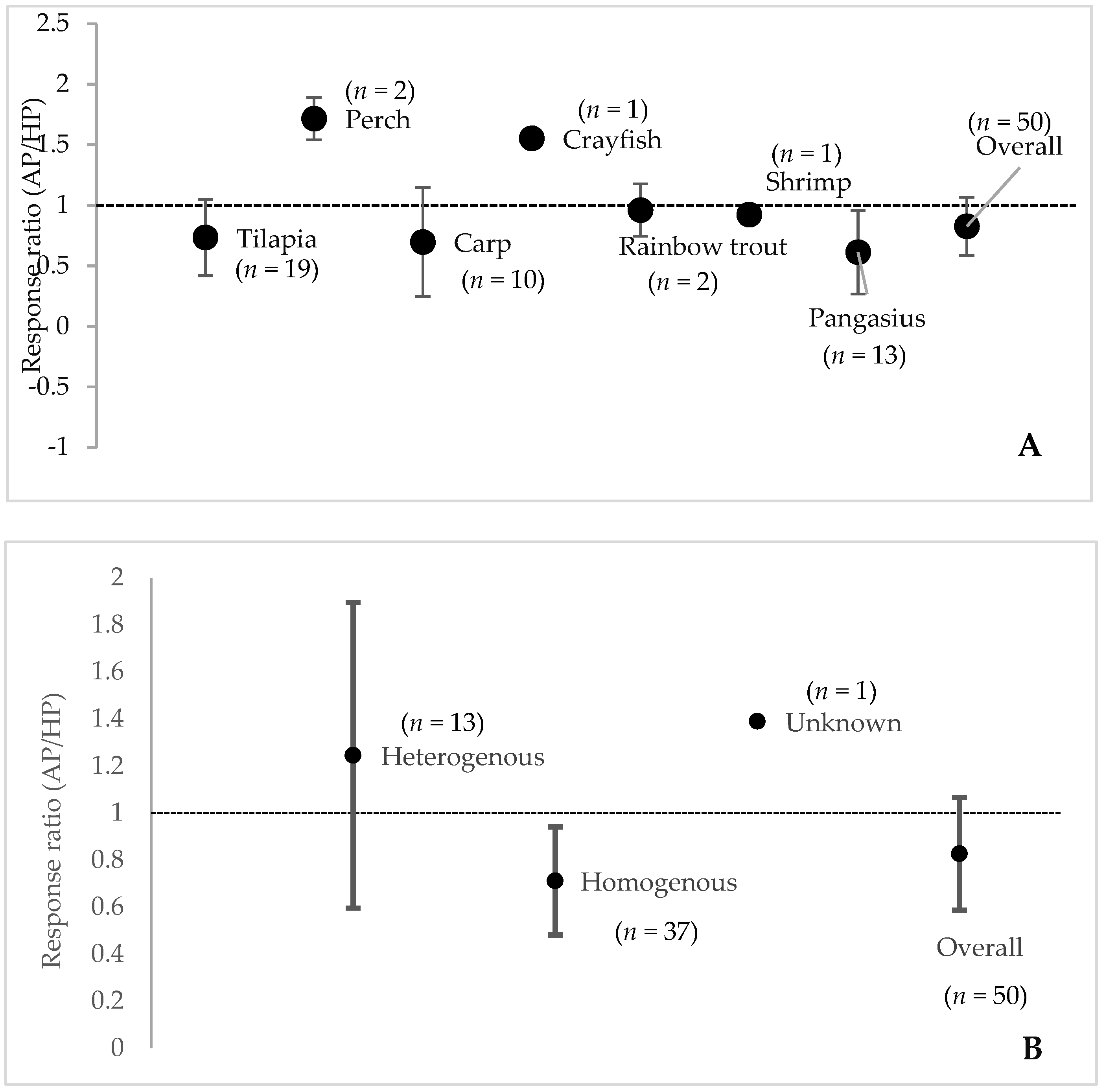

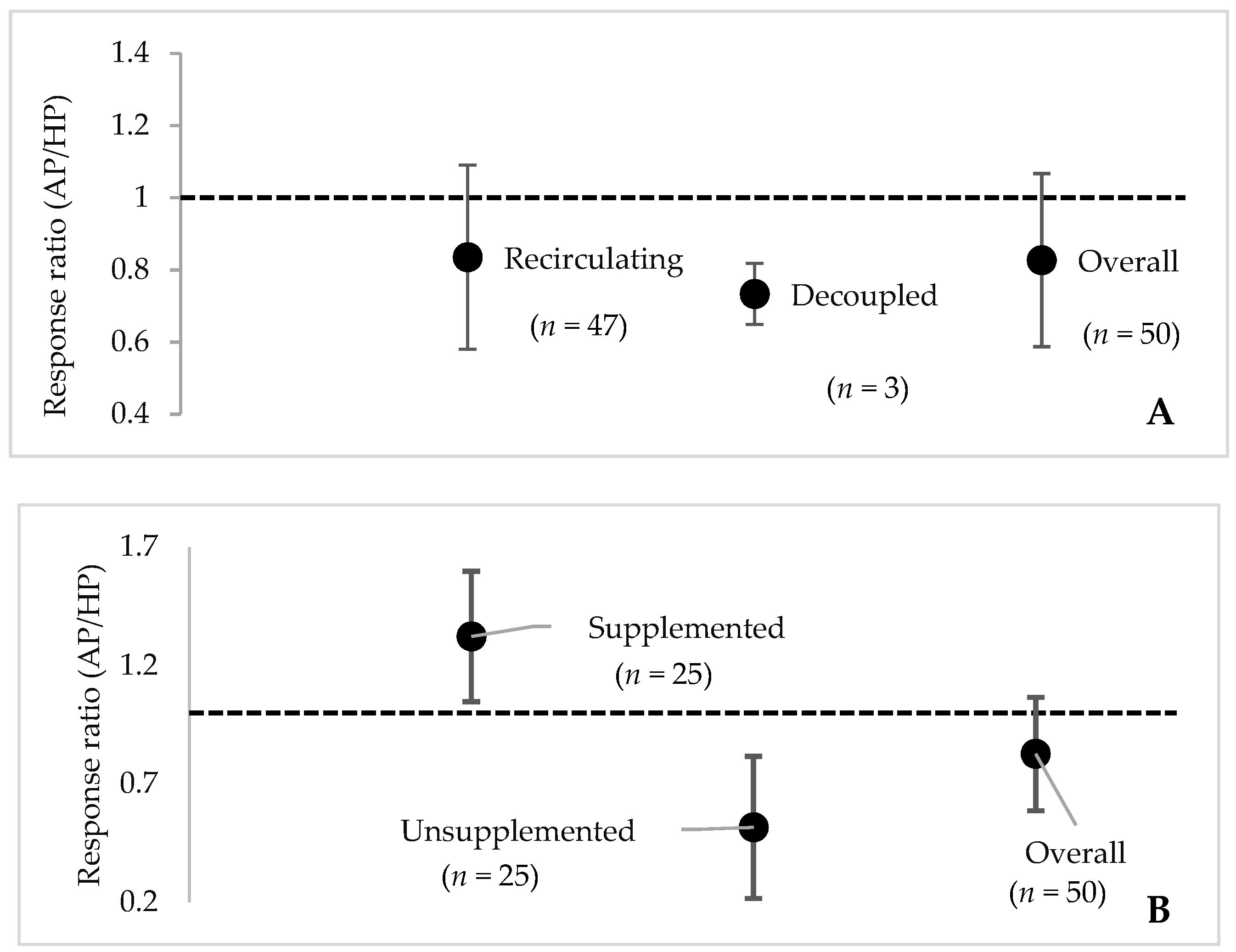

3.4. Moderators

3.5. Stocking Density and Feed Crude Protein Content

4. Discussion

4.1. Crop Yield Across Studies

4.2. Subgroup Analysis

5. Conclusions

6. Challenges of This Study and Recommendations

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rakocy, J. Hargreaves Integration of vegetable Hydroponics with fish culture: A review. In Proceedings of the Techniques for Modern Aquaculture; American Society of Agricultural Engineers, St. Joseph, MI, USA, 21–23 June 1993; pp. 112–136. [Google Scholar]

- Graber, A.; Junge, R. Aquaponic Systems: Nutrient recycling from fish wastewater by vegetable production. Desalination 2009, 246, 147–156. [Google Scholar] [CrossRef]

- Cohen, A.; Malone, S.; Morris, Z.; Weissburg, M.; Bras, B. Combined Fish and Lettuce Cultivation: An Aquaponics Life Cycle Assessment. Procedia CIRP 2018, 69, 551–556. [Google Scholar] [CrossRef]

- Nichols, M.A.; Savidov, N.A. Aquaponics: A nutrient and water efficient production system. Acta Hortic. 2012, 947, 129–132. [Google Scholar] [CrossRef]

- Belsare, S.S.; Singh, H.; Yadav, S.R.; Kunjir, S.N. Aquaponics: The food production system of the future. InfoFish Int. 2007, 4, 8–13. [Google Scholar]

- Price, C. A sustainable option for local food production. Fish Farmer 2009, 32, 32–34. [Google Scholar]

- Tyson, R.V.; Danyluk, M.D.; Simonne, E.H.; Treadwell, D.D. Aquaponics—Sustainable vegetable and fish co-production. Proc. Fla. State Hortic. Soc. 2012, 125, 381–385. [Google Scholar]

- Nehar, S. Aquaponics: A novel approach of sustainable means of food production. Sci. Cult. 2013, 79, 227–230. [Google Scholar]

- Kloas, W.; Gross, R.; Baganz, D.; Graupner, J.; Monsees, H.; Schmidt, U.; Staaks, G.; Suhl, J.; Tschirner, M.; Wittstock, B.; et al. A new concept for aquaponic systems to improve sustainability, increase productivity, and reduce environmental impacts. Aquac. Environ. Interact. 2015, 7, 179–192. [Google Scholar] [CrossRef]

- Blidariu, F.; Drasovean, A.; Grozea, A. Evaluation of phosphorus level in green lettuce conventional grown under natural conditions and aquaponic system. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Anim. Sci. Biotechnol. 2013, 70, 128–135. [Google Scholar]

- Roosta, H.R.; Hamidpour, M. Mineral nutrient content of tomato plants in aquaponic and hydroponic systems: Effect of foliar application of some macro- and micro-nutrients. J. Plant Nutr. 2013, 36, 2070–2083. [Google Scholar] [CrossRef]

- Reyes-Flores, M.; Sandoval-Villa, M.; Rodriguez-Mendoza, N.; Trejo-Tellez, L.I.; Sanchez-Escudero, J.; Reta-Mendiola, J. Aquaponics nutrient concentration in effluent for production of Solanum lycopersicum L. Rev. Mex. Cienc. Agric. 2016, 7, 3529–3542. [Google Scholar]

- Goddek, S.; Joyce, A.; Gross, A.; Delaide, B.P.L.; Eding, E.H.; Verreth, J.; Keesman, K.J.; Keizer, L.C.P.; Reuter, M.; Morgenstern, R.; et al. Nutrient mineralization and organic matter reduction performance of RAS-based sludge in sequential UASB-EGSB reactors. Aquac. Eng. 2018, 83, 10–19. [Google Scholar] [CrossRef]

- Roosta, H.R.; Afsharipoor, S. Effects of different cultivation media on vegetative growth, ecophysiological traits and nutrients concentration in strawberry under hydroponic and aquaponic cultivation systems. Adv. Environ. Biol. 2012, 6, 543–555. [Google Scholar]

- Alcarraz, E.; Bustamante, A.; Wacyk, J.; Flores, M.; Tapia, M.L.; Escalona, V. Quality of lettuce (Lactuca sativa L.) grown in aquaponic and hydroponic systems. Acta Hortic. 2018, 1194, 31–38. [Google Scholar] [CrossRef]

- Anderson, T.S.; Villiers, D.; Timmons, M.B.; Martini, M.R.; Villiers, D.; Timmons, M.B. Growth and tissue elemental composition response of butterhead lettuce (Lactuca sativa, cv. Flandria) to hydroponic conditions at different pH and alkalinity. Horticulturae 2017, 3, 41. [Google Scholar] [CrossRef]

- Love, D.C.; Fry, J.P.; Li, X.; Hill, E.S.; Genello, L.; Semmens, K.; Thompson, R.E. Commercial aquaponics production and pro fi tability: Findings from an international survey. Aquaculture 2015, 435, 67–74. [Google Scholar] [CrossRef]

- Palm, H.W.; Bissa, K.; Knaus, U. Significant factors affecting the economic sustainability of closed aquaponic systems. Part II: Fish and plant growth. AACL Bioflux 2014, 7, 162–175. [Google Scholar]

- Palm, H.W.; Knaus, U.; Appelbaum, S.; Goddek, S.; Strauch, S.M.; Palm, H.W. Towards commercial aquaponics: A review of systems, designs, scales and nomenclature. Aquac. Int. 2018, 26, 813–842. [Google Scholar] [CrossRef]

- Boxman, S.E.; Qiong, Z.; Bailey, D.; Trotz, M.A. Life cycle assessment of a commercial-scale freshwater aquaponic system. Environ. Eng. Sci. 2017, 34, 299–311. [Google Scholar] [CrossRef]

- Zou, Y.; Hua, Z.; Zhanga, J.; Xieb, H.; Guimbaudc, C.; Fanga, Y.; Zou, Y.; Hu, Z.; Zhang, J.; Xie, H.; et al. Effects of pH on nitrogen transformations in media-based aquaponics. Bioresour. Technol. 2016, 210, 81–87. [Google Scholar] [CrossRef]

- Groenveld, T.; Kohn, Y.Y.; Gross, A.; Lazarovitch, N. Optimization of nitrogen use efficiency by means of fertigation management in an integrated aquaculture-agriculture system. J. Clean. Prod. 2019, 212, 401–408. [Google Scholar] [CrossRef]

- Liang, J.Y.; Chien, Y.H. Effects of feeding frequency and photoperiod on water quality and crop production in a tilapia-water spinach raft aquaponics system. Int. Biodeterior. Biodegrad. 2013, 85, 693–700. [Google Scholar] [CrossRef]

- Delaide, B.; Goddek, S.; Gott, J.; Soyeurt, H.; Jijakli, M.H. Lettuce (Lactuca sativa L. var. sucrine) growth performance in complemented aquaponic solution outperforms hydroponics. Water 2016, 8, 467. [Google Scholar] [CrossRef]

- Jordan, R.A.; Ribeiro, E.F.; Oliveira, F.C.; Geisenhoff, L.O.; Martins, E.A.S. Yield of lettuce grown in hydroponic and aquaponic systems using different substrates. Rev. Bras. Eng. Agric. Ambient. 2018, 22, 525–529. [Google Scholar] [CrossRef]

- Goddek, S.; Vermeulen, T. Comparison of Lactuca sativa growth performance in conventional and RAS-based hydroponic systems. Aquac. Int. 2018, 26, 1377–1386. [Google Scholar] [CrossRef] [PubMed]

- Buzby, K.M.; Waterland, N.L.; Semmens, K.J.; Lin, L.S. Evaluating aquaponic crops in a freshwater flow-through fish culture system. Aquaculture 2016, 460, 15. [Google Scholar] [CrossRef]

- Delaide, B.; Delhaye, G.; Dermience, M.; Gott, J.; Soyeurt, H.; Jijakli, M.H. Plant and fish production performance, nutrient mass balances, energy and water use of the PAFF Box, a small-scale aquaponic system. Aquac. Eng. 2017, 78, 130–139. [Google Scholar] [CrossRef]

- Wortman, S.E.; Douglass, M.S.; Kindhart, J.D. Cultivar, Growing Media, and Nutrient Source Influence Strawberry Yield in a Vertical, Hydroponic, High Tunnel System. HortTechnology 2016, 26, 466–473. [Google Scholar] [CrossRef]

- Savidov, N.A.; Hutchings, E.; Rakocy, J.E. Fish and plant production in a recirculating aquaponic system: A new approach to sustainable agriculture in Canada. Acta Hortic. 2007, 742, 209–222. [Google Scholar] [CrossRef]

- Enduta, A.; Jusoh, A.; Ali, N.; Wan Nik, W.B.; Endut, A.; Jusoh, A.; Ali, N.; Nik, W.B.W. Nutrient removal from aquaculture wastewater by vegetable production in aquaponics recirculation system. Desalin. Water Treat. 2011, 32, 422–430. [Google Scholar] [CrossRef]

- Knaus, U.; Palm, H.W. Effects of fish biology on ebb and flow aquaponical cultured herbs in northern Germany (Mecklenburg Western pomerania). Aquaculture 2017, 466, 51–63. [Google Scholar] [CrossRef]

- Pinho, S.M.; Lemos de Mello, G.; Fitzsimmons, K.M.; Emerenciano, M.G.C. Integrated production of fish (pacu Piaractus mesopotamicus and red tilapia Oreochromis sp.) with two varieties of garnish (scallion and parsley) in aquaponics system. Aquac. Int. 2018, 26, 99–112. [Google Scholar] [CrossRef]

- Shorten, A.; Shorten, B. What is meta-analysis? Evid. Based Nurs. 2013, 16, 3–4. Available online: https://ebn.bmj.com/content/16/1/3 (accessed on 9 August 2019). [CrossRef] [PubMed]

- Borenstein, M.; Hedges, L.V.; Higgins, J.P.T.; Rothstein, H.R. Introduction To Meta Aalysis; John Wiley & Sons, Ltd.: Chichester, UK, 2009; ISBN 9780470057247. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta Analyses: The PRISMA Statement. 2009. Available online: https://journals.plos.org/plosmedicine/article?id=10.1371/journal.pmed.1000097 (accessed on 31 March 2019).

- Wortman, S.E. Crop physiological response to nutrient solution electrical conductivity and pH in an ebb-and-flow hydroponic system. Sci. Hortic. 2015, 194, 34–42. [Google Scholar] [CrossRef]

- Lajeunesse, M.J. On the meta-analysis of response ratios for studies with correlated and multi-group designs. Ecology 2011, 92, 2049–2055. [Google Scholar] [CrossRef]

- R Core Team (2018). R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria; Available online: https://www.R-project.org/ (accessed on 2 June 2019).

- Buhmann, A.K.; Waller, U.; Wecker, B.; Papenbrock, J. Optimization of culturing conditions and selection of species for the use of halophytes as biofilter for nutrient-rich saline water. Agric. Water Manag. 2015, 149, 102–114. [Google Scholar] [CrossRef]

- Higgins, J.P.T.; Thompson, S.G. Quantifying heterogeneity in a meta-analysis. Stat. Med. 2002, 21, 1539–1558. [Google Scholar] [CrossRef]

- Rosenthal, R. The “file drawer problem” and tolerance for null results. Psychol. Bull. 1979, 86, 638–641. [Google Scholar] [CrossRef]

- Bittsánszky, A.; Uzinger, N.; Gyulai, G.; Mathis, A.; Junge, R.; Villarroel, M.; Kotzen, B.; Kőmíves, T. Nutrient supply of plants in aquaponic systems. Ecocycles 2016, 2, 17–20. [Google Scholar] [CrossRef]

- Goddek, S.; Delaide, B.; Mankasingh, U.; Ragnarsdottir, K.V.; Jijakli, H.; Thorarinsdottir, R. Challenges of sustainable and commercial aquaponics. Sustainability 2015, 7, 4199–4224. [Google Scholar] [CrossRef]

- Yi, Y.; Li, Z.; Song, C.; Kuipers, O.P. Exploring plant-microbe interactions of the rhizobacteria Bacillus subtilis and Bacillus mycoides by use of the CRISPR-Cas9 system. Environ. Microbiol. 2018, 20, 4245–4260. [Google Scholar] [CrossRef] [PubMed]

- Tyson, R.V.; Simonne, E.H.; Davis, M.; Lamb, E.M.; White, J.M.; Tyson, R.V.; Simonne, E.H.; Davis, M.; Lamb, E.M.; White, J.M. Effect of Nutrient Solution, Nitrate-Nitrogen Concentration, and pH on Nitrification Rate in Perlite Medium. J. Plant Nutr. 2007, 30, 901–913. [Google Scholar] [CrossRef]

- Tyson, R.V.; Simonne, E.H.; Treadwell, D.D.; Davis, M.; White, J.M. Effect of Water pH on Yield and Nutritional Status of Greenhouse Cucumber Grown in Recirculating Hydroponics. J. Plant Nutr. 2008, 31, 2018–2030. [Google Scholar] [CrossRef]

- Tyson, R.V.; Simonne, E.H.; Treadwell, D.D.; White, J.M.; Simonne, A. Reconciling pH for ammonia biofiltration and cucumber yield in a recirculating aquaponic system with perlite biofilters. HortScience 2008, 43, 719–724. [Google Scholar] [CrossRef]

- Bown, M.J.; Sutton, A.J. Quality control in systematic reviews and meta-analyses. Eur. J. Vasc. Endovasc. Surg. 2010, 40, 669–677. [Google Scholar] [CrossRef] [PubMed]

- Sirakov, I.; Velichkova, K.; Stoyanova, S.; Slavcheva-Sirakova, D.; Staykov, Y. Comparison between two production technologies and two types of substrates in an experimental aquaponic recirculation system. Sci. Pap. Ser. E-Land Reclam. Earth Obs. Surv. Environ. Eng. 2017, 6, 98–103. [Google Scholar]

- Schmautz, Z.; Loeu, F.; Liebisch, F.; Graber, A.; Mathis, A.; Bulc, T.G.; Junge, R.; Griessler Bulc, T.; Junge, R. Tomato productivity and quality in aquaponics: Comparison of three hydroponic methods. Water 2016, 8, 533. [Google Scholar] [CrossRef]

- Buzby, K.M.; Lin, L.S. Scaling aquaponic systems: Balancing plant uptake with fish output. Aquac. Eng. 2014, 63, 39–44. [Google Scholar] [CrossRef]

- Knaus, U.; Palm, H.W. Effects of the fish species choice on vegetables in aquaponics under spring-summer conditions in northern Germany (Mecklenburg Western Pomerania). Aquaculture 2017, 473, 62–73. [Google Scholar] [CrossRef]

- Goddek, S.; Espinal, C.A.; Delaide, B.; Jijakli, M.H.; Schmautz, Z.; Wuertz, S.; Keesman, K.J. Navigating towards decoupled aquaponic systems: A system dynamics design approach. Water 2016, 8, 303. [Google Scholar] [CrossRef]

- Goddek, S. Opportunities and Challenges of Multi-Loop Aquaponic Systems. Ph.D. Thesis, Wageningen University, Wageningen, The Netherland, 2017; ISBN 9789463431729. [Google Scholar]

- Pickens, J.M. Integrating Effluent from Recirculating Aquaculture Systems with Greenhouse Cucumber and Tomato Production. Ph.D. Thesis, Auburn University, Auburn, AL, USA, 2015. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayipio, E.; Wells, D.E.; McQuilling, A.; Wilson, A.E. Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis. Sustainability 2019, 11, 6511. https://doi.org/10.3390/su11226511

Ayipio E, Wells DE, McQuilling A, Wilson AE. Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis. Sustainability. 2019; 11(22):6511. https://doi.org/10.3390/su11226511

Chicago/Turabian StyleAyipio, Emmanuel, Daniel E. Wells, Alyssa McQuilling, and Alan E. Wilson. 2019. "Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis" Sustainability 11, no. 22: 6511. https://doi.org/10.3390/su11226511

APA StyleAyipio, E., Wells, D. E., McQuilling, A., & Wilson, A. E. (2019). Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis. Sustainability, 11(22), 6511. https://doi.org/10.3390/su11226511