A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites

Abstract

1. Introduction

2. Study Area and Data

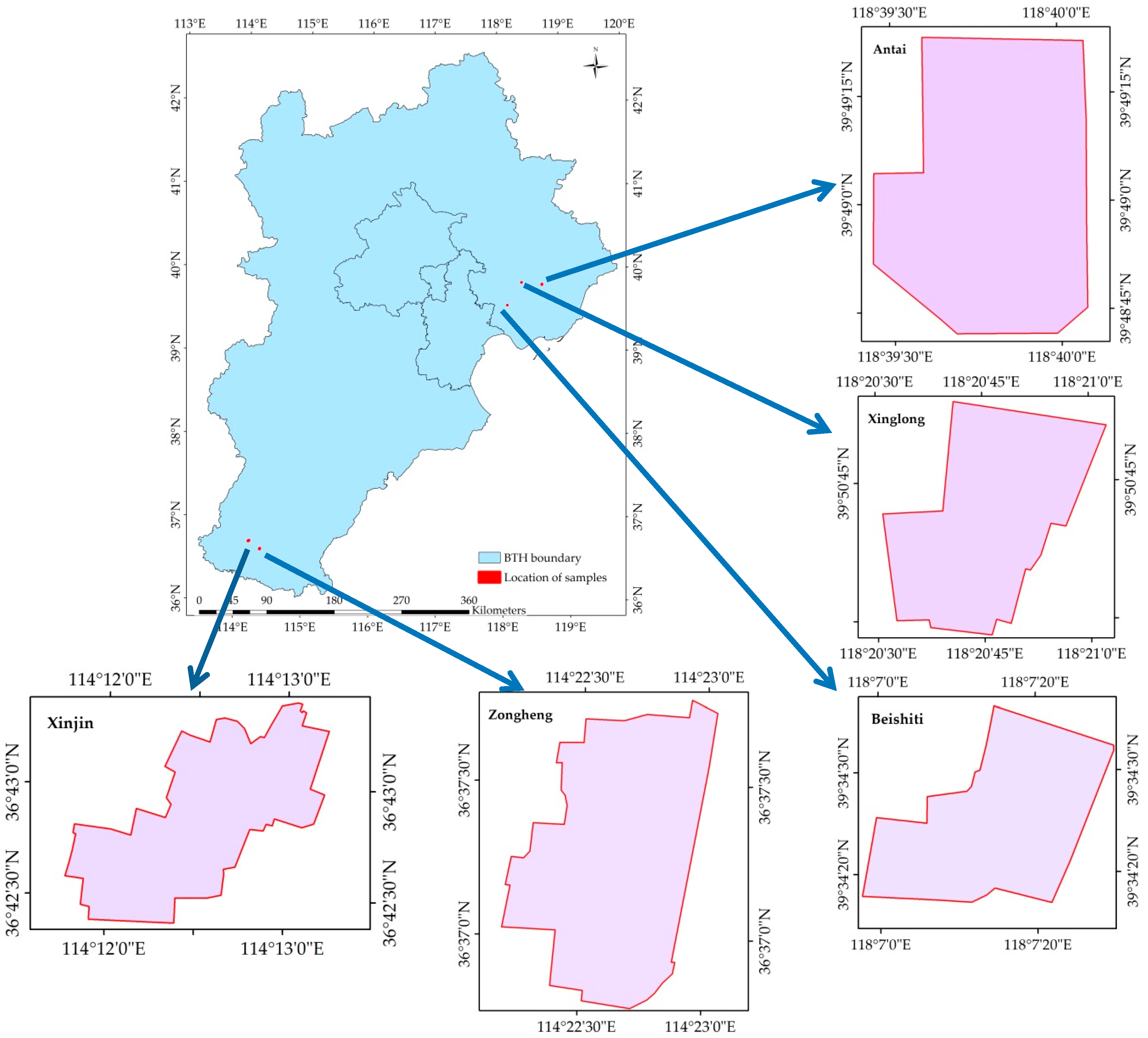

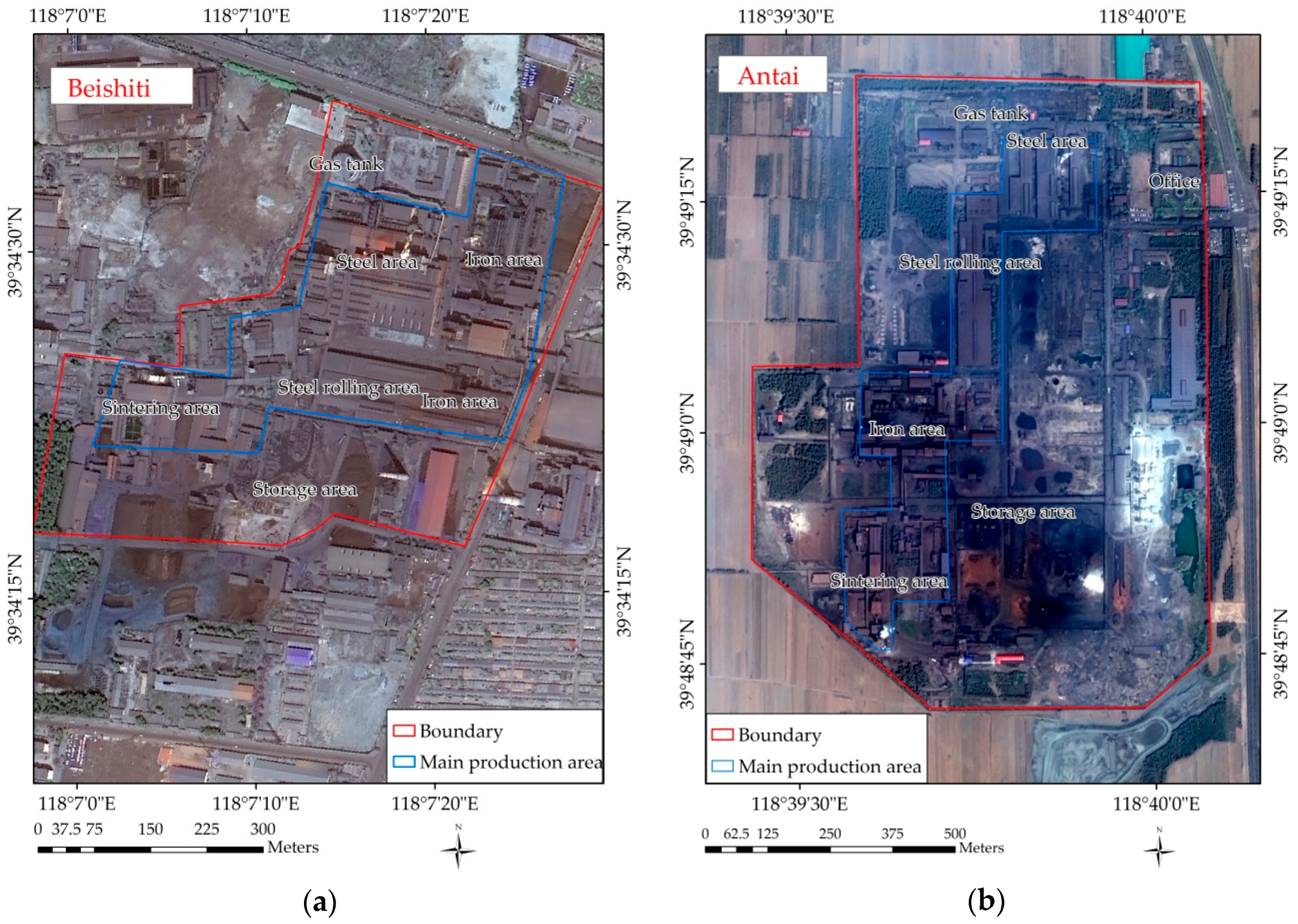

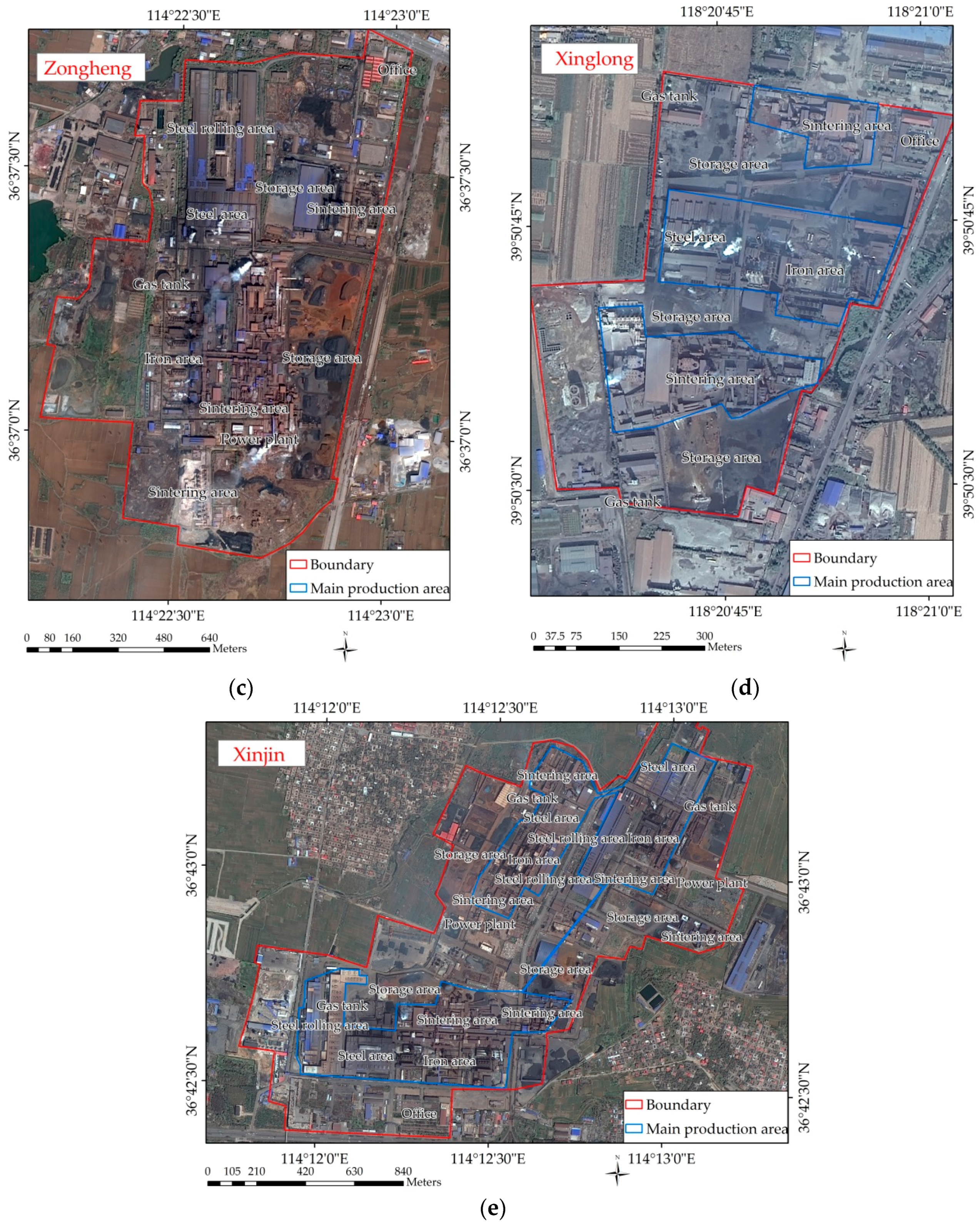

2.1. Study Area

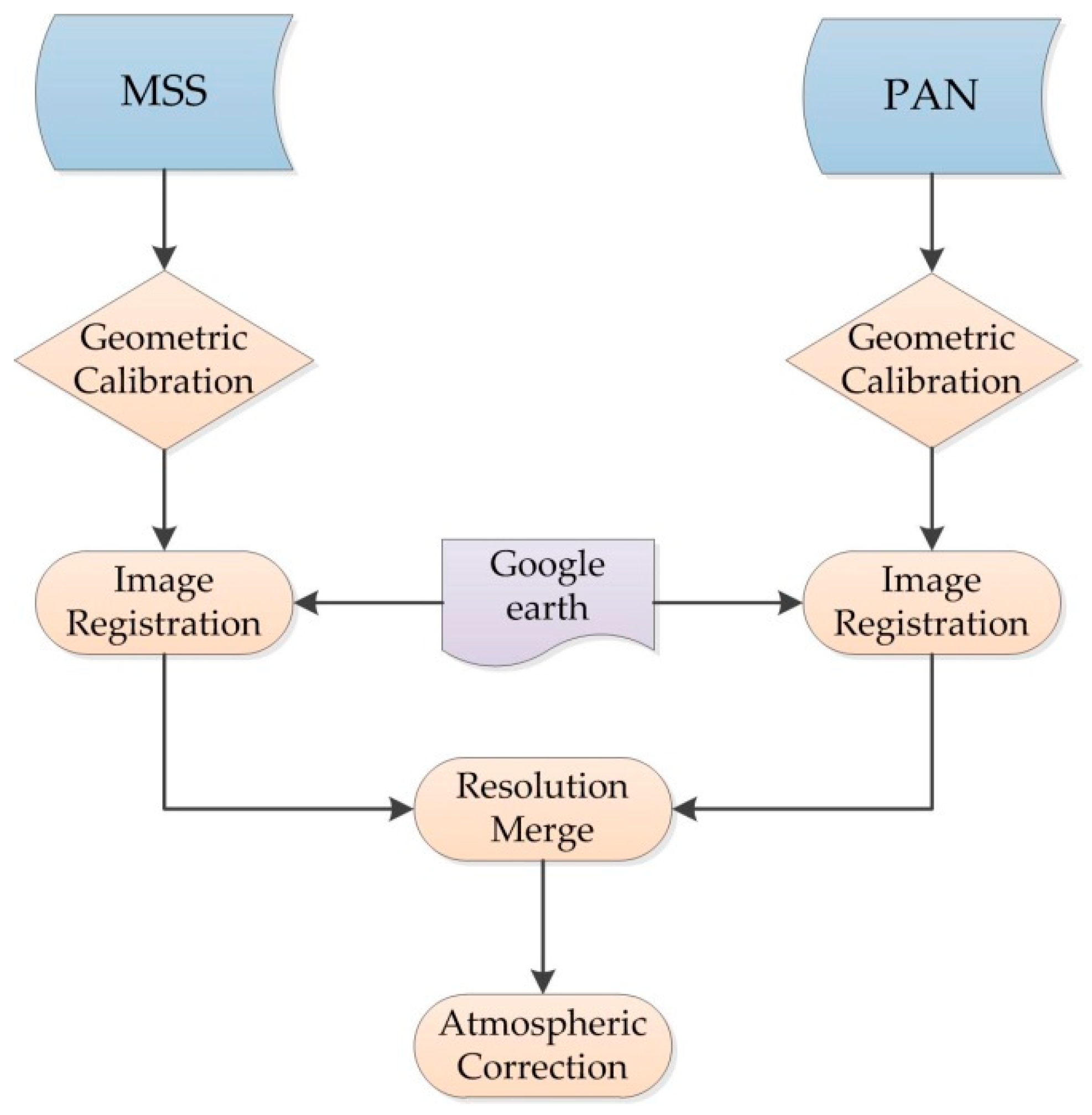

2.2. Data and Preprocessing

2.2.1. Landsat 8 TIRS Data

2.2.2. High-Resolution Images

2.2.3. Auxiliary Data

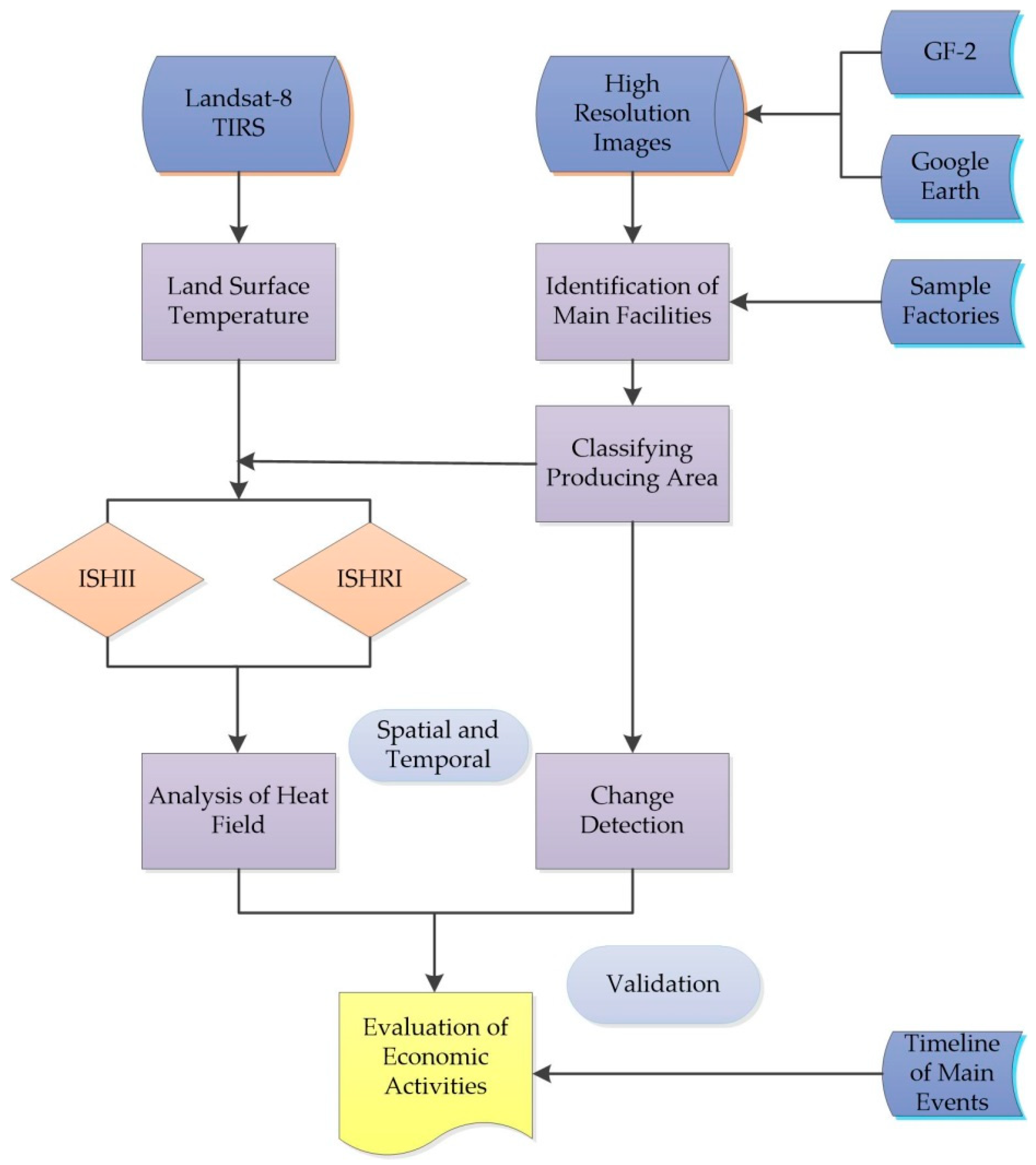

3. Methodology

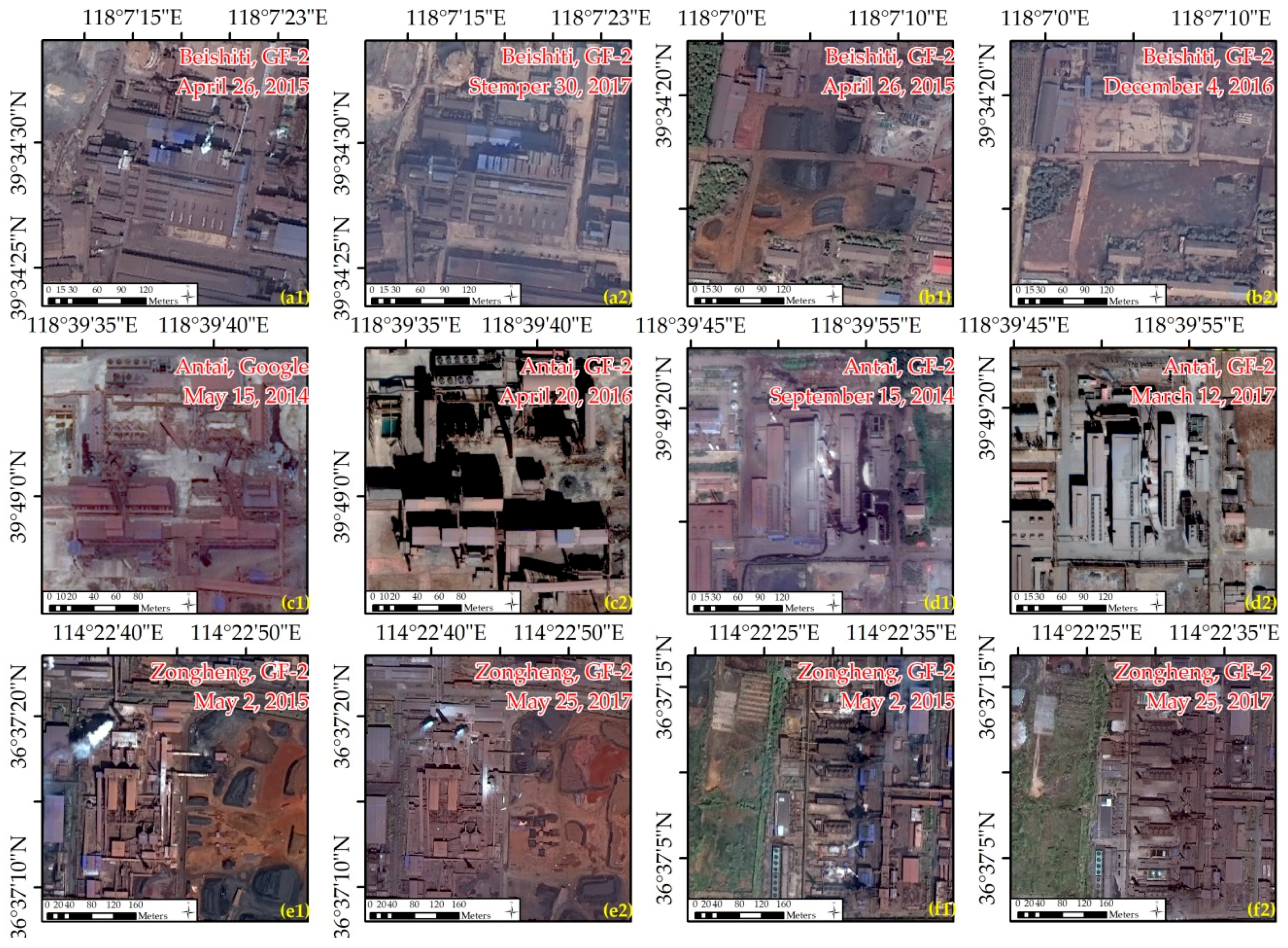

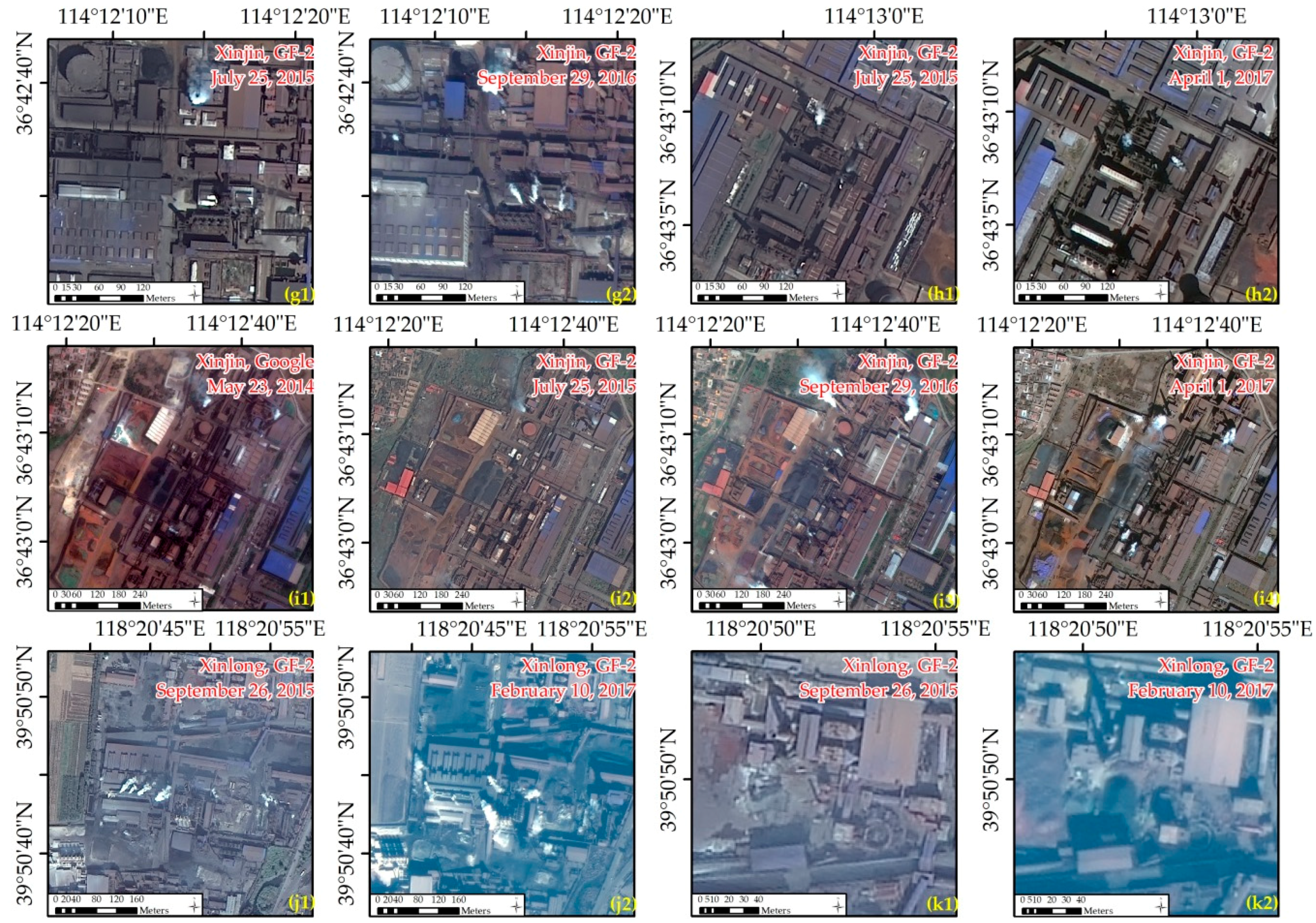

3.1. Identification and Change Detection Based on GF-2

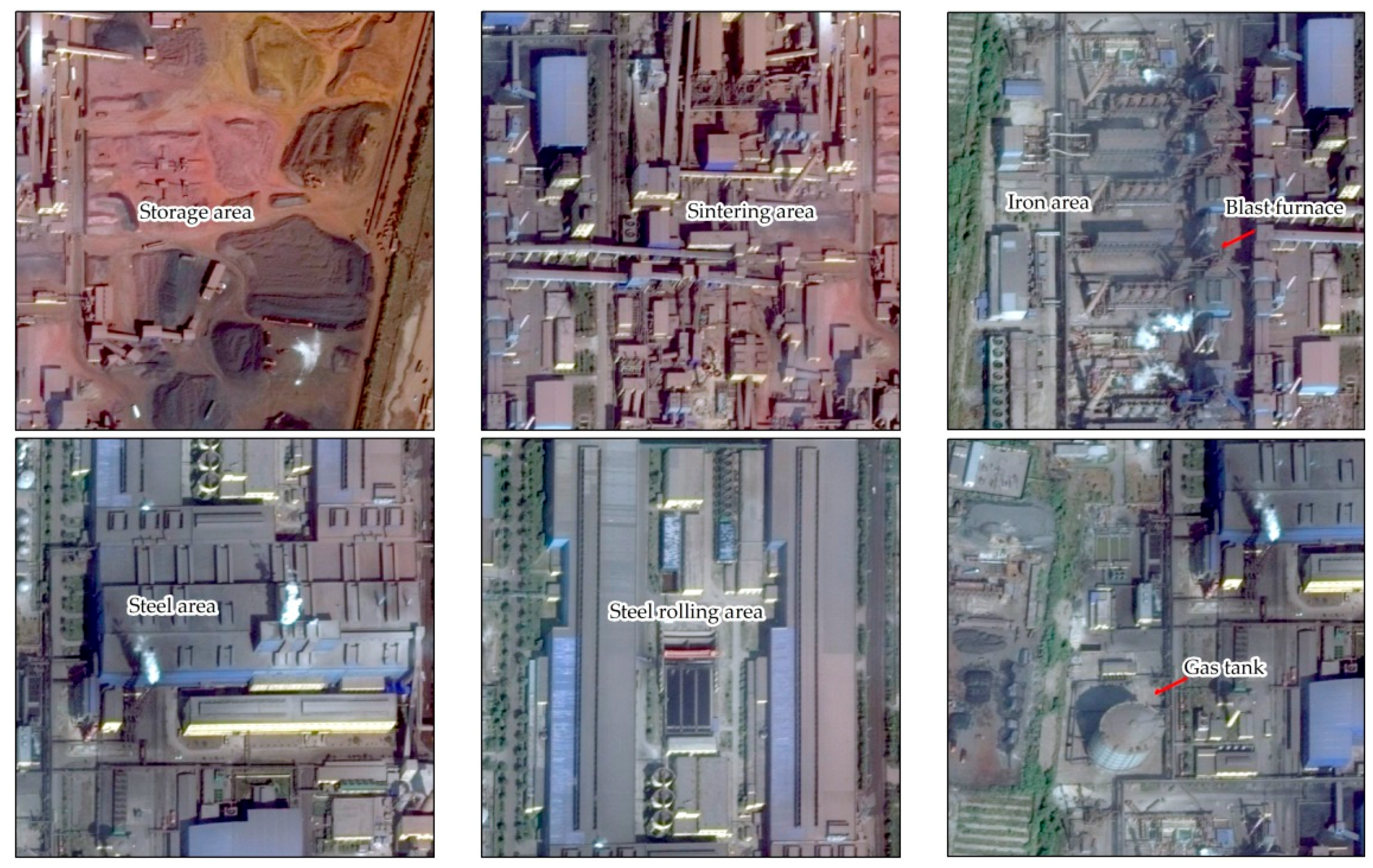

3.1.1. Identification of Main Functional Areas and Production Facilities

- Storage area: The production requires quantities of raw materials stored in the storage area. In some factories, reddish brown ore, black coal, and white limestone are piled in the open storage area [45].

- Sintering area: Sintering is the pretreatment of raw material. Generally, the functional area is close to the storage area, and these areas connected by a strip transfer channel. The dust vacuum machines have a cuboid shape on the remote sensing image, and they are often arranged in groups.

- Iron area: Ironmaking is an important sector of iron and steel production. The furnace is a typical marker indicating a complex independent building with a variety of connecting pipelines and plant equipment. The furnace chimney and cooling equipment can be observed. Generally, the number and volume of furnaces represent the production capacity of the factory.

- Steel area: The steel area is located close to the iron area with dense transportation [45]. The main facility has a converter and most equipment is installed inside the buildings.

- Steel rolling area: Rolling is the process of shaping the steel products through the use of rotating rolls, including hot and cold steel rolling.

- Gas tank: This equipment represents an important indicator of an iron and steel factory.

- Parking area: The open parking area for cars can reflect certain production conditions.

- Office area: The office area has independent buildings, with a tiny park or green areas.

- Self-provided power plant: In general, large iron and steel factories have their own power plants to recycle waste heat and gas heat with a white cooling tower.

3.1.2. Change Detection on GF-2

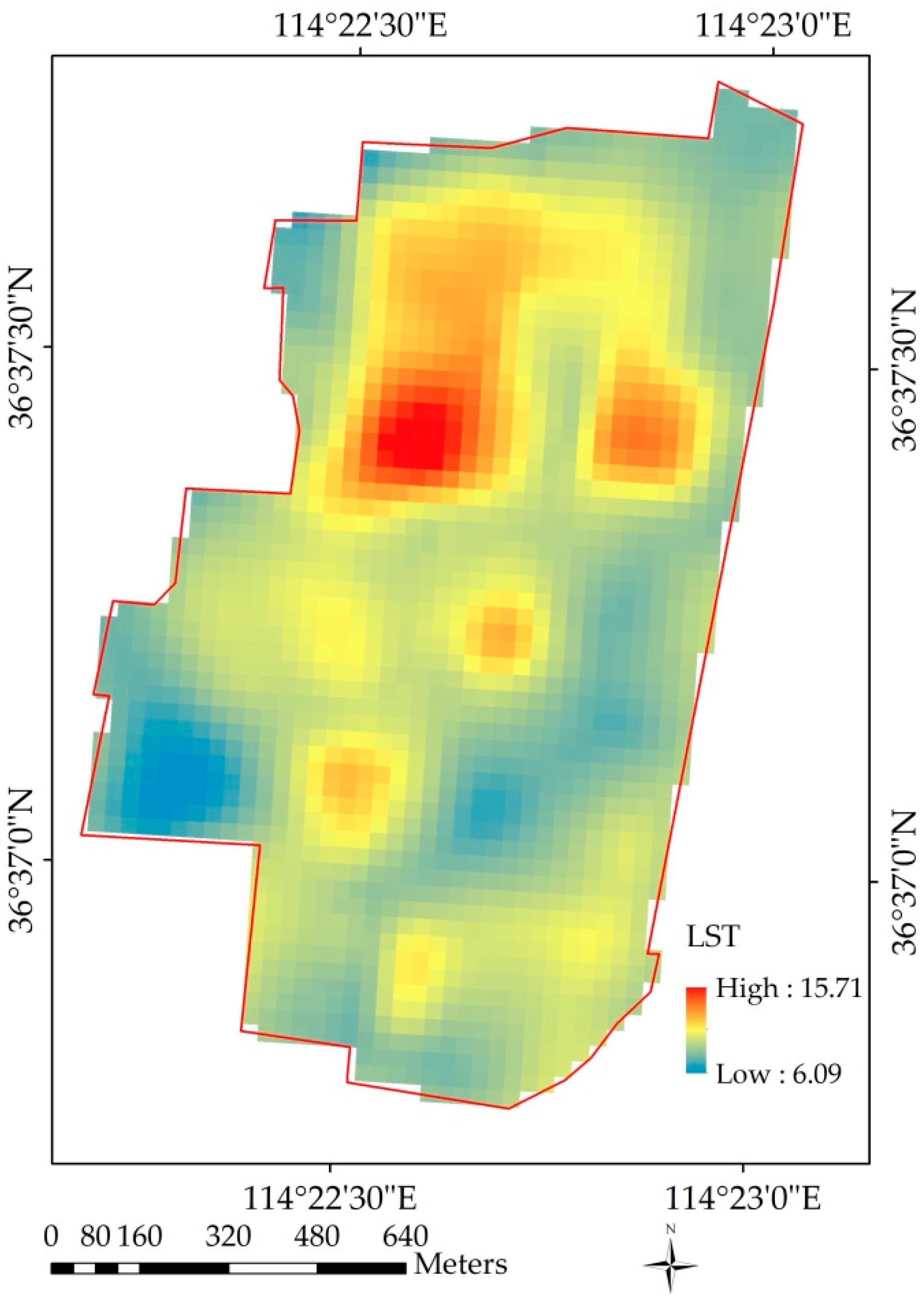

3.2. Quantitative Analysis of the Heat Field inside a Factory Based on LST

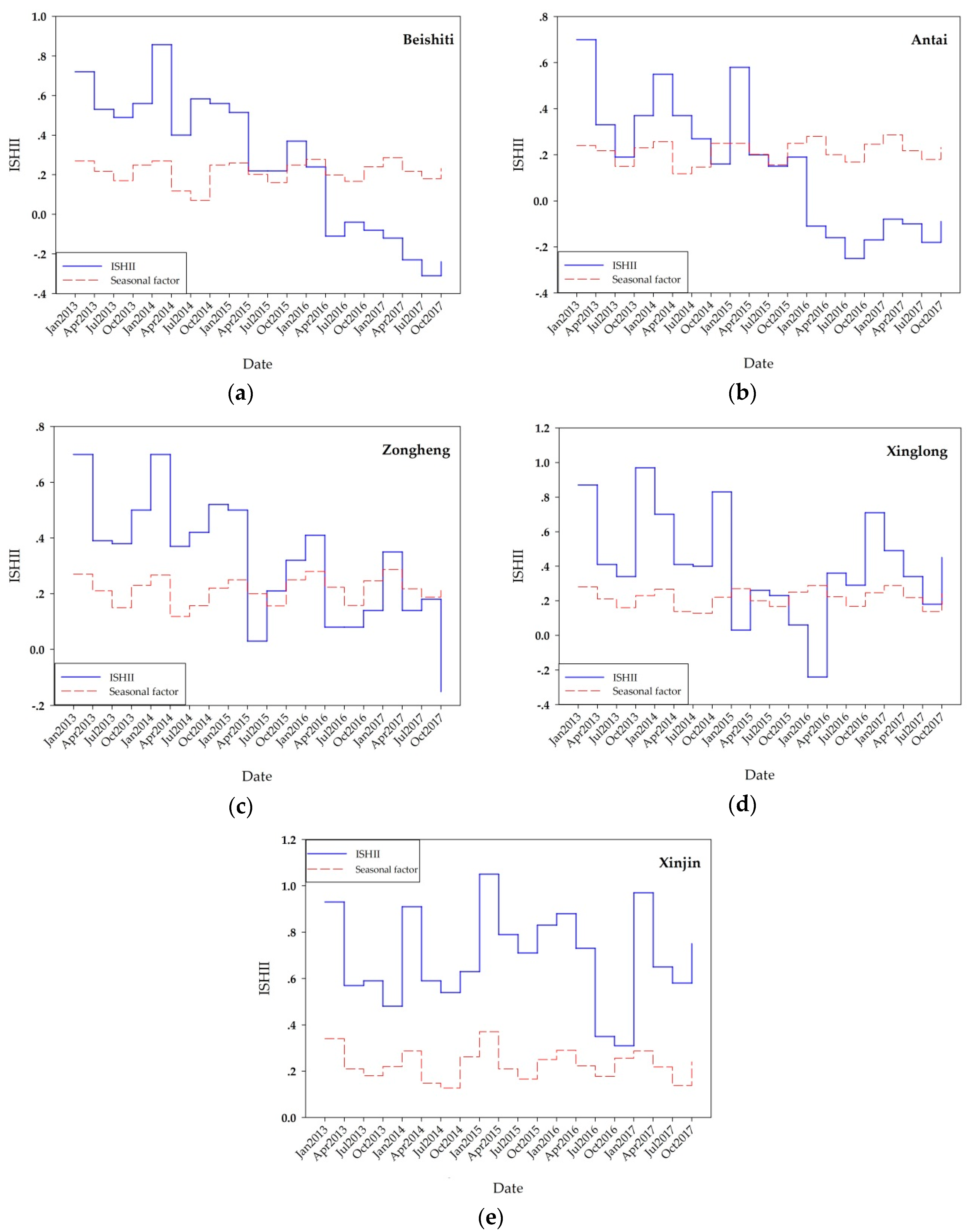

3.2.1. ISHII

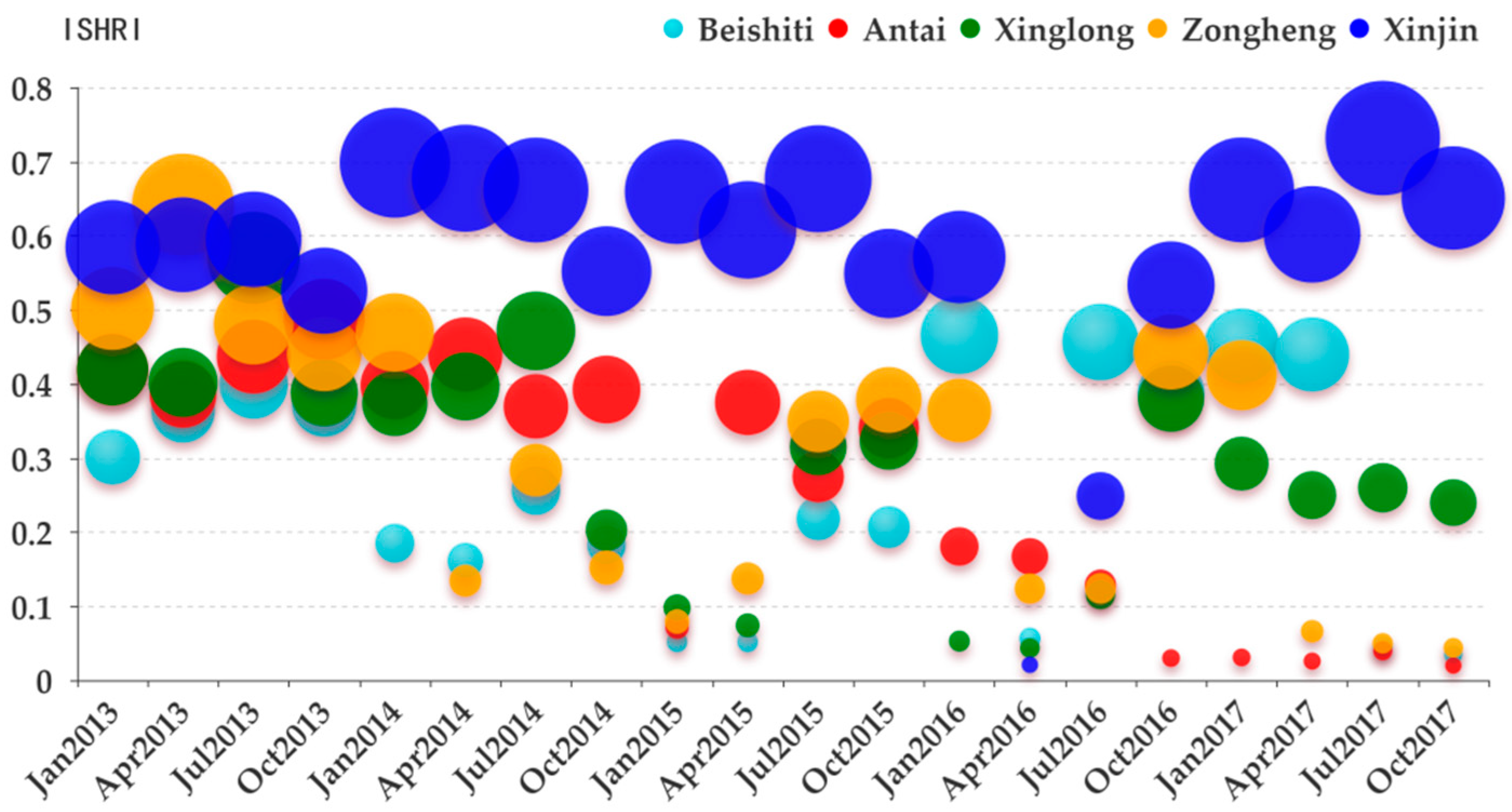

3.2.2. ISHRI

4. Results

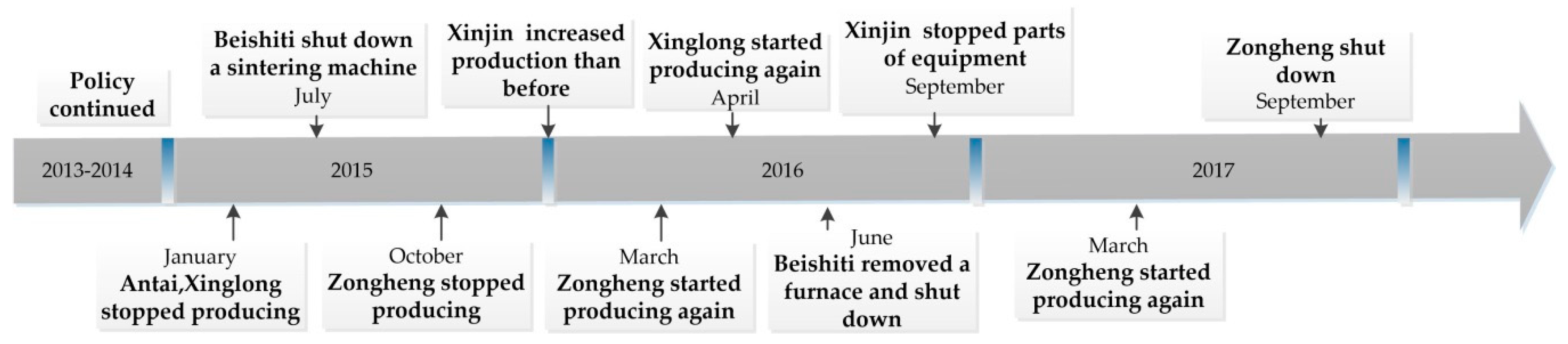

4.1. Time Series Analysis

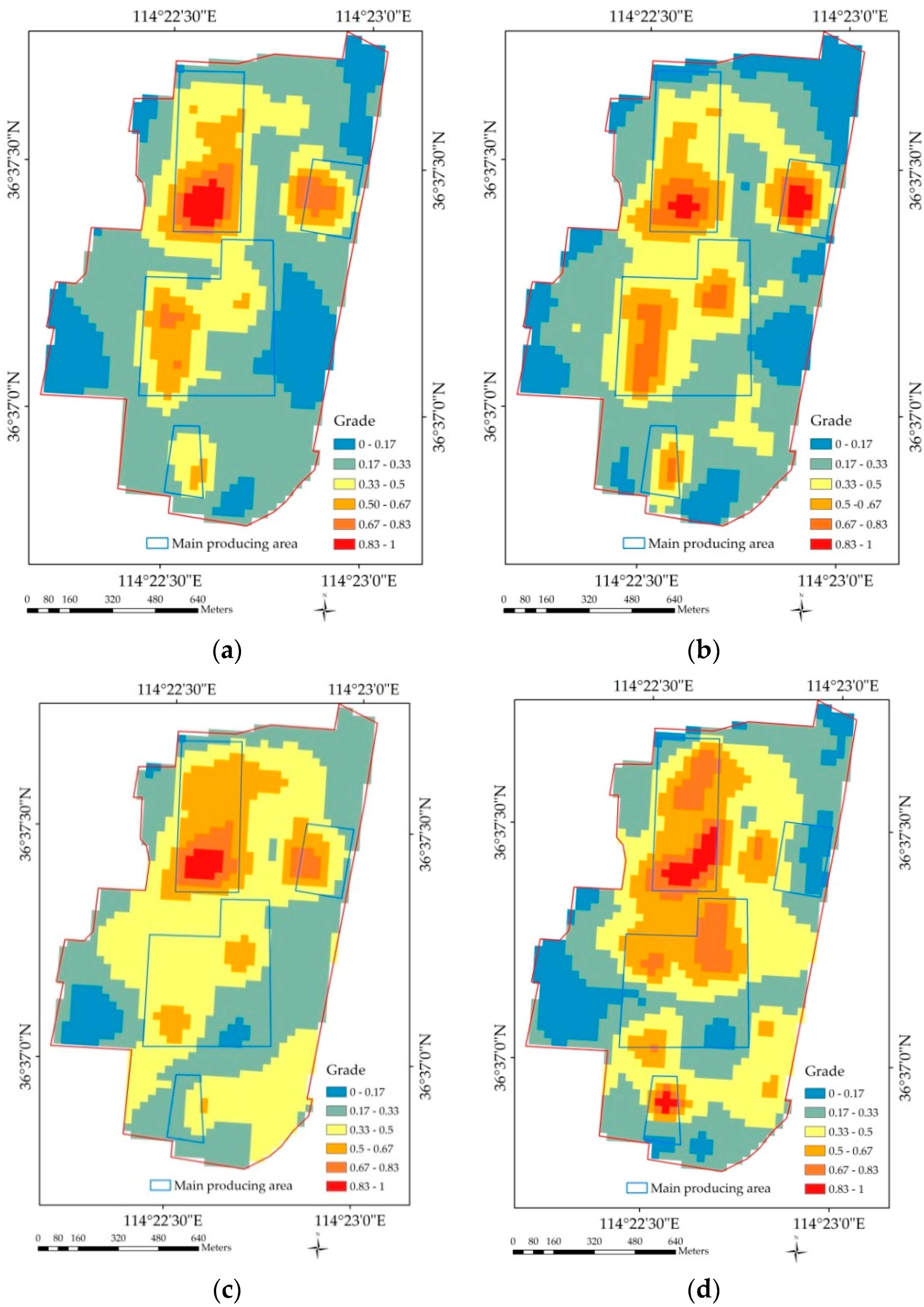

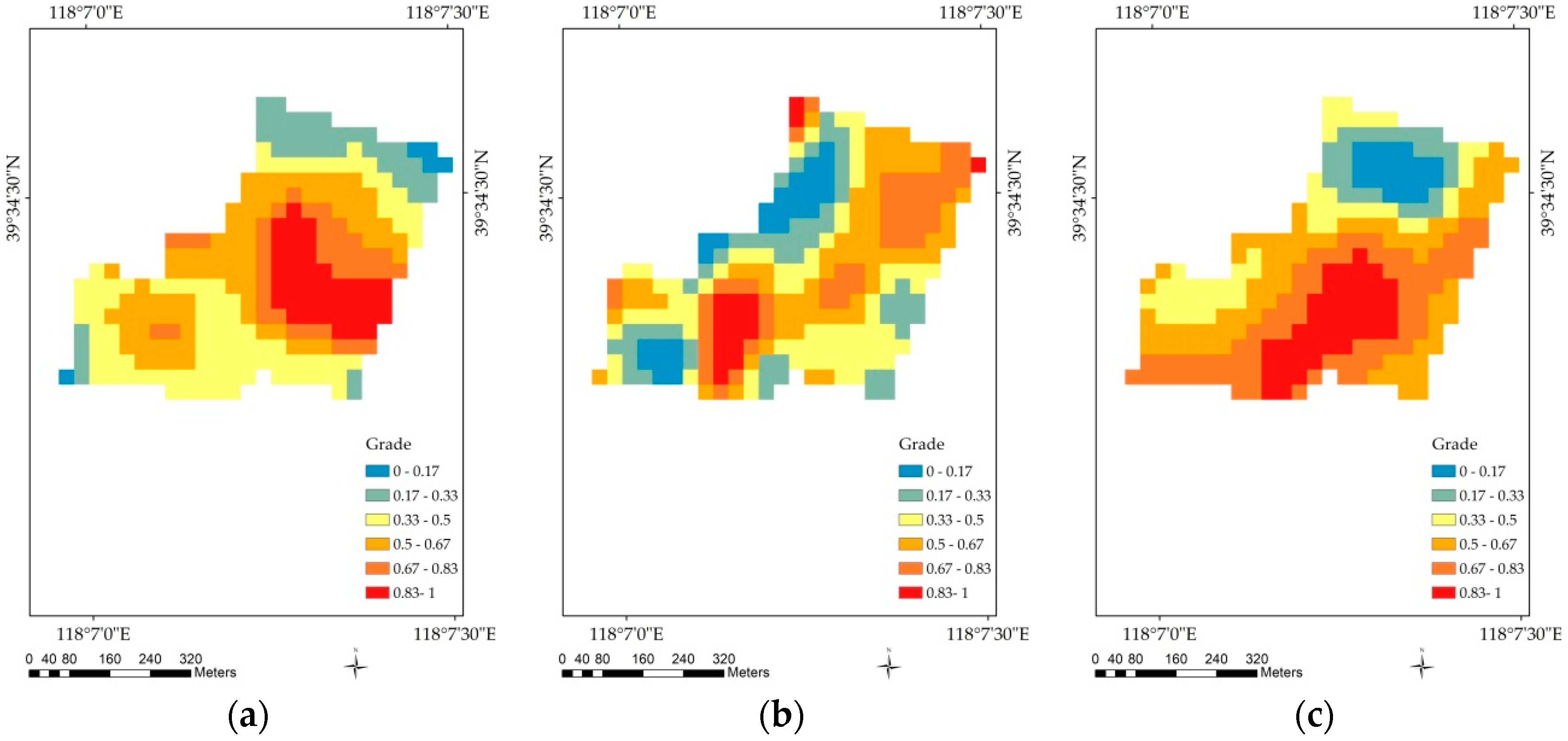

4.2. Spatial Pattern Analysis

4.3. The Changes Detection of Production Facilities

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Martinuzzi, A.; Blok, V.; Brem, A.; Stahl, B.; Schönherr, N. Responsible research and innovation in industry—Challenges, insights and perspectives. Sustainability 2018, 10, 702. [Google Scholar] [CrossRef]

- Shatokha, V. The sustainability of the iron and steel industries in ukraine: Challenges and opportunities. J. Sustain. Metall. 2016, 2, 106–115. [Google Scholar] [CrossRef]

- Shatokha, V. Environmental sustainability of the iron and steel industry: Towards reaching the climate goals. Eur. J. Sustain. Dev. 2016, 5, 289. [Google Scholar] [CrossRef]

- Iron and Steel Industry in China. Available online: https://www.nytimes.com/2015/03/03/business/energy-environment/china-takes-on-steel-smog.html (accessed on 14 May 2016).

- What China’s Steel Capacity Cuts Can Do for Iron Ore Prices. Available online: https://marketrealist.com/2017/03/analysts-expecting-iron-ore-prices (accessed on 1 February 2017).

- Bo, X.; Zhao, C.L.; Wu, T.; Su, Y. Emission inventory with high temporal and spatial resolution of steel industry in the Beijing-Tianjin-Hebei Region. China Environ. Sci. 2015, 8, 2554–2560. [Google Scholar]

- Ouma, Y.O. Advancements in medium and high resolution earth observation for land-surface imaging: Evolutions, future trends and contributions to sustainable development. Adv. Space Res. 2016, 57, 110–126. [Google Scholar] [CrossRef]

- Justice, C.O.; Vermote, E.; Townshend, J.R.; Defries, R.; Roy, D.P.; Hall, D.K.; Salomonson, V.V.; Privette, J.L.; Riggs, G.; Strahler, A. The moderate resolution imaging spectroradiometer (MODIS): Land remote sensing for global change research. IEEE Trans. Geosci. Remote Sens. 1998, 36, 1228–1249. [Google Scholar] [CrossRef]

- Gaur, A.; Eichenbaum, M.K.; Simonovic, S.P. Analysis and modelling of surface Urban Heat Island in 20 Canadian cities under climate and land-cover change. J. Environ.Manag. 2018, 206, 145–157. [Google Scholar] [CrossRef] [PubMed]

- Yuan, G.-L.; Sun, T.-H.; Han, P.; Li, J. Environmental geochemical mapping and multivariate geostatistical analysis of heavy metals in topsoils of a closed steel smelter: Capital Iron & Steel Factory, Beijing, China. J. Geochem. Explor. 2013, 130, 15–21. [Google Scholar]

- Zhao, H.; Ma, Y.; Chen, F.; Liu, J.; Jiang, L.; Yao, W.; Yang, J. Monitoring quarry area with Landsat long time-series for socioeconomic study. Remote Sens. 2018, 10, 517. [Google Scholar] [CrossRef]

- Doll, C.N.; Muller, J.-P.; Morley, J.G. Mapping regional economic activity from night-time light satellite imagery. Ecol. Econ. 2006, 57, 75–92. [Google Scholar] [CrossRef]

- Doll, C.H.; Muller, J.-P.; Elvidge, C.D. Night-time imagery as a tool for global mapping of socioeconomic parameters and greenhouse gas emissions. AMBIO 2000, 29, 157–162. [Google Scholar] [CrossRef]

- Li, X.; Li, D. Can night-time light images play a role in evaluating the syrian crisis? Int. J. Remote Sens. 2014, 35, 6648–6661. [Google Scholar] [CrossRef]

- Chinese Satellite Manufacturing Index (SMI). Available online: https://spaceknow.com/china/ (accessed on 3 April 2017).

- Mert, M.S.; Dilmaç, Ö.F.; Özkan, S.; Karaca, F.; Bolat, E. Exergoeconomic analysis of a cogeneration plant in an iron and steel factory. Energy 2012, 46, 78–84. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, C.; Zhan, W.; Sun, C.; Murch, B.; Ma, L. Identifying industrial heat sources using time-series of the VIIRS Nightfire product with an object-oriented approach. Remote Sens. Environ. 2018, 204, 347–365. [Google Scholar] [CrossRef]

- Ma, P.; Dai, X.; Guo, Z.; Wei, C.; Ma, W. Detection of thermal pollution from power plants on China’s eastern coast using remote sensing data. Stoch. Environ. Res. Risk Assess. 2017, 31, 1957–1975. [Google Scholar] [CrossRef]

- Oke, T.R. City size and the urban heat island. Atmos. Environ. 1973, 7, 769–779. [Google Scholar] [CrossRef]

- Lo, C.P.; Quattrochi, D.A.; Luvall, J.C. Application of high-resolution thermal infrared remote sensing and GIS to assess the urban heat island effect. Int. J. Remote Sens. 1997, 18, 287–304. [Google Scholar] [CrossRef]

- Li, Z.-L.; Becker, F. Feasibility of land surface temperature and emissivity determination from AVHRR data. Remote Sens. Environ. 1993, 43, 67–85. [Google Scholar] [CrossRef]

- Sobrino, J.; El Kharraz, J.; Li, Z.-L. Surface temperature and water vapour retrieval from modis data. Int. J. Remote Sens. 2003, 24, 5161–5182. [Google Scholar] [CrossRef]

- Sobrino, J.A.; Jiménez-Muñoz, J.C.; Paolini, L. Land surface temperature retrieval from Landsat TM 5. Remote Sens. Environ. 2004, 90, 434–440. [Google Scholar] [CrossRef]

- Jiménez-Muñoz, J.C.; Sobrino, J.A.; Skoković, D.; Mattar, C.; Cristóbal, J. Land surface temperature retrieval methods from Landsat-8 thermal infrared sensor data. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1840–1843. [Google Scholar] [CrossRef]

- Van der Meer, F.; Hecker, C.; van Ruitenbeek, F.; van der Werff, H.; de Wijkerslooth, C.; Wechsler, C. Geologic remote sensing for geothermal exploration: A review. Int. J. Appl. Earth Observ. Geoinf. 2014, 33, 255–269. [Google Scholar] [CrossRef]

- Saraf, A.K.; Choudhury, S. Thermal remote sensing technique in the study of pre-earthquake thermal anomalies. J. Ind. Geophys. Union 2005, 9, 197–207. [Google Scholar]

- Meng, Q.; Zhang, L.; Sun, Z.; Meng, F.; Wang, L.; Sun, Y. Characterizing spatial and temporal trends of surface urban heat island effect in an urban main built-up area: A 12-year case study in Beijing, China. Remote Sens. Environ. 2018, 204, 826–837. [Google Scholar] [CrossRef]

- Chen, X.-L.; Zhao, H.-M.; Li, P.-X.; Yin, Z.-Y. Remote sensing image-based analysis of the relationship between urban heat island and land use/cover changes. Remote Sens. Environ. 2006, 104, 133–146. [Google Scholar] [CrossRef]

- Weng, Q.; Lu, D.; Schubring, J. Estimation of land surface temperature–vegetation abundance relationship for urban heat island studies. Remote Sens. Environ. 2004, 89, 467–483. [Google Scholar] [CrossRef]

- Xu, H.Q.; Chen, B.Q. An image processing technique for the study of urban heat islandchanges using different seasonal remote sensing data. Remote Sens. Technol. Appl. 2003, 18, 129–133. [Google Scholar]

- Zhou, W.; Huang, G.; Troy, A.; Cadenasso, M. Object-based land cover classification of shaded areas in high spatial resolution imagery of urban areas: A comparison study. Remote Sens. Environ. 2009, 113, 1769–1777. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Q.; Li, Y.; Liu, S.; Wang, Z.; Zhu, L.; Wang, Z. An overview of satellite remote sensing technology used in China’s environmental protection. Earth Sci. Inform. 2017, 10, 137–148. [Google Scholar] [CrossRef]

- Hu, X.; Weng, Q. Impervious surface area extraction from IKONOS imagery using an object-based fuzzy method. Geocarto Int. 2011, 26, 3–20. [Google Scholar] [CrossRef]

- Beijing-Tianjin-Hebei Region. Available online: https://en.wikipedia.org/wiki/Jingjinji (accessed on 15 April 2016).

- Landsat 8 Tirs Data. Available online: http://glovis.usgs.gov/ (accessed on 15 December 2016).

- Yu, X.; Guo, X.; Wu, Z. Land surface temperature retrieval from Landsat 8 TIRS—Comparison between radiative transfer equation-based method, split window algorithm and single channel method. Remote Sens. 2014, 6, 9829–9852. [Google Scholar] [CrossRef]

- Qin, Z.; Karnieli, A.; Berliner, P. A mono-window algorithm for retrieving land surface temperature from Landsat TM data and its application to the Israel-Egypt border region. Int. J. Remote Sens. 2001, 22, 3719–3746. [Google Scholar] [CrossRef]

- Du, C.; Ren, H.; Qin, Q.; Meng, J.; Zhao, S. A practical split-window algorithm for estimating land surface temperature from Landsat 8 data. Remote Sens. 2015, 7, 647–665. [Google Scholar] [CrossRef]

- Jiménez-Muñoz, J.C.; Cristóbal, J.; Sobrino, J.A.; Sòria, G.; Ninyerola, M.; Pons, X. Revision of the single-channel algorithm for land surface temperature retrieval from Landsat thermal-infrared data. IEEE Trans. Geosci. Remote Sens. 2009, 47, 339–349. [Google Scholar] [CrossRef]

- Gf-2 Data. Available online: http://www.cresda.com/CN/ (accessed on 1 April 2018).

- Sobrino, J.A.; Jiménez-Muñoz, J.C.; Sòria, G.; Romaguera, M.; Guanter, L.; Moreno, J.; Plaza, A.; Martínez, P. Land surface emissivity retrieval from different vnir and tir sensors. IEEE Trans. Geosci. Remote Sens. 2008, 46, 316–327. [Google Scholar] [CrossRef]

- Qin, Z.H.; Li, W.J.; Xu, B.; Chen, Z.X.; Liu, J. The estimation of land surfaceemissivity for Landsat TM6. Remote Sens. Land Resour. 2004, 3, 28–33. [Google Scholar]

- De-Capacity in Iron and Steel Industry of China. Available online: http://www.google.com (accessed on 12 September 2017).

- Industrial Efficiency Technology Database. Available online: http://ietd.iipnetwork.org/ (accessed on 24 May 2016).

- Chen, P.F.; Lu, L.; Zhu, H.Z.; Zhu, Y.Q.; Wang, Y. Research on the suitability of image at different resolutions for theidentification of steel enterprise using remote sensing. J. Geo-Inf. Sci. 2015, 17, 1119–1127. [Google Scholar]

- Lillesand, T.; Kiefer, R.W.; Chipman, J. Remote Sensing and Image Interpretation; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Li, H.; Zhou, Y.; Li, X.; Meng, L.; Wang, X.; Wu, S.; Sodoudi, S. A new method to quantify surface urban heat island intensity. Sci. Total Environ. 2018, 624, 262–272. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.H. Urban heat island. Int. J. Remote Sens. 1992, 13, 2319–2336. [Google Scholar] [CrossRef]

- Dodge, Y. The Oxford Dictionary of Statistical Terms; Oxford University Press: Oxford, UK, 2003; ISBN 0-19-920613-9. [Google Scholar]

- Agam, N.; Kustas, W.P.; Anderson, M.C.; Li, F.; Neale, C.M. A vegetation index based technique for spatial sharpening of thermal imagery. Remote Sens. Environ. 2007, 107, 545–558. [Google Scholar] [CrossRef]

- More Industrial Overcapacity to be Cut for High-Quality Economy in 2018. Available online: http://www.chinadaily.com.cn (accessed on 12 April 2018).

- Duan, W.J.; Lang, J.L.; Cheng, S.Y.; Jia, J.; Wang, X.Q. Air pollutant emission inventory from iron and steel industry in Beijing-Tianjin-Hebei Region and its impact on PM2.5. Environ. Sci. 2018, 14, 1–14. [Google Scholar]

- Liu, Y.J.; Ding, H. Variation in air pollution tolerance index of plants near a steel factory: Implication for landscape-plant species selection for industrial areas. WSEAS Trans. Environ. Dev. 2008, 4, 24–32. [Google Scholar]

| Band Name | Band | Spatial Resolution | Temporal Resolution |

|---|---|---|---|

| OLI 1 | 0.43–0.45 | 30 m | 16 days |

| OLI 2 | 0.45–0.52 | 30 m | |

| OLI 3 | 0.53–0.60 | 30 m | |

| OLI 4 | 0.63–0.68 | 30 m | |

| OLI 5 | 0.85–0.89 | 30 m | |

| OLI 6 | 1.56–1.66 | 30 m | |

| OLI 7 | 2.10–2.30 | 30 m | |

| OLI 8 | 0.50–0.68 | 15 m | |

| OLI 9 | 1.36–1.39 | 30 m | |

| TIRS 1 | 10.6–11.2 | 100 m | |

| TIRS 2 | 11.5–12.5 | 100 m |

| Band Name | Number | Band | Spatial Resolution | Temporal Resolution |

|---|---|---|---|---|

| PAN 1 | 1 | 0.45–0.90 | 1 m | 5 days |

| MSS 2 | 2 | 0.45–0.52 | 4 m | |

| 3 | 0.52–0.59 | 4 m | ||

| 4 | 0.63–0.69 | 4 m | ||

| 5 | 0.77–0.89 | 4 m |

| Name | Area | Furnace | Converter | Production | Workers |

|---|---|---|---|---|---|

| Antai | 74 ha | 1 × 450 m3, 1 × 1080 m3 | 1 × 32 t, 2 × 35 t | 200 kt | - |

| Beishiti | 38 ha | 2 × 600 m3 | 2 × 55 t | - | 3000 |

| Xinglong | - | 1 × 450 m3, 1 × 530 m3, 1 × 1080 m3 | 3 × 50 t | 200 kt | - |

| Xinjin | - | 2 × 1280 m3, 2 × 2080 m3, 2 × 450 m3, 1 × 600 m3, 2 × 1080 m3 | 2 × 40 t, 2 × 120 t | 515 kt | 6500 |

| Zongheng | - | 4 × 580 m3 | 2 × 85 t | 500 kt | 4000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhao, F.; Wang, S.; Liu, W.; Wang, L. A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites. Sustainability 2018, 10, 1935. https://doi.org/10.3390/su10061935

Zhou Y, Zhao F, Wang S, Liu W, Wang L. A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites. Sustainability. 2018; 10(6):1935. https://doi.org/10.3390/su10061935

Chicago/Turabian StyleZhou, Yi, Fei Zhao, Shixin Wang, Wenliang Liu, and Litao Wang. 2018. "A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites" Sustainability 10, no. 6: 1935. https://doi.org/10.3390/su10061935

APA StyleZhou, Y., Zhao, F., Wang, S., Liu, W., & Wang, L. (2018). A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites. Sustainability, 10(6), 1935. https://doi.org/10.3390/su10061935