Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Case Study: Zero Brine

2.1.1. Goal and Scope Definition

2.2.2. Life Cycle Inventory Analysis

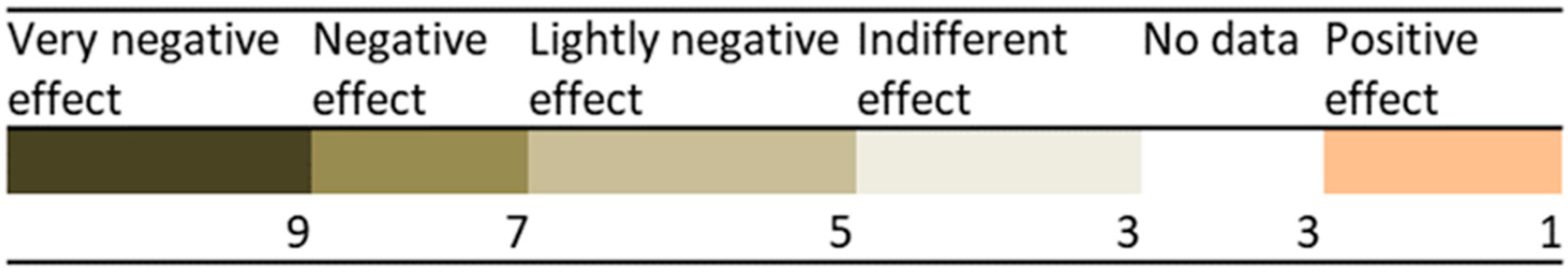

Data Collection and Assessment of Subcategories

Activity Variable

- CON: Consumption of product X based on functional unit

- C: Capacity of producing product X per hour

3. Results and Discussion

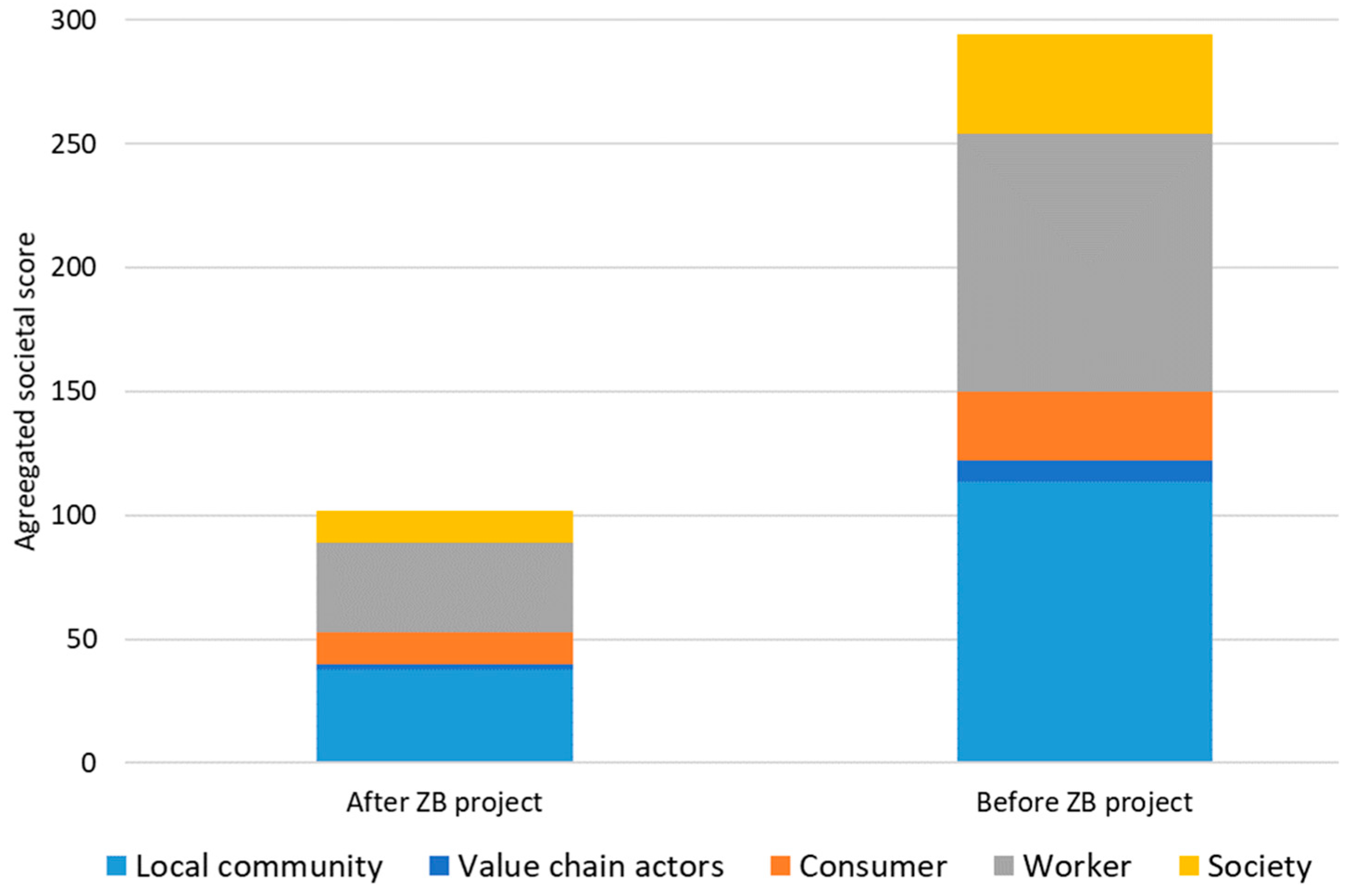

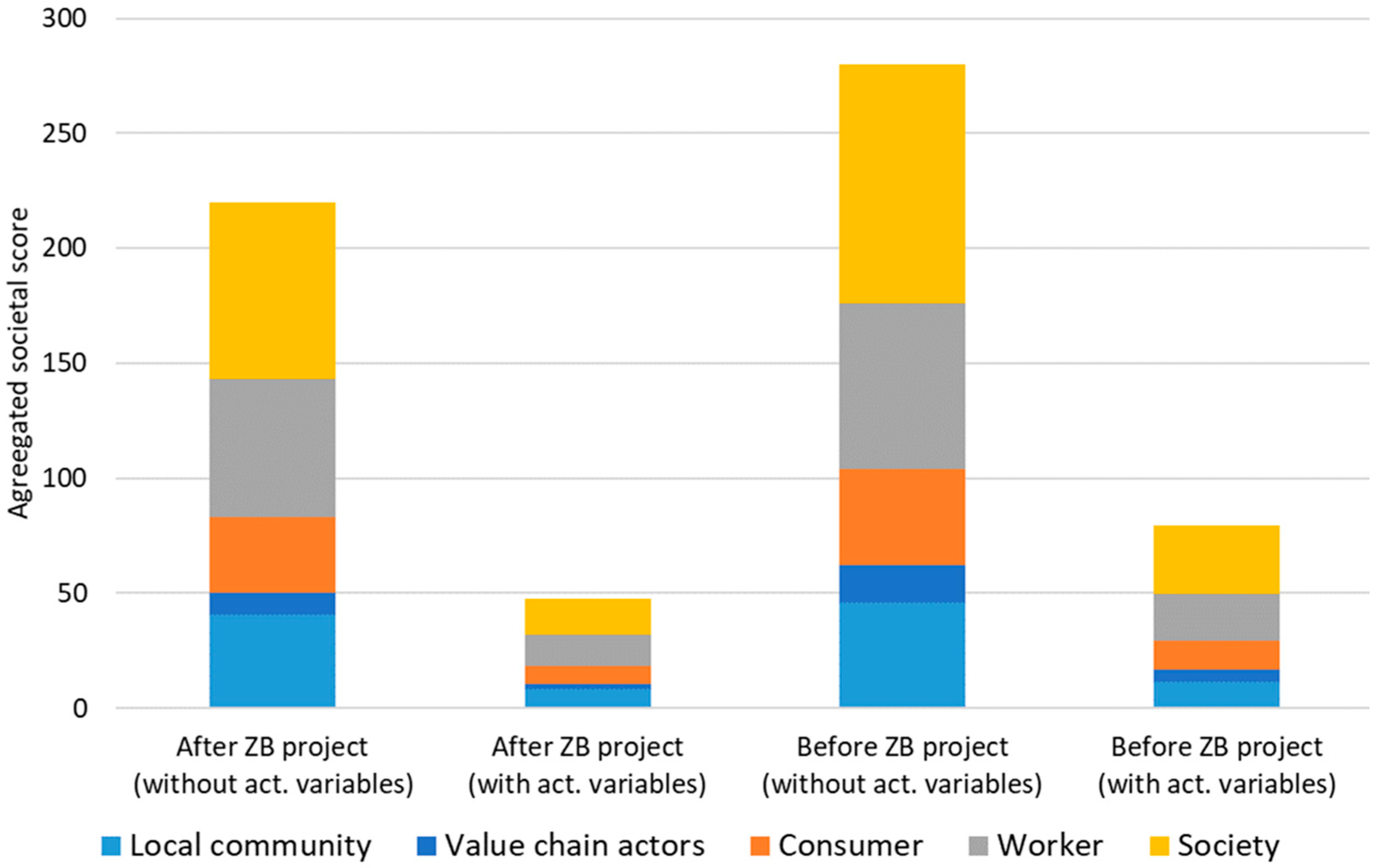

3.1. Life Cycle Impact Assessment and Interpretation

3.2. Aggregation before and after Change

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Report on Critical Raw Materials for the EU. Report of the Ad hoc Working Group on Defining Critical Raw Materials; Ref. Ares (2015)1819503; European Commission: Brussels, Belgium, 2014; pp. 1–41. [Google Scholar]

- Skoczko, I. Efficiency estimation of water purification with various filtration mate. Desalin. Water Treat. 2018, 134, 99–108. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive 2008/98/Ec of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; Official Journal of the European Union: Brussels, Belgium, 2008. [Google Scholar]

- Pérez-González, A.; Urtiaga, A.M.; Ibáñez, R.; Ortiz, I. State of the art and review on the treatment technologies of water reverse osmosis concentrates. Water Res. 2012, 46, 267–283. [Google Scholar] [CrossRef] [PubMed]

- Bourguignon, D. Circular Economy Package. Four Legislative Proposals on Waste; EPRS|European Parliamentary Research Service: Brussels, Belgium, 2016. [Google Scholar]

- Joint Research Center (JRC). Critical Raw Materials and the Circular Economy; Joint Research Center (JRC): Luxembourg, 2017; pp. 1–102. [Google Scholar]

- European Commission. Study on the Review of the List of Critical Raw Materials. Final Report; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Sajid Hussain, I.; Head, O.M. Case Study of a Zero Liquid Discharge facility in Textile Dyeing Effluents at Tirupur. 2012. Available online: http://seip.urban-industrial.in/live/hrdpmp/hrdpmaster/igep/content/e48745/e49028/e51431/e51468/SajidHussain.pdf (accessed on 20 October 2019).

- Panagopoulos, A.; Haralambous, K.-J.; Loizidou, M. Desalination brine disposal methods and treatment technologies—A review. Sci. Total Environ. 2019, 693, 133545. [Google Scholar] [CrossRef] [PubMed]

- Skoczko, I.; Szatylowicz, E. The analysis of physico-chemical properties of two unknown filter materials. J. Ecol. Eng. 2016, 17, 148–154. [Google Scholar] [CrossRef][Green Version]

- Riabova, L.A. Social License to Operate for Mining Companies in the Russian Arctic as a Tool for Development of Host Territories. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/302/1/012116/meta (accessed on 20 October 2019).

- Didyk, V.; Bay-Larsen, I.; Sandersen, H.; Ivanova, L. Sustainability and Mining: The Case of the Kola Peninsula; ResearchGate: Berlin, Germany, 2018. [Google Scholar]

- United Nations General Assembly. Resolution A/60/1 Adopted by the General Assembly. 2005 World Summit Outcome; United Nations General Assembly: New York, NY, USA, 2005. [Google Scholar]

- Brundtland, G.H. Report of the World Commission on Environment and Development: Our Common Future; United Nations: New York, NY, USA, 1987. [Google Scholar]

- Benoît, C.; Norris, G.A.; Valdivia, S.; Ciroth, A.; Moberg, A.; Bos, U.; Prakash, S.; Ugaya, C.; Beck, T. The guidelines for social life cycle assessment of products: Just in time! Int. J. Life Cycle Assess. 2010, 15, 156–163. [Google Scholar] [CrossRef]

- Clift, R.; Sim, S.; King, H.; Chenoweth, J.; Christie, I.; Clavreul, J.; Mueller, C.; Posthuma, L.; Boulay, A.-M.; Chaplin-Kramer, R.; et al. The Challenges of Applying Planetary Boundaries as a Basis for Strategic Decision-Making in Companies with Global Supply Chains. Sustainability 2017, 9, 279. [Google Scholar] [CrossRef]

- Kühnen, M.; Hahn, R. Indicators in Social Life Cycle Assessment: A Review of Frameworks, Theories, and Empirical Experience. J. Ind. Ecol. 2017, 21, 1547–1565. [Google Scholar] [CrossRef]

- UNEP/SETAC Life Cycle Initiative. The Methodological Sheets for Subcategories in Social Life Cycle Assessment (S-LCA); UNEP/SETAC Life Cycle Initiative: Ghent, Belgium, 2013; pp. 1–152. [Google Scholar]

- UNEP/SETAC Life Cycle Initiative. Guidelines for Social Life Cycle Assessment of Products. Social and Socio-Economic LCA Guidelines Complementing Environmental LCA and Life Cycle Costing, Contributing to the Full Assessment of Goods and Services within the Context of Sustainable Development; UNEP/SETAC Life Cycle Initiative: Ghent, Belgium, 2009. [Google Scholar]

- Weidema, B. ISO 14044 also applies to social LCA. Int. J. Life Cycle Assess. 2005, 10, 381. [Google Scholar] [CrossRef]

- Lehmann, A.; Zschieschang, E.; Traverso, M.; Finkbeiner, M.; Schebek, L. Social aspects for sustainability assessment of technologies—Challenges for social life cycle assessment (SLCA). Int. J. Life Cycle Assess. 2013, 18, 1581–1592. [Google Scholar] [CrossRef]

- Mathe, S. Integrating participatory approaches into social life cycle assessment: The SLCA participatory approach. Int. J. Life Cycle Assess. 2014, 19, 1506–1514. [Google Scholar] [CrossRef]

- Jørgensen, A. Social LCA—A way ahead? Int. J. Life Cycle Assess. 2013, 18, 296–299. [Google Scholar] [CrossRef]

- Weidema, B.P.; Pizzol, M.; Schmidt, J.; Thoma, G. Attributional or consequential Life Cycle Assessment: A matter of social responsibility. J. Clean. Prod. 2018, 174, 305–314. [Google Scholar] [CrossRef]

- Rugani, B.; Benetto, E.; Igos, E.; Quinti, G.; Declich, A.; Feudo, F. Towards prospective life cycle sustainability analysis: Exploring complementarities between social and environmental life cycle assessments for the case of Luxembourg’s energy system. Mater. Tech. 2014, 102, 605. [Google Scholar] [CrossRef]

- Kudoh, Y.; Sagisaka, M.; Chen, S.S.; Elauria, J.C.; Gheewala, S.H.; Hasanudin, U.; Romero, J.; Sharma, V.K.; Shi, X. Region-specific indicators for assessing the sustainability of biomass utilisation in East Asia. Sustainability 2015, 7, 16237–16259. [Google Scholar] [CrossRef]

- Ren, J.; Manzardo, A.; Mazzi, A.; Zuliani, F.; Scipioni, A. Prioritization of bioethanol production pathways in China based on life cycle sustainability assessment and multicriteria decision-making. Int. J. Life Cycle Assess. 2015, 20, 842–853. [Google Scholar] [CrossRef]

- Fontes, J. Handbook for Product Social Impact Assessment; Version 3.0; Roundtable for Social Metrics; PRé Sustainability: Amersfoort, The Netherlands, 2016. [Google Scholar]

- Opher, T.; Shapira, A.; Friedler, E. A comparative social life cycle assessment of urban domestic water reuse alternatives. Int. J. Life Cycle Assess. 2018, 23, 1315–1330. [Google Scholar] [CrossRef]

- Frederiksen, T. Corporate social responsibility, risk and development in the mining industry. Resour. Policy 2018, 59, 495–505. [Google Scholar] [CrossRef]

- Chvileva, T.A.; Golovina, E.I. Publication of reporting of metallurgical companies in context of the concept of corporate sustainable development. J. Ind. Pollut. Control 2017, 33, 926–930. [Google Scholar]

- Ravochkin, N.; Shchennikov, V.; Syrov, V. Corporate Social and Ecological Responsibility of Russian Coal Mining Companies. E3S Web Conf. 2017, 21, 04017. [Google Scholar] [CrossRef]

- Gulakov, I.; Vanclay, F. Social impact assessment in the Russian Federation: Does it meet the key values of democracy and civil society? Impact Assess. Proj. Apprais. 2018, 36, 494–505. [Google Scholar] [CrossRef]

- Shail, R.; Wall, F.; Varul, M.; Whitbread-Abrutat, P.; Baciu, C.; Ejdemo, T.; Lovric, I.; Udachin, V. Corporate Social Responsibility within the Mining Industry: Case Studies from Across Europe and Russia. In Proceedings of the Aachen International Mining Symposia (AIMS): 5th International Conference, Aachen, Germany, 14–17 June 2011. [Google Scholar]

- Kokko, K.; Buanes, A.; Koivurova, T.; Masloboev, V.; Pettersson, M. Sustainable mining, local communities and environmental regulation. Barents Stud. 2015, 2, 50–81. [Google Scholar]

- EAO Media.ru Kuldursky Brucite Mine in the Jewish Autonomous Region Increases Production 2016. Available online: https://www.eastrussia.ru/en/news/kuldurskiy-brusitovyy-rudnik-v-eao-v-2018g-planiruet-rasshirenie-proizvodstva/ (accessed on 26 March 2019).

- East of Russia Analytical Agency. The Border Crossing Point at Pashkovo in the EAO for Export to China Brucite is Planned to be Introduced in 2019. 2018. Available online: https://www.eastrussia.ru/en/news/punkt-pogranpropuska-pashkovo-v-eao-pod-eksport-v-kitay-brusita-planiruetsya-vvesti-v-2019g/ (accessed on 26 March 2019).

- Our region—The Far East Personal interview with Alexander Ezhov, Director general of Russian Mining Chemical Comapny LLC 2015. Available online: https://www.eastrussia.ru/material/do-kitaya-zdes-skoro-budet-mostom-podat/ (accessed on 26 March 2019).

- Wu, R.; Yang, D.; Chen, J. Social life cycle assessment revisited. Sustainability 2014, 6, 4200–4226. [Google Scholar] [CrossRef]

- Chhipi-Shrestha, G.K.; Hewage, K.; Sadiq, R. “Socializing” sustainability: A critical review on current development status of social life cycle impact assessment method. Clean Technol. Environ. Policy 2015, 17, 579–596. [Google Scholar] [CrossRef]

- Macombe, C.; Leskinen, P.; Feschet, P.; Antikainen, R. Social life cycle assessment of biodiesel production at three levels: A literature review and development needs. J. Clean. Prod. 2013, 52, 205–216. [Google Scholar] [CrossRef]

- Griesshammer, R.; Buchert, M.; Gensch, C.-O.; Hochfeld, C.; Manhart, A.; Reisch, L.; Rüdenauer, I. PROSA—Product Sustainability Assessment Guideline; Öko-Institut e.V.: Breisgau, Germany, 2007. [Google Scholar]

- Hunkeler, D. Societal LCA Methodology and Case Study (12 pp). Int. J. Life Cycle Assess. 2006, 11, 371–382. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Lehmann, A.; Muñoz, P.; Antón, A.; Traverso, M.; Rieradevall, J.; Finkbeiner, M. Application challenges for the social Life Cycle Assessment of fertilizers within life cycle sustainability assessment. J. Clean. Prod. 2014, 69, 34–48. [Google Scholar] [CrossRef]

- Di Noi, C.; Ciroth, A.; Mancini, L.; Eynard, U.; Pennington, D.; Blengini, G.A. Can S-LCA methodology support responsible sourcing of raw materials in EU policy context? Int. J. Life Cycle Assess. 2019. [Google Scholar] [CrossRef]

- European Commission. Raw Materials Information System (RMIS): Towardsv2.0—An Interim Progress Report & Roadmap; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Institute for Economics & Peace. Global Peace Index 2018: Measuring Peace in a Complex World; Institute for Economics & Peace: Sydney, Australia, 2018. [Google Scholar]

- World Intellectual Property Organization Country Profile: Netherlands. Available online: http://www.wipo.int/members/en/contact.jsp?country_id=130 (accessed on 9 August 2018).

- The World Economic Forum. World Economic Forum. 2018. Available online: https://www.weforum.org/ (accessed on 9 August 2018).

- United States Department of State—Bureau of Democracy, Human Rights, and Labor. Russia 2017 Human Rights Report; Country Reports on Human Rights Practices for 2017: Washington, DC, USA, 2017. [Google Scholar]

- Amnesty International. Amnesty International Report 2017/18. The State of the World Human Rights; Amnesty International: London, UK, 2018. [Google Scholar]

- International Resource Panel. Global Material Flows Database. 2018. Available online: https://www.resourcepanel.org/ (accessed on 10 December 2018).

- Mangen, M.J.; Friesema, I.H.M.; Pijnacke, R.; Mughini Gras, L.; van Pelt, W. Disease Burden of Food-Related Pathogens in the Netherlands, 2017; RIVM: Bilthoven, The Netherlands, 2018. [Google Scholar]

- World Bank. World Bank Group—International Development, Poverty, & Sustainability; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Schwab, K. The Global Competitiveness Report 2016–2017; Insight Report; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- CSR Netherlands. International CSR in the Dutch Chemical Sector; CSR: Utrecht, The Netherlands, 2015; p. 58. [Google Scholar]

- Privacy International. National Privacy Ranking 2007—Leading Surveillance Societies Around the World; Privacy International: London, UK, 2007. [Google Scholar]

- The Law Library of Congress. Global Legal Research Center Government Services Feedback Practices in Selected Jurisdictions; The Law Library of Congress: Washington, DC, USA, 2017. [Google Scholar]

- Global Reporting SDD—GRI Database. 2018. Available online: https://database.globalreporting.org/ (accessed on 26 March 2019).

- ECOLEX The Gateway to Environmental Law. 2018. Available online: https://www.ecolex.org/ (accessed on 19 May 2019).

- International Labour Organization. National Labour Law Profile; International Labour Organization: Geneva, Switzerland, 2011. [Google Scholar]

- Global Slavery Index. The Global Slavery Index 2016; Global Slavery Index: Nedlands, Australia, 2016. [Google Scholar]

- U.S. Department of State. Country Reports on Human Rights Practices for 2017; U.S. Department of State Diplomacy in Action; U.S. Department of State: Washington, DC, USA, 2017.

- Countryeconomy.com NMW—National Minimum Wage 2019. Available online: https://countryeconomy.com/national-minimum-wage (accessed on 26 March 2019).

- United Nations. UN Gender Statistics; United Nations: New York, NY, USA, 2016. [Google Scholar]

- World Bank Databank. Data for Netherlands and Russian Federation. Available online: https://data.worldbank.org/?locations=NL-RU (accessed on 26 March 2019).

- Transparency International Corruption Perceptions Index 2017. Available online: www.transparency.org (accessed on 26 March 2019).

- Chen, W.; Holden, N.M. Social life cycle assessment of average Irish dairy farm. Int. J. Life Cycle Assess. 2017, 22, 1459–1472. [Google Scholar] [CrossRef]

- Dreyer, L.C.; Hauschild, M.Z.; Schierbeck, J. Characterisation of social impacts in LCA. Part 2: Implementation in six company case studies. Int. J. Life Cycle Assess. 2010, 15, 385–402. [Google Scholar] [CrossRef]

- Valente, C.; Brekke, A.; Modahl, I.S. Testing environmental and social indicators for biorefineries: Bioethanol and biochemical production. Int. J. Life Cycle Assess. 2018, 23, 581–596. [Google Scholar] [CrossRef]

- Holger, S.; Petra, Z.; Josephine, M.; Andrea, S.; Sandra, V.; Jürgen-Friedrich, H. The social footprint of permanent magnet production based on rare earth elements-a social life cycle assessment scenario. Energy Procedia 2017, 142, 984–990. [Google Scholar] [CrossRef]

- Evides Waterbedrijf B.V. Annual Report 2017. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=2&ved=2ahUKEwjnso3Eiq3lAhXiKqYKHUETBmYQFjABegQIARAC&url=https%3A%2F%2Fwww.evides.nl%2F-%2Fmedia%2Ffiles%2Fjaarverslagen%2Fevides-annual-report-2017-summary.pdf&usg=AOvVaw2-d9dXp3mrGi1z-FEp8z97 (accessed on 20 October 2019).

- Mulder, J.W. (Evides Industriewater B.V., Rotterdam, The Netherlands). Personal communication, 2018.

- Van den Broek, W. (Evides Industriewater B.V., Rotterdam, The Netherlands). Personal communication, 2018.

- De Groot, M.T. (AkzoNobel N.V., Amsterdam, The Netherlands). Personal communication, 2018.

- ENGIE. 2017 Management Report and Annual Consolidated Financial Statements; ENGIE: La Défense, France, 2018; p. 186. [Google Scholar]

- ENGIE. 2016 Integrated Report. A New Vision of the Energy World; ENGIE: La Défense, France, 2017; p. 52. [Google Scholar]

- Degeratu, C. (Europiren B.V., Rotterdam, the Netherlands). Personal communication, 2018.

- Di Noi, C.; Ciroth, A. Environmental and Social Pressures in Mining. Results from a Sustainability Hotspots Screening. Resources 2018, 7, 80. [Google Scholar] [CrossRef]

| Stakeholder Relationships | DW | Chlor–Alkali 1 and 2 | Magnesium Distributor | Electricity Provider | Russian Mining Company |

|---|---|---|---|---|---|

| DWP | 1 | Mass | Mass | Energy | - |

| Chlor–alkali plant | Mass | 1 | - | Energy | - |

| Magnesium distributor | Mass | - | 1 | - | Mass |

| Electricity provider | Energy | Energy | - | 1 | - |

| Russian mining company | - | - | Mass | - | 1 |

| DW Company | Chlor–Alkali Company | Electricity Provider | Magnesium Distributor | Russian Mining Company | |

|---|---|---|---|---|---|

| Coefficient (h) | 1 | 0.0002 | 0.007 | 0.15 | 0.53 |

| Stakeholder Categories | Impact Categories | Hotspots Inventory Indicators | Netherlands | Russia |

|---|---|---|---|---|

| Local community | Delocalization and migration a | International Migrants as a Percentage of Population | 3 | 3 |

| Community engagement b | Public Trust of Politicians | 5 | 5 | |

| Freedom of Peaceful Assembly and Association | 3 | 5 | ||

| Transparency of Government Policymaking | 1 | 7 | ||

| Respect of indigenous rights c | Human Rights Issues Faced by Indigenous Peoples | 3 | 3 | |

| Indigenous Land Rights Conflicts/Land Claims | 1 | 7 | ||

| Access to immaterial resources d | Freedom of Expression in Country of Operation | 1 | 9 | |

| Levels of Technology Transfer | 1 | 7 | ||

| Access to material resources e | Extraction of Material Resources | 5 | 7 | |

| Levels of Industrial Water Use | 5 | 3 | ||

| Percentage of Population (Urban, Rural, Total) with Access to Improved Sanitation Facilities | 1 | 5 | ||

| Safe and healthy living conditions f | Burden of Disease by Country | 1 | 3 | |

| Pollution Levels by Country | 1 | 1 | ||

| Presence/Strength of Laws on Construction Safety Regulations by Country | 5 | 5 | ||

| Secure living conditions g | Strength of Public Security in Country of Operation | 5 | 7 | |

| Total | 38 | 76 | ||

| Value chain actors | Respect of intellectual property rights h | General intellectual property rights and related issues associated with the economic sector | 1 | 3 |

| Promoting social responsibility i | Industry code of conduct in the sector | 1 | 3 | |

| Total | 2 | 6 | ||

| Consumer | Feedback mechanism j | Presence of feedback mechanisms | 1 | 1 |

| Privacy k | Country privacy ranking | 3 | 5 | |

| Transparency l | Presence of a law or norm regarding transparency (by country and/or sector) | 3 | 3 | |

| Sector transparency rating; number of organizations by sector that published a sustainability report | 3 | 3 | ||

| End-of-life responsibility m | Strength of national legislation covering product disposal and recycling | 3 | 3 | |

| Total | 13 | 15 | ||

| Worker | Freedom of association and collective bargaining n | Evidence of restriction to freedom of association and collective bargaining | 3 | 9 |

| Evidence of country/sector/organization or factory disrespect or support to freedom of association and collective bargaining | 3 | 9 | ||

| GRI: HR4 operations identified in which the right to exercise freedom of association and collective bargaining may be at significant risk, and actions taken to support these rights | 3 | 7 | ||

| Fair salary o | Minimum wage by country (Euros) | 5 | 7 | |

| Hours of work p | Excessive Hours of work | 1 | 1 | |

| Child labour q | Percentage of children working by country | 1 | 1 | |

| Forced labour r | Percentage (estimate) of forced labour by region | 3 | 9 | |

| Government response rating to modern slavery | 7 | 9 | ||

| Equal opportunities s | Women in the Labor force participation rate by country | 3 | 3 | |

| Country gender index ranking | 3 | 7 | ||

| Health and safety t | Occupational accident rate by country or sector | 1 | 3 | |

| Social benefit/social security u | Social security expenditure by country and branches of social security | 3 | 3 | |

| Total | 36 | 68 | ||

| Society | Public commitment to sustainability issues v | Existence of (legal) obligation on public sustainability reporting | 1 | 3 |

| Engagement of the chemical sector regarding sustainability | 3 | 3 | ||

| Contribution to economic development w | Economic situation of the country | 1 | 5 | |

| Corruption x | Risk of corruption in the country and/or sub-region | 7 | 9 | |

| Risk of corruption in the sector | 1 | 7 | ||

| Total | 13 | 27 |

| Stakeholder Categories | Impact Categories | Hotspots Inventory Indicators | Pre-Botlek Stage | Botlek Stage | Post-Botlek Stage | Russian Mining | ||

|---|---|---|---|---|---|---|---|---|

| High Purity Salt | Electricity | DW | Chlor–Alkali | Magnesium | ||||

| Local community | Local employment | Percentage of workforce hired locally | 1 | 3 | 1 | 1 | 5 | 1 |

| Strength of policies on local hiring preferences | 3 | 3 | 3 | 3 | 3 | 1 | ||

| Percentage of spending on locally based suppliers | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Total (without coefficients) | 7 | 9 | 7 | 7 | 11 | 5 | ||

| Total (with coefficients) | 0.0014 | 0.063 | 7 | 0.0014 | 1.65 | 2.65 | ||

| Value chain actors | Promoting social responsibility | Industry code of conduct in the sector | 1 | 1 | 1 | 1 | 5 | 7 |

| Total (without coefficients) | 1 | 1 | 1 | 1 | 5 | 7 | ||

| Total (with coefficients) | 0.0002 | 0.007 | 1 | 0.0002 | 0.75 | 3.71 | ||

| Consumer | Health and Safety | Presence of consumer complaints (at organizational level) | 5 | 5 | 5 | 5 | 3 | 3 |

| Quality of or number of information/signs on product health and safety | 1 | 1 | 1 | 1 | 1 | 5 | ||

| Feedback mechanism | Presence of feedback mechanisms | 1 | 1 | 1 | 1 | 1 | 1 | |

| Total (without coefficients) | 7 | 7 | 7 | 7 | 5 | 9 | ||

| Total (with coefficients) | 0.0014 | 0.049 | 7 | 0.0014 | 0.75 | 4.77 | ||

| Worker | Freedom of association and collective bargaining | Evidence of restriction to freedom of association and Collective bargaining | 3 | 3 | 3 | 3 | 3 | 3 |

| Evidence of organization or factory disrespect or support to freedom of association and collective bargaining | 3 | 3 | 3 | 3 | 3 | 3 | ||

| GRI: HR4 Operations identified in which the right to exercise freedom of association and collective bargaining may be at significant risk, and actions taken to support these rights | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Child labour | Percentage of children working by sector | 1 | 1 | 1 | 1 | 1 | 1 | |

| GRI HR6 Operations identified as having significant risk for incidents of child labour, and measures taken to contribute to the elimination of child labour | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Forced labour | Percentage (estimate) of forced labour by region (%) | 1 | 1 | 1 | 1 | 1 | 1 | |

| Total (without coefficients) | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Total (with coefficients) | 0.0024 | 0.084 | 12 | 0.0024 | 1.8 | 6.36 | ||

| Society | Public commitment to sustainability issues | Engagement of sector regarding sustainability | 1 | 1 | 1 | 1 | 5 | 5 |

| Prevention and mitigation of conflicts | Is the organization doing business in a region with ongoing conflicts? | 7 | 3 | 3 | 7 | 3 | 7 | |

| Is the organization doing business in a sector that features linkages to conflicts? | 3 | 3 | 3 | 3 | 3 | 7 | ||

| Is the organization doing business in a sector otherwise linked to the escalation or de-escalation of conflicts? | 3 | 3 | 3 | 3 | 3 | 7 | ||

| Contribution to economic development | Relevance of the considered sector for the (local) economy | 3 | 3 | 3 | 3 | 3 | 1 | |

| Total (without coefficients) | 17 | 13 | 13 | 17 | 17 | 27 | ||

| Total (with coefficients) | 0.0034 | 0.091 | 13 | 0.0034 | 2.55 | 14.31 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsalidis, G.A.; Korevaar, G. Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study. Sustainability 2019, 11, 5945. https://doi.org/10.3390/su11215945

Tsalidis GA, Korevaar G. Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study. Sustainability. 2019; 11(21):5945. https://doi.org/10.3390/su11215945

Chicago/Turabian StyleTsalidis, Georgios Archimidis, and Gijsbert Korevaar. 2019. "Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study" Sustainability 11, no. 21: 5945. https://doi.org/10.3390/su11215945

APA StyleTsalidis, G. A., & Korevaar, G. (2019). Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study. Sustainability, 11(21), 5945. https://doi.org/10.3390/su11215945