Eco-Industrial Park (EIP) Development in Viet Nam: Results and Key Insights from UNIDO’s EIP Project (2014–2019)

Abstract

1. Introduction

2. Country Context

2.1. Challenges

2.2. Drivers for Eco-Industrial Parks in Viet Nam

3. Materials and Methods

- Policy development: UNIDO and the World Bank Group have been supporting the MPI in developing technical EIP guidelines (launched in July 2018) with the approved Decree 82, including support to operationalize the Decree, e.g., through International Expert Group meetings [26,30,31,32]. Other policy interventions undertaken as part of the Project cover a review of existing legislative and institutional frameworks of industrial parks toward the development of EIPs [8], the formulation of standards requirements, and a roadmap for developing eco-industrial parks [26,31,33], and EIP related topic trainings and awareness raising workshops.

- Company interventions: Resource Efficient and Cleaner Production (RECP) entails the continuous improvement of processes, products, and services in order to increase efficiency and reduce risks to humans and the environment. RECP addresses the three sustainability dimensions in a synergistic manner: (a) Heightened economic performance through improved productive use of resources; (b) environmental protection through conservation of resources and minimization the industry’s impact on the natural environment; and (c) social enhancement by providing jobs and protecting the well-being of workers and local communities [34,35]. As part of the Project, RECP assessments were undertaken with companies located in the pilot industrial parks. These assessments covered staff trainings, site visits to assess the production process, identification of opportunities, (pre)feasibility studies, and implementation of feasible options.

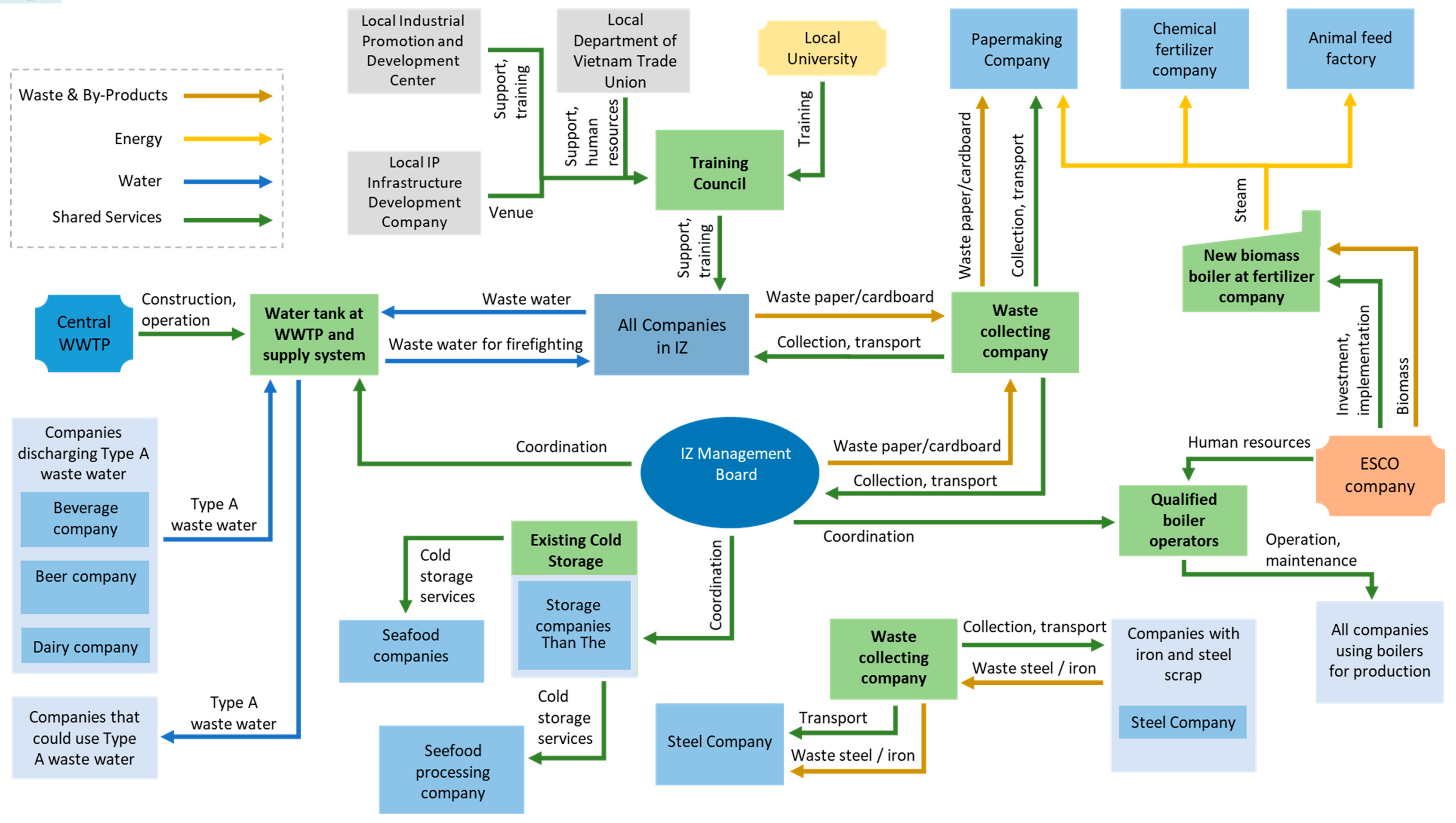

- Park level interventions: A key focus of the park level interventions of the Project was to identify and support the implementation of industrial symbioses in the pilot industrial parks participating in the Project (e.g., Khánh Phú IZ, Hòa Khánh IZ, and Trà Nóc 1&2 IZ). Industrial symbiosis engages traditionally separate industries in a collective approach to competitive advantage involving physical exchange of materials, energy, water, and/or by-products [36]. Industrial symbiosis often deals with the use of a previously disposed waste (as solid, liquid, gas) from one facility by another facility to provide a valuable by-product.

4. Results

4.1. Results—Policy Development

4.2. Results—Company Interventions

Illustrative Examples of Results

4.3. Results—Park Level Interventions

Illustrative Examples of Results

4.4. Summary of Project Results

- Intensive capacity-building and awareness-raising at all levels. A total of 264 local officials (from the Provincial People’s Committee, Department of Science and Technology, Department of Natural Resources, Department of Industry and Trade, industrial park management of three provinces) and government officials, experts, researchers (from the Ministry of Natural Resources and Environment (MONRE), Ministry of Science and Technology (MOST), Ministry of Industry and Trade (MOIT), MPI, Ministry of Construction (MOC), Ministry of Finance (MOF), Department of Natural Resources, Department of Industry and Trade, Department of Commerce, Viet Nam Union of Science and Technology Associations, Environmental Industry Association, Vietnam Small and Medium Enterprise Association and universities) were trained on international EIP models, the social and environmental requirements of EIP development, the development, implementation and management of EIP, and new policy and technical guidelines for EIP in Viet Nam. A total of 43 local and national-level officials took part in study tours in Japan, China, Denmark, Austria, and Switzerland and were trained in the establishment, development, and operation of EIPs, their institutional and policy requirements, technical and social minimum requirements, and industrial symbiosis.

- The ratio of RECP options identification and their implementation is around 80%, which is considered to be high. RECP options related to electricity savings account for the highest proportion (over 50%) of total options identified and implemented in the parks in all three provinces.

- The process of implementing RECP options helped companies achieve substantial benefits in terms of efficient use of resources (electricity, water, fuel, raw materials, chemicals), gaining economic benefits and reducing emissions to the environment as well as improving working conditions for workers. The RECP options implemented range from simple good housekeeping to more complex technology modifications, covering a range of industry sectors. They demonstrated value in improving the economic and environmental performance of companies in Viet Nam, in particular resource intensive industries such as food, cement, textiles, mechanical processing, and fertilizer production.

- Capacity-building in chemicals management in industrial parks and their companies. A total of 292 technical managers and staff from companies located in three industrial parks and central officials were trained on electricity efficiency in IZs and chemical management in industries.

- Capacities in resource efficiency and cleaner production (RECP) built/strengthened among company staff. Four hundred one company staff and technical managers from companies located in three selected industrial parks were trained through 8 classroom RECP trainings organized between January 2016 and September 2017.

- Implementation of resource efficiency measures in selected industrial processes. Seventy three companies in the three selected IZs assessed in RECP and in potential for implementation of clean and low‑carbon technology. The total number of RECP solutions suggested for the 73 companies was 1 039, of which 933 were implemented.

- Identification of industrial symbiosis options in selected parks. A total of 61 opportunities were identified in the four IZs, of which 18 were selected for further development in a more detailed feasibility study.

- Increased public awareness on issues concerning EIP development. A total of 2 163 participants from organizations (including scientific institutions (universities), non-governmental organizations (NGOs), public institutions, IZ authorities and associations) were identified and participated in awareness-raising events.

- The results achieved at company level contributed to the development of eco-enterprises and EIPs, as defined in Government Decree No. 82/2018 on regulating the management of industrial and economic zones [14].

5. Discussion and Conclusions

6. Lessons Learned and Next Steps

- Although the new decree 82/2018/NÐ-CP increases the transparency of EIP development in the country, legal barriers to implement EIPs in reality still exist, and these mainly relates to lack of available and reliable data, guidelines on waste and wastewater reuse, and recycling and minimum standards to reuse it [30].

- Initial awareness raising and creating early successes in the Project is essential. Convincing companies that it is for their own benefit can take a lot of time and effort. Once the early adopters have results, then all the neighboring companies wish to join and benefit from the Project.

- Overall, there is often a lack of available data at company, park, provincial, and national level. Data on the quantities and qualities of resources (e.g., raw materials, wastes, and by-products, energy, and water) is needed before being able to assess the potential for industrial symbiosis in an industrial park. Collecting these basic data can be a time-consuming process. Therefore, strengthening resource monitoring at all levels should be a priority.

- Commitment of the company management board is the key factor to the success of the company level interventions. At companies with high commitment, many RECP options are implemented immediately with specific benefits, encouraging enterprises to implement and maintain options till the end of the RECP programme.

- The company teams established play an important role in implementing and maintaining the effectiveness of the RECP and industrial symbiosis options identified. The teams need to be supported by the management board of the companies as well as IZ management, and maintained after the actual assessments have been completed in order to ensure that feasible options are implemented effectively.

- Technical assistance provided to companies demonstrated that RECP options can be low- or no cost and easy to implement with high returns on companies’ investments. Simple and no investment cost options should be implemented immediately. In addition to the immediate environmental and financial savings, this will also motivate and create confidence for the company to deploy RECP options with higher investment costs.

- For technology upgrades and investments, it is necessary to inform companies on available green financial funds and preferential loans to implement the RECP and industrial symbiosis options and provide support on how to access these funds. This was one of the key drivers for the Project to prepare a customized handbook on accessing green financing in Viet Nam [44].

- Feasible distances: This is generally a key success factor as transportation can make up a significant proportion of the costs to enable an industrial synergy. A clear distinction must be made between synergies inside and outside an industrial park (e.g., material exported for road construction). Obviously, this latter case is more sensitive to transportation issues.

- Viable technology and equipment: Modification and investment in technologies are often required to implement industrial symbiosis. For instance, a by-product may need to be processed to meet the technical and market requirements. Without a suitable and proven technology available to treat, convert or transport a by-product, a synergy project would be not feasible.

- Diversity of industries: Having different industrial sectors usually results in a wide variety of resource input and output flows available for inter-industry exchanges. Similarly, having companies of different sizes (including SMEs) can facilitate the development of symbiosis by offering opportunities for valorizing different volume streams.

- License to operate: Policy and regulations can help improve resource efficiencies at company and industrial park levels (Moreau et al. 2017). As outlined above, regulations in Viet Nam are currently a barrier to the development of industrial symbiosis, because by-products and effluent are traditionally considered to be waste and are therefore constrained by stringent regulations to avoid illegal disposal of contaminated material.

- Recognize full set of benefits: The benefits of industrial symbiosis often go beyond return on-investment, as the benefits can also cover risk mitigation, improved productivity, and improved environmental and social performance. Investment decisions must therefore account for the full set of economic, environmental, and social benefits.

- Return on investment: The implementation of industrial symbiosis needs a favorable return on investment and so-called low-hanging fruit for the beneficiaries, as often the decision on their investment is competing with investments in other areas.

- Access to finance: Investments can sometimes be significant to implement industrial synergies. This is particularly the case for utility synergies and shared infrastructures in industrial parks. Financial incentives can help decreasing the payback period. As industrial symbiosis often require an investment, the availability of financing solutions is clearly a key factor for successful implementation [16].

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Côté, R.; Cohen-Rosenthal, E. Designing eco-industrial parks: A synthesis of some experience. J. Clean. Prod. 1998, 6, 181–188. [Google Scholar] [CrossRef]

- Erkman, S.; Ramaswamy, R. Cleaner production at the system level: Industrial ecology as a tool for development planning. Clean. Prod. 2000, 2, 173–178. [Google Scholar]

- Geng, Y.; Zhang, P.; Côté, R.P.; Fujita, T. Assessment of the national eco-industrial park standard for promoting industrial symbiosis in China. J. Ind. Ecol. 2009, 13, 15–26. [Google Scholar] [CrossRef]

- GIZ. Guidelines for Sustainable Industrial Areas—Version 1.0 (October); Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Eschborn, Germany, 2015. [Google Scholar]

- Indigo Development. An Eco-industrial Park Definition for the Circular Economy. 2005. Available online: http://www.indigodev.com/Defining_EIP.html (accessed on 30 June 2017).

- Lowe, E.A. Eco-Industrial Parks: A Handbook; Asian Development Bank: Manila, Philippines, 2001. [Google Scholar]

- Massard, G.; Jacquat, O.; Zürcher, D. International Survey on Eco-Innovation Parks: Learning from Experiences on the Spatial Dimension of Eco-Innovation; FOEN: Bern, Switzerland, 2014. [Google Scholar]

- UNIDO. Global Assessment of Eco-Industrial Parks in Developing and Emerging Countries: Achievements, Good Practices and Lessons Learned from Thirty-Three Industrial Parks in Twelve Selected Emerging and Developing Countries; United Nations Industrial Development Organization: Vienna, Austria, 2016. [Google Scholar]

- WBG. Low-Carbon Zones—A Practitioner’s Handbook; World Bank Group, Investment Climate Department: Washington, DC, USA, 2014. [Google Scholar]

- UNIDO. Implementation Handbook for Eco-Industrial Parks; United Nations Industrial Development Organization: Vienna, Austria, 2017. [Google Scholar]

- UNIDO; WBG; GIZ. An International Framework for Eco-Industrial Parks; World Bank Group: Washington, DC, USA, 2017. [Google Scholar]

- GIZ. Sustainable Industrial Area Toolbox; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Eschborn, Germany, 2017. [Google Scholar]

- Roberts, B.H. The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: An Australian case study. Appl. Ind. Ecol. 2004, 12, 997–1010. [Google Scholar] [CrossRef]

- Government of Viet Nam Decree No.82/2018/ND-CP. Management of Industrial Parks and Economic Zones; Government of Viet Nam Decree No.82/2018/ND-CP: Hanoi, Vietnam, 2018.

- Van Berkel, R. Regional Resource Synergies for Sustainable Development in Heavy Industrial Areas: An Overview of Opportunities and Experiences; Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- WBG. Mainstreaming Eco-Industrial Parks; World Bank Group: Washington, DC, USA, 2016. [Google Scholar]

- Veiga, L.B.E.; Magrini, A. Eco-industrial park development in Rio de Janeiro, Brazil: A tool for sustainable development. J. Clean. Prod. 2009, 17, 653–661. [Google Scholar] [CrossRef]

- Yu, C.; de Jong, M.; Dijkema, G.P.J. Process analysis of eco-industrial park development. The case of Tianjin, China. J. Clean. Prod. 2014, 64, 464–477. [Google Scholar] [CrossRef]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Fujii, M. Quantitative Assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. Environ. Sci. Technol. 2009, 43, 1271–1281. [Google Scholar] [CrossRef] [PubMed]

- Van Beers, D.; Corder, G.; Bossilkov, A.; van Berkel, R. Industrial symbiosis in the Australian minerals industry—The cases of Kwinana and Gladstone. J. Ind. Ecol. 2007, 11, 55–72. [Google Scholar] [CrossRef]

- MONRE. Report on National Environment: Viet Nam Industrial Environment; Ministry of Natural Resources and Environment of Viet Nam: Cầu Giấy, Vietnam, 2009.

- UNIDO. Mpi Project Document ‘Implementation of Eco-Industrial Park Initiative for Sustainable Industrial Zones in Viet Nam’; United Nations Industrial Development Organization: Vienna, Austria, 2014. [Google Scholar]

- Government of Viet Nam. National Target Program of Use of Energy Saving and Efficiency for 2006–2015 Period; Prime Minister Decision 79/2006/QD-TTg: Hanoi, Viet Nam, 2006.

- Government of Viet Nam. National Strategy of Integrated Solid Waste Management; Prime Minister Decision 2149/QD-TTg: Hanoi, Viet Nam, 2009.

- Government of Viet Nam. Strategy of Resource Efficiency and Cleaner Production in Industry by 2020; Prime Minister Decision 1419/2009/QD-TTg: Hanoi, Viet Nam, 2009.

- UNIDO. Eco-Industrial Parks Vietnam: Stakeholder Analysis and Development Roadmap; United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- MPI. Annual Report 2018; Department of Economic Zone Management, Ministry of Planning and Investment: Hanoi, Viet Nam, 2018. [Google Scholar]

- MPI. Annual Report 2017; Department of Economic Zone Management, Ministry of Planning and Investment: Hanoi, Viet Nam, 2017.

- Chuc, N.G.; Dong, T.D.; Thuc, N.T. Efforts toward sustainable manufacturing: Cleaner production and eco-industrial parks in Viet Nam. In Environmental Sustainability in Asia: Progress, Challenges and Opportunities in the Implementation of the Sustainable Development Goals; Series 1—Viet Nam; Korea Environment Institute: Sejong, Korea, 2017. [Google Scholar]

- UNIDO. Vietnam heads towards Eco-Industrial Parks. In Proceedings of the Second Expert Group Meeting: Implementation of Eco-Industrial Parks in Viet Nam: Opportunities, Challenges and Barriers, Ho Chi Minh City, Viet Nam, 8–9 November 2018; United Nations Industrial Development Organization: Vienna, Austria, 2018. [Google Scholar]

- UNIDO. Eco-Industrial Parks Viet Nam: Social and Economic Indicators for Eco-Industrial Parks in Viet Nam; United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- IFC. Technical and Financial Diagnostic of Eco-Opportunities in Industrial Parks of Viet Nam: Development of Eco-Industrial Park Technical Guidelines for Viet Nam; International Finance Corporation, World Bank Group: Washington, DC, USA, 2018. [Google Scholar]

- Massard, G.; Leuenberger, H.; Dong, T.D. Standards requirements and a roadmap for developing eco-industrial parks in Viet Nam. J. Clean. Prod. 2018, 188, 80–91. [Google Scholar] [CrossRef]

- UNIDO Resource Efficient and Cleaner Production (RECP). Available online: https://www.unido.org/cp/o5153.html (accessed on 30 June 2017).

- UNIDO. Cleaner Production Toolkit; UNIDO: Vienna, Austria, 2008. [Google Scholar]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- IFC; MPI. National Technical Guidelines for Eco-Industrial Parks in Viet Nam; Ministry of Planning and Investment: Hanoi, Viet Nam, 2019; Unpublished.

- UNIDO; MPI. Eco-Industrial Park Viet Nam Socio-Economic Requirements: A Review of International and Vietnamese Experiences; United Nations Industrial Development Organization: Vienna, Austria; Ministry of Planning and Investment of Viet Nam: Hanoi, Viet Nam, 2019. [Google Scholar]

- UNIDO. Eco-Industrial Parks Viet Nam: Handbook on Prevention, Preparedness and Response to Environmental Accidents from Industrial Zones; United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- UNIDO. Eco-Industrial Parks Viet Nam: Vietnamese Policy Documents for Supporting Communities to Monitor Environmental Impacts from Industrial Zones; United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- VNCPC; ENTEC. Provision of Services for RECP Training and Monitoring—Final Report; Viet Nam National Cleaner Production Centre and Environmental Technology Centre for United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- VNCPC; Sofies. Reports on Industrial Symbiosis Feasibility Studies at Tra Noc Industrial Zone (Can Tho), Khanh Phu Industrial Zone (Ninh Binh), and Hoa Khanh Industrial Zone (Da Nang); Viet Nam National Cleaner Production Centre and Sofies Group for United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- UNIDO; MPI. Review and Assess the Existing Legal Framework, Policies and Regulations on Industrial Parks in Viet Nam; United Nations Industrial Development Organization: Vienna, Austria, 2016. [Google Scholar]

- UNIDO. Handbook on How to Access Green Financing in Viet Nam; United Nations Industrial Development Organization: Vienna, Austria, 2019. [Google Scholar]

- Van Beers, D. Application of the Cleaner Production Framework to the Development of Regional Synergies in Heavy Industrial Areas: A Case Study of Kwinana (Western Australia); Curtin University of Technology: Perth, Australia, 2009. [Google Scholar]

- Chiu, A.S.F.; Yong, G. On the industrial ecology potential in Asian Developing Countries. Appl. Ind. Ecol. 2004, 12, 1037–1045. [Google Scholar] [CrossRef]

| Ninh Binh | Da Nang | Can Tho | Total | |

|---|---|---|---|---|

| Investment (Euro) | 4,101,465 | 2,857,108 | 2,905,877 | 9,864,450 |

| Benefit (Euro) | 2,014,587 | 1,747,193 | 4,824,279 | 8,586,058 |

| Raw material (ton) | 443 | 8177 | 744 | 9363 |

| Electricity (kWh) | 9,347,734 | 9,802,470 | 38,674,662 | 57,824,866 |

| Fresh water (m3) | 37,145 | 298,467 | 1,130,348 | 1,465,960 |

| LPG (ton) | 74 | 7 | 64 | 145 |

| Chemical (ton) | 17 | − | 11 | 28 |

| Coal (ton) | 9743 | 4781 | − | 14,524 |

| Wood (ton) | 507 | 1328 | 759 | 2594 |

| Natural gas (Sm3) | − | − | 335,095 | 335,095 |

| Rice husk (briquettes) | − | − | 688 | 688 |

| Steam (ton) | − | − | 3765 | 3765 |

| CO2eq (ton) | 34,254 | 21,033 | 36,423 | 91,710 |

| PCDD/F (µg) | 7103 | 4856 | 5986 | 17,945 |

| COD (kg) | 3224 | 35,200 | 131,444 | 169,868 |

| Solid waste (ton) | 1111 | 7854 | 2272 | 11,237 |

| Waste water (m3) | 36,241 | 278,188 | 1,043,259 | 1,357,688 |

| Industry Sector/Product | Paper Factory | ||

|---|---|---|---|

| Production process | The paper factory produces kraft, industrial roll, and carton package with the capacity of 15,000 tons/year. The company has joined Project since January 2016 and has established a RECP team with nine members. The paper production process involves the following steps:

| ||

| RECP options implemented | 22 RECP options have been implemented between January 2016 and January 2019, while 4 have not been implemented yet. | ||

| No. | Implemented RECP options | Benefits | |

| 1 | Issue regulation for cleaning and maintenance of electrical cabinets and motors | Engine runs more durable; and reduced power consumption | |

| 2 | Install electricity meter for every production line to control separately the electricity consumption benchmark for production lines | Monitoring norms used to detect leaks and losses. | |

| 3 | Repair roof to increase natural light and ventilation to save electricity | Reduced power consumption | |

| 4 | Invest the solar battery system | Increase of renewable energy use and reduced power consumption | |

| 5 | Control and regulate water consumption for washing conveyor | Reduced water consumption | |

| 6 | Increase treatment efficiency of WWT system to raise recycling water rate | Reduced pollutants in waste water | |

| 7 | Investment in four new high-pressure sprayers (two big machines and two small machines) for washing conveyor | Reduced water consumption | |

| 8 | Build roof for material storing area or press material for better maintenance and control consumption benchmark | Reduced materials consumption | |

| 9 | Remind worker to collect pulp on floor and clean floor at the end of working shift | Reduced materials consumption | |

| 10 | Regular monitoring of the quality of the pulp, especially the concentration of pulp (homogeneity of pulp) before making paper. | Increasing quality of paper, reduced materials consumption | |

| 11 | Insulate steam distribution pipeline of lines 4 and 2 | Reduced fuel consumption | |

| 12 | Insulate condensate recovering pipeline and a number of steam containing tanks of lines 1,2,4, 6 | Reduced fuel consumption | |

| 13 | Insulate condensate recovering tanks | Reduced fuel consumption | |

| 14 | Invest supply water treatment system for boiler | Extended boiler life | |

| 15 | Training to improve skill and responsibility of boiler operation workers | Reduced fuel consumption | |

| 16 | Use good quality wood (with humidity less than 40%, wood dried to meet less than 35% humidity before using | Improved quality and reduced operating cost | |

| 17 | Remove scale and blowdown regularly | Improved quality and reduced operating cost | |

| 18 | Replace three existing blowers by one of 7.5 HP for supplying wind into boiler | Reduced electricity consumption | |

| 19 | Adjust frequency of smoke fan based on suction pressure to ensure balance between fire and wind | Reduced electricity consumption | |

| 20 | Install meter to measure steam consumption for each line | Reduced electricity consumption | |

| 21 | Increase water removing capacity by investing in long net paper making machine | Reduced water consumption | |

| 22 | Invest in fluidized boiler system, capacity of 8 tons/h with three stages steam system. | Reduced fuel consumption and operating cost | |

| Benefits | Resource benefits: | ||

| Materials savings—scrap paper (tons/year) | 213 | ||

| Water savings (m3/year) | 6592 | ||

| Electricity savings (MWh/year) | 2460 | ||

| Fuel savings (tons of coal/year) | 1110 | ||

| Environmental benefits (reduced emissions): | |||

| Reduction of solid waste (tons/year) | 15 | ||

| Reduction of wastewater (m3/year) | 5274 | ||

| Reduction of CO2 (tons/year) | 2260 | ||

| Reduction of Teq PCDD/F (µg/year) | 1013 | ||

| Avoided COD emission (kg/year) | 922 | ||

| Financials: | |||

| Total of investment cost for RECP (billion VND) | 15.7 | ||

| Total of saving cost (billion VND/year) | 5.8 | ||

| Pay-back time | Less than 3 years | ||

| Industry Sector/Product. | Floating Glass | ||

|---|---|---|---|

| Production process | The company produces 300 tons of construction white glass per day. The number of employees in the factory are 300. The company joined the Project since January 2016. The company’s RECP team has four members. The float glass production process involves the following steps:

| ||

| RECP options implemented | The following 11 RECP options have been implemented under the Project since January 2016. | ||

| No. | Implemented RECP options | Benefits | |

| 1 | Fix the bad contact and invest in an infrared thermometer to monitor temperature | Reduced electricity consumption | |

| 2 | Replace these lamps by compact 75W or 50 W when they are damaged | Reduced electricity consumption | |

| 3 | Transfer some capacitors from central to branch power load to reduce the motor voltage drop | Reduced electricity consumption | |

| 4 | Contact local electric authority to decrease wire voltage to 380 ± 2.5% | Reduced electricity consumption | |

| 5 | Put more attention in managing and controlling the status of material and a clear plan of buying/storage | Reduced materials consumption | |

| 6 | Heat up fuel (coal) to optimal temperature before being sprayed into burning chamber | Reduced fuel consumption | |

| 7 | Have a plan for furnace maintenance to repair partially broken area | Reduced fuel consumption | |

| 8 | To change to more efficient heater for melting tin tank | Reduced electricity consumption | |

| 9 | Maintain and replace by the new furnace | Reduced electricity consumption | |

| 10 | Should be equipped with a roof to protect materials and control their consumption | Reduced materials consumption | |

| 11 | Take advantage of heat in the emission to dry fuel | Reduced fuel consumption | |

| Benefits | Resource benefits: | ||

| Chemicals savings | |||

| ● Sand (tons/year) | 124 | ||

| ● Soda (tons/year) | 32 | ||

| Electricity savings (MWh/year) | 3700 | ||

| Fuel savings (tons of coal/year) | 3431 | ||

| Environmental benefits (reduced emissions): | |||

| Reduction of solid waste (tons/year) | 343 | ||

| Reduction of wastewater (m3/year) | 12,715 | ||

| Reduction of CO2 (tons/year) | 12,465 | ||

| Reduction of Teq PCDD/F (µg/year) | 2512 | ||

| Financials: | |||

| Total of investment cost for RECP (billion VND) | 103 | ||

| Total of saving cost (billion VND/year) | 18.5 | ||

| Pay-back time | Around 5 years | ||

| Item | Khanh Phu IZ (Ninh Binh) | Hoa Khanh IZ (Da Nang) | Tra Noc 1&2 IZ (Can Tho) | Total |

|---|---|---|---|---|

| Number of companies surveyed | 22 | 57 | 58 | 137 |

| Number of industrial symbiosis opportunities | ||||

| Identified | 14 | 22 | 25 | 61 |

| Feasibility studies | 4 | 7 | 8 | 19 |

| Feasible and up for implementation | 0 | 4 | 6 | 10 |

| Already implemented | 0 | 1 | 1 | 2 |

| Total environmental benefits for feasible opportunities | ||||

| GHG (tCO2/yr) | 24,955 | 18,190 | 27,331 | 70,475 |

| Water (m3/yr) | 0 | 885,333 | 0 | 885,333 |

| Waste (t/yr) | 82,440 | 2004 | 0 | 84,444 |

| Total economic benefits for feasible opportunities | ||||

| Average payback period (min-max) | 0.3–7.5 year | 0.3–7.9 year | 1–3 year | |

| Capital investment (USD) | 1,834,741 | 999,385 | 1,745,113 | 4,579,239 |

| Capital already invested or committed (USD) | 0 | 999,385 | 1,745,113 | 2,744,498 |

| Savings (USD/yr) | 2,186,625 | 466,134 | 790,655 | 3,443,414 |

| IS Opportunity | Biogas Recovery at One Company for Use As Fuel in the Boiler of an Adjacent Company. | |

|---|---|---|

| Key challenges |

| |

| Solutions |

| |

| Stakeholders involved | Management of the two companies. | |

| Status of implementation | Implemented. | |

| Environmental savings |

| |

| Social benefits |

| |

| Financial aspects | Savings (USD/yr) | 5.39 billion VND VND/year in biomass costs reduction (231,420 USD/year). |

| Required investment | 2.6 billion VND (112,294 USD). | |

| Payback time | 3 months. | |

| Financing options | The investment was done by the energy company.Additional financing was provided by state incentives as described in Decree 04/2009/NĐ-CP (14/01/2009):

| |

| IS Opportunity. | Mutualization of the Use of Boilers between Three Companies. | |

|---|---|---|

| Key challenges |

| |

| Solutions |

| |

| Stakeholders involved | Management of the three companies involved. | |

| Status of implementation | Under implementation. | |

| Environmental savings |

| |

| Social benefits |

| |

| Financial aspects | Savings (USD/yr) | 25.2 billion VND (1,082,846 USD). |

| Required investment | 22.5 billion VND (966,113 USD) with OPEX of 17,742.3 million VND (762,388 USD). | |

| Payback time | 3 years. | |

| Financing options | Bank loan (60% of the total amount). As mentioned in Decree 82, the company could apply for a loan from the Vietnam Development Bank. The specific bank will be selected by the company. | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stucki, J.; Flammini, A.; van Beers, D.; Phuong, T.T.; Tram Anh, N.; Dong, T.D.; Huy, V.Q.; Hieu, V.T.M. Eco-Industrial Park (EIP) Development in Viet Nam: Results and Key Insights from UNIDO’s EIP Project (2014–2019). Sustainability 2019, 11, 4667. https://doi.org/10.3390/su11174667

Stucki J, Flammini A, van Beers D, Phuong TT, Tram Anh N, Dong TD, Huy VQ, Hieu VTM. Eco-Industrial Park (EIP) Development in Viet Nam: Results and Key Insights from UNIDO’s EIP Project (2014–2019). Sustainability. 2019; 11(17):4667. https://doi.org/10.3390/su11174667

Chicago/Turabian StyleStucki, Jérôme, Alessandro Flammini, Dick van Beers, Tran Thanh Phuong, Nguyen Tram Anh, Tran Duy Dong, Vu Quoc Huy, and Vuong Thi Minh Hieu. 2019. "Eco-Industrial Park (EIP) Development in Viet Nam: Results and Key Insights from UNIDO’s EIP Project (2014–2019)" Sustainability 11, no. 17: 4667. https://doi.org/10.3390/su11174667

APA StyleStucki, J., Flammini, A., van Beers, D., Phuong, T. T., Tram Anh, N., Dong, T. D., Huy, V. Q., & Hieu, V. T. M. (2019). Eco-Industrial Park (EIP) Development in Viet Nam: Results and Key Insights from UNIDO’s EIP Project (2014–2019). Sustainability, 11(17), 4667. https://doi.org/10.3390/su11174667