1. Introduction

The circular economy among the leading contemporary economy trends considers the environmental issues and sustainability of the business. Its definitions and concepts have differed in most research studies, including Geissdoerfer et al. [

1]. Based on the relevant research studies [

1,

2,

3], the circular economy is defined as a closed-loop system, in which the production resources, environmental losses, and energy leakages are minimized. Various strategies and techniques have been proposed and implemented in order to minimize the usages and losses of these resources.

The usages and productions of refurbished products are all the representative activities of circular economy. The sales of refurbished products and their relevant supply chains activities are among the most frequently applied circular economy techniques. While many research studies have provided several effective remanufacturing/refurbishing processes and techniques, most of these studies have been limited in the domain of plants and the factory planning level. This shows that more expanded agendas (e.g., the investments and strategies for gathering recycling components) have been studied less comparatively. This paper provides a new and effective production planning framework that considers additional recycling investments strategies in order to overcome these issues. While the existing strategies (e.g., additional installment of collecting facilities, special promotion for the gatherings or recycling exchange compensation) may boost the collection of more recycling components, excessive investments might harm the corporate or business profits. This paper considers both the collection strategies and current production constraints in tandem with the proposed integrated framework.

The proposed framework characteristics are summarized while considering more vague uncertainties and the embedded nonlinearities. While a general process planning has several uncertainties, including unclear demand and supply abilities, the circular economy-based process planning should consider the more expanded uncertainties, together with the return rates of the recycling modules. Additionally, the prediction time horizon for the return rate is not aligned with the overall production planning time horizon. It results from the fact that the gathering of the recycling modules mainly depends on the number of products sold prior. Subsequently, its gathering pattern has the typical nonstationary characteristics. Moreover, the efforts for enhancing the return rate for obtaining a considerable number of recycling modules exponentially increase. This tendency can be through nonlinear cost functions of recycling investments.

This paper integrates these characteristics when considering the economic and environmental viewpoints through stochastic programming approaches. The embedded uncertainties are captured while using time-series data analyses and the relevant probabilities. Nonlinear profit and cost structures are modelled while using fitted nonlinear functions. The integrated model is a type of stochastic nonlinear programming models. A more effective and accurate solving method is required for the proposed framework, while numerous research studies provided effective solving techniques. In order to solve the circular economy-based process planning including the assertion of gathering investments for refurbished modules, this paper provides an integrated stochastic programming framework while using Monte-Carlo’s sample average approximation and the memetic algorithm. The framework is implemented for a software program supporting circular economy-based production planning, so as to prove the effectiveness and solving techniques of the proposed framework. Its effectiveness is then tested through comparisons of the results under various scenarios and analyses in this study.

The following section presents the relevant background information and literature reviews.

Section 3 describes the strategic decision framework and the mathematical model supporting the circular economy.

Section 4 proposes the efficient algorithms for the suggested framework. Ultimately, its effectiveness is confirmed with the implementation of the framework and its numerical analyses in

Section 5.

2. Background and Literature Review

Circular economy is a main stream economy concept that is being fronted by every government, municipality, and corporation, as highlighted in the previous section. Circular economy has emerged fast with cooperative movements and regulations, while similar concepts and activities have been discussed and implemented widely since 2000. Numerous research studies have defined the term Circular Economy (CE) and categorized it while using various concepts.

Table 1 shows the recent CE concepts, keywords, and main ideas. These studies can be considered through integrations and modifications of the past former CE studies.

While several studies have discussed the concepts and definitions of the circular economy, the next phase is on how to enhance the current CE. These issues are related to the detailed activities for CE. Ellen MacArthur Foundation (EMF) [

6] used as a main referencing source for many CE research studies, categorizes these activities into six phases: Reuse, Repair, Refurbishment/Remanufacturing, Repurpose, and Recycling. Although the recycling method is the broadest CE activity among them, most of existing activities are too ineffective to generate an executable production planning. “Refurbishment/Remanufacturing” is focused more as the main CE activity in this paper, since this study focuses on an executable circular economy-based production planning.

Many research studies examined production planning frameworks on the remanufacturing processes. Savaskan et al. [

10] provided a price strategy for a refurbished product and Kim et al. [

11] developed a strategic pricing framework for a closed loop supply chain while using the remanufacturing process.

Table 2 summarizes the characteristics of the current production planning frameworks in regards to the remanufacturing processes.

However, most of the research studies ignore investments and the relevant activities that enhance the product circularity. Existing research studies examine a production planning while using already recycled products or an estimation of the amount. While the additional investments for increasing return rate for End-of-Life (EOL) part are comparatively ignored, they establish mathematical programming models within fixed ranges of the returning rates. Consequently, the subsequent uncertainties (e.g., customers’ uncertainty and modeling parameters) are modeled into fuzzy logic-based mathematical programming or nonlinear programming models. As described in the previous section, the existing studies fail to incorporate efforts for enhancing products’ or modules’ circularity in their production planning. In this paper, these strategies are classified as “passive investment strategies for remanufacturing”. The efforts or investment to enhance return rates for EOL parts are needed in order to actively enhance CE. However, the bulk of the existing papers have ignored these efforts and their economic analyses. As a result, this paper suggests an integrated framework that simultaneously considers existing production constraints and investments for the refurbished product’s circularity. For this concept, the proposed framework is classified as “active investment strategies for remanufacturing”.

The quantifying efforts for computing the circularity have been attempted by a number of research studies. Cullen [

4] provided a circularity measure with (1) based on the amount of the recovered EOL material.

Linder et al. [

17] modified (1) while using the economic values as a product-level circularity measure. However, these research studies are limited by the fact that the efforts used to increase circularity are deeply disconnected with the production planning. This paper redefines circularity and integrates it with production planning. The detailed explanations are described in the following section.

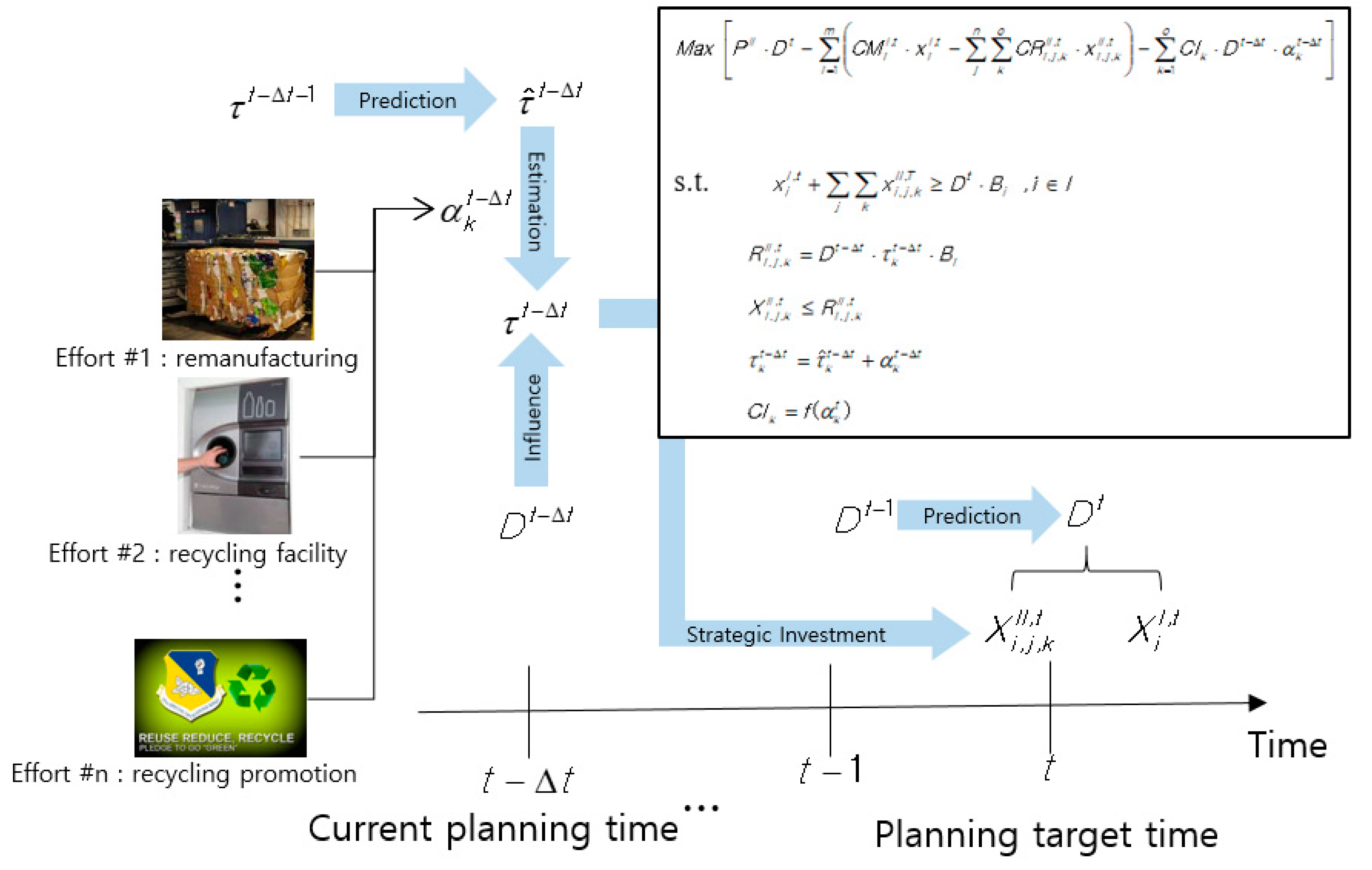

Figure 1 shows several efforts and methods for increasing the circularity of the refurbishing components.

As shown in

Figure 1, there are different strategies that can be applied to enhance circularity in an overall production system. The installation of additional collectors, recycling centers, distribution centers, or service centers can enhance refurbishing components’ circularity. Reike et al. [

18] summarized several methods for increasing the circularity. Likewise, promotions and advertisement [

19] can reinforce industrial ecology. However, these methods have different Return on Investments (ROI). Additionally, it is evident that the ROI of each investment has nonlinear characteristics for achieving the target circularity. Additionally, the investment planning time horizon has to precede the production planning time. These considerations make it more difficult to effectively generate a circular economy-based production planning.

In regards to uncertainties, embedding on the circular economy is much broader when compared to those in a general production planning. The circularity rates and relevant uncertainties are entrenched more in the circular economy-based production planning while a general production planning handles several uncertainties from its demand and supply. This study simultaneously considers these uncertainties with stochastic and nonlinear characteristics.

The proposed model is based on an integrated stochastic nonlinear programming model to meet the economic and environmental planning goals. The stochastic programming model and its analyses are examined while using a number of research studies [

20,

21]. However, it is impossible to directly apply the existing studies’ methods to the proposed framework, since the model in consideration has several demerits: information uncertainty, disparities in planning/investment time horizon, and nonlinear price characteristics. As a result, the following section provides a new and effective framework for maximizing corporate profits that simultaneously meets the criteria of high circularity.

3. Strategic Decision Framework and Its Mathematical Model Supporting Circular Economy

This section describes the overall proposed strategic decision framework for supporting circular economy. The targeted refurbished product is manufactured while using various components including: new parts, remanufactured parts, reused parts, and recycled parts.

Figure 2 shows an example of a Bill of Material (BOM) for a refurbished product.

As shown in

Figure 2, the refurbished product is manufactured and assembled while using various types of components, coupled with a variety of remanufacturing methods. This study also investigates the effective proportions of newly manufactured components and recycled components. The effective proportions of manufacturing components that were based on this research indicate that an efficient manufacturing BOM comprise of subcomponents with less production costs that meet the customers’ needs. This paper is distinguished from other studies due to the consideration of gathering strategies while there are numerous related research studies on remanufacturing and recycling economy: extended advertisement, and additional installation of collecting facilities and incentive policies, as illustrated in

Figure 1. While other studies only focus on the effective use of the already returned components, this paper considers the potential cost of returning components while using these investments. More collection may be achieved if these investments are effective, hence contributing more to circular economy. For this reason, the proposed framework is considered to be a more active strategy to support circular economy.

A refurbished product is comprised of several components or modules. A module is a newly manufactured part (

) or a refurbished component (

).

Table 3 represents the descriptions of the detailed variables and parameters.

Each component has a manufacturing cost per a unit (

or

) in regards to its manufacturing types, respectively. While a completely new product only comprises of each

, a refurbished product comprises of several

’ s and

’ s. The required number of the

ith module is represented as

in a product. When

is the customer’s demand for a refurbished product at time

t, the number of collected components (

) has to be considered. (2) denotes the constraints for meeting

.

The returned amount

depends on the return rate

. (3) denotes the relationship between

and

.

The usage of “

” denotes that the reused/remanufactured/recycled components are collected at time

before meeting customers’ demand at time t. As shown in Equation (3), it is reasonable that

at time t is collected not from current customers’ demand

, but from the previous consumed amount

. In this manner,

is interpreted as the returning time horizon of a products. Subsequently, (4) denotes the relationship between

and

.

In general, a factory tends to produce the product using the refurbished or reused part with the constraint, if recycling parts exist. However, returned parts may be insufficient for meeting () in a general situation. While existing production plans attempt to use its new part in the situation, this study considers another alternative plan—efforts in enhancement of the return rates at planning time .

The investment cost (

) is additionally needed when the

kth investment is determined while using an effective strategy. In general,

is represented while using a nonlinear function of

in (5).

where

is a nonlinear function

However, these investments consider additional efforts for collecting refurbishing products. It means that a certain constant amount at time

can be collected without additional efforts. (6) denotes this situation.

The estimation of

can be achieved by a number of statistical methods (e.g., time series analysis and other data mining methods) with the previous historical data.

Section 4 provides the detailed estimation and analyses. Subsequently, (5) is substituted by (7) in this manner.

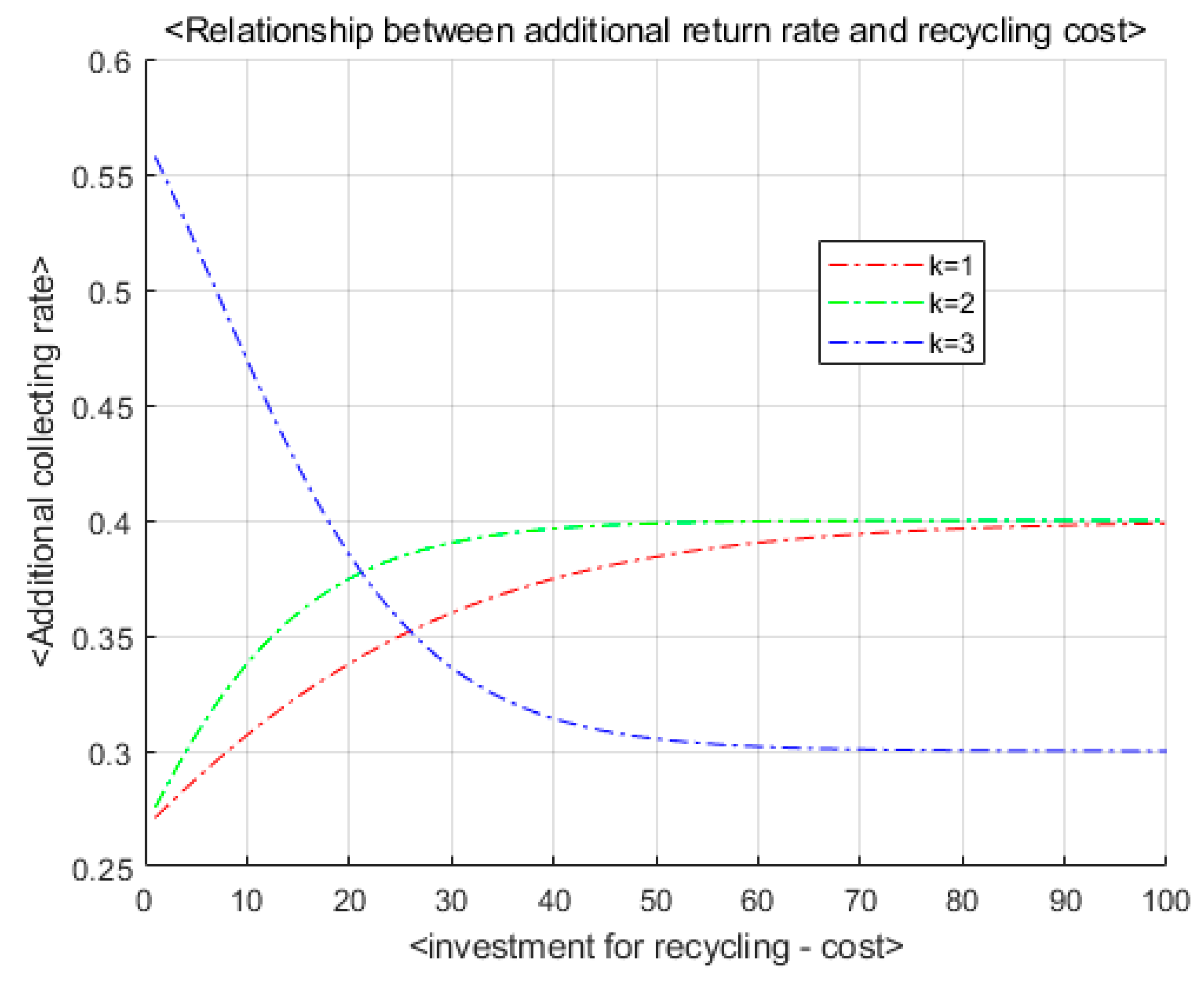

Figure 3 shows an example of a nonlinear function explaining the relationship between

and

. As shown in

Figure 3, each

means an index that represents each investment (1: advertisement, 2: additional installment of collecting facilities, and 3: incentive policy).

This research focuses on the effective gathering investment strategy while considering the existing returned volume, the predicted return rates, and an estimated demand. The demand (

) is determined while using previous market data and forecasts. Since various uncertainties are embedded in its prediction, it is only rational that the demand be represented while using a probability density function.

Figure 4 shows the estimated

that is represented using a probability distribution.

The Formulas (2)–(7) are used as constraints in determining the effective manufacturing strategy for a refurbished product. The objective (8) of the decision at time

is to maximize the profit while considering the difference in price of the product and the overall production cost.

The mathematical programming model provided is categorized as a stochastic nonlinear programming model. The model has the characteristics of a stochastic programming model since

is represented while using a probability distribution. Additionally, the model has nonlinear terms from (7) and (8). Consequently, several parameters that are embedded in the model have to be estimated through statistical analyses.

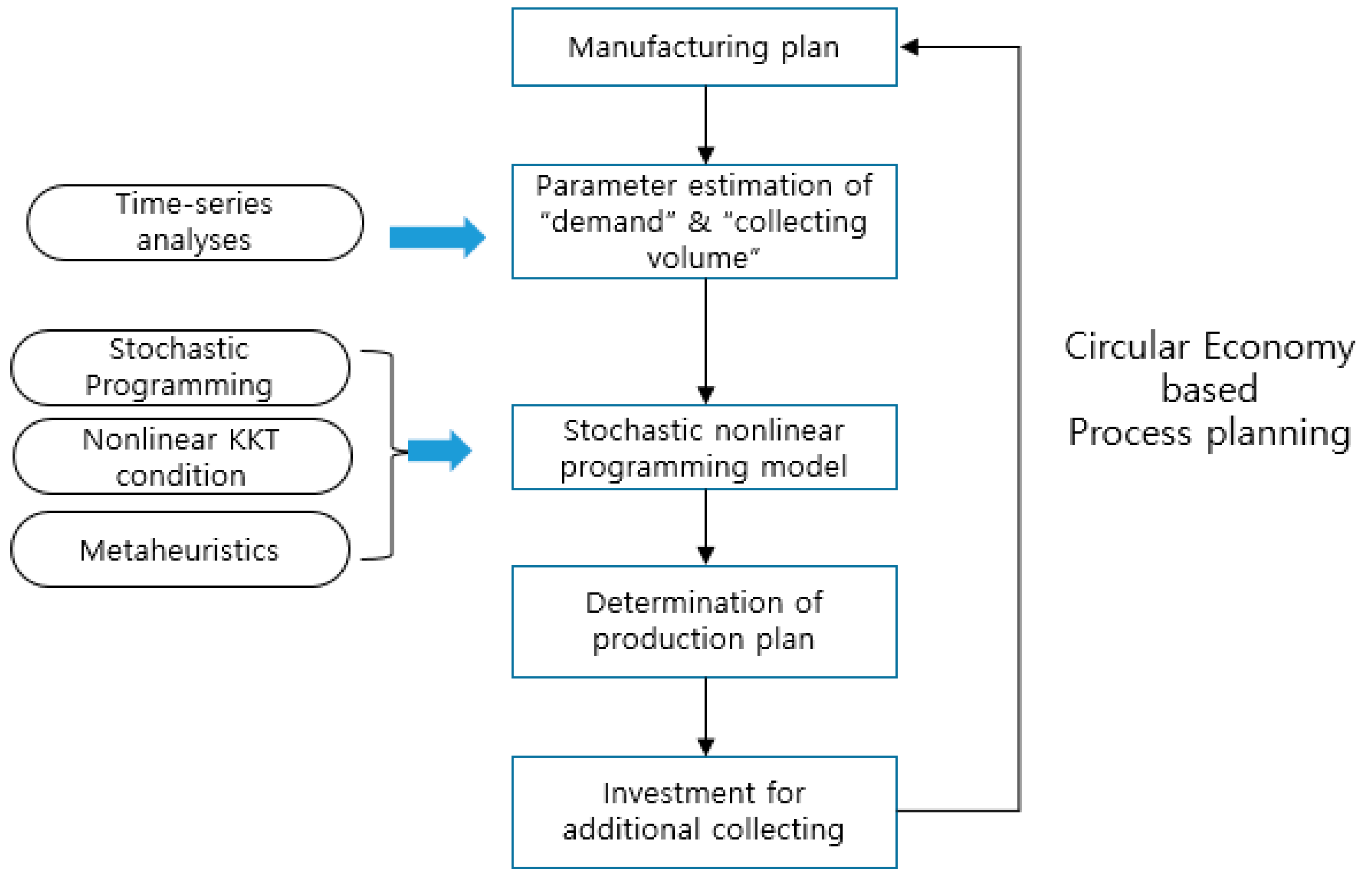

Figure 5 illustrates the overall procedures for the proposed effective production planning.

The following section illustrates the detailed methodologies that are applied in solving the proposed model.

4. Parameter Estimation and Analysis Using Stochastic Nonlinear Optimization

As highlighted in the previous section, the proposed mathematical model shares the characteristics of a stochastic nonlinear programming. Moreover, statistical analyses have to be satisfied in advance as the prerequisite determinations for estimating the parameters and . This study uses a time-series based method to approximate the model parameters.

Figure 6 shows a flow diagram for implementing the proposed circular economy-based process planning. The accurately predicted demand (

) and the collecting volume (

) heavily influence on the solutions and analyses of the proposed model. The estimations of

and

are estimated while using the current manufacturing plans and data, and are mainly driven using a time series technique. This research utilizes Autoregressive Integrated Moving Average (ARIMA) method or other nonlinear prediction methods for covering nonstationary data. The analyses of many research studies [

22,

23,

24] assumes that most of the production demands and manufacturing related tendencies follow the nonstationary stochastic characteristics. Although

can be monitored or directly estimated while using one of those methods,

is predicted using several existing time-series methods that enhance the accuracy of these estimations. These values are then represented while using a random variable

following a Gaussian distribution

. Both parameters

and

are estimated while using the predicted results from several time-series methods. Instead of the single value-based prediction, the application of this probability distribution enhances the representation power of the estimated demand.

can then be replaced with (9) while using a stochastic programming through recourse model with the bounds.

where

.

As shown in the objective function (10), the mathematical model is categorized as a two-stage stochastic programming with the recourse model.

In the case that a nonlinearity condition (7) is excluded, a general method of applying the stochastic transformations and KKT conditions [

20] can be used, owing to its near-optimal solution. However, the existence of the provided conditions results in the difficulties in determining the global minimum from the recourse model. In order to overcome this discrepancy, many research of the studies, including Sakalauskas [

25] and Shapiro [

26], provided the Monte-Carlo based stochastic nonlinear programming solving—Sample averaging approximation (SAA) method. This paper applies the SAA method to generate more effective solutions. However, the solutions that were obtained using SAA method [

27] are compared with different criteria, such as unbiasedness, consistency, and convergence. According to Shapiro [

28], (9) can be replaced with (11), where

is the probability for ith scenario.

where

is the i

th sample from

Subsequently, (12) is driven by the Law of Large Numbers [

29].

It can be easily ascertained that the estimator

is the unbiased and consistent estimator of

, as each

is an

i.i.d. sample and driven from Gaussian distribution

. The sample size

is determined while using the empirical test following the criteria (13) In order to support the convergence condition of the estimator, where

, and

are the parameters from Kleywegty et al. [

30].

(12) and (13) make it possible to solve the proposed model while using the Monte-Carlo based SAA method. The remaining issues include the handling of the nonlinear conditions and the terms resulting from (7). These issues can be addressed while using memetic based metaheuristics [

31]. The memetic algorithm [

32,

33] is a type of metaheuristics method that combines the current metaheuristics and local searching techniques. While metaheuristic algorithms attempt to discover more solutions that are more improved when compared to the current local optimum, they are limited in regards to their searching efficiencies, such as solution accuracy and convergence. In general, the obtained quality of a local solution using metaheuristics is less than the quality that was obtained while using the heuristics method with the same input range. The local optimum searching method is combined with a metaheuristic algorithm in order to overcome these limitations. In a memetic algorithm, an alternative solution is realized while using an optimization method. It guarantees the quality of the calculated local solution within its local range. Consequently, the local solution is morphed into a better solution while using a metaheuristic. Neri and Cotta [

34] summarized the existing literatures using memetic algorithms. Numerous applications and research studies, including the one by Neri and Cotta [

34], use several memetic algorithms that combine various local search methods and metaheuristics to find finding more efficient parameters or solutions. This paper applies a memetic method for finding more efficient investment strategies, which supports circular economy. The applied memetic method utilizes a gradient searching technique in place of the local searching and a Genetic Algorithm as a metaheuristics method. Choo and Lee [

35] applies the similar memetic learning framework to determine the parameters in a deep learning machine.

As a local searching method, this study uses a KKT based gradient method. Each constraint ((2)–(6)) is combined to (10) with each Lagrange multiplier. Subsequently, each decision variable’s update is achieved while using the driven Lagrange function

and each differential

, where

ϕ is a decision variable.

where

= a Lagrange multiplier for the constraint type (2).

and,

𝜂 = a step length

(14) and (15) denotes the learning procedures for each production and returning component, respectively. Similarly, (16) denotes how each investing strategy is learned for the more effective circular economy.

The usages of different step sizes (

and

) result from the different resolutions of the decision variables

and

. The more improved solution is attempted using the Genetic algorithm (GA) when a local optimum is arrived using (14), (15), and (16). The genotype conversion is achieved using the binary number conversion from a decimal number. For instance, an initial value of a decision variable

is obtained while using (17) and a randomly generated number

.

The generated decimal value is converted into the corresponding binary value. Afterwards, crossover is achieved while using Single-point crossover [

36]. The mutation is achieved with a conversion (0→1 or 1→0) of its binary value in a randomly determined position. This position is determined using (18), where

is the binary representation of the decimal value n and d(n) is the digit number of n.

where

= the rounded-off value of n.

Table 4 shows the applied Genetic algorithm procedure in this research. The provided algorithm has four parameters:

th,

p,

r, and

m.

th is a threshold value specifying the termination criterion of the algorithm.

p is the number of the tested solutions in each GA iteration.

r is the fraction of the solution set that is to be replaced by the crossover operation and

m indicates the mutation rate.

The overall solution procedure for the proposed model combines the Genetic algorithm that is shown in

Table 4 with the gradient based local searching provided in (14), (15), and (16). During these processes,

is projected while using the sample averaging approximation method. The mathematical model provided and the stochastic nonlinear programing based method contributes to the estimation of effective collecting strategies. As the reputation of circular economy grows more and more, production/collection quantities and related BOM portions become crucial decision factors. The relevant collecting investments, together with their budget strategies, have to be considered in this model. The proposed framework is considered as an effective remanufacturing in support of the circular economy. The ensuing section describes the developed remanufacturing systems and its numerical studies’ analyses.

5. Development of Remanufacturing Framework and Its Numerical Analysis

This section describes the implementation of the proposed framework and the numerical analyses while using the proposed software program. The system includes several information/parameter panels and three graph windows.

Table 5 represents the roles and functions of each panel/windows.

Table 6 shows an analyzed numerical example to illustrate the effectiveness of the proposed framework.

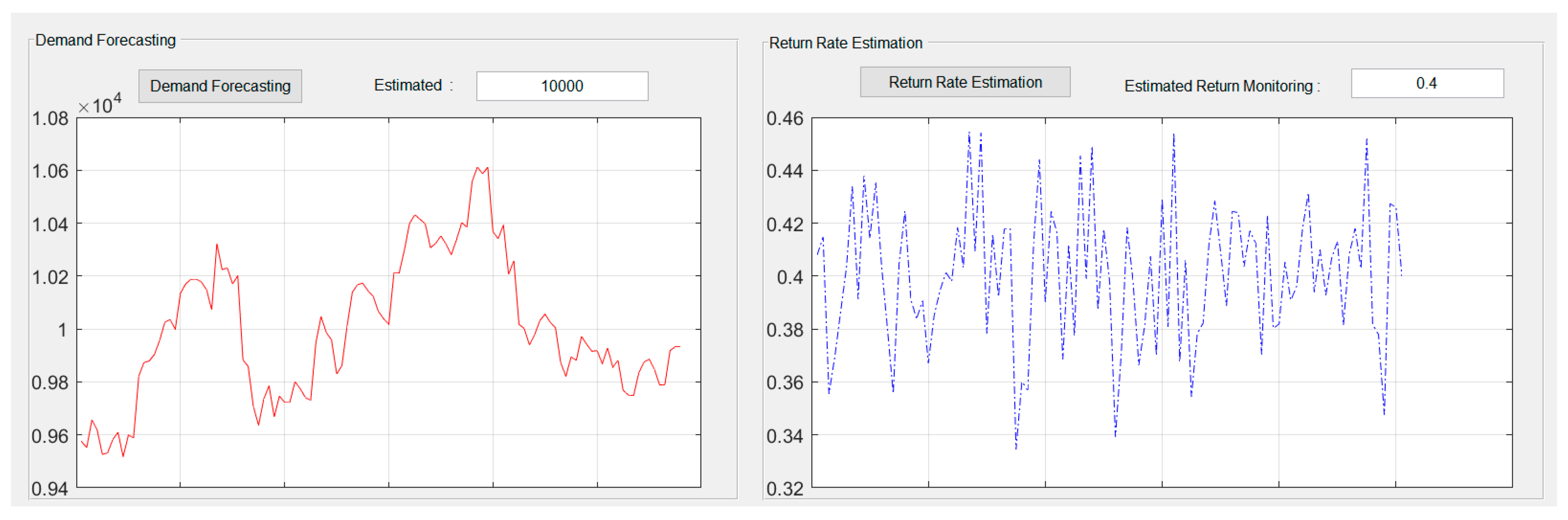

The current return rate data and historical demand data in the customized formats are read in the system after inputting the initial solutions and parameters in the developed system. These data is then plotted and analyzed, as shown in

Figure 7.

As shown in

Figure 7, the data is analyzed while using various time-series methods. The best fitted model in this scenario is proven to be the ARIMA (3, 1, 2) model and the prediction is presented while using a Gaussian distribution

. In addition, the current return rate is estimated to be 0.4. Consequently, to generate the solution of the suggested mathematical programming model, the parameters of the memetic algorithm are inputted to the system.

The solution is then generated and the changes of the objective values plotted, as shown in

Figure 8.

As illustrated in

Figure 8, the objective function value is enhanced and converged to a near-maximum value while using the proposed memetic algorithm. The generated solution supports the circular economy in regard to the fact that the production plan pursues more gathering of recycling components while considering business profits. In addition, it reduces the environmental pollutions due to the use of recycling components.

The solution (Case III) is compared with the other cases to prove the effectiveness of the proposed framework: the case that ignores refurbishing (Case I) and the remanufacturing case barring additional returning investments (Case II).

Table 7 provides these solutions and comparisons.

The case with additional returning efforts has the largest profit in addition to the largest utilization rate of recycling modules, as shown in

Table 7. Based on the analyses, the third scenario that applies the proposed framework has twice the recycling modules keeping the maximal profit compared to the second case. Additionally, it is inferred that the third case might contribute to sustainable manufacturing while using less energy as a result. These results can be differ based on the assumed conditions and parameters. However, the proposed model and the solving framework are considered as effective production planning framework that supports circular economy with regards to the additional investment strategies for increased collection, which are evaluated quantitatively under stochastic and nonlinear business environments.

6. Conclusions and Further Studies

The circular economy is among the representative trends leading contemporary society. As more efficient business techniques and management methodologies evolve for maximum corporate profits, there has been growing concerns regarding the preservation environments for the future generation, leading to growing with the governmental and municipalities’ regulations. These trends have a lot of terminologies, including the circular economy, sustainable engineering, and closed-loop SCM. This paper concentrates on the more active and detailed production planning that supports circular economy. In particular, more focus is put on the decision making for additional investment strategies for recycling products collection. There are existing portfolios for investment strategies, such as promotions, additional installments of gathering facilities, and/or other incentive policies. Existing production planning constraints have to be considered, although these tasks could guarantee more returns of recycling components.

The majority of the circular economy environments have more uncertainties when compared to existing contemporary economies. The uncertainties in returning amount and qualities of recycling modules are also embedded, despite existing contemporary economies having uncertainties in demand and supply abilities and production parameters. Consequently, the circular economy-based production planning has to reflect on the existing planning constraints, additional investments, and more piled uncertainties. This paper proposes a stochastic nonlinear programming model-based production planning framework to solve these issues. In the proposed framework, the demand information is captured through a probability distribution. In addition, the uncertain return rate and the costs of recycling components are represented while using nonlinear function. It is difficult to obtain the exact solution set that meets the circular economy criteria because the framework consists of stochastic and nonlinear characteristics. As a result, this paper presents new and efficient techniques, such as the sample averaging approximation method based on Monte-Carlo method and the memetic algorithm. The use of the Monte-Carlo based sample averaging approximation method helps to handle the uncertainties that are embedded in the circular economy environment. Consequently, the mathematical model is transformed into a Lagrange function while using nonlinear K.K.T. conditions. To generate effective solution sets for the function, the memetic algorithm, which combines Gradient based local search and Genetic algorithm, is utilized. The framework is implemented in a software program supporting circular economy-based production planning in order to prove the effectiveness of the proposed framework in addition to its solving techniques. Thus, its effectiveness is proven through the comparisons of results under various scenarios and analyses. While the proposed framework considers recycling investment framework with uncertain demand and nonlinear recycling cost, this research ignores the suggestion of detailed investment strategies, such as additional network generation or activities for extra efforts. The proposed framework handles these features only in regards to nonlinear costs. Additionally, this research ignores the current integrations of the environmental effects and environment assessments. It is considered that the effectiveness of the proposed framework is enhanced when these assessments are integrated.

As further studies, the broader expansions of the proposed framework are considered. The production planning framework presented particularly focuses on the existing production parameters and extra efforts in the enhancement of the returning rate. The framework covering the overall lifecycle of its supply chain networks is necessary while the current framework handles production planning.