Superfruit in the Niche—Underutilized Sea Buckthorn in Gilgit-Baltistan, Pakistan

Abstract

:1. Introduction

- Assess the current situation and problems during collection, drying, and marketing of sea buckthorn fruits in the Gilgit-Baltistan area of Pakistan as an example of a highland plant value chain;

- Recognize the preferences of collectors regarding fruit traits for the sake of future cultivation and introduction; and

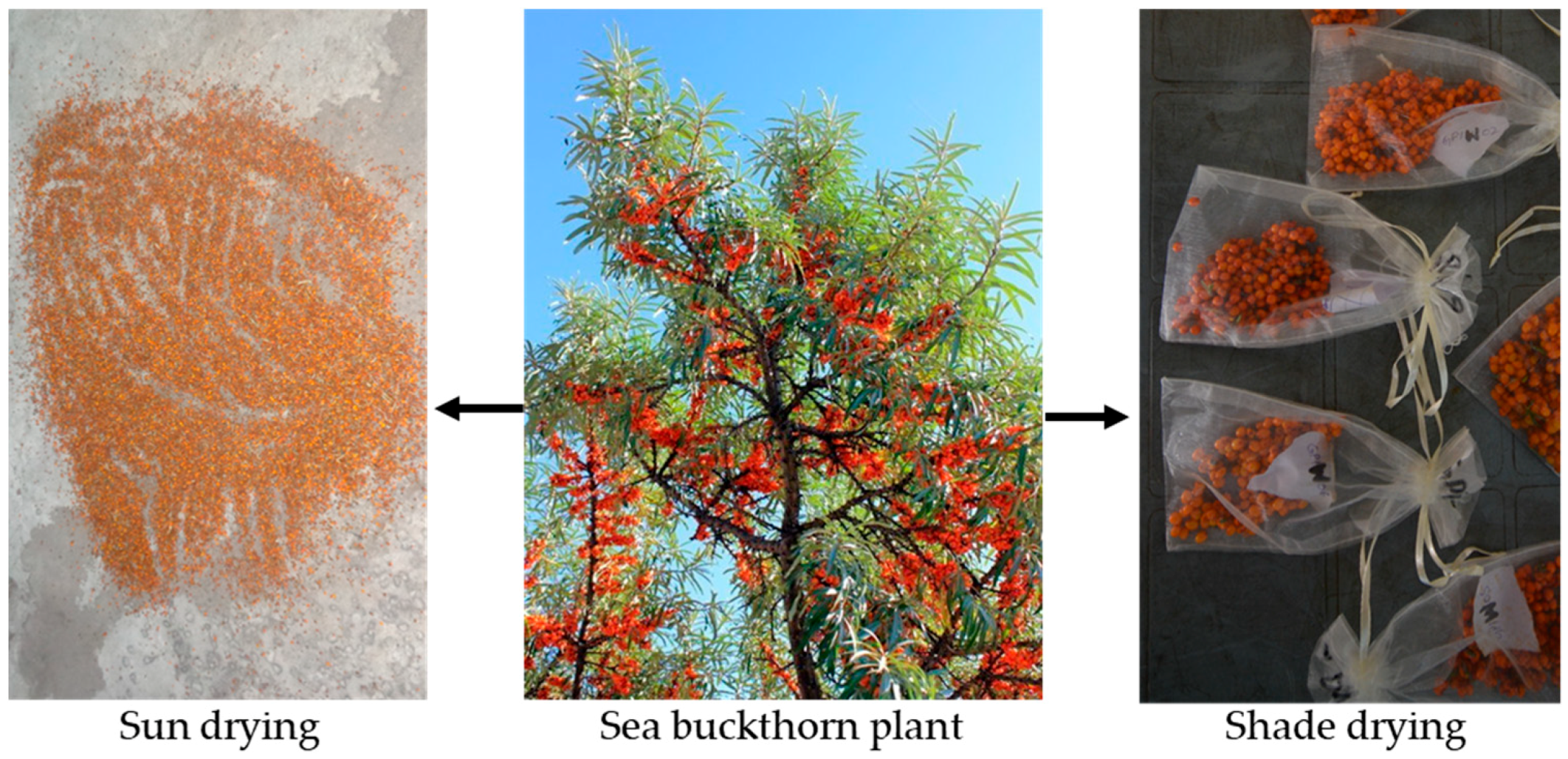

- Examine fruit vitamin C losses under traditional drying (sun drying) versus shade drying conditions.

2. Materials and Methods

2.1. Study Area

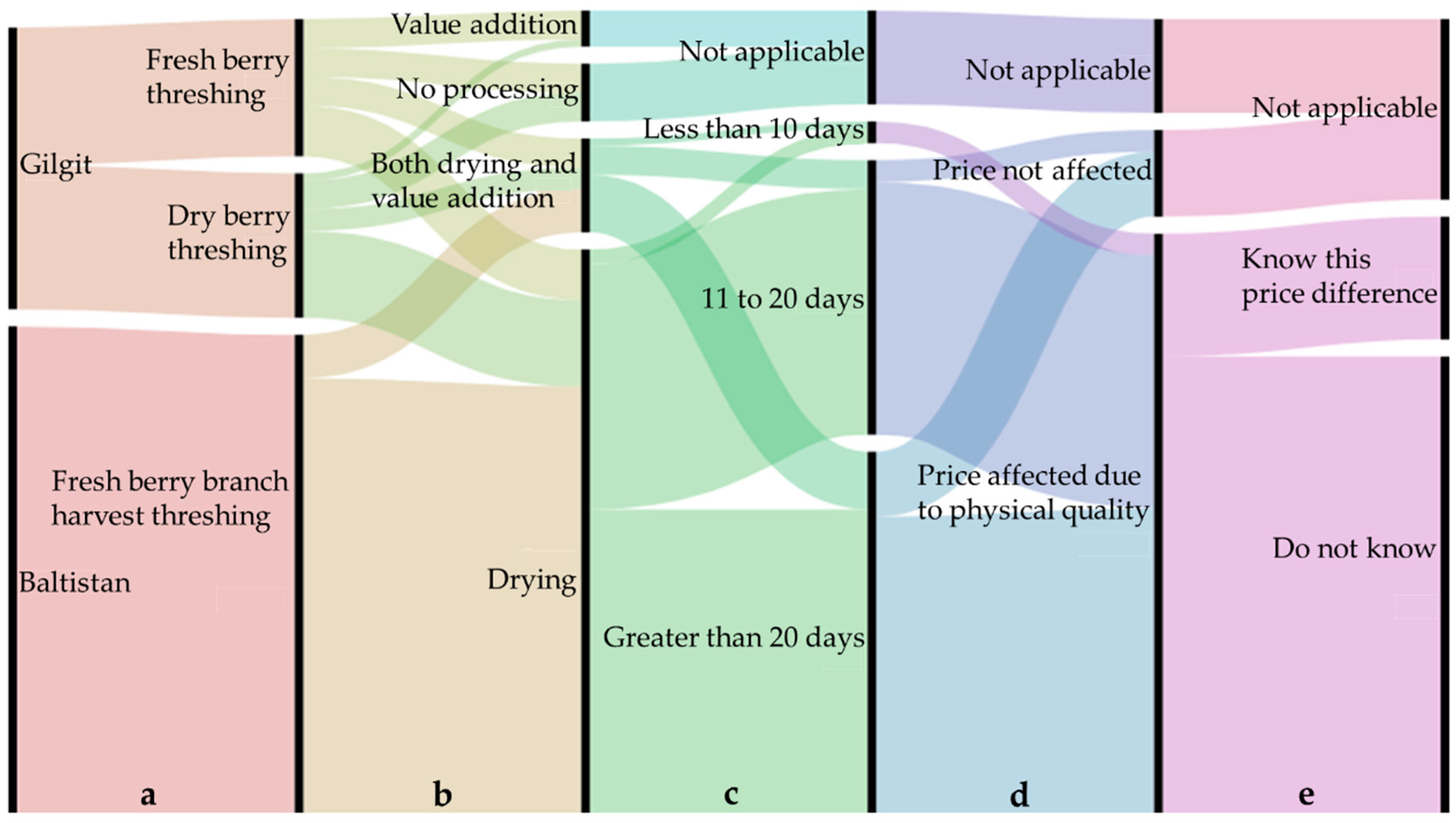

2.2. Survey on Sea Buckthorn Management, Harvest, and Post-Harvest Handling Practices

- status of collection and subsistence through sea buckthorn;

- current conditions and methods of harvest and post-harvest handling (collection of berries, storing, drying, value addition through product development);

- description of particular problems during collection, drying (number of days required for drying, price affected due to quality of drying), and marketing of sea buckthorn berries;

- perception of collectors about required/needed trainings and impact of already acquired trainings from government, NGOs, and private companies;

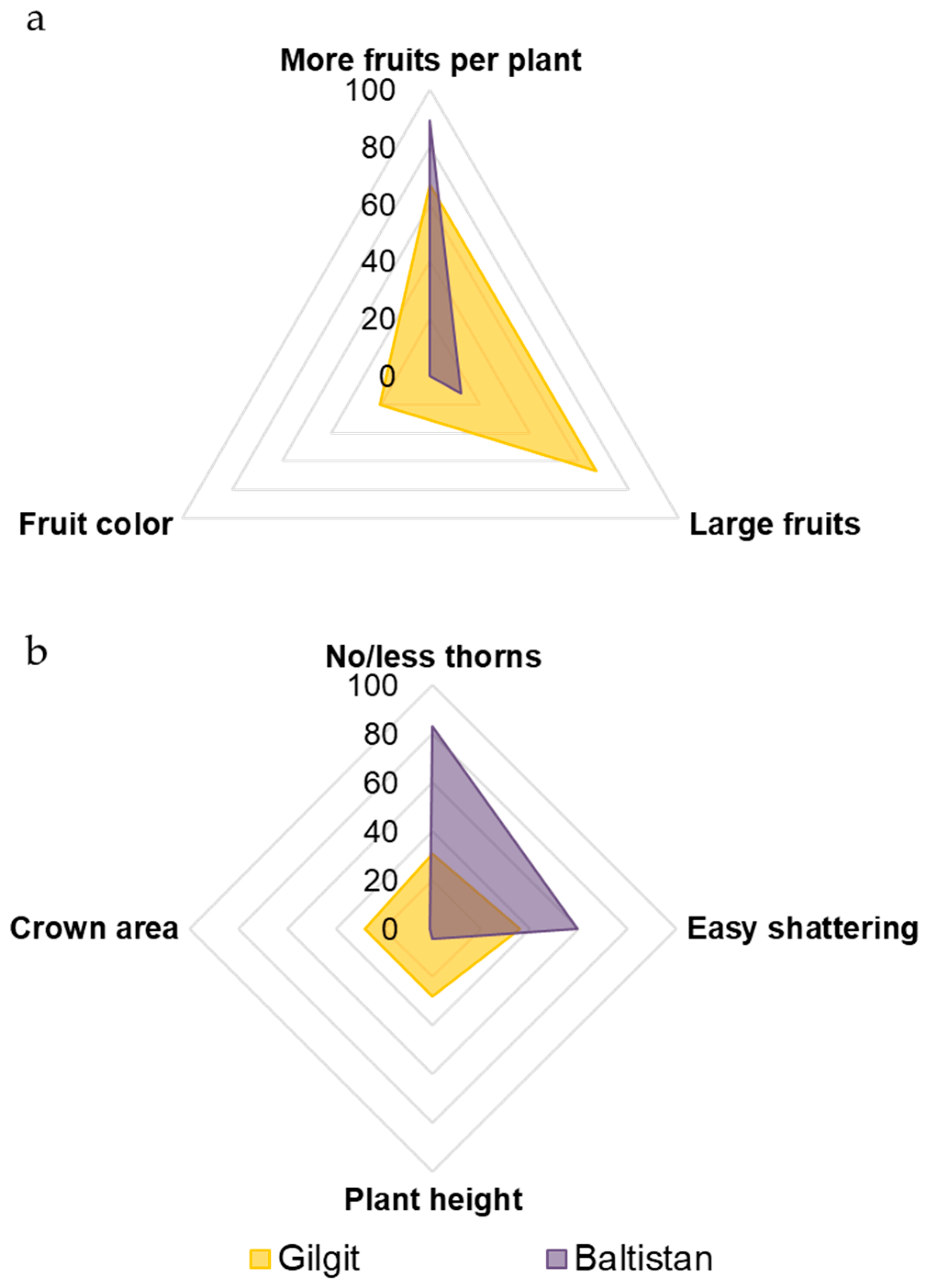

- identification of collectors’ perception about preferred dendrological and fruit traits.

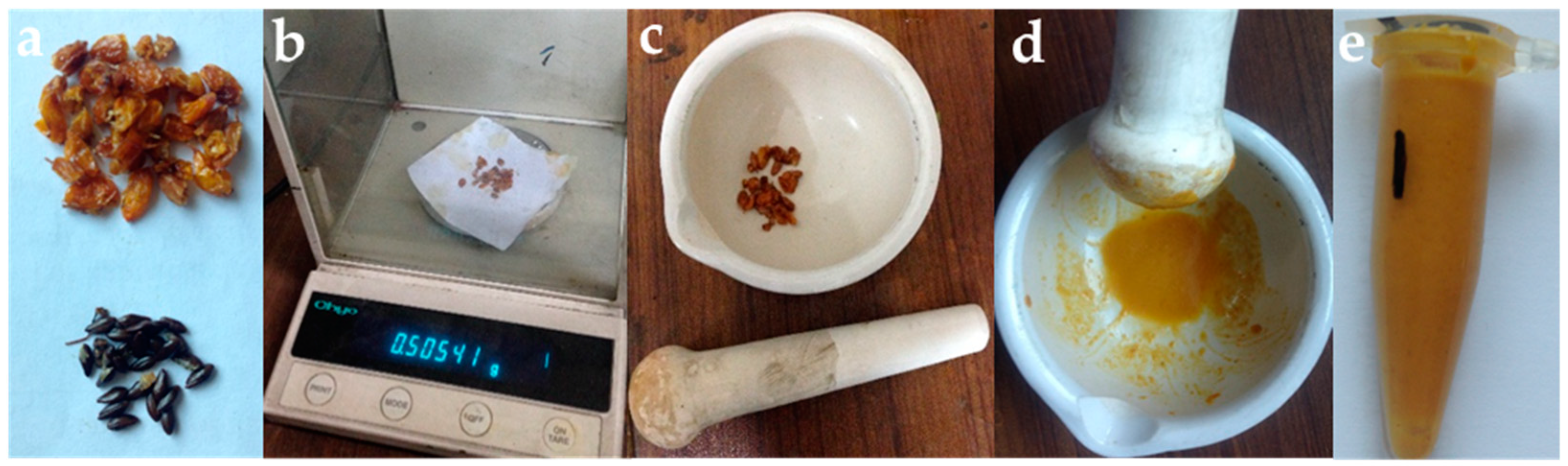

2.3. On-Farm Drying and Laboratory Experiment

2.4. Statistical Analysis

3. Results

3.1. Survey on Sea Buckthorn Management, Harvest, and Post-Harvest Handling Practices

3.1.1. Status and Subsistence through Collection

3.1.2. Conditions and Methods of Harvest to Post-Harvest Handling

3.1.3. Collectors’ Problems

3.1.4. Collectors’ Perception about Trainings

3.1.5. Preferred Plant and Fruit Traits by Collectors

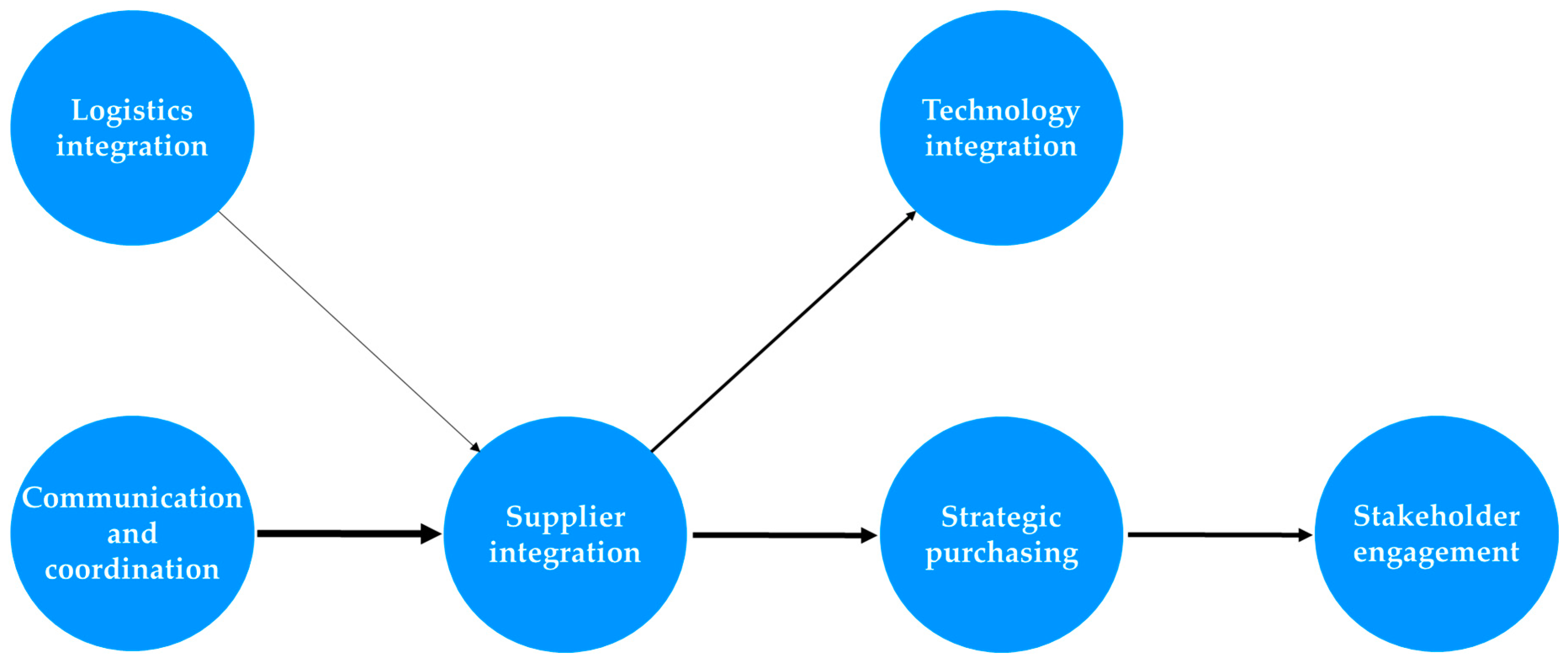

3.1.6. Sustainable Supply Chain Constructs

3.2. On-Farm Drying and Laboratory Experiment

3.2.1. Days Required for Drying and Moisture Content

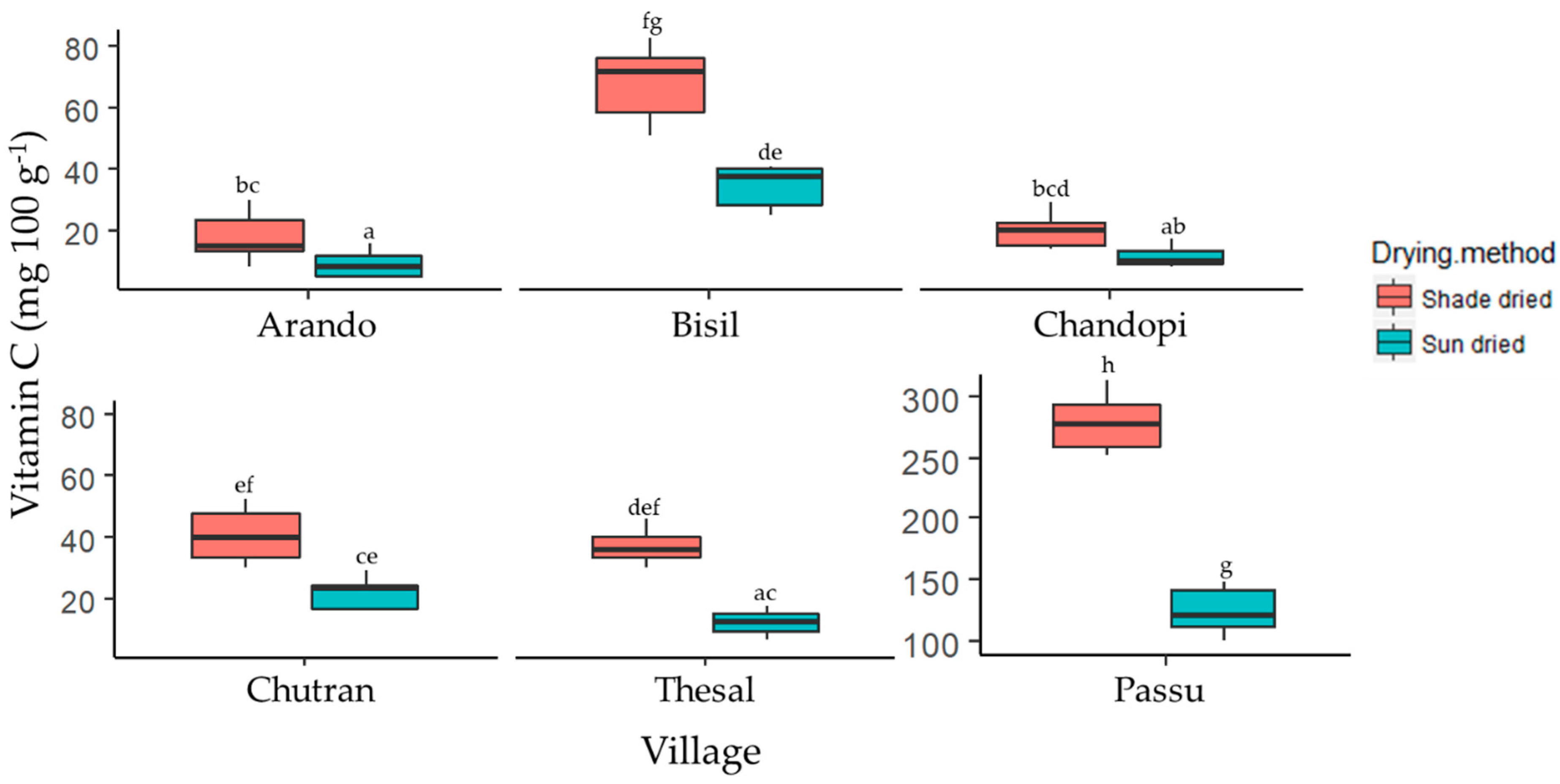

3.2.2. Concentration of Ascorbic Acid

4. Discussion

4.1. Status of Collection, Post-Harvest Handling, and Management

4.2. Quality Loss Due to Sun Drying of Sea Buckthorn Berries

4.3. Sea Buckthorn Supply Chain

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Items/Factors | Loadings | Cronbach’s α | CR | AVE |

|---|---|---|---|---|---|

| Stakeholder Engagement (SE) | |||||

| 1 | Take on board other supply chain actors while making business decisions | 0.908 | 0.858 | 0.904 | 0.704 |

| 2 | Share business-related information with other supply chain actors | 0.910 | |||

| 3 | Government and non-government organizations (NGOs) provide relevant support for business development | 0.722 | |||

| 4 | Supplier/colleagues share business-related information with you | 0.801 | |||

| Long-Term Relationship (LR) | |||||

| 1 | Do business together for a long time | 0.027 | 0.322 | 0.354 | 0.224 |

| 2 | Crucial time agent stands with collector | 0.753 | |||

| 3 | Harvester committed to fulfill demand | 0.139 | |||

| 4 | Good mutual understanding for business expansion | 0.711 | |||

| 5 | Kinship/friendship is a basic trust tool for business | −0.171 | |||

| Technology Integration (TI) | |||||

| 1 | Record keeping books used in business process | 0.777 | 0.850 | 0.900 | 0.692 |

| 2 | Mobile phones are the main source for business dealings | 0.864 | |||

| 3 | Payments are done through online bank transactions | 0.789 | |||

| 5 | Mobile phones are the main source for communication with business suppliers/colleagues | 0.893 | |||

| Logistics Integration (LI) | |||||

| 1 | Face transportation/logistic problems | 0.657 | 0.765 | 0.842 | 0.518 |

| 2 | Sharing same logistic resources | 0.649 | |||

| 3 | Supplies reached warehouses on time at other destinations | 0.832 | |||

| 4 | Quality deteriorates during transportation | 0.721 | |||

| 5 | Smooth flow of material and information from suppliers to buyers | 0.731 | |||

| Strategic Purchasing (SP) | |||||

| 1 | Multiple purchasers’ selection is done for selling | 0.943 | 0.951 | 0.968 | 0.911 |

| 2 | Strategic purchasing can play an important role for future business sustainability | 0.956 | |||

| 3 | Purchasing as a tool of competition | 0.965 | |||

| Supplier Integration (SI) | |||||

| 1 | Meet regularly with suppliers/colleagues | 0.703 | 0.778 | 0.858 | 0.602 |

| 2 | Capacity building and training are given to suppliers | 0.841 | |||

| 3 | Information regarding supply, demand, quality, and price is shared | 0.783 | |||

| 5 | Suppliers have rights in business planning decisions | 0.770 | |||

| Communication and Coordination with Suppliers (CCS) | |||||

| 1 | Good communication and coordination with business-related | 0.892 | 0.897 | 0.925 | 0.712 |

| 2 | Information shared with suppliers | 0.906 | |||

| 3 | Information shared timely and frequently for supplier business betterment | 0.911 | |||

| 4 | Market-related information is shared | 0.710 | |||

| 5 | Demand invoices are shared | 0.783 |

| Hypothesized Path | β | T-Statistics | p-Value |

|---|---|---|---|

| Logistics integration -> Supplier integration | 0.060 | 4.844 | <0.001 |

| Supplier integration -> Technology integration | 0.097 | 5.384 | <0.001 |

| Strategic purchasing -> Stakeholder engagement | 0.074 | 8.269 | <0.001 |

| Supplier integration -> Strategic purchasing | 0.076 | 8.923 | <0.001 |

| Communication and coordination -> Supplier integration | 0.054 | 13.302 | <0.001 |

| CCS | LI | SP | SE | SI | TI | |

|---|---|---|---|---|---|---|

| Communication and coordination (CCS) | 1.000 | |||||

| Logistics integration (LI) | 0.591 | 1.000 | ||||

| Strategic purchasing (SP) | 0.654 | 0.530 | 1.000 | |||

| Stakeholder engagement (SE) | 0.749 | 0.522 | 0.624 | 1.000 | ||

| Supplier integration (SI) | 0.895 | 0.717 | 0.667 | 0.756 | 1.000 | |

| Technology integration (TI) | 0.535 | 0.386 | 0.310 | 0.448 | 0.535 | 1.000 |

References

- Rongsen, L. Sea Buckthorn: A Multipurpose Plant Species for Fragile Mountains, 20th ed.; International Centre for Integrated Mountain Development (ICIMOD): Kathmandu, Nepal, 1992; pp. 18–20. [Google Scholar]

- Tang, X.; Tigerstedt, P.M. Variation of physical and chemical characters within an elite sea buckthorn (Hippophae rhamnoides L.) breeding population. Sci. Hortic. 2001, 88, 203–214. [Google Scholar] [CrossRef]

- Andersson, S.C.; Olsson, M.E.; Johansson, E.; Rumpunen, K. Carotenoids in sea buckthorn (Hippophae rhamnoides L.) berries during ripening and use of pheophytin a as a maturity marker. J. Agric. Food Chem. 2008, 57, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Kallio, H.; Yang, B.; Peippo, P. Effects of different origins and harvesting time on vitamin C, tocopherols, and tocotrienols in sea buckthorn (Hippophae rhamnoides L.) berries. J. Agric. Food Chem. 2002, 50, 6136–6142. [Google Scholar] [CrossRef] [PubMed]

- Jamyansan, Y.; Badgaa, D. Bioactive substances of Mongolian sea buckthorn (Hippophae rhamnoides L.). In Sea Buckthorn (Hippophae rhamnoides L.): A Multipurpose Wonder Plant; Singh, V., Ed.; Daya Publishing House: New Delhi, India, 2005; pp. 145–150. [Google Scholar]

- Baoru, Y.; Riina, M.; Pentti, H.; Heikki, P. Phytosterols in sea buckthorn (Hippophae rhamnoides L.) berries: Identification and effects of different origins and harvesting times. J. Agric. Food Chem. 2001, 49, 5620–5629. [Google Scholar] [CrossRef]

- Upadhyay, N.K.; Kumar, M.Y.; Gupta, A. Antioxidant, cytoprotective and antibacterial effects of sea buckthorn (Hippophae rhamnoides L.) leaves. Food Chem. Toxicol. 2010, 48, 3443–3448. [Google Scholar] [CrossRef]

- Yang, B.; Kallio, H.P. Fatty acid composition of lipids in sea buckthorn (Hippophae rhamnoides L.) berries of different origins. J. Agric. Food Chem. 2001, 49, 1939–1947. [Google Scholar] [CrossRef]

- Grey, C.; Widén, C.; Adlercreutz, P.; Rumpunen, K.; Duan, R.-D. Antiproliferative effects of sea buckthorn (Hippophae rhamnoides L.) extracts on human colon and liver cancer cell lines. Food Chem. 2010, 120, 1004–1010. [Google Scholar] [CrossRef]

- Gupta, R.; Singh, V. Mineral composition of sea buckthorn (Hippophae rhamnoides L.). In Sea Buckthorn (Hippophae rhamnoides L.): A Multipurpose Wonder Plant; Singh, V., Ed.; Daya Publishing House: New Delhi, India, 2005; pp. 272–284. [Google Scholar]

- Ahmed, S.; Joyia, M.F. Northern areas strategy for sustainable development. In Background Paper: Water-Pakistan, Northern Areas Programme; International Union for Conservation of Nature and Natural Resources: Gilgit, Pakistan, 2003; p. 67. [Google Scholar]

- Sea Buckthorn Management Practices in a Changing Climate: A Case Study of Pakistan; ICIMOD Manual: Rawalpindi, Pakistan, 2017.

- Zeb, A. Chemical and nutritional constituents of sea buckthorn juice. Pak. J. Nutr. 2004, 3, 99–106. [Google Scholar]

- Sabir, S.; Maqsood, H.; Hayat, I.; Khan, M.; Khaliq, A. Elemental and nutritional analysis of sea buckthorn (Hippophae rhamnoides ssp. turkestanica) berries of Pakistani origin. J. Med. Food 2005, 8, 518–522. [Google Scholar] [CrossRef] [PubMed]

- Lebeda, A. Official use of sea buckthorn fruits in Ukarine. Sea buckthorn a resource of health, a challenge to modern technology. In Proceedings of the 1st Congress of the International Sea Buckthorn, Berlin, Germany, 14–19 September 2003. [Google Scholar]

- Byers, T.; Perry, G. Dietary carotenes, vitamin C, and vitamin E as protective antioxidants in human cancers. Annu. Rev. Nutr. 1992, 12, 139–159. [Google Scholar] [CrossRef]

- Linster, C.L.; van Schaftingen, E. Vitamin C. FEBS J. 2007, 274, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Marks, J. Biological functions of vitamins. In The Technology of Vitamins in Food; Ottaway, P.B., Ed.; Springer: Boston, MA, USA, 1993. [Google Scholar]

- Shrimpton, D. Nutritional aspects of vitamins. In The Technology of Vitamins in Food; Ottaway, P.B., Ed.; Springer: Boston, MA, USA, 1993. [Google Scholar]

- Rousi, A.; Aulin, H. Ascorbic acid content in relation to ripeness in fruits of six Hippophae rhamnoides clones from Phyhaeranta, SW Finland. Ann. Agric. Fenn. 1977, 16, 80–87. [Google Scholar]

- Yang, H.; Wang, S.; Su, X. A study on the dynamic variation of ascorbic acid in Hippophae. Hippophae 1988, 4, 41–44. [Google Scholar]

- Yao, Y.; Tigerstedt, P.M.; Joy, P. Variation of vitamin C concentration and character correlation between and within natural sea buckthorn (Hippophae rhamnoides L.) populations. Acta Agric. Scand. B. Soil Plant Sci. 1992, 42, 12–17. [Google Scholar] [CrossRef]

- Moser, U.; Bendich, A.; Machlin, L. Handbook of Vitamins; FAO: New York, NY, USA, 1991. [Google Scholar]

- Perino-Issartier, S.; Abert-Vian, M.; Chemat, F. Solvent free microwave-assisted extraction of antioxidants from sea buckthorn (Hippophae rhamnoides L.) food by-products. Food Bioprocess Technol. 2011, 4, 1020–1028. [Google Scholar] [CrossRef]

- Doymaz, I.; Pala, M. The thin-layer drying characteristics of corn. J. Food Eng. 2003, 60, 125–130. [Google Scholar] [CrossRef]

- Santos, P.; Silva, M. Retention of vitamin C in drying processes of fruits and vegetables—A review. Dry. Technol. 2008, 26, 1421–1437. [Google Scholar] [CrossRef]

- Marques, L.G.; Silveira, A.M.; Freire, J.T. Freeze-drying characteristics of tropical fruits. Dry. Technol. 2006, 24, 457–463. [Google Scholar] [CrossRef]

- Bal, L.M.; Meda, V.; Naik, S.; Satya, S. Sea buckthorn berries: A potential source of valuable nutrients for nutraceuticals and cosmoceuticals. Food Res. Int. 2011, 44, 1718–1727. [Google Scholar] [CrossRef]

- Cenkowski, S.; Yakimishen, R.; Przybylski, R.; Muir, W. Quality of extracted sea buckthorn seed and pulp oil. Can. Biosyst. Eng. 2006, 48, 3.9–3.16. [Google Scholar]

- Suryakumar, G.; Gupta, A. Medicinal and therapeutic potential of sea buckthorn (Hippophae rhamnoides L.). J. Ethnopharmacol. 2011, 138, 268–278. [Google Scholar] [CrossRef] [PubMed]

- Beveridge, T.; Li, T.S.; Oomah, B.D.; Smith, A. Sea buckthorn products: Manufacture and composition. J. Agric. Food Chem. 1999, 47, 3480–3488. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V. Sea buckthorn: A potential bioresource in Himalayas. Invent. Intell. 2003, 38, 159–167. [Google Scholar]

- Li, T.S. Product development of sea buckthorn. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, VA, USA, 2002; pp. 393–398. [Google Scholar]

- Li, T.S.; Beveridge, T.H. Sea buckthorn (Hippophae rhamnoides L.): Production and Utilization; National Research Council Press: Ottawa, ON, Canada, 2003. [Google Scholar]

- Hu, I.; Xia, J.; Tu, X. Achievements and experiences of construction and development of Hippophae rhamnoides resource in China. Sci. Soil Water Conserv. 2008, 6, 98–102. [Google Scholar]

- Oyungerel, D.; Juuperelmaa, U.; Nasanjargal, D.; Altangoo, G.; Battumur, S. Distribution and genetic resource of Mongolian natural wild sea buckthorn (Hippophae rhamnoides L.). Mong. J. Agric. Sci. 2014, 13, 55–59. [Google Scholar] [CrossRef]

- Gonchigsumlaa, G. Competitiveness of Pastoral Livestock Production and Sea Buckthorn Farming in Mongolia: Application of Policy Analysis Matrix. Ph.D. Thesis, Georg-August-Universität Göttingen, Göttingen, Germany, 2016. [Google Scholar]

- Stobdan, T.; Phunchok, T. Value Chain Analysis of Seabuckthorn (Hippophae rhamnoides L.) in Leh Ladakh; Ministry of Agriculture and Farmer Welfare, Government of India: New Dehli, India, 2017.

- Pretty, J.; Smith, G.; Goulding, K.; Groves, S.; Henderson, I.; Hine, R.; King, V.; van Oostrum, J.; Pendlington, D.; Vis, J. Multi-year assessment of Unilever’s progress towards agricultural sustainability II: Outcomes for peas (UK), spinach (Germany, Italy), tomatoes (Australia, Brazil, Greece, USA), tea (Kenya, Tanzania, India) and oil palm (Ghana). Int. J. Agric. Sustain. 2008, 6, 63–88. [Google Scholar] [CrossRef]

- Planning & Development Department, Government of the Gilgit-Baltistan and UNICEF Pakistan. Multiple Indicator Cluster Survey, 2016–2017; Final Report for Planning & Development Department; Government of the Gilgit-Baltistan and UNICEF Pakistan: Gilgit, Pakistan, 2017.

- World Bank. Pakistan–Gilgit-Baltistan Economic Report: Broadening the Transformation; World Bank: Islamabad, Pakistan, 2011. [Google Scholar]

- Ali, R.; Ali, B.K.A.; Khan, M.Z.; Khan, G.; Abbas, S.; Ali, E.H.M. Baseline study of vegetation in Doyan Valley district Astore, Gilgit-Baltistan, Pakistan. IJETST 2014, 1, 7–19. [Google Scholar]

- Nawaz, M.; Krutovsky, K.; Mueller, M.; Gailing, O.; Khan, A.; Buerkert, A.; Wiehle, M. Morphological and genetic diversity of sea buckthorn (Hippophae rhamnoides L.) in the Karakoram mountains of northern Pakistan. Diversity 2018, 10, 76. [Google Scholar] [CrossRef]

- Ismail, I.; Sohail, M.; Gilani, H.; Ali, A.; Hussain, K.; Hussain, K.; Karky, B.S.; Qamer, F.M.; Qazi, W.; Ning, W. Forest inventory and analysis in Gilgit-Baltistan: A contribution towards developing a forest inventory for all Pakistan. Int. J. Clim. Chang. Strateg. Manag. 2018, 10, 616–631. [Google Scholar] [CrossRef]

- Beske, P.; Seuring, S. Putting sustainability into supply chain management. Supply Chain Manag. Int. J. 2014, 19, 322–331. [Google Scholar] [CrossRef]

- Khalid, R.U.; Seuring, S. Analyzing base-of-the-pyramid research from a (sustainable) supply chain perspective. J. Bus. Ethics 2019, 155, 663–686. [Google Scholar] [CrossRef]

- Vachani, S.; Smith, N.C. Socially responsible distribution. Strategies for reaching the bottom of the pyramid. Calif. Manag. Rev. 2008, 50, 52–84. [Google Scholar] [CrossRef]

- McMullen, J.S. Delineating the domain of development entrepreneurship: A market-based approach to facilitating inclusive economic growth. Entrepreneursh. Theory Pract. 2011, 35, 185–193. [Google Scholar] [CrossRef]

- Hill, R.P. A naturological approach to marketing exchanges: Implications for the bottom of the pyramid. J. Bus. Res. 2010, 63, 602–607. [Google Scholar] [CrossRef]

- Galariotis, E.; Villa, C.; Yusupov, N. Recent advances in lending to the poor with asymmetric information. J. Dev. Stud. 2011, 47, 1371–1390. [Google Scholar] [CrossRef]

- Gino, F.; Staats, B.R. The microwork solution. Harv. Bus. Rev. 2012, 90, 92–96. [Google Scholar]

- Berger, E.; Nakata, C. Implementing technologies for financial service innovations in base of the pyramid markets. J. Prod. Innov. Manag. 2013, 30, 1199–1211. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a theory of supply chain management: The constructs and measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Viswanathan, M.; Seth, A.; Gau, R.; Chaturvedi, A. Ingraining product-relevant social good into business processes in subsistence marketplaces: The sustainable market orientation. J. Macromark. 2009, 29, 406–425. [Google Scholar] [CrossRef]

- Arnould, E.J.; Mohr, J.J. Dynamic transformations for base-of-the-pyramid market clusters. J. Acad. Mark. Sci. 2005, 33, 254–274. [Google Scholar] [CrossRef]

- Kistruck, G.M.; Beamish, P.W.; Qureshi, I.; Sutter, C.J. Social intermediation in base-of-the-pyramid markets. J. Manag. Stud. 2013, 50, 31–66. [Google Scholar] [CrossRef]

- Halme, M.; Lindeman, S.; Linna, P. Innovation for Inclusive Business. Intrapreneurial Bricolage in Multinational Corporations. J. Manag. Stud. 2012, 49, 743–784. [Google Scholar] [CrossRef]

- Ramachandran, J.; Pant, A.; Pani, S.K. Building the BoP producer ecosystem: The evolving engagement of Fabindia with Indian handloom artisans. J. Prod. Innov. Manag. 2012, 29, 33–51. [Google Scholar] [CrossRef]

- Berger, R.; Choi, C.J.; Kim, J.B. Responsible leadership for multinational enterprises in bottom of pyramid countries: The knowledge of local managers. J. Bus. Ethics 2011, 101, 553–561. [Google Scholar] [CrossRef]

- Ramani, S.V.; SadreGhazi, S.; Duysters, G. On the diffusion of toilets as bottom of the pyramid innovation: Lessons from sanitation entrepreneurs. Technol. Forecast. Soc. Chang. 2012, 79, 676–687. [Google Scholar] [CrossRef]

- Bretz, F.; Hothorn, T.; Westfall, P. On multiple comparisons in R. R News 2002, 2, 14–17. [Google Scholar]

- How to Make an Alluvial Diagram. Available online: https://rawgraphs.io/learning/how-to-make-an-alluvial-diagram/ (accessed on 11 March 2019).

- Ringle, C.; Wende, S.; Becker, J. SmartPLS 3. Available online: http://www.smartpls.de (accessed on 15 September 2019).

- Santos, J.R.A. Cronbach’s alpha: A tool for assessing the reliability of scales. J. Ext. 1999, 37, 1–5. [Google Scholar]

- Churchill, G.A.; Iacobucci, D. Marketing Research: Methodological Foundations; Dryden Press: New York, NY, USA, 2006. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Fraering, M.; Minor, M.S. Sense of community: An exploratory study of US consumers of financial services. Int. J. Bank Mark. 2006, 24, 284–306. [Google Scholar] [CrossRef]

- Balt, G.; Chen, X.; Balt, S. Assessment of the socia-economic benefits of two indigenous fruit tree: Apple (Gornoaltaiskoje) and sea buckthorn (Altaja) to the people of Biger rural city in Western Region of Mongolia. Open Access Libr. J. 2016, 3, 1–7. [Google Scholar] [CrossRef]

- MLUL. Pionier im märkischen Sand—Auf den Spuren des Sanddorns in Brandenburg. Ministerium für Infrastruktur und Landwirtschaft des Landes: Potsdam, Germany, 2013. Available online: https://mlul.brandenburg.de/cms/media.php/lbm1.a.3310.de/Sanddorn_Teil1_web.pdf (accessed on 16 October 2019).

- Malik, A.; Siddique, M.; Sofi, P.; Butola, J. Ethnomedicinal practices and conservation status of medicinal plants of north Kashmir Himalayas. Res. J. Med. Plants 2011, 5, 515–530. [Google Scholar] [CrossRef]

- Ssegawa, P.; Kasenene, J.M. Medicinal plant diversity and uses in the Sango Bay area, southern Uganda. J. Ethnopharmacol. 2007, 113, 521–540. [Google Scholar] [CrossRef] [PubMed]

- Sagar, V.; Kumar, P.S. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Rocha, R.; Melo, E. Influence of drying process on the quality of medicinal plants: A review. J. Med. Plant Res. 2011, 5, 7076–7084. [Google Scholar] [CrossRef]

- Martinazzo, A.; Melo, E.; Barbosa, L.d.A.; de FF Soares, N.; Rocha, R.; Randuz, L.; Berbert, P. Quality parameters of Cymbopogon citratus leaves during ambient storage. Appl. Eng. Agric. 2009, 25, 543–547. [Google Scholar] [CrossRef]

- Smith, J.P.; Ramaswamy, H.S.; Simpson, B.K. Developments in food packaging technology. Part II. storage aspects. Trends Food Sci. Technol. 1990, 1, 111–118. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging—Roles, materials, and environmental issues. J. Food Sci. 2007, 72, 39–55. [Google Scholar] [CrossRef]

- Larsen, H.O.; Smith, P.D. Stakeholder perspectives on commercial medicinal plant collection in Nepal: Poverty and resource degradation. Mt. Res. Dev. 2004, 24, 141–148. [Google Scholar] [CrossRef]

- Schippmann, U.; Leaman, D.J.; Cunningham, A. Impact of Cultivation and Gathering of Medicinal Plants on Biodiversity: Global Trends and Issues; Inter-Department Working Group on Biology Diversity for Food and Agriculture, FAO: Rome, Italy, 2002. [Google Scholar]

- Hamilton, A.C. Medicinal plants, conservation and livelihoods. Biodivers. Conserv. 2004, 13, 1477–1517. [Google Scholar] [CrossRef]

- Kala, C.P.; Dhyani, P.P.; Sajwan, B.S. Developing the medicinal plants sector in northern India: Challenges and opportunities. J. Ethnobiol. Ethnomed. 2006, 2, 32. [Google Scholar] [CrossRef]

- Larsen, H.O.; Olsen, C.S. Unsustainable collection and unfair trade? uncovering and assessing assumptions regarding central Himalayan medicinal plant conservation. Biodivers. Conserv. 2007, 16, 1679–1697. [Google Scholar] [CrossRef]

- Mahapatra, A.K.; Tewari, D. Importance of non-timber forest products in the economic valuation of dry deciduous forests of India. For. Policy Econ. 2005, 7, 455–467. [Google Scholar] [CrossRef]

- Ravinder Reddy, C.; Wani, S.; Reddy, L.; Reddy, G.; Koppula, P.; Alur, A. Public-Private Sector Partnership in Diversifying Semi-Arid Tropical (SAT) Systems through Medicinal and Aromatic Plants; Working Paper; International Crops Research Institute for the Semi-Arid Tropics: Patancheru, India, 2008. [Google Scholar]

- Jalihal, S. Contract Farming in Medicinal Plants: A Case of Coleus in Karnataka. Master’s Thesis, University of Agricultural Sciences, Dharwad, India, 2009. [Google Scholar]

- Pradeep Kumar, D. Economics of Medicinal and Aromatic Plants of Andhra Pradesh and Telangana States. Bachelor’s Thesis, Acharya NG Ranga Agricultural University, Hyderabad, India, 2016. [Google Scholar]

- Bradford, K.J.; Dahal, P.; Van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 2018, 71, 84–93. [Google Scholar] [CrossRef]

- Kiaya, V. Post-Harvest Losses and Strategies to Reduce Them; Technical Paper on Postharvest Losses. Available online: https://www.actioncontrelafaim.org/wp-content/uploads/2018/01/technical_paper_phl__.pdf (accessed on 20 October 2019).

- Ruan, C.; Qin, P.; Zheng, J.; He, Z. Genetic relationships among some cultivars of sea buckthorn from China, Russia and Mongolia based on RAPD analysis. Sci. Hortic. 2004, 101, 417–426. [Google Scholar] [CrossRef]

- Albrecht, H. Characters and properties of sea buckthorn varieties selected in eastern Germany. Erwerbsobstbau 1990, 331, 53–55. [Google Scholar]

- Sanna, K.; Petruneva, E. Producing sea buckthorn of high quality. In Proceedings of the 3rd European Workshop on Sea Buckthorn, EuroWorks, Naantali, Finland, 14–16 October 2014. [Google Scholar]

- Yahya, M.; Sopian, K.; Daud, W.; Othman, M.; Yatim, B. Design of solar assisted dehumidification of air drying system for medicinal herbs: Pegaga leaf. In Proceedings of the Second Asian-Oceania Drying Conference (ADC), Batu Feringhi, Malaysia, 20–22 August 2001; pp. 383–392. [Google Scholar]

- Jain, D.; Tiwari, G. Thermal aspects of open sun drying of various crops. Energy 2003, 28, 37–54. [Google Scholar] [CrossRef]

- Belessiotis, V.; Delyannis, E. Solar drying. Sol. Energy 2011, 85, 1665–1691. [Google Scholar] [CrossRef]

- Kaya, A.; Aydın, O.; Kolaylı, S. Effect of different drying conditions on the vitamin C (ascorbic acid) content of Hayward kiwifruits (Actinidia deliciosa Planch). Food Bioprod. Process. 2010, 88, 165–173. [Google Scholar] [CrossRef]

- Chin, S.; Siew, E.; Soon, W. Drying characteristics and quality evaluation of kiwi slices under hot air natural convective drying method. Int. Food Res. J. 2015, 22, 2188–2195. [Google Scholar]

- Çağlarirmak, N. Ochratoxin A, hydroxymethylfurfural and vitamin C levels of sun-dried grapes and sultanas. J. Food Process. Preserv. 2006, 30, 549–562. [Google Scholar] [CrossRef]

- Ndawula, J.; Kabasa, J.; Byaruhanga, Y. Alterations in fruit and vegetable β-carotene and vitamin C content caused by open-sun drying, visqueen-covered and polyethylene-covered solar-dryers. Afr. Health Sci. 2004, 4, 125–130. [Google Scholar] [PubMed]

- Murthy, Z.; Joshi, D. Fluidized bed drying of amla (Emblica officinalis L.). Dry. Technol. 2007, 25, 883–889. [Google Scholar] [CrossRef]

- Chong, C.H.; Law, C.L.; Cloke, M.; Abdullah, L.C.; Daud, W.R.W. Drying kinetics, texture, color, and determination of effective diffusivities during sun drying of chempedak. Dry. Technol. 2008, 26, 1286–1293. [Google Scholar] [CrossRef]

- Chong, C.H.; Law, C.L.; Cloke, M.; Hii, C.L.; Abdullah, L.C.; Daud, W.R.W. Drying kinetics and product quality of dried chempedak. J. Food Eng. 2008, 88, 522–527. [Google Scholar] [CrossRef]

- Chong, C.H.; Law, C.L.; Cloke, M.; Abdullah, L.C.; Wan Daud, W.R. Drying models and quality analysis of sun-dried ciku. Dry. Technol. 2009, 27, 985–992. [Google Scholar] [CrossRef]

- London, T.; Hart, S.L. Next Generation Business Strategies for the Base of the Pyramid: New Approaches for Building Mutual Value; Pearson Education: Delhi, India, 2010. [Google Scholar]

- Parmigiani, A.; Rivera-Santos, M. Sourcing for the base of the pyramid: Constructing supply chains to address voids in subsistence markets. J. Oper. Manag. 2015, 33, 60–70. [Google Scholar] [CrossRef]

| Regions | District | Villages | No. of Household | ||

|---|---|---|---|---|---|

| Total | Interviewed | ||||

| Collector | Commissioner | ||||

| Gilgit | Hunza | Shimshal | 240 | 20 | 4 |

| Passu | 300 | 4 | 1 | ||

| Gulmit | 220 | 15 | 2 | ||

| Baltistan | Shigar | Arando | 90 | 15 | 1 |

| Bisil | 78 | 12 | 1 | ||

| Chutron | 120 | 15 | 3 | ||

| Chandopi | 140 | 15 | 3 | ||

| Thesil | 160 | 15 | 2 | ||

| Total | 1348 | 111 | 17 | ||

| Constructs | Description | References |

|---|---|---|

| Stakeholder engagement | To avoid any gray areas in the sustainable business operations, “transparency includes not only reporting to stakeholders, but actively engaging stakeholders and using their feedback and input to both secure buy-in and improve supply chain processes.” | [47,48] |

| Long-term relationships | Strategically managed trustworthy long-term relationships with key suppliers in particular and other supply chain actors in general, impacting positively on firm performance. | [49,50] |

| Technology integration | Presence and mode of electronic transactions and communication for the efficient flow of information among supply chain actors. | [51,52] |

| Logistics integration | The backbone of the modern supply chain, providing the necessary infrastructure to successfully meet market demands through seamless logistics integration based on regular lines of communication for exchanging information about the three cornerstones of logistics: warehouses, inventory, and transportation between buyer and seller. | [47,53,54,55] |

| Strategic purchasing | Proactive and long-term focus in making purchasing decisions that will drive the firm’s success. | [56,57] |

| Supplier integration | Communication and coordination with suppliers to seamlessly integrate them into focal firm activities for more efficient achievement of sustainability objectives. | [58,59] |

| Communication and coordination with suppliers | Enhanced communication and active coordination with suppliers as a prerequisite for supplier integration and sustainable supply chain management. | [60,61] |

| Groups | Berry Sale (US$) | Byproduct Sale (US$) | |

|---|---|---|---|

| Collector | Berries only (n = 93) | 181 (125) a ± 196 | - |

| Berries and byproducts (n = 18) | 213 (101) a ± 247 | 378 (75) a ± 831 | |

| Commission agent | Berries and byproduct (n = 17) | 838 (385) b ± 924 | 307 (0) b ± 878 |

| Variable | Unit | Group | Mean | Min. | Max. |

|---|---|---|---|---|---|

| Experience | Year | Collector | 4 ± 3 | 1 | 19 |

| Year | Commission agent | 6 ± 4 | 1 | 18 | |

| Amount collected/purchased | kg | Collector | 110 ± 136 | 15 | 1250 |

| kg | Commission agent | 3356 ± 3201 | 500 | 10,000 | |

| Selling price for collectors | US$ kg−1 | Current | 1.82 ± 0.38 | 0.96 | 2.4 |

| US$ kg−1 | Demand increase | 2.84 ± 0.73 | 1.44 | 4.81 | |

| Firewood for household use | US$ year−1 | Estimated price | 511 ± 142 | 240 | 923 |

| Total | |||||

| Family labor involved in collection of berries | % | Men | 22 | ||

| % | Women | 53 | |||

| % | Children under 15 years | 25 | |||

| Picking area | % | Owned | 62 | ||

| % | Community land | 10 | |||

| % | Both | 28 | |||

| Picking from other land than picking area | % | Allowed | 46 | ||

| % | Not allowed | 54 |

| Problems During Collection | Response Frequency (%) |

|---|---|

| Lack of collection equipment | 74 |

| Unmanaged/dense stands | 71 |

| Lack of storage facility | 41 |

| Difficult collection due to lack of harvesting knowledge | 37 |

| Problems During Drying | |

| Harsh weather (strong winds and rainfall) | 95 |

| Dust | 93 |

| Grading issues | 48 |

| Drying equipment unavailability | 34 |

| More days needed for drying | 15 |

| Bird damage | 14 |

| Quality deterioration | 12 |

| Problems During Marketing | |

| Lack of market access | 57 |

| Transportation due to poor road infrastructure | 34 |

| No regulated fix price | 33 |

| Potential Solutions | |

| Availability of drying units | 76 |

| Availability of grading units | 43 |

| Provisions of latest harvesting tools | 55 |

| Training Demand | Response Frequency (%) | |

|---|---|---|

| Latest collection methods | 76 | |

| Value addition | 60 | |

| Latest drying methods | 38 | |

| Grading techniques | 17 | |

| Marketing techniques | 16 | |

| Cultivation practices | 6 | |

| Yes | No | |

| Have you taken any type of training? | 28 | 72 |

| Theme of received training | ||

| Safety measures during collection | 81 | |

| Product development | 74 | |

| Maintenance of plants | 35 | |

| Marketing | 23 | |

| Estimated Model | |

|---|---|

| SRMR | 0.092 |

| d_ULS | 2.734 |

| d_G | 1.716 |

| Chi-square | 452.915 |

| NFI | 0.735 |

| Villages | Drying Method | n | Moisture % | DRD | Sig |

|---|---|---|---|---|---|

| Passu | Shade | 5 | 31 | 15 | ac |

| Sun | 5 | 28 | 9 | ab | |

| Thesal | Shade | 5 | 33 | 16 | bc |

| Sun | 5 | 34 | 8 | a | |

| Chandopi | Shade | 5 | 35 | 15 | ac |

| Sun | 5 | 33 | 9 | ab | |

| Chutran | Shade | 5 | 35 | 30 | d |

| Sun | 5 | 34 | 15 | ac | |

| Bisil | Shade | 5 | 31 | 20 | cd |

| Sun | 5 | 30 | 12 | ac | |

| Arando | Shade | 5 | 26 | 30 | d |

| Sun | 5 | 26 | 19 | c | |

| Total | 60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawaz, M.A.; Khan, A.A.; Khalid, U.; Buerkert, A.; Wiehle, M. Superfruit in the Niche—Underutilized Sea Buckthorn in Gilgit-Baltistan, Pakistan. Sustainability 2019, 11, 5840. https://doi.org/10.3390/su11205840

Nawaz MA, Khan AA, Khalid U, Buerkert A, Wiehle M. Superfruit in the Niche—Underutilized Sea Buckthorn in Gilgit-Baltistan, Pakistan. Sustainability. 2019; 11(20):5840. https://doi.org/10.3390/su11205840

Chicago/Turabian StyleNawaz, Muhammad Arslan, Asif Ali Khan, Usman Khalid, Andreas Buerkert, and Martin Wiehle. 2019. "Superfruit in the Niche—Underutilized Sea Buckthorn in Gilgit-Baltistan, Pakistan" Sustainability 11, no. 20: 5840. https://doi.org/10.3390/su11205840

APA StyleNawaz, M. A., Khan, A. A., Khalid, U., Buerkert, A., & Wiehle, M. (2019). Superfruit in the Niche—Underutilized Sea Buckthorn in Gilgit-Baltistan, Pakistan. Sustainability, 11(20), 5840. https://doi.org/10.3390/su11205840