1. Introduction

The global community adopted the 12 Sustainable Development Goals (SDG) in 2015 setting the agenda for addressing a range of global economic, social and environmental issues [

1]. SDG 6 is to “ensure the availability and sustainable management of water and sanitation for all” with target 6.3 including “By 2030 […] halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally”. This is an ambitious target, given that in 2015, three in five people worldwide did not use safely managed sanitation services, systems where excreta are safely disposed in situ or safely transported and treated off-site [

2]. Both centralized (sewered) and decentralized (on-site) systems can fail to meet this “safely managed” criterion as wastewater treatment plants may not be working efficiently and the collected fecal sludge may be dumped indiscriminately [

3]. Typically, human excreta are treated as a waste that needs to be disposed of rather than a resource which contributes to their mismanagement. There are possible opportunities from fecal sludge for the circular economy that may include energy, nutrient recovery and the creation of products [

4,

5]. The circular economy also creates a great opportunity for incentivizing and stimulating sustainable sanitation by providing an additional income stream and reducing the sanitation service cost to the user [

6]. Trimmer and Guest [

7] analyzed the potential for 56 of the world’s largest cities and found that closing nutrient loops in cities is most feasible in Africa, Asia and Europe due to the cropland density local to these cities.

Recovering nutrients from fecal sludge constitutes an avenue for returning nutrients back to soil, which could help tackle other SDGs. SDG 2 for instance aims to achieve zero hunger with target 2.3 aiming to double the agricultural productivity of small-scale farmers by increasing access to inputs and to markets [

1]. Target 15.3 also deals with farming aiming to combat desertification and restore degraded land; composted sewage sludge is made up of 50% organic matter and therefore attractive for restoring soil health [

8]. Targets 11.6, 12.2 and 12.5 of the SGDs aim to reduce waste generation and adverse human impact on the environment [

1]. Recovering nutrients from excreta fits within the water-energy-food nexus and contributes to tackling water and food production challenges simultaneously [

9].

When considering the circular economy for sanitation it is essential to assess the market for potential products or they will not provide the additional income stream that is desired [

10]. Composting is a relatively ‘low tech’ solution for organic matter decomposition, which can remove pathogens from fecal sludge if the high temperatures achieved in the initial thermophilic phase are maintained for long enough (3 consecutive days above 55 °C for in-vessel composting, 15 consecutive days above 55 °C for windrow composting [

11]). Composting can therefore constitute an attractive solution for treating fecal sludge, providing an opportunity to sanitize fecal sludge, recover nutrients from human excreta and returning them back to soil, often in areas where soil organic matter is becoming depleted due to agricultural practices or a lack of fertilizer use [

12]. Compost however is recognized as a low-value product [

13], and it is essential to consider the economics of composting when planning a new facility as it is possible for the cost of production to be greater than the revenue from sales [

14,

15]. The composting of municipal solid waste is well known but the composting of fecal sludge is less well-known and not well understood [

16].

A risk of composting fecal sludge is that external wastes (e.g.: plastics, batteries and other household waste) are present. This can be avoided using container-based sanitation systems [

16]. These do not rely on sewerage networks or any permanent infrastructure. Container-based sanitation systems use mobile toilets that do not require any investment by any stakeholders into additional infrastructure, which is often attractive for most urban slum dwellers who rent the spaces they live in. The model is based on a rental and servicing fee, making it affordable but also aiming to build a lasting relationship with the service provider, as well as the appropriate and safe management of the toilet waste [

13]. Container-based sanitation has been recognized as a promising solution to sanitation in densely populated areas but has not been studied extensively yet [

17,

18,

19].

Several container-based sanitation companies successfully produce human excreta derived fertilizer and sell their full production in the local market; however, in this emerging sub-sector, there has been no study into why these companies have achieved success and what the barriers preventing further scale-up are. The aim of this paper is to identify the enabling conditions for their success and the challenges they are faced with. Two container-based sanitation ventures that successfully sell their compost were selected to determine the factors that enabled their success in the circular economy as well as the challenges overcome and barriers still faced.

2. Materials and Methods

A case study research approach was chosen to investigate the barriers and enabling conditions for commercializing human excreta derived fertilizer and determine the factors that are location or case-specific and those that are common across geographical locations. A case study approach was most appropriate to explore this question, as Yin [

20] points out: “A case study is an empirical enquiry that investigates a contemporary phenomenon (the “case”) in depth and within its real-world context, especially when the boundaries between phenomenon and context may not be clearly evident”.

Yin [

19] also emphasizes the need to clearly define boundaries for a case study, which he calls “bounding the case”. In this research, the criteria to select the cases were as follows:

Case studies were developed on sanitation ventures which:

provide container-based sanitation systems emptied at least weekly (i.e. not pit latrines),

cover the full sanitation value chain (provide toilets, collect excreta and treat them),

operate in low and middle-income countries,

produce fertilizers from human excreta at full scale,

were selling the fertilizers in the local market in July 2016.

The sanitation organizations that fulfilled the criteria set for selecting case studies when the study was carried out were Sustainable Organic Integrated Livelihoods (SOIL) in Haiti and Sanergy in Kenya. The characteristics of each venture and the fertilizers they produce will be presented in the following section.

The same research activities were carried out for both case studies to allow for comparison from a range of different sources: interviews and observations. A series of stakeholder interviews were carried out in each location including the sanitation venture’s employees, international organizations such as the FAO, local food industry stakeholders such as vegetable exporters and NGOs implementing agricultural projects, as summarized in

Table 1. Customer interviews could only be carried out with SOIL customers as Sanergy customers could not be contacted because of their data protection policies. Three regular customers of SOIL were interviewed; all were growing plants in nurseries. A purposive sampling approach was followed to identify interviewees. Company employees were purposively sampled according to their job position and involvement in fertilizer production or sales. Compost customers selected were those who were available and agreed to be interviewed in the time period when the fieldwork was carried out (five weeks in July 2016). Interviews were carried out in a semi-structured format to allow for a comparison between interviews whilst also allowing the conversation to flow, and for the interviewee to expand more freely in certain areas encouraged by the interviewer’s prompts. Interviews with employees aimed to characterize the perceived success factors for compost sales, their understanding of the compost’s properties and their suggestions for improvement. The topics covered in the interviews with sanitation company employees included different aspects of the compost production process, the challenges faced for selling it and company strategies. Interviews with compost customers were centred on their perceptions, experiences and opinions with compost use. The topics discussed in the interviews with international organizations covered the agricultural context of the country, the fertilizer market, soil health and the main challenges faced by farmers.

Pre-arranged interviews were recorded and transcribed, certain interviews occurred through spontaneous conversation and detailed notes were taken. Consent for data collection and use was obtained from all respondents. Interview transcriptions and notes were manually coded using the software NVivo [

21] following a descriptive coding approach as outlined by Saldaña [

22], by initially coding sections by describing their general topic without considering the connection between different codes. These codes were then arranged into themes to allow comparison across stakeholders and case studies.

SOIL started as a not-for-profit organization in 2006 in Northern Haiti with the approach of access to safe sanitation being a human right. Their aim is to provide dignified and safe sanitation to deprived communities that are not served by municipal sanitation in two cities of Haiti, Cap Haitian and Port au Prince. SOIL provides household dry toilets, which are leased; a service fee is collected monthly directly from customers.

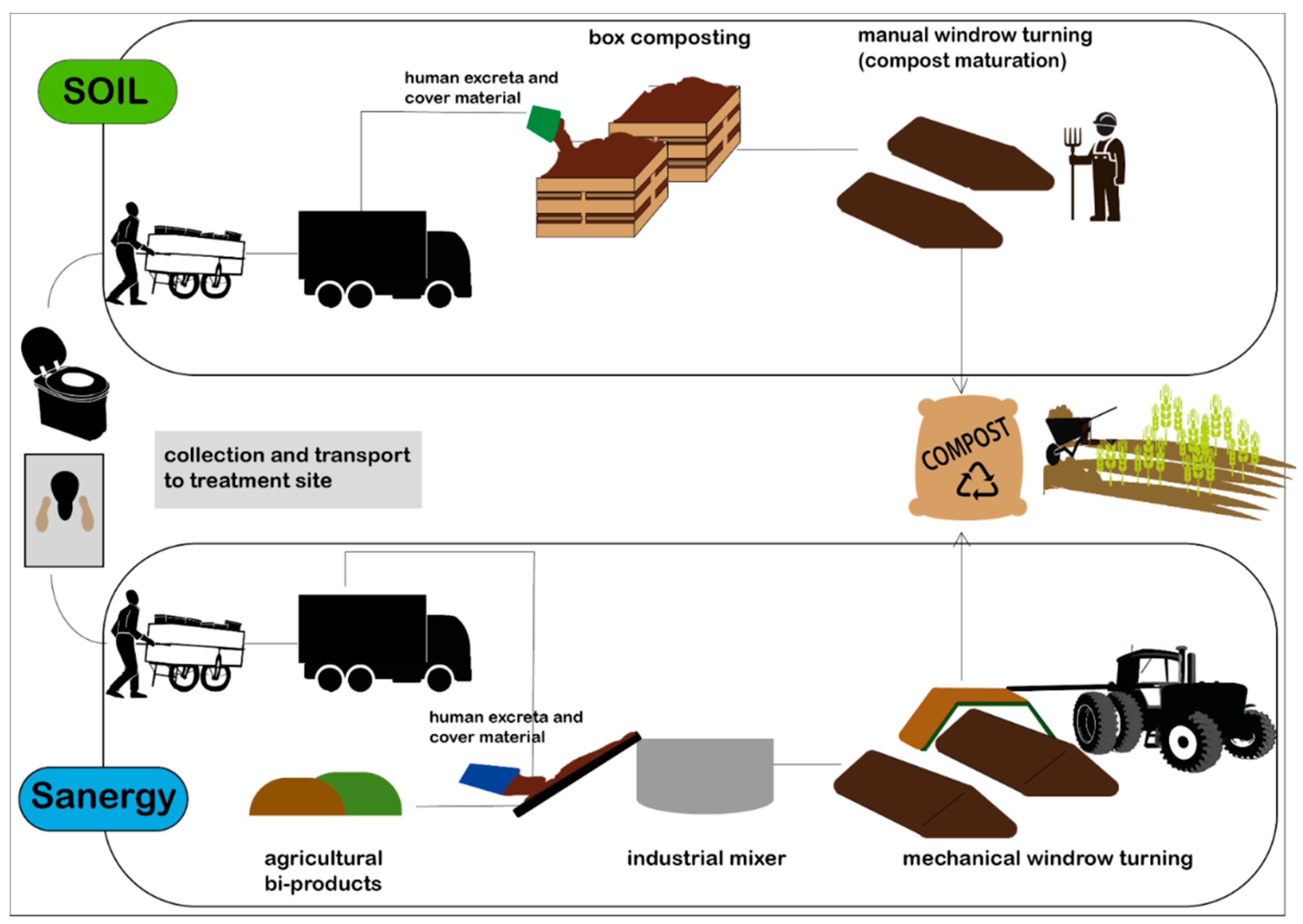

SOIL provides its 6000 customers with urine-diverting toilets at a cost of

$3.20 per month, and six collectors collect the feces weekly (about 350 tonnes per year) and transform it into compost. Urine is not collected at present, customers are responsible for disposing of it, and commonly they just use a drain. Feces are contained in buckets which are sealed, collected in carts and transferred to the waste treatment site by truck. Toilet customers add a cover material after each toilet use: sugar cane bagasse or peanut husks, included in the service fee charged by SOIL, to obtain the optimal carbon to nitrogen ratio for composting. The buckets are emptied into large composting bins; the walls are made up of pallets filled with carbon-rich material like straw to allow for air to flow through and provide sufficient aeration in the bin. The treatment process has previously been described in Berendes et al. [

23] and Piceno et al. [

24]. The bin is sealed when full and left untouched for 2–3 months depending on the temperature and pathogen concentration evolution in the compost bins. The compost bin is then emptied, and the material arranged into windrows where further degradation of the material occurs. The piles are turned once a month for about six more months until the compost properties fulfil the quality criteria set internally. There are six full time compost team workers. Temperature, moisture, pH and

E.coli concentration are monitored throughout the process to ensure compliance with WHO standards for thermophilic composting and the safety of the final product [

25]. SOIL has chosen to sell its fertilizer to NGOs because they can buy it in large quantities and have larger purchasing power than farmers.

Sanergy is a social enterprise that provides safe sanitation in urban slums of Nairobi through shared dry toilets since 2011. Their urine-diverting dry toilets are part of a franchise system, Fresh Life Initiative, which local entrepreneurs join. They invest in a toilet and operate it as a pay-per-use public toilet, at a cost of $0.05 per use. Another model exists where toilets are installed in accommodation compounds and leased to landlords as an extra service provided to tenants. The toilet entrepreneur or tenants (depending on the toilet model) are responsible for the maintenance and cleaning of the toilet, for sourcing cover material, usually sawdust, and adding it to the feces. A third model exists for toilets installed in schools where toilets are sold to head teachers at a subsidized price to ensure adequate sanitation coverage for all pupils. A trial system with household toilets was also underway at the time of the visit. A total of 30,000 people were being served at the time of the research, and there are 60 employees in composting and collection. The sanitation and the waste management arm of Sanergy are separate; the toilet business, Fresh Life Initiative, being not-for-profit and the waste management arm, Sanergy, as a social enterprise, which collects and treats toilet waste.

Similarly to the previous system, the waste is collected in sealed containers and transported by truck to the waste treatment facility, about 400 tonnes per month. There the containers are emptied into a mixing tank where additional organic wastes are added such as agricultural residues. After the mixing phase, the material is laid out in windrows, which are mechanically turned and watered. Process performance is periodically monitored by measuring process parameters (temperature, moisture, pH, CO2, pathogen concentration, germination tests). The resulting compost is sieved, bagged and sold for agricultural use once the piles meet the WHO guideline standards [

25] which permits their sale to vegetable growers, who receive a good return on investment from using fertilizer.

The fertilizer production processes are different between the two ventures as illustrated in

Figure 1 but several of the challenges they face are similar.

3. Results

3.1. Challenges Faced in the Production of Human Excreta Derived Fertiliser

3.1.1. Sourcing of Additional Composting Material

Additional organic matter needs to be sourced locally to obtain the right carbon to nitrogen ratio for composting and ensure efficient treatment of the excreta. SOIL needs to source the cover material for the feces that it provides customers with. In Sanergy’s treatment system, feces are co-composted with additional organic matter such as food waste or agricultural by-products. Seasonal variation in material availability and changes in attitudes from providers created challenges for both companies for the procurement of extra organic materials. Arrangements with providers are shifting to formal contracts.

“If people have to get rid of their waste they will pay to do it. The thing is when we come to say ‘we want your waste, we can get rid of it for you’. They say ‘okay but we actually want you to pay‘ and that’s not logical“.

—Sanergy employee

Variation in the additional organic material also affects the properties of the final compost so variations in supplier are not desirable. Both companies were trialing different composting materials and trying to secure reliable suppliers of organic matter. High costs of transport also added difficulty for sourcing additional composting material. In Kenya for instance large scale agricultural producers can be up to 50 km from Sanergy’s composting plant, and multiple sources are needed to meet the volumes that Sanergy needs, which makes it challenging to calculate compost production costs. Another Sanergy employee said that “it’s really difficult, especially for carbon sources. […]. A lot of it is where the large-scale farming is, which is mid- to western Kenya, so even if it’s cheap then transportation makes it expensive”.

3.1.2. Transport

Transport was also a challenge for the transfer of excreta from the toilets to the treatment sites, which often have to be in specific areas. SOIL transported excreta initially in carts and then material is transferred to a truck for the final 15km to the treatment site. Cities often have designated areas for waste treatment, which are in the outskirts of the city and difficult to access, creating an additional challenge to the economic viability of the treatment process. In Port au Prince for instance, at the time of visit, the treatment site was initially confined to an area behind the municipal landfill, which was unhygienic. The landfill was made up of disorganized mounds of waste and open fires causing thick smog as well as puddles of leachate and stagnant water where animals roamed (although the treatment site was fenced off from these animals and cleared of waste). The treatment site then had to be relocated to another waste management area because it was often inaccessible due to indiscriminate waste dumping blocking roads or roads being inaccessible after heavy rains. In Nairobi, the treatment site was located in a designated waste treatment area next to a wastewater treatment plant more than one hour’s drive (32 km) away from the collection point and accessible through dirt road only requiring specific vehicles to access it.

3.1.3. Process Optimization and Robustness

Quality control procedures and schedules were in place in both production sites, ensuring the compost produced was free of weed seeds and pathogens harmful for humans and plants. Pathogen elimination was monitored by regularly measuring temperature in the piles as well as pathogen testing at different stages of the process to ensure product compliance with the WHO guidelines for the reuse of excreta [

25]. An additional challenge faced for these ventures in low-income country was a lack of locally available laboratories that have the capacity or are willing to test human excreta derived fertilizer. As a result, both companies had built their own in-house labs (in partnership with leading research universities, such as UKZN and UC-Berkeley in Sanergy’s case) to carry out these tests. Sanergy also undertake periodic independent testing of end products at labs in Nairobi. The authors also performed a full characterization of both compost types which is provided in Moya Diaz-Aguado [

26].

Given the novelty of composting source-separated human excreta at a large scale, both SOIL and Sanergy put continued efforts into improving their product and optimizing production processes with teams dedicated to compost optimization and agricultural performance of the compost. This involved extensive experiments with minimal production time being a priority. Nutrient analyses were also regularly carried out on both compost products to monitor quality and provide detailed information to customers. Both ventures tested the quality of their products and their effects on crops in in-house field trials.

The composition of both composts was clearly labelled, and customers were appreciative of this. Clients valued knowing the nutrient content of the compost and getting guidance on how to apply it:

“With SOIL compost it’s different, you have the full composition and you can easily prepare your dosage”.

—SOIL compost client

One of the clients also appreciated the fact that the quality of the product was constant and recalled how they had previously to ‘make do’ with what was available.

3.2. Compost Commercialization Strategies and Challenges

Both SOIL and Sanergy were selling their full compost production (3 and 48 tonnes per month respectively, at $250 and $380/tonne) at the time of the field visits and were scaling up production as they were increasing the number of toilet customers. Both companies chose to sell their product at a premium price, which was seen by two SOIL customers who grow plants in nurseries as a sign of quality. One of the clients quoted a Haitian proverb that says that ‘that which is of good quality is expensive’ (SOIL compost client). A SOIL compost client who also used the compost in nurseries however said that if the compost was cheaper they would be willing to buy larger quantities.

The two companies targeted very different customer segments for compost sales. SOIL benefited from the fact that many international organizations are present in Haiti working in reforestation projects as well as with farmers. These organizations can afford to buy compost at a premium price and SOIL were able to secure them as customers from the early stages of production. Additional clients found out about the compost mainly through word of mouth, so few marketing efforts were put into obtaining new compost clients. Sanergy on the other hand used a much more active marketing and sales approach to sell directly to farmers. Their current target was medium-scale horticultural farmers in rural areas of Kenya. A fleet of salesmen covered the rural areas where cash crop farmers are concentrated, they directly approached farmers and provided guidance for compost application. This approach required educating the farmers initially to help them understand the needs of their soil and the benefits compost could have for them.

Neither companies sought distributors for their compost at this time because of the current lack of market for organic fertilizers; it was thought unlikely that farmers would pick the compost from the shops where they currently buy chemical fertilizer. The availability and distribution of alternative organic fertilizers both in Kenya and Haiti was very poor. One Sanergy employee said that “the reality is that the distribution of organic fertilizers is very poor, so most farmers have never used it before and don’t have access to it”. This was verified during interviews with the FAO.

In Haiti the fertilizer market is unstable, it has been heavily disrupted by a history of failed subsidy systems, as confirmed during interviews with the FAO and IDB. At present, there are no fertilizer subsidies in place and there is a lack of government input or direction in the sector. The landscape for organic fertilizers is mostly informal with few products formally available on the market. Similarly, in Kenya the government subsidizes the demand for mineral fertilizers but does not intervene with organic fertilizers.

“The fertilizer market here, chemical fertilizer, it’s very chaotic, it’s completely dominated by interventions from the State every now and then depending on their financial ability”.

—IDB Haiti

“I think we’re probably leaders in compost production in Haiti but mostly because there’s hardly anyone else.”

—SOIL employee

3.3. Barriers to Accessing a Wider Range of Customers

Several organizations working with smallholders in Haiti were interviewed. These organizations work directly with farmers and aim to promote sustainable farming practices as well as facilitating their access to markets and especially international markets, coffee and cocoa beans mainly. The target is to produce high-end products and given the traditional farming practices used (no application of mineral fertilizes or pesticides), these farms can easily be certified as organic. Organization representatives stated that if their farmers were to apply fertilizers on their fields, they would have to be certified organic. Certifying bodies however do not accept human excreta as a valid input for organic certified fertilizers, so that market segment remains inaccessible for SOIL.

In Kenya, the export of agricultural goods is one of the pillars of the economy. Horticultural farms growing crops for export have more purchasing and investment power than others:

“When we talk about export there’s no problem. Even the smallholders when it comes to export, they have some problems but really, they have no [major] problems.”

—FAO Kenya

These exporters could therefore be good potential clients for Sanergy’s compost. Exporters however must abide to international farming standards set by their buyers to be able to export their goods. The most common standard specifying agricultural practices is Global GAP [

27], which states that no human sewage sludge can be used on certified fields. The uncertainty prevents some farmers producing crops for export from being willing to invest in human excreta derived compost as discussed in Moya et al. [

28].

3.4. Overall Company Strategies

Both companies had different business models and strategies. SOIL’s main focus was on sanitation provision with compost sales aiming to recover treatment costs.

“If our goal is to provide sanitation what we want to do is cover as much as we can of our waste treatment costs so we want to sell it at a high price”

—SOIL

Another long-term aim of SOIL was to turn their different activity areas into private businesses and ideally to involve the local or national government in the operation and maintenance of the waste treatment site.

Sanergy’s focus on the other hand was to shift from treating human excreta only to becoming a larger organic waste management company. They seek to provide affordable waste management services, especially sanitation services, and become profitable through the re-use of organic residues for agricultural purposes. Sanergy had also been experimenting with the production of Black Soldier Fly Larvae, anaerobic digestion, hydrothermal carbonization and pyrolysis as ways of realizing the circular economy for sanitation.

Sanergy would like to integrate sanitation waste into the wider waste management strategy of a city and be able to create a partnership with municipalities to provide city-wide sustainable waste management solutions. Sanergy also aimed to reduce the cost of production of their compost so they could provide it to a wider range of farmers.

3.5. Involvement of Public Bodies

Neither sanitation ventures received capital investment from the government for the creation or operation of their toilet or waste management activities. Both projects started with donor funds and grants without involvement of the local government and still operate without public funds, though both groups have now developed strong collaborative working relationships with the public sector, for example for new regulations. This is something that both ventures expressed wanting to change. Sanergy aimed to create a public-private partnership with the Nairobi municipality within the next two to three years. Similarly, SOIL’s aim was to outsource toilet waste treatment in 5–10 years when ideally it would be run by the Haitian government in partnership with a private partner.

Both ventures would also welcome local authorities adopting and implementing a regulatory framework for sanitation enterprises, which does not exist presently. Container-based solutions to sanitation and companies taking care of the full sanitation chain are novel and therefore are not currently regulated in Kenya or in Haiti.

“We’re sort of like Uber and AirBnB, we work in grey space and we try slowly to work with the government to regularize what we do”.

—Sanergy

The commercialization of compost derived from human excreta is also novel and unregulated. The lack of certifications was perceived as a barrier for wider acceptance and commercialization. Human excreta derived fertilizer does not fit exactly into existing legislation. Currently the best available are WHO guidelines or national regulations on biosolids from other countries but their abidance to those regulations is not controlled. Given the lack of local regulations on biosolids reuse or lack of regulation-enforcement bodies locally, the effectiveness of pathogen reduction achieved in the waste treatment process was based on the honesty of these ventures and trust of the customers, which had been achieved by Sanergy and SOIL.

Local authorities however do not always have the organizational capacity to implement regulations. In Haiti for instance, the local authority responsible for sanitation, DINEPA (National Directorate for Water Supply and Sanitation), is younger than SOIL, founded in 2009 and their capacity is still limited.

3.6. Challenges to Profitability

Neither of the two ventures made a profit from compost sales at the time when these case studies were carried out. The cost of transport and treatment still outweighed the revenue that could be generated from compost sales, even when sold at a premium. Both ventures have looked for markets closer to them but the agricultural regions are not close to the cities where residues are produced.

Sanergy’s strategy to overcome this was to scale up volumes of waste processed, diversify the types of waste treated as well as the end products sold. Additionally, both businesses are seeking to establish partnerships with the government to help finance the public goods that come from improved sanitation and waste management. At present both ventures are supported by grants, charitable donations and private investments.

Challenges to Accessing Smallholder Farmers

The most disadvantaged and largest in numbers are subsistence farmers but they are also the hardest to reach or to sell to, and neither SOIL nor Sanergy currently reached them with their compost. Interviews with international agricultural organizations such as FAO in both countries or the IDB in Haiti highlighted similar issues faced by farmers. Low education level, lack of means to pay for fertilizers, difficulty to access markets and transport were challenges typically faced by smallholders, making them a difficult target for compost sales. Extension programs generally primarily promote the use of chemical fertilizers.

“In terms of sustainability, if the project is finished, there’s no more market”.

—IDB Haiti

“So much of the agricultural education that’s been done over the past few decades is pushing fertilizer usage, chemical fertilizer usage. So how do you get people to realize the value of saving their soils and preserving it for the future?”

—Sanergy

Local smallholder farmers practice very traditional agriculture with little infrastructure, relying on rainfall for irrigation and with little or no fertilizer input.

“Always the most limiting in most of the cases is water. […] Then come other things like good quality seeds, fertilizers and good agronomic practices but mainly water”.

—FAO Kenya

“they’re not used in most of the country [fertilizers] […] People here practice almost natural agriculture”.

—FAO Haiti

A lack of appropriate infrastructure is a major barrier for farmers, both for supplying fertilizers to rural areas and for farmers to sell their produce or accessing markets. One of the interviewees quoted what a beneficiary of a farming training program had said “But my problem is that after two or three seasons, what are we going to do with it? [harvested crops]”—FAO Haiti.

“Sometimes the farmers produce but they don’t know where to sell or they produce a lot at very low prices”.

—FAO Kenya

5. Conclusions

These two studies showed that it is feasible to realize the circular economy for sanitation, that is to provide safe and sustainable sanitation in urban slums, and to produce fertilizers that have an outlet in the local market. The two organizations had different models of production and sales of compost, but similarities could be seen across both cases and contexts. Continuous and rigorous efforts were needed to establish a successful venture capable of producing and selling compost derived from human excreta. Detailed and efficient organization and management of the production sites along with thorough risk mitigation practices and testing schedules were essential to ensure product integrity and avoid contamination. Both sanitation ventures considered here successfully managed to secure initial customers, but the costs of transport, operation and maintenance however outweighed profits. These container-based sanitation ventures would greatly benefit from public financing for providing a service that has a positive impact on public health, reducing the incidence of disease in the communities and producing sustainable organic amendments. Examples from other parts of the world show that financial or policy government assistance are instrumental in the success of compost marketing. Successful public-private partnerships can be established and taxes or government incentives can have positive impact on the economic viability of compost production from organic residues. Having a range of products in the market is possibly more viable than only producing compost from human excreta, calling for a wider waste management solution for fecal sludge.

A principal challenge for the widespread commercialization of composts from human excreta was the lack of clear regulations or certifications to accredit the quality and give more credibility to these products. The production and commercialization of compost also requires a different skillset from the provision of sanitation; thus, there is a need for collaboration across sectors to achieve the optimal solution to sanitation, waste management and agricultural challenges, and to develop appropriate policies for ensuring the adoption of new technologies.