Development of a New Method for the Quantitative Generation of an Artificial Joint Specimen with Specific Geometric Properties

Abstract

:1. Introduction

2. Background Theory

3. Development of a New Method and its Parametric Study

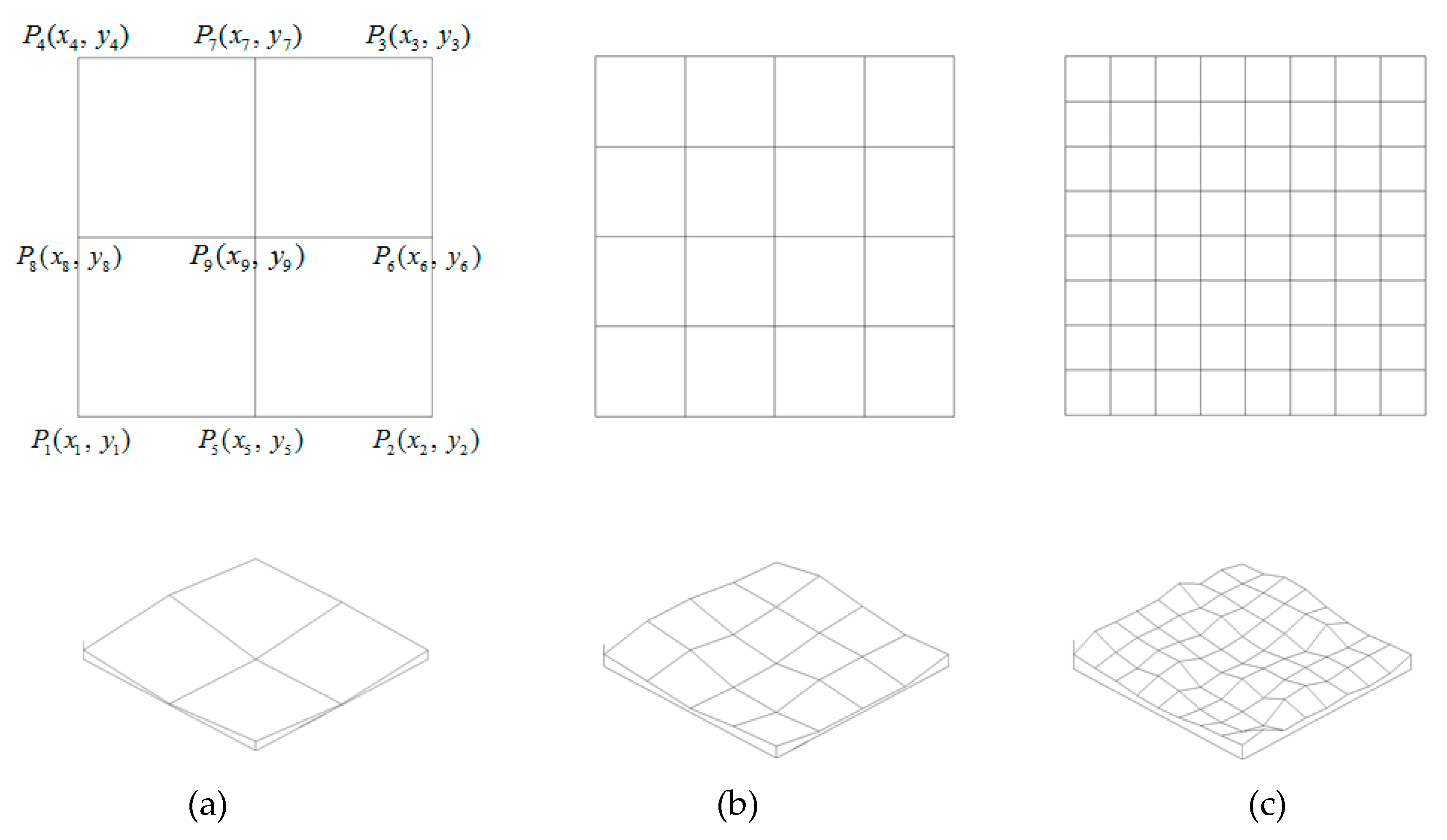

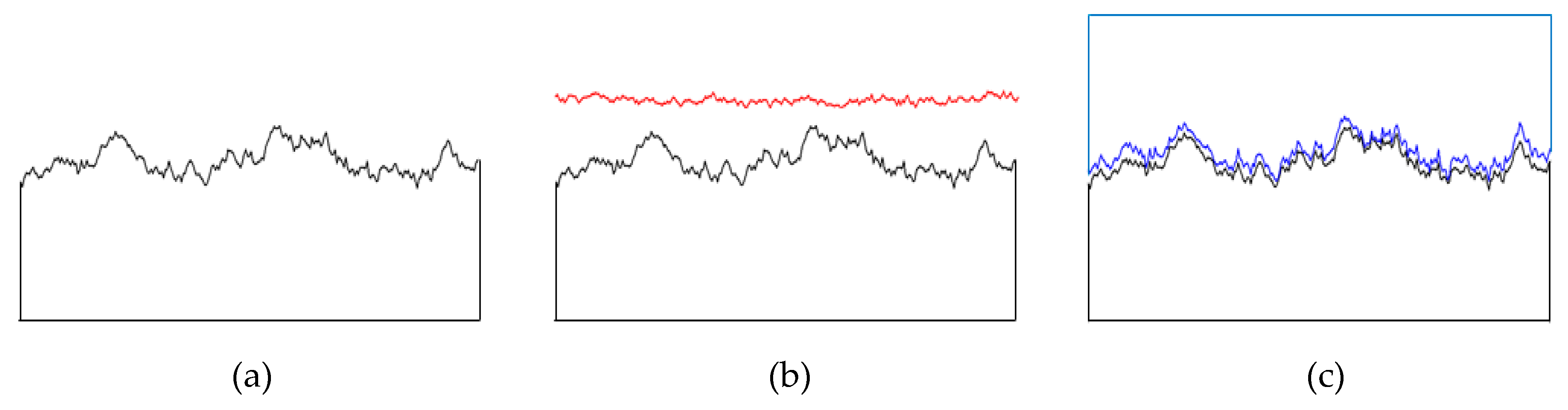

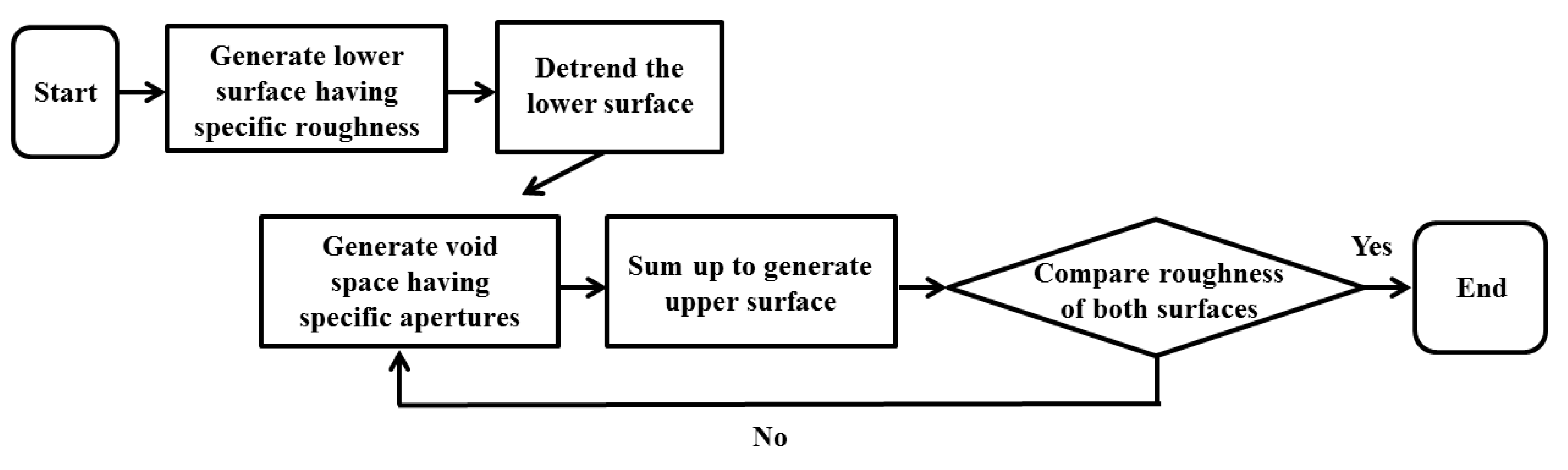

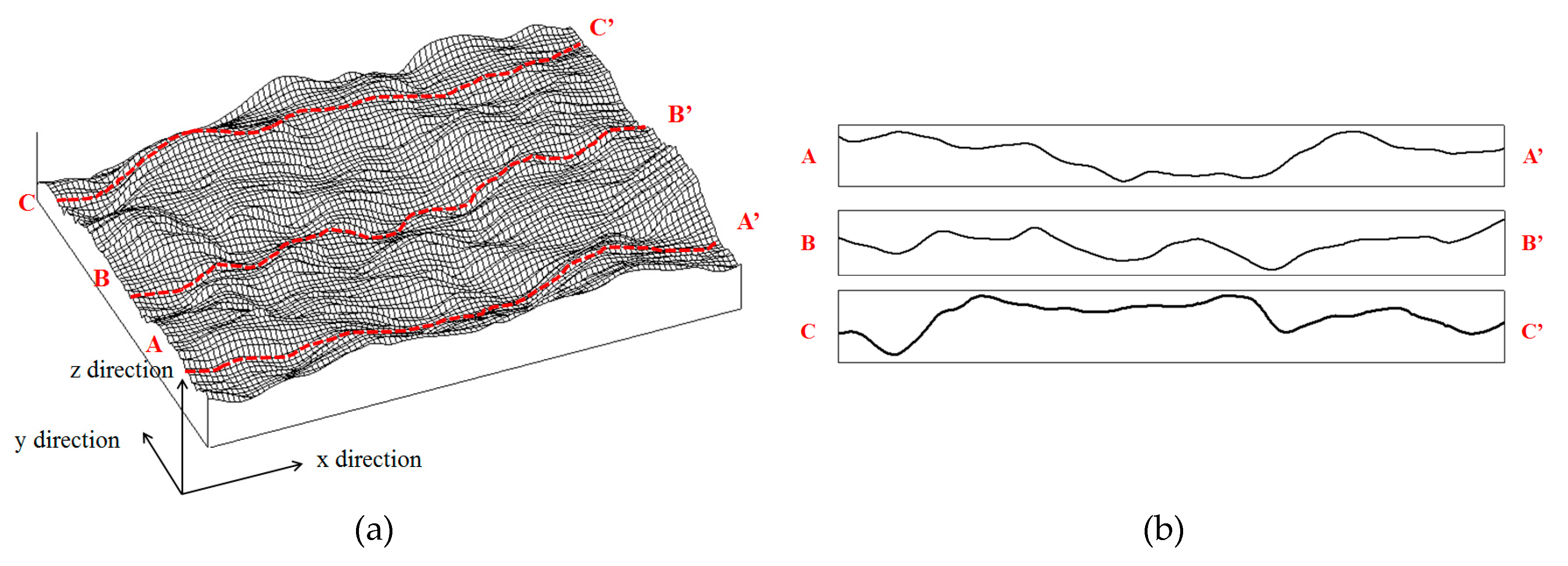

3.1. Development of a New Method for Generating Three-Dimensional Joint Specimens

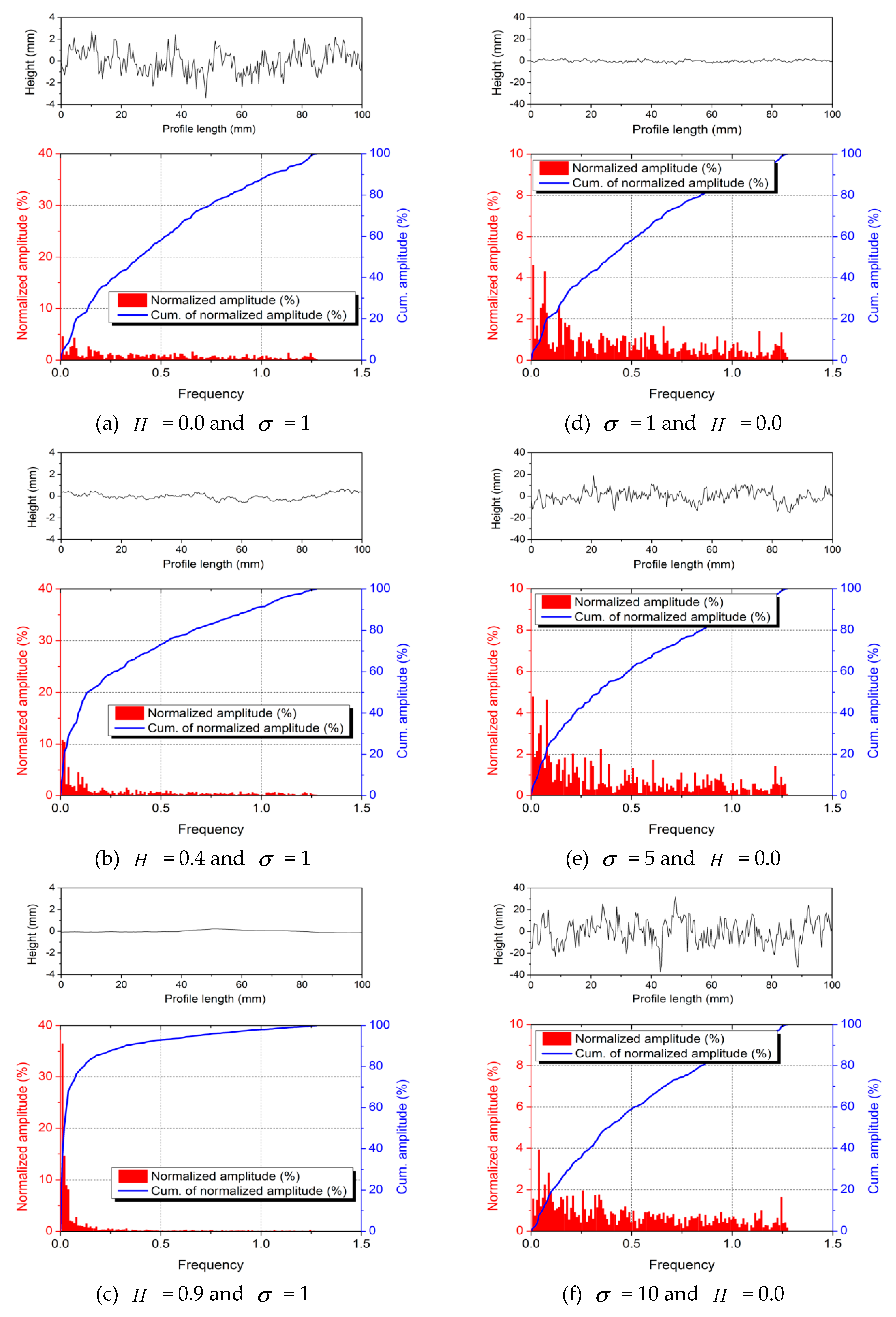

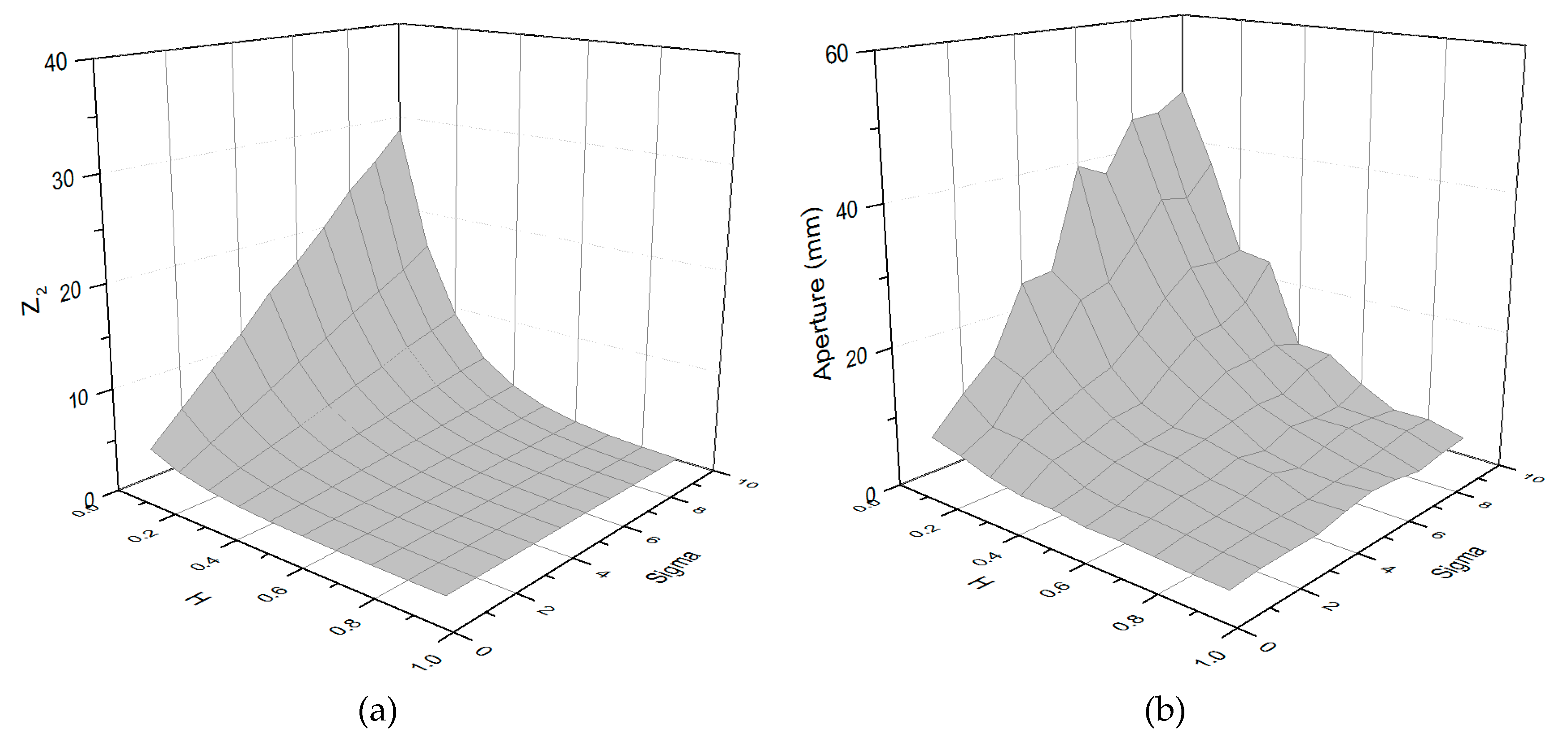

3.2. Parametric Study for Generating Joint Specimen

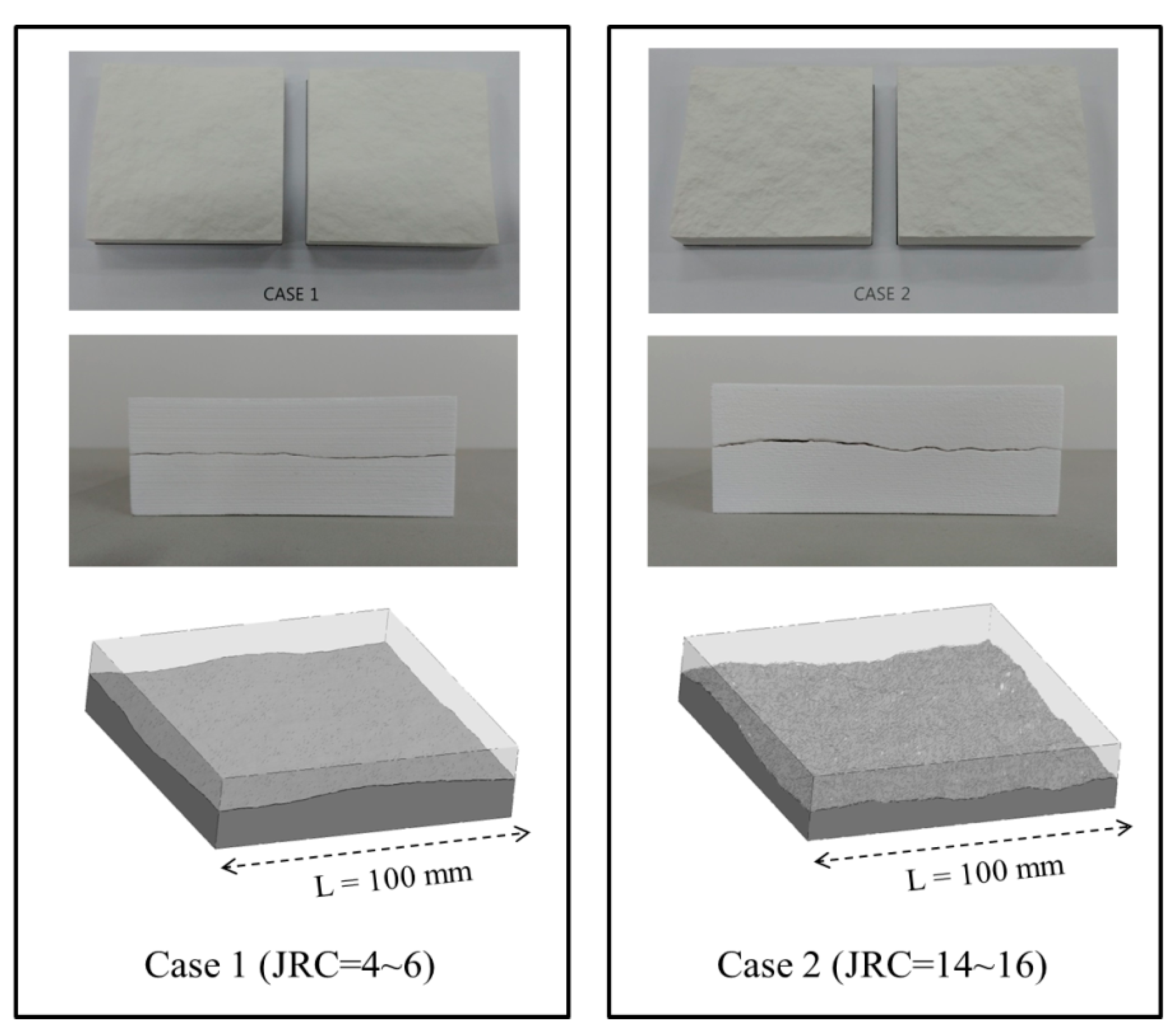

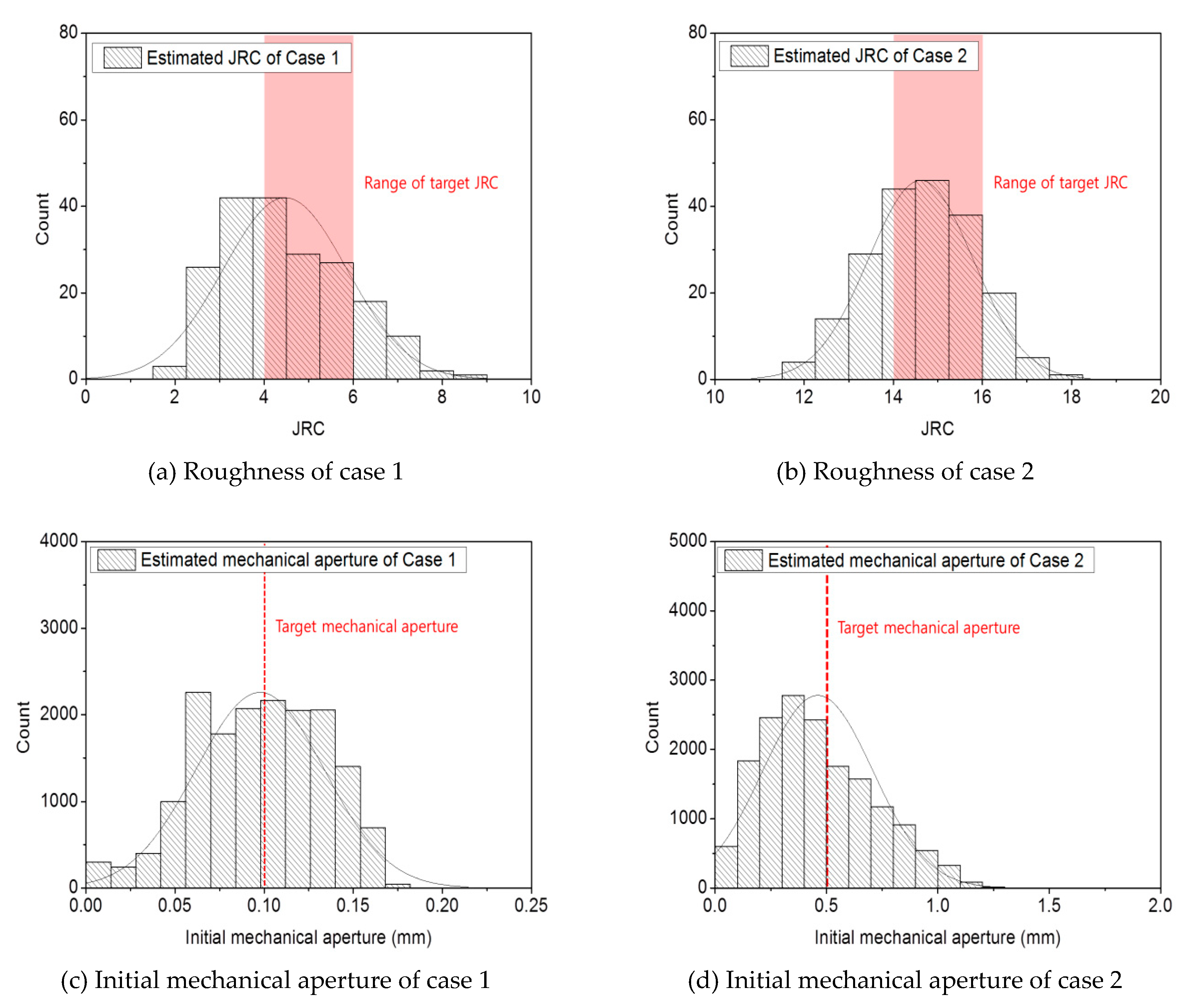

4. Verification and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Makurat, A.; Barton, N.; Rad, N.S.; Bandis, S. Joint conductivity variation due to normal and shear deformation. In Proceedings of the International Symposium on Rock Joints, Leon, Norway, 4–6 June 1990; pp. 535–540, ISBN 90 6191 109 5. [Google Scholar]

- Esaki, T.; Du, S.; Mitani, Y.; Ikusada, K.; Jing, L. Development of a shear-flow test apparatus and determination of coupled properties for a single rock joint. Int. J. Rock Mech. Min. Sci. 1999, 36, 641–650. [Google Scholar] [CrossRef]

- Lee, H.S.; Cho, T.F. Hydraulic characteristics of rough fractures in linear flow under normal and shear load. Rock Mech. Rock Eng. 2002, 35, 299–318. [Google Scholar] [CrossRef]

- Hakami, E.; Larsson, E. Aperture measurement and flow experiments on a single natural fracture. Int. J. Rock Mech. Min. Sci. 1996, 33, 395–404. [Google Scholar] [CrossRef]

- Min, K.B.; Rutqvist, J.; Elsworth, D. Chemically and mechanically mediated influence on the transport and mechanical characteristics of rock fractures. Int. J. Rock Mech. Min. Sci. 2009, 46, 80–89. [Google Scholar] [CrossRef]

- Brown, S. Fluid flow through rock joints: The effect of surface roughness. J. Geophys. Res. Solid Earth 1987, 92, 1337–1347. [Google Scholar] [CrossRef]

- Hakami, E. Aperture Distribution of Rock Fractures. Ph.D. Thesis, Division of Engineering Geology, Royal Institute of Technology, Stockholm, Sweden, 1995. [Google Scholar]

- Olsson, R.; Barton, N. An improved model for hydromechanical coupling during shearing of rock joints. Int. J. Rock Mech. Min. Sci. 2001, 38, 317–329. [Google Scholar] [CrossRef]

- Bandis, S.; Lumsden, A.; Barton, N. Fundamentals of rock joint deformation. Int. J. Rock Mech. Min. Sci. 1983, 20, 249–268. [Google Scholar] [CrossRef]

- Pyrak-Nolte, L.J.; Morris, J.P. Single fractures under normal stress: The relation between fracture specific stiffness and fluid flow. Int. J. Rock Mech. Min. Sci. 2000, 37, 245–262. [Google Scholar] [CrossRef]

- Zhao, J.; Brown, E. Hydro-thermo-mechanical properties of joints in the Carnmenellis granite. Q. J. Eng. Geol. 1992, 25, 279–290. [Google Scholar] [CrossRef]

- Tse, R.; Cruden, D. Estimating joint roughness coefficients. Int. J. Rock Mech. Min. Sci. Abstr. 1979, 16, 303–307. [Google Scholar] [CrossRef]

- Barton, N. Review of a new shear-strength criterion for rock joints. Eng. Geol. 1973, 7, 287–332. [Google Scholar] [CrossRef]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practices. Rock Mech. Rock Eng. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Park, J.; Song, J. Numerical method for the determination of contact areas of a rock joint under normal and shear loads. Int. J. Rock Mech. Min. Sci. 2013, 58, 8–22. [Google Scholar] [CrossRef]

- Singh, K.K.; Sing, D.N.; Ranjith, P.G. Laboratory simulation of flow through single fractured granite. Rock Mech. Rock Eng. 2015, 48, 987–1000. [Google Scholar] [CrossRef]

- Yeo, I.; Freitas, M.; Zimmerman, R. Effect of shear displacement on the aperture and permeability of a rock facture. Int. J. Rock Mech. Min. Sci. 1998, 35, 1051–1070. [Google Scholar] [CrossRef]

- Gentier, S.; Riss, J.; Archambault, G.; Flamand, R.; Hopkins, D. Influence of fracture geometry on shear behavior. Int. J. Rock Mech. Min. Sci. 2000, 37, 161–174. [Google Scholar] [CrossRef]

- Raja, J.; Radhakrishnan, V. Analysis and synthesis of surface profiles using Fourier series. Int. J. Mach. Tool Des. Res. 1977, 17, 245–251. [Google Scholar] [CrossRef]

- Patir, N. A numerical procedure for random generation of rough surfaces. Wear 1978, 47, 263–277. [Google Scholar] [CrossRef]

- Xie, H. Fractals in Rock Mechanics; Balkema: Rotterdam, The Netherlands, 1993; ISBN 9054101334. [Google Scholar]

- Seo, H.; Um, J. Generation of roughness using the random midpoint displacement method and its application to quantification of joint roughness. Tunn. Undergr. Space 2012, 22, 196–204. (In Korean) [Google Scholar] [CrossRef]

- Iwano, M.; Einstein, H. Stochastic analysis of surface roughness, aperture and flow in a single fracture. In Proceedings of the EUROCK 1993, Lisbon, Portugal, 21–24 June 1993; pp. 135–141. [Google Scholar]

- Choi, S.; Lee, S.; Jeon, S. Generation of a 3D artificial joint surface and characterization of its roughness. Tunn. Undergr. Space 2016, 26, 516–523. (In Korean) [Google Scholar] [CrossRef]

- Grasselli, G.; Egger, P. Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int. J. Rock Mech. Min. Sci. 2003, 40, 25–40. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Song, J.; Choi, B. A constitutive model for shear behavior of rock joints based on three-dimensional quantification of joint roughness. Rock Mech. Rock Eng. 2013, 46, 1513–1537. [Google Scholar] [CrossRef]

- Esaki, T.; Du, S.; Jiang, Y.; Wada, Y.; Mitani, Y. Relation between mechanical and hydraulic apertures during shear-flow coupling test. In Proceedings of the 10th Japan Symposium on Rock Mechanics, Osaka, Japan, 22–23 January 1998; pp. 91–96. [Google Scholar]

- Riss, J.; Gentier, S.; Sirieix, C.; Archambault, G.; Flamand, R. Degradation characteristics of sheared joint wall surface morphology. In Proceedings of the 2nd North America Rock Mechanics Symposium, Montreal, QC, Canada, 19–21 June 1996; pp. 1343–1349, ISBN 90 5410 838 X. [Google Scholar]

- Hakami, E.; Stephansson, O. Experimental technique for aperture studies of intersecting joints. In Proceedings of the ISRM International Symposium—Eurock 93, Lisboa, Portugal, 21–24 June 1993; pp. 301–309. [Google Scholar]

| Roughness | Initial Mechanical Aperture (mm) | |

|---|---|---|

| Case 1 | 4~6 | 0.1 |

| Case 2 | 14~16 | 0.5 |

| Initial Mechanical Aperture (mm) | ||||||

|---|---|---|---|---|---|---|

| Target Value | Estimated Results | Target Value | Estimated Results | |||

| Ave. | S.D. | Ave. | S.D. | |||

| Case 1 | 4~6 | 4.47 | 1.39 | 0.1 | 0.0977 | 0.0360 |

| Case 2 | 14~16 | 14.62 | 1.17 | 0.5 | 0.4611 | 0.2481 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.; Lee, S.; Jeong, H.; Jeon, S. Development of a New Method for the Quantitative Generation of an Artificial Joint Specimen with Specific Geometric Properties. Sustainability 2019, 11, 373. https://doi.org/10.3390/su11020373

Choi S, Lee S, Jeong H, Jeon S. Development of a New Method for the Quantitative Generation of an Artificial Joint Specimen with Specific Geometric Properties. Sustainability. 2019; 11(2):373. https://doi.org/10.3390/su11020373

Chicago/Turabian StyleChoi, Seungbeom, Sudeuk Lee, Hoyoung Jeong, and Seokwon Jeon. 2019. "Development of a New Method for the Quantitative Generation of an Artificial Joint Specimen with Specific Geometric Properties" Sustainability 11, no. 2: 373. https://doi.org/10.3390/su11020373

APA StyleChoi, S., Lee, S., Jeong, H., & Jeon, S. (2019). Development of a New Method for the Quantitative Generation of an Artificial Joint Specimen with Specific Geometric Properties. Sustainability, 11(2), 373. https://doi.org/10.3390/su11020373