1. Introduction

Steel construction is growing very rapidly all over the world [

1,

2,

3]. Apart from making the steel building economical in terms of cost, time and quality, experts are also working on making those steel buildings environmentally friendly and green throughout its life-cycle [

1,

4,

5,

6].

Overall, steel is an expensive material as compared to the rest but when it comes to the cost-savings during the life span of the structure, steel proves to be a very affordable material [

3,

7]. Steel can also be made rust proof by the application of special coated paints [

2]. Apart from that, steel is an insect and termite resistant material and the maintenance cost is lower during its life span as compared to other materials [

8].

Pre-engineered steel buildings prove to be very economical and environmentally friendly as compared to conventional steel frames [

5,

7]. Pre-engineered steel structures result in reduction in factors that are contributing to global warming and pollution. Pre-engineered steel buildings usually save a lot of landfill space. Pre-engineered steel frames have longer life spans. Once the design life is over, most of the pre-engineered steel buildings end up at a recycling center where they are melted and used for the other purposes rather than being dumped at the local available land/ground, thus reducing construction and demolition waste [

8].

Construction of pre-engineered steel buildings saves energy, and, as a result of that, it cuts down on heating and cooling bills. There is much less chance of error during construction of pre-engineered buildings as everything is pre-fabricated in the factory to an accuracy of millimeters [

9,

10]. Once constructed, there is very little chance that the steel frames will creep and loosen with the passage of time, windows and doors that are framed within jambs and headers inside the building continue to remain tightly shut, and, as a result, the chances of air leaks are very minimal.

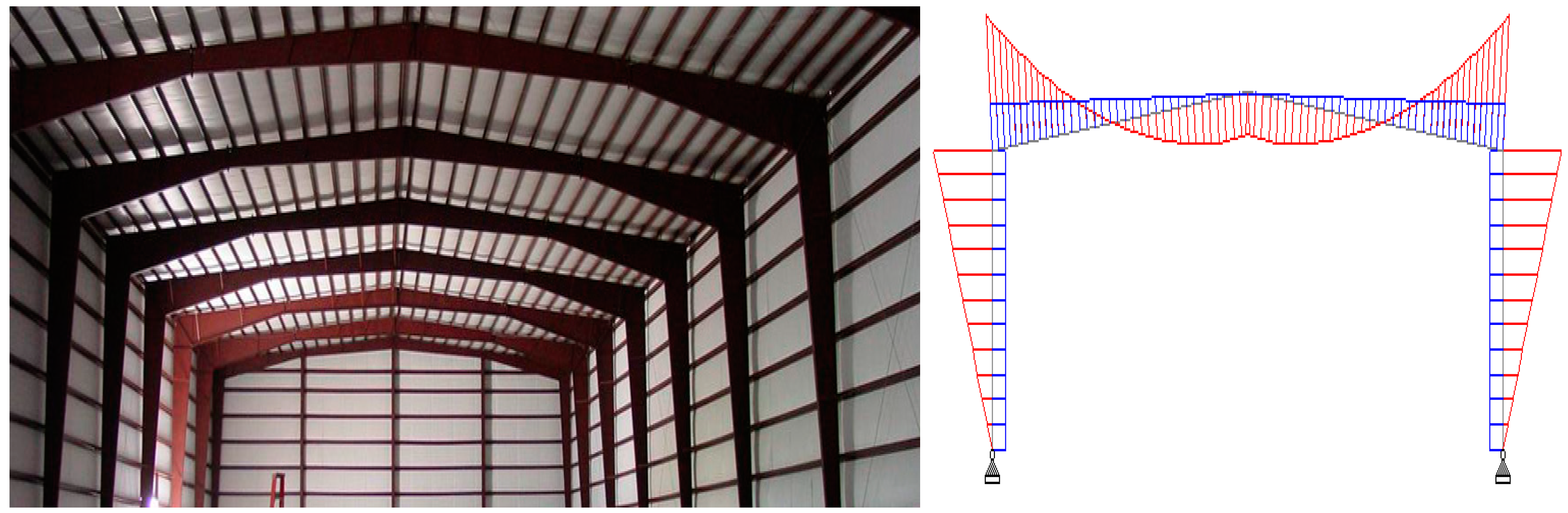

Pre-engineered design is a new terminology where the excess steel is avoided by tapering the sections as per the bending moment’s envelope [

9]. The section-moment simulation method results in lightweight structural members, which mainly contribute to the reduction of weight and cost of the structure. PEBs are designed and fabricated in the factory, then transported to the construction site in a completely knocked down condition and all structural components are assembled and erected with nut-bolts on site as per the construction plan, thereby reducing the construction time and wastage as compared to convention steel where structural members are welded on site, thus reducing wastage and energy [

7,

9,

10,

11].

Pre-engineering primary framing structure is an assembly of I-shaped structural members. The I-shaped beams are usually formed in the factory by welding steel plates together to form the I-sections. The I-section beams are then assembled on site with bolted connections to form the entire frame of the pre-engineered building. Steel Manufacturers taper the framing members as per the required specifications and design codes to account for the local loading effects. Larger plate dimensions are used in areas where the load effects are higher, whereas the secondary structural elements such as roof purlins, side and end wall girts consist of Cold Formed Z- and C-shaped members [

9,

10,

11].

In the construction industry, most of the clients demand longer spans i.e., large spacing between columns along with larger bay spacing in steel buildings so that they can easily locate their racking system, equipment and machinery. The concept of pre-engineered buildings enables for achieving longer spans and large bay spacing values [

9]. Design engineers mostly use a method of tapered sections to design pre-engineered steel frames with large spans, thus eliminating excess steel by the method of tapered section, which is as per the shape of the bending Moment Diagram as shown in

Figure 1.

In the past, significant research has been done on the design and performance evaluation of hot rolled steel sections, which are used for the construction of Conventional Steel Buildings (CSB) frames. For instance, Ren and Zeng [

12] conducted an experimental and numerical study to evaluate the capacity of a various I-shaped hot rolled steel column section by selecting the different slenderness ratios and load eccentricities. Ellobody [

13] modeled the buckling behavior of hot rolled steel stiffened and unstiffened hollow slender sections using the Finite Element Method. Dowling et al. developed a design method by using tapered steel portal frames for the industrial buildings located in the United Kingdom and discussed the advantages and role of slender webs in achieving the economy of the steel buildings [

14]. Rangelov determined the effective stiffness of slender steel sections for deflection calculations [

15]. The feasibility of tapered beam-column joints for the steel construction was elaborated by Šapalas et al. [

16] and Deb and Gulati attempted to reduce the weight of CSB truss buildings by using genetic algorithms [

17]. Saka used genetic algorithms to optimize the design of conventional pitched roof steel frames [

18]. Chan et al. determined the nonlinear behavior of pitched roof steel framed when subjected to sequential loading [

19]. Horridge and Morris compared the design and cost of CSB low pitched portal frames with pinned-base stanchions, low pitched lattice girders with fixed-base, pitched roof trusses with fixed-base and two-layer space frames with fixed-base [

20]. Chan discussed the stability design procedures for the conventional steel structures by evaluating the theory and practice in steel construction [

21]. However, there are very few who have opted for PEB steel as an area of research. Saleem et al. [

22] optimized the steel weight of PEB buildings by proposing a relationship between an unbraced length ratio of the members and flange slenderness of slender built-up sections. He considered a wide range of steel sections having non-compact and slender flanges and webs. Saleem et al. determined the optimum values of flange and web slenderness to have a minimum weight of a built-up steel section [

22]. Wankhade and Pajgade [

23] compared between the design procedures of PEB and CSB steel buildings. They effectively convey that PEB structures can be easily designed by simple design procedures in accordance with country standards. In addition, they concluded that PEB structures are more advantageous than CSB structures in terms of cost effectiveness, quality control speed in construction and simplicity in erection. Their paper also imparts simple and economical ideas on preliminary design concepts of PEBs. The concept depicted clarifies the design procedure of a PEB concept. Charkha and Latesh worked on a senior design project specialized in the economization of a steel Building using tapered steel sections. They used a few techniques and used different tapered steel sections to achieve the economic sustainability in an optimum quantity. In addition, they presented a cooperative study of PEB and CSB [

24]. Firoz et al. just elaborated on the design procedures for PEB steel buildings [

25].

In the recent past, different researchers have compared the PEB steel frames with CSB frames. For instance, Pradip and Lande compared a truss roof conventional building with a PEB frame of 22.0 m width and 7.5 m height and found that PEB structure weight is 35% less than the weight of a conventional CSB truss frame [

26]. Shashank and Kulkarni compared a 12.0 m wide steel frame and found that PEB steel frames are 33% lighter than the CSB steel frames [

27]. Darshan et al. also performed a similar kind of study using PEB and CSB frames of 20 m width and tried hot rolled tube sections for CSB frames [

28]. He found 35% reduction in the PEB frame weight compared to CSB. Thakre et al. and Titiksh et al. just elaborated on the advantages of PEB steel frames with CSB frames [

29,

30]. Pradeep and Rao compared the forces and moments of a 20 m CSB truss frame with a PEB frame and found it is 26% lighter than the CSB truss frame [

31]. Similar kinds of studies were also performed by Takre et al., Pradeep et al. and by Titiksh et al. [

29,

30,

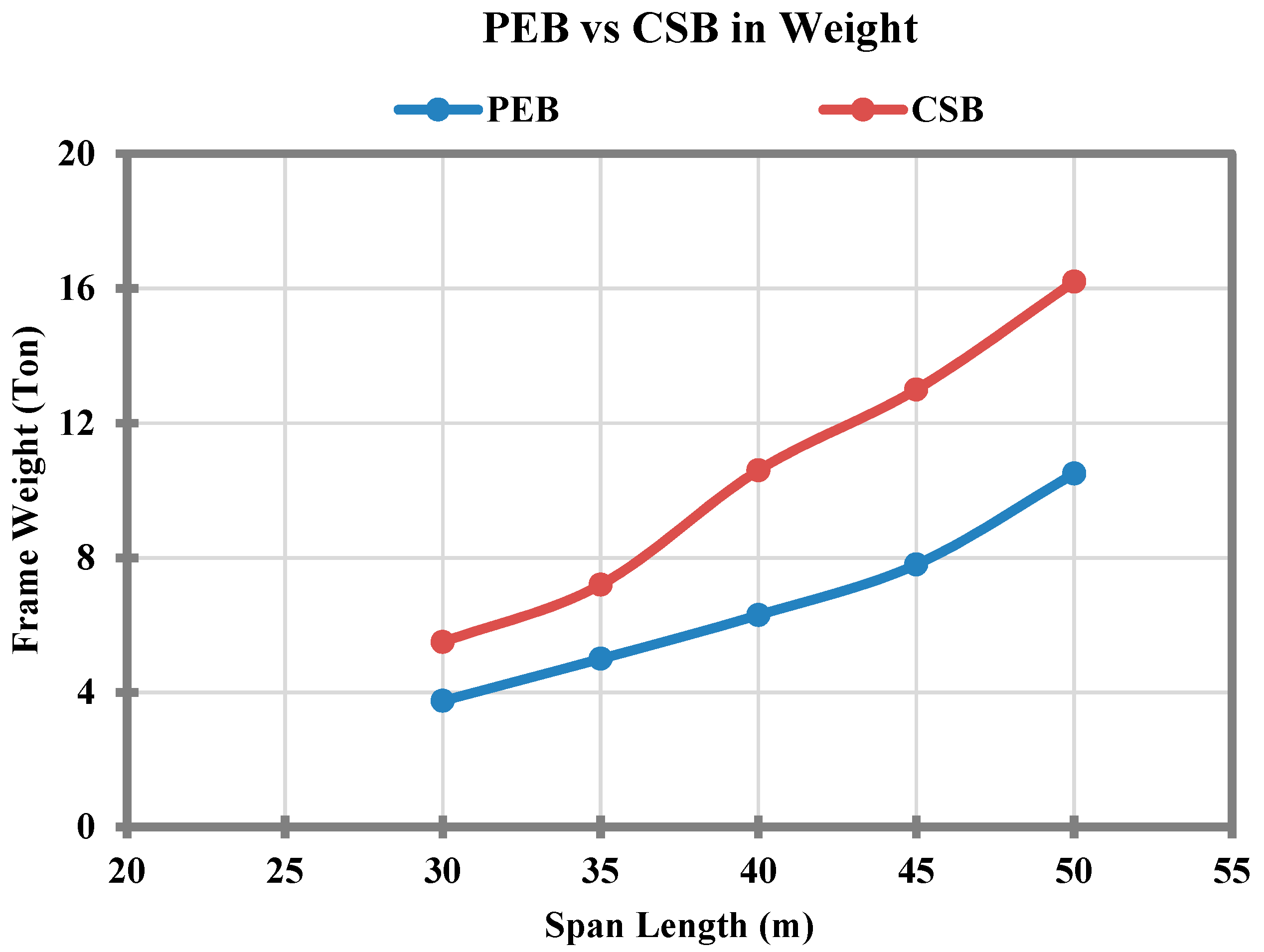

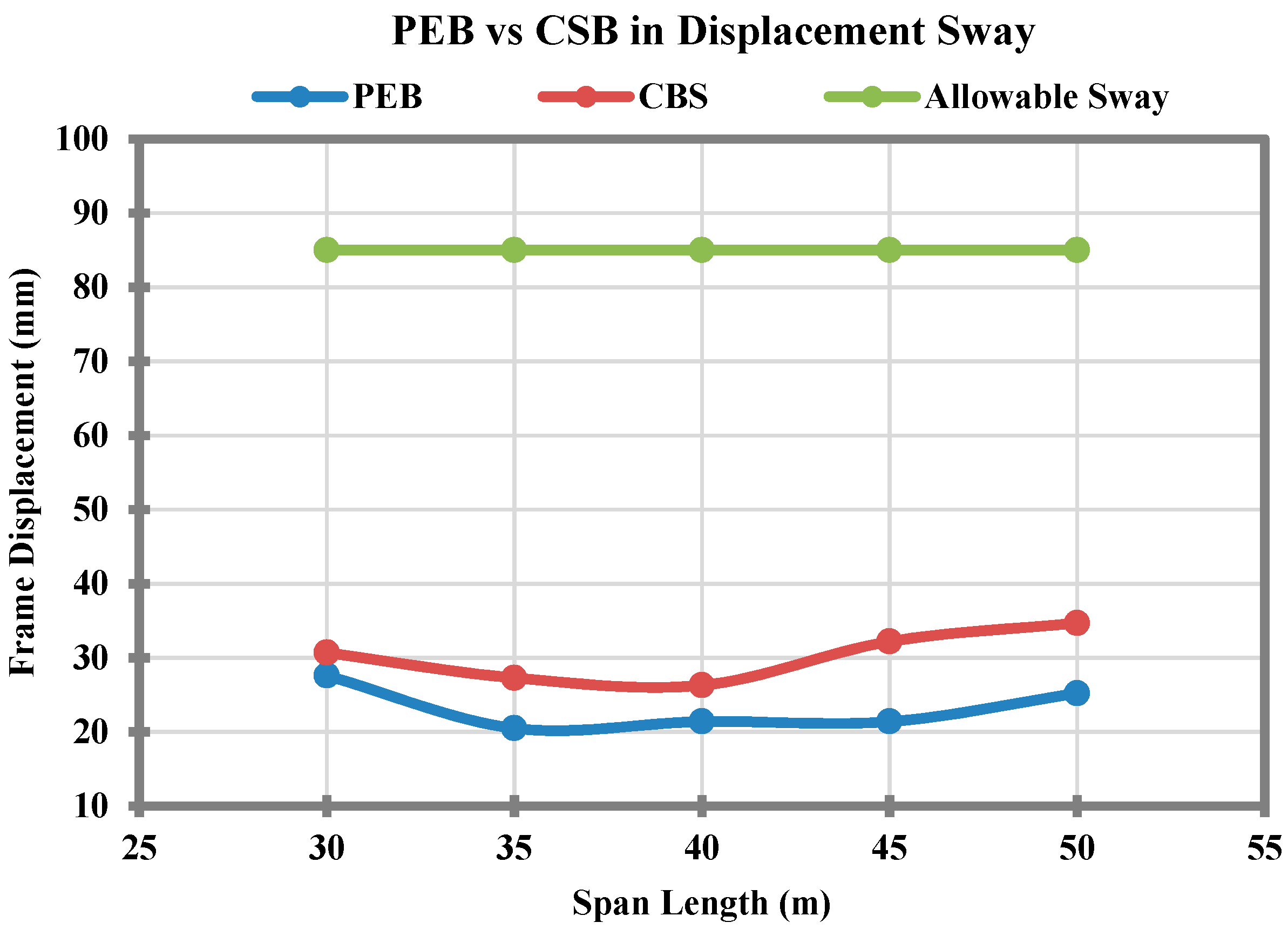

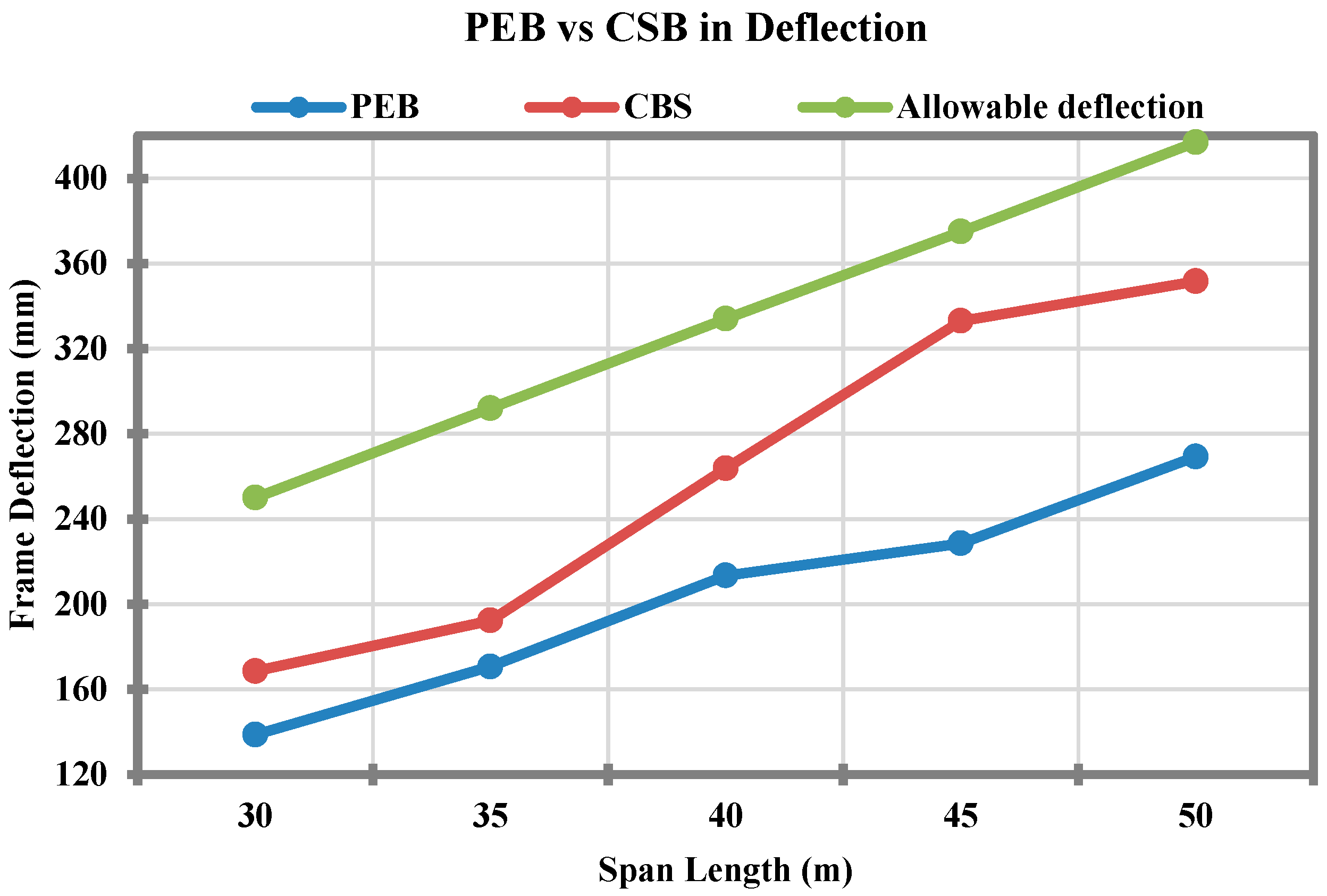

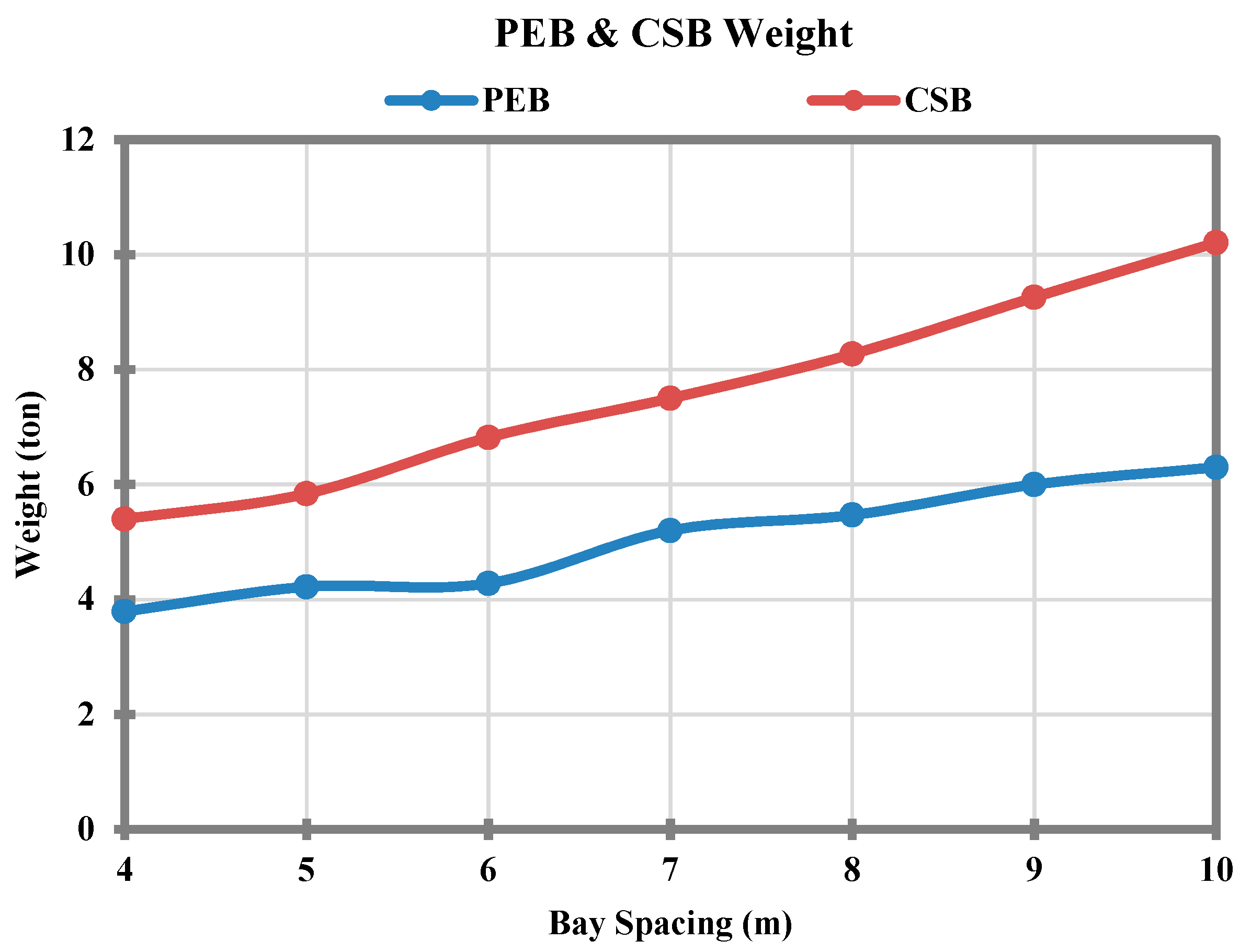

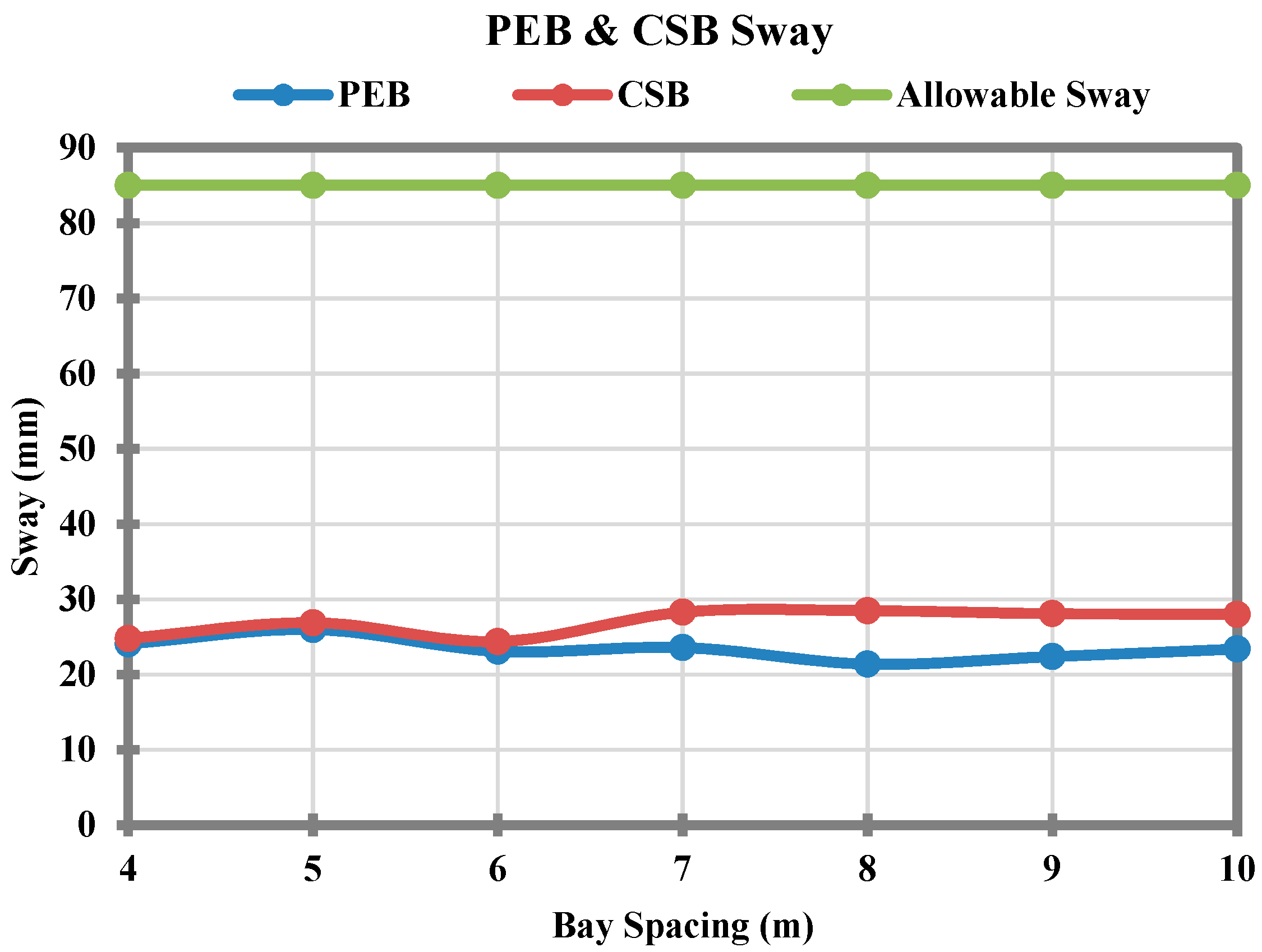

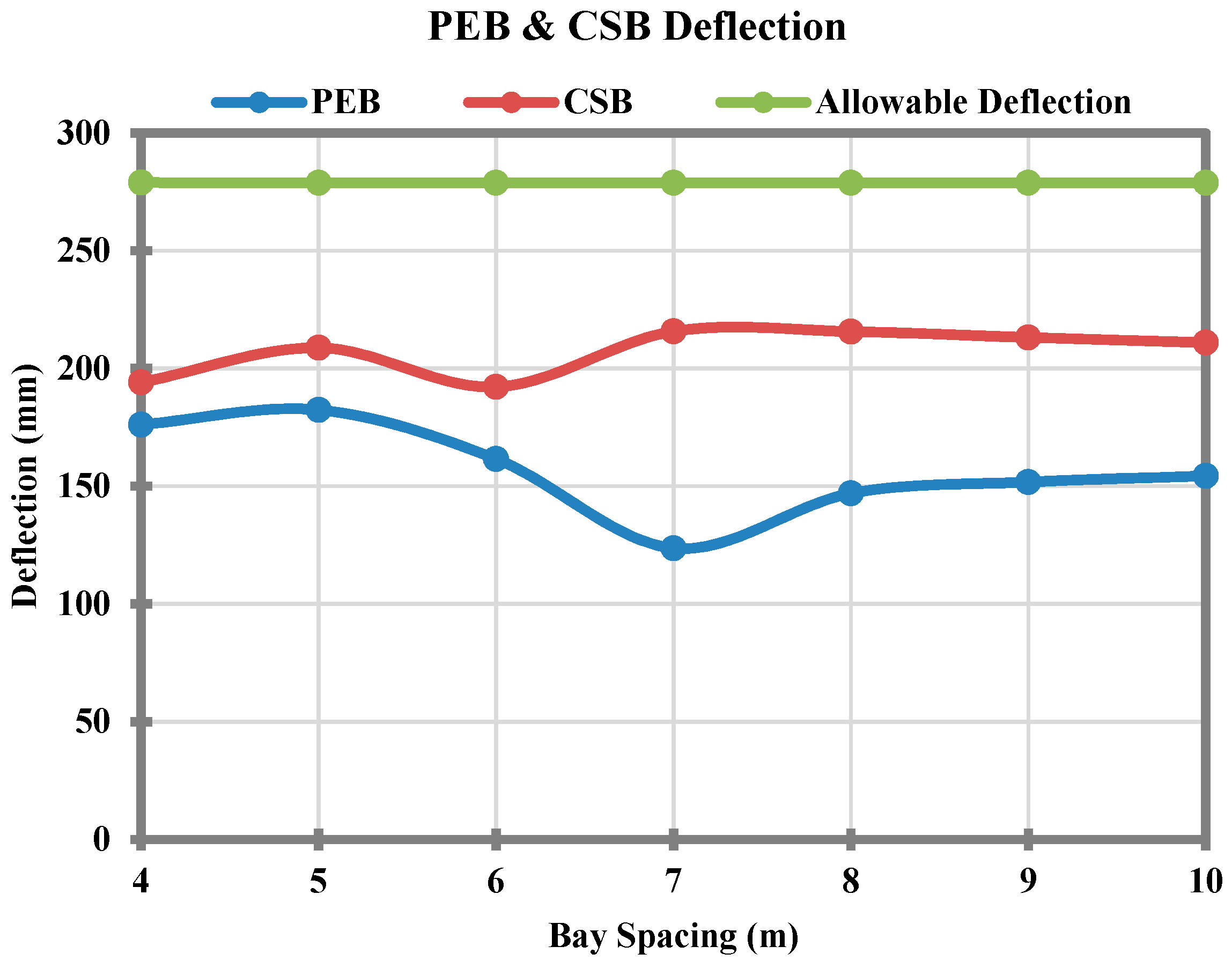

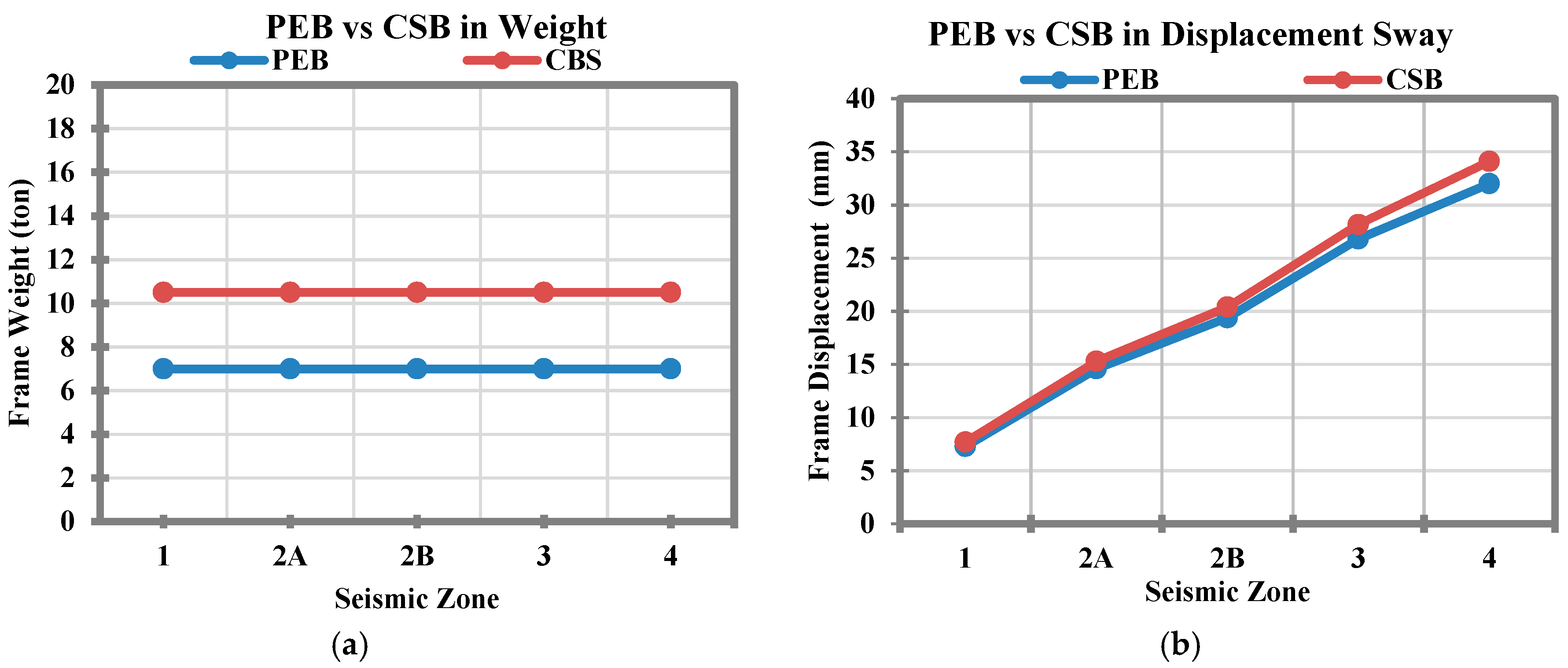

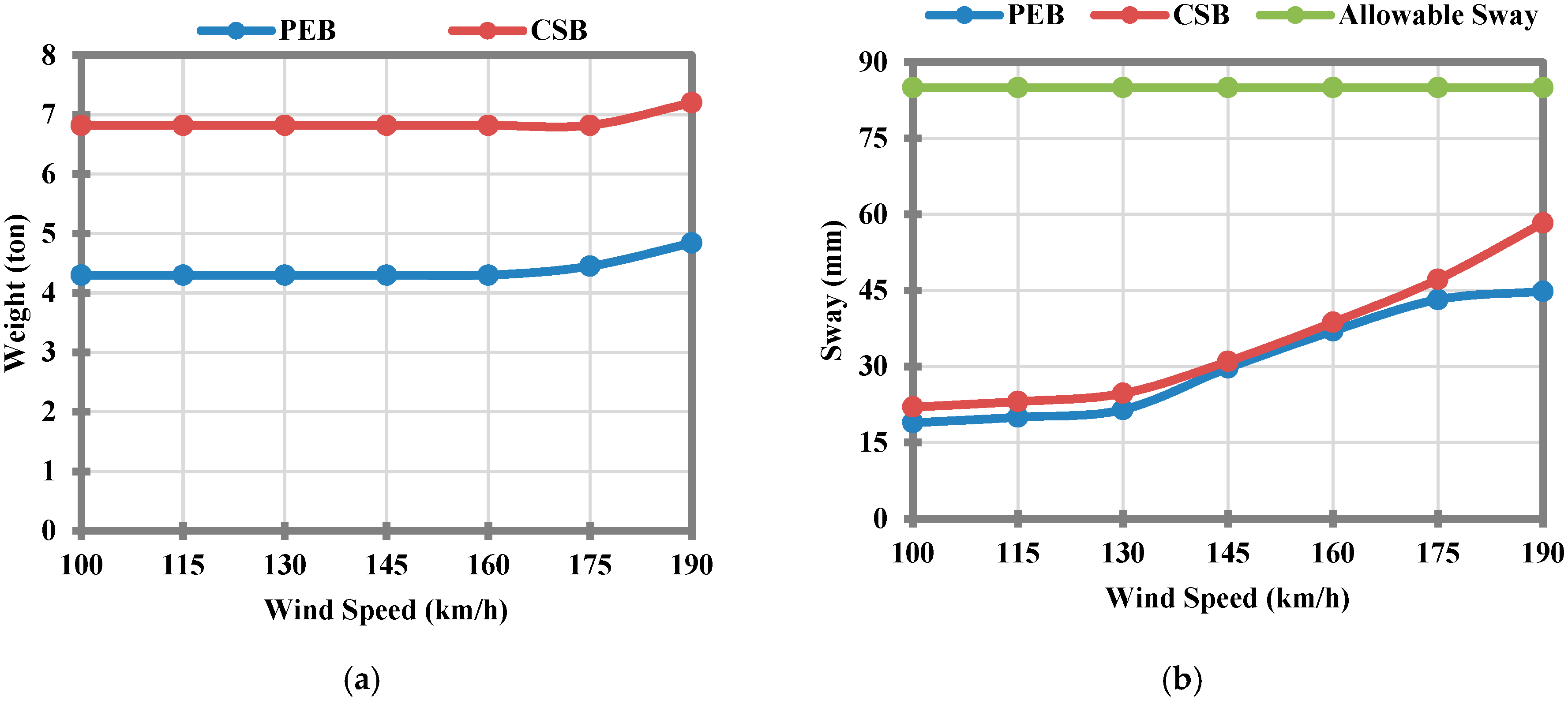

31]. All of the aforementioned research works present the weight comparison for a frame that consists of a single span. However, the percentage reduction in frame weight is a function of frame span, bay spacing and the lateral force effects. Moreover, the aforementioned studies just present the comparison of single PEB and CSB frames in terms of weight and cost only. No information regarding the structural response (sway and deflection), the effect of wind forces and the effect of seismic forces is presented in detail. The current study elaborates on the effect of frame span, bay spacing and lateral forces on the economy achieved by the use of PEB steel frames. In order to achieve these objectives, a detailed study was planned and 48 different frames were analyzed, profiled, designed and optimized. In the first part of the study, spans of the frames (for both CSB and PEB) were varied from 30 m to 35 m, 40 m, 45 m and 50 m and the effect of this variation is monitored in terms of weight, deflection and sideway of the frames and later on these values were also compared with the allowable values of MBMA 2006. In the next part, the bay spacing of the frames varied from 4 m to 5, 6, 7, 8, 9, and 10 m, respectively. In the third and fourth part, the seismic forces and wind forces were gradually varied. The effect of all these variations was compared in terms of weight and deflections.

2. Materials and Methods

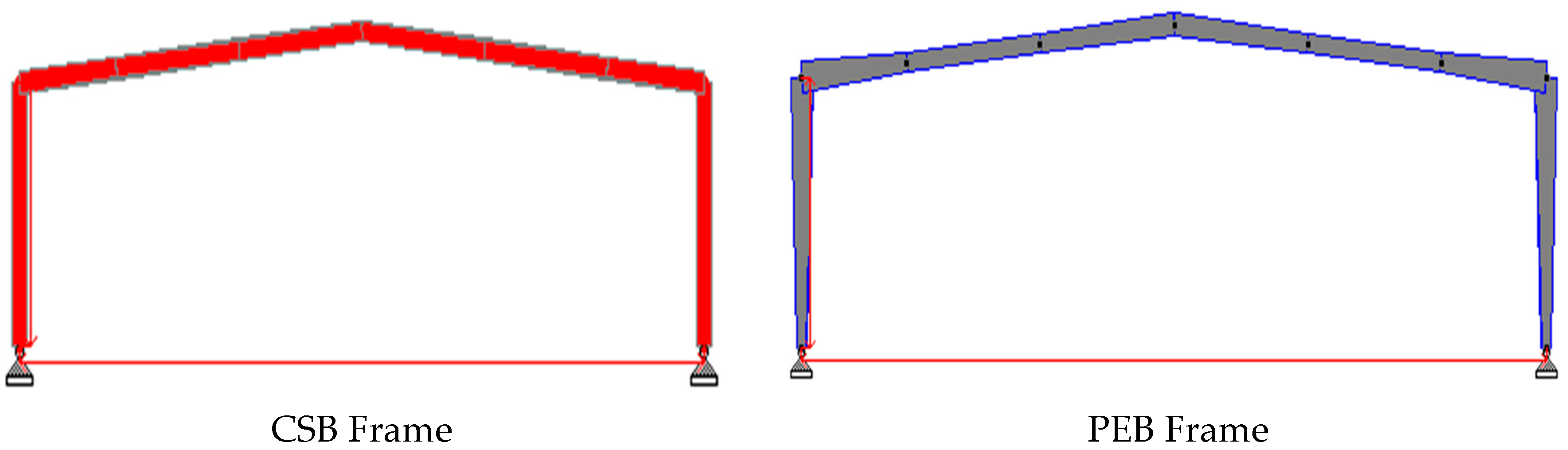

In the present research study, all of the required information such as building layout as well as span lengths and bay-spacing of pre-engineered steel building is decided based upon the most common industrial buildings construction practices in the Middle East or Gulf Region of the world. A detailed study was planned to investigate the behavior of CSB and PEB steel buildings. Different frame spans, bay spacing values, seismic loads and wind forces were the main parameters of the study as given in

Table 1. The dead, live and wind loads were calculated using the American Society of Civil Engineers Minimum Design Loads (ASCE/SEI 7-10) [

32] and seismic forces were calculated using Uniform Building Code (UBC 97) [

33]. The design of the frames was carried using the American Institute of Steel Construction Specification for Structural Steel Buildings (ANSI/AISC 360-10) [

34] and all the material strengths were conforming to ASTM A572—15 [

35]. The serviceability checks for the lateral displacements and vertical deflections were considered by applying the limiting values proposed by the Metal Building Manufacturing Association (MBMA 2006) [

36]. The steel main frames were analyzed and designed by using Finite Element Method based computer software STAAD PRO. The steel frames were subjected to the different load combinations and the frames sections were optimized by using the technique of the bending moment profile. The steel frames were subjected to the load combinations consisting of dead, collateral, live, wind and earthquake as given in

Table 2. The steel main frames were analyzed by considering the building under fully enclosed conditions. The research work mainly discusses the comparison between PEB frame and CSB main frames steel weight, lateral displacement (sway) and vertical displacement (deflection). The whole study is comprised of four parts. In the first part, the frame spans were varied from 30 m to 50 m with an interval of 5 m (See

Table 1) and the effect of span on the frame weight, sway and deflection was determined. In the second part, the frame span was kept constant at 33 m and the bay spacing is varied from 4 m to 10 m as given in

Table 1. In the third and fourth part, the frames were subjected to different seismic forces and wind speeds according to UBC 97 [

33] and ASCE/SEI 7-10 [

32], respectively. A typical CSB and a PEB frame modelled in STAAD Pro. is shown in

Figure 2.

5. Conclusions

In this research study, the PEB and CSB frames were subjected to various loading affects to compare their performance in terms of weight and displacements. The frame span, bay spacing, seismic earthquake zones and different wind speed has been selected and were the parameters of the research study. In the current study, the performance of the PEB and CSB frames is compared in terms of frame weight, lateral sway and deflection. The current study mainly compares the steel weight and the cost comparison was not conducted because the steel price per metric ton is a variable, and it varies from country to country and is highly dependent on the global financial market conditions. The cost of the pre-engineered building is also dependent upon the location of the project and transportation freight (via sea or land). The majority of the pre-engineered steel suppliers charge the fabrication price per metric ton; therefore, any reduction in the frame weight will be proportional to steel fabrication price per metric ton only.

A number of steel frames were analyzed and designed using FEM-based computer package (Staad Pro.). The use of tapered sections in pre-engineered steel structure plays a significant role in reducing steel weight by roughly 35% of the weight of the conventional steel structure. As a result, the size of the foundation will be minimized due to the reduction in dead load. An overall reduction of 30–40% in steel weight was observed in the main frames, which spanned between 30 and 50 m. For bigger frame spans (40 m, 45 m and 50 m), a higher percentage reduction in frame weight was found as compared to smaller frame spans. A similar kind of trend was also observed for higher bay spacing values. The seismic forces has no significant effect on the frame weights (both CSB and PEB) because of the lesser weight and lighter roofing of the building. However, on the other hand, due to the lesser weight of the frames and load over it, wind forces became more critical and play a vital role in governing the design of the frames. The earthquake forces may become critical for multilevel PEB steel frames, which have intermediate mezzanine floors of significantly higher dead and live loads. For all of the frames analyzed, the PEB steel frames have shown lesser lateral and vertical displacements compared to conventional hot-rolled steel frames. This is because of the better control over the cross-sectional sizes and tapering technology of steel sections. By choosing thicker sections of the CSB frames, the displacement will become closer to the PEB frame, but it will result in higher steel weight. One of the reasons for higher CSB frame weights is no availability of a series of hot rolled sections. For instance, if a design section fails at a given loading, then the next available option of the hot rolled sections may result in increased tonnage. To have a lighter CSB frame weight, it is highly desirable to have a variety of sections available in the inventory of a hot-rolled table. PEB construction is environmentally friendly because of energy efficiency and the elimination of material wastage through cutting and welding. In the PEB industry, the fabrication processes are monitored and performed inside the factory, while in conventional steel construction, all fabrication work is performed on-site, resulting in material waste. Pre-engineered building construction gives the end users a much more economical and better solution for long span structures where large clear span and rapid construction are the utmost priority of the builders.