1. Introduction

Coal is the most abundant and important energy resource in China. It accounts for 71.7% and 67% of domestic primary energy production and consumption, respectively. It is unlikely that the contribution of coal to China’s energy supply will be significantly reduced in the immediate future. Currently, China’s annual coal production is about 3.5–4 billion tons, accounting for more than one-third of global coal production, of which about 2.5 billion tons originate from underground mining [

1,

2,

3].

Figure 1 shows the annual coal production in China [

4]. However, with the large-scale exploitation of coal resources, some damage to the ecological and geological (eco-geological) environment has inevitably occurred.

Studies of the eco-geological environment consider the relationship between the geological environment and ecology, including the influence of various geological bodies, geological processes, environmental changes, biological effects, and biological activities (mainly human activities) on the geological environment [

5]. Previous studies have revealed a negative relationship between human coal mining activities and the eco-geological environment, as follows. (1) There are more than half of China’s remaining coal under villages, railways, and surface water. About 8.76 billion tons of coal mining is affected by structures (villages and railways). (2) Currently, the land damaged by subsidence exceeds 1.1 million hm

2 and it is increasing at an annual rate of 30,000–40,000 hm

2 every year. (3) About 6 billion m

3 of mine water is annually discharged in China, but the utilization rate is only 31.87%. (4) The amount of CH

4 discharged through mine ventilation is currently 20–25 billion m

3 per year, which is about 300–400 million tons of greenhouse gases. (5) There are more than 1600 sites of gangue dumps in China, and more than 400 sites among them are burning. The weights of these gangue dumps are already more than 5 billion tons, and the areas of them cover more than 16,000 hm

2.

It can be seen that the underground coal mining process has caused serious and permanent destruction, including damage to ground structures, land subsidence and contamination, loss of water resources and pollution, and air pollution, as well as ecological degradation and imbalance [

1,

2,

3,

6]. The continuous decline in the quality of the eco-geological environment in mining areas seriously threatens the livelihoods of residents, and it hinders the sustainable development of resources and the environment. It has become a social and environmental problem that requires an urgent solution.

The international community has expressed much concern regarding how best to coordinate the relationship between the exploitation of coal resources and the protection of the eco-geological environment. As early as the 15th to 16th centuries, the impact of surface and strata movement that is caused by underground mining on human life and production was noted [

7]. In the early 15th century, disputes and lawsuits concerning mining-induced property damage were recorded in British courts. Belgium has enacted specific decrees on the damage to underground aquifers in Liege due to mining, and established a special committee in 1839 to investigate the damage, which led to the original “vertical theory” hypothesis of mining subsidence. In the 1970s, developed countries, such as the United States, Germany, Canada, and Australia, attached great importance to environmental protection and management in mining areas, and formulated a strict system of environmental protection and assessment. Good results were achieved by strengthening environmental management and land reclamation. In the 1980s, China enacted national regulations regarding damage control in mining. A code was established for leaving some coal pillars in place when mining under buildings, water bodies, railways, and in the main shaft of a mine. More systematic environmental investigations and research in mining areas began in the late 1990s, especially since the establishment of the Ministry of Land and Resources, which resulted in mining-induced eco-geological environmental damage attracting great attention. In the 21st century, the protection of the eco-geological environment has attracted increasing attention from governments and the mining industry with the proposal and implementation of the sustainable development strategy of the United Nations, and the related legislation has been strengthened. The integration of mineral resources development and environmental protection has become an important trend in the development of the international mining industry.

In recent years, many researchers have also conducted studies of the relationship between coal mining and eco-geological environmental protection.

Regarding the protection of land resources, Shi et al. [

8] investigated land subsidence disasters and their potential countermeasures. Zhou et al. [

9] analyzed the formation and development mechanisms of ground fissures based on the key stratum structure. Wang et al. [

10] reported the developing trend for the occurrence of ground subsidence disasters and also considered the countermeasures that are used to control them, with the Pingdingshan mining area being used as an example. Diao et al. [

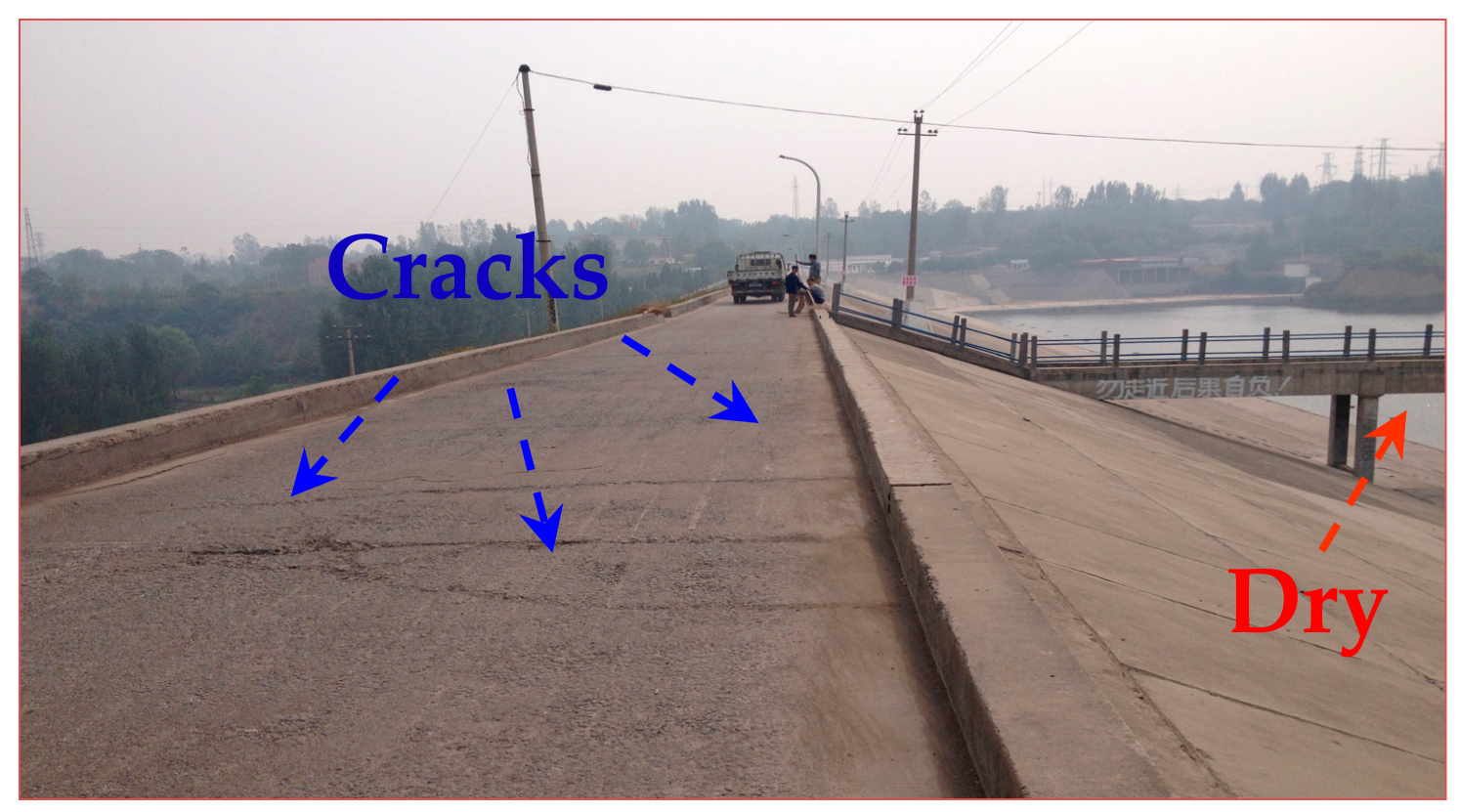

11] combined differential synthetic aperture radar (SAR) interferometry and the probability integral method to monitor the three-dimensional deformation of a mining area. Chen et al. [

12] conducted a series of field monitoring exercises and comparisons with previous studies, and acquired the evolutionary characteristics of dynamic subsidence parameters and surface cracks in fragile-ecological mining areas. Bai et al. [

13] analyzed the application of granular filling materials to reduce existing surface subsidence in the northwestern coal mining areas of China. Guo et al. [

14] studied the solid filling mining technique as a means of subsidence control and farmland conservation.

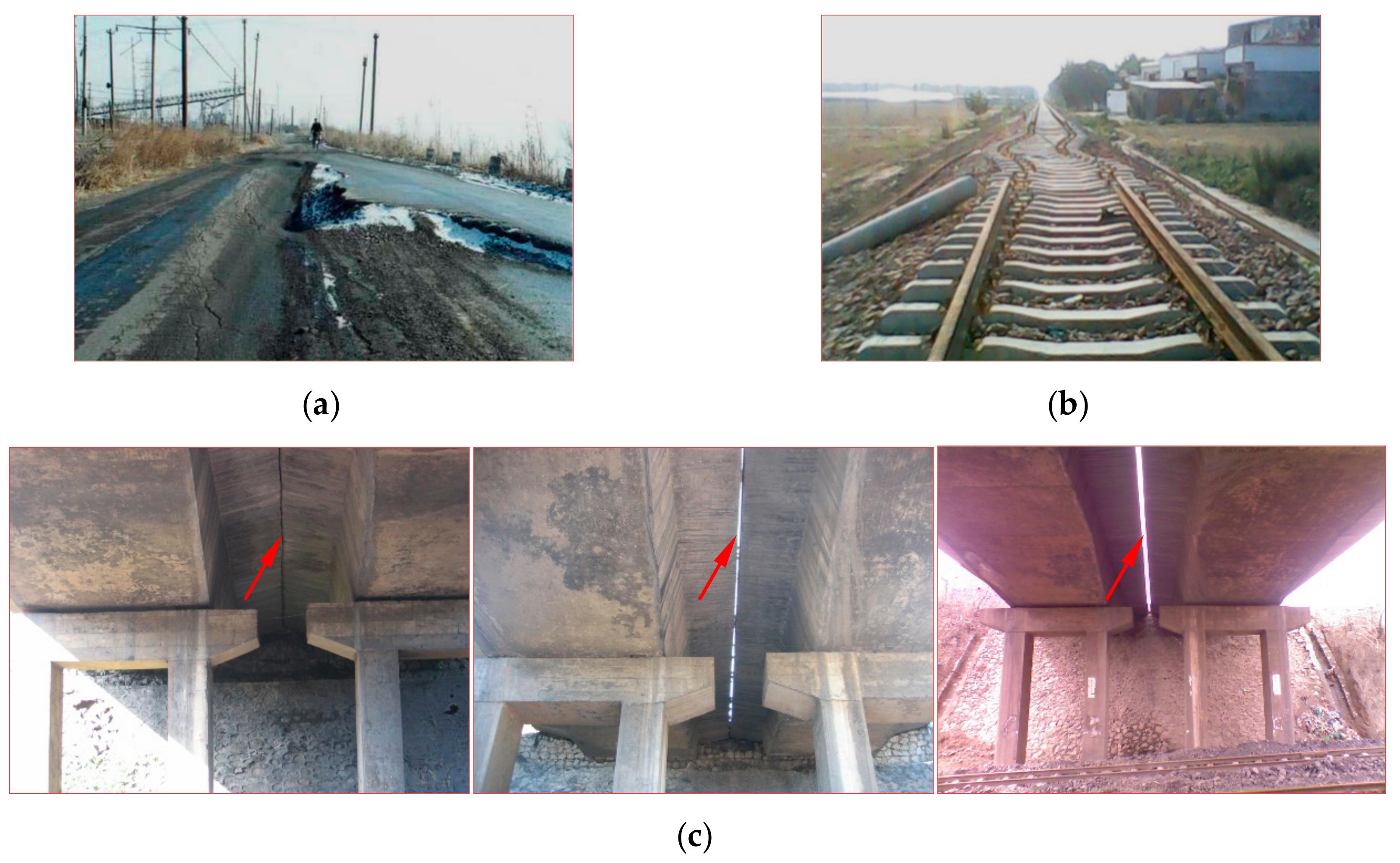

In a study of damage to structures, Diao et al. [

15,

16] evaluated the building damage in mining subsidence area by combining subsidence theory with a slope stability analysis, and assessed mining-induced damage to structures while using interferometric synthetic aperture radar (InSAR) time series analysis. Guo and Xu [

17] studied the feasibility of the in-situ reconstruction of houses in mining-affected areas. Strzalkowski [

18] considered the impact of mining based on an example of building deformation and damage. Djamaluddin [

19] evaluated ground movement and damage to structures in a coal mining area while using a new geographic information system (GIS) coupling model. Ostrowski [

20] predicted the probability of damage to building structures in mining areas using a logit model. Li et al. [

21] considered a mining scheme design for super-high water backfill strip mining, and was able to realize safe mining under buildings.

Regarding the protection of water resources, Guo et al. [

22] analyzed the interaction of surface and groundwater sources that were affected by mining while using hydrochemical and isotopic techniques. Xu et al. [

23] used a physical simulation to study strata failure and its impact on an overlying unconsolidated aquifer at various mining depths. Yin et al. [

24] built water inrush conceptual site models for coal mines, which provided a technical reference for preventing water inrush. Wang et al. [

25] studied the effect of coal field structure in controlling a mine water inrush, and proposed corresponding countermeasures, which had practical significance for mine water disaster control. Li et al. [

26] investigated the protection of surface water resources in a mining process under varying strata thicknesses. Qiao et al. [

27] discussed the effects of coal mining on shallow water resources in semi-arid areas. Wang et al. [

28] studied the mechanisms and evolution of control technologies that are used in water flow areas in long wall mining in shallow coal seams beneath gully topography. Wu et al. [

29] predicted and analyzed the mine water inflow and groundwater levels for coal mining operations in the Pangpangta coalfield. Yang et al. [

30] studied the technologies that are used for the in-situ purification of mine water in Shendong mining area.

Regarding the protection of natural ecology, Zhang et al. [

31] discussed the impact of coal mining and processing on the atmosphere, water, and other components of the ecological environment. Dai et al. [

32] studied the impact of mining on grassland ecosystems and the livelihoods of local people, using Inner Mongolia as an example. Yan et al. [

33] built a two-level extension comprehensive evaluation model for the evaluation of ecological environmental quality in mining areas, and chose a certain coal mining area to conduct applied research. He et al. [

34] evaluated the ecological security in a mining area that is based on the pressure-state-response framework, followed by the network analytic hierarchy process and gray relational analysis (PSR-ANP-GRAY). Dai et al. [

35] studied the characteristics of each phase of the whole coal life cycle, with the coal industry in China as an example, and conducted an ecological risk assessment. Xu et al. [

36] analyzed an ecological coal mining based dynamic equilibrium strategy to reduce pollution emissions and energy consumption. Hu et al. [

37] discussed the impact of coal resource exploitation on the eco-environment and its restoration in west China. Li et al. [

38] established a model and then evaluated the loss of ecosystem services in coal mining. Zhang et al. [

39] discussed the dynamic changes in soil and vegetation during the varying ecological recovery conditions of abandoned mines. Wright et al. [

40] conducted a 13-month study of mine drainage, water chemistry, and river ecology, with the aim of better understanding water pollution issues in closed coal mines.

Regarding environmental pollution that is caused by coal gangue and its utilization, Hua et al. [

41] analyzed the distribution and leaching characteristics of heavy metals in coal gangue, and evaluated its potential ecological risk. Gayday and Vaysman [

42] evaluated the negative impact of coal gangue on the ecological environment of a mining area and proposed some countermeasures. Guo et al. [

43] developed an approach to protect cultivated land from subsidence and mitigate the contamination from colliery gangue heaps. Xu et al. [

44] discussed the site selection of recycling facilities based on equilibrium strategy to mitigate coal gangue contamination. Lu et al. [

45] discussed the use of environment-oriented low-cost porous mullite ceramic membrane supports, which were fabricated from coal gangue and bauxite. Wei et al. [

46] studied the technologies that were used to synthesize a low-temperature, fast, single-firing body for porcelain stoneware tiles while using coal gangue. Wang et al. [

47] assessed the feasibility of using coal gangue and fly ash as a filling in slurry materials.

For the construction of green mines, Qi et al. [

48] simulated the sustainable effect of green mining construction policies on the coal mining industry in China. Qian et al. [

49] proposed the concept of sustainable mining, and developed a framework that was based on the five aspects of green mining, safe mining, efficient mining, economic mining, and energy saving, and low carbon. Huang et al. [

50] discussed green and sustainable mining based on the solid dense stowing-mining method. Chang et al. [

51] discussed the implementation of paste backfill mining techniques in Chinese coal mines. Ma et al. [

52] studied water-preserving mining techniques for shallow buried coal seams in ecologically vulnerable coal fields, taking the Shendong coal field as an example. Liu et al. [

53] proposed an integrated gas control and green mining technology for use in deep mines based on ultra-thin seam mining. Hao et al. [

54] explored the technologies that are used in mine land reclamation and ecological reconstruction, taking Shanxi Province as an example. Xiao et al. [

55] studied the technologies used in land reclamation and ecological restoration in resource-exhausted cities, taking Huaibei as an example.

Several researchers have conducted studies in specific technical fields, such as the damage to structures, land, water, and natural ecosystems that are caused by mining. However, the formation mechanism, characteristics, and current situation of eco-geological environmental damage, together with the corresponding mitigation measures, have not been systematically analyzed.

Mining-induced damage has not been effectively prevented in China’s mining areas due to the use of traditional concepts and technologies, and management problems. With the requirement for sustainable development throughout the international mining industry, it is necessary to systematically study eco-geological environmental protection and resource exploitation as a whole.

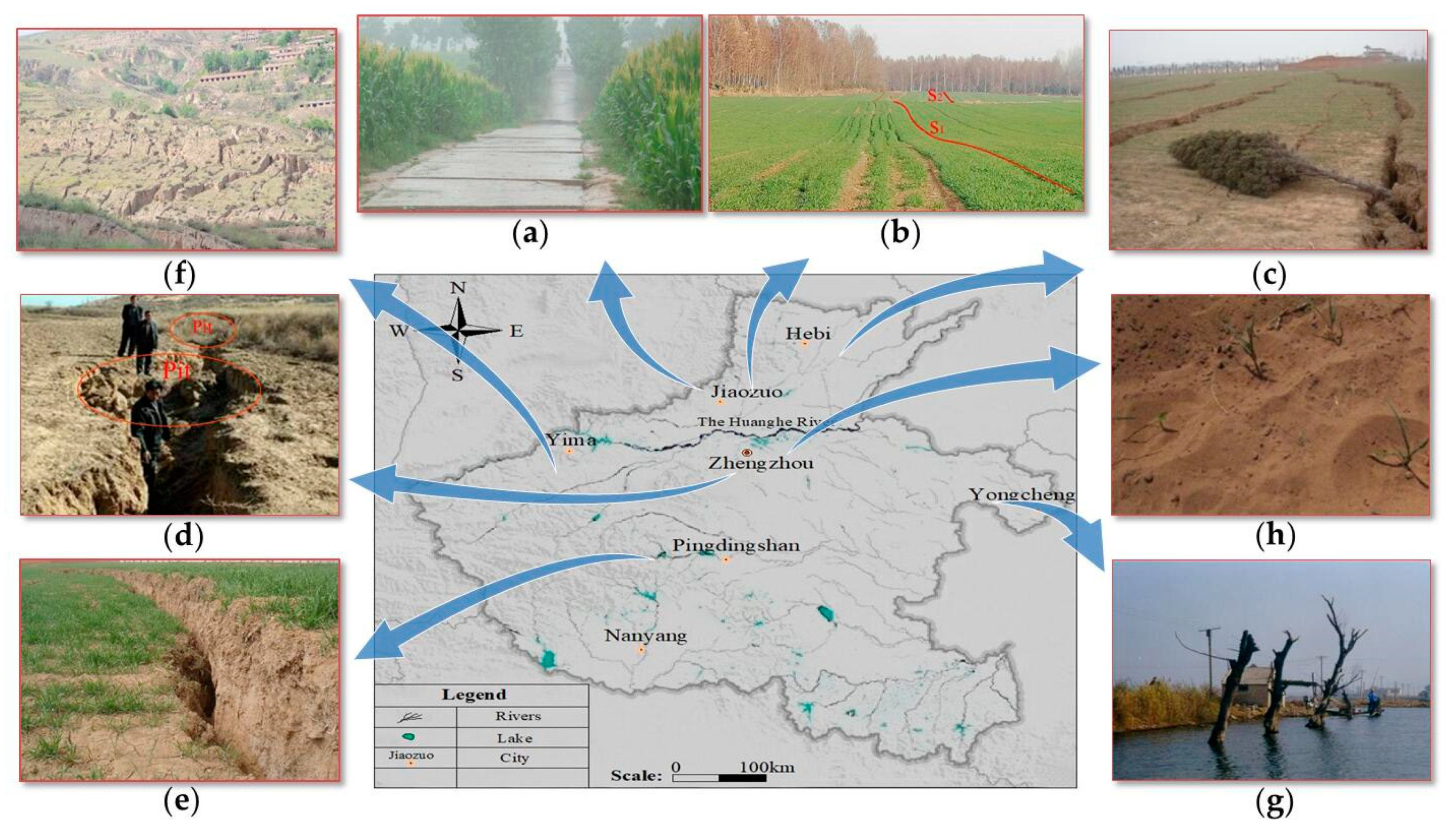

Henan Province is one of the 14 large coal bases planned by the Chinese state. Large-scale coal mining activities began in the early 20th century. The eco-geological environment of a mining area is complex and diverse, and the damage that is caused by underground mining is very serious. These conditions are representative of the mining-induced damage experienced in China. In this paper, first, the situation regarding the eco-geological environment and coal mining are introduced. Subsequently, the formation mechanism, types, characteristics, and status of mining-induced eco-geological environmental damage are discussed. Finally, appropriate mitigation measures are proposed.

4. Mitigation Measures for Environmental Damage from Coal Mining

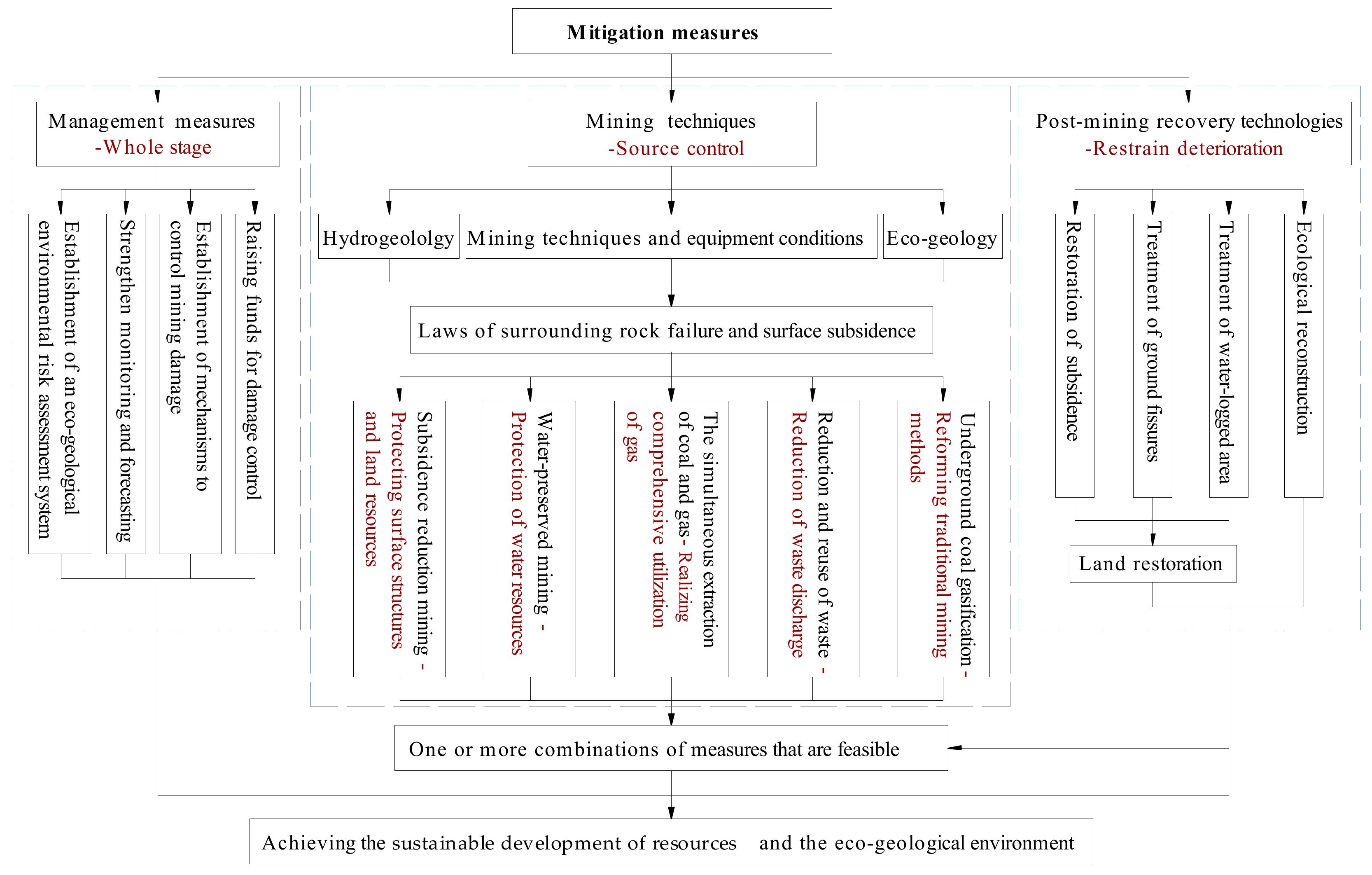

The eco-geological environment plays a vital role in the survival and development of human societies. However, conflicts between the exploitation of coal resources and the protection of the eco-geological environment have become increasingly prominent. Based on an analysis of the formation mechanisms and the characteristics of mining-induced damage, surrounding rock failure and surface subsidence have been determined to be the direct causes. The ongoing problems are due to inadequate management practices and the use of inappropriate mining techniques. The potential mitigation techniques mainly include the three aspects of management measures, mining techniques, and post-mining recovery technologies.

Figure 14 shoes the potential mitigation techniques.

4.1. Management Measures

4.1.1. Four Main Measures

(1) The establishment of an eco-geological environmental risk assessment system. The establishment of a risk assessment system is of great significance for coal mine safety production and environmental protection. Coal mining is characterized by damage to key ecological compartments (soil, structure, water, atmosphere, vegetation, etc.). Based on an analysis of the eco-geological environmental effects of coal mining, a comprehensive assessment index system (which can be constructed from the three dimensions of nature, society, and economy) can be established. Subsequently, according to a comprehensive assessment of the environmental quality in mining areas, a risk assessment model for the eco-geological environment in mining areas can be established. Finally, combined with relevant statistical data, and technical and economic indices, a risk assessment of the eco-geological environment in mining areas can be realized. The risk assessment should include the scope of the damage, as well as the type and nature of the corresponding damage control measures, which enables risk prediction to be realized and guidance to be produced [

33,

34,

35,

73].

(2) Strengthen monitoring and forecasting. The geological conditions within a coal mine are complex. Coal enterprises should strengthen their investigations of the hydrogeological and eco-geological environment of mines, analyze the formation mechanism of mining-induced damage, and then select the appropriate mining techniques to minimize the damage to the eco-geological environment. In the mining process, the monitoring and prediction of mining damage should be conducted to ensure that preventative and control measures are applied as soon as possible.

(3) Establishment of mechanisms to control mining damage. For damage control, the treatments that are applied should be timely and accurate. Scientific research institutes provide feasibility studies of possible mining damage control techniques and comprehensive treatment schemes have been designed. Coal enterprises and relevant departments should consult these reports and operate the necessary mining techniques and control the technologies accordingly. Thus, an efficient operational mechanism for coal mining damage control can be established.

(4) Raising funds for damage control. Opening up funding channels is the key towards the implementation of mining damage control. This should consistently follow the main principles of damage and control, damage, and compensation. It is mandatory for coal enterprises to include environmental restoration costs in the production costs of coal and to draw them in full and on time. Coal enterprises should establish and continually improve a feasible advance payment system for mining damage control projects by coordinating their resources, environment, and construction departments, so as to guarantee the availability of funds.

4.1.2. Applied Results of Management Measures

Appropriate management measures need to be applied through all stages of the coal mining process, which will guarantee pre-mining prevention, in-mining control, and post-mining recovery. The frequent occurrence of mining damage in China, the difficulty of restoring the ecological environment, and the difficulty of resolving social conflicts are closely related to this. Through dynamic comprehensive evaluation and risk assessment of ecological environment quality in Yanzhou mining area [

33], the results show that: first, the quality of the ecological environment in this mining area is level III, while the overall environmental management and environmental protection conditions are poor and they should be strengthened; second, the quality of land, air, and noise are poor in this mining area; third, the speed of the improvement of the quality of the ecological environment is relatively slow. Risk assessment measures provide a reference for the restoration of eco-geological environment in the mining area and point out the key points of the work in the future.

4.2. Mining Techniques

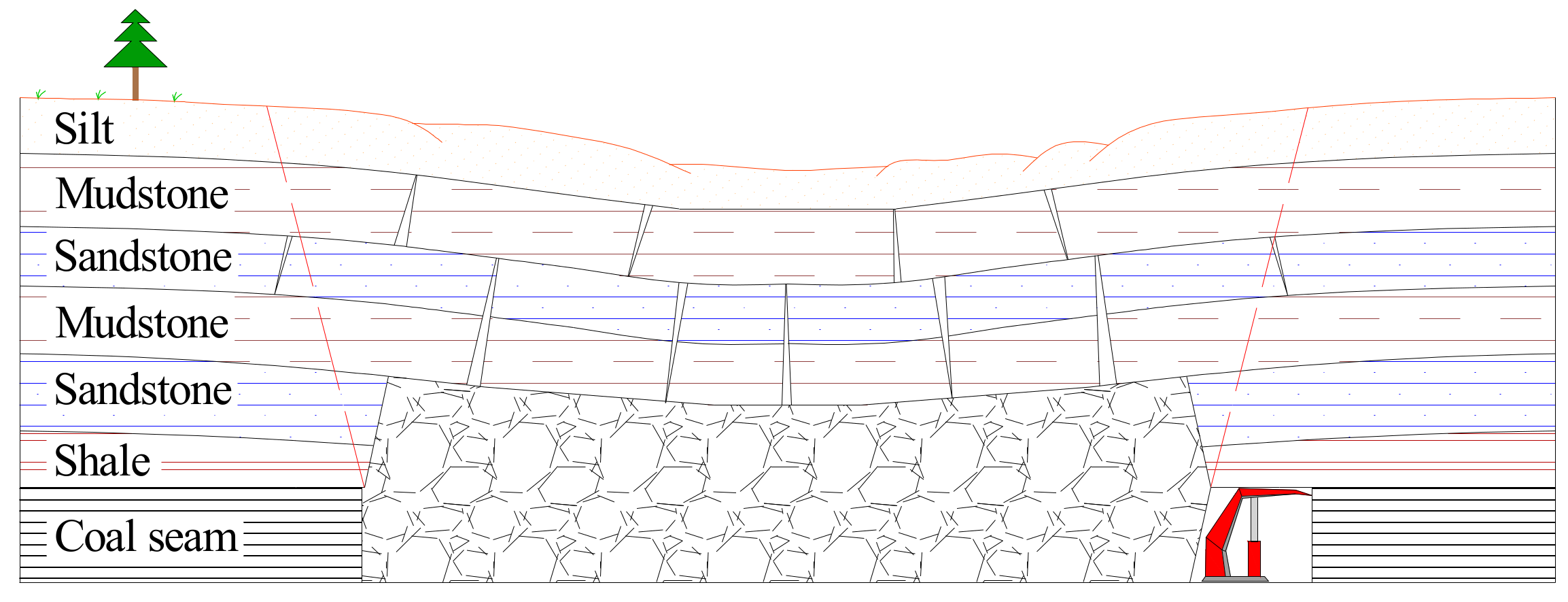

Mining-induced damage is mainly related to strata movement after mining, especially the deformation and failure of overlying strata [

62,

63]. Therefore, it is of great significance to study the law of deformation and the failure of overlying strata when selecting appropriate mining techniques and adopting the corresponding control technologies.

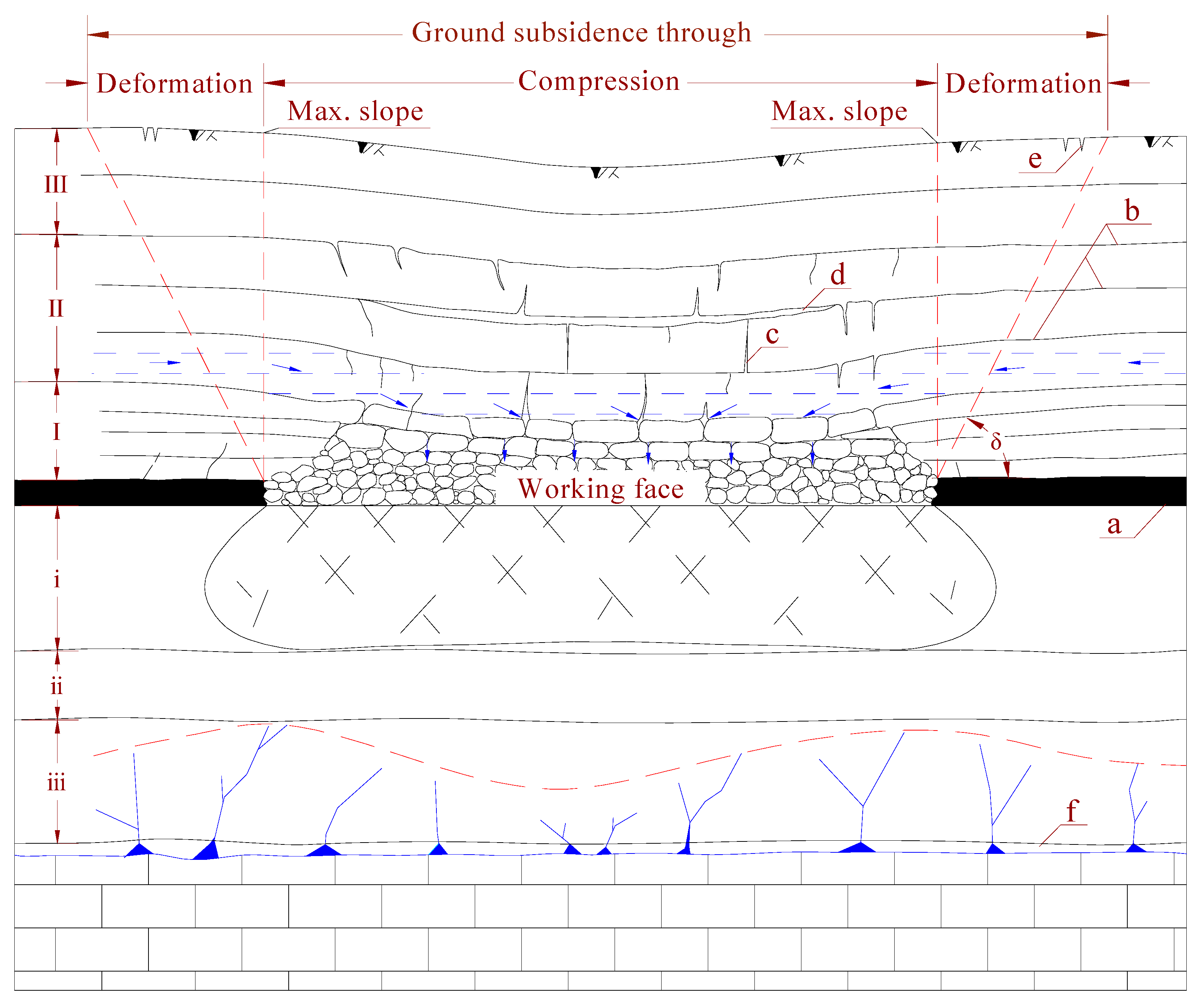

Figure 15 shows the characteristics of deformation and the failure of overburden, and the distribution of abutment pressure.

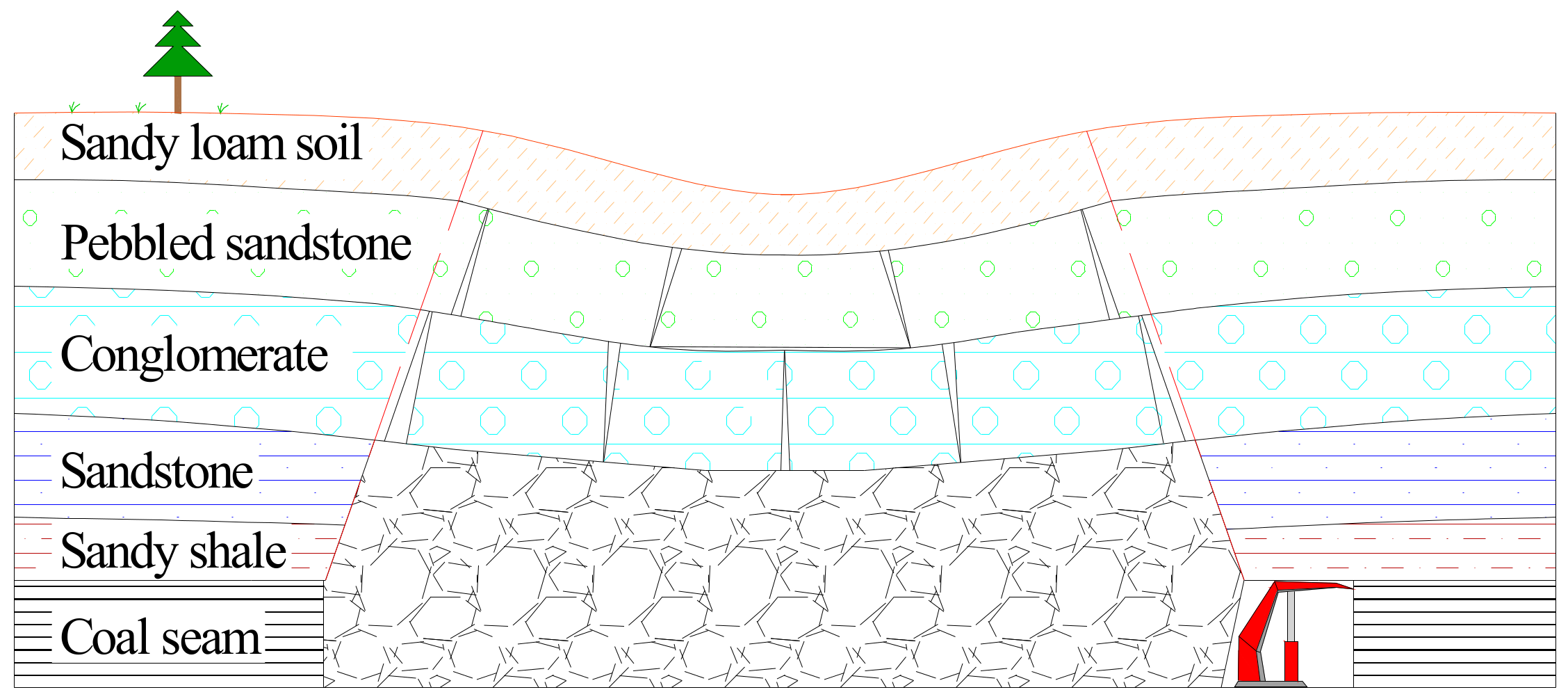

Figure 15 shows the arrangement of an underground coal mine longwall working face, which generally has a length of between 200–400 m. With the advance of the working face, the shearer excavates the full thickness of the coal seam. The hydraulic support moves forward with the advance of the working face and supports the roof over time. The overlying strata behind the support lose support and begin to deform and collapse, as follows.

(1) In the range of 30–40 m in front of and 2–4 m behind the working face, the strata are supported by coal seams and hydraulic supports. The vertical displacement of roof strata is very small, but the horizontal displacement is substantial. Tensile fracture occurs in the overlying strata behind the working face. This area is referred to as the coal seam support area (A).

(2) In the range of 2–4 to 30 m behind the working face, the strata lose the support of the coal seam and the roof rock strata are severely subsided and broken. The roof immediately begins to loosen and collapse, with the collapse being gradually transmitted upward to the main roof. The subsidence velocity of each stratum gradually decreases from a downward to upward direction, resulting in interlayer separation. This area is referred to as the overburden separation area (B).

(3) For 30 m behind the working face, to facilitate access to the coal seam, the fractured rock blocks are again supported by the caving rock. The subsidence velocity of each stratum gradually increases from a downward to upward direction, and the strata begin to compact each other. This area is referred to as the re-densing area (C).

(4) In the vertical direction, the overlying strata can be divided into a caving zone (I), fracture zone (II), and bending subsidence zone (III) (

Section 3.1 describes this in detail).

(5) Generally, there is a key stratum in the overlying strata, which has the characteristics of large thickness, high strength, and large bearing capacity. Its deformation and breakage will lead to the synchronous deformation and breakage of all or part of the overlying strata, and control the movement of all strata in part or up to the surface of the stope.

(6) Mining destroys the original stress equilibrium state of a rock mass, resulting in the redistribution of stress, forming different degrees of abutment pressure around the mining face. The abutment pressure along the direction in which the working face is advancing can be divided into a stress-concentration area (a), stress-relaxation area (b), and stress-stabilization area (c). The peak abutment pressure occurs in front of the working face to the coal wall in the limit equilibrium area (d). The peak point is 2–10 m away from the coal wall, and the peak value can reach 2–4 times γH. On the other side of the peak point of abutment pressure is the elastic area (e), where the coal and surrounding rock are in a state of elastic compression. The abutment pressure is generally distributed in the range of 30–60 m in front of and 40–120 m behind the working face, and it moves forward with the advancing working face.

By studying the law of rock movement and failure, combined with the key stratum theory [

74], and by investigating and researching mine hydrogeology, mining techniques and equipment conditions, and the eco-geological environment of the mining area, the most appropriate coal mining technique can selected to maintain the stability of the overburden or reduce the degree of damage and the height of overburden, which enables the harmonious development of coal mining, together with protection of the ecological environment.

The application of a suitable mining technique can be used to control damage at its source, which is the most direct, long-term, and effective means of control. According to the mechanism and characteristics of the damage to land, structures, water, and the atmospheric environment, the most suitable mining technique is mainly selected by considering the following aspects: (1) subsidence reduction mining for the protection of surface structures and land resources; (2) water preservation techniques for the protection of water resources; (3) mining techniques for the simultaneous extraction of coal and gas to realize the comprehensive utilization of gas; and, (4) mining techniques that will ensure waste emission reduction and reuse to reduce waste discharges.

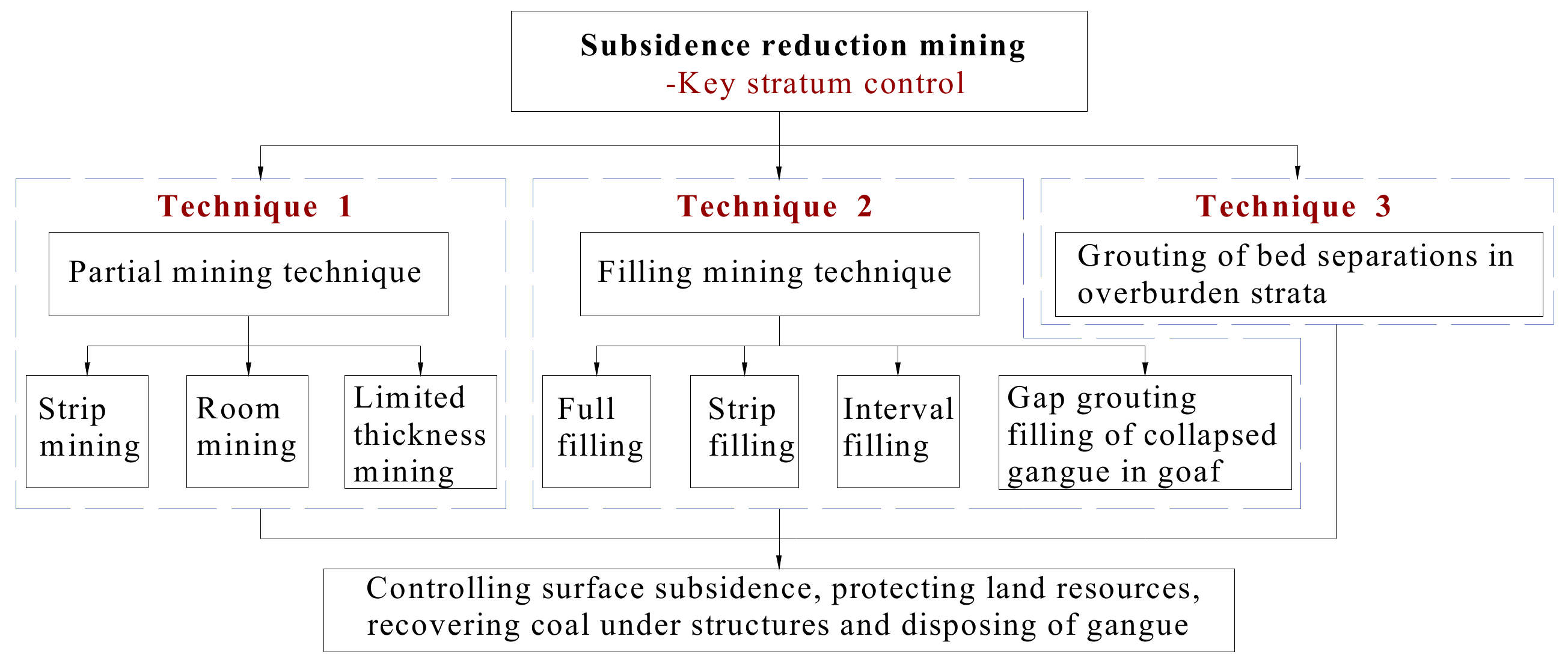

4.2.1. Subsidence Reduction Mining

Subsidence reduction mining is a technique to reduce the surface subsidence for the protection of land resources and ground structures. Previous studies have shown that [

75] the main key stratum of the overburden plays a controlling role in the process of surface movement, and the breakage of the main key stratum will lead to rapid surface subsidence. The rate of surface subsidence will sharply increase with the periodic breakage of the main key stratum. Therefore, by considering the studies of the fracture characteristics of the key strata and by selecting the appropriate mining technique, the long-term stability of the key strata of the overburden can be maintained; thus, controlling surface subsidence. Subsidence reduction mining generally consists of the partial mining technique, filling mine technique, and the grouting of bed separations in overburden strata.

Figure 16 shows a technical schematic of subsidence reduction mining.

- (1)

Partial mining

Partial mining techniques mainly include strip mining [

76], room mining [

77] and limited thickness mining [

78]. A “coal pillar—overlying strata-key strata” system is constructed to control the deformation of the overlying strata and surface, and consequently protect land resources, highways, and structures on the ground. However, there are some shortcomings, such as a low coal recovery rate and low mining efficiency.

- (2)

Filling mining

Filling mining [

13] involves filling the goaf in the process of coal mining, and constructing the structure system of “filling body-overlying strata-key strata” to control the deformation of overlying strata and surface. It is widely applied and it can be effective in areas where the overburden and surface deformation requirements are strict. It is widely used for the mining activities above confined aquifers and when mining under structures, water, and railways [

4].

According to the different filling materials, a variety of filling mining techniques, such as solid [

4,

14], paste [

51,

79], and high water material [

21], have been developed. However, the high cost, increased process flow, and low production efficiency have restricted its application.

Partial filling techniques [

80,

81], such as strip filling, interval filling, and gap grouting filling of collapsed gangue have been developed in recent years and can effectively balance the relationship between filling cost and overburden deformation and failure. The overburden is supported by the key stratum structure, filler material, and coal pillars; thus, controlling surface subsidence. Where conditions allow, coal gangue can be used as a filling material, which can effectively reduce the filling costs, while reducing land contamination by piled gangue.

- (3)

Grouting of bed separations in overburden strata

Filling materials can be injected into the overburden space by surface boreholes under high pressure according to the discontinuous characteristics of movement and deformation of overburden strata, which restricts the development of the overburden separation zone and protects key strata, thus realizing the control of surface movement and deformation.

Determining the location of key strata in overburden strata and mastering the characteristic parameters of separation and breakage are the basis of a feasibility analysis of the drilling arrangement, grouting process design, and the evaluation of subsidence reduction [

82]. Practice has shown [

3] that the effect of separated layer grouting is optimal when the key stratum is close to its initial breakage. The layout of boreholes and the optimal use of grouting to reduce subsidence should ensure that the key stratum never breaks.

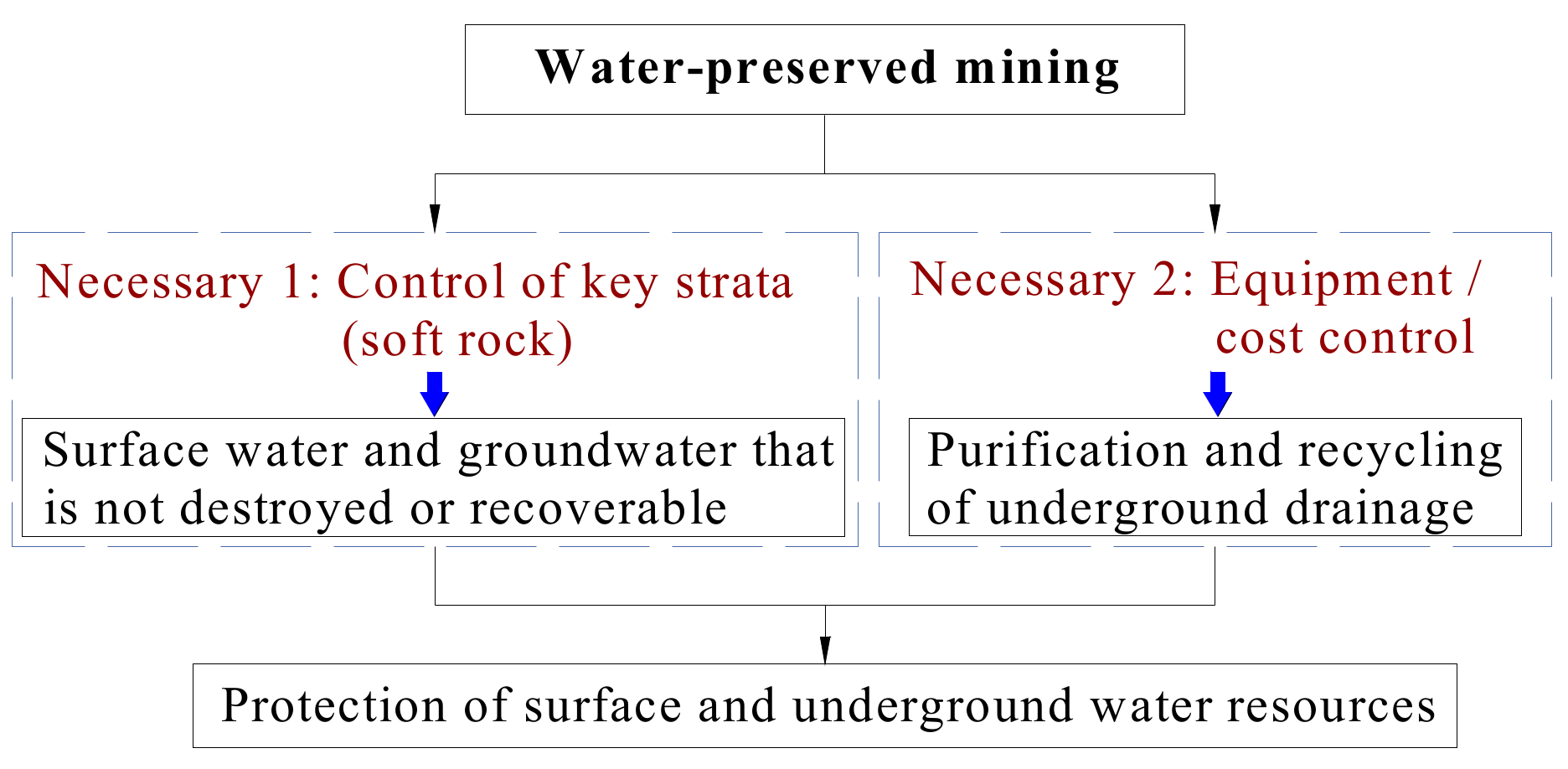

4.2.2. Water-Preserved Mining

After coal seam mining, surface subsidence will change the flow direction of surface water, and with the breakage of key strata in the overlying strata, groundwater in the region will form a descending funnel. By considering the failure law of overlying strata and the formation mechanism of a groundwater funnel after mining, and the taking measures to use appropriate mining methods and ground grouting, the disturbance to the hydrological environment in a mining area can be minimized, thus realizing water preserved mining.

Figure 17 shows the technical system of water-preserved mining.

Soft rock strata are the key strata for the study of groundwater seepage. They will be re-compacted with the advance of the working face, thus closing the fissures and forming an impermeable layer. With a rainwater recharge, the descending groundwater funnel will disappear and the groundwater level will be restored. The impact on surface ecology depends on the time interval between funnel formation and disappearance [

52]. Therefore, water-preserved mining mainly consists of two aspects, with one being surface-groundwater that is not destroyed or recoverable [

83], and the other being the purification and recycling of underground drainage [

30].

In recent years, the concept of a coal mine groundwater reservoir has been proposed and implemented, which provides a new way to solve the problems of water shortages and the destruction of the original groundwater system due to coal mining [

49,

84].

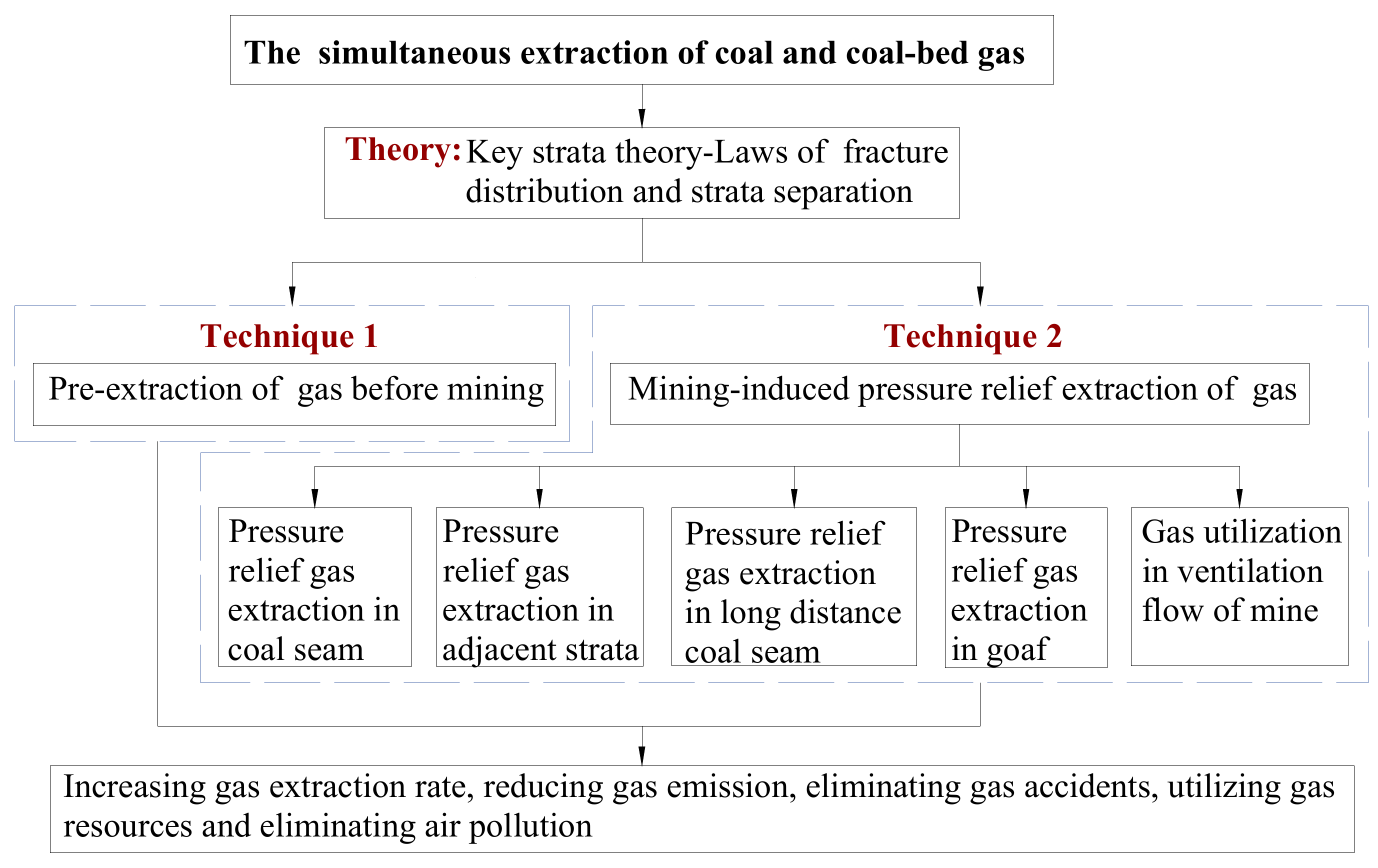

4.2.3. The Simultaneous Extraction of Coal and Gas

The simultaneous extraction of coal and gas means that both coal and coal-bed gas is exploited as a mine resource, effectively realizing the co-mining of the two resources [

85]. The effect of gas exploitation mainly depends on the original permeability of the coal seam. Practice has shown [

49] that the permeability of the coal seam will increase by tens to hundreds of times after the deformation and movement of strata, which creates conditions for gas migration and mining. The methods used to extract coal-bed gas can be divided into pre-extraction and mining-induced pressure relief extraction according to the theory of key strata in strata movement, and through the study of the distribution law of a joint fissure field and strata separation law in coal seam mining.

Figure 18 shows the technical system of the simultaneous extraction of coal and gas.

Through coal-bed gas extraction, not only can the risk of gas outbursts be eliminated regionally, but a high gas coal seam can also be converted into a low gas coal seam, and the mining efficiency of an outburst coal seam can be greatly improved. Since 1949, coal and gas outburst accidents have occurred more than 1500 times in China’s coal mines. In 2001, the number of deaths due to gas accidents reached 2356, accounting for 40% of the total deaths in Chinese coal mines [

86,

87]. In 2007, China’s coal-bed gas extraction capacity was 4.4 billion m

3. In the past ten years, great progress has been made in developing the theory and technology of the simultaneous extraction of coal and gas in China. In 2017, the gas extraction volume from coal mines in China was 17.8 billion m

3, which was four times higher than that in 2007. The number of gas accidents is also declining with the increase in coal-bed gas extraction. There were seven gas accidents in 2017, which was 90.7% lower than in 2007 [

88].

Figure 19 shows the volume of gas extraction and the number of gas accidents in China.

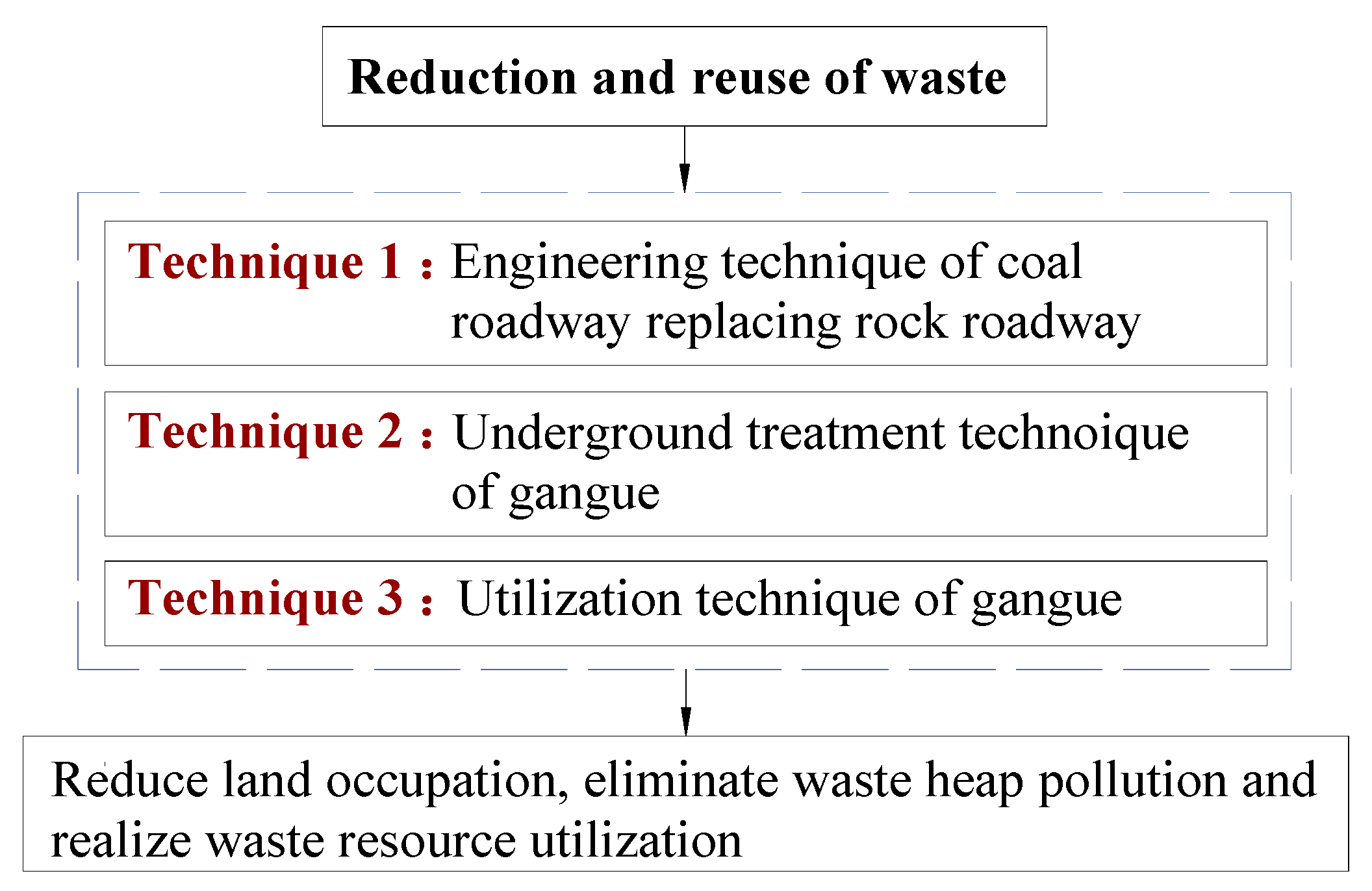

4.2.4. Reduction and Reuse of Waste

The reduction and reuse of waste can be used to minimize the discharge of waste from underground production, and to make comprehensive use of the extracted waste, which eliminates the accumulation of waste hills.

First, a coal roadway is used to replace a rock roadway in coal mining to reduce waste discharges from the source [

89]. Second, through the establishment of underground gangue transportation, storage, and filling systems, the gangue that is produced underground is directly filled into the goaf and abandoned roadways to realize filling mining [

4,

14]. Third, the comprehensive utilization of gangue can be realized while using gangue as a filling material for subsidence reduction or land reclamation, or for making building materials and other new materials, and generating electricity [

45,

46,

47].

Figure 20 shows the technical system of waste discharge reduction and reuse.

4.2.5. Underground Coal Gasification

Underground coal gasification [

86,

90,

91,

92] is a technology that transforms underground coal into combustible gas in situ through thermochemical reactions. This represents a fundamental change to traditional coal mining methods and it is integral to the technique of green mining. The application of this technology in coal mines not only greatly reduces the amount of underground engineering required and reduces the hard work conducted by personnel underground, but it also eliminates the environmental pollution that was caused by coal mining and the harm caused by coal combustion to the ecological environment.

Coal underground gasification was first proposed by William Siemens, a German scientist, in 1868, and it has a history dating back more than 100 years. After more than a century of development, researchers have conducted theoretical and practical studies of underground coal gasification, clean utilization of coal gas, and the environmental impact, including many field studies.

The underground coal gasifier includes mine type and drilling type according to the construction method. Mine gasification is generally applied to the recovery and utilization of waste coal resources in old mines. Drilling gasification is generally suitable for the mining of original coal seam. The revolutionary technology is the injection point retrogression gasification process that was proposed by the United States. This technology has been applied and developed in Australia and China, respectively.

4.2.6. Applied Results of Mining Techniques

The use of an appropriate mining technique is the most direct and effective way to solve the problem of eco-geological environment damage from coal mining. It is apparent that the overburden separation area is the transition area between the coal seam support area and the re-densing area, and is the area where mining damage is transmitted most intensely by considering the deformation and failure of overburden rock and the occurrence of abutment pressure, which is very important for the prevention and control of mining-induced damage (as shown in

Figure 15). While considering the theory of key strata, cracks and separation should be minimized and avoided in the mining process, and the integrity of key strata should be maintained, realizing the control of the surface by overlying strata.

- (1)

Subsidence reduction mining.

Filling mining is an important development in coal mining. The technique is relatively mature, and it can make use of a variety of materials. The field application effect and promotional value are remarkable. In the Zhucun mine of Jiaozuo mining area, the paste filling mining technique is applied to mining coal under villages [

79]. The thickness of coal mining is 1.3 m and the full filling is adopted. The maximum surface subsidence (

wmax) is 105 mm and the subsidence factor (

q) is 0.08. The maximum inclination of surface (

imax) is 1.2 mm·m

-1 and the maximum horizontal deformation (

εmax) is 1.0 mm·m

−1.

Partial mining technique, such as strip mining, room mining, and limited thickness mining, can effectively reduce ground subsidence by setting coal pillars and reducing coal mining volume.

Strip mining is widely used in China, and the result of subsidence reduction is obvious. In the Zhongxing coal mine of Shaanxi province [

76], the thickness of the coal seam is 5 m and the dip angle is 5 degrees. When the mining width is 100 m and the remaining width is 80 m, the maximum surface subsidence (

wmax) is 386 mm and the maximum horizontal movement (

umax) is 120 mm. The mining subsidence factor (

q) is 0.0775. Safe mining under buildings has been realized.

Room mining has been used throughout a considerable period of the history of coal mining worldwide, including the U.S., Australia, South Africa, India, and China. In the Shenfu-Dongsheng mining area, there are many Chinese room mining cases [

77]. The coal seam is buried within 150 m from the ground surface. After decades of exploitation, the coordinated development of coal resource and the environment has been realized. However, it is necessary to evaluate and monitor the stability of coal pillars in goaf and take protective measures. This technology is usually not used in rock burst mines.

Limited thickness mining is also applied in special mining conditions. Peigou coal mine of Zhengzhou mining area applies this technique to exploit coal under reservoirs [

78]. The total thickness of coal seam is 7.8 m. The mining limit is 5 m in the range of reservoir protection pillar and 2.8 m under dam. The maximum inclination of the dam (

imax) is 2 mm·m

−1, the maximum horizontal deformation (

εmax) is 3 mm·m

−1, and the maximum curvature (

kmax) is 0.01 × 10

−3·m−

1. The damage grade of the dam is within grade II.

Grouting of bed separations in overburden strata and coal mining in panel do not interfere with each other and have a good result of subsidence reduction. Huafeng coal mine has been grouted in separated zones by arranging continuous integrated grouting boreholes along the inclined direction beneath the thick conglomerate [

82]. The subsidence reduction efficiency of grouting reached at 44.6%, and 940,000 tons of coal resources were recovered.

Subsidence reduction mining has been applied in many areas of China with remarkable results. However, partial mining has low recovery coefficients, which is a serious waste of resources. Due to the non-renewability of coal resources, they should be used as little as possible when conditions permit.

- (2)

Water-preserved mining.

The control of weak strata is the key in this technique, because it directly determines the degree of leakage and the recovery rate of overburden water. In Bulianta coal mine of Shendong mining area [

83], the protections of overlying aquifer and surface ecological environment are realized by adopting the method of rapid advance of panel and combining with special measures, such as reducing mining height, backfilling, and grouting.

The concept of establishing a groundwater reservoir is novel, and it has been applied in the field. In the Shennan mining area, shallow groundwater resources are exhausted due to mining cracks. By using the goaf water storage (water volume is about 2.1 million m

3), the water demand of industry, ecology, and agriculture is satisfied [

84]. There are currently 32 coal mine underground reservoirs that have been built in the Shendong mining area. They provide more than 95% of the water used in the mining area, supporting the coal mining industry and protecting the underground water resources in water-deficient areas [

30,

49].

- (3)

Simultaneous extraction of coal and gas.

Gas extraction can prevent gas outburst and realize resource utilization, which has been widely used in methane mines in China. In the application of pre-extraction of gas before mining [

87], through six months’ pre-extraction in Jiangjiahe coal mine, the gas extraction volume reached 3.53 million m

3, and the gas content of coal in a panel decreased from 8.32–8.52 m

3·t

−1 to 2.53–3.75 m

3·t

−1. In the application of mining-induced pressure relief extraction of gas, the Huainan mining area has achieved remarkable results through ten years of exploration: (1) the mechanization of coal mining increased from 30% to 85%; (2) mining panel has been reduced from 70 to 35, but coal production has increased from 10 million tons to nearly 60 million tons; (3) the maximum annual production of fully mechanized panel increased from 0.6 million tons to 5 million tons; (4) the recovery rates of resources in mining area and a panel are 85% and 95% respectively; (increased from 5%; and, (5) the gas extraction volume increased from 10 million m

3 to 250 million m

3, the extraction rate to 48%, and the mortality rate of million tons decreased from 4.01 to about 0.1 [

86].

Although the current extraction theory has been extensively studied and many extraction methods have been developed, there are still many problems that need to be solved due to the complexity of underground hydrogeological conditions. Due to the importance of eliminating regional outbursts, the amount of time that is consumed in gas extraction construction accounts for more than 80% of the preparation work of the whole panel, and regional outburst elimination work lasts for 2–3 years. This not only increases the costs of mining, but it also significantly hinders the normal production of a mine.

- (4)

Waste discharge reduction and reuse.

The replacement of rock roadway by coal roadway can effectively reduce waste discharge, greatly improve construction speed, and reduce mining costs. Xinxing coal mine adopts the technique when preparing new mining area [

89]. The length of roadway excavation is 1820 m; the construction period is shortened by 10 months; the cost is reduced by 37.49 million yuan; and, more coal is produced by 5.1 million tons.

The application of underground treatment technique of gangue not only reduces or even eliminates the corresponding damages, but it also realizes the reuse and recycling of wastes. In Xingtai and Huayuan coal mines, gangue is used as filling material of solid dense stowing-mining method [

50]. The average subsidence rate (subsidence depth/seam mining height) of Xintai coal mine was about 19.43 mm·m

−1, and in Huayuan coal mine area it was about 38.47 mm·m

−1.

Gangue can be used not only for underground filling and land reclamation, but also for making new materials, such as building bricks, ceramic bricks, ceramic membrane supports, etc., realizing resource utilization [

45,

46,

47]. Moreover, the reduction in the volume of waste discharged can effectively solve the problems land contamination and environmental pollution.

- (5)

Underground coal gasification.

Underground coal gasification technology has obvious advantages in the mining of compressed coal under buildings, and the exploitation of inferior and abandoned coal resources when traditional mining methods cannot be used or are restricted by economic conditions. At present, underground coal gasification has been extensively studied and tested in Russia, the United States, Canada, China, Australia, and other countries. The underground gasification process of “long passage, large cross section, and two stages” that was proposed by the China University of Mining and Technology has been widely used in the Xuzhou, Xinwen, Xiyang, and Tangshan mining areas, and it has achieved good results [

86,

91]. However, there are several problems that remain. First, the large burned-out area left by the underground coal after gasification mining will cause surface subsidence, destruction of water resources, and landslides. Second, the ash that is produced by underground coal gasification is soaked and leached in groundwater, which results in the diffusion, pollution, and poisoning of groundwater resources by carcinogenic benzene and phenol.

Therefore, in the treatment of the burned-out area, it is first necessary to use a filling technology to fill the burned-out area, ensure the controlling role of the key strata in the overburden structure, and solve the problem of surface subsidence. It is also necessary to use a water-filling dissolution method to extract pollutants from the ash, reduce the concentrations of the remaining pollutants, and protect the groundwater resources.

4.3. Post-Mining Recovery Technologies

In areas where the eco-geological environment has been destroyed, it is particularly necessary to undertake remediation measures to promote the restoration of the ecological environment and realize the coordinated development of the economy, society, and environment. There are two main steps in post-mining recovery. The first is land restoration that is based on preventing surface subsidence and cracks, and the control of water-logging, and the second is ecological reconstruction.

4.3.1. Land Restoration

- (1)

Treatment of surface subsidence and water-logging.

1) Drainage. In subsidence areas with shallow ground subsidence and low groundwater levels, a drainage system can be established to reduce the groundwater level, and land restoration can be realized by combining surface renovation projects. This method only requires small amounts of engineering, has a high efficiency, and it does not change the original use of the land. However, the long-term management of water conservancy facilities is needed to prevent flooding. This method is limited by its application conditions and it can only be applied to a small number of gently sloping areas, where coal mining subsidence has occurred.

2) Deep excavation and shallow filling. In a subsidence area with deep ground subsidence and a high groundwater level, this method can be used to further excavate the deep subsidence area. The extracted soil can then be used to fill the shallow subsidence area. After reclamation, the subsidence area can be used for fish farming and as agricultural land. This method is simple to operate, has wide applicability, large economic benefits, and remarkable ecological benefits. Therefore, it is widely used in the reclamation of mining subsidence land.

3) Filling. This method is a reclamation method for treating a subsidence area with filling materials. It requires the filling materials to not cause secondary pollution to the land. Generally, with the exploitation and utilization of coal, there are large volumes of fly ash and gangue wastes in coal mining areas. The processing of fly ash [

93] and gangue [

94] can be used to fill the collapse area. This not only realizes the reclamation of subsidence land, but it also utilizes the solid wastes that are produced by mining. Therefore, this treatment has the optimal economic benefits.

4) Direct use. For large-scale perennial water-logged subsidence areas, especially areas with deep water-logging or unstable subsidence, fish farming, storage of flood water as an irrigation water source, and water parks can be developed to fully utilize the land [

64].

- (2)

Treatment of ground fissures.

1) Phytoremediation. Phytoremediation is an artificially induced restoration, based on “soil and water conservation—optimum plant coordinated planting—rhizosphere environment improvement” [

95]. This method is mainly aimed at crack treatment to ensure the closure of a uniform subsidence area. The vegetation used should be drought-tolerant and barren-land resistant plants, such as grasses and shrubs.

2) Engineering restoration. The main engineering restoration treatments are grouting, filling, and reclamation. This method is mainly aimed at the treatment of obvious cracks in non-uniform subsidence areas. Large cracks are first treated by engineering restoration, and the land is then restored by phytoremediation technologies.

3) Synchronization of mining and restoration. This is a combination of active protection and restoration. First, during mining, the uniform subsidence area should be enlarged as far as possible to mitigate the impact of mining. Subsequently, with the emergence of subsidence cracks, there should be a timely filling and plugging to protect the ecological conditions of the soil, which thereby reduces the impact on ecosystems and speeding up ecological restoration.

4.3.2. Ecological Reconstruction

For land restoration, ecosystem health, and environmental safety are the goal. The ecological environment can be reconstructed by applying the theories of ecology, biology, environment, agriculture, economics, and systems engineering, and by following the principles of species symbiosis and material recycling, and then adopting the ecological engineering technologies of three-dimensional planting and food chain structure [

55,

69,

96]. It is of great practical and strategic significance to alleviate the conflict between people and land, ensure food security, improve the living environment, and promote the harmonious development of people and nature.

4.3.3. Applied Results of Post-Mining Recovery Technologies

Various technologies are necessary for the restoration of the damaged eco-geological environment, which are also the key to preventing further deterioration of the environment.

In view of the situation of surface subsidence and cracks, soil erosion, and vegetation degradation, Shendong mining area adopts filling, combining with natural restoration, phytoremediation, engineering restoration, and synchronization of mining and restoration, to gradually restore the land ecology of the mining area [

95]. In the Pingdingshan mining area, measures of drainage, deep excavation and shallow filling, land reclamation, and transformation were adopted to recover the damaged land for perennial and seasonal water accumulation areas [

10]. The filling reclamation model with fly ash or gangue as filler has been widely used in the Henan mining area, Huaibei mining area, and Fushun mining area, and it has achieved remarkable results [

69].

In view of the ecological damage that is caused by mining, Huaibei city and Suzhou city, through the investigation and analysis of surface subsidence and ecological destruction, adopted land reuse and ecological reconstruction measures to improve the ecological environment of mining areas [

55,

96]; Yangquan mining area uses gangue for land reclamation, which makes the comprehensive index of ecological effects of landscape ecology reach 0.3615, and it maintains the stability of the mining area landscape [

94]; Pingdingshan mining area develops three-dimensional ecological agriculture in the subsidence area, strengthens the comprehensive utilization of coal gangue, and improves the ecological environment of mining area [

10].

5. Discussion and Conclusions

5.1. Discussion

In this paper, aiming at the problem of mining-induced eco-geological environmental damages, Henan Province is taken as an example for investigation and study. At present, lots of scholars mainly focus on a specific technical field of mining damage research, such as the prevention and control of structure damage, gangue filling subsidence reduction mining technique, and so on. However, there are few systematic and comprehensive analyses on the formation mechanism, determination methods, types, characteristics, and status of mining-induced eco-geological environmental damages.

Analyzing the transmission characteristics of deformation and the failure of overlying and floor strata in the vertical direction revealed the formation mechanism of mining-induced damage. The failure of the roof formed an “upper three zones”. Correspondingly, the floor formed the “lower three zones”. It is of great practical significance to study the height of each zone and the main types of disasters that could potentially occur to enable the production of guidance and mitigate mining-induced damages.

The main types of mining-induced eco-geological environmental damage could be summarized as damage to surface structures, land resources, water resources, air, and the natural ecology. The types and characteristics of mining-induced damage could be summarized based on the geological, geomorphological, and mining conditions.

Through the analysis of mining-induced eco-geological environmental damages, combined with the research results of many scholars in specific technical fields, mitigation measures were proposed. Most importantly, mitigation measures are the key part in this paper, which mainly includes management measures, mining techniques, and post-mining recovery technologies. In addition, the applied results of mitigation measures are also presented, respectively, and the results show that the mitigation effect is very good.

In general, the formation mechanism, types, and characteristics of mining-induced damage investigated in this study have universal adaptability to similar mining and eco-geological conditions in the coal mining areas. The mitigation measures also provide a technical reference for preventing mining-induced damage and speeding up ecological restoration in mining areas with similar conditions. With the progress of science, the available mitigation measures are continuously developing. Mining techniques, as the most critical step to control environmental damage, should be considered to be an important research and development direction to achieve green and efficient mining. Mining damage in China is extensive, with many restoration projects that are large and time-consuming. New technologies and methods should be constantly explored to ensure the timely recovery of damage and achieve the harmonious development of resources and the environment.

5.2. Conclusions

(1) Henan Province is one of the 14 large-scale coal bases in China, which is located in the transitional zone between the second and third terrain ladders of China and it spans two tectonic units. The geological features and ecological environmental characteristics display wide spatial variations throughout this district, which is an ecologically fragile region of stepped transition type.

(2) Based on the condition of the eco-geological environment and the coal mining industry in Henan mining area, the formation mechanism of mining-induced damage is analyzed. The destruction characteristics and status of ground structures, land resources, water resources, the atmospheric environment, and natural ecology induced by coal mining in Henan Province are discussed, respectively.

(3) The mitigation measures are presented, i.e., management measures, mining techniques, and post-mining recovery technologies. The analysis of mining-induced eco-geological environmental damage and mitigation measures is of importance for the prevention of eco-geological disasters, and the promotion of efficient and environmentally sustainable exploitation of coal resources.