Abstract

In Ljubljana, the capital of Slovenia, surface road traffic prevails and there is a strong need to free urban areas and use underground space for public transport. As a result of excessive use of combustion engines, the concentration of particulate matter and CO2 emissions in Ljubljana is high and is of public concern. For this purpose, several studies have been made in which sustainable development of underground transport has been considered as an alternative for rail, inter-rail and city traffic. The city of Ljubljana lies on quite a diverse geological substratum, consisting of alluvial and lacustrine deposits. A complex hydrogeological situation comprising a high water table and perched water supply zones located within the urban environment presents a particular challenge for underground construction. For this reason, a research study concerning the sustainable development of underground traffic in the Ljubljana Basin was carried out. The results of the study presented in the paper highlight the possible technological conditions for the development of underground transport with a particular emphasis on sustainability and environmental impact.

1. Introduction

The basic principles of sustainable mobility in Ljubljana are understood from a sociological perspective as fulfilment of the needs of current and future populations for free movement, accessibility, communication, exchange, and formation of links without sacrificing other fundamental human or ecological values. In particular, the subject of this research is focused on the sustainable development of underground transport in the Ljubljana Basin as the organizing principle for meeting the needs of the Ljubljana population for urban mobility, while at the same time sustaining the ability of hydrogeological and other natural systems to remain fully functional during construction and in the future.

In Ljubljana and its surroundings, transport using personal vehicles is predominant, which has, until now, channeled public investment solely into the modernization of road infrastructure. Clearly, in the long term, this is unsustainable due to the high environmental impact of transport solely based on the use of combustion engines. In Ljubljana, air with concentrations of particulate matter (PM10 < 10 µg/m3) higher than the 50 µg/m3 allowed is common, especially during the winter months and during the six-month-long heating season. To address the issue of the long-term sustainable development of transport in Ljubljana, the possibility of the use of underground space has been considered in different studies, such as: Conditions for managing the public transport of the Ljubljana Urban Region (LUR) [1], and the study on the modernization of the Ljubljana railway hub [2]. In these reports the variants containing the need for extensive underground construction were studied, but no attention was paid to technical details, build-ability or ecological issues related to such an investment. As emphasized by Shepherd and Ortolano [3] when promoting sustainable urban development, the sustainability principles should be considered integrally and systematically, including the engineering aspect presented here, which should be made part of the planning and policy context.

The purpose of this research was to examine the relevant conditions for the development of urban underground traffic in the Ljubljana Basin. The research work was based on the following methodology: (a) identification of the geological, geomorphological and hydrogeological conditions relevant for underground construction, (b) selection of the appropriate type of tunneling, (c) evaluation of short-term and long-term environmental impact and (d) interpretation of the results in terms of sustainability of the development. The research work, carried out as a desk study, was concentrated on gathering and evaluating relevant information including the spatial distribution of specific data, such as historical borehole logs, evaluation of soil and rock parameters, long-term hydrogeological monitoring, distribution of water-protected areas and others. Numerical analyses were used for the determination of the environmental impact, notably the assessment of subsidence caused by the tunneling. In particular, the focus of the research was the short-term and long-term effects of tunneling on the complex hydrogeological systems of the Ljubljana Basin. In particular, the groundwater was seen as a major valuable resource, and sustainability must be considered with great care, as emphasized by Becker et al. [4].

Two critical conditions were considered: (a) sustainable build-ability, and (b) the consequent environmental impact. Several types of underground construction were considered including cut-and-cover and conventional mining and other tunneling methods. Particular attention is given to TBM (Tunnel Boring Machine) technology, which was considered the most relevant as it is widely used for tunnel construction in urban environments, most commonly for the construction below the ground water table and in very diverse geological conditions typical of the Ljubljana Basin.

The range of available geological and geomechanical data related to the potential routes for the expansion of the underground transport in the Ljubljana Basin are presented in this paper. The conclusions are derived regarding sustainable build-ability, including selection of the appropriate tunneling and mining methods. In particular, the purpose of the study was to determine the sustainability of the development of underground transportation by addressing the following questions: (a) what are the conditions for underground construction in the Ljubljana Basin, (b) is the use of TBM technology appropriate for these conditions, and (c) what would be the potential environmental impact for this type of construction?

2. Planning of Underground Transport Links in Ljubljana

In spatial and functional senses, Ljubljana is developed as a regional center and national metropolis integrating the urban settlements of some 500,000 to 700,000 habitants. In the last two decades, despite the increase in mobility, the number of rides using public transport dropped from 168 million to 90 million, so that now almost 71% of the population uses private cars for urban mobility, which is one of the highest percentages in comparison with other European cities of similar size. During the period 2001 to 2008 the number of private cars per 1000 capita increased from 475 to 529 causing permanent rush-hour congestion of the roads and prompting the need for further investment in road infrastructure [1]. This closed vicious circle is clearly unsustainable in the long term, so Ljubljana needs efficient and integrated public transport.

In a socio-economic sense, authorities considered the use of underground space in the Ljubljana Basin as an appropriate alternative to the current unsustainable state [5]. The benefits of integrated development of public transport will bring to Ljubljana the status of an urban region of European significance. This potential was recognized by the program ESPON (European Spatial Planning Observation Network), which placed Ljubljana into the category of MEGA (Metropolitan European Growth Area) urban areas, together with the neighboring cities of Milan, Bologna, Munich, Vienna, Bratislava, and Budapest [6].

In the study on the regulation of public transport of Ljubljana carried out by Bensa et al. [1], six systemic solutions were examined, including the Park and Ride (P+R) concept, in which the three main express lines of public transport including the partial use of the existing transport system were considered. It was established that an underground metro system powered by electricity is more sustainable in comparison with the other options. The advantages of underground transport comprising the total length of 35 km were summarized in three main categories: (a) the maximum passenger transport capacity, (b) no local emissions and (c) the highest average velocities.

In addition to the study by Bensa et al. [1] a study on the modernization of the Ljubljana railway hub was also carried out by Žličar et al. [2] with emphases on the sustainable development of the existing railway infrastructure. The aim was to separate passenger and freight traffic through the city center using the deepening of the routes of the currently surface bound railway lines. Variant 1, which was chosen as an optimal solution provides the arrangement of an existing main Ljubljana train station at −1 level (8 m below ground; approaching tunnels at 16 m below ground) and the construction of the freight track routes at −2 level (16 m below ground; approaching tunnels 25 m below ground). The arrangement of railway routes at levels −1 and −2, which were considered in the study throughout the broader city center of Ljubljana, is shown in Figure 1. The total track length considered in the study was 163.1 km, of which there were 61.6 km of tunnels, 8.7 km of bridging facilities or overpasses and 92.7 km of the open track. Variant 1 of Žličar et al. [2] was in line with Variant 4 of Bensa et al. [1] so together, they were considered as optimal, realistic, and highly probable infrastructure development for the city of Ljubljana in the near future.

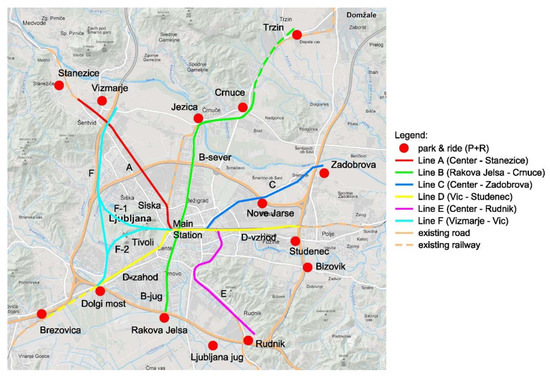

Figure 1.

A combination of the tunneling routes (A to F) in Ljubljana Basin, based on the studies of Bensa et al. [1] and Žličar et al. [2].

Socio-economic consequences of the utilization of the underground space, which is readily available for the regulation of public transport and railway traffic, would bring huge benefits to both Ljubljana and Slovenia. Space is increasingly considered in sustainability transition research [7] encompassing concepts of location, uneven development, scaling, and local embeddedness aiming to raise awareness to appropriate spatial distribution of resources to achieve sustainability. The regulation of the inter-rail and city traffic using underground space would significantly improve persistent air quality issues in Ljubljana by reducing the PM10 and CO2 emissions. However, this would be only the by-product of the main effect, which comes as a consequence of the particular location of Slovenia at the cross-roads of the freight traffic between West and East Europe.

Located at the crossing of the two European motorway corridors X and V, Ljubljana motorway ring road is heavily congested by the road freight traffic directed to and from the five northern Adriatic Sea ports of Koper (Slovenia), Trieste and Venice (Italy) and Rijeka and Krk (Croatia); all being within one to two hours driving distance from Ljubljana. The main benefit from the regulation of the Ljubljana railway hub would be the re-direction of the freight traffic from the motorways to the railways. As emphasized by several authors [8,9,10], the freight road traffic is a major worldwide environmental issue, which needs sustainable solution. The potential environmental benefits of re-routing of the road freight traffic to railways in Slovenia are significant for obvious reasons. The freight traffic damages the motorway network infrastructure and is one of the main polluters of the environment. In the long term, the impact on the deterioration of the motorway network in Slovenia is considerable.

As part of the wider assessment of transport policy in Slovenia the decision makers across the political spectrum already accepted the concept of re-routing the freight traffic to railways as a sustainable solution [5]. Some of the activities on the enlargement of the capacity of critical sections of the railway network are already under-way (e.g., construction of the second railway lane between the logistic center Divača and the port of Koper).

For the research in this study, the integration of Variant 1 of Žličar et al. [2] and Variant 4 of Bensa et al. [1] shown in Figure 1, was used to determine the optimum location of the potential underground lines for the metro and the railway network in the Ljubljana Basin. It can be seen in the figure that the underground lines are routed along the main arterial roads and connect the (P+R) car parks. All the lines are linked to the main Ljubljana station so that the railway lines run along the existing corridors but at different depths. Use of the existing corridors is regarded as a sustainable solution to overcome the restricted conditions for the new developments in the ground water-protected areas. The exemption of this rule is made only for track F, which runs along the new route, but is located outside the ground water-protected areas. The total length of the potential underground tunnel network is 62.5 km.

3. Geological and Hydrogeological Conditions

3.1. Geological and Geomorphological Features

In terms of structural geology, the location of Ljubljana city represents a sedimentary basin filled with Quaternary sediments. The basement rock consists of Carboniferous and Permian sandstones, conglomerates and marls, and partly also Triassic and Jurassic limestone and dolomites. The northern part of the Ljubljana Basin is filled with glacial-fluvial deposits of the river Sava, which have a thickness of up to 100 m, and consist mainly of layered carbonate gravel with layers or conglomerate and occasionally clay and sand lenses, which are water bearing. In contrast, the southern part of Ljubljana Basin is filled with lacustrine and river deposits, which are extremely heterogeneous. They consist of intermittent layers of clay, gravel, sand, mud, lake chalk and peat. In this part, basement rock is located at a depth of 200 m, with outcrops on the surface in the form of the centrally located hills of the Šišenski and Grajski hill, and to the south, of the Golovec hill.

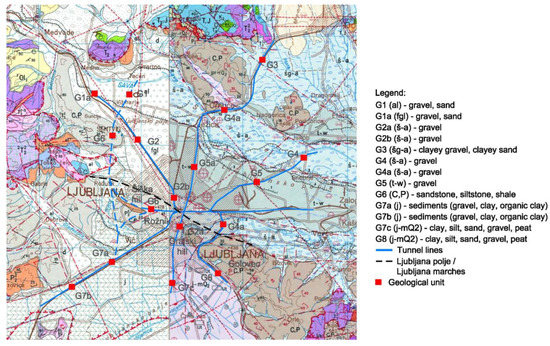

The geological map of the Ljubljana Basin is shown in Figure 2. In terms of geomorphology, the Ljubljana Basin is divided between two distinctive zones: the Ljubljana Marshes in the south-west and the Ljubljana “polje” (Polje in the following) in the north-east, the border of which is designated in Figure 2. The predominant part of the soil sediments in the Ljubljana Marshes and the Ljubljana Polje were deposited in the Pleistocene and Holocene eras and are generally normally consolidated. The alluvial sediments from that period in the Ljubljana Polje extend to the surface, so that the Pleistocene deposits consist of predominantly Sava gravel and conglomerates found at various depths [11]. Due to the relatively high differences in the velocity of the flow at the time of deposition, the ancient watercourses contributed to a large amount of sediment accumulation, which often caused a rapid filling up of the collapsed terrain. A different process occurred in the Ljubljana Marshes, in which the drainage of the waters from south to the north was closed by the then existing hills. The rapid sedimentation of river sediments was followed by the slower lacustrine sedimentation and sedimentation in slowly flowing and meandering rivers.

Figure 2.

Geological map of the Ljubljana Basin overlapped by the possible tunnel routes.

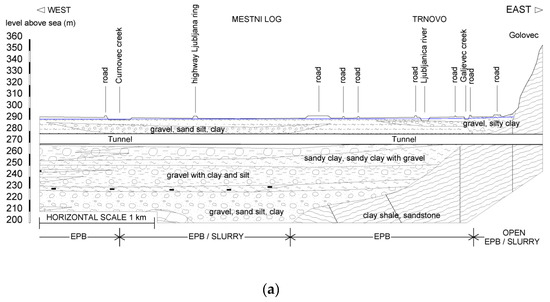

The result of these relatively recent geological developments is the extremely heterogeneous composition of the soil throughout the area of the Ljubljana Basin, with a clear distinction between the deposits of the Ljubljana Polje and the Ljubljana Marshes. The typical geological cross sections for the Ljubljana Marshes and the Ljubljana Polje, which clearly demonstrate the points given above, are shown in Figure 3.

Figure 3.

Typical geological cross sections for (a) the Ljubljana Marshes and (b) the Ljubljana Polje and selection of the appropriate TBM technologies for excavation at tunnel level.

3.2. Hydrogeological Features

Given the diverse geological and geomorphological conditions, the Ljubljana Basin is also a hydrogeological environment of highly complex features. The basin is supplied by the two major rivers Ljubljanica and Sava and their tributaries. River Ljubljanica is interconnected with the groundwater of the Ljubljana Marshes, for which the entire precipitation area of karst springs catchment area covers about 1300 km2. There are several levels of groundwater on the outskirts of the northern-west part of Ljubljana, in which the layers of gravel and clay rapidly exchange. These upper horizons of groundwater flow into the lower horizon, which is located at a depth of approximately 24 m. In the central part of Ljubljana, the permeable and less permeable sediments also exchange rapidly, therefore two central horizons of groundwater can be detected. The top of the upper horizon is located somewhere almost on the surface, otherwise at a depth of 2 to 4 m. The upper layer is fed from the west side and overflows over the lower groundwater horizon, located at a depth of approximately 15 m. The groundwater level varies due to the local exchange of more or less permeable layers, for which the permeability of the aquifer is estimated to be between 5.0 × 10−4 m/s and 1.0 × 10−3 m/s [12].

In the northern-east part of Ljubljana, there is an aquifer of the Ljubljana Polje, which is one of the largest and most important aquifers in Slovenia. The aquifer is mostly unconfined, and in the south-western part of the area there are less permeable layers, which allow for the formation of perched water tables and drift aquifers. The quantity of groundwater in the Ljubljana Polje is strongly dependent on the state of the Sava River and the condition of its riverbed. The aquifer permeability is estimated to be between 2.0 × 10−4 m/s and 2.0 × 10−3 m/s [12].

On the Ljubljana Marshes, closed zones are used for the supply of drinking water to the entire city population. The two aquifers are connected so that a part of the groundwater from the Ljubljana Marshes drains through to the aquifer of the Ljubljana Polje, which is also used for the water supply at some closed zones. Altogether, the complexity of the hydrogeological conditions and the interconnection between the two aquifers dictate strong regulations on the protection of groundwater in the entire basin.

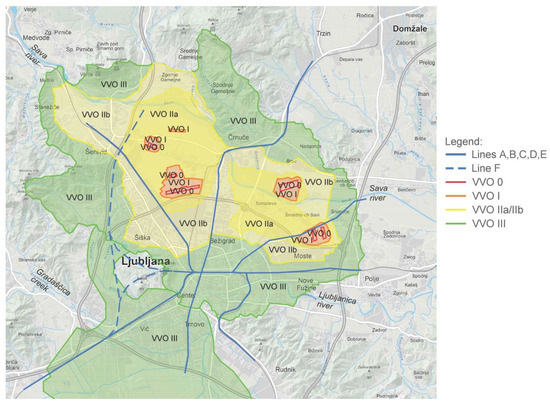

Protected groundwater areas in the Ljubljana Basin located relative to the potential underground routes of the railway and public transport are shown in Figure 4. The two Decrees [13,14] on the groundwater protection area for the Ljubljana Basin aquifers stipulate that underground structures may, exceptionally, be built in the narrower and the wider ground water protection area (GWPA–VVO in Slovenian) (areas VVO II and VVO III in the figure). However, such activities are not allowed around the narrowest protection (area VVO I) and within the direct water supply zones (VVO 0). In addition, as required by the Decree, the two conditions must be met for any underground construction works: (a) excavations in the narrowest and narrower water conservation areas are not permitted unless they are made more than two meters above the highest groundwater level, and (b) excavations in the wider water protection area are permitted above the mean surface water level, except in cases where the construction is exceptionally permitted under the condition that the aquifer’s transmissibility would not be reduced by more than 10%. Further on, the Decree stipulates that tunnels and subways may, exceptionally, be built in the narrower and wider water protection area (VVO II A, VVO II B and VVO III A) and the construction of these facilities is permitted without exception in the wider water protection area (VVO III B), in which a less severe protection regime applies.

Figure 4.

Overlap of the possible tunneling routes and the groundwater protected areas of the Ljubljana Basin (VVO—groundwater protected area).

The data on the location of the potential underground routes and the groundwater protected areas are summarized in Table 1 with an aim to determine the overlap of the tunnels with the water protection areas of the Ljubljana Marshes and the Ljubljana Polje. It can be concluded that the predominant part of the Ljubljana Polje is defined by at least one of the classes of the water protection area, which is certainly a big obstacle for any underground construction. For this reason, the planned routes are selected along the existing corridors so that they do not interfere with the water supply zones (VVO 0) or the narrowest protection areas (VVO I), in which the construction is fully prohibited.

Table 1.

The overview of the possible tunnel lines crossing the groundwater protected areas of the Ljubljana Basin.

3.3. Composition of Soils along the Possible Tunnel Routes

Data on the composition and properties of soil along the routes of potential tunnels were obtained from the Institute for Mining, Geotechnology and Environment (IRGO), namely from the previously prepared geotechnical interpretative reports. Based on the available data the values of geotechnical characteristics and the grain compositions of the individual geological units were selected and attributed to the particular tunnel routes, as shown in Table 2.

Table 2.

The summary of the geological units crossed by the possible tunneling routes in the Ljubljana Basin.

It can be concluded from Table 2 that the tunnels run through eight main geological units for which seven variations of the soil composition can be determined based on the available data. Tunnel lines B-south, D and E at depth from 16 m to 25 m are mostly located in fine-grained to coarse-grained soils with the presence of groundwater in the central and southern part of the Ljubljana Marshes. In the northern part of the Ljubljana Polje, the relevant soils are predominantly sand and gravels, with the parties of clayey or silty soils including conglomerates at some sections (Tunnel lines A, B-north, C and F). The basement rock is deeper in the western part and is approaching the surface in the eastern part of the Ljubljana Polje, while the depth of the groundwater is about 20 m.

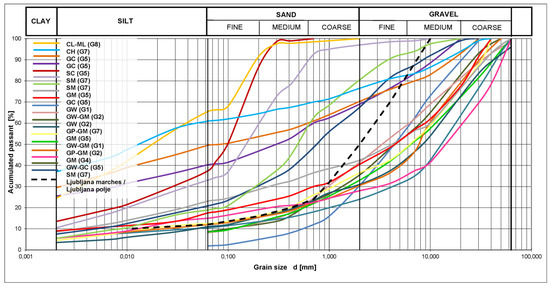

In addition to the geomechanical properties of the soil, the granularity of the soil is considered in particular detail as one of the key factors for the preliminary selection of the method of tunneling. The percentage of the individual fractions in particular has the critical impact on the Tunnel Boring Machine (TBM) performance for several reasons. The behavior of the material in the excavation chamber, the effectiveness of providing support for the excavation of the face, the removal of material, the use of additives, the possibility of further processing of the excavated material are all implicated by the granularity of excavated soil. The graph, presented in Figure 5, shows the representative grain curves for the soil layers, which were selected along the possible routes of the tunnels at depths of 16 m to 25 m in the Ljubljana Basin, both in the Ljubljana Marshes and in the Ljubljana Polje.

Figure 5.

Characteristic granulometric curves for soils on the possible tunnel routes in the Ljubljana Basin.

4. The Methods of Tunneling Applicable in Ljubljana Basin

Conventional methods of tunneling such as drill and blast mining or mechanical excavation in the context of the NATM—New Austrian Tunneling Method (i.e., Spread Concrete Lining method) were considered as part of this study. However, due to extremely difficult and complex geological and hydrogeological conditions explained in the previous section, the conventional mining methods, and the cut-and-cover method, failed the criteria of build-ability at acceptable costs and were ruled out. Due to its advantages compared to the conventional tunneling methods, the TBM technology, which is used worldwide for tunnel construction in urban environments (most commonly for the construction below the ground water table and in very diverse geological conditions), was regarded applicable and feasible for the Ljubljana Basin. Also, TBM technology was considered the most appropriate regarding the long-term effects of tunneling on the natural hydrogeological system, as the fully sealed variant ensures no interference with the water supply zones critical to Ljubljana. For this reason, only the TBM technology was considered in detail, as presented in the following.

The machines for mechanized tunnel construction (TBM) are usually divided into three categories, which are all potentially applicable in the Ljubljana Basin. These are the tunnel boring machines: (a) without shield (gripper TBM), (b) shield machines (single or double shield machines) and (c) adaptable shield machines with combined process technology. The gripper TBM and combined process technology machines are often used in soft rocks. Soft rock in the Ljubljana Basin is found in the form of outcrops of soft Carboniferous and Permian rocks of the Šišenski and Grajski hill, and the hills of Rožnik and Golovec (see Figure 2).

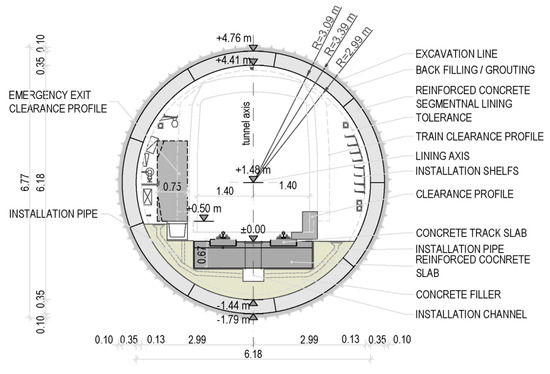

The TBM shield machines are regarded to be the most suitable for the use in the soft soils of the Ljubljana Basin. The basic principle of mechanized tunnel construction of the entire profile is based on driving the cylindrical shaped machine along the axis of the tunnel, where the temporary support is carried out using a rotating cutting wheel and different temporary methods of stabilizing the face. The space between the shield and the ground is filled, so that the shield takes the ground weight and prevents inflows of groundwater, while the stability of the face is ensured at all times. The permanent support system consists of segmented lining, which is installed inside the shield immediately behind the head of excavation. The conditions of face stability in the heterogeneous material of the Ljubljana Basin would vary greatly according to geological conditions and the presence of groundwater. Five different ways were considered to ensure the stability of the tunnel face during the excavation: (a) natural support, (b) mechanical support with a cutting wheel, (c) compressed air support, (d) slurry support and (e) earth pressure balance support. Since heterogeneous ground conditions prevail within a very sensitive hydrogeological environment, the two TBM technologies with single-shield system (Single-Shield Machines or SSM) were selected following the rationale of providing the most appropriate face support for the given local conditions. These are: Slurry type machine (slurry machine) and Earth Pressure Balance machine (EPB machine). Single-Shield Machines are mainly used in soft rock or in over-consolidated ground, in which the face can be supported solely by the cutting head. The lower bound for axial compressive strength of the ground, in which the SSM can be used in the open mode is around 5 MN/m2; the value relevant for stiff clays in the Ljubljana Basin. However, it is expected that it would be necessary to provide the full face support during the excavation for most soils, which are normally consolidated. The characteristics of the slurry machine and the EPB machine relevant to the sustainability of the underground construction are presented and discussed below in some detail. The characteristic cross-section of a TBM excavated one-track tunnel including the support system of segmental reinforced concrete lining, which is expected to be used in the Ljubljana Basin, is shown in Figure 6.

Figure 6.

Characteristic TBM cross-section of one-track tunnel including the support system of reinforced segmental concrete lining.

4.1. Slurry Machine

Considering the sensitivity of the hydrogeological environment it is regarded that the most appropriate way to support the face when using SSM is by slurry, as this can be carried out in controlled manner, so that the low environmental impact can be achieved. The technological treatment of the slurry, which comprises settling, filtering, and improving the slurry properties during the excavation, can be achieved with a high degree of efficiency in clean soils. It is emphasized that the use of the slurry machine requires more control in layers with a high proportion of fine particles, since the treatment of the excavated material and suspension becomes technically less efficient.

During the use of the slurry machine, the stability of the face is not only controlled by the density and viscosity of the bentonite slurry, but also heavily depends on the permeability of the soil. SSM machines are generally suitable for coarse-grained soils with the mixed grain and can be used for the conditions of groundwater table high above the tunnel. In the case of a higher permeability (k > 5 × 10−3 m/s), which is widely present in the Ljubljana Basin, there is a risk of uncontrolled leakage of the slurry into the ground and pollution of the environment. In such cases, it is possible to improve the rheological properties of the excavated material by adding fine particles (d < 0.063 mm) to the excavating chamber. This ensures better stability of the face and contributes to the effective drive while lowering the risk of leakage. The anticipated average daily progress of the slurry machine for the conditions in the Ljubljana Basin is between 10 m and 15 m per day.

4.2. EPB Machines

During the use of the EPB machine, the excavated material is kept in an excavation chamber to be used for the face support. The pressure of the excavated soil to the face of the excavation is controlled by a pressure bulkhead, which is hydraulically adjusted so that the pressure of the soil is regulated by the speed of the material removal. The material needed to provide the support pressure must have the properties of plastic soil, which is often ensured by adding fine grains or other suitable artificial materials. Usually, the EPB machine is most suitable for soil that includes the content of fine particles (< 0.063 mm) above 30%. In rough and mixed soils containing solid particles, which are readily present in the Ljubljana Basin, a strong increase in the pushing force and the torque of the cutting head would be required for efficient operation. To reduce the torque load, the properties of the soil muck can be partly improved using additives (bentonite, foam, polymers, etc.). For the conditions of the Ljubljana Basin, the use of foams and polymers would be environmentally risky, so it would be necessary to tightly manage construction waste to reduce the impact on the environment. The anticipated average daily progress of the EPB machine for the conditions in the Ljubljana Basin is between 8 m and 12 m per day.

For the excavation of the soft rock for driving through the Ljubljana hills (Šišenski hill, Rožnik, Grajski hill and Golovec,) both slurry and EPB machines would be suitable while operating in the open regime. Here the average rate of progress is expected to be higher, some 20 m per day.

5. Conditions of the Use of Appropriate TBM Technology in the Ljubljana Basin

The methods of preliminary selection of the TBM technology depend mainly on the boundary conditions dictated by the geomechanical parameters of rock, the granulometric composition of soils and the presence of groundwater. The selection of the appropriate TBM technology for the Ljubljana Basin were checked out according to the following guidelines and recommendations: (a) the guidelines of the International Tunneling Association [15], (b) the Specifications and guidelines for the use of special products for Mechanized Tunneling of European Federation of National Associations Representing for Concrete [16], (c) the guidelines of the Austrian Association of Geomechanics (Österreichische Gesellschaft für Geomechanik—ÖEGG) [17], (e) the guidelines of the German Committee for the Underground Construction (Deutsche Ausschuss für Unteridisches Bauen—DAUB) [18], and (f) the recommendations found in the technical literature based on the experience of the already executed projects [19,20,21,22]. For the sake of clarity, only the interpretation of the most relevant guidelines for the Ljubljana Basin will be given in the following.

5.1. ITA Guidelines

The International Tunnelling and Underground Space Association (ITA) guidelines, summarized in Table 3, provide a comprehensive set of areas of suitability for each type of TBM based on granulometric composition of soils. According to ITA guidelines the EPB machine is regarded more suitable for fine-grained materials, the slurry machine for coarse-grained materials, while both devices are regarded appropriate for coarse-grained layers in which conglomerates are present. The selection of the areas suitable for the Ljubljana Basin is indicated in the table. It can be seen that it is not possible to select a single type of machine for the variety of the existing conditions. As indicated in the table, the advantage can be given to slurry machine, as it is regarded more reliable in the given hydrogeological conditions and thus has less environmental impact. However, EPB has the advantage of the possibility for the upgrade of the tools allowing for additional measures to be undertaken to pass through difficult interchange between the layers. Both machines can be used in hard layers, such as conglomerates and clay slates.

Table 3.

Soil conditions relevant for the Ljubljana Basin superimposed on the tabular form of ITA guidelines for the selection of TBM.

5.2. DAUB Guidelines

The German guidelines DAUB [23], which provide the most detailed instructions for the selection of the appropriate TBM for the given ground conditions, are summarized in Table 4. The highlighted areas of geomechanical parameters for the soils of the Ljubljana Basin shown in the table reflect the local suitability of TBM. It can be concluded that the DAUB guidelines applied to soils of the Ljubljana Basin foresee the use of TBM with single shield (SSM), which operate with the excavation of the entire profile (V). For the conditions of the areas under consideration, both the slurry machine (SM-V4) and EPB (SM-V5) are recommended. The slurry machine, generally categorized as suitable for fine-grained soils with or without the presence of groundwater, is selected for the proportion of fine particles of 0.02 mm, which should be below 10%; otherwise the recycling of the slurry can be difficult. The second suggested type of the machine is again EPB, which is categorized in the table as the best suited for fine-grained soils. This means that the fraction of the fine particles <0.063 mm must be at least 30% or more, which provides the required properties of the material mixture in the excavating chamber, when combined with the water and additives.

Table 4.

Soil parameters relevant for the Ljubljana Basin superimposed on tabular form of DAUB guidelines for the selection of TBM.

Based on DAUB Guidelines, it can be again concluded that one single type of machine does not cover the entire range of geomechanical properties of soils present in the Ljubljana Basin. The best-fitting machine is clearly a slurry machine, which can be fully appropriate with the use of some additional measures. However, the conditions of rapidly changing geomechanical properties expected in the Ljubljana Marshes are not accounted for in Table 4, so the need to use EPB machine could not be excluded. It is also clear that the EPB machine would not be fully suitable for cleaner gravel—sand layers, which are predominant in the Ljubljana Polje. In this area, if the EPB are used, heavy measures including the addition of fine grains, foams and polymers should be used to support the face properly.

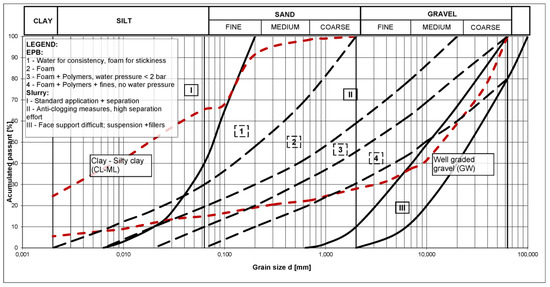

5.3. Thewes Recommendations

Thewes (2007) gives the recommendations for the efficient operation of TBM presented in the diagram shown in Figure 7. Three areas are allocated for slurry machines, annotated I, II and III respectively, under the following categorization: (a) I—the use of anti-fouling additives, the suspension is difficult to separate, (b) II—the optimal range of use, the separation is smooth, (c) III—the use of additives and fine particles for the effective support of the face. The four areas allocated for the EPB, annotated 1, 2, 3 and 4 respectively, are categorized as: (a) 1 use of water for consistency and foam to reduce adhesion, (b) 2 optimum operation of the device, use of foam to support the face, (c) 3 use of foam and polymer suspensions; water pressure < 2 bar, and (d) 4 use of foam, polymer suspensions and fine particles; water pressure = 0 bar. As indicated in Figure 7, based on the collected data for soils of the Ljubljana Basin, we can establish that the field of the EPB technology spreads also in the area of sand and gravel, mainly due to the introduction of additives in the form of foam and polymer suspensions. Again, it can be concluded that only slurry and EPB machines cover the needed range of properties for the soil layers of the Ljubljana Basin.

Figure 7.

Overlap of the selected granulometric curves for soils on the possible tunnel routes in the Ljubljana Basin with the Thewes guidelines for the selection of TBM.

5.4. Selection of Appropriate TBM Technology

The lengths of the sections for the each of the lines in the Ljubljana Basin, suitable for the appropriate type of TBM machine and selected based on this research study are presented in Table 5 (see additionally Figure 2). On the presented sections in the Ljubljana Polje, in which the sand-gravel material predominates (routes: A, B-North, C and D-East), a slurry machine should be used. In the clay layers of lacustrine origin in the Ljubljana Marshes (lines: B-south, D-West, E and part of the line F with connections), the EPB device should be used. For the soft-rock conditions (mainly on line F), both EPB and slurry machine can be used on these sections, namely in open mode. In conclusion, regarding the total of 62.49 km of tunnels, the length of the appropriate conditions for the slurry machine is 38.5 km, or 61.5%; for the EPB machine is 17.9 km or 28.7%, while both machines can be used in the open mode along the length of some 6.1 km or 9.8%.

Table 5.

Summary of the lengths of the sections of each tunnel line suitable for the particular type of TBM machine in Ljubljana Basin.

As already indicated, the use of the EPB machine can be environmentally inappropriate in more permeable ground (in particular in the events of a standstill, failure, maintenance, etc.). On the other hand, the use of the slurry machine can be inadequate in layers with a high proportion of fine particles, since the treatment of the excavated material and suspension becomes very difficult. For the reasons given above, neither of machines can be excluded for the construction of possible tunnel routes so it is conclusive that both types of the machines will be needed in the Ljubljana Basin. Alternatively, a purposefully built single machine, featuring a combination of the both slurry and EPB regimes, is likely to be successful. The anticipated uses of the type of the TBM machine for the given characteristic conditions in the Ljubljana Marches and in the Ljubljana Polje are given in Figure 3.

6. Assessment of the Environmental Impact

The following environmental impacts, which are likely to be caused by mining in the Ljubljana Basin using TBM technology, were considered as the most important: (a) subsidence of the surface and possible damage to the existing buildings, (b) groundwater pollution, (c) production of excavated material and waste, and (d) noise, dust, and vibrations. Each of the impacts is evaluated to assess the sustainability of the development for the particular conditions of the Ljubljana Basin.

6.1. Impact on the Existing Buildings Caused by Subsidence

In the case of urban tunneling, the subsidence at the surface is one of the key factors, which can affect the stability or serviceability of existing buildings. The five main types of subsidence caused by TBM tunneling were distinguished: (a) subsidence that occurs in the area of the cutting head due to ground collapse or at the place of the inbuilt and injected lining, and is regarded inevitable, (b) subsidence that occurs due to ground relaxation, (c) progress that is too quick so that not all the phases of works are fully completed, (d) the deformation of the shield, and (e) the secondary effects caused by the vibrations of the progressing machine. All of these can be reduced by good quality of work and the use of the additional support measures at the time of construction, which are routinely applied. Also, the external measures of the subsidence control, such as compensation grouting, can be readily applied in the Ljubljana Basin. Along the routes of the predicted tunnels, which are running mostly under the existing railway lines (except for the new line F), no presence of the buildings particularly sensitive to ground subsidence is foreseen.

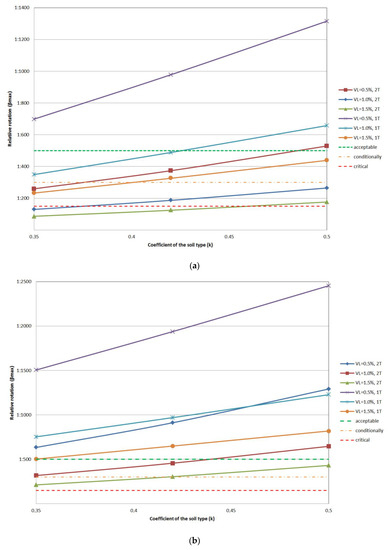

To determine the magnitude of the possible settlements troughs caused by the tunneling, the two typical design cases were considered: (a) two one-track tunnels with an excavation diameter of 6.5 m (exc. area of 74.2 m2) featuring an axis distance of 15 m and (b) one two-track tunnel with an excavation diameter of 11.2 m (exc. area of 100.1 m2). The estimate was made using the empirical approach for the calculation of the green-field settlements based on Gaussian distribution, developed by Peck [24] and upgraded by O’Reilly and New [25], which takes into account the depth of the tunnel, the diameter of the tunnel, the area of the tunnel face and the coefficient of the soil type. A parametric analysis was performed, in which the three values of the volume loss (VL) were considered as the reasonable estimate for good, intermediate, and poor ground conditions, respectively: 0.5%, 1.0% and 1.5%. It should be noted that the assumed levels of the VL cannot be strictly associated with the ground conditions, but also to the quality of the tunneling process as a whole and its capacity to adapt the actual soil conditions. The two expected characteristic depths of the tunnel levels, namely 16 m and 25 m, where selected for the analyses. The coefficient k was chosen within the boundaries of 0.35, which is used for coarse-grained soils and 0.5 used for normally consolidated clays, so that the values of k = 0.35, 0.42 and 0.50 were used to cover the expectation of the large heterogeneity of the soils. Therefore, a matrix of the 36 combinations of boundary conditions, summarized in Table 6, was the subject of the parametric study.

Table 6.

Results of the parametric study on the maximum settlement caused by tunneling.

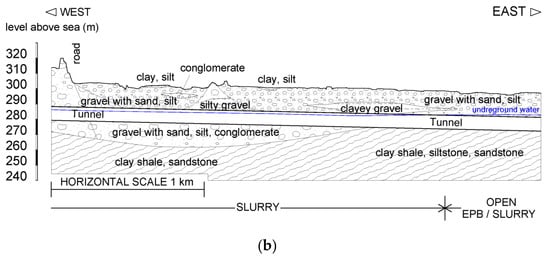

The results of the analyses clearly demonstrate that the maximum settlements (smax) can be expected for a single, two-track tunnel, for which the critical case is seen for normally consolidated, fine-grained, soils at shallow depths. Moreover, the absolute settlements for a single two-track tunnel are 2.6 times larger than for the two one-track tunnels in shallow conditions and 1.6 times larger in deep conditions. In general, it can be expected that settlements at two one-track tunnels are smaller, but this does not apply for the width of the settlement trough above the tunnel. It can be concluded from the results that the width of the settlement trough is some 12% to 25% wider for two one-track tunnels.

The results also demonstrate that the settlements for the two one-track tunnels are expected to be within the allowable limits for all possible cases. Eurocode 7 prescribes 50 mm for the maximum absolute settlement, which can be higher if the relative rotations caused by sagging and hogging are within the acceptable values. To estimate possible impacts on buildings and infrastructure the value of the maximum rotation (βmax) was calculated. For the conventional structures the standard allows for the maximum acceptable rotation 1:500, conditionally the limit value can be 1:300. With a relative rotational value of 1:150, it is likely that the serviceability limit state would be reached or even that the stability of the structure would be compromised. The results show that in the case of a single two-track tunnel for both shallow and deep conditions, the relative rotations are large and beyond the allowable limits given above.

For a single two-track tunnel the acceptable values of maximum relative rotations are only to be achieved at the depth of 25 m and for VL of 0.5%. In the case of parallel one-track tunnels, the effects are considerably smaller and easily within the controllable range. The results are exceeding the conditionally limit value only at a depth of 16 m and for a VL of 1.5%. The results of the parametric study for different values VL and soil type coefficient k are presented separately for one two-track (single) tunnel and two one-track (double) tunnels in Figure 8, for 16 m and 25 m depth, respectively. It can be seen that the two one-track tunnels give much more environmentally sustainable subsidence impact than a single (large), two-track tunnel. The two one-track tunnels are also more appropriate for the safety and rescue conditions in the operational phase so, despite the obvious economic disadvantage, this is clearly the most appropriate solution for the possible underground transportation in the Ljubljana Basin.

Figure 8.

Variation of the maximum relative rotation at the surface relative to the volume loss and soil type coefficient k for one two-track (single 1T) tunnel and two one-track (double 2T) tunnel at: (a) 16 m and (b) 25 m depth.

6.2. Other Impacts

As already discussed, the predominant part of the Ljubljana Basin is defined by at least one of the classes of the water protection area. For this reason, the TBM technology was initially selected as the most appropriate, since the fully sealed variant ensures no long-term interference with the water supply zones. Additionally, the planned routes are selected along the existing corridors so that they do not interfere with the direct water supply areas or the narrowest protection areas, in which the construction is fully prohibited. The most exposed area is the southern part of Ljubljana city, where the groundwater level is close to the surface. In this area either EPB or slurry type of machine can be used. At any rate, the highest risk in the Ljubljana Basin is related to the possible pollution of the underground water due to use of different foams or fillers, which are necessary for the face protection when using EPB machine. Thus, in these areas, the advantage should be given to slurry machines to mitigate the risk of pollution.

Highest emissions of dust and noise can be expected in supportive and logistics centers, in which the concrete segments will be manufactured and delivered, and the excavated material would be processed. These above-ground activities are easily contained and should therefore not have a considerable impact on the environment.

The vibrations generated by the operation of the TBM are considerably lower than in the conventional sequential mining method but are continuous. The values obtained from the literature [26] show that the ground oscillation of magnitude from 0.1 mm/s to 0.3 mm/s can be estimated at a depth of 16 m and from 0.07 mm/s to 0.2 mm/s at a depth of 25 m. These values are significantly lower than the allowed velocities of 20 mm/s to 26 mm/s stipulated by Austrian standard ÖNORM S 9020:1986 or of 5 mm/s to 20 mm/s by German standard DIN 4150:2001.

The total amount of 4.6 × 106 m3 of material is estimated from the excavation of the single two-track tunnels and 6.3 × 106 m3 for the excavation of the double one-track tunnels for all routes. Total excavated materials given for different type of materials and divided between single two-track tunnel (single track) and double one-track tunnel (double-track) are presented in Table 7. Concerning the disposal of the excavated material a clear distinction should be made for the excavation using slurry machine and excavation using EPB. The excavation material resulting from the use of slurry machine is generally coarser, freer of additives and is therefore easily reusable. The slurry machine, which is applicable for coarse-grained materials, is estimated to result in 2.85 × 106 m3 of excavated material for two one-track tunnels and 3.85 × 106 m3 for single two-track tunnel.

Table 7.

Total excavated material for different type of materials divided for one two-track tunnel (single track) and two one-track tunnels (double-track).

The EPB method, which is applicable for fine-grained materials, would amount to 1.33 × 106 m3 of excavated material for two single track tunnels and 1.79 × 106 m3 for the single two-track tunnel. It should be noted that the clayey materials excavated by the EPB, which are mostly present in the Ljubljana Marshes, cannot be reused, but must be permanently disposed of at the locations intended for surplus materials at high environmental cost.

For the utilization of TBM in the open mode the estimated amount of excavated material around the Ljubljana hills is 0.45 × 106 m3 for single track tunnels and 0.61 × 106 m3 for double-track tunnels. This material, in general, would be the most suitable for further use in embankments.

The results of the analyses of the construction waste caused by the use of TBM technology in the Ljubljana Basin are shown in Table 8. The individual waste categories and their shares in processing were analyzed by the method suggested by Renghausen [27]. The results are given as a percentage of the total waste, of which 75% originates from the excavation and 25% originates from other construction works. It can be concluded that only 6% of the waste is estimated to be contaminated, so it must deposited and maintained on purpose-built landfill.

Table 8.

The estimate of the type and percentile of the waste as a result of the underground construction in the Ljubljana Basin.

7. Discussion and Conclusions

A research study on the conditions for sustainable development of underground transport in the Ljubljana Basin was carried out based on several studies, in which underground transport was considered as an alternative for rail, inter-rail and city traffic. Current environmental impact of the surface public transport, based solely on the use of combustion engines, is high and unsustainable in the long term. On the other hand, the main benefit from the regulation of the Ljubljana railway hub using underground transport would be the re-direction of freight traffic from the motorways to the railways, resulting in a highly integrated traffic solution. This will establish Ljubljana’s central role as a junction of the European corridors X and V and the link to other MEGA urban areas in the vicinity. Although the investment of this development will be high (a rough estimate is some 8.4 billion euros), future generations will be able to establish efficient links and promote Ljubljana as a powerful entity in a region connecting Middle Europe with the Balkans and Mediterranean Sea with Eastern Europe.

Given the diverse geological and geomorphological conditions, the Ljubljana Basin is also a complex hydrogeological environment featuring several aquifers both in the Ljubljana Polje and the Ljubljana Marshes, which are used for the city water supply. The underground construction in the Ljubljana Basin was therefore deemed highly demanding and a sustainability study was needed as part of a wider socio-economical assessment. This study was carried out with an aim to investigate the conditions for the sustainable construction of underground transport. It was concluded that TBM technology has an advantage to other construction methods as the potential environmental impact would be within reasonable and controllable limits.

The results of the studies on the future underground traffic in Ljubljana city were used to determine the possible optimal routes for the tunnels. The total length of 62.49 km of the potential tunnels at depths from 16 m to 25 m was considered in the study. The routes were superimposed on the known geological and hydrogeological conditions and the selection of the appropriate type of TBMs was made. The selection was carried out considering the criteria of sustainable build-ability and the lowest possible environmental impact.

It was concluded that these two types of TBM are the most appropriate: (a) Slurry machine, which uses slurry for the support of the face of the excavation, and (b) Earth Balance Pressure (EPB) machine. For the heterogeneous conditions of the Ljubljana Basin it was not possible to exclude one of the two types, so both would be needed, or alternatively a purposefully built combination of the two. Out of the total of 62.5 km of tunnels the appropriate conditions for the slurry machine cover 38.5 km (61.5%); for the EPB machine 17.9 km (28.7%), while both machines can be used along the length of some 6.1 km (9.8%). For the drive through the soft rocks of the Ljubljana hills both slurry and EPB machines would be suitable for work in the open regime.

The study considered the key potential environmental impacts, as follows: (a) subsidence of the surface and the possible damage to the existing buildings, (b) pollution of groundwater, (c) generation of the excavated material and waste, and (d) noise, dust, and vibrations. The parametric study on the subsidence demonstrated that two one-track tunnels would have less impact than the single double-track tunnel for any particular route, resulting in almost no damage to the existing buildings. Two one-track tunnels are also more appropriate for the safety and rescue requirements in the operational phase, so despite the obvious economic disadvantage, this is clearly a preferred sustainable solution.

The highest risk of underground construction is associated with hydrogeological system, which is dictated by unique geological and geomorphological conditions in the Ljubljana Basin. The impact on the groundwater pollution could be controlled by the choice of the routes utilizing the existing corridors and avoiding the prime protection and the direct water supply areas. However, a full evaluation of the impact on groundwater is needed for the use of different foams or fillers, which would be necessary for the operation of the EPB machine. Other forms of environmental impact, namely treatment of the excavated material and waste, noise, dust, and vibrations, are regarded to be fully controllable using the appropriate measures.

Finally, it can be concluded that the development of the underground traffic network in Ljubljana is sustainable within the margins of reasonable and controllable environmental impact. Further investigation is needed to examine the balance between economic growth that will result from this development and the effects of social well-being in the long term.

Author Contributions

Conceptualization, V.J. and J.L.; Methodology, J.L.; Software, B.V.; Validation, V.J., B.V. and J.L.; Formal Analysis, B.V.; Investigation, B.V.; Resources, V.J.; Data Curation, B.V.; Writing-Original Draft Preparation, V.J.; Writing-Review & Editing, V.J.; Visualization, B.V.; Supervision, J.L.; Project Administration, V.J.; Funding Acquisition, V.J.

Funding

This research received no external funding.

Acknowledgments

The Authors are thankful to the Institute for Mining, Geotechnology and Environment (IRGO) for the use of the archives on geotechnical site investigations, which were carried out in the Ljubljana Basin on various projects in the past. The authors would like to thank IRGO Consulting d.o.o. for provision of internal funding to this research project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bensa, B. Strokovne Podlage Urejanja Javnega Prometa v Regiji, Končno Poročilo; Regionalna Razvojna Agencija Ljubljanske Urbane Regije: Ljubljana, Slovenia, 2009; p. 429. (In Slovene) [Google Scholar]

- Žličar, B.; Fimpler, J.; Šemrov, D. Study of Variants for Ljubljana Railway Transport hub. In Proceedings of the 10th Slovenian Congress of Road Infrastructure and Traffic, Society for Research on Roads in the Traffic Sector of Slovenia, Portorož, Slovenia, 20–22 October 2010; pp. 313–321. (In Slovene). [Google Scholar]

- Shepherd, A.; Ortolano, L. Strategic environmental assessment for sustainable urban development. Environ. Impact Assess. Rev. 1996, 16, 321–335. [Google Scholar] [CrossRef]

- Becker, V.; Myrttinen, A.; Barth, J.A.C.; Bayer, P. A Summary on the Special Issue “Sustainability of Groundwater”. Sustainability 2011, 3, 1792–1795. [Google Scholar] [CrossRef]

- Ministry of Infrastructure, Transport Directorate. Resolution on Transport Policy in Republic of Slovenia (Resolucija o Prometni Politiki Republike Slovenije (RePPRS)) (Intermodalnost: Čas za Sinergijo); No. 58; Official Gazette of Republic Slovenia: Ljubljana, Slovenia, 2006.

- Pichler-Milanović, N.; Zavodnik-Lamovšek, A.; Espon, T. Territorial Approaches for New Governance, Applied Research 21 January 2013, Annex 11, Case Study 11: Public Transport Strategies in Ljubljana Urban Region (LUR); Faculty of Civil and Geodetic Engineering, Spatial Planning Chair: Ljubljana, Slovenia, 2013. [Google Scholar]

- Levin-Keitel, M.; Mölders, T.; Othengrafen, F.; Ibendorf, J. Sustainability Transitions and the Spatial Interface: Developing Conceptual Perspectives. Sustainability 2018, 10, 1880. [Google Scholar] [CrossRef]

- Kim, N.S.; Van Wee, B. Assessment of CO2 emissions for truck-only and rail-based intermodal freight systems in Europe. Transp. Plan. Technol. 2009, 32, 313–333. [Google Scholar] [CrossRef]

- Tob-Ogu, A.; Kumar, N.; Cullen, J.; Ballantyne, E.E.F. Sustainability Intervention Mechanisms for Managing Road Freight Transport Externalities: A Systematic Literature Review. Sustainability 2018, 10, 1923. [Google Scholar] [CrossRef]

- Hwang, T.; Ouyang, Y. Urban Freight Truck Routing under Stochastic Congestion and Emission Considerations. Sustainability 2015, 7, 6610–6625. [Google Scholar] [CrossRef]

- Drobne, F.; Tovornik, S. Obvestilo o raziskavah geoloških pogojev za gradnje na območju mesta Ljubljane. Geologija 1961, 7, 269–274. (In Slovene) [Google Scholar]

- Mencej, Z. Prodni zasipi pod jezerskimi sedimenti Ljubljanskega barja. Geologija 1989, 31–32, 517–553. (In Slovene) [Google Scholar]

- Uredba o Vodovarstvenem Obmocju za Vodno Telo Vodonosnikov Ljubljanskega Barja in Okolice Ljubljane; No. 115/07, 09/08-popr. 65/12 in 93/13; Official Gazette of Republic Slovenia: Ljubljana, Slovenia, 2008. (In Slovene)

- Uredba o Vodovarstvenem Obmocju za Vodno Telo Vodnonosnika Ljubljanskega Polja; No. št. 43/15; Official Gazette of Republic Slovenia: Ljubljana, Slovenia, 2015. (In Slovene)

- ITA—International Tunnelling Association. Working Group No. 2. Guidelines for the Design of Shield Tunnel Lining. Tunn. Undergr. Space Technol. 2000, 15, 303–331. [Google Scholar] [CrossRef]

- EFNARC. Specification and Guidelines for the Use of Special Products for Mechanised Tunnelling (TBM) in Soft Ground and Hard Rock; EFNARC: Farnham, UK, 2005; p. 45. [Google Scholar]

- Atzl, G.; Bach, D. Richtlinie für die Geotechnische Planung von Untertagbauten mit Kontinuirlichem Vortrieb; ÖGG—Österreichische Gesellschaft für Geomechanik: Salzburg, Austria, 2013; p. 49. [Google Scholar]

- Maidl, B.; Herrenknecht, M.; Maidl, U.; Wehrmeyer, G. Mechanised Shield Tunnelling, 2nd ed.; Wilhelm Ernst & Sohn: Berlin, Germany, 2012. [Google Scholar]

- Maidl, U. Erweiterung der Einsatzbereiche der Erddruckschielde Durch Bodenkonditionierung mit Schaum. Ph.D. Thesis, Fakultät für Bau- und Umweltingenieurwissenschaften, Ruhr-Univesität Bochum, Bochum, Germany, 1995. [Google Scholar]

- Budach, C. Untersuchungen zum Erweiterten Einsatz von Erddruckschilden in Grobkörnigem Lockergestein. Ph.D. Thesis, Fakultät für Bau- und Umweltingenieurwissenschaften, Ruhr-Univesität Bochum, Bochum, Germany, 2011. [Google Scholar]

- Langmaack, L.; Ibarra, J. Speciality Chemicals for Tunnel Boring Machines. In Proceedings of the Rapid Excavation and Tunnelling Conference, Short Tunnelling Lecture, San Francisco, CA, USA, 19–22 June 2011. [Google Scholar]

- Thewes, M. TBM Tunnelling challenges—Redefining the state of the art. In Proceedings from ITA-AITES World Tunnelling Conference—Underground Space—The 4th Dimension of Metropolises; Bartak, J., Hrdina, I., Romancov, G., Zlamal, J., Eds.; Taylor & Francis: Prague, Czech Republic, 2007; pp. 13–21. [Google Scholar]

- Maidl, U.; Frietzsche, W.; Grübl, F.; Kirschke, D.; Lehmann, G.; Leucker, R.; Placzek, D.; Rieker, K.; Stephan, D.; Thewes, M.; et al. Empfehlung zur Auswahl von Tunnelvortriebsmaschinen. Deutscher Ausschuss für Unterirdisches Bauen (DAUB); ITA-AITES: Essen, Germany, 2010; p. 48. [Google Scholar]

- Peck, R.B. Deep excavations and tunnelling in soft ground. In Proceedings of the 7th International Conference Soil Mechanics and Foundations, Engineering, Held in Mexico City, 1969; Sociedad Mexicana de Mecanica: Mexico City, Mexico, 1969. [Google Scholar]

- O’Reilly, M.P.; New, B.M. Settlements above tunnels in the United Kingdom—Their magnitude and prediction. In Proceedings of the Tunnelling ’82 IMM, Brighton, UK, 7–11 June 1982. [Google Scholar]

- Hiller, D.M. The prediction and mitigation of vibrations impacts of tunnelling. In Proceedings of the Acoustics—Breaking New Ground, Gold Coast, Australia, 2–3 November 2011; pp. 1–8. [Google Scholar]

- Renghausen, R.; Tauriainen, R.; Raedle, A. TBM and spoil treatment selection process—Case history Crossrail C310 Thames Tunnel, Slurry TBM versus EPB TBM. Geomech. Tunn. 2014, 7, 45–54. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).