Proposal for Planning an Integrated Management of Hazardous Waste: Chemical Park, Jiangsu Province, China

Abstract

1. Introduction

2. Current State of HWM at Chemical Parks in Jiangsu Province

2.1. Current HWM Approaches in Chemical Parks in Jiangsu Province

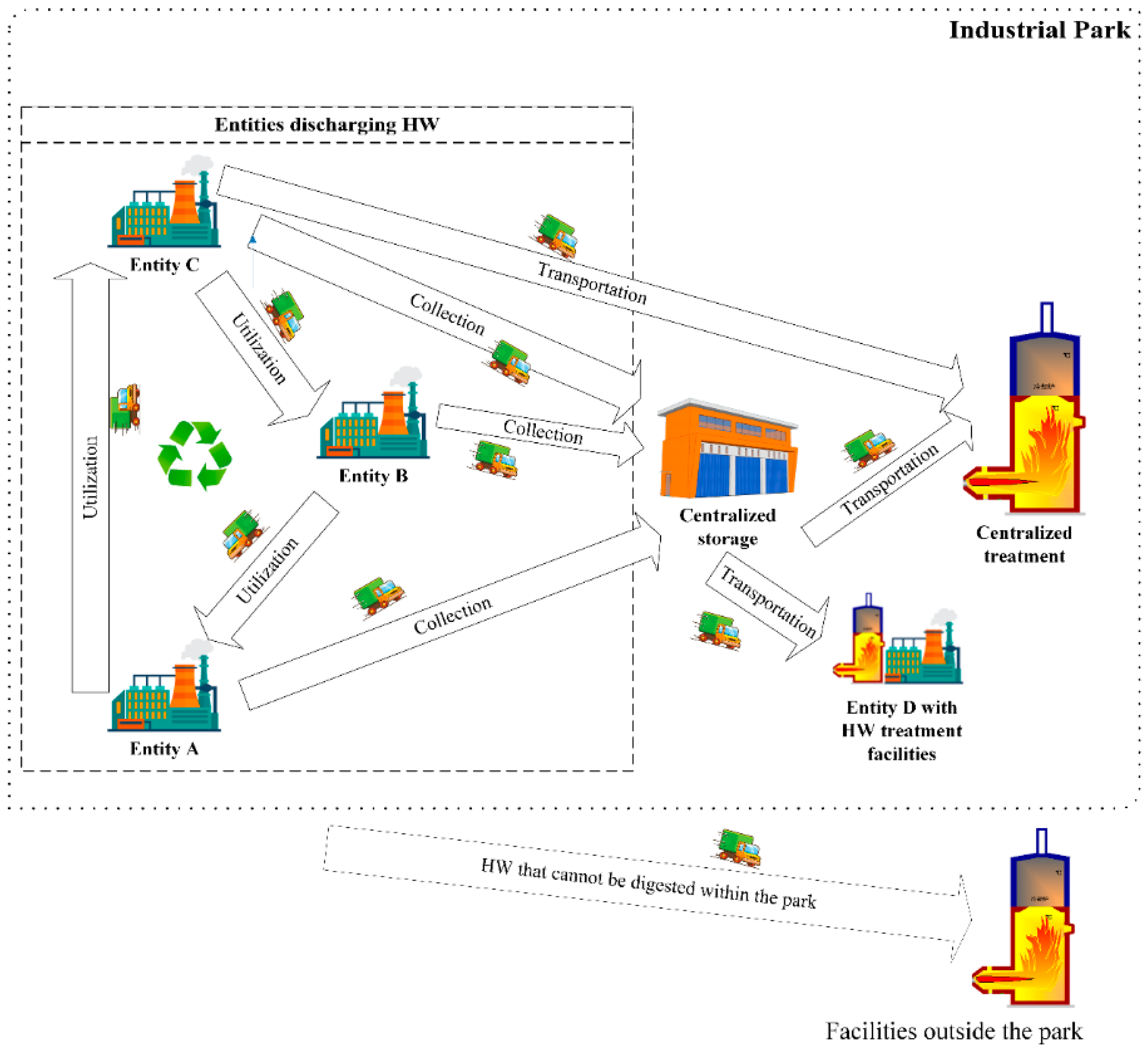

2.1.1. Innovation Action of Centralized Storage and Collection

2.1.2. Dynamic Management Systems for HW

2.2. Problems to Be Addressed

3. Methodologies for Integrated HW Management

3.1. Principles

3.1.1. Integrated Closed Management

3.1.2. Data Unification

3.1.3. Clustering Management

3.1.4. Application of Intelligent Technologies

3.2. Potential Approaches

3.2.1. Unified Environmental Butler (EB) Service

3.2.2. Intelligent Standard Box System (ISBS)

3.2.3. System Optimization Scenarios

4. Results and Discussion

4.1. Clustering Management

4.2. Application of Intelligent Technologies

4.3. Unified Environmental Butler (EB) Service

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Standing Committee of the National People’s Congress. Law of the People’s Republic of China on the Prevention and Control of Environment Pollution Caused by Solid Wastes. 2016 Revision. Available online: http://zfs.mee.gov.cn/fl/200412/t20041229_65299.shtml (accessed on 14 May 2019). (In Chinese)

- Li, M.; Xu, J.; Li, B. Analysis of Development of Hazardous Waste Disposal Technology in China. IOP Conf. Ser. Earth Environ. Sci. 2018, 178, 12027. [Google Scholar] [CrossRef]

- Torretta, V.; Rada, E.C.; Schiavon, M.; Viotti, P. Decision support systems for assessing risks involved in transporting hazardous materials: A review. Saf. Sci. 2017, 92, 1–9. [Google Scholar] [CrossRef]

- Fazzo, L.; Minichilli, F.; Santoro, M.; Ceccarini, A.; Della Seta, M.; Bianch, F.; Comba, P.; Martuzzi, M. Hazardous waste and health impact: A systematic review of the scientific literature. Environ. Health A Glob. Access Sci. Source 2017, 16, 107. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Huang, Q.; Wang, Q.; Zhou, B.; Li, J. Hazardous waste generation and management in China: A review. J. Hazard. Mat. 2008, 158, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Environmental Protection of the People’s Republic of China. Directory of National Hazardous Wastes. 2016 Revision. Available online: http://www.mee.gov.cn/gkml/hbb/bl/201606/t20160621_354852.htm (accessed on 14 May 2019). (In Chinese)

- Zhang, M.; Wang, Y.; Song, Y.; Zhang, T.; Wang, J. Manifest system for management of non-hazardous industrial solid wastes: Results from a Tianjin industrial park. J. Clean. Prod. 2016, 133, 252–261. [Google Scholar] [CrossRef]

- Guiding Opinions on Further Strengthening the Safe Production of Hazardous Chemicals. 2008. Available online: http://www.shsafety.gov.cn/aqzd/cbzhjs/wjhhpqy/xgwjgz/28340.htm (accessed on 14 May 2019). (In Chinese)

- Bao, J.; Wang, W.; Zhou, H. Planning and Management of Hazardous Wastes in Jiangsu Chemical Industry Park; Hohai University Press: Nanjing, China, 2018. (In Chinese) [Google Scholar]

- Arebey, M.; Hannan, M.A.; Basri, H.; Begum, R.A.; Abdullah, H. Integrated technologies for solid waste bin monitoring system. Environ. Monitor. Assess. 2011, 177, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Environmental Protection of the People’s Republic of China. Annual National Report on Environmental Control of Solid Waste Pollution in Large and Medium Cities. 2018. Available online: http://gts.mee.gov.cn/gtfwgl/gtfwjkglgg/201901/P020190102329655586300.pdf (accessed on 14 May 2019). (In Chinese)

- Jiangsu Municipal People’s Government Notice. 2018. Available online: http://www.jiangsu.gov.cn/module/download/downfile.jsp?classid=0&filename=d66fe7408cc54b619208bd82bcfadbae.pdf (accessed on 14 May 2019). (In Chinese)

- Geng, Y.; Zhu, Q.; Haight, M. Planning for integrated solid waste management at the industrial park level: A case of Tianjin, China. Waste Manag. 2007, 27, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Ozaki, H.; Sharma, K.; Phanuwan, C.; Fukushi, K.; Polprasert, C. Management of hazardous waste in Thailand: Present situation and future prospects. J. Mat. Cycle. Waste Manag. 2003, 5, 31–38. [Google Scholar] [CrossRef]

- Guiding Opinions of the Ministry of Industry and Information Technology on Promoting the Well-Regulated Development of Chemical Park Zones. 2015. Available online: http://www.miit.gov.cn/newweb/n1146295/n1652858/n1652930/n4509650/c4533643/content.html (accessed on 14 May 2019). (In Chinese)

- Ling, J.; Wang, B.; Wen, X. Thinking on promoting the innovation of solid Waste Management by Big Data. Chin. J. Environ. Manag. 2016, 29–32. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, T.; Quan, Y.; Dong, R. Research on the framework of the Environmental Internet of Things. Int. J. Sustain. Dev. World Ecol. 2013, 20, 199–204. [Google Scholar] [CrossRef]

- Bin, S.; Zhiquan, Y.; Jonathan, L.S.C.; Jiewei, D.K.; Kurle, D.; Cerdas, F.; Herrmann, C. A Big Data Analytics Approach to Develop Industrial Symbioses in Large Cities. Procedia CIRP 2015, 29, 450–455. [Google Scholar] [CrossRef]

- Tian, J.; Han, S.; Chen, Y.; Chen, L. Third party environmental governance of chemical industrial pollution. Chem. Eng. Trans. 2017, 62, 613–618. [Google Scholar] [CrossRef]

- Lu, H.; Fan, B.; Yuan, L.; Li, Y. RFID-Based Hazardous Waste Management Platform Establishment. Procedia Eng. 2012, 29, 4–8. [Google Scholar] [CrossRef][Green Version]

- Ghose, M.K.; Dikshit, A.K.; Sharma, S.K. A GIS based transportation model for solid waste disposal--a case study on Asansol municipality. Waste Manag. 2006, 26, 1287–1293. [Google Scholar] [CrossRef] [PubMed]

- Hannan, M.A.; Abdulla Al Mamun, M.; Hussain, A.; Basri, H.; Begum, R.A. A review on technologies and their usage in solid waste monitoring and management systems: Issues and challenges. Waste Manag. (NY) 2015, 43, 509–523. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of promoting industrial symbiosis in a chemical industrial park: A case of Midong. J. Clean. Prod. 2016, 135, 995–1008. [Google Scholar] [CrossRef]

- Tian, J.; Shi, H.; Chen, Y.; Chen, L. Assessment of industrial metabolisms of sulfur in a Chinese fine chemical industrial park. J. Clean. Prod. 2012, 32, 262–272. [Google Scholar] [CrossRef]

- PAGE. Transition to a Green Economy in China’s Jiangsu Province: A Stocktaking Report. 2016. Available online: http://www.un-page.org/files/public/page_china_stocktakingreport_2016.pdf (accessed on 14 May 2019).

- Gutierrez, J.M.; Jensen, M.; Henius, M.; Riaz, T. Smart Waste Collection System Based on Location Intelligence. Procedia Comput. Sci. 2015, 61, 120–127. [Google Scholar] [CrossRef]

- Vitorino de Souza Melaré, A.; Montenegro González, S.; Faceli, K.; Casadei, V. Technologies and decision support systems to aid solid-waste management: A systematic review. Waste Manag. (NY) 2017, 59, 567–584. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Xu, M.; Wang, J.; Zhao, L.; Xie, S. Spatio-temporal evolution of regional inequality and contribution decomposition of economic growth: A case study of Jiangsu Province, China. Pap. Reg. Sci. 2018, 1–14. [Google Scholar] [CrossRef]

| Types | Name of the Documents | Revision/Release Time |

|---|---|---|

| Laws | Law of the People’s Republic of China on the Prevention and Control of Environment Pollution Caused by Solid Wastes (2016 Revision) | Revised in 2016 |

| Regulations | Jiangsu Province Solid Waste Pollution Environment Prevention and Control Regulations | Revised in 2017 |

| Judicial Interpretation | Interpretation of the Supreme People’s Court and the Supreme People’s Procuratorate on Several Issues concerning the Application of Law in the Handling of Criminal Cases of Environmental Pollution (2016) | Released in 2016 |

| Departmental Rules | Directory of National Hazardous Wastes (2016 Revision) | Revised in 2016 |

| Identification standards for solid wastes general rules | Released in 2017 | |

| General specifications of engineering and technology for hazardous waste disposal | Released in 2014 | |

| Technical specification for coprocessing of solid waste in cement kiln | Released in 2014 | |

| Guidelines for environmental impact assessment of hazardous wastes in construction projects | Released in 2017 |

| Region | Location | Number of Chemical Parks | |

|---|---|---|---|

| South-Jiangsu | Nanjing | 1 | 24 |

| Suzhou | 9 | ||

| Wuxi | 6 | ||

| Changzhou | 5 | ||

| Zhenjiang | 3 | ||

| Central-Jiangsu | Yangzhou | 1 | 12 |

| Nantong | 6 | ||

| Taizhou | 5 | ||

| North-Jiangsu | Xuzhou | 4 | 17 |

| Lianyungang | 4 | ||

| Suqian | 2 | ||

| Yancheng | 4 | ||

| Huaian | 3 | ||

| Typical Issues of HWM in a Chemical Park in Jiangsu Province | |

|---|---|

| At the Management Level |

|

| At the Treatment and Disposal Level, Taking Several Types of Hazardous Waste for Example. |

|

| Part 1 | Site selection and construction conditions |

| Part 2 | Engineering design for centralized storage of hazardous waste |

| Part 3 | Utilities and supporting implementation programs |

| Part 4 | Fire protection design |

| Part 5 | The environmental protection |

| Part 6 | Labor protection, occupational safety and industrial hygiene design |

| Part 7 | The risk assessment |

| Part 8 | Organization and implementation of engineering projects and allocation of human resources |

| Part 9 | Project implementation plan |

| Part 10 | Project investment estimation |

| Element | Description |

|---|---|

| Standard Box Facility | Basic modules include container and intelligent identification modules (passive radio frequency identification [RFID]). Optional modules include intelligent logistics lock (w/o global positioning system [GPS]) and GPS equipment |

| Smart Scale | Intelligent scale components are weighing parts, 4G communication components, and RFID components Smart scale weighs and uploaded weight information; uploaded data are bound to the server |

| Server | Responds to requests from smart scales as well as application systems and processes transmitted data |

| Application Programs | Used on PC or mobile devices for comprehensive processing of information provided by the terminal and back-end equipment for daily operations of the business. Can be installed on a dedicated industrial personal digital assistant or a smartphone. See Figure 6. |

| Function | Description |

|---|---|

| Weighing | Measures the weight of waste, and then transfers weight information to the logic control section |

| Logic Control | Performs subsequent functions according to the “setting” function based on data to be transmitted to other components |

| Data Transmission | 3G/4G module, sending/receiving information |

| Battery (Optional) | Independent power supply to the device when external power is not connected |

| Other Attachments | Voice playback components to generate prompt information such as “scale ready to weigh,” “weighing completed, please remove item”. Light emitting diode lamp components to provide network failure tips and other information |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Bao, J.; Yuan, S.; Zhou, H.; Li, G. Proposal for Planning an Integrated Management of Hazardous Waste: Chemical Park, Jiangsu Province, China. Sustainability 2019, 11, 2846. https://doi.org/10.3390/su11102846

Wang W, Bao J, Yuan S, Zhou H, Li G. Proposal for Planning an Integrated Management of Hazardous Waste: Chemical Park, Jiangsu Province, China. Sustainability. 2019; 11(10):2846. https://doi.org/10.3390/su11102846

Chicago/Turabian StyleWang, Weixia, Jian Bao, Sijia Yuan, Haiyun Zhou, and Guoping Li. 2019. "Proposal for Planning an Integrated Management of Hazardous Waste: Chemical Park, Jiangsu Province, China" Sustainability 11, no. 10: 2846. https://doi.org/10.3390/su11102846

APA StyleWang, W., Bao, J., Yuan, S., Zhou, H., & Li, G. (2019). Proposal for Planning an Integrated Management of Hazardous Waste: Chemical Park, Jiangsu Province, China. Sustainability, 11(10), 2846. https://doi.org/10.3390/su11102846