Water Degradation by China’s Fossil Fuels Production: A Life Cycle Assessment Based on an Input–Output Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Defining Indicators of Water Degradation Intensities

2.2. Life Cycle Assessment via a Mixed-Unit Input–Output (MUIO) Model

2.3. Assessing the Dilution Water and Grey Water Footprint

2.4. Data Sources

3. Results and Discussion

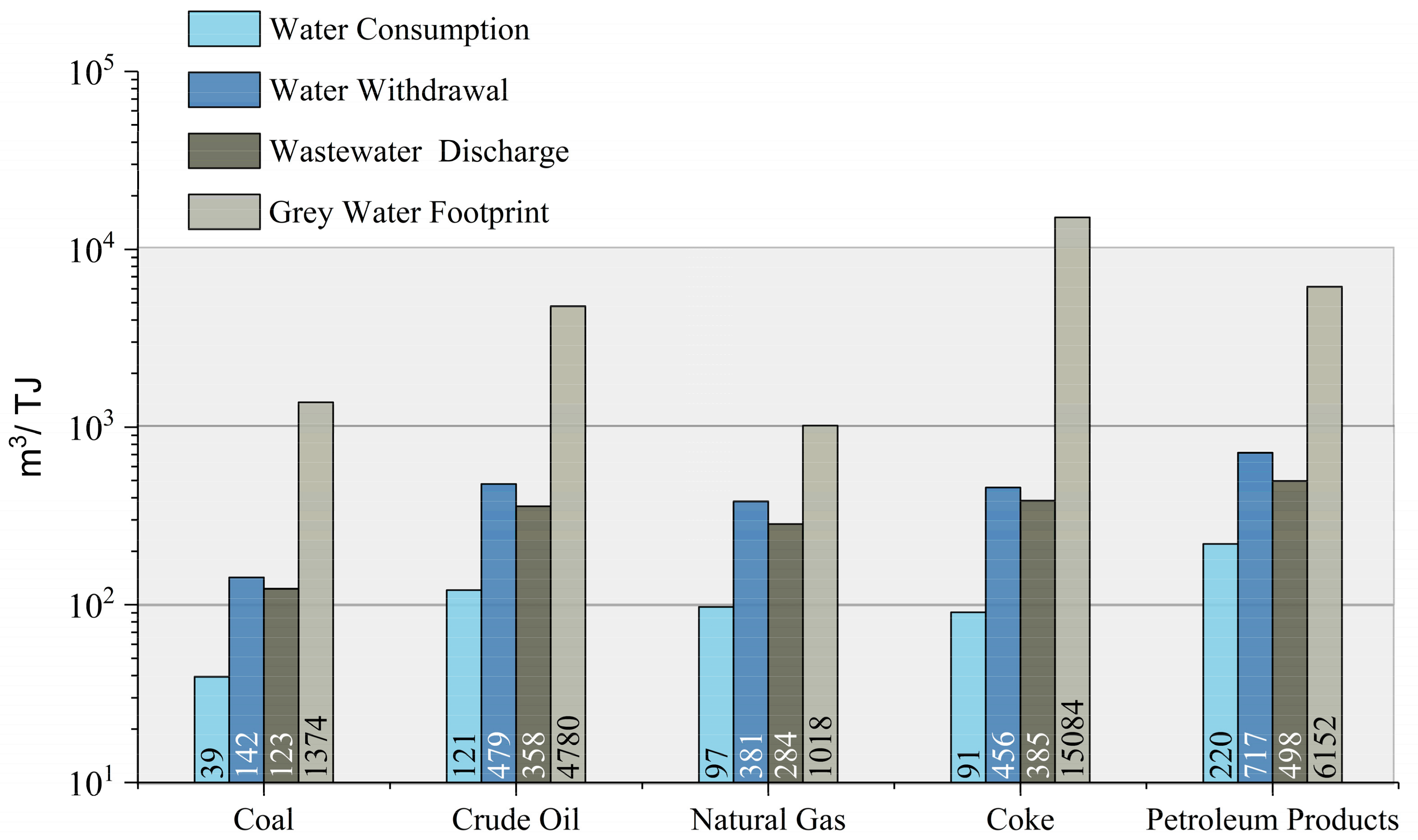

3.1. Water Depletion and Pollution in the Life Cycle of Fossil Fuel Production

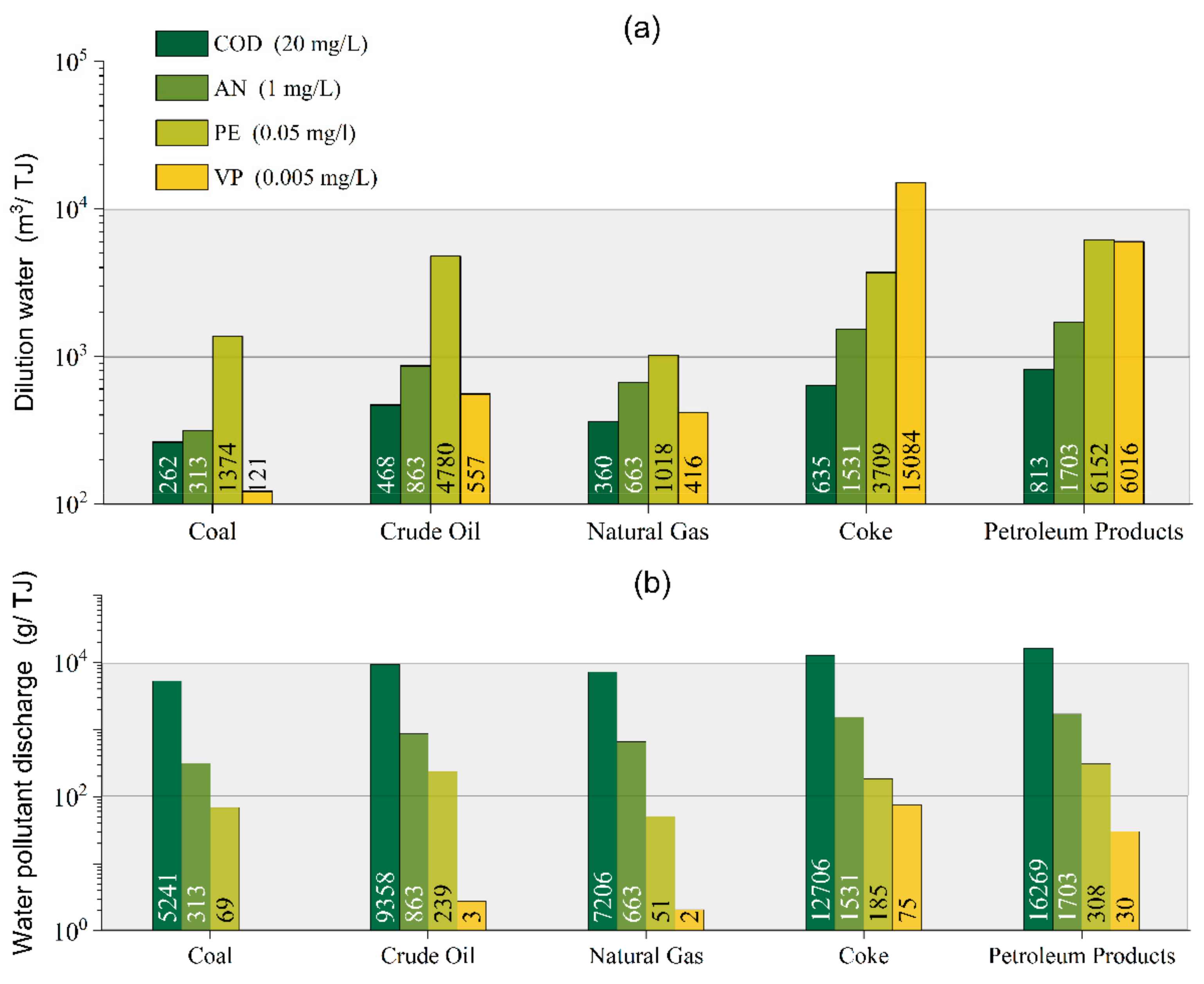

3.2. Water Pollutants in the Life Cycle of Fossil Fuel Production

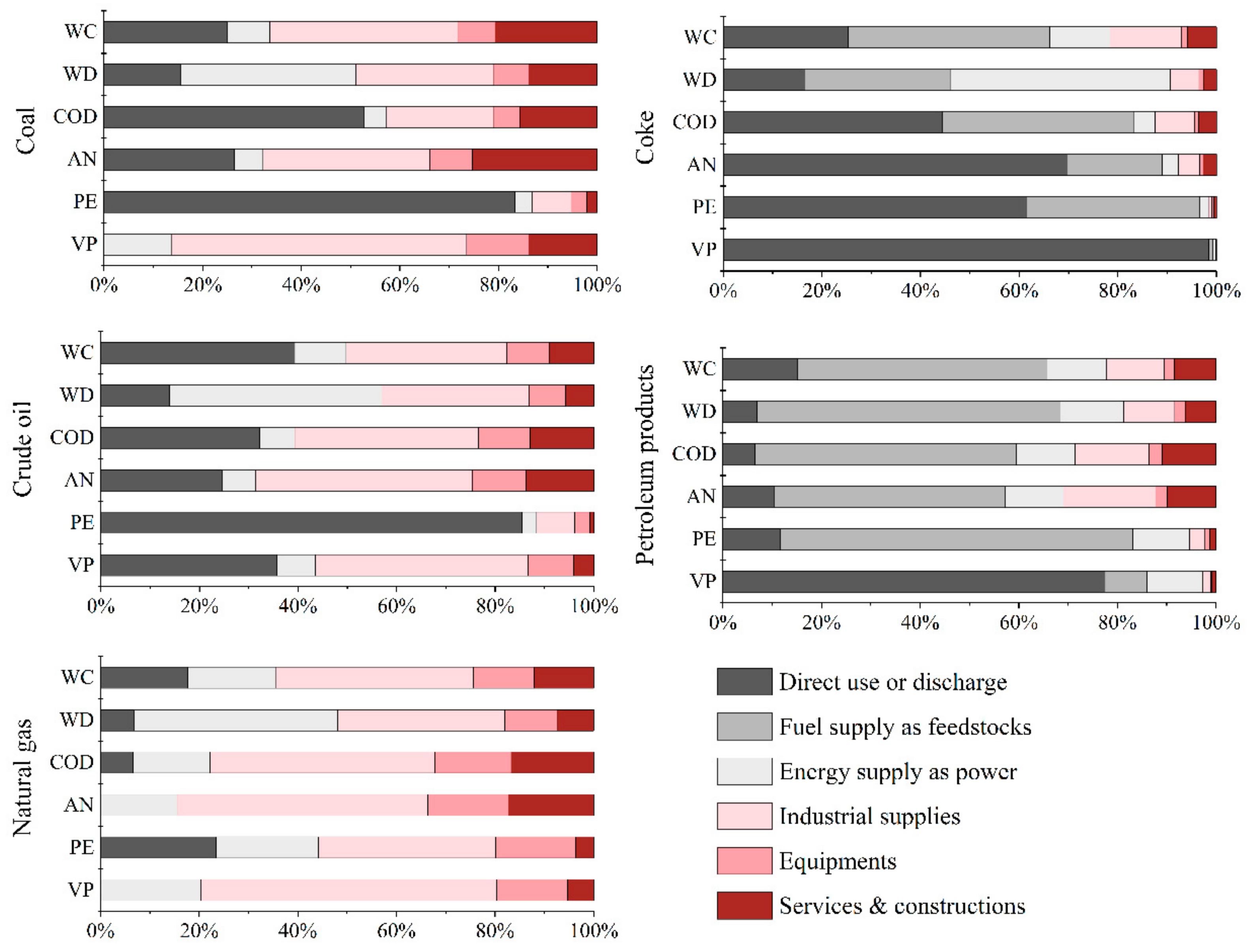

3.3. Sectoral Shares of Life Cycle Water Depletion and Pollution from Fossil Fuel Production

3.4. The Performance of Water Saving and Pollution Mitigation of Fossil Energy Industries

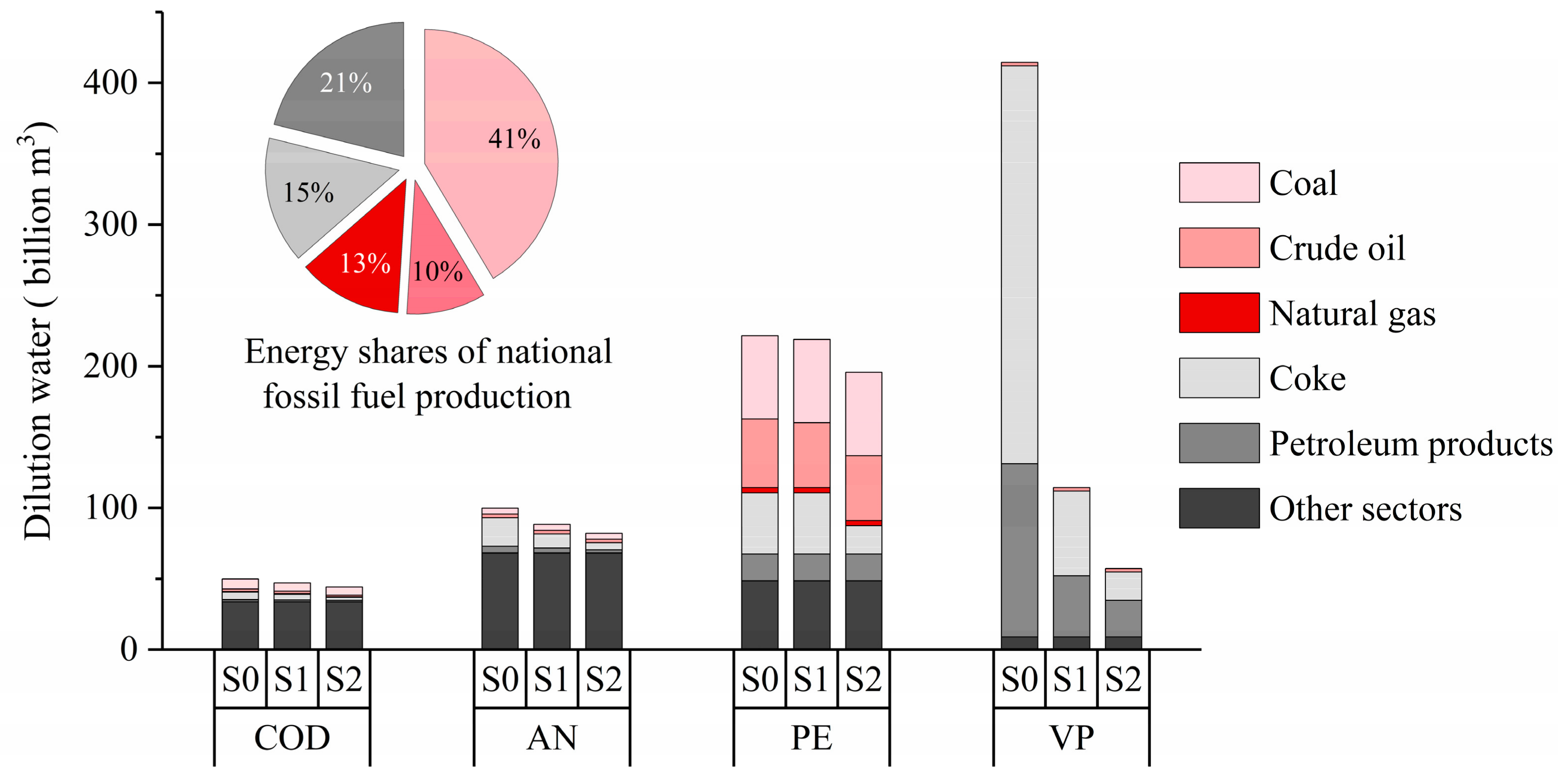

3.5. Scenario Analysis for Water Pollution from Fossil Fuel Sectors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- U.S. Energy Information Administration (EIA). International Energy Outlook. 2018. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 17 July 2019).

- Wang, C.Y.; Li, P.G.; Liu, Y. Investigation of water-energy-emission nexus of air pollution control of the coal-fired power industry: A case study of Beijing-Tianjin-Hebei region, China. Energy Policy 2018, 115, 291–301. [Google Scholar] [CrossRef]

- Qin, Y.; Curmi, E.; Kopec, G.M.; Allwood, J.M.; Richards, K.S. China’s energy-water nexus—Assessment of the energy sector’s compliance with the “3 Red Lines” industrial water policy. Energy Policy 2015, 82, 131–143. [Google Scholar] [CrossRef]

- Pan, L.Y.; Liu, P.; Ma, L.W.; Li, Z. A supply chain based assessment of water issues in the coal industry in China. Energy Policy 2012, 48, 93–102. [Google Scholar] [CrossRef]

- Zhang, X.X.; Liu, J.G.; Tang, Y.; Zhao, X.; Yang, H.; Gerbens-Leenes, P.W.; van Vliet, M.T.H.; Yan, J.Y. China’s coal-fired power plants impose pressure on water resources. J. Clean. Prod. 2017, 161, 1171–1179. [Google Scholar] [CrossRef]

- Shang, Y.; Lu, S.; Li, X.; Hei, P.; Lei, X.; Gong, J.; Liu, J.; Zhai, J.; Wang, H. Balancing development of major coal bases with available water resources in China through 2020. Appl. Energy 2016, 194, 735–750. [Google Scholar] [CrossRef]

- Xu, M.; Li, C.; Lu, S. Sustainable Water Resources Utilization on Energy Industry Based on the Gray Water Footprints Assessment in Hunan Province. Energy Procedia 2017, 105, 3758–3764. [Google Scholar] [CrossRef]

- Zakrutkin, V.; Sklyarenko, G.; Gibkov, E.; Reshetnyak, O.; Rodina, A. Environmental Problems of Coal-Mining Territories (Water Pollution). In International Multidisciplinary Scientific GeoConference; Surveying Geology & Mining Ecology Management (SGEM): Sofia, Bulgaria, 2016; pp. 87–93. [Google Scholar]

- Annual Report of China’s Environmental Statistics 2016; Ministry of Environmental Protection of China: Beijing, China, 2017.

- Chai, L.; Liao, X.W.; Yang, L.; Yan, X.L. Assessing life cycle water use and pollution of coal-fired power generation in China using input-output analysis. Appl. Energy 2018, 231, 951–958. [Google Scholar] [CrossRef]

- Liu, J.G.; Zhao, D.D.; Gerbens-Leenes, P.W.; Guan, D.B. China’s rising hydropower demand challenges water sector. Sci. Rep.-UK 2015, 5, 11446. [Google Scholar] [CrossRef] [PubMed]

- Lin, G.; Jiang, D.; Duan, R.; Fu, J.Y.; Hao, M.M. Water Use of Fossil Energy Production and Supply in China. Water 2017, 9, 513. [Google Scholar] [CrossRef]

- Gerbens-Leenes, W.; Hoekstra, A.Y.; van der Meer, T.H. The water footprint of bioenergy. Proc. Natl. Acad. Sci. USA 2009, 106, 10219–10223. [Google Scholar] [CrossRef] [PubMed]

- Ding, N.; Liu, J.; Yang, J.; Lu, B. Water footprints of energy sources in China: Exploring options to improve water efficiency. J. Clean. Prod. 2018, 174, 1021–1031. [Google Scholar] [CrossRef]

- Liao, X.; Hall, J.W.; Eyre, N. Water use in China’s thermoelectric power sector. Glob. Environ. Chang. 2016, 41, 142–152. [Google Scholar] [CrossRef]

- Zhang, C.; Zhong, L.; Fu, X.; Wang, J.; Wu, Z. Revealing Water Stress by the Thermal Power Industry in China Based on a High Spatial Resolution Water Withdrawal and Consumption Inventory. Environ. Sci. Technol. 2016, 50, 1642–1652. [Google Scholar] [CrossRef] [PubMed]

- DeNooyera, T.A.; Peschel, J.M.; Zhang, Z.X.; Stillwell, A.S. Integrating water resources and power generation: The energy-water nexus in Illinois. Appl. Energy 2016, 162, 363–371. [Google Scholar] [CrossRef]

- Byers, E.A.; Hall, J.W.; Amezaga, J.M. Electricity generation and cooling water use: UK pathways to 2050. Glob. Environ. Chang. 2014, 25, 16–30. [Google Scholar] [CrossRef]

- Fthenakis, V.; Kim, H.C. Life-cycle uses of water in U.S. electricity generation. Renew. Sustain. Energy Rev. 2010, 14, 2039–2048. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Gerbens-Leenes, P.W.; Hoekstra, A.Y. The consumptive water footprint of electricity and heat: A global assessment. Environ. Sci. Water Res. Technol. 2015, 1, 285–297. [Google Scholar] [CrossRef]

- Siddiqi, A.; Anadon, L.D. The water-energy nexus in Middle East and North Africa. Energy Policy 2011, 39, 4529–4540. [Google Scholar] [CrossRef]

- Shang, Y.Z.; Hei, P.F.; Lu, S.B.; Shang, L.; Li, X.F.; Wei, Y.P.; Jia, D.D.; Jiang, D.; Ye, Y.T.; Gong, J.G.; et al. China’s energy-water nexus: Assessing water conservation synergies of the total coal consumption cap strategy until 2050. Appl. Energy 2018, 210, 643–660. [Google Scholar] [CrossRef]

- Hawkins, T.; Hendrickson, C.; Higgins, C.; Matthews, H.S.; Suh, S. A mixed-unit input-output model for environmental life-cycle assessment and material flow analysis. Environ. Sci. Technol. 2007, 41, 1024–1031. [Google Scholar] [CrossRef]

- Zhang, C.; Anadon, L.D. Life cycle water use of energy production and its environmental impacts in China. Environ. Sci. Technol. 2013, 47, 11467–14459. [Google Scholar] [CrossRef] [PubMed]

- Standard of Surface Water Quality in China; Ministry of Environmental Protection of China: Beijing, China, 2002.

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual. Earthscan 2011, 31, 181–182. [Google Scholar]

- Zeng, Z.; Liu, J.; Savenije, H.H.G. A simple approach to assess water scarcity integrating water quantity and quality. Ecol. Indic. 2013, 34, 441–449. [Google Scholar] [CrossRef]

- Liu, C.; Kroeze, C.; Hoekstra, A.Y.; Gerbens-Leenes, W. Past and future trends in grey water footprints of anthropogenic nitrogen and phosphorus inputs to major world rivers. Ecol. Indic. 2012, 18, 42–49. [Google Scholar] [CrossRef]

- Guan, D.; Hubacek, K.; Tillotson, M.; Zhao, H.; Liu, W.; Liu, Z.; Liang, S. Lifting China’s water spell. Environ. Sci. Technol. 2014, 48, 11048–11056. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Yang, Z.; Liu, G.; Casazza, M.; Yin, X. Analyzing virtual water pollution transfer embodied in economic activities based on Gray Water Footprint: A case study. J. Clean. Prod. 2017, 161, 1064–1073. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Global grey water footprint and water pollution levels related to anthropogenic nitrogen loads to fresh water. Environ. Sci. Technol. 2015, 49, 12860–12868. [Google Scholar] [CrossRef]

- Cai, B.; Wang, C.; Zhang, B. Worse than imagined: Unidentified virtual water flows in China. J. Environ. Manag. 2017, 196, 681–691. [Google Scholar] [CrossRef]

- Cazcarro, I.; Duarte, R.; Sánchez-Chóliz, J. Downscaling the grey water footprints of production and consumption. J. Clean. Prod. 2016, 132, 171–183. [Google Scholar] [CrossRef]

- Wu, B.; Zeng, W.; Chen, H.; Zhao, Y. Grey water footprint combined with ecological network analysis for assessing regional water quality metabolism. J. Clean. Prod. 2016, 112, 3138–3151. [Google Scholar] [CrossRef]

- Liao, X.W.; Chai, L.; Xu, X.F.; Lu, Q.; Ji, J.P. Grey water footprint and interprovincial virtual grey water transfers for China’s final electricity demands. J. Clean. Prod. 2019, 227, 111–118. [Google Scholar] [CrossRef]

- Feng, K.S.; Hubacek, K.; Pfister, S.; Yu, Y.; Sun, L.X. Virtual Scarce Water in China. Environ. Sci. Technol. 2014, 48, 7704–7713. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Chen, B. Tracking inter-regional carbon flows: A hybrid network model. Environ. Sci. Technol. 2016, 50, 4731–4741. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, Y.; Chen, B. Multiregional input–output and ecological network analyses for regional energy–water nexus within China. Appl. Energy 2017, 227, 353–364. [Google Scholar] [CrossRef]

- Liao, X.; Chai, L.; Ji, J.; Mi, Z.; Guan, D.; Zhao, X. Life-cycle water uses for energy consumption of Chinese households from 2002 to 2015. J. Environ. Manag. 2019, 231, 989–995. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhong, L.; Liang, S.; Sanders, K.T.; Wang, J.; Xu, M. Virtual scarce water embodied in inter-provincial electricity transmission in China. Appl. Energy 2017, 187, 438–448. [Google Scholar] [CrossRef]

| Coal | Crude Oil | Natural Gas | Petroleum Products | Coke | |

|---|---|---|---|---|---|

| Heating value (MJ/kg) | 20.41 | 41.84 | 53.07 | 42.04 | 28.56 |

| Indicators | Coal Mining and Washing | Oil and Gas Extraction | Oil Refining and Coking | Industry Total |

|---|---|---|---|---|

| Ratio of expense on wastewater treatment to industry profit | 12% | 7% | 7% | 3% |

| Expense of wastewater treatment per unit volume of wastewater (¥/m3) | 1.06 | 3.12 | 5.17 | 1.54 |

| Recycle rate of water use | 56% | 80% | 94% | 90% |

| Recycle rate of wastewater | 23% | 94% | 11% | 59% |

| Removal rate of COD | 65% | 97% | 88% | 86% |

| Removal rate of AN | 64% | 91% | 90% | 82% |

| Removal rate of PE | 70% | 99% | 97% | 94% |

| Removal rate of VP | 75% | 98% | 98% | 98% |

| Fossil Fuel Extraction Sectors | COD | AN | PE | VP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AVG | STD1 | STD2 | AVG | STD1 | STD2 | AVG | STD1 | STD2 | AVG | STD1 | STD2 | |

| Coal | 86.0 | 70.0 | 70.0 | 2.6 | 25.0 | 15.0 | 1.8 | 5.0 | 5.0 | 0.0 | 0.5 | 0.5 |

| Crude oil | 156.2 | 150.0 | 100.0 | 11.0 | 25.0 | 15.0 | 10.6 | 10.0 | 10.0 | 0.1 | 0.5 | 0.5 |

| Natural gas | 56.6 | 150.0 | 100.0 | 0.0 | 25.0 | 15.0 | 1.4 | 10.0 | 10.0 | 0.0 | 0.5 | 0.5 |

| Coke | 107.2 | 80.0 | 40.0 | 20.3 | 10.0 | 5.0 | 2.2 | 2.5 | 1.0 | 1.4 | 0.3 | 0.1 |

| Petroleum products | 64.3 | 60.0 | 50.0 | 10.8 | 8.0 | 5.0 | 2.2 | 5.0 | 3.0 | 1.4 | 0.5 | 0.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Liang, Y.; Chai, L.; Han, Z.; Ma, S.; Lyu, J.; Li, Z.; Yang, L. Water Degradation by China’s Fossil Fuels Production: A Life Cycle Assessment Based on an Input–Output Model. Sustainability 2019, 11, 4130. https://doi.org/10.3390/su11154130

Su Y, Liang Y, Chai L, Han Z, Ma S, Lyu J, Li Z, Yang L. Water Degradation by China’s Fossil Fuels Production: A Life Cycle Assessment Based on an Input–Output Model. Sustainability. 2019; 11(15):4130. https://doi.org/10.3390/su11154130

Chicago/Turabian StyleSu, Yuqi, Yi Liang, Li Chai, Zixuan Han, Sai Ma, Jiaxuan Lyu, Zhiping Li, and Liu Yang. 2019. "Water Degradation by China’s Fossil Fuels Production: A Life Cycle Assessment Based on an Input–Output Model" Sustainability 11, no. 15: 4130. https://doi.org/10.3390/su11154130

APA StyleSu, Y., Liang, Y., Chai, L., Han, Z., Ma, S., Lyu, J., Li, Z., & Yang, L. (2019). Water Degradation by China’s Fossil Fuels Production: A Life Cycle Assessment Based on an Input–Output Model. Sustainability, 11(15), 4130. https://doi.org/10.3390/su11154130