1. Introduction

In a railway freight system, commodities can be divided into two categories: bulk commodities (e.g., coal, ore, oil, etc.) and high value-added commodities (e.g., electronics, foods, etc.). The transportation of bulk commodities is generally less sensitive to shipping time but concerned more with shipping costs, while that of high value-added shipments is usually concerned with shipping time and punctuality.

In recent years, with the government control of carbon emissions, some goods, mostly high value-added shipments, have been shifted from roads to railways. According to statistics released by the China Railway, from 2015 to 2018, the total amount of freight transported by railway first decreased and then increased, while the number of high value-added shipments continually increased. The growth rates of high value-added shipments transported by rail were 18.7%, 25%, 9.3% and 2.3% from 2015 to 2018, respectively.

High value-added shipments are strict about the delivery time. At present, express scheduled freight trains are mainly formed between the distribution centers with large freight flows, such as the China Railway Express and the Yangtze River Express. However, it is not economical to provide express trains for scattered high value-added shipments. Therefore, how to deliver these scattered shipments quickly is an urgent problem to be solved. This paper proposes a new transportation pattern approach, namely the method of reserving axle loads (here, the “method of reserving axle loads” means that a train makes room at the departing station, so that the train can pick up some wagons at other stations), which can improve the delivery speed of high value-added shipments in regions without express train services as well as attract more high value-added shipments to the railway.

The main work and innovation points of this paper are as follows:

(i) A method using long-distance direct trains to reserve axle loads for high value-added shipments in the regions without express train service is proposed.

(ii) The accumulation cost of freight cars in reclassification yards is analyzed and deduced in detail by using the method of reserving axle loads.

(iii) Compared to the traditional method, the whole process and costs of railway transportation for high value-added shipments using the method of reserving axle loads are analyzed.

(iv) Aiming at minimizing the total cost of the whole process of transportation, a mathematical model for the high value-added shipments in regions without express train services is constructed. The model can be solved in four scenarios: reserving axle loads for departing; reserving axle loads for arriving; reserving axle loads for both departing and arriving; and not reserving axle loads. The practicability of the model was tested by two numerical examples.

The remainder of this paper is organized as follows.

Section 2 summarizes the literature related to car-to-block, block-to-train and car-to-train problems.

Section 3 introduces the delivery methods of general trains and express trains and puts forward the method of using the long-distance direct train to transport the high value-added shipments in the area without express train services.

Section 4 analyzes the car-hours saved for the accumulation process of freight cars in a classification yard under the approach of reserving axle loads. In

Section 5, a mathematical model for high value-added shipments in regions without express train services according to the method of reserving axle loads is proposed. The results of two numerical examples are presented in

Section 6. Finally, concluding remarks and future research directions are given in

Section 7.

2. Literature Review

To deliver high value-added shipments from regions without express train services to their destinations by train can be viewed as the car-to-train assignment problem, since it also involves the process of turning cars into a train. Generally, there are two consolidation processes at the core of the car-to-train assignment: the car-to-block assignment and the block-to-train assignment.

The car-to-block assignment problem is sometimes called the blocking plan problem, which determines how to aggregate a large number of shipments/freight cars into blocks [

1]. Since the blocking plan problem is a large-scale complex combinatorial optimization problem, abundant studies have tried to solve it. A nonlinear mixed-integer programming model for the railway blocking problem was introduced by Bodin et al. [

2], which is one of first models for determining a classification strategy for overall classification yards in a railway system. Newton et al. [

3] extended a network design problem in which yards are represented by nodes and blocks by arcs. They then developed a branch-and-bound algorithm to solve it. Barnhart and Jin [

4] formulated the railroad blocking problems as a network design problem and designed an approach to decompose the mixed integer programming problem into two simple sub-problems. Ahuja et al. [

1] proposed an algorithm called the large-scale neighborhood search to solve the blocking plan problem. That algorithm can also handle a variety of practical and business constraints that are necessary for implementing a solution. They reported that the computational results obtained using real data are efficient and robust.

There are diverse mathematical models for the rail blocking problem. For example, Yaghini et al. [

5] presented a mathematical formulation in which the objective is to minimize the costs of delivering all commodities. They attempted to solve that model by using a metaheuristic algorithm based on ant colony optimization and compared it with the quality of solutions generated with CPLEX software. Afterwards, the authors of [

6] stated that the basic idea of the proposed algorithm is to use a simulated annealing algorithm to explore the solution space. Lin et al. [

7] modeled the car-to-train problem as a bi-level programming problem, in which the upper-level finds an optimal train connection service, and the lower-level assigns each shipment to a sequence of train services and determines the frequency of services. Liu et al. [

8] developed a flow assignment model for the quantitative analysis of diverting truck freight to railway and adopted a method that uses tangent lines to constitute envelope curve to linearize the model. Lin et al. [

9] designed a bi-level programming model for railway network design, which can deal with empty car flow and relationships among the links in a corridor. Hasany and Shafahi [

10] developed a mixed-integer program (MIP) for the railroad blocking problem and designed a new heuristic to solve the proposed model. That heuristic decomposed the model into two sub-problems of manageable size. To solve the railroad blocking problem with uncertain demand and supply resources, Hasany and Shafahi [

11] developed a two-stage stochastic program model with two solution methods.

The block-to-train assignment problem determines which block will be placed on which train. Some studies were devoted to minimizing overall train complexity and the need to swap blocks en-route from one train to another. Kwon et al. [

12] used a time–space network representation technique to represent car moves on sequences block-to-train assignments on a general-merchandise rail service network. The paper improved current freight car scheduling practices and described a dynamic freight car routing and scheduling. The problem was formulated as a linear multi-commodity flow problem in that paper. Similarly, Jha et al. [

13] considered the block-to-train assignment problem, which is based on blocking plan and train schedule, and proposed heuristic algorithms based on the path-based formulation. Hwang and Ouyang [

14] proposed a customized network assignment model for rail freight shipment demand and developed an adapted convex combination algorithm to find the shipment routing equilibrium. To minimize the sum of all expected delays and all running times, Borndörfer et al. [

15] provided a mixed-integer nonlinear programming (MINLP) formulation and then used a piecewise linear approximation to reduce the MINLP to a mixed-integer linear model (MILP). Xiao et al. [

16] presented a comprehensive optimization model of the formation plan to deliver all of the commodities with the minimum car-hour consumption at the technical yards which considered the one-block train and two-block train simultaneously. After the railroad blocking plan was generated, the author defined an integer programming optimization model to solve the block-to-train assignment problem. The model aimed to maximize the total cost savings of the whole railroad network compared to the single-block train service plan, where each block was allocated to a direct train service. Aiming at maximizing the total cost savings of the whole railroad network, an integer programming optimization model was defined to solve the block-to-train assignment problem by Xiao et al. [

17]. In [

17], the model was then improved to a path-based formulation, which had far fewer decision variables. The mathematical models developed by Lin et al. [

18] meant to adjust freight flows between their shortest paths and non-shortest paths based on the 0-1 knapsack problem, which provided a new way to solve the block-to-train problem. Then, Lin et al. [

19] designed a bi-level programming model that can deliver the high value-added shipments by using express scheduled train in a railway network, which provided some implications for this study.

Since the car-to-block assignment and block-to-train assignment are two continuous processes, some researchers tried to establish models to directly solve the car-to-train assignment problem. Crainic et al. [

20] focused on the problems of routing freight traffic, scheduling train services and allocating classification work, and proposed a general optimization model and a heuristic algorithm for solving the multi-commodity flow problem. Haghani [

21,

22] made a detailed description about the empty car distribution problem and presented the formulation and solution of a combined train routing and makeup, and empty car distribution model. Keaton et al. [

23] described a model about blocking and routing plans for freight cars in single carload general commodity service and used a Lagrangian relaxation technique to solve this problem. Then, Keaton [

24] modeled the problem of determining optimal train connections, frequencies, and blocking and routing plans for freight cars as an all-integer linear programming problem, in which the objective was to minimize train cost, car time cost, and yard classification cost. Based on a cyclic three-layer space–time network, Zhu et al. [

25] proposed a model which integrated service selection and scheduling, car classification and blocking, train makeup, and routing of time-dependent customer shipments. Considering the average travel time of trains, the energy consumption and the user satisfaction, Sun et al. [

26] presented a multi-objective optimization model for train plan.

The above studies only researched the transportation problem of ordinary goods and rarely involved high value-added shipments in regions without express train services. Next, we aim at using the method of reserving axle loads to optimize the transport scheme of these high value-added shipments.

3. Problem Description

The method of reserving axle loads is an approach to shorten the delivery time of high value-added shipments without express train services. In order to better discuss this method, we need to learn about the general way of delivering freights by railway.

3.1. The Delivering Process of General Freights

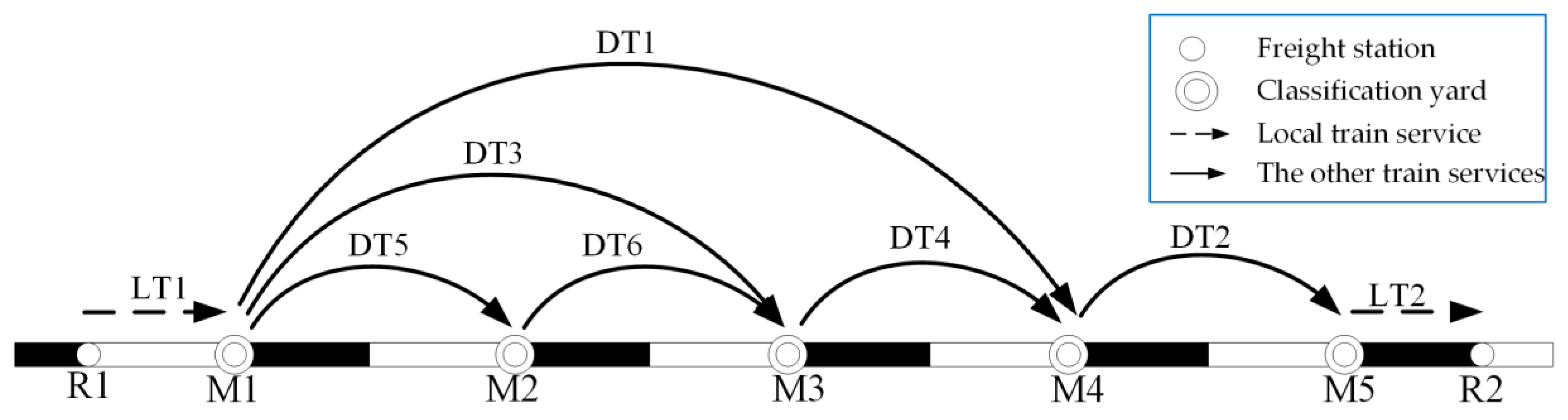

General freights are generally delivered by four kinds of train services, viz. the direct train services, the through train services, the shuttle train services and the local train services. If there are enough freights between loading and unloading areas, the direct train can be operated, which will not be classified on the way. For example, general freights such as coal will be transported by direct train to the unloading site. However, some freights are too small to meet the requirements of operating direct trains. In general, the freight cars should be delivered to the adjacent classification yard by local trains, and then combined with other freight cars so that they can be sent together to the destination station according to the blocking plan. As shown in

Figure 1, there are shipments to be delivered from freight station R1 to freight station R2. Firstly, the shipments will be delivered to classification yard M1 (M refers to the classification yard) by local train service LT1, and then be transported to the destination according to the blocking plan. There are three strategies in total.

- i)

R1 → LT1 → DT1 → DT2 → LT2 → R2

- ii)

R1 → LT1 → DT3 → DT4 → DT2 → LT2 → R2

- iii)

R1 → LT1 → DT5 → DT6 → DT4 → DT2 → LT2 → R2

In strategy iii), the shipments are classified five times. In contrast, only three classification operations are needed in strategy i).

According to the farthest station rule, the wagon flow will choose a train service that can transport cars to the next classification yard as far as possible. In practice, the farthest station rule is a general way used to determine which car should choose which train service. Taking

Figure 1 as an example, the freight rail cars from R1 to R2 will be delivered by strategy i) under the farthest station rule. However, due to the differences in classification times and fees at each classification yard, using the farthest station rule to deliver freight railcars may not be the optimal one. In addition, not all of the wagon flows can be transported by train services with the longest distance on account of the reclassification capacity constraints of classification yards.

3.2. The Delivering Process of High Value-Added Shipments Using Express Scheduled Trains

Because high value-added freights are sensitive to shipping time, the railway company would arrange express scheduled trains in the railway logistics center where there are large-scale shipments that need to be transported.

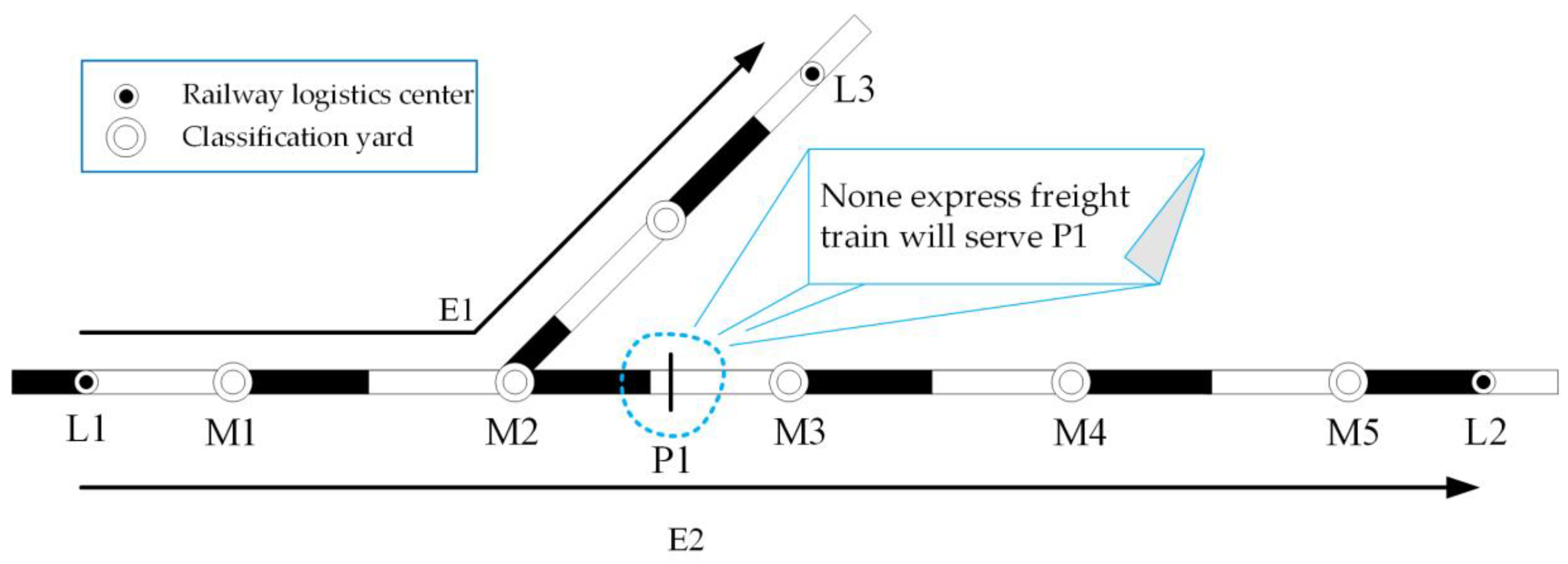

The express scheduled train, which is operated based on a regular timetable, is similar to the passenger train. It can be divided into three levels on the basis of the operating speed: 160, 120 and 80 km/h, while the general freight train is usually less than 50 km/h. The ways of delivering high value-added shipments by express scheduled trains mainly include the through trains (see E1 in

Figure 2) and the pick-up trains (a pick-up is the placement of a block of cars into a train; see E2 in

Figure 2).

Most of the high value-added shipments will be transported like E1 (see

Figure 2; E1 and E2 refer to express train service), which will be classified in the railway logistics center, and then be directly shipped to L4 through E1. When the shipments of L1 (L1, L2, L3 and L4 refer to railway logistics centers) are too small to be delivered by a whole train, then the train departing from L1 will pick up some shipment cars in L2 and L3 and then be delivered to L4 directly (see E2 in

Figure 2).

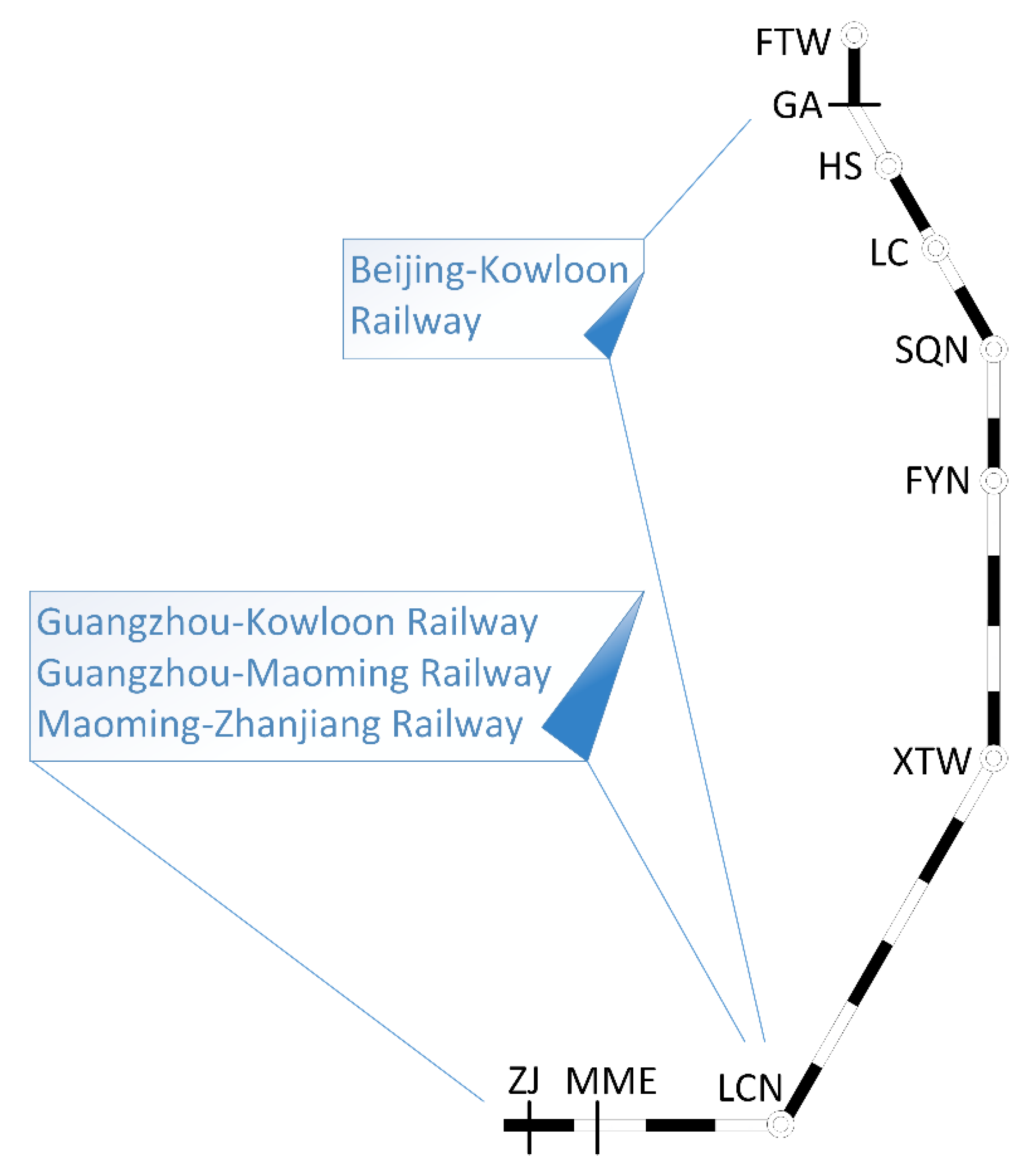

3.3. The Delivering Process of High Value-Added Shipments in Regions Without Express Train Services

A region without express train services is different from a region with express train services, which refers to the area in which the wagon flow is insufficient to operate the express scheduled train. Generally, there are two conditions:

i) None of the express scheduled trains stop at the high value-added shipments area P1 (see E1 in

Figure 3).

ii) Express scheduled trains pass through the area P1 (see E2 in

Figure 3).

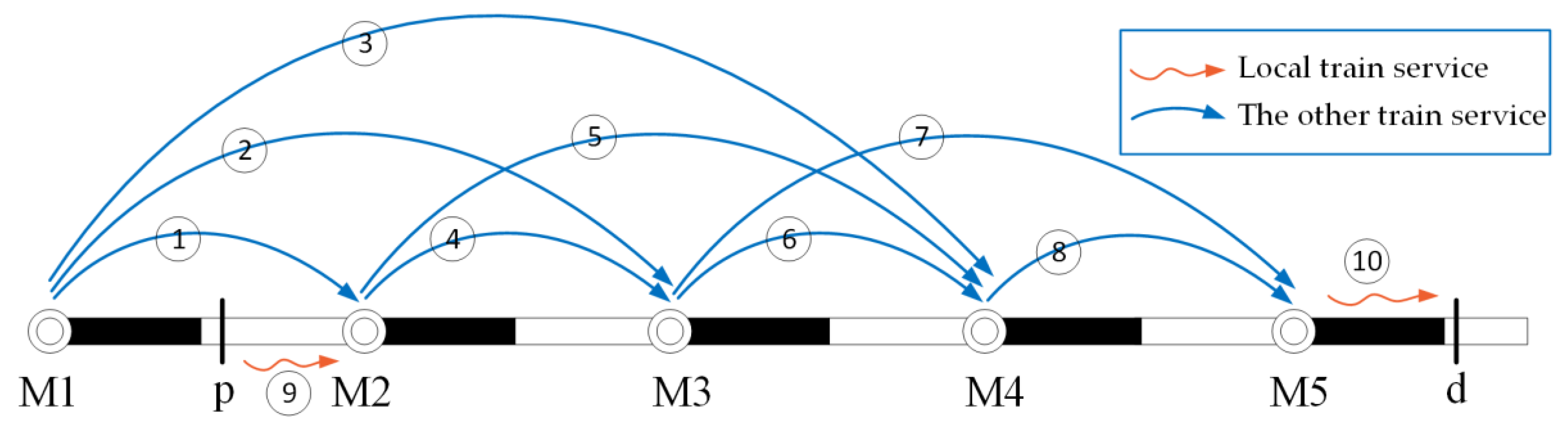

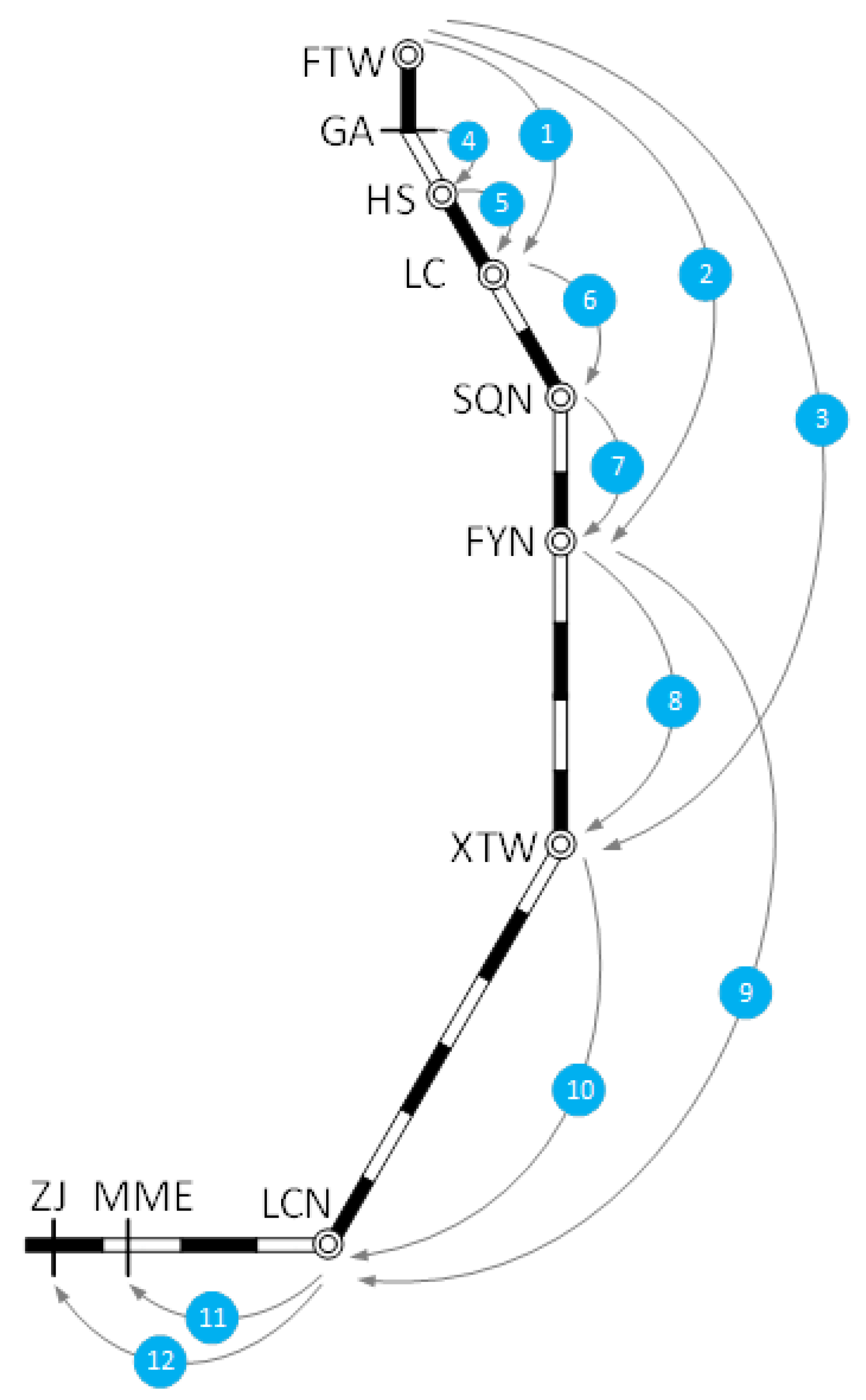

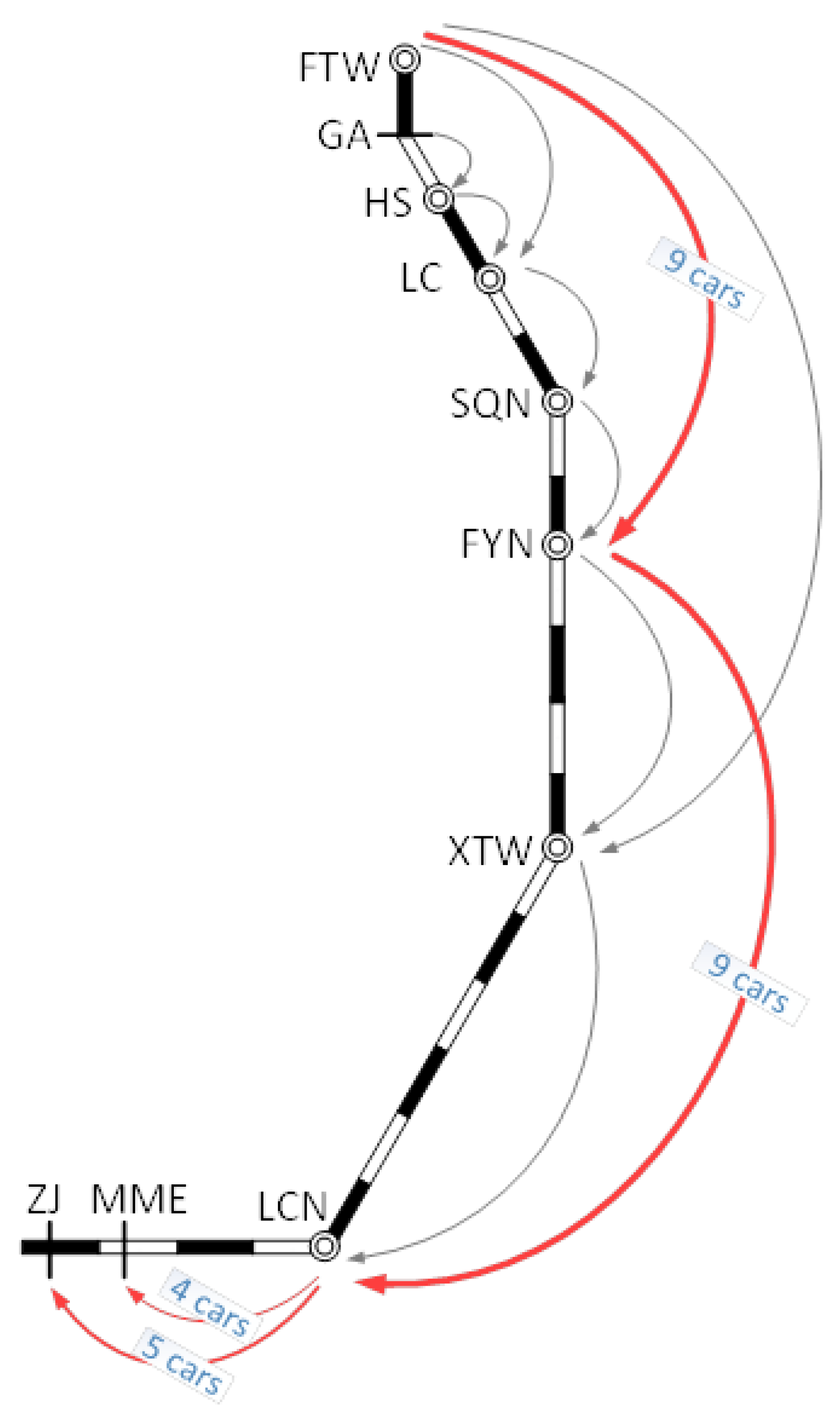

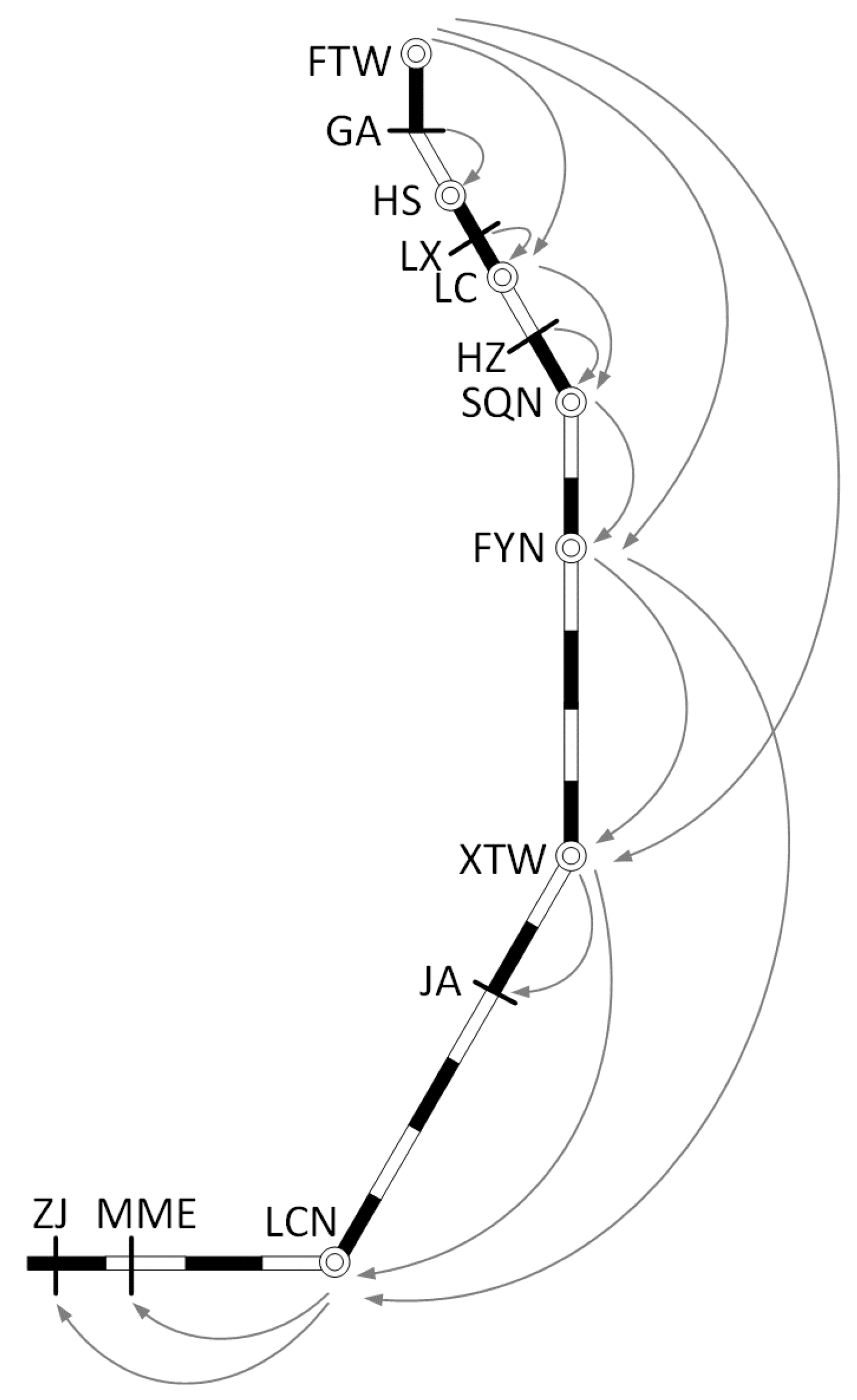

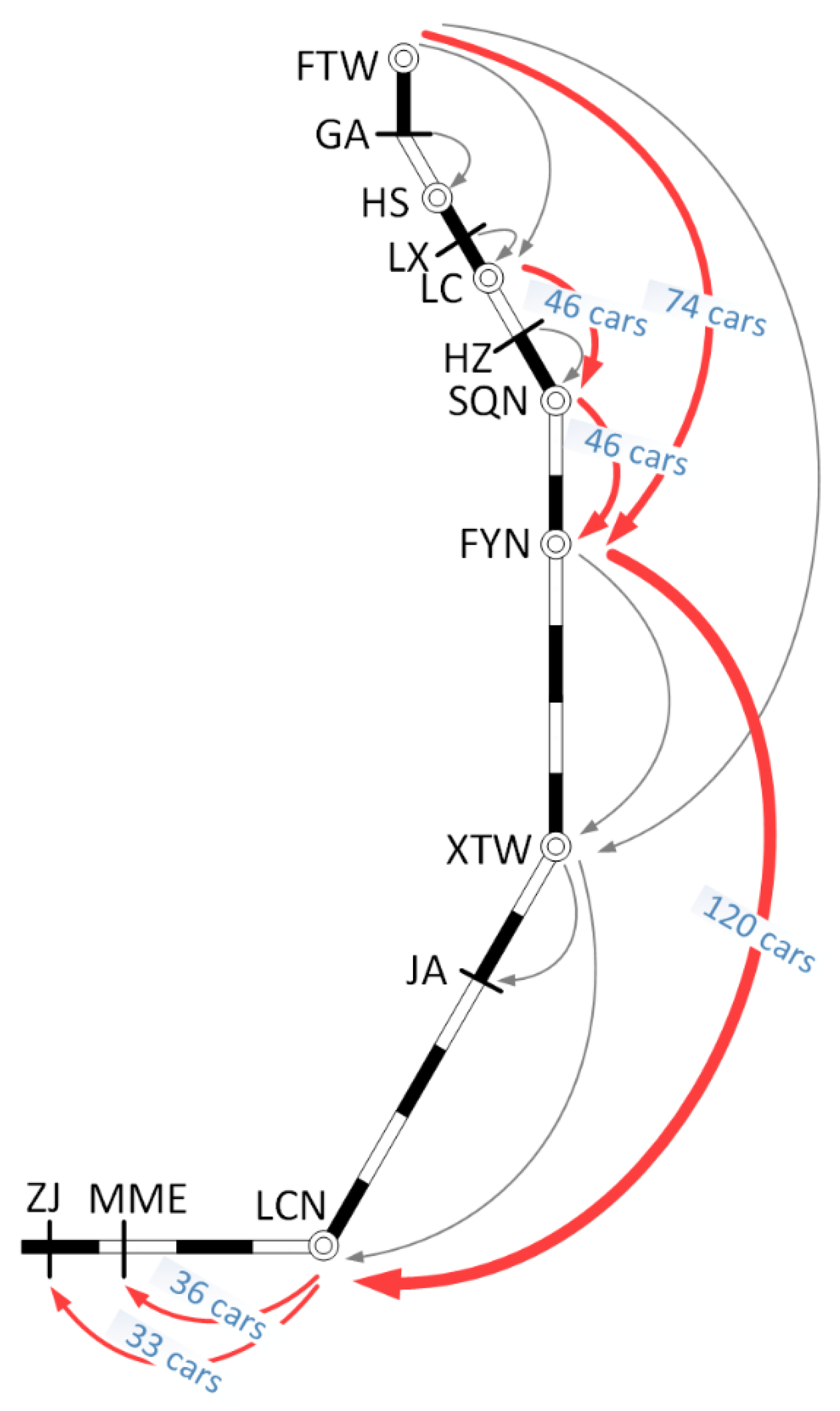

Traditionally, the high value-added shipments in the regions without express train services are usually delivered by the local train to the adjacent classification yard, and then they are delivered to the destination station according to the freight blocking plan of the railway company. Assuming that there are high value-added shipments from logistics station p to destination station d (see

Figure 4), then three strategies can be adopted in the traditional method:

- i)

⑨ → ④ → ⑥ → ⑧ → ⑩

- ii)

⑨ → ⑤ → ⑧ → ⑩

- iii)

⑨ → ④ → ⑦ → ⑩

In strategy i), the shipments need to be reclassified four times (at the classification yards M2, M3, M4 and M5). In strategy ii), the shipments need to be classified three times (at classification yard M2, M4 and M5). In strategy iii), the shipments need to be sorted three times (at the classification yards M2, M3and M5).

In the above strategies, the high value-added shipments at station p must be classified at the classification yard M2, which is the first classification yard it passes through. Can high value-added shipments be delivered more quickly and more economically if the first classification yard where these freights at station p are classified is not M2, but M3, M4 or M5? A new idea which is called reserving axle loads for high value-added shipments has been used, which is using direct trains from the classification yard M1 to pick up the high value-added freight railcars of station p.

Supposing that the railway company demands that a train cannot depart until it has 50 cars, if there are five high value-added freight cars that need to be picked up at station p, then the number of cars in the train departing from M1 will be 45 under the method of reserving axle loads. Firstly, the wagons of high value-added shipments at station p can join arc ①, arc ② or arc ③.

If arc ① is chosen, the delivering process may be ①→⑤→⑧→⑩, ①→④→⑦→⑩ or ①→④→⑥→⑧→⑩.

Similarly, if arc ② is chosen, the delivering process may be ②→⑦→⑩ or ②→⑥→⑧→⑩.

If arc ③ is chosen, the delivering process can be ③→⑧→⑩.

Suppose the delivery due date of the high value-added shipments is known. Next, we will address which arcs should be selected for high value-added shipments in regions without express train services after analyzing the time saved in the accumulation process of freight cars in the next section.

4. Time Saving in the Accumulation Process of Freight Cars at the Classification Yard Using the Method of Reserving Axle Loads

In railway transportation, trains should meet the requirements set by the railway company, e.g., a train cannot depart until 50 cars are accumulated. At the classification yard, a train is made up of several blocks which arrive at the station one after another. Therefore, the first block has to wait for the next blocks, and so it takes a certain amount of time to form a train. We define the time from the first car arriving at the classification yard to the last car arriving at the classification yard which can form a train as the accumulation cost of freight cars. This process accounts for 40%~50% of the whole operating process at the classification yard, thus it cannot be ignored.

Assuming that there is a direct train service arc DT with

railcars to be accumulated at the classification yard M, traditionally, the railway company requires that the size of the train (number of rail cars attached to the locomotive) running in DT is

. Let

denote the number of trains running in DT per day. Then, the following formula can be obtained.

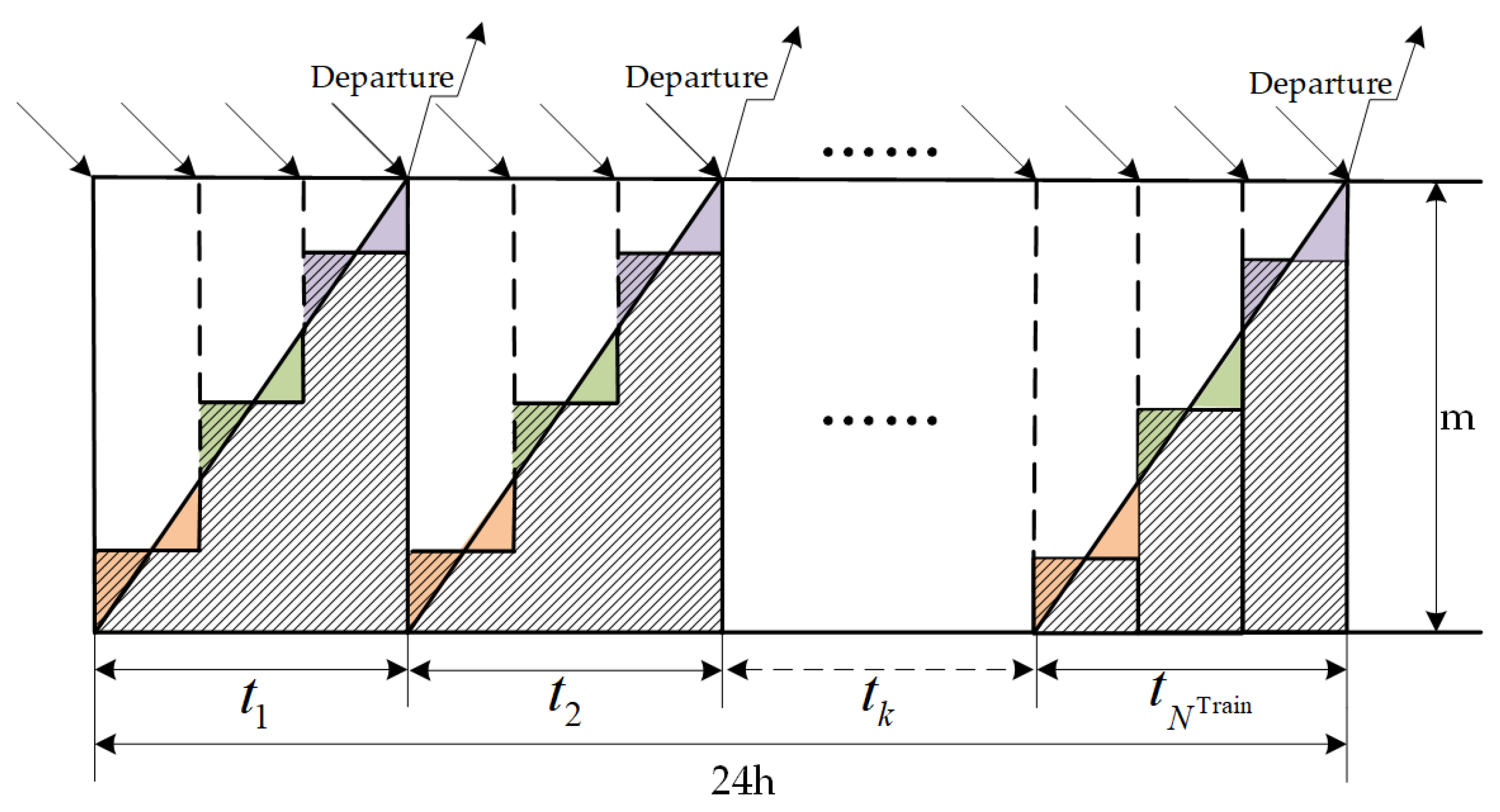

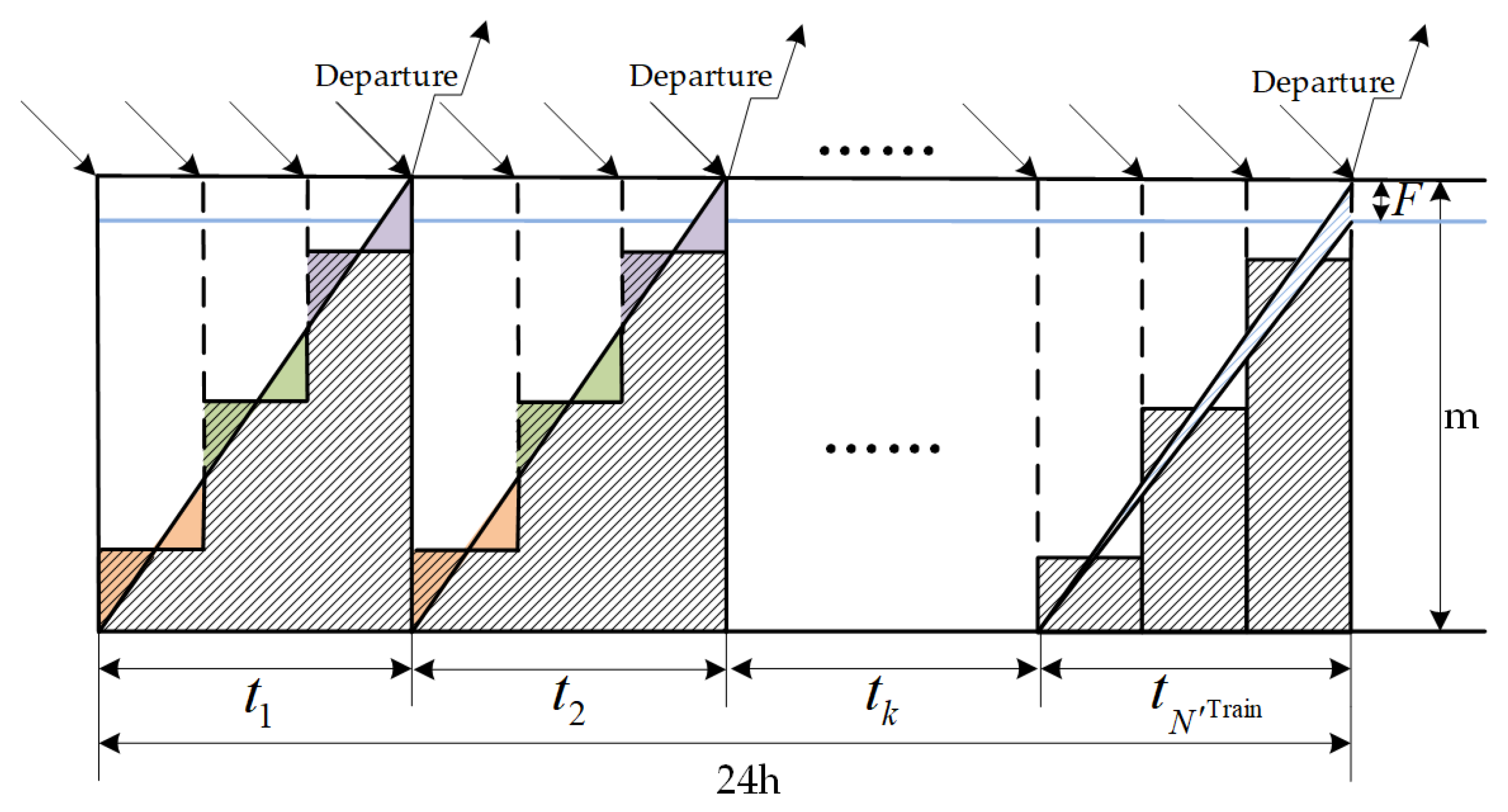

We define

as the car-hours incurred from the accumulation process of the freight cars of the train

, and it can be represented by the polygon area of shadow within oblique (as shown in

Figure 5). When the wagon flows are equal in size and can arrive equably, the car-hours for the accumulation process of freight cars can be substituted by the triangle area based on side

and height

.

where

indicates the time to form the train

.

If there is no interruption among these trains, then the total car-hours

within a day can be formulated as Equation (3).

Thus, the time of accumulation process for each car

is expressed in Equation (4).

If the method of reserving axle loads is used, then the number of cars accumulated at the classification yard is not

but

(supposing the number of high value-added freight cars waiting at station

is

). Therefore, the car-hours for the accumulation process of freight cars can be saved. The accumulation process of freight cars using the method of reserving axle roads at the classification yard is shown in

Figure 6.

Let

denote the number of trains running in DT per day by using the method of reserving axle loads:

We define

as the total car-hours using the method of reserving axle loads.

If the average car-hours for each train is

, then Equation (6) can be written as Equation (7).

Let

denote the car-hours saved per day in the accumulation process of freight cars using the method of reserving axle loads.

The derivation process is as follows.

5. Mathematical Model

The model proposed in this section aims to use long-distance direct trains to reserve axle loads for high value-added shipments without express train services. Since the mathematical model involves the method of reserving axle loads, we call it the model of reserving axle loads (Model-RAL). Now let be the set of all stations, be the set of classification yards, be the set of railway freight stations with high value-added shipments, and be the set of terminal stations. Let represent the set of direct trains. Define a set to indicate that the station can be served by the train service arcs in , and then define a set to indicate that the station can be served by the train service arcs in .

The notations used in the mathematical model are described as follows:

Subscripts:

: Subscripts of the classification yards;

: The loading station with high value-added shipments;

: The unloading station;

: The front classification yard adjacent to the station ;

: The rear classification yard adjacent to the station .

Parameters:

: The distance from classification yard to the loading station , where is the in ;

: The distance from the unloading station to the classification yard , where is the in ;

: The distance from the loading station to the unloading station ;

: The number of cars which originate at yard and are destined for yard ;

: The frequency of direct trains which are dispatched from yard to ;

: The frequency of local trains which are dispatched from to ;

: The frequency of local trains which are dispatched from to ;

: Departing cost when using local trains to deliver the freights from to ;

: Arriving cost when using local trains to deliver the freights from to ;

: The cost per car for capacity waste of locomotive and line due to reserving axle loads;

: The transfer cost per car at classification yard ;

: The operation time per car for transfer at classification yard ;

: The stopping time of a train to pick up cars at station ;

: The stopping time of a train to drop off cars at station ;

: Additional travel time when using local trains to deliver the freights from to ; note that the travel speed of the local train is lower than that of the direct train;

: Additional travel time when using local trains to deliver the freights from to ;

: The delivery due date of high value-added shipments from to ;

: Conversion factor from car-hour to fee;

: Average travel speed of a direct train;

: The number of cars with high value-added shipments from to waiting to be picked up at station ;

: The size of a normal train dispatched from to in the traditional method (the railway company demands that a train cannot depart until it has cars);

If there are cars from to at station , then there will be cars in the train departing from the rear classification yard .

Decision variables

The next step is to analyze the costs of high value-added shipments throughout the transportation process.

(1) Departing:

There are two situations according to the train services selected by cars in the departing stage.

1) The departing cost

by using local train to deliver cars from station

to the adjacent classification yard

.

2) The departing cost by using direct train , which consists of three parts.

(i) Savings due to reduced car-hours in the accumulation process at classification yard ()

If high value-added cars at station

choose the train service

, then it will save time in the accumulation process of freight cars at classification yard

. The process of that is deduced in

Section 4.

(ii) Cost of locomotive and line capacity wastes caused by reserving axle loads ()

Train service

reserves axle loads for high value-added shipments of express station

, which means that the train in section

is not in a state of full axles and will cause the capacity waste of locomotive and line.

(iii) Cost of the stopping delay of direct trains ()

When the direct train arrives at station

, it will stop and wait for the high value-added shipments to join in. Thus, a waiting fee of the direct train is generated.

Note that

(2) Traveling:

The traveling costs include the transfer cost at the classification yard after the departure from station

(the first part of Equation (15)) and cost of travelling on the rail line (the second part of Equation (15)).

where

indicates the unit cost of a freight car running on the rail line. Since the

is fixed, we omit it and just consider the transfer cost.

(3) Arriving:

Just like departing, there are two situations.

1) The arriving cost

by using local train to transport cars from

to

.

2) The arriving cost by using direct train to drop off the cars at station , which consists of two parts.

(i) Cost of locomotive and line capacity wastes in ()

Train service

drops off the high value-added cars at station

, which means that the train in section

is not in a state of full axles and will cause the capacity waste of locomotive and line.

(ii) Cost of the stopping delay of direct trains ()

When the direct train arrives at station

, it will stop and drop off the high value-added cars. Thus, a waiting fee of the direct train is generated.

Note that

Thus, the objective function (total cost) of the Model-RAL can be expressed as follows:

The constraints in Equations (22) – (24) ensure that the high value-added shipments can be sent to the corresponding terminals. Equation (22) indicates that the high value-added shipments cars at station can only be served by one train; Equation (23) ensures the flow balance of the stations; Equation (24) ensures that the freight cars of are delivered to the terminal station by only one train. The constraints in Equation (25) are bounded by the predefined due date. If Equation (25) is not satisfied, it is overdue for the high value-added shipments, then the corresponding scheme shall not be adopted. In fact, the cars with high value-added shipments cannot meet the direct train when they arrive at classification yard but often need to wait for a period of time. We take the average waiting time as at classification yard , and similarly in and in . Equation (26) presents 0–1 variables constraints.