Experimenting and Modeling Thermal Performance of Ground Heat Exchanger Under Freezing Soil Conditions

Abstract

:1. Introduction

2. Methodology

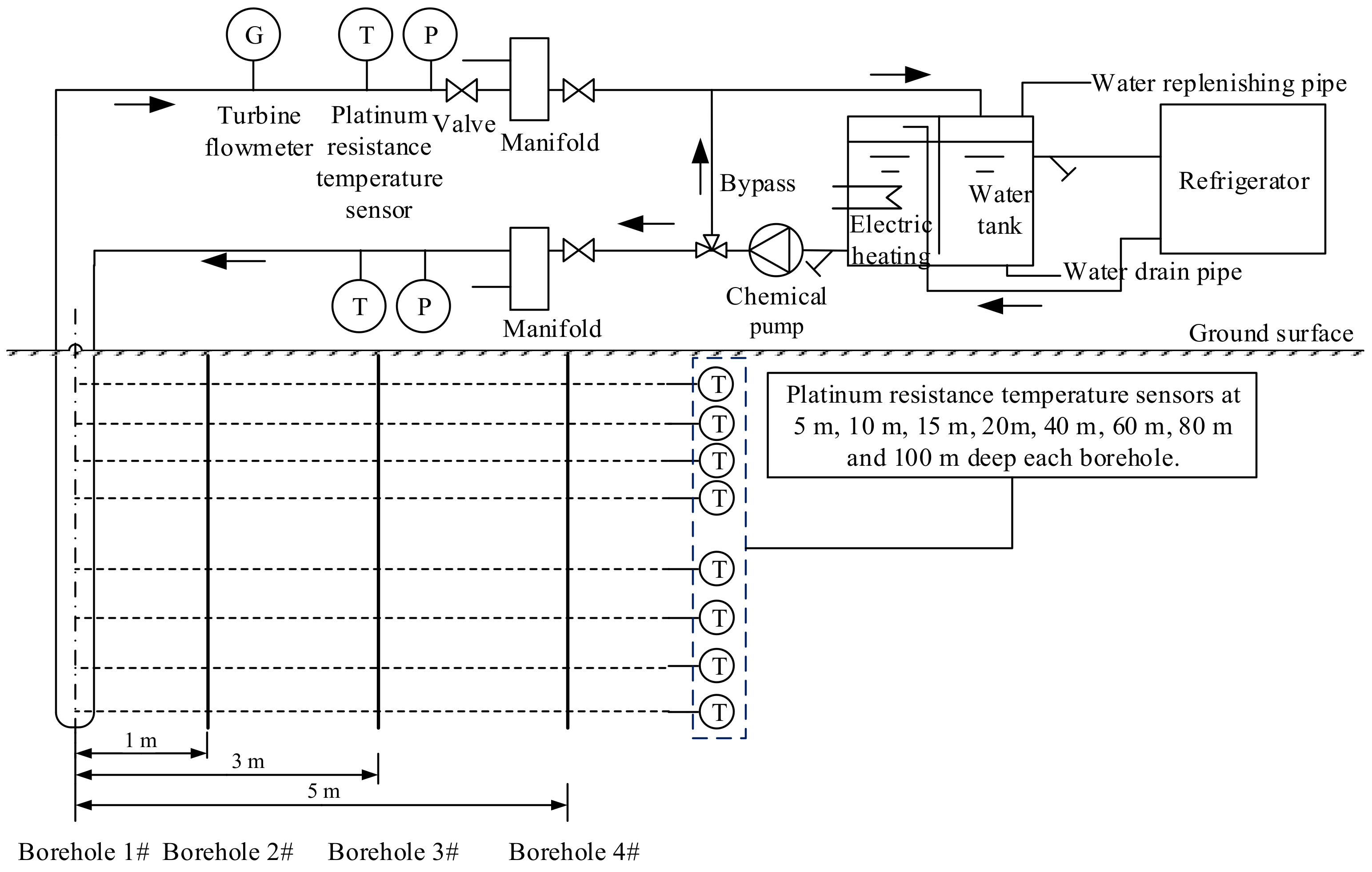

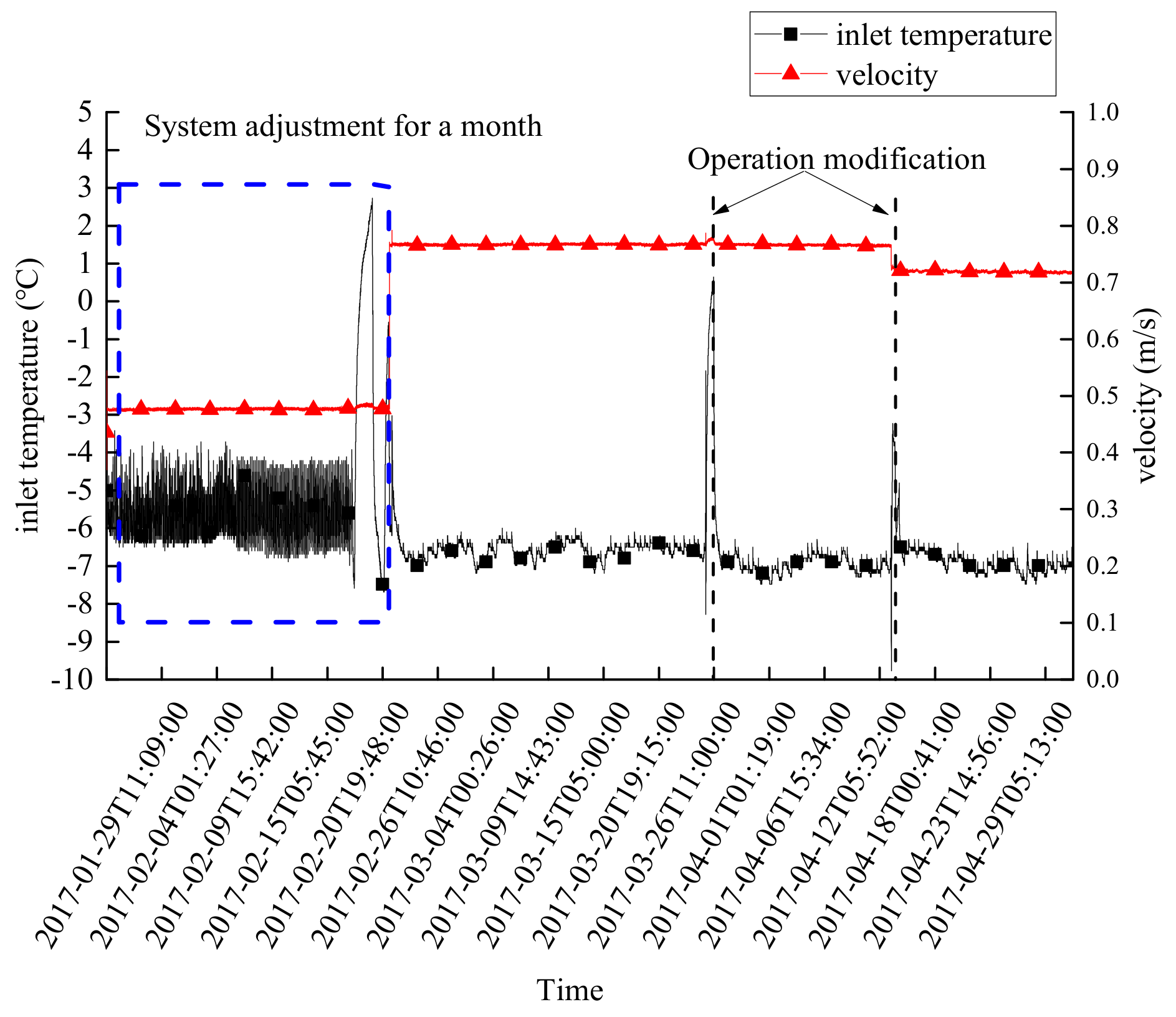

2.1. Experimental Set-Up

2.2. RC Model Development

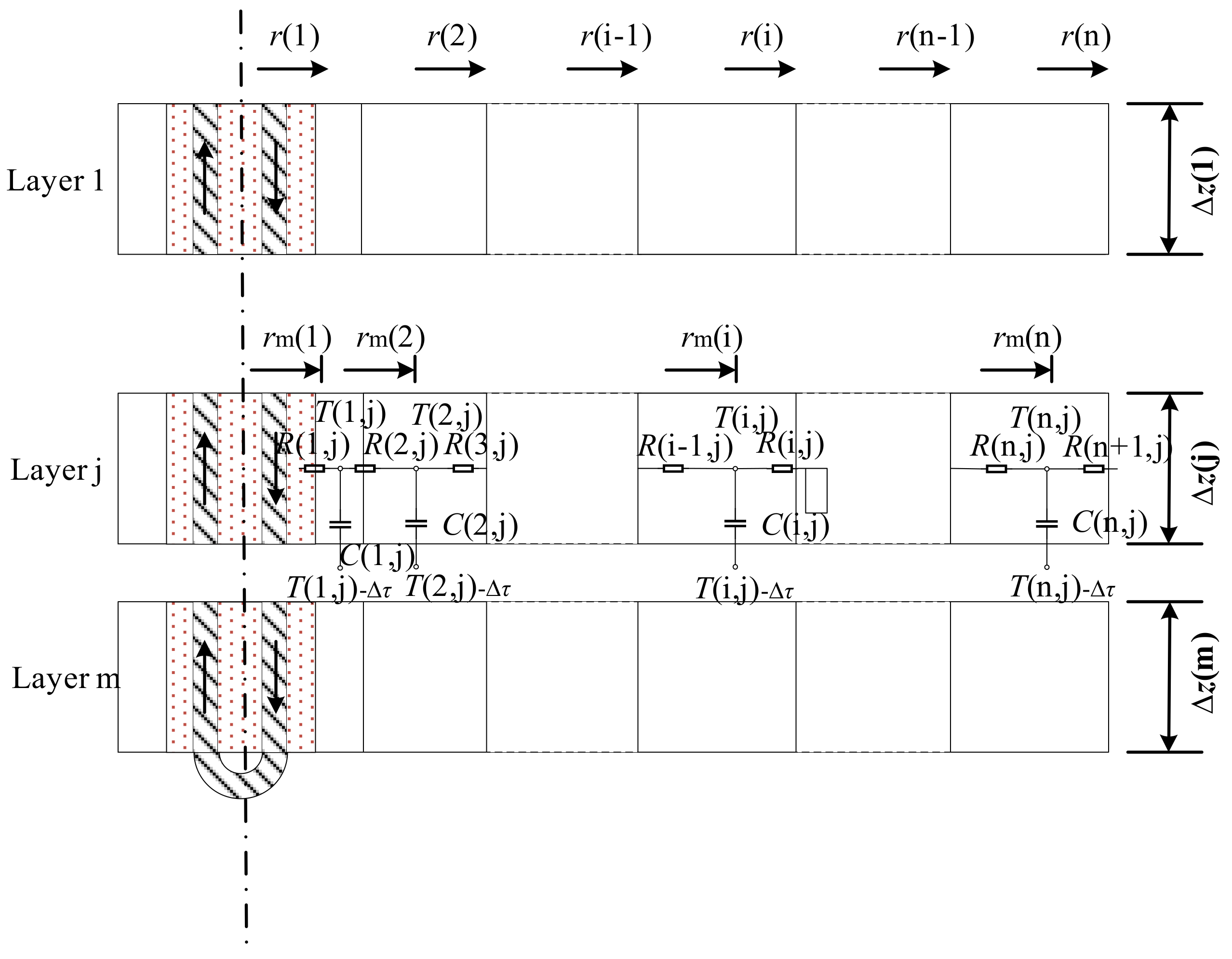

2.2.1. General RC Model

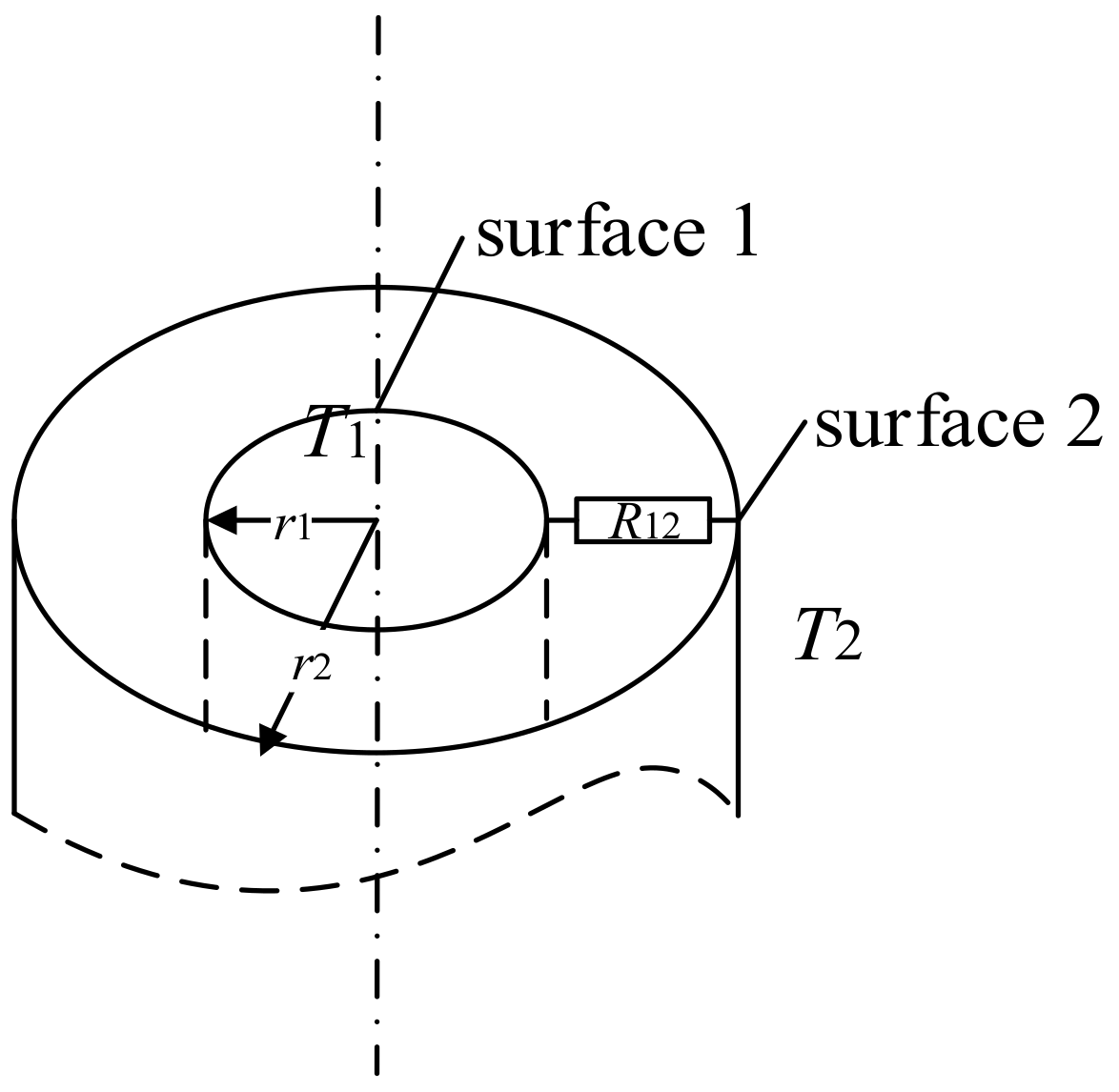

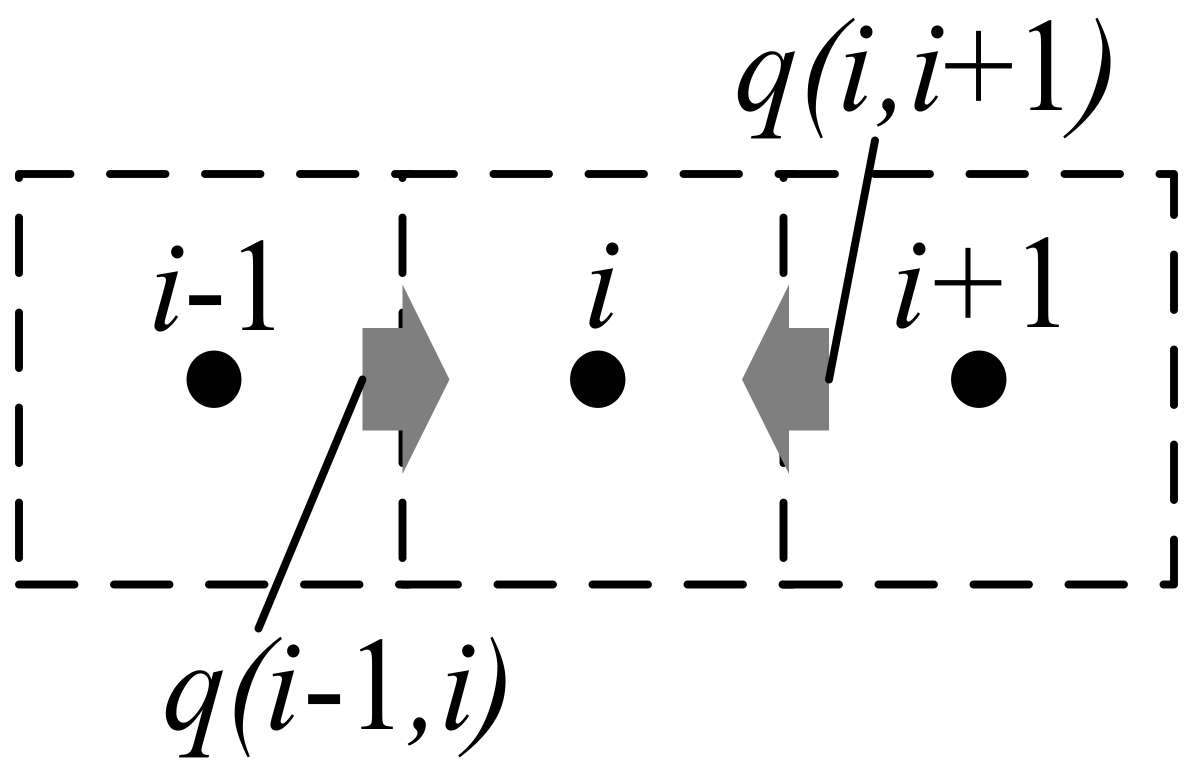

2.2.2. Soil RC model

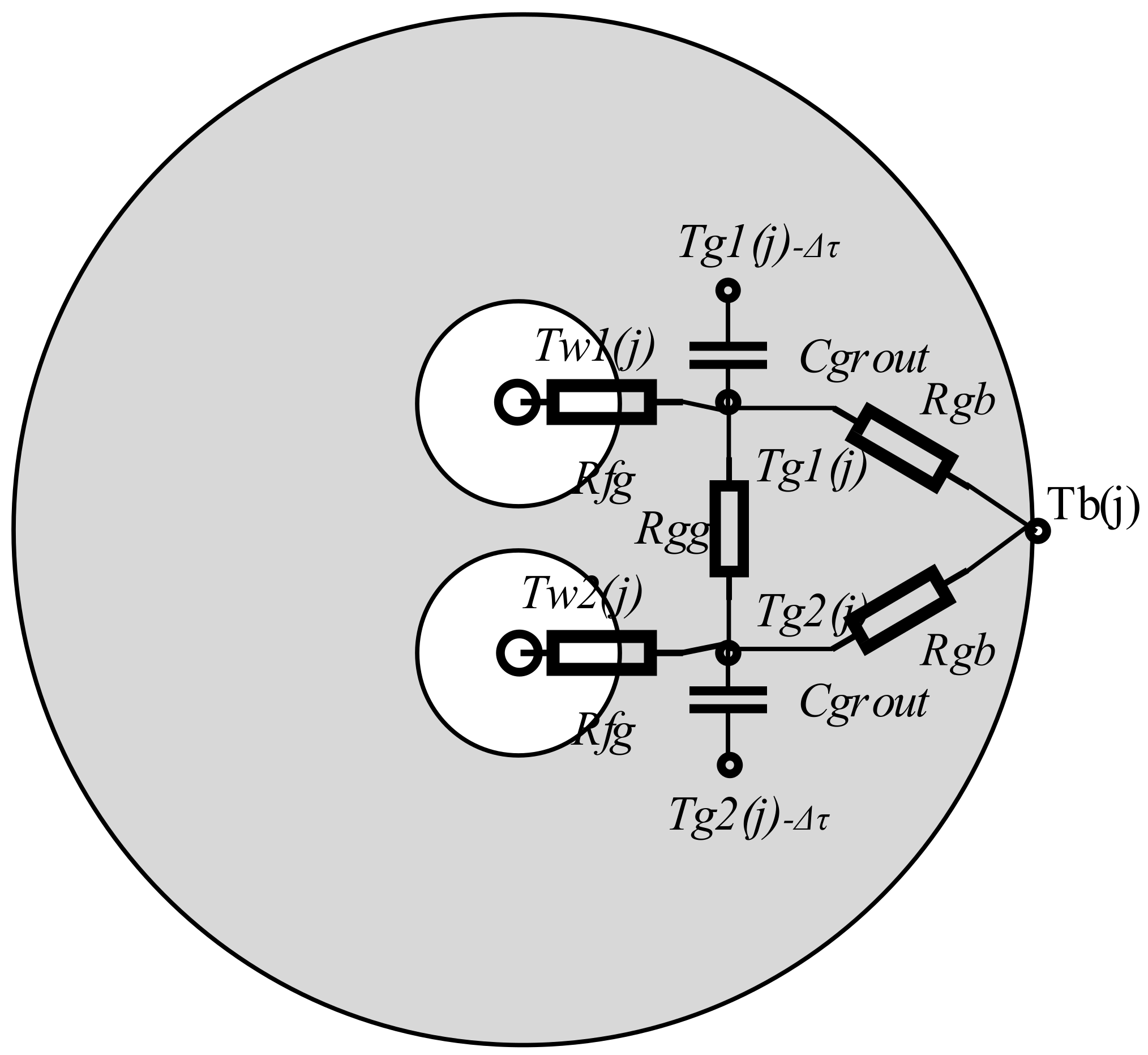

2.2.3. Borehole and Pipes’ RC Model

2.2.4. Model Solving

2.2.5. Module for Freezing Condition

2.2.6. Inputs and Outputs for RC Model

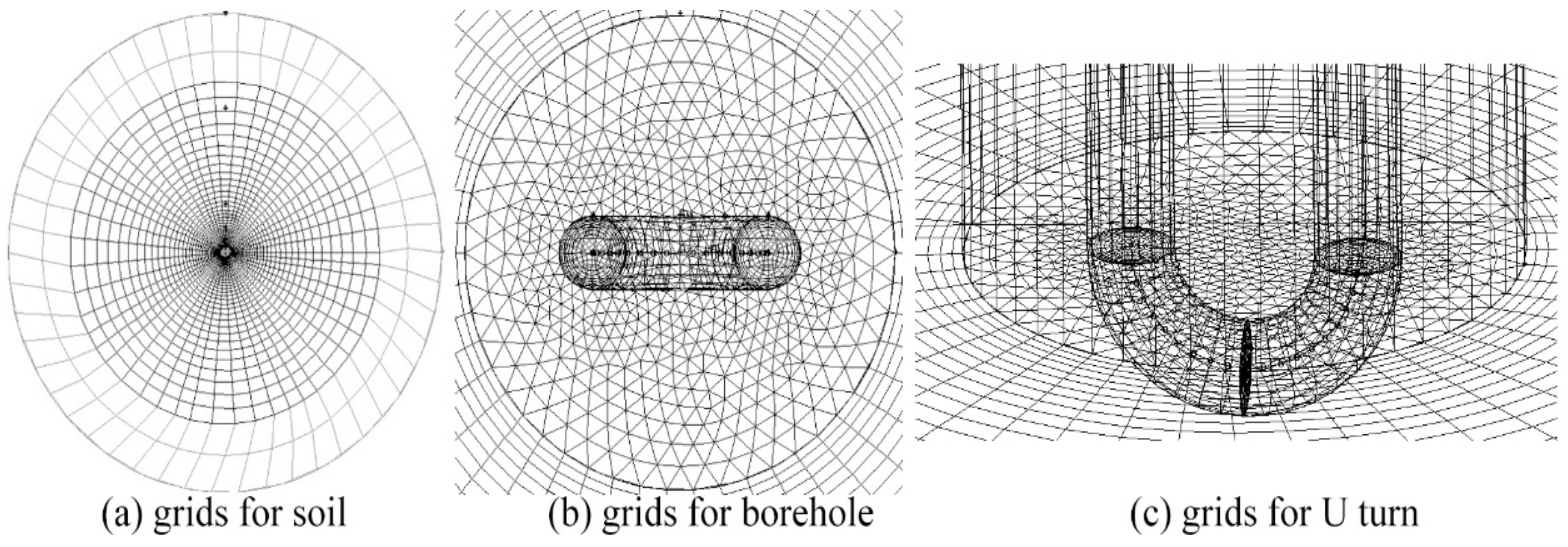

2.3. CFD Model Description

3. Results and Discussion

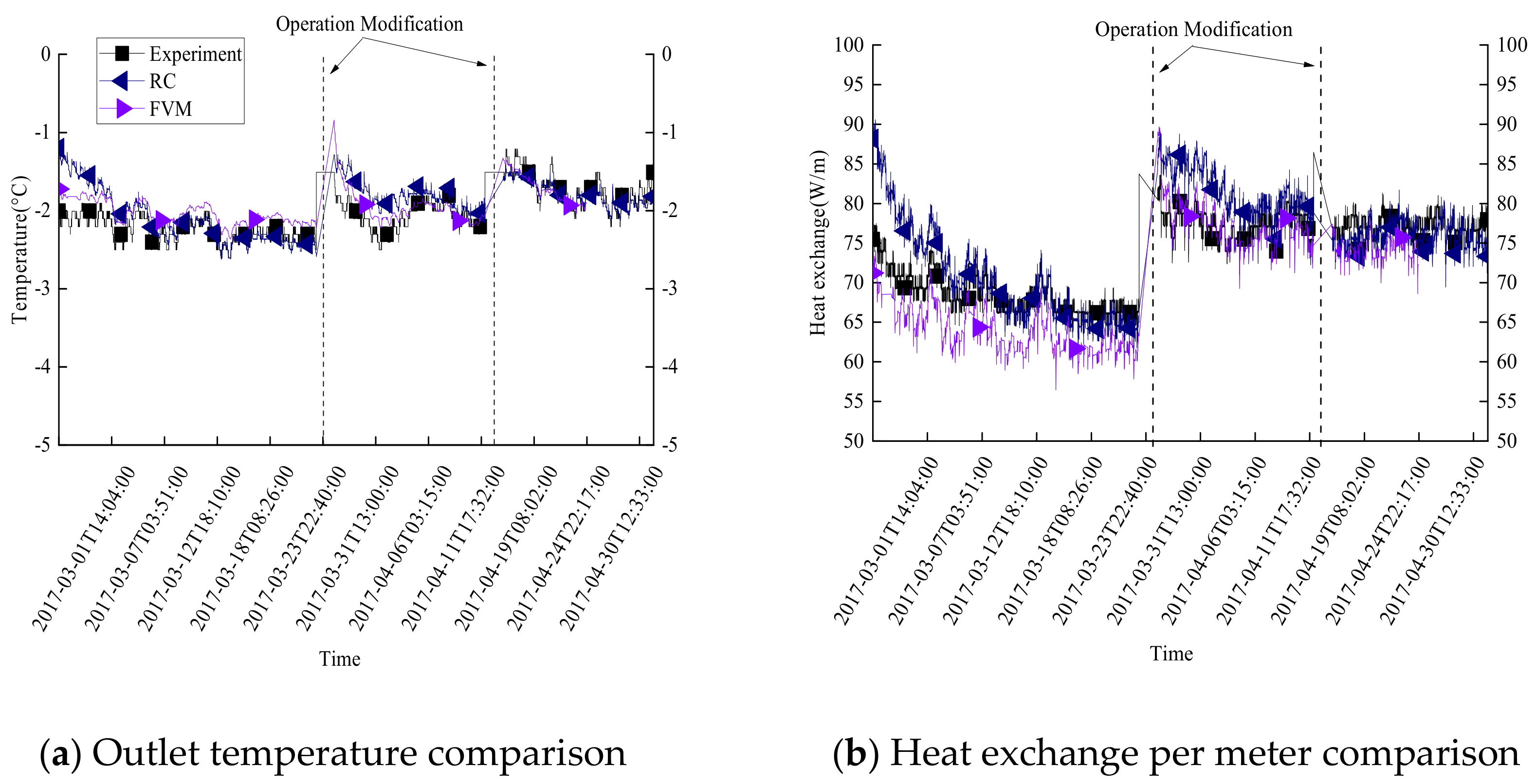

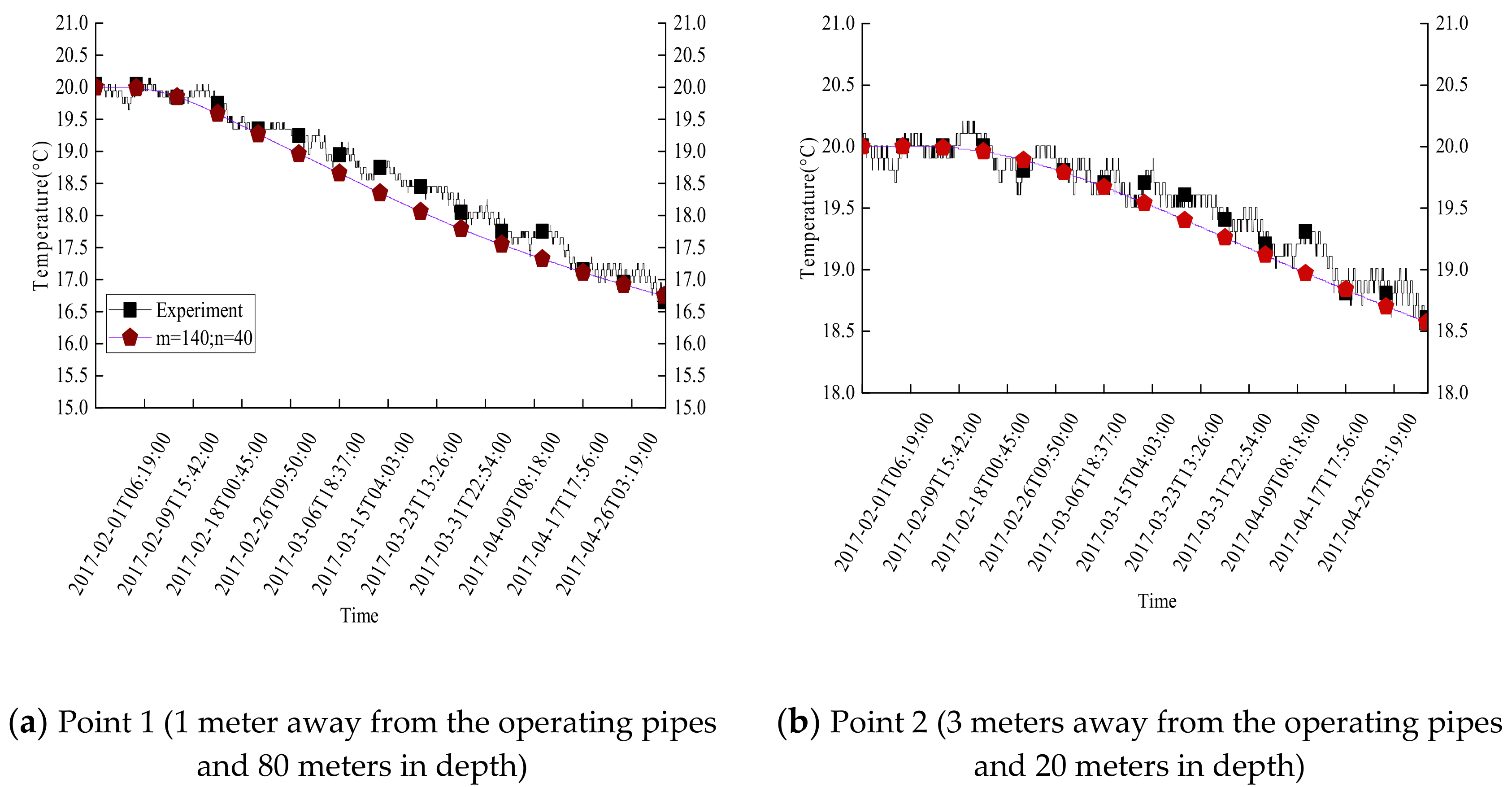

3.1. RC Model Validation

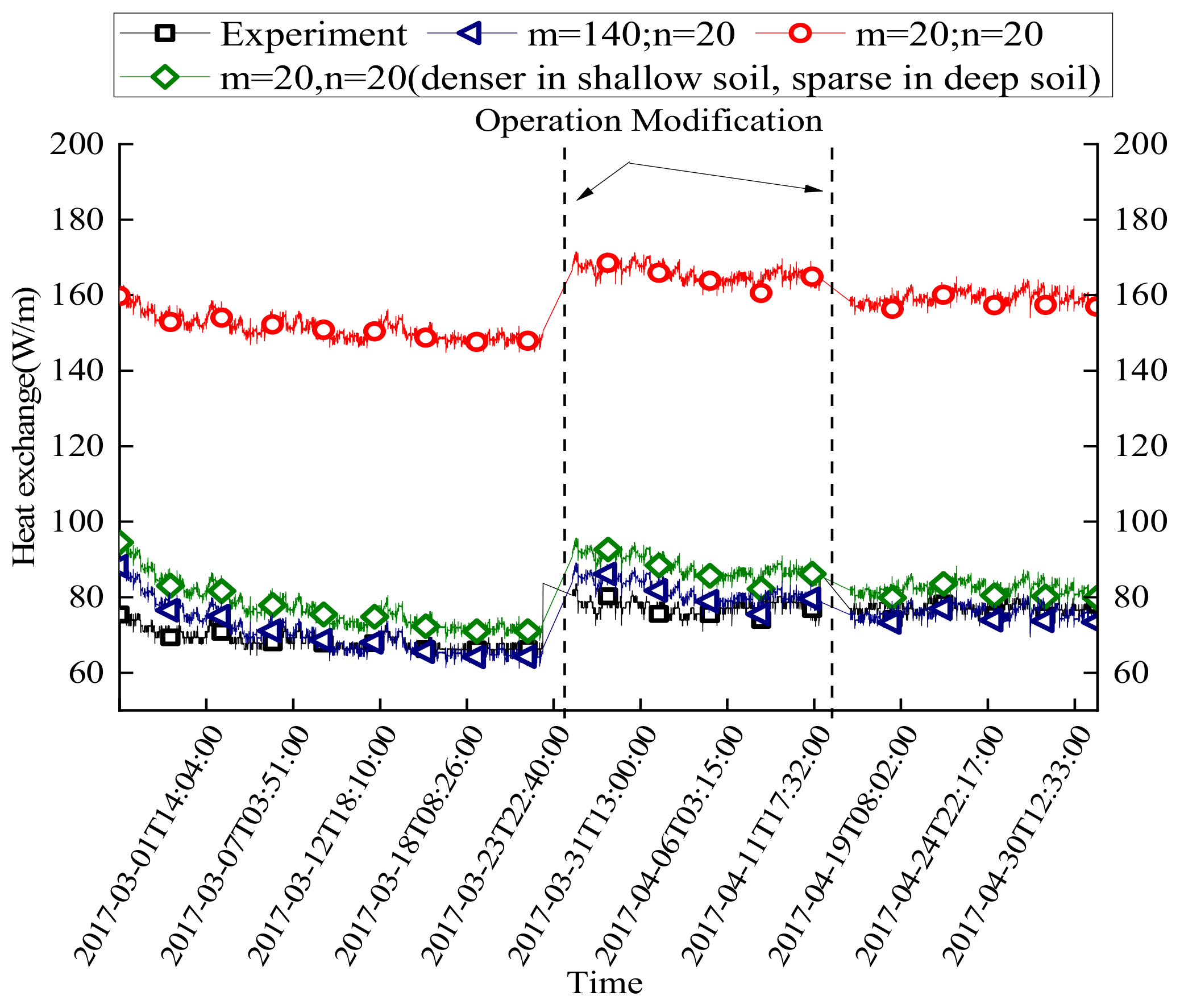

3.1.1. Heat Exchange Validation

3.1.2. Temperature Distribution Validation

3.2. Freezing Soil and GHE Thermal Performance

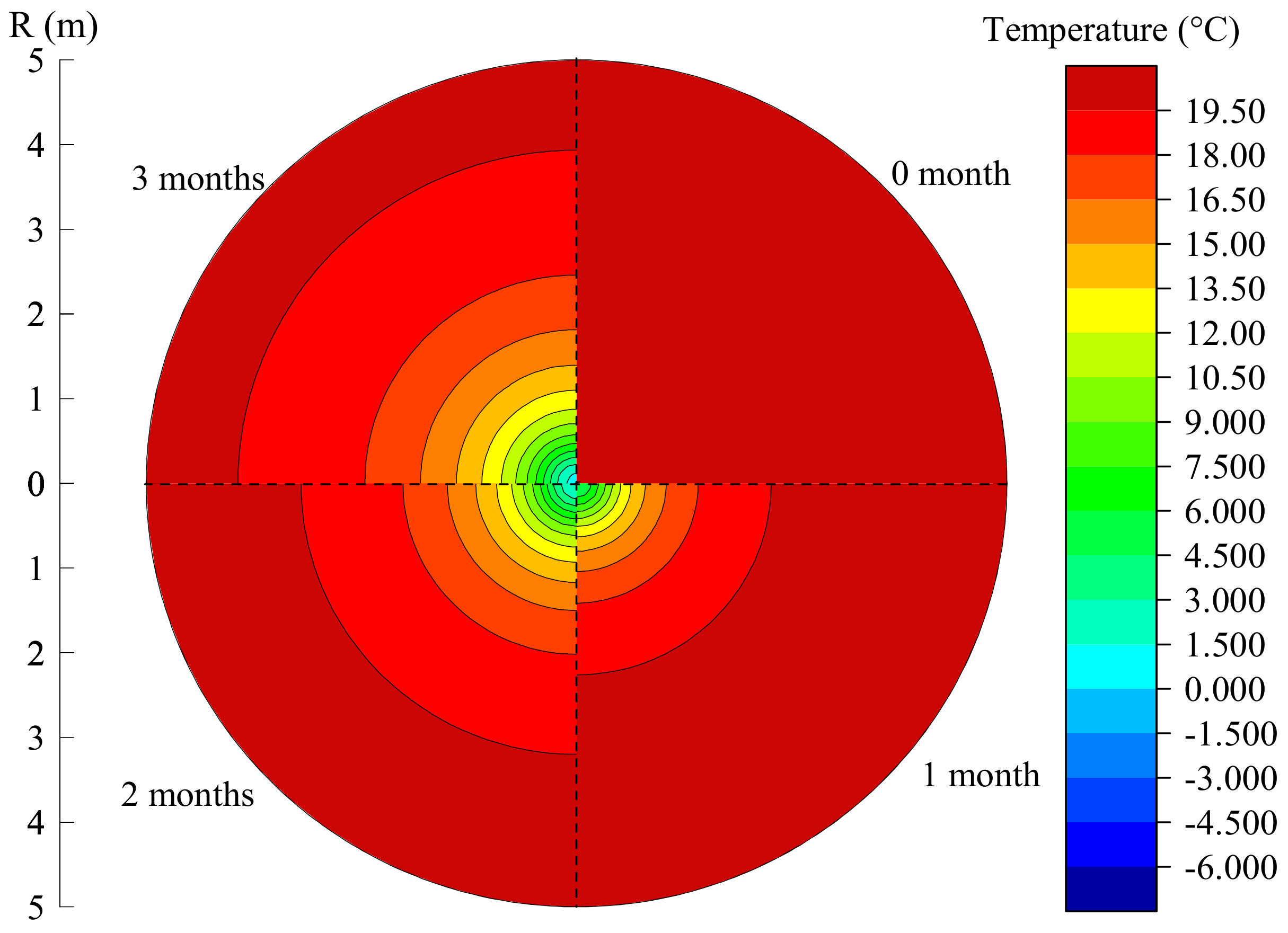

3.2.1. Effects on Temperature Distribution

3.2.2. Effects on Frozen Zone

3.2.3. Effects on the Heat Transfer Rate

3.3. Model Optimization

3.4. Limitations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| a | thermal diffusivity (m2/s) | Greek letters | |

| c | specific heat (J/(kg·K)) | λ | thermal conductivity (W/(m·K)) |

| C | volume thermal capacity per meter(J/(m·K)) | ρ | density (kg/m3) |

| da | pipe outside diameter (m) | τ | time (s) |

| deq | equivalent diameter of pipes (m) | Δτ | discretization time step (s) |

| di | pipe inside diameter (m) | Δz | vertical length of control volume of ground (m) |

| dz | grout centroid diameter (m) | ||

| H | liquid latent heat (J/kg) | Subscripts | |

| i | radial ground discretization index (dimensionless) | ar | pipe to pipe |

| j | vertical ground discretization index (dimensionless) | b | borehole |

| L | length of pipe (m) | Subscripts | |

| mw | fluid flow rate (kg/s) | g | grout |

| m | vertical maximum discretization index (dimensionless) | fg | fluid to grout |

| n | radial maximum discretization index | fr | frozen |

| Nu | Nusselt number (dimensionless) | gg | grout to grout |

| Pr | Prandtl number (dimensionless) | gb | grout to borehole wall |

| q | heat flux (W) | in | inlet |

| Re | Reynolds number (dimensionless) | out | outlet |

| rmax | radius from axis borehole beyond which the undisturbed ground temperature is assumed (m) | ufr | unfrozen |

| rb | borehole radius (m) | w | fluid |

| rm | barycentric radius (m) | ||

| R | thermal resistance (K/W) | Abbreviations | |

| Rcond1 | pipe wall thermal resistance (K/W) | CFD | computational fluid dynamics |

| Rcond2 | pipe wall to grout resistance (K/W) | FDM | finite difference method |

| Rconv | convection thermal resistance (K/W) | FVM | finite volume method |

| s | shank spacing (m) | GHE | ground heat exchanger |

| T | temperature (K) | GSHP | ground source heat pump |

| To | undisturbed temperature of ground (K) | RC | resistance capacitance |

| Tb | wall temperature of borehole (K) | GLD | ground loop design |

| W | soil moisture content (%) | GLHEPRO | ground loop heat exchanger design software |

| x | parameter used for locating the left of mass of the grout |

Appendix A

References

- Xu, W.; Liu, Z. Development and Prospect of Ground Source Heat Pump Technology in China. Build. Sci. 2013, 29, 26–33. [Google Scholar]

- Vasilyev, G.P.; Peskov, N.V.; Burmistrov, A.A.; Timofeev, N.A.; Zakharov, P.E.; Yurchenko, I.A. Ground Source Heat Pump Modeling: Accounting of Ground Moisture Freezing-Melting in a Model of Heat Transfer outside Deep Borehole. Appl. Mech. Mater. 2014, 704, 102–112. [Google Scholar] [CrossRef]

- Ingersoll, L.R.; Plass, H.J. Theory of the ground pipe heat source for the heat pump. Heat. Pip. Air Cond. 1948, 54, 339–348. [Google Scholar]

- Deerman, J.D. Simulation of Vertical U-tube Ground-coupled Heat Pump Systems using the Cylindrical Heat Source Solution. ASHRAE Trans. 1991, 97, 287–295. [Google Scholar]

- Dahua, W.; Haifeng, Z.; Shuqiang, G. In Situ Test and the Analysis of Theoretical Applicability of Double U Type Pile Buried Tube Heat Exchanger. Geol. Sci. Technol. Inf. 2016, 35, 226–230. [Google Scholar]

- Bernier, M.A. Ground-coupled heat pump system simulation. ASHRAE Trans. 2001, 107, 605–616. [Google Scholar]

- Rottmayer, S.P.; Beckman, W.A.; Mitchell, J.W. Simulation of a single vertical U-tube ground heat exchanger in an infinite medium. ASHRAE Trans. 1997, 103, 651–659. [Google Scholar]

- Muraya, N.K.; O’Neal, D.L.; Heffington, W.M. Thermal interference of adjacent legs in a vertical U-tube heat exchanger for a ground-coupled heat pump. ASHRAE Trans. 1996, 102, 12–21. [Google Scholar]

- Yavuzturk, C.; Spitler, J.D.; Rees, S.J. A short time step response factor model for vertical ground loop heat exchangers. ASHRAE Trans. 1999, 105, 475–485. [Google Scholar]

- Bai, L.; Wang, P.X. Simulation on Ground Temperature Change of GSHP System in Severe Cold Regions. Adv. Mater. Res. 2014, 945-949, 2820–2824. [Google Scholar] [CrossRef]

- Shen, G.M.; Xu, Y.; Zhou, J.Y.; Hu, P.F.; Xiao, H. The Study of Soil Temputerature Change of GSHP System in Winter Conditions. Appl. Mech. Mater. 2013, 405–408, 2969–2974. [Google Scholar] [CrossRef]

- Eskilson, P. Thermal Analysis of Heat Extraction Boreholes. Ph.D. Thesis, University of Lund, Lund, Sweden, September 1987. [Google Scholar]

- Li, M.; Li, P.; Chan, V.; Lai, A.C.K. Full-scale temperature response function (G-function) for heat transfer by borehole ground heat exchangers (GHEs) from sub-hour to decades. Appl. Energy 2014, 136, 197–205. [Google Scholar] [CrossRef]

- Hellström, G. Ground Heat Storage: Thermal Analysis of Duct Storage Systems. Ph.D. Thesis, University of Lund, Lund, Sweden, May 1991. [Google Scholar]

- Sharqawy, M.H.; Mokheimer, E.M.; Badr, H.M. Effective pipe-to-borehole thermal resistance for vertical ground heat exchangers. Geothermics 2009, 38, 271–277. [Google Scholar] [CrossRef]

- Carli, M.D.; Tonon, M.; Zarrella, A.; Zecchin, R. A computational capacity resistance model (CaRM) for vertical ground-coupled heat exchangers. Renew. Energy 2010, 35, 1537–1550. [Google Scholar] [CrossRef]

- Zarrella, A.; Capozza, A.; Carli, M.D. Analysis of short helical and double U-tube borehole heat exchangers: A simulation-based comparison. Appl. Energy 2013, 112, 358–370. [Google Scholar] [CrossRef]

- Bauer, D.; Heidemann, W.; Müller-Steinhagen, H.; Diersch, H.J.G. Thermal resistance and capacity models for borehole heat exchangers. Int. J. Energy Res. 2015, 35, 312–320. [Google Scholar] [CrossRef]

- Pasquier, P.; Marcotte, D. Short-term simulation of ground heat exchanger with an improved TRCM. Renew. Energy 2012, 46, 92–99. [Google Scholar] [CrossRef]

- Maestre, I.R.; Gómez, P.Á.; Pérez-Lombard, L. A new RC and g-function hybrid model to simulate vertical ground heat exchangers. Renew. Energy 2015, 78, 631–642. [Google Scholar] [CrossRef]

- Kurylyk, B.L.; Hayashi, M. Improved Stefan Equation Correction Factors to Accommodate Sensible Heat Storage during Soil Freezing or Thawing. Permafr. Periglac. Processes 2016, 27, 189–203. [Google Scholar] [CrossRef]

- Tian, B. Research on Operation Characteristic of Ground Heat Exchanger for Ground Coupled Heat Pump System in Cold Climate. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, June 2010. [Google Scholar]

- Zheng, T.; Shao, H.; Schelenz, S.; Hein, P.; Vienken, T.; Pang, Z.; Kolditz, O.; Nagel, T. Efficiency and economic analysis of utilizing latent heat from groundwater freezing in the context of borehole heat exchanger coupled ground source heat pump systems. Appl. Therm. Eng. 2016, 105, 314–326. [Google Scholar] [CrossRef]

- Congedo, P.M.; Colangelo, G.; Starace, G. CFD simulations of horizontal ground heat exchangers: A comparison among different configurations. Appl. Therm. Eng. 2012, 33–34, 24–32. [Google Scholar] [CrossRef]

- Flaga-Maryanczyk, A.; Schnotale, J.; Radon, J.; Was, K. Experimental measurements and CFD simulation of a ground source heat exchanger operating at a cold climate for a passive house ventilation system. Energy Build. 2014, 68, 562–570. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, J.; Shi, C.; Zhao, B. Study on soil layer of constant temperature. Acta Energ. Sol. Sin. 2007, 28, 494–498. [Google Scholar]

- Wu, W.; Wang, B.; You, T.; Shi, W.; Li, X. A potential solution for thermal imbalance of ground source heat pump systems in cold regions: Ground source absorption heat pump. Renew. Energy 2013, 59, 39–48. [Google Scholar] [CrossRef]

- You, T.; Wu, W.; Shi, W.; Wang, B.; Li, X. An overview of the problems and solutions of soil thermal imbalance of ground-coupled heat pumps in cold regions. Appl. Energy 2016, 177, 515–536. [Google Scholar] [CrossRef]

| Pipe thermal conductivity | 0.6 W/(m·K) |

| Pipe outside diameter | 32 mm |

| Pipe inner diameter | 25 mm |

| The diameter of the borehole | 160 mm |

| Borehole length | 100 m |

| Filling material around the pipe | Borehole soil |

| Parameters | Value | |

|---|---|---|

| Density [kg/m3] | 1925 | |

| Moisture content | 40% | |

| Volumetric heat capacity [J/(m3·K)] | 3,936,600 (unfrozen) | 3,087,700 (frozen) |

| Conductivity [W/(m·K)] | 1.84 (unfrozen) | 2.98 (frozen) |

| Depth underground (m) | 5 | 10 | 15 | 20 | 40 | 60 | 80 | 100 |

| Temperature (°C) | −2.6 | −3.0 | −3.8 | −2.4 | −1.5 | −2.6 | −2.1 | −0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, S.; Yang, X.; Zhou, X.; Luo, M.; Zhang, X. Experimenting and Modeling Thermal Performance of Ground Heat Exchanger Under Freezing Soil Conditions. Sustainability 2019, 11, 5738. https://doi.org/10.3390/su11205738

Tu S, Yang X, Zhou X, Luo M, Zhang X. Experimenting and Modeling Thermal Performance of Ground Heat Exchanger Under Freezing Soil Conditions. Sustainability. 2019; 11(20):5738. https://doi.org/10.3390/su11205738

Chicago/Turabian StyleTu, Shuyang, Xiuqin Yang, Xiang Zhou, Maohui Luo, and Xu Zhang. 2019. "Experimenting and Modeling Thermal Performance of Ground Heat Exchanger Under Freezing Soil Conditions" Sustainability 11, no. 20: 5738. https://doi.org/10.3390/su11205738

APA StyleTu, S., Yang, X., Zhou, X., Luo, M., & Zhang, X. (2019). Experimenting and Modeling Thermal Performance of Ground Heat Exchanger Under Freezing Soil Conditions. Sustainability, 11(20), 5738. https://doi.org/10.3390/su11205738