1. Introduction

The extensive diversity of microorganisms allied with the greatest biodiversity on the planet confers great potential to the Amazon region to provide raw material for various production chains and industry sectors. Paradoxically, the production and consumption model adopted by most societies, and specifically capitalist society [

1,

2,

3] has caused an increase in the use of biological resources and compromised the integrity of ecosystem maintenance, bringing damaging consequences for humanity. The State of Amazonas is the largest state of Brazil, representing about 30% of the Amazon region and possesses a large proportion of the natural resources of the region. From a geographic, socioeconomic, and environmental point of view the State of Amazonas is an important player in questions of resource use and economic development since it has an area of 1,559,146.876 km², approximately 18% of Brazilian territory, and has a population of 4,080,611 [

4] with a large variety of productive chains that are integrated into the capital of Manaus, where the principal economic activities of the state are concentrated.

With a dense urban and commercial nucleus, Manaus is classified as the largest city in the North region of Brazil and the 7th in the country, with a gross domestic product (GDP) of R

$ 70.296 billion [

5] and a population estimated at 2,145,444 inhabitants [

6]. During the last five decades Manaus has grown exponentially with the installation of the Center of Industrial Production of Manaus. This industrial center has strengthened the local and regional economies because it provides a job and income to workers, including those from neighboring States, thus consolidating the development model that attempts to satisfy the assumptions of sustainability [

7]. This industrial center was structured following the same policies and principles that created the Manaus Free Trade Zone (FTZ), with about 500 industries, indirectly and directly generating more than a half a million jobs [

8], especially in the electronics, motorcycle, and chemical sectors. In 2018, the industrial center of Manaus had revenue of R

$ 93.9 billion [

9]. In addition to the aforementioned sectors, there are also present representatives of agroindustry, tourism, aquaculture, and ceramics, the latter occupying a strategic position in the development of the entire metropolitan region of Manaus—RMM. Ceramic production is an important activity in the context of Brazilian industrial production, with about 2.5 billion ceramic pieces produced each year. In the state of Amazonas, the city of Iranduba is responsible for about 80% of the production of red ceramics in the state [

10]. It is important to highlight that this position is relevant principally to the urban nucleus of the city of Manaus, which consumes about 95% of the entire production of the ceramic industry production center in Iranduba.

Currently, the ceramic industry production center in Iranduba unifies 18 industries that are geographically situated in an area of extensive geologic diversity and potential with respect to the ideal type of clay needed for the production of red ceramics [

11]. However, the lack of innovative solutions and limited technological resources have obliged the ceramic industry production center in Iranduba to use native forest wood as raw material for firing the kilns. Wood is the principal energy source and the industrial base for the production of ceramics, thus establishing a dilemma with respect to the pressure put on the native forest and the systematic application of fines levied by government environmental protection agencies [

12,

13]. The wood used in the ceramic industry production center comes from primary and secondary forest, and this makes Iranduba one of the largest industrial consumers of native wood of the State of Amazonas [

14,

15]. Due to environmental problems and worldwide pressure, the judicial system has intensified it actions in order to protect the forest [

16,

17], with the goal of avoiding deforestation and guaranteeing that the transport of wood used in the ceramic production kilns has the proper documentation stating that is has come from acceptable sources. However, the implementation of these legal actions has only served to aggravate the situation of the ceramic industry production center in Iranduba because some companies now engage in clandestine transport of wood and are subject to fines being levied by government environmental protection agencies.

This panorama is coupled with the existence of extensive deposits of clay raw material near the center of the city and a large unspecialized labor force that is absorbed by the ceramic industry production center. The lack of wood needed to fire the ceramic kilns thus reduces the number of jobs available to poor families that live on the periphery of Manaus. These barriers impact the cost of production and therefore cause an increase in price of the products made in this ceramic production center. In addition to the operational difficulties of generating energy for the kilns, the ceramic industry production center in Iranduba has been dealing with many structural problems, aggravated by the current situation of economic stagnation, and this has caused gradual reductions in the volume of ceramics produced and threatened the sustainability of this important industrial sector [

18]. With respect to formal education, obtaining information from people that are from different areas of knowledge and levels of education is not an easy task, but it is possible when the investigation is conducted in a ludic manner. The mandala aids in this task by transforming these different types of knowledge into a single logical diagram that contains the perceptions that reflect inherent knowledge of production chains. In this context, the objective of this research was to systematize a methodology that can evaluate the spatial and temporal dynamics of the production chain in the ceramic industry production center of Iranduba through the use of a mandala in order to provide strategies for sustainable production to the State of Amazonas, Brazil.

2. Materials and Methods

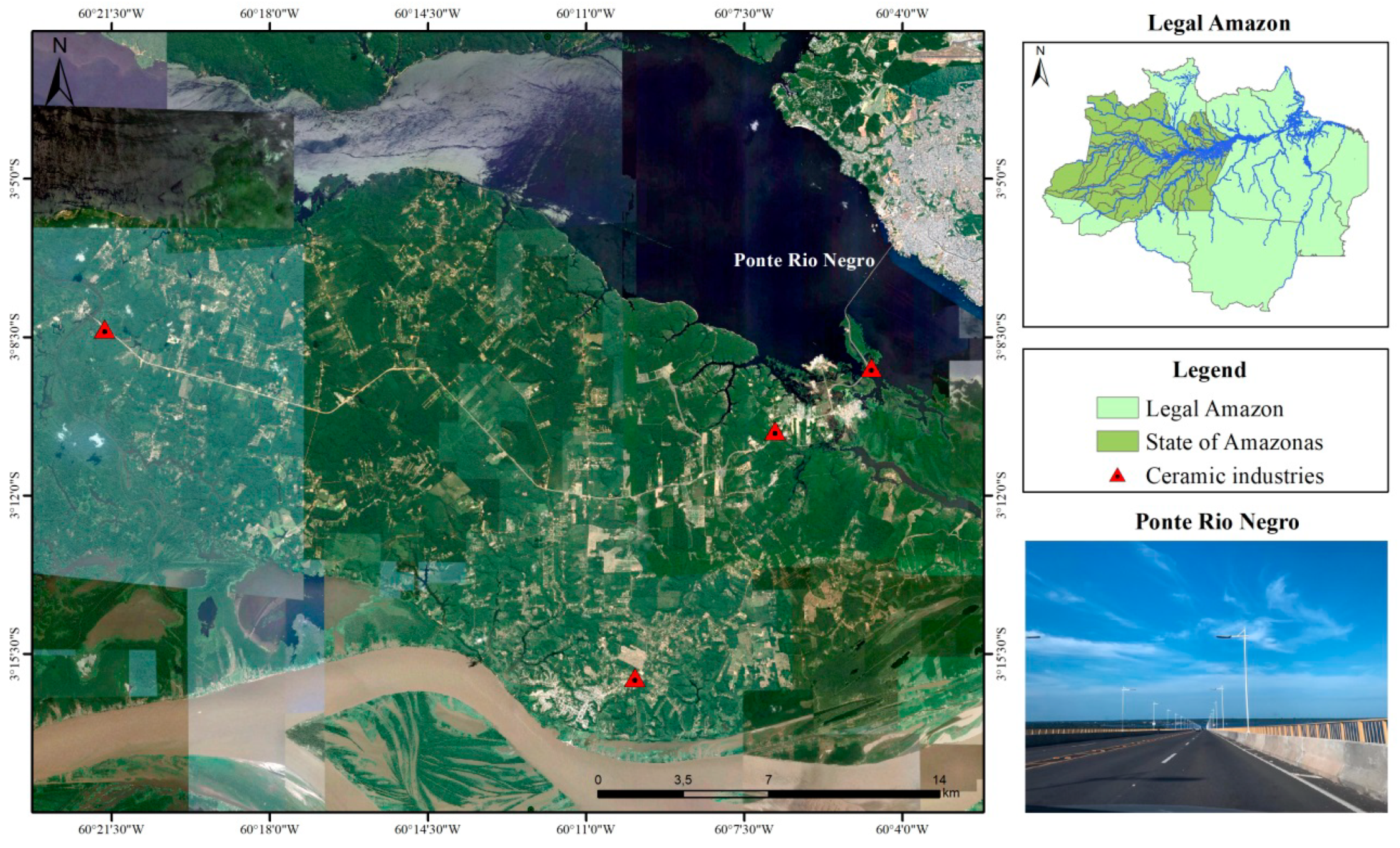

The ceramic industry production center of Iranduba is on the right margin of the Negro River and in front of the city of Manaus (

Figure 1). The production and transport of bricks to Manaus is facilitated by the bridge over the Negro River.

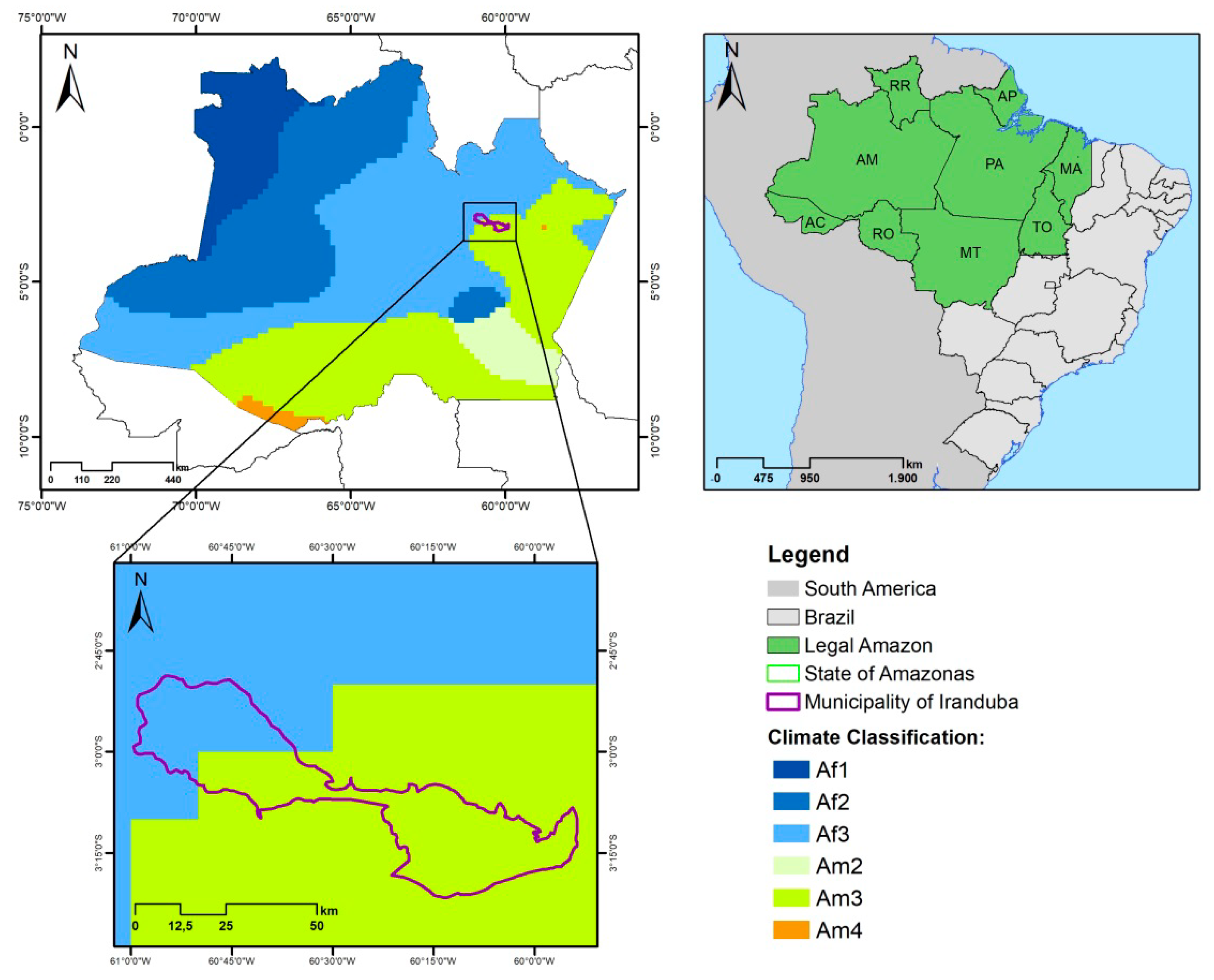

In order to identify the spatial variability of climate conditions in the study area, information from Martorano [

19] was used, including an adaptation of the Köppen method proposed [

20]. Data from the National Institute of Meteorology (INMET) and the National Water Agency (ANA) were also used, together with matrix data from the WorldClim Global Climate Data platform, with interpolated data at a spatial resolution of 1 km [

21], in agreement with the data extraction assumptions described [

22,

23]. In the municipality of Iranduba, in the State of Amazonas, the predominant climate type is Af

3, principally in the northeast of the municipality, and transitions to Am

3 which predominates in the rest of the area, and these classifications have monthly rainfall above and below 60 mm, respectively, during the months with the lowest amount of rainfall in the Amazon region (

Figure 2).

A brief historical summary of the concept of a mandala is provided in order to better understand how the mandala is able to evaluate and synthesize the productive processes associated with the ceramic industry production center. In this context, this study consists of a proposal for structuring and promoting a practical application of a mandala, which has the triad of investigation, education, and action as its focus [

24]. A mandala is a construction that has been used for more than 2000 years and that permits the establishment of bridges and the creation of interdependent relationships with diverse areas of knowledge, independent of its interpretation [

25]. It is constructed of circular designs, intricate patterns, or symbols [

26]. For the current research, three steps were identified as being necessary to the systematization process in order to delineate the spatial and temporal dynamics of the production chain of the ceramic industry production center in Iranduba, Amazonas, Brazil.

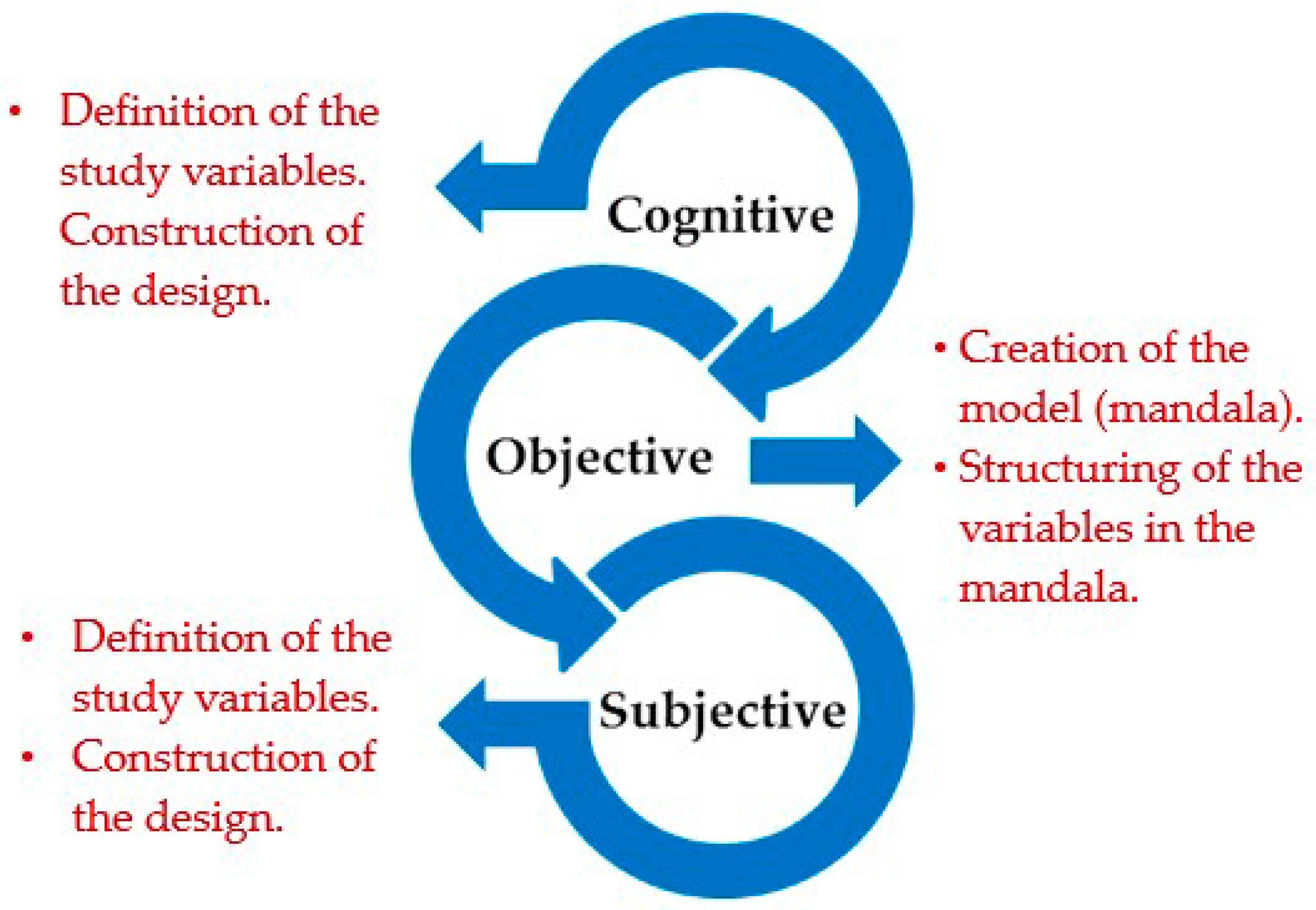

Initially, possible situations were elaborated that characterize links and/or problems associated with the productive chain of the ceramic production center. This cognitive map was elaborated using a scheme that contemplated variables that were essential to the execution of this research, and subsequently these variables were delimited into seven different concepts that would then be described in an illustrative manner using a mandala. These innovative technologies could be used as artistic tools to create new expressions, cause social impact, and highlight steps involved in conception and execution of tasks [

27].

In the second step, the mandala was divided into seven fragments and subdivided into three levels with the goal of demonstrating the range of approaches necessary to complete this research. Objectively, the fragments of the mandala were defined as being historical in nature, and these variables are related to the origin of the raw material (characteristics of the soil and energy sources), climate, economic and financial aspects, general data about the ceramic industry production center, and the sustainability of the business model from an environmental, social, and economic perspective. These fragments represent all the steps or links in the production chain of the ceramic production center of Iranduba. In the third step the more subjective aspects were delineated in order to identify and analyze factors that could be considered adequate or adjusted to the model designed in the previous step. In this way, different perceptions and opinions of other researchers were captured in order to evaluate and improve the format of the mandala (

Figure 3).

In order to evaluate the areas with greatest potential in the ceramic industry production center in Iranduba, Amazonas, a database with the clay contents at different soil depths was used from the SoilGrids database, which is an automatic soil mapping system based on advanced methods of spatial prediction. SoilGrids has a collection of maps of soil classification and properties that can be updated worldwide at a spatial resolution of 1 km.

3. Results

Figure 4 shows that the methodological structure based on the mandala serves to describe the logical scheme and the systematization of the spatial and temporal dynamics of the productive chain of the ceramic industry production center in Iranduba. A mandala is structured as if it were a work of art open to interpretation and new possibilities so that different observers can choose their own conditions, sequences, forms, problems, responses and reflections as spaces for dialogue and construction [

28,

29]. From the perspective of cognitive development, the construction of a mandala is the result of various steps that can be improved during the course of the process, thus corroborating the idea that the learning process is social and cultural in nature and is constructed through interaction between previously acquired knowledge and new learning experiences, and in the center of the mandala there is a central point which represents its essence, and the remainder of the elements are linked to this central point and to a certain degree depend on it [

25].

Although mandalas have been used since primordial times in human history as traditionally religious tools [

30] and also as psychotherapeutic strategies for different populations [

31,

32], the instrument can also be used to characterize the structure and fragmentation of knowledge during research in the area of sustainability, as in the ceramic production center of Iranduba. The section of historical aspects shown in the mandala recount the principal events related to the ceramic production center from 1980 until 2018. The section of soil variables involves pedology and geology, which aid in the determination of clay composition. The section sources of energy contemplates non-woody residuals not used in the production of ceramics, biomass from agroforests, and wood used in the process of baking ceramic artifacts in kilns. The section climatic variables takes into account local air temperature and relative humidity and rainfall local, and the section financial variables deals with production volumes, costs, and operational receipts. Additionally, the database section addresses public policies, legislation, and stakeholders of the ceramic sector, while the section sustainability concentrates on social, economic, and environmental aspects of the ceramic production center.

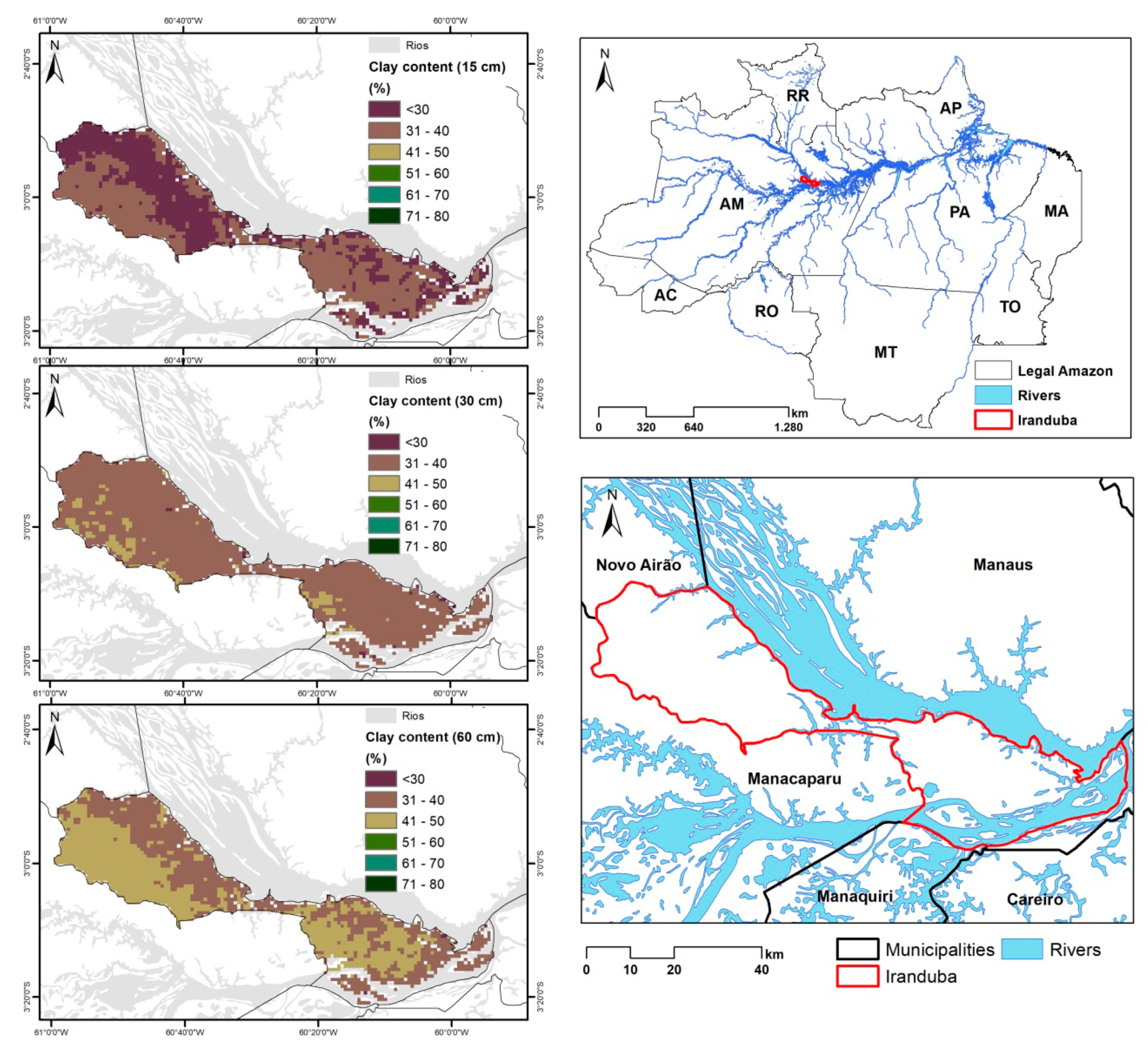

Clay content in the soil of the municipality of Iranduba, AM gradually increases through the profile (

Figure 5). At the 15 cm depth the percent clay content is the lowest in the profile with soil classes with 31% to 40% clay and some with less than 30%. However, at 60 cm clay contents are above 40% in a large part of the municipality. Therefore, a large part of the municipality is classified as having a soil type that is a loamy clay to clayey.

It is important to emphasize that since the 1980s, when the ceramic-brick kiln sector migrated to the city of Manaus and settled on the right margin of the Negro River due to a high rate of urban expansion [

33], the ceramic industries in the region have had an important role in the economic activity and social life of the population of Amazonas. Furthermore, the intense pressure from urban growth during the last few decades in the region has been characterized by an unorganized and unplanned occupation of the area [

34]. The changes are typical of the current pattern of economic production and consumption and have contributed to the stagnation of the ceramic sector in the State of Amazonas and the lack of inclusion of technological advances that exist in other regions of the country. However, even with the absence of public policies needed to strengthen the ceramic industry in the region there has been growth in the demand for ceramic products, and this has stimulated the appearance of new industries around Manaus, especially near Iranduba and Manacapuru [

13]. The principal factors that have contributed to the growth of new industries and strengthening of the ceramic industry in this region of the State of Amazonas are a) the existence of extensive deposits of clay raw material; b) proximity to the principal consumer center linked by the Manoel Urbano-AM-070 highway; and c) the preponderance and large supply of an unspecialized labor force that is paid low wages [

35]. It is estimated that at the height of the real estate expansion boom, production at the ceramic industry center reached around 100 to 128 million pieces, of which about 90% were ceramic blocks [

14,

35].

Previous studies done by the State Nucleus for Local Productive Arrangements of Amazonas (NEAPL/AM), in partnership with diverse private and public institutions from different spheres of government ratified the cities of Iranduba and Manacapuru as the principal centers of the ceramic industry of the State of Amazonas. However, these studies exposed the large diversity of difficulties confronted by this segment of the region’s industry, which were principally linked to environmental problems, inadequate infrastructure, and inefficiency and low productivity of the kilns used for brick baking, and these factors consequently had repercussions for the remainder of the links in the productive chain and resulted in elevated prices for the finished products.

Starting in 2007, the city of Iranduba, together with the municipalities of Careiro da Várzea, Manacapuru, Itacoatiara, Novo Airão, Presidente Figueiredo, and Rio Preto da Eva were officially aggregated into the nucleus-municipality of Manaus, thus creating the Metropolitan region of Manaus (RMM) and reconfiguring the region to a total area of 101,475 km², composed of eight municipalities, according to the Complementary State Law (Lei Complementar Estadual) nº. 52/07. Subsequently, the State Law nº. 64/2009 modified Article 1° of the Complementary State Law n°. 52/2007 and included the municipalities of Careiro Castanho, Autazes, Silves, Itapiranga, and Manaquiri into the composition of the RMM, thus becoming the largest metropolitan area in Brazil, with an area of 127,169 km².

Even in light of the many obstacles and technological limitations confronted by the sector, research has shown that between 2009 and 2010, the ceramic industry of the State of Amazonas generated between 3.5 and four thousand jobs, directly and indirectly, with an estimated production of 35 tons of bricks/month, with Iranduba and Manacapuru being the principal producers of red ceramics. The city of Iranduba alone was responsible for about 75% the entire production of bricks and roof tiles in the State [

36].

The new composition of the RMM created an ontogeny (

study in developmental biology, that examines the development of an organism and/or its structural units, for example a cell, an organ, a system, or even a society) and greater dynamism between the ceramic industry center of Iranduba and the main city of Manaus [

37], since Manaus concentrates about 90% of the State’s entire income and absorbs a significant portion of the production originating in the ceramic industry center of Iranduba and Manacapuru [

38]. Since the formalization of the RMM, Iranduba has been the city of Amazonas that has had the largest positive effect on its economy, registering an increase in companies that deal in commerce, services, and industry due to its proximity to Manaus [

37]. Furthermore, this city has the largest quantity of ceramic industries in Amazonas [

39], and the production of ceramics is one of its principal economic activities that is integrated to the city of Manaus. Currently, Iranduba is responsible for about 80% of the total red ceramic production of the state of Amazonas, producing about 10 million bricks per month and generating about 2000 direct and indirect jobs in the city, with about 6000 workers including third-party employees and suppliers [

10].

4. Discussion

Developmentalist logic and the transformation of the global capitalist economy are provoking the emergence of new productive agglomerations as well as a reworking of traditional productive agglomerations, especially those that arose during the period of development by the Ford corporation during the XX century [

40]. Currently, the introduction of technological innovations in order to compete against economic rivals and capture a larger portion of existing demand is absolutely essential for a company to be able to maintain itself active in the market. Nevertheless, productive efficiency and competition are not sufficient by themselves to guarantee the sustainability of a business. Companies should search for new markets and seek to dominate them, as described by Kim and Mauborgne [

41], in what they refer to as the blue oceans concept. For these authors, these oceans represent models or market spaces that have not been explored yet and that can create or capture new demand. However, the authors believe that the majority of these blue oceans still have not yet been mapped, and this means that the ceramic industry center at Iranduba can still be open to the strategies explained by the red oceans, where these waters are defined by the actual economic structure of the sector, represented by the absence of solid and systematic principles of risk management in an efficient manner.

In this context, the industries of the ceramic industry center need to synergistically combine their forces to explore new spaces in unexplored markets, because according to the Syndicate of the Ceramic Kiln Industry of the State of Amazonas—SINDICER/AM [

18], during the last two years many companies within the ceramic industry have ceased operations, and left behind a large quantity of equipment and unemployed labor. This entity estimates that only in 2016 the ceramic industry registered a production volume decrease of 55% when compared to 2015, although SINDICER/AM still has 18 ceramic companies aggregated in Iranduba, a few are in the process of closing due to market retraction in the sector.

Currently, the ceramic industry market in Brazil is very heterogeneous and is formed by 6903 companies that operate in the red ceramics subsector of the industry. The principal products of the red ceramic sector are: Blocks, bricks, roof tiles, hollow or perforated bricks, wall and floor tiles, slabs, tubes, light aggregates for construction material, besides products that have other uses such as expanded pyro-clays, ornamental objects, and domestic utensils, all having common clay as the main raw material source. These are, in the majority, of small size and are located nearby the consumer markets in their respective regions, with an estimated participation in GDP of about 1% [

42]. However, since the majority of construction companies currently have projects that are temporarily on hold due to larger-scale economic trends, the ceramic sector in Iranduba has been negatively impacted through a substantial decrease in orders for material, and this has led to other consequences such as social problems due to unemployment directly and indirectly linked to this sector, and a decrease in tax revenue that impedes the government from financing urban improvement projects. Another factor that has had a negative impact on the ceramic industry in Amazonas is related to the fact that many potential home buyers are currently having economic difficulties and this had led to a large increase in legal termination of contracts for new home building, and this has had a direct negative effect on construction companies, and an indirect one on the ceramic industry in Iranduba [

18]. Therefore, due to this scenario, the real estate sector has merely transferred the consequences of low demand to the ceramic sector.

In spite of the fact that red ceramic, also known as structural ceramic, is responsible for R

$ 18 billion in annual revenue, and generates 293,000 direct jobs and 900,000 indirect ones [

43], and is part of a larger set of productive chains that composes the Civil Construction Complex [

42], currently the national market for the ceramics sector is completely stagnant, and this has led to the failure of a substantial number of companies, which suggests that the policies and actions implemented by governments around the country could be incorrect. Since the principal products of the red ceramics subsector (blocks, bricks, and tubes) are very well distributed throughout the country, the actual unfavorable economic scenario necessitates incremental improvements within the existing markets of the red ocean [

41].

In order to illustrate the results of this economic slowdown in the real world, in one of the principal companies in the ceramic industry center in Iranduba, 300,000 pieces/week were made in two daily shifts, seven days/week. Currently, on average, 90,000 to 100,000 pieces/week are made in one daily shift of 6 h with prices per 1000 bricks oscillating between R$ 350.00 to R$ 370.00, with sales restricted only to the immediate region around the Negro River, including Manaus and the municipalities where this industry is situated. Due to the reduction and suspension of 40% of contracts, the company has also had to reduce the number of employees from 86 to 16. This has then led to the stoppage of the operation of large production equipment and their substitution for equipment of lower productive capacity. However, even with the adoption of these measures, companies continue to deal with excessive operational costs because these enterprises were projected and invested in based on expectations of growth in market demand and for a production capacity larger than currently needed. According to SINDICER/AM, during the last two years nine companies ceased operation in the ceramic industry center of Amazonas and it is probable that six more companies will close their doors in 2019. In addition to the operational and financial difficulties that led to the failure of these companies and the loss of jobs, the ceramic industries also were impacted by the stagnation in the Industrial Center of Manaus (PIM), because with the lack of growth in the economy and the strategic decision of many companies in the PIM to reuse pallets that were previously discarded, the ceramic industry has had to resort to the use of wood from forests to fire their kilns, and this has caused additional production costs to be incurred.

In light of this unproductive and unexpected scenario, coupled with the current air of political instability in the State of Amazonas and Brazil, it is fundamental that the companies in the ceramic industry center adapt themselves and discover new alternatives, evaluating all the organizational and strategic variables of the sector that favor the creation of and navigation in blue oceans in dynamic economic environments [

44].

From a practical point of view, the construction of a mandala is a dynamic and interpretative process through which external information is interpreted and reinterpreted as a function of an explanatory model, and this process can become more complex and abstract as it progresses [

45]. It is a tool that has the potential to provide objective and subjective results by identifying the position, intervention strategies, and changes that can occur during the design of research [

46]. Mandalas demonstrate the fragmentation and reintegration of knowledge through active imagination, providing a technical-scientific vision of a research strategy, and can also serve as a guide for researchers to synthesize the various biochemical, biomolecular, and biocomputational fragments in order to help to direct the completion of a research process. At the same time, a mandala represents a type of map guiding researchers on their journey to new insights interconnecting all parts of a process [

47]. Furthermore, when constructed in groups, mandalas arise from the dialectic between subject, group, and the problem being researched, in an attempt to understand, through systematic and open processes, thus permitting the development of non-linear approaches for complex situations that are studied [

48]. Another aspect observed using the mandala is the gaps and unexplored spaces in the current market situation of the ceramic industry center at Iranduba, and the mandala allowed for the visualization of the necessity that this sector must discover new management tools that will permit the exploration of new blue oceans [

41].

This line of scientific thinking in the form of a mandala is very similar to the fundamentals of the circular economy, demonstrating how processes are generated, autoregulate, and harmoniously function in a cyclical manner, in contrast to the predominant linear model [

49]. When there is a disequilibrium in specific ecological niches, important ecosystem services are compromised. This implies that there is a necessity to change the linear model, a model that has stimulated an uncommon form of economic growth that has surpassed the planet’s support capacity [

50]. The adoption of a structured system similar to that of the circular economy and that considers ecological processes, industrial ecology, and the blue economy, among others, will tend to collaborate with the construction of a structural model that is capable of strengthening social aspects and aggregating economic value and natural resource conservation in the Amazon. The mandala expresses a diagnostic of this process, permitting an analysis of biophysical and socioeconomic variables in order to elucidate strategies for sustainable planning for the ceramic industry center at Iranduba.