1. Introduction

Global climate change due to human activities has received considerable attention all over the world [

1,

2,

3]. The Intergovernmental Panel on Climate Change (IPCC), in its fifth assessment report, stated that the impact of humans on the climate system is obvious and constantly increasing, and various effects have been observed on all continents. The IPCC also argued to limit the increase in the global temperature below 2 °C with significant and sustained reductions in greenhouse gas (GHG) emissions [

4]. The carbon footprint, as a quantitative expression of GHG emissions from activities, aids in emission management. It is conceptually viewed as a global warming potential (GWP) indicator and is a tool to guide relevant emission cuts and verifications [

5]. By quantifying the emissions of a specific product or process, the main sources of the emission can be identified, providing an opportunity for environmental efficiency improvements and cost reductions. Since the late 1980s, China has become the largest developing country in the world and has undergone significant changes in terms of industrialization and urbanization [

6]. Fast development is often accompanied by environmental and social problems. Due to the processes of industrialization and urbanization, China has become a huge consumer of energy and the biggest emitter of GHGs, such as CO

2 [

7].

Cement manufacturing is an energy-intensive industry, consuming approximately 12–15% of the total energy consumption of a country [

8]. Additionally, it is one of the largest anthropogenic CO

2 emitters, accounting for 5–7% of total anthropogenic CO

2 emissions [

9]. From 1985 onward, China’s cement production has ranked first in the world [

10], accounting for 57.28% of world production in 2018 [

11]. However, this large industry in China is facing challenges due to low profit, excessive production capacity [

12], and heavy pollution on the environment [

13]. The large-scale CO

2 emissions associated with the increase in cement production has raised concerns regarding its environmental impact. Prior research has concentrated on sustainable development strategies for the cement industry on the improvement of the clinker production process, energy reduction and carbo dioxide emission reduction. For the clinker production perspective, the introduction of modified low-energy clinkers as well as the modern clinker cooler can reduce the energy requirement and increase the energy efficiency [

14,

15]. Furthermore, the clinker process can be more sustainable by laying the foundation for recycling or reducing the waste heat loss [

16]. For the energy reduction perspective, efficient kiln drivers, heat recovery for power generation, the use of high-pressure grinding rolls and vertical roller mills can bring effective energy reduction during cement production [

15,

17]. For the carbon emission reduction perspective, the increased use of bio-fuels as a substitute for traditional fuels, CO

2 capture and storage technology and the use of blended cement (clinker is substituted with other materials) instead of traditional cement can reduce CO

2 emissions [

10,

17,

18]. Controlling capacity use is also a good method for CO

2 reduction [

9]. Currently, the carbon emissions in the cement industry stem mainly from the burning of the clinker (calcination of calcareous raw material and combustion of fossil fuels), which is responsible for 90–95% of all CO

2 emissions during cement production [

19]. Thus, carbon emission reduction in the cement industry mainly relies on the improvement of clinkers or clinker substitution technologies [

20,

21]. However, efforts by traditional industries, especially in developing countries, are approaching the limits of what they can do. The new clinker technology is not practical, especially for present-day China. The technology to develop new calcination methods to abandon traditional clinkers is not yet mature, and the cement industry may lose its advantages of low cost and the ease of production when this new technology is introduced.

Many methods for carbon emission reduction in the cement industry have been applied, but little is known about packaging in the industry. Packaging is an indispensable part of both the intermediate and final products in industrial production. However, prior studies mainly focused on the carbon emissions of single raw packaging materials, such as polypropylene (PP) and polyethylene (PE). The lack of research into the relevance and combination of these materials (packaging) poses challenges for carbon emission reduction in packaging. The peak cement production is predicted to occur in 2015–2020 [

22]. After 2020, the consumption is expected to be stable at approximately 0.8 billion tons every year [

23]. With the large amount of cement use, the volume of carbon emissions embodied in the use of packaging is tremendous, and solving this issue has been problematic.

Previous studies have attached importance to the carbon emissions of packaging. Some researchers have proven that the environmental impact of packaging is substantial and serious. For example, Robertson et al. assessed the carbon emissions of kiwifruit packaging from New Zealand to Japan and Germany using life cycle assessment (LCA) methodology, and estimated the carbon footprint of kiwifruit packaging and transport to range from 0.33 to 0.67 kg CO

2 per kilogram depending on the pack type and market [

24]. Liu et al. investigated the carbon emissions of beer packaging during the whole life cycle, including the production from the raw material, packaging process, transportation, consumption, and recycling using a mixed LCA methodology. The result showed that the total carbon emissions of each glass brewage packaging vessel is 489.867 g across the whole life cycle, and the production process accounts for 74.3% of the total carbon emissions [

25]. Wang introduced LCA modeling to assess the carbon emission of AI-PE-Pa complex packaging and the result showed that more than 80% of GHG emissions of the AI-PE-Pa complex packaging were from the production of paper, aluminum foil, and plastic [

26]. Choi et al. measured the carbon footprint of packaging films made from LDPE, PLA, and PLA/PBAT blends with three waste scenarios using LCA methodology [

27].

In 2016, China’s cement production reached 2.397 billion tons, decreasing to 2.316 billion tons in 2017 [

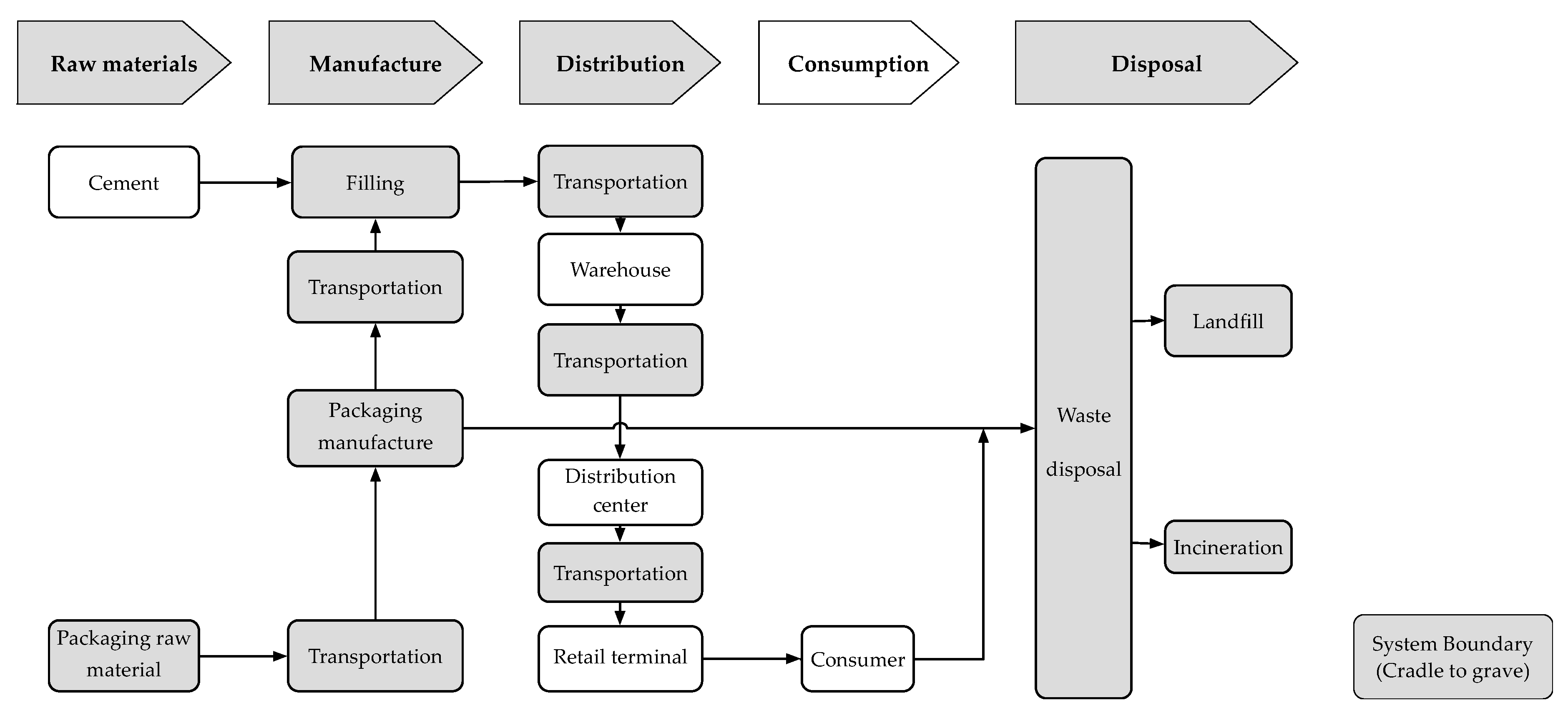

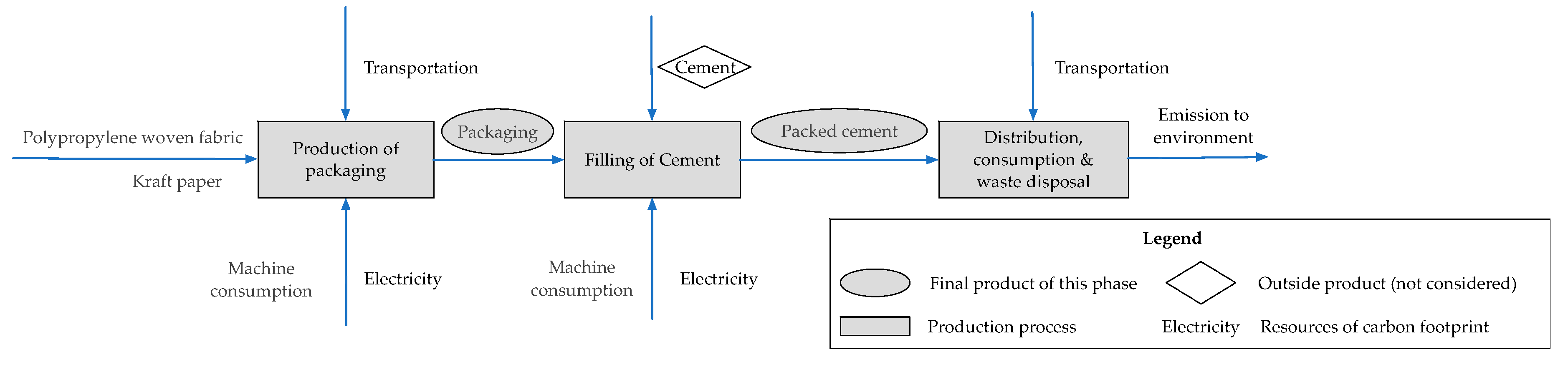

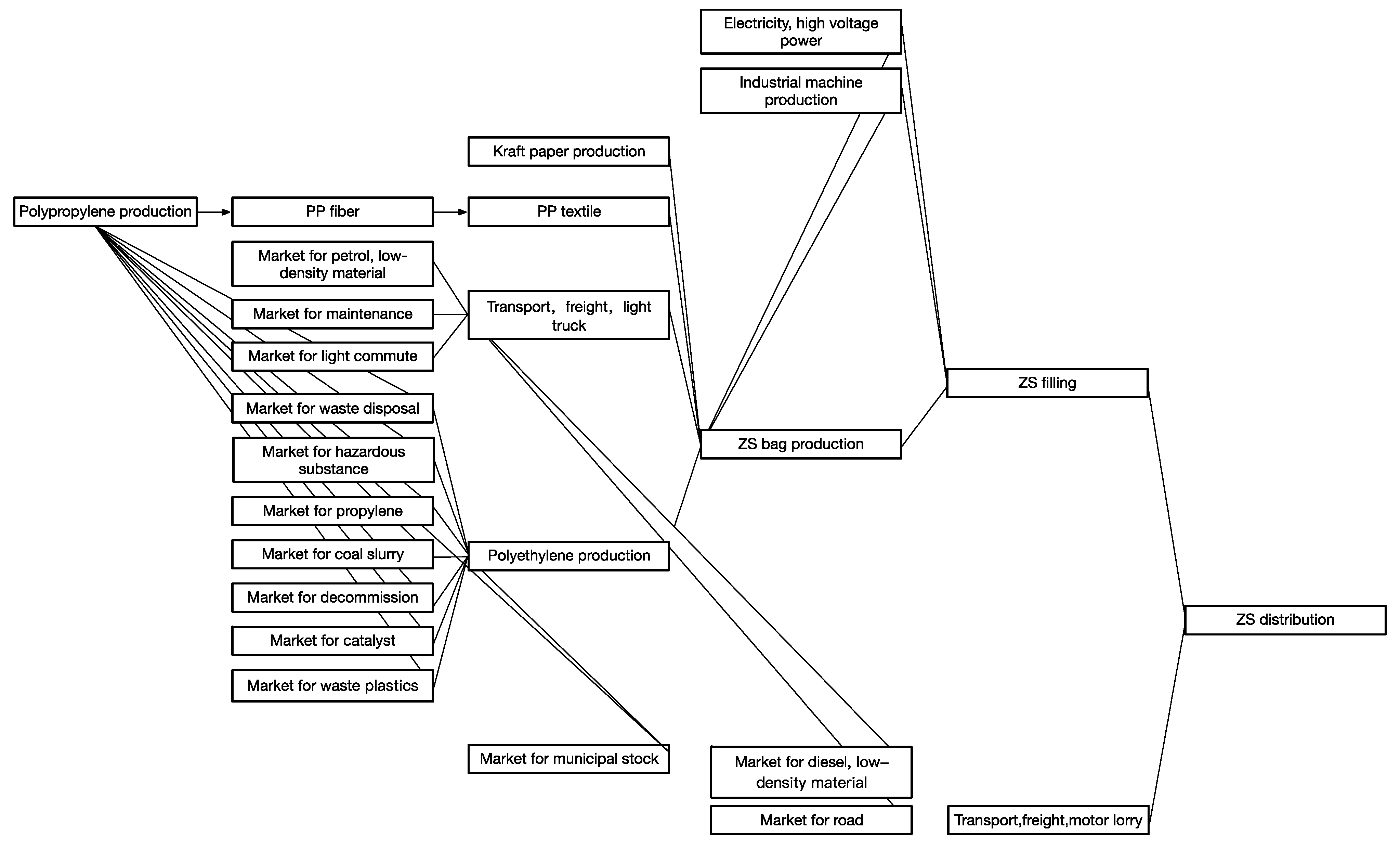

28]. Apart from the 1.448 billion tons of bulk cement that did not require packaging, 17.369 billion bags were needed in 2017, assuming that the other 0.868 billion tons of the cement were packed at 50 kg/bag. The cement industry is producing high amounts pollution and is unable to renovate the current clinker technology. Thus, this paper proposes a new carbon emission reduction measurement for cement manufacturers to realize low carbon development and reduce carbon emissions in cement packaging. The purpose of this study was to quantify the carbon emissions of cement packaging using the life cycle assessment approach. Using inventory analysis, the carbon emitted into the environment from the material consumption, energy consumption, and waste disposal in cement packaging were determined. By defining three kinds of popularly-used packaging, the carbon emissions of different types of packaging and suggestions provided for cement manufacturers were determined. By comparing the carbon emissions of different regions in China with different bulk rates, the relationship between the bulk rate and carbon emissions of cement packaging was clarified. Based on the results, some countermeasures are proposed for emissions reduction in China’s cement packaging industry.

4. Discussion

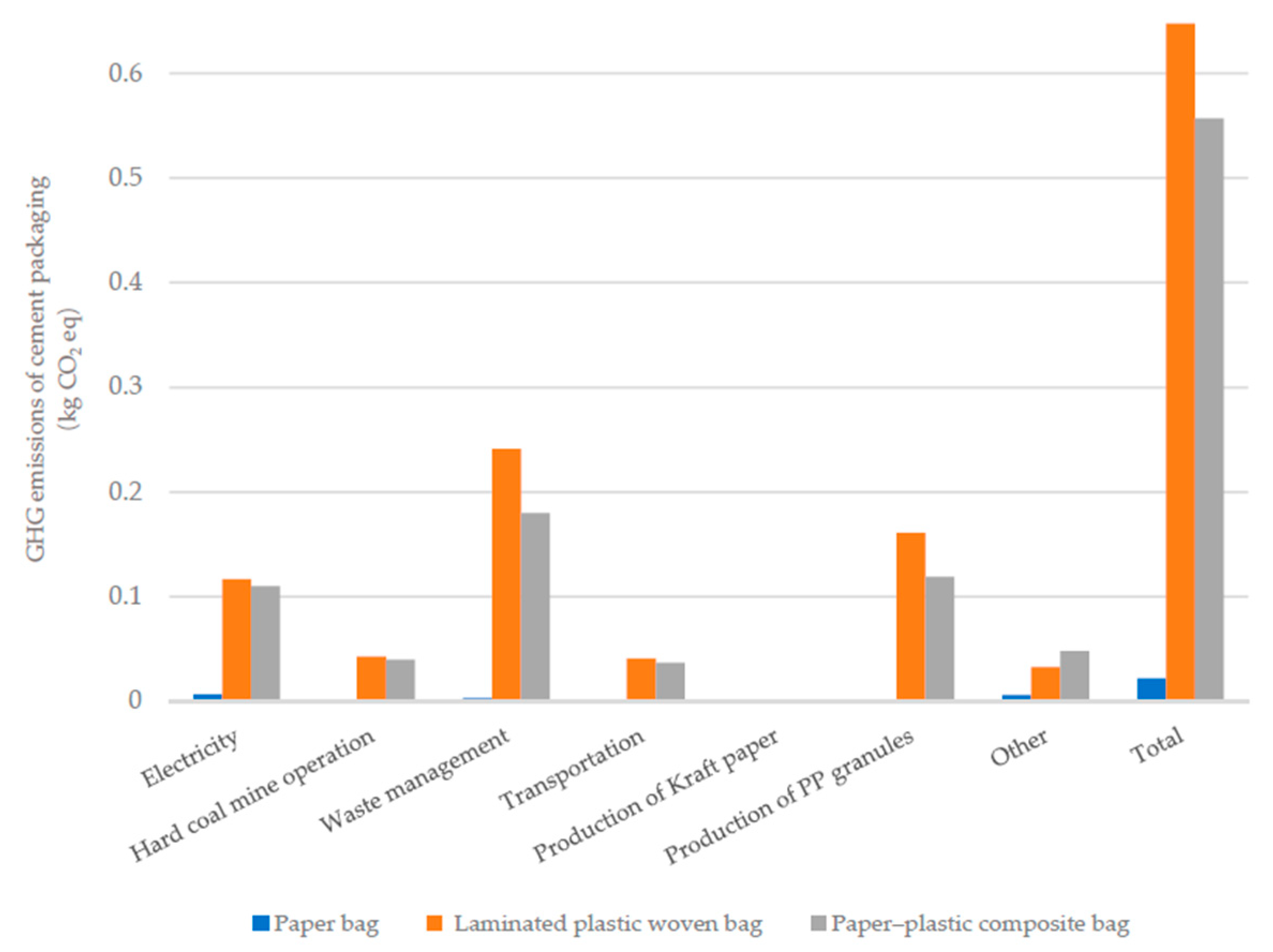

This study estimated the carbon emissions from China’s cement packaging to propose suggestions for cement manufacturers in China to reduce carbon emissions. The results showed that carbon emissions are largely emitted from laminated plastic woven bags. The consumption of electricity and PP accounts for the largest proportion of total carbon emissions in the production phase. Our results provide evidence to support countermeasures for carbon emissions in China’s cement industry.

4.1. Carbon Emissions Reduction Measures in Packaging Choices

A reduction in the use of laminated plastic woven bags would markedly reduce carbon emissions. From an economy perspective, the most widely used cement bags in practice are laminated plastic woven bags. By separately comparing each cement packaging type within the production chain, this study found that using paper–plastic composite bags instead of the laminated plastic woven bags would significantly reduce the total carbon emissions of cement packaging.

Paper–plastic composite bags consume more types of raw material compared with laminated plastic woven bags but consume less material. The carbon footprint is 10.92% lower than that of laminated plastic woven bags. Therefore, using a paper–plastic composite bag can significantly reduce the carbon footprint of the packaging. The physical strength of the paper bag is not as good as the other two bags, resulting in a higher loss rate in transportation. Thus, the paper bags is not considered as an option.

4.2. Carbon Emission Reduction Measures in Use of Recycled Material

Recycled materials can be used during bag production, but the strength of the recycled materials is not as good as those produced with new materials.

According to the GB9774-2010 requirements [

36], under the premise of consistent mechanical properties, the mass per unit area of fresh materials in paper–plastic composite bags and laminated plastic woven bags are ≥65 g/m

2 and ≥71 g/m

2, and the requirements for recycled materials are ≥71 g/m

2 and ≥77 g/m

2, respectively. When calculating the carbon footprint of the recycled material, it is assumed that the recycled material stems from the cement packaging and is calculated using the same method as for cement packaging. The recycled material is only recycled once. The weight of the recycled material increases by 9.84% as required by the national standard. The carbon footprint of packaging materials and transportation also increases by 9.84%. The carbon footprint of a paper bag using recycled material is 0.00282 kg CO

2 eq. The carbon footprint of transportation during recycling is relatively low and the data of the energy consumption of related machine during recycling is not available. Therefore, the actual carbon footprint is expected to be higher as the carbon footprint is not incorporated in the recycling process. The carbon footprint of the new Kraft paper used in paper bags is 0.00563 kg CO

2 eq, and the carbon footprint of the raw materials is reduced according to this ratio. That is, the carbon footprint of each packaging type decreases by 47.44% based on the raw materials. The carbon footprint of the raw material of the laminated plastic woven bag is 0.162 kg CO

2 eq, and 0.141 kg CO

2 eq for the raw material of paper–plastic composite bags. In the production phase, the carbon footprints is expected to decrease significantly by 15.85%, 20.59%, and 20.03% for paper, laminated plastic woven, and paper–plastic composite bags, respectively.

Assuming that the material is completely recycled and the recycled material is only recycled once, the data in

Table 11 is obtained, which shows the carbon footprint of packaging using recycled material and the emissions reduction over the whole life cycle.

4.3. Carbon Emission Reduction Measures in the Electricity Consumption

The carbon emissions from electricity consumption stem mainly from coal combustion for generating electricity and energy consumption in coal mining, accounting for 43.6–54.4% over the whole life cycle. A large proportion of carbon emissions for industrial products and processes usually originates from electricity consumption, such as the cobalt extraction process [

44] and aluminum production [

45]. The current method of power generation is mainly coal. An increase in the proportion of nuclear power and water power generation and a decrease in the proportion of coal generation could reduce the carbon emissions of cement packaging. Furthermore, this study recommends that the government should provide subsidies or preferential policies to coal production enterprises that adopt energy-saving technologies.

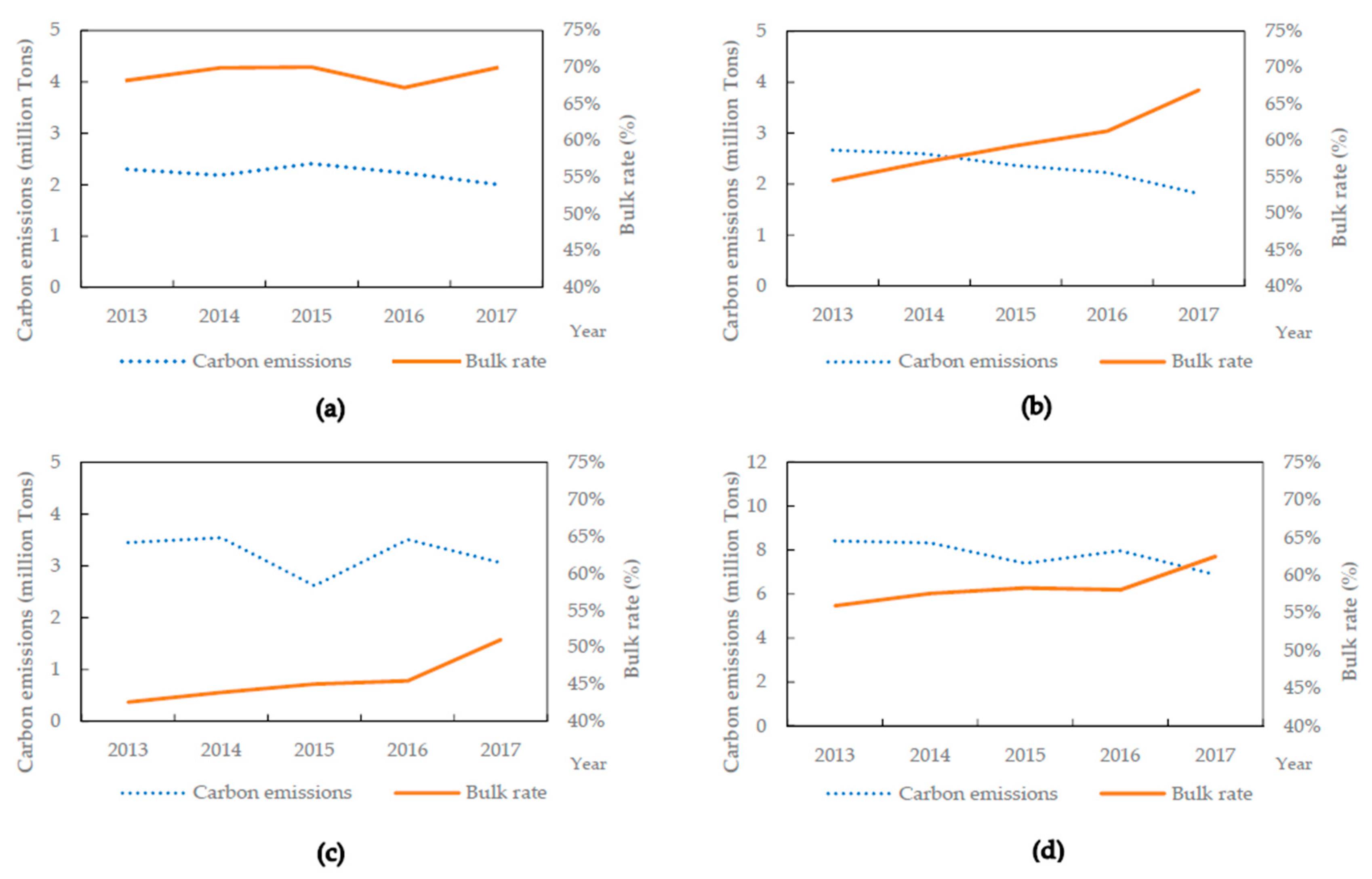

4.4. Carbon Emission Reduction Measures in Using Bulk Cement

Due to cement’s characteristics, it is usually transported with packaging. However, this leads to a massive consumption of cement packaging, resulting in carbon emissions and energy consumption. China has encouraged the use of bulk cement since the 1950s. The government has published a restrictive bagging policy and encourages bulk policy as the main policy to encourage the use of bulk cement and has formulated a series of policy documents to accelerate the development of bulk cement in China. A significant issue is improving the bulk cement transportation method. Using modern logistics means improving the traditional transportation methods, and constructing a modern logistics system could help promote the development of bulk cement. Furthermore, research and development of the corresponding technologies and production equipment, loading, unloading, restoring, transporting, and use of bulk cement is required. Finally, the production of bulk cement should be industrialized and intensive.

To sum up, if cement manufacturers choose paper-plastic composite bag with the use of recycled material, the carbon emission reduction of a single bag is 0.281 kg CO2 eq. In 2017, using the paper-plastic composite bag with recycled material instead of the laminated plastic woven bag can reduce carbon emissions with 4.88 million tons CO2 eq.

5. Conclusions

This paper used LCA methodology to assess the whole life cycle carbon emission of three kinds of widely used cement packaging in China, defining the goal and scope of this assessment, building a complete system and conducting a rigorous inventory analysis of the standard cement packaging used in China. Several results were obtained from this investigation: Firstly, the most widely used laminated plastic woven bag emits the most carbon dioxide followed by paper–plastic composite bags and paper bags; secondly, for a production perspective, electricity consumption accounts for the highest proportion of total carbon emissions. Using new energy such as nuclear power and water power could reduce the carbon emissions of cement packaging significantly. Finally, using recycled material in certain production phases and preferring paper–plastic composite bags simultaneously can reduce the carbon emissions of China’s cement packaging.

This investigation, however, has some limitations that need addressing in future. First, the economic considerations of paper–plastic composite bags were disregarded. Although the paper–plastic composite bag is more environmentally friendly, it might be more expensive than laminated plastic woven bags. The damp-proof characteristic of paper–plastic composite bags is lower than laminated plastic woven bags. Thus, the economic applicability and environmental protection must be balanced. Second, this study was limited to only considering the CO2 emissions of the packaging. Other important impact categories should be considered when comparing these three kinds of packaging, for example, the water footprint. The authors will conduct a more comparable and comprehensive investigation in the future.