1. Introduction

As one of the largest developing countries in the world, China has realized a dramatic increase in crop production during the past few decades, as well as economic and social improvement in rural areas [

1]. At the beginning of 2013, the Communist Party of China (CPC) Central Committee proposed the development of the ‘family farm’ as a new type of agricultural organization to adapt to the current agricultural development period and facilitate agricultural production [

2]. Since then, many family farms have emerged in China.’

Family farms rely on family members as the main labor force and engage in the scale, intensive, commercialized production and management of agriculture, and use agricultural income as the main household income (Communist Party of China Document No.1, the Central Committee of the Communist Party of China& State council of China, December 2012). Family farms are an important modern agricultural microeconomic organization that can liberate labor forces and promote modern agriculture processes [

3,

4]. A review of agricultural census data shows that family farms constitute over 98% of all farms, and cover 53% of agricultural land globally. Across distinct contexts, family farming plays a critical role in global food production [

5]. For the case of China, according to the industry, there were 142,000 family farms engaged in planting by the end of June 2015, accounting for 59.0% of the total number of family farms, of which 84,000 were engaged in grain production, accounting for 59.0% of the total number of planting family farms [

6]. The family farm of moderate scale, which has been widely developed in China, is the appropriate development path for Chinese agriculture [

2]. The production of family farms cannot only provide sufficient food for the public, but also bring considerable income for the household. Thus, it is important to measure family farms’ production activity performance to distinguish good and bad practices and provide information to decision-makers (e.g., farm owners, policy makers, etc.) who aim to improve operations.

One of the most important policy goals is the increases in agricultural productivity and technical efficiency, since agriculture is one of the significant contributors to overall economic growth [

7]. However, such increases are also accompanied by serious environmental problems caused by agriculture. First, China produces a huge amount of various straw crops, accounting for nearly one-third of global production. For example, a yield of 1.04 billion tons is produced in 2015 [

1]. In most eastern and southern areas in China, more than 30% of straw crop was burned directly after harvest [

8], releasing a great deal of greenhouse gas and particulate pollutants and resulting in greater environmental and social impacts [

9,

10]. Second, owing to the lack of careful judgement for the use of chemical inputs, such as pesticides, serious diffused pollution coming from agriculture is increasing, which not only damages the ecological environment but also restricts sustainable agricultural development [

11]. In addition, many studies concluded that pesticides in water could cause acute or chronic harm to the health of humans and other species [

12,

13]. Recently, much more attention has been paid to straw utilization by Chinese government (Notice of the promotion and release of 10 straw utilization models, Office of China’s Ministry of Agriculture, 20 May 2017. Notice on Printing and Distributing the Action Plan for Straw Treatment in Northeast China, China’s Ministry of Agriculture, 20 June 2017). Since April 2014, the government has officially banned direct straw burning with strict regulations (Measures for the Implementation of the Air Pollution Prevention and Control Action Plan (Trial), State council of China, October 2014), and has imposed stricter rules on pesticide usage than before (Notice on Strengthening the Monitoring of Pesticide Safety Risks, Office of China’s Ministry of Agriculture, 27 June 2014). Meanwhile, better monitoring strategies are developed [

14].

As such, studies about the management and environmental performance of family farms are meaningful, and it is good for policy makers and farm owners to realize the existent potential for improving the operation of family farms, as well as to provide support through policies developed under recent reforms in China. Here, we take family farms that yield grains and cereals as our research project for illustrative purposes.

For performance evaluation in production, efficiency is usually defined as the ratio of the sum of weighted inputs dividing the sum of weighted outputs [

15,

16]. Farrell provided important measures for technical and allocative efficiency [

17]. Following studies emerged to estimate the production frontier in terms of performance. The methodologies developed involve parametric and nonparametric approaches. However, the parametric approach requires the specification of a functional form, implying structural restrictions allowing for misspecification effects. Taking into account the considerations described above, DEA is selected in this study. The origin of DEA dates to 1978, thanks to the work of Charnes et al., using mathematical programming [

15].

Considered as a powerful tool for performance evaluation, the DEA cross-evaluation method has been widely applied for ranking performance in various areas [

18,

19,

20]. Despite the wide application of the cross-efficiency method, there are still some disadvantages to using the average cross-efficiency approach to evaluate DMUs, such as losing the connection with the weights by simply averaging among the intermediary cross efficiencies [

21], which means that this technique cannot help decision makers via providing appropriate weights. A great many studies have been implemented to modify the DEA cross-efficiency method to make it a more powerful measurement approach [

22,

23,

24,

25,

26,

27,

28]. However, none of them have the discriminating ability to provide abundant and precise information for decision makers due to the lack of full consideration of the digital feature of each criterion (Rating DMU) in the cross-efficiency matrix. For example, the difference between self-evaluation (CCR efficiency) and peer-evaluation (cross efficiency), have not been involved in the cross-efficiency models mentioned above, which is also an important feature to be considered for the peer evaluation mode while conducting the cross-efficiency measurement process.

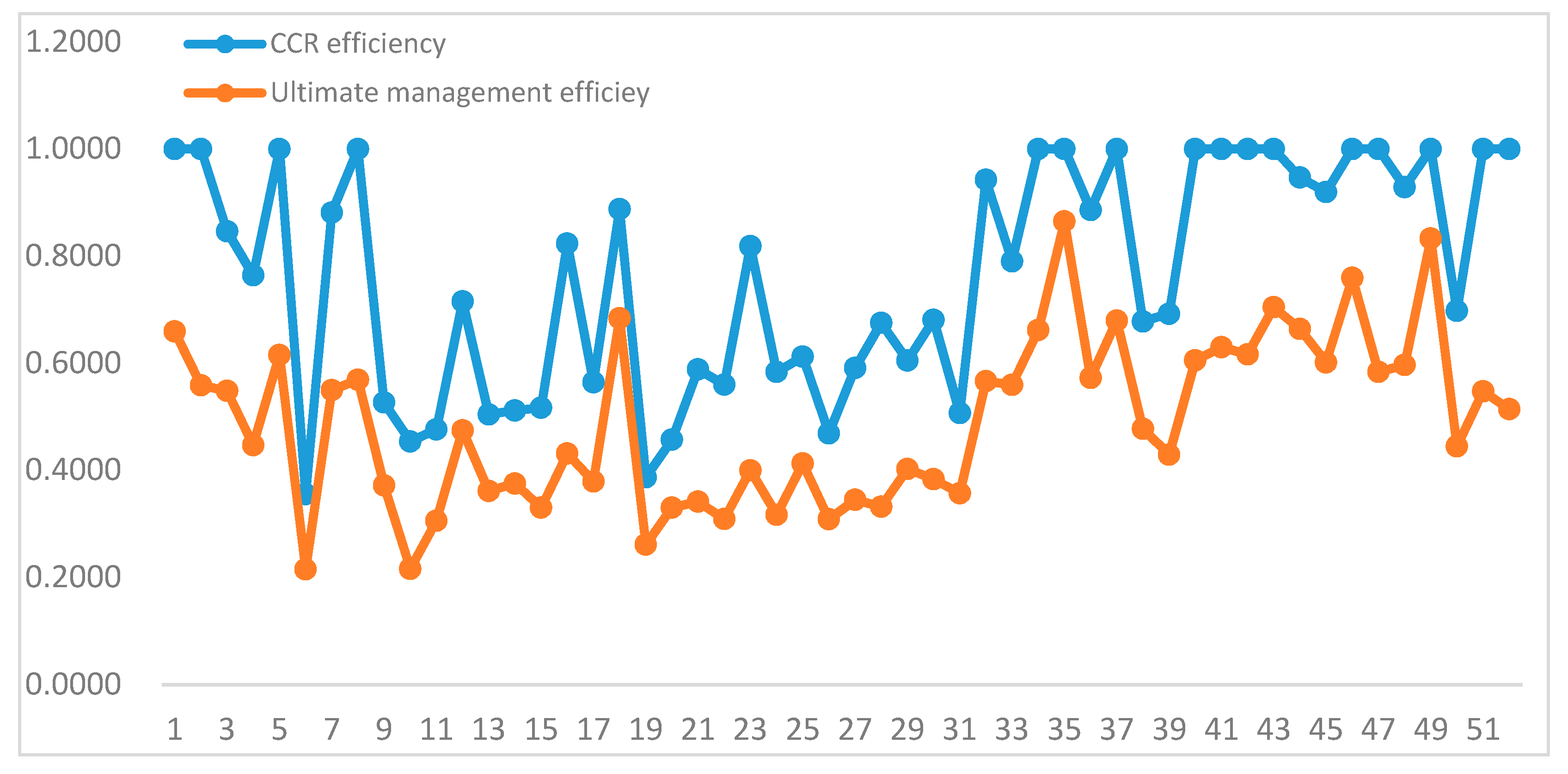

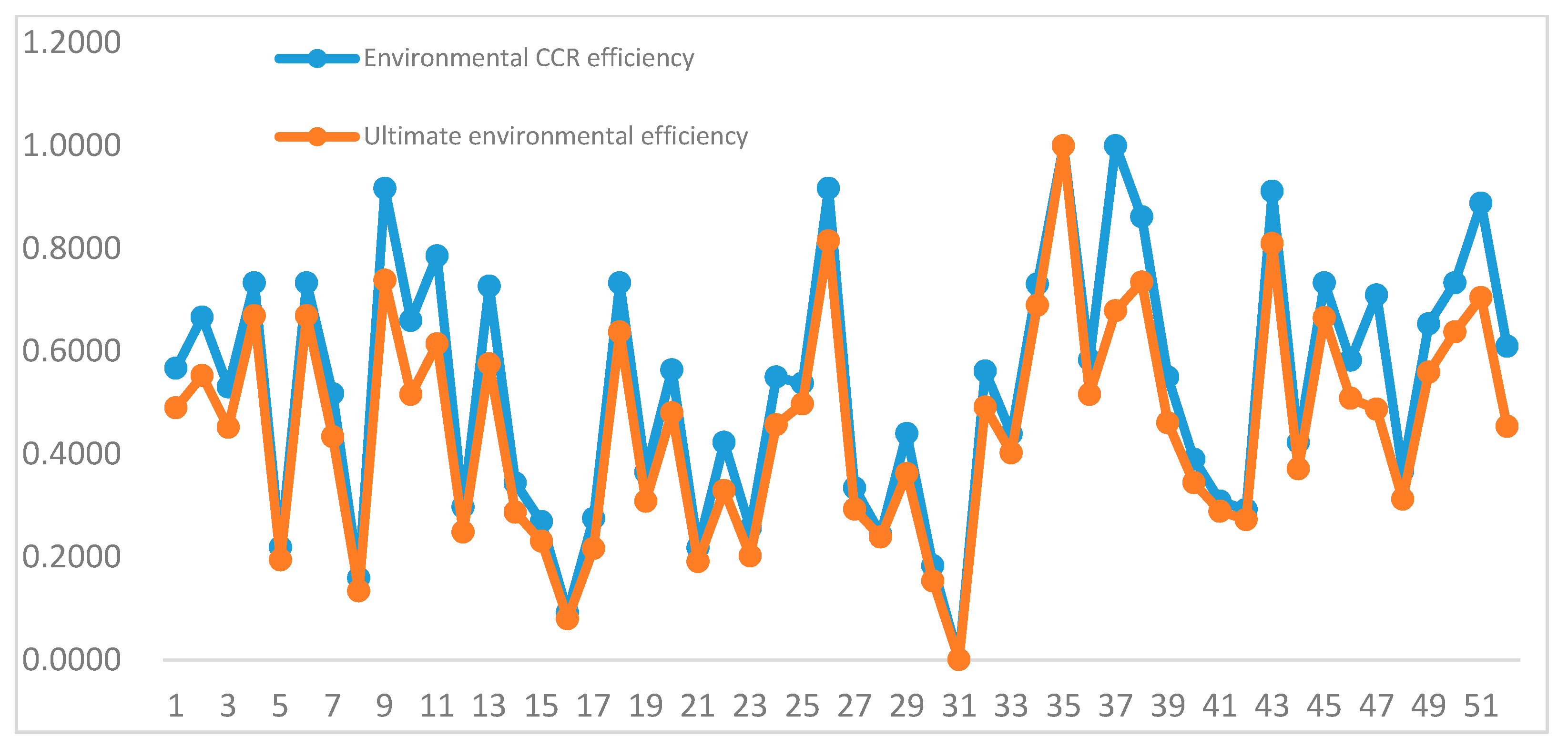

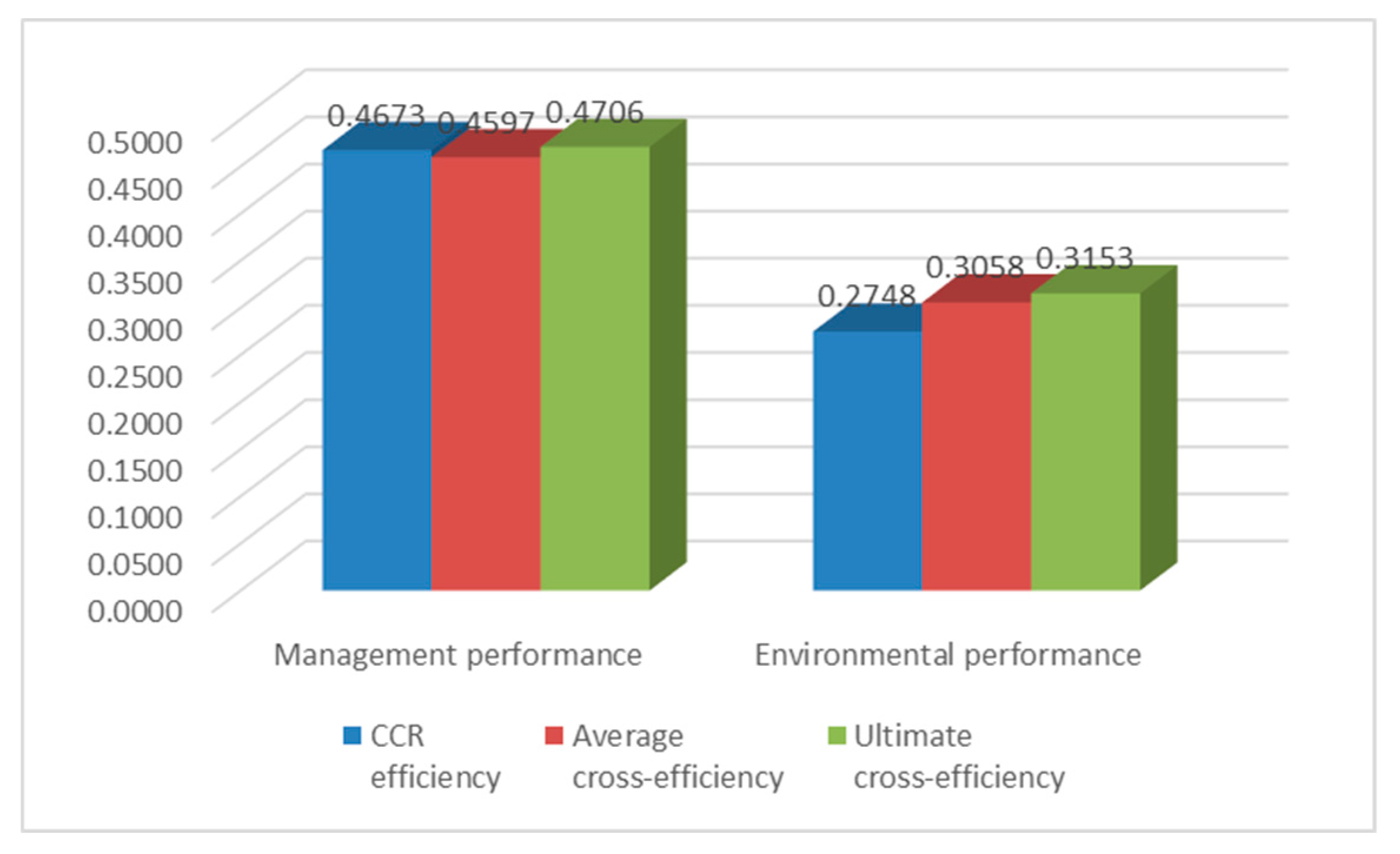

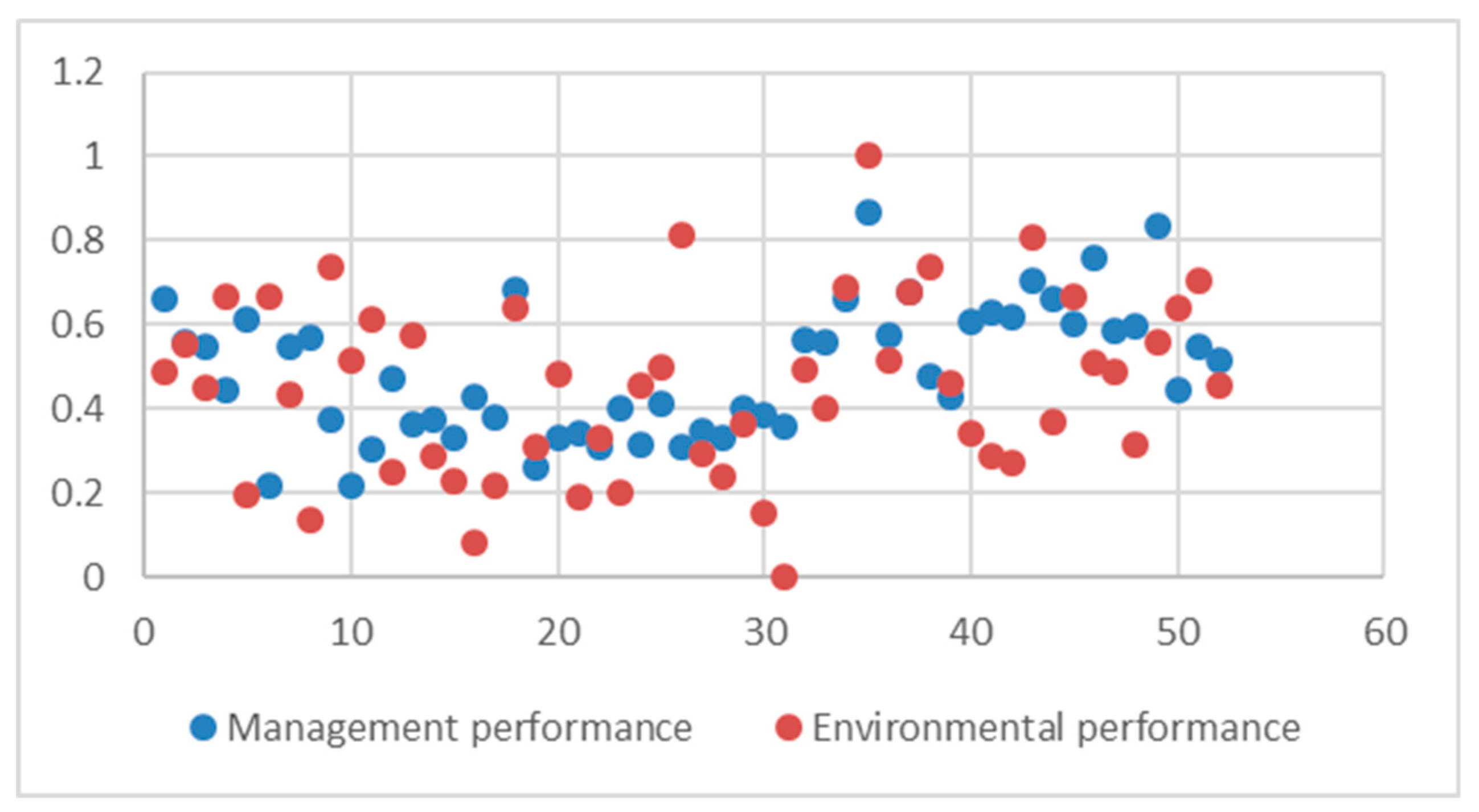

In this case, this study creatively proposes the ultimate comprehensive cross-efficiency evaluation approach (UCCE) with better discriminating ability, which is integrated with two statistical concepts, the Mahalanobis distance and the variation coefficient, such that the numerical characteristics for each criterion can be taken into account and the reliable evaluation results can be produced. We firstly applied it to address the problem of family farm performance evaluation in this work. The management performance evaluation is used to evaluate family farms’ operational efficiency, and their evaluation system consists of utilized agricultural area, labor wages, land rent, machinery operation cost, fertilizer input, pesticide input, and seed input as input measures and crop output value as an output measure. Environmental performance refers to the measurement of relative environmental impact using a measurement system composed of pesticide use per hectare and fertilizer use per hectare as inputs and straw recycling rate as an output index. Family farms are agricultural production units administered by the government, which are at the early stages of development. Each year, the government aims to summarize success and failure and then reward those outstanding family farms to set an example for other farms for improving productivity and reducing negative environmental impacts. In this study, we evaluated family farms’ relative performance and offered a full rank in our proposed UCCE framework. The 35th family farm ranks the first place regarding both management and environmental performance, with performance scores of 0.8648 and 1.0000 while the sixth farm comes bottom concerning management performance with 0.2152 and the 31st farm produces the lowest environmental score of 0.0005. There is weakly positive relationship between the efficiency of the two aspects.

Additionally, we aimed to determine each selected variable’s degree of influence on family farms’ performance. To handle it, we proposed the gray relational analysis. The dependent variable is the estimated score of family farms’ UCCE efficiency (both in terms of management and environmental) and the explanatory variables are their relevant inputs and outputs. For example, we use fertilizer input per hectare, pesticide use per hectare, and straw recycling rate as explanatory variables, while the environmental efficiency score is used as a dependent variable. The result shows that the three explanatory variables have the nearly same degree of influence on environmental performance.

In general, major scientific contribution of this work can be summarized as follows: (i) we firstly designed the evaluation system about family farm’s management and environmental performance and collected the related data of 52 family farms in 2017 in China; (ii) we creatively proposed the UCCE approach to adapt to the issue of family farm’s performance evaluation in this paper; (iii) the relationship between management and environmental performance is investigated and then factors influencing the performance score are further explored and ranked, using gray relational analysis.

The structure of this article includes: The following section summarizes some related literature. The third part depicts the posed means and collected data. The means applies to the fourth section, and then analysis and discussion are conducted. The last part draws some conclusions and discusses the completion of this work.

3. Methods and Data

3.1. Cross Efficiency Evaluation

Suppose there are n DMUs and each DMUj(j = 1, 2 ..., n) has m different inputs xij(i = 1, 2 ..., m) and s different outputs, yrj(r = 1, 2 ..., s).DEA cross-efficiency is generated by the following two steps:

Step 1: The self-evaluation mode of DEA is represented by the constant return-to-scale (CRS) DEA model by Charnes et al. (1978). The model for DMU

d(

d = 1, 2, …,

n)’s efficiency evaluation is expressed as

where

urd and

vid represent the weights for the

rth output and

ith input for DMU

d, respectively. For each DMU

d, we obtain a set of optimal weights (

) by solving model (1).

Step 2: Apply the weights derived from Step 1 to all DMUs to obtain the cross-efficiency values of each of the DMUs. We define Edj as the cross-efficiency of each DMUj using the optimal weights of DMUd. The algorithm for calculating Edj is

Next, we list the cross-efficiency matrix (CEM) in

Table 1.

Then, the traditional cross efficiency value of each DMUj, , an average of all is calculated by

It is obvious that the cross-efficiency value generated by Formula (3) is an average one, which means it treats every evaluation criterion as equal. However, there are at least three shortcomings when the average cross-efficiency is used to evaluate and rank the DMUs:

(1) Averaging cross-efficiency causes a loss of association with the weights [

21]. The average cross-efficiency is not the only way to rate the units. One might also consider the range, variance, or the median as alternative ranking factors [

24].

(2) The original efficiency score obtained from self-evaluation mode plays a distinctive role in the final overall assessment and ranking, since it lies on the leading diagonal of the CEM [

25]. Therefore, it is unreasonable to regard them equally with other cross-efficiency scores.

Due to the simple aggregation method that ignores the relative importance of the cross-efficiency scores, it is often difficult for the average cross-efficiency approach to reveal all the DMUs’ real performance [

27].

3.2. Determination of Ultimate Comprehensive Cross-Efficiency

Assume there are k alternatives with t evaluation criteria to be evaluated for decision-making. It is an ideal case for decision makers that each DMU scores with great dissimilarity for each given attribute, because this makes it easy to distinguish and rank all the alternatives. However, the actual conditions do not always cooperate with the ideal case, but are rather complicated.

Zeleny states that, “If all available alternatives scores are approximately equal with respect to a given attribute, then such an attribute will be judged unimportant by most decision makers. Such an attribute does not help in making a decision” [

44]. Zeleny’s viewpoint can be applied to evaluate the decision-making units. The decision-making matrix can be expressed as

According to Zeleny, it is reasonable to assign a small weight to the

ith criterion if this criterion generates similar values across all alternatives [

24].

In the case of cross-efficiency aggregation, the relationship between our decision-making matrix and the cross-efficiency matrix is:

To evaluate DMU

j under Criterion

d(d = 1, 2 ...,

n) means to apply the optimal weights of DMU

d to DMU

j and obtain cross-efficiency value

Edj. The dissimilarity of the efficiency values under the rating DMU

d is measured by the variation coefficient, which shows the extent of variability in relation to the mean of efficiency values. Meanwhile, the cross-efficiency evaluation method is used to improve the power of DEA in discriminating the efficient DMUs by incorporating peer evaluation [

45]. Therefore, the difference between self-evaluated efficiency and peer-evaluated efficiency should be taken into account. Considering this, the statistical concept of ‘Mahalanobis distance’ is employed to measure the difference between this study and the viewpoint that the impact of each column’s unit in

Table 1 should be reduced.

3.2.1. Principle of the UCCE Approach

Considering the research subject in this study, the principle of this proposed method is assigning aggregation weights corresponding to the digital features, including the variation coefficient and the Mahalanobis distance of each criterion. The operation of family farms presents unique features due to the influence of natural and social factors, which means that each family farm has a group of particular input-output data. Each time we evaluate a family farm’s performance by model (1), we would obtain a corresponding set of optimal weights. In the cross-efficiency evaluation approach, we take each set of optimal weights as an evaluation criterion for all DMUs (family farms). For the purpose of the objectivity of a family farm’s performance evaluation, it is reasonable to apply weights in accordance with the digital features of the criterion described above.

3.2.2. Calculation Procedure of UCCE

Finally, the procedure for the calculation of the proposed UCCE approach is defined as

Step 1. We define for rating DMUd and for the self-evaluation CCR score. Both Pd and O are points in the N-dimensional Euclidean space.

Step 2. Calculate the difference between self-evaluated efficiency and peer-evaluated efficiency using the Mahalanobis distance between point P

d and O

where

represents the variance of the rated DMU

j’s cross-efficiency scores,

and

Step 3. The variation coefficient for rating DMU

d is expressed by

where the standard deviation value for rating DMU

d is calculated by

and

Step 4. Normalize the sequence of the Mahalanobis distance and the sequence of coefficient variation to avoid the impacts of units.

Step 5. The weights to aggregate the cross-efficiency scores of DMU

j(

j = 1, 2 ...,

n) are defined as

The weights derived from Formula (6) take both the distance and the variation coefficient of a criterion into account. The larger the value of parameter λd is, the more important the criterion is.

Consequently, the ultimate comprehensive cross-efficiency can be aggregated as

3.3. Gray Relational Analysis

Gray relational analysis is one of the most widely used models of gray system theory that has been applied in various fields of engineering and management [

46,

47,

48]. The agricultural production system is actually a gray system with incomplete information. Family farms are a representative agricultural production unit. Therefore, we apply GRA to investigate the production variables’ impacts on family farms’ performance in this study.

When the units in which a DMU is measured are different for different variables, the influence of some variables may be neglected. This may be the case if some performance variables have a very large range [

49]. Therefore, it is necessary to process all performance values of every DMU into a comparability sequence by a process analogous to equalization. For an efficiency-determination problem, both inputs and outputs are potential variables that influence the ultimate efficiency, and we regard each DMU as an observation. The GRA is used to rank important variables that affect the efficiency of DMUs. If there are m variables and n observations, the

ith variable can be expressed as

Xi(

i = 1, 2 ...,

m). The observed data of the cross-efficiency and variables are shown as

where

is the observed value of the

ith variable and

is the cross-efficiency value. The term

Xi can be translated into a comparable sequence

by

in order to reduce the impact of different units, where

is the mean value of the n observations of

Xi. Meanwhile, the efficiency sequence is transformed in the same way:

Let , .

We denote:

where

is the GRA coefficient between

and

, and α is the distinguishing coefficient,

.

Deng stated that the value of 0.5 is normally applied [

50]. After calculating for the gray relational coefficient

, the gray relational grade can then be calculated as

Here, denotes the normalized weight of criterion j, where with equal weights. The proposed methodology, which applies GRA to rank the most important variable with respect to family farms’ performance, is thus developed. The rank-ordering algorithm is applied to determine the ranking of the variables.

The gray relational grade indicates the degree of similarity between the comparability sequence and the reference sequence [

50]. In this case, if a comparability sequence for a certain variable obtains the highest gray relational grade with the UCCE efficiency sequence, this means that the variables have the largest influence on family farms’ performance, and these variables are the most important.

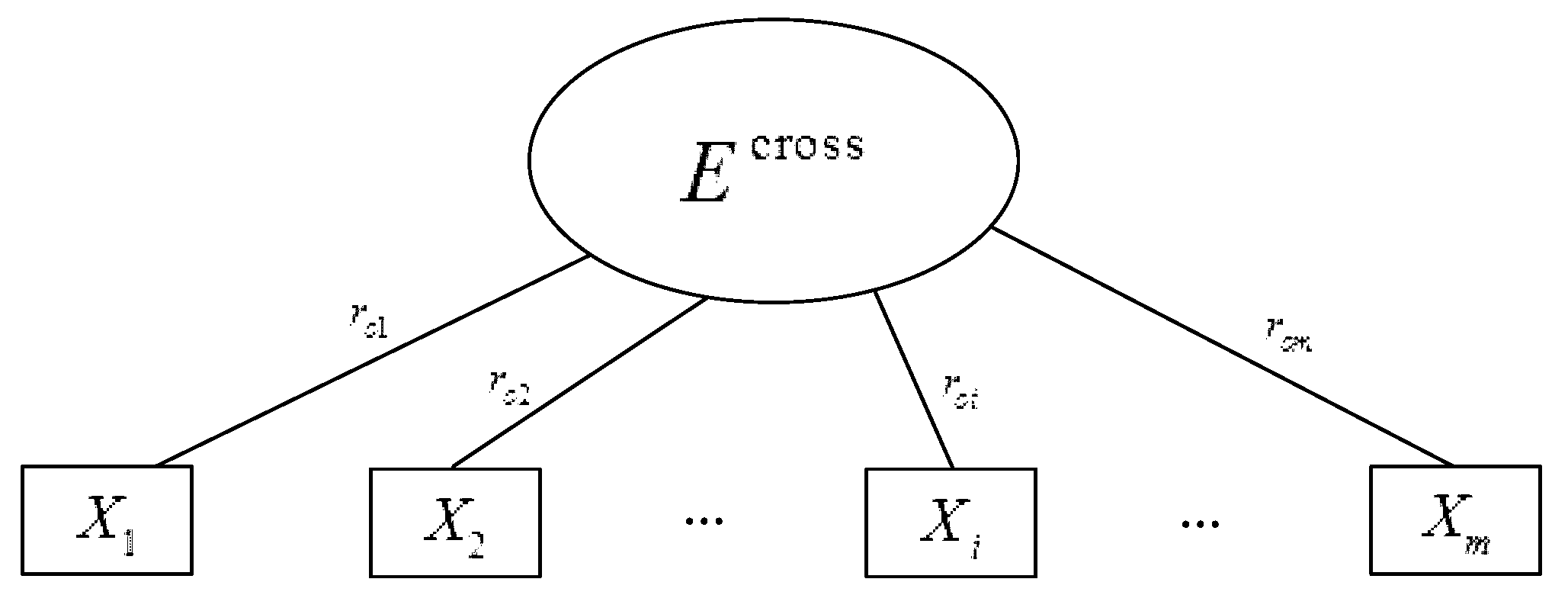

Figure 1 shows the relationship between cross-efficiency and relevant variables.

3.4. Data Collection

We chose a sample of 52 representative family farms that distribute across Jilin and Shandong provinces and produce various grain crops, including corn, rice, wheat, sorghum, soybean, etc.

Field investigation and face-to-face interviews were carried out with farm owners, members and local agricultural enterprises. The data used in this paper are obtained from operations in 2017, and each family farm is considered as an independent DMU.

Two regional differences affecting agricultural production between the two provinces are summarized as follows: (i) one season crop in Jilin, two seasons in Shandong due to the temperature difference; and (ii) family farms in Jilin has larger land area, and conduct more intensive and large-scale operation than Shandong.

3.4.1. Variables for Management Performance Evaluation

For illustrative purpose and without a loss of generality, seven inputs and one desirable output, which cover the whole production activity of family farms, are selected to evaluate family farms’ management performance.

Table 2 shows all the variables selected. Labor Wages were quantified as the total value of RMB spent for family farms’ labor use (family workers and independent workers, both permanent and temporary) in each operation related to agricultural production. Utilized agricultural area is the operation area of a family farm. It is the total area that every family farm produces crops on. Land rent is the RMB cost of the UAA. A family farm’s own land is regarded as equal to their contracted land, both of which are priced according to the market conditions at that time. Machinery operation cost is determined by the expense (RMB) of renting large agricultural machines and the cost of irrigation. Fertilizer input includes expenditures on all kinds of fertilizers (RMB), which have different impacts and contributions during the crop growth stage. Pesticide input refers to the expenditures (RMB) of all pesticides used throughout the whole crop growth stage. Seed input is the cost (RMB) of crop seeds (such as corn seeds) or seedlings (such as rice seedlings) at the preliminary stage. The crop output value is the only desirable output selected. We use the crop yield multiplied by the market price to get this indicator, which reflects family farms’ yearly outcomes.

3.4.2. Variables for Environmental Performance Evaluation

We selected two inputs and one output, as are shown in

Table 3, to evaluate the 52 family farms’ environmental performance: the fertilizer input per hectare (FIPH) and pesticide input per hectare (PIPH) as input indicators, and the straw recycling rate (SRR) as the output indicator. The three selected variables cover the environmental issues in the field of agriculture that receive the greatest attention from both the government and the public in China.

As a variety of fertilizers and pesticides that function differently are applied during the crop growth stage, it is not wise to simply add them together by their weight. Therefore, we calculate the fertilizer input and pesticide input per hectare by Chinese Yuan (CNY) based on the analysis of field research that more spent on fertilizers and pesticides means less concern about the negative impact on the environment for each family farm.

The SRR is the occupation proportion of appropriately disposed of straw of the total amount produced. This variable is defined as a ratio with a value between 0 and 1, theoretically, and it can be equal to 0 or 1. The observed data of the SRR is between 0 and 1.0. Straw that is appropriately disposed of is straw that is sent to power plants, crushed to be used as fertilizer for the farmland or reused as cattle feed instead of being burned directly without any decontamination measures.

5. Conclusions

Family farms are important production organizations that contribute to realizing China’s agricultural modernization. At present, China’s agriculture has not yet fully achieved large-scale production and is still in the development phase. At this phase, family farms play a vital role as a new agricultural production entity and they will have a large impact on China’s economy.

In line with the family farm performance evaluation issue, we modified the DEA cross-efficiency approach (UCCE) by taking unique features of family farms into consideration. Regarding the use of each rating DMU’s optimal weight as an evaluation criterion, we assigned reasonable weights to each criterion and took into account the two statistical quantities, variation coefficient and Mahalanobis distance. The evaluation results show a significant improvement contributed by our proposed approach from multiple perspectives:

- (1)

It effectively reduces the number of efficient DMUs.

- (2)

The results of our ultimate cross-efficiency generate the highest variation coefficient compared with CCR efficiency and average cross-efficiency.

- (3)

It lowers the CCR efficiency value due to the reduction of the impact of self-evaluation.

The main reasons for the above improvements are that our approach takes the diversity of the evaluation results into account, as suggested by Zeleny. Regarding the cross-efficiency matrix, the diversity of the evaluation results is expressed by the variation coefficient of each row and the Mahalanobis distance between CCR efficiency results and each row of the cross efficiency matrix.

By analyzing all the family farms’ management and environmental performance, and by combining it with the information gathered from field research, several conclusions are drawn below.

- a)

There is weak positive correlation between family farms’ management performance and environmental performance.

- b)

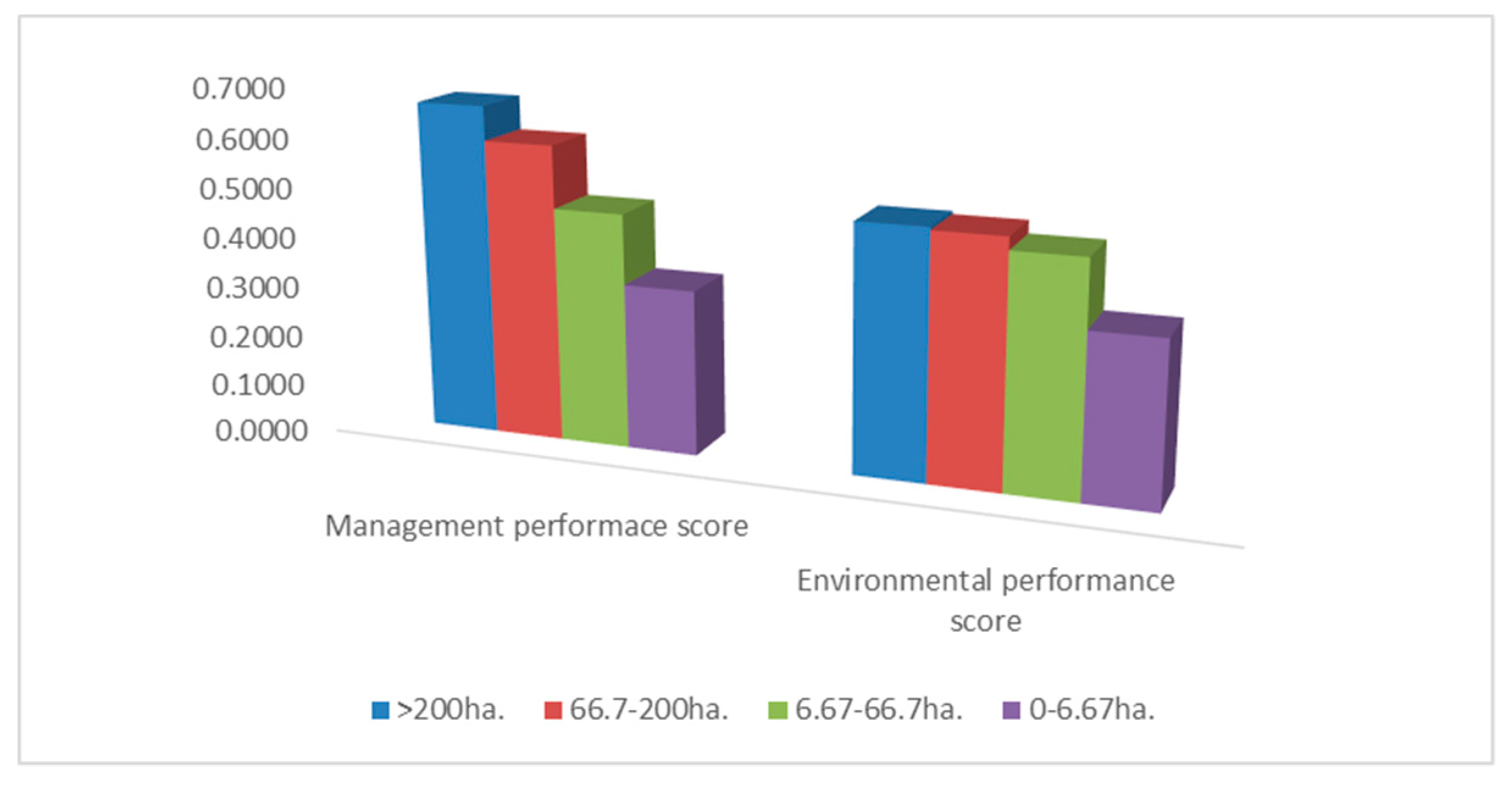

There is a corresponding increase for all 52 selected family farms’ management and environmental performance with the expansion of utilized agricultural area. However, a higher variation extent for management performance than environmental performance is presented.

- c)

According to the results of field research, farm owners’ management skills and experience play a great role in family farms’ daily operation. Farmers who are aware of the needs of environmental protection are usually those experienced farmers who have long-term plans for their family farm’s development.

- d)

Based on the evaluation results of our selected family farms, we conclude that the number of crop species has an obvious impact on family farms’ management performance and family farms in Jilin province performed better than those of Shandong in 2017.

- e)

The variables’ ranking order regarding their degree of influence on management performance is: labor wages, utilized agricultural area, land rent, machinery operation cost, fertilizer input, pesticide input, seed input, and crop output. There is an urgent demand for technological instruction for family farms, especially those that operate on a large scale. Farm owners need sufficient market information to make a decision about the production plan for the next year and improve agricultural production sales.

- f)

The variables’ ranking order regarding their degree of influence on environmental performance is: fertilizer input per hectare, pesticide input per hectare, and straw recycling rate. New technology focusing on reducing the usage of fertilizer and pesticides should be introduced by the government. Meanwhile, laws that prohibit the burning of straw to avoid air pollution are urgently needed. Livestock breeding and mushroom cultivation can consume the straw and generate biological organic fertilizer.

Some limitations exist in this work. Firstly, we only collected the production data of 2017 rather than a time series data due to time constraint. Secondly, the sample size is relatively small and all the regional distribution is not wide enough. As future work, our research will pay attention to two aspects: (i) based on this research, time series data will be collected to conduct a trend analysis of family farm’s management and environmental performance and we would expand the sample size; and (ii) the proposed method UCCE will be applied in other fields, such as energy saving assessment and green evaluation. Moreover, software related to assessment methods will be designed and applied in the assessment process.