Selection of the Most Suitable Alternative Fuel Depending on the Fuel Characteristics and Price by the Hybrid MCDM Method

Abstract

:1. Introduction

2. Literature Review

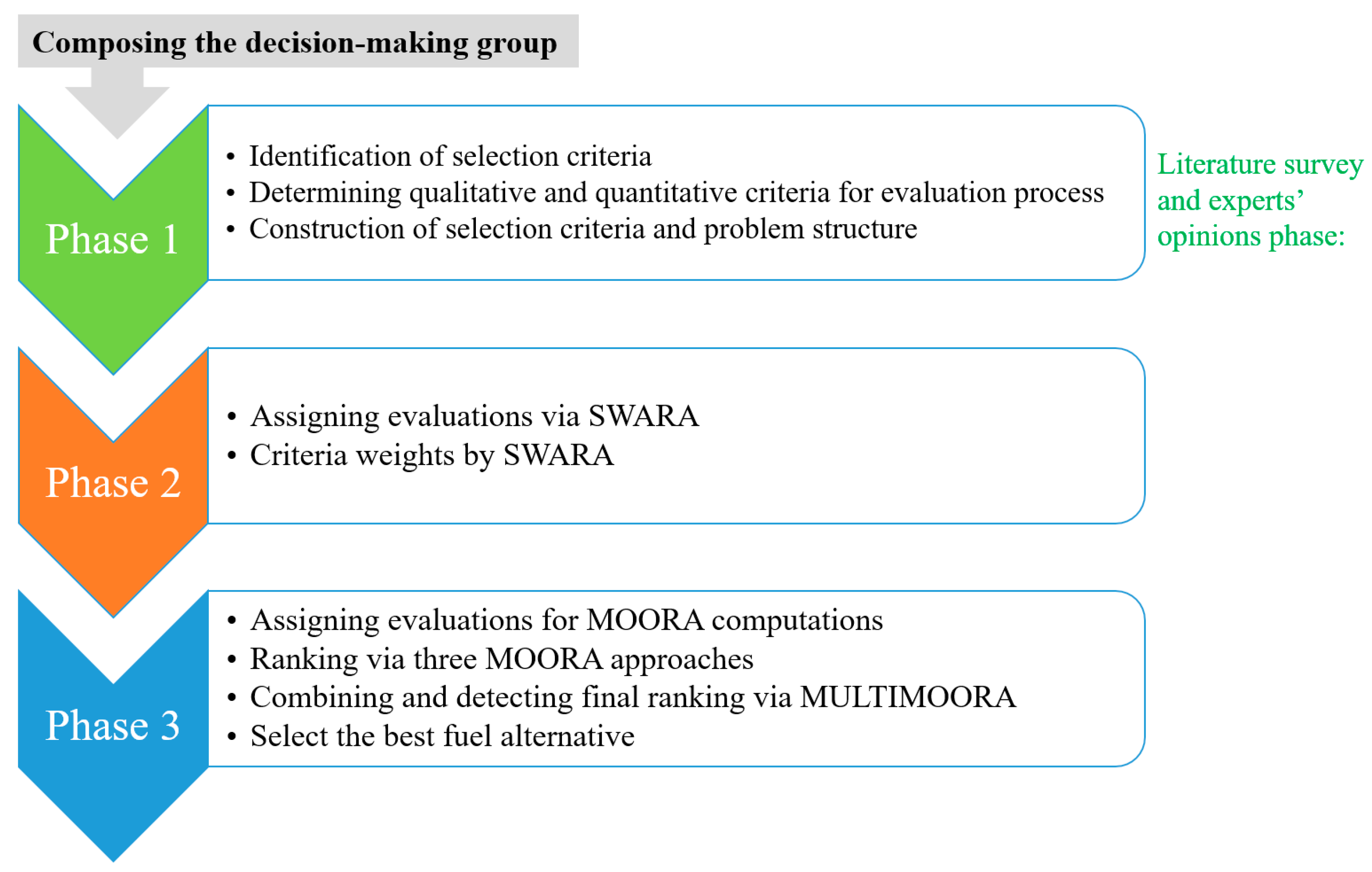

3. Materials and Methods

3.1. The Step-Wise Weight Assessment Ratio Analysis (SWARA) Method

3.2. Multi-Objective Optimization on the Basis of Ratio Analysis (MOORA) Method

3.2.1. The Ratio System (RS) Approach

3.2.2. The Reference Point (RP) Approach

3.2.3. The Weighted Full Multiplicative form (FMF) Approach

3.2.4. The Theory of Dominance

3.2.5. The Sensitivity Analysis

4. Methodology, Criteria, and Alternatives

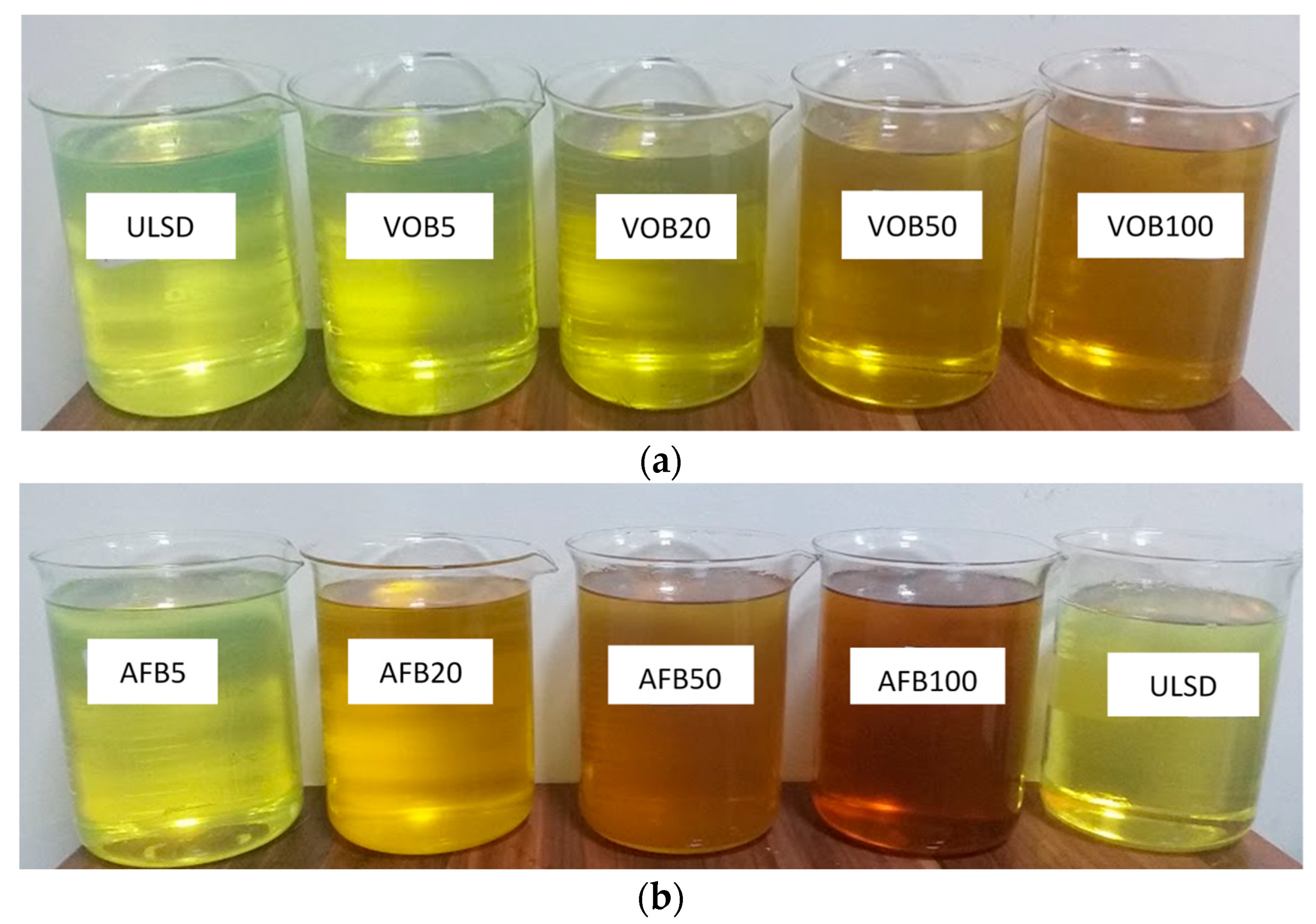

4.1. Alternative Fuels

4.2. Criteria for the Best Fuel Selection

4.2.1. Calorific Value (C1)

4.2.2. Cetane Number (C2)

4.2.3. Oxygen Content Rate (C3)

4.2.4. Fuel Price (C4)

4.2.5. Flashpoint (C5)

4.2.6. Viscosity (C6)

4.2.7. Lubricity (C7)

4.2.8. Iodine Number (C8)

4.2.9. Water Content (C9)

5. Computation

5.1. Computation of Criteria Weights Using SWARA

5.2. Computation of Ranking Using MULTIMOORA

5.3. The Sensitivity Analysis for the Integrated Method

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jahirul, M.I.; Brown, R.J.; Senadeera, W.; O’Hara, I.M.; Ristovski, Z.D. The use of artificial neural networks for identifying sustainable biodiesel feedstocks. Energies 2013, 6, 3764–3806. [Google Scholar] [CrossRef]

- Okoro, O.; Sun, Z.; Birch, J. Catalyst-Free Biodiesel Production Methods: A Comparative Technical and Environmental Evaluation. Sustainability 2018, 10, 127. [Google Scholar] [CrossRef]

- Balki, M.K.; Cavus, V.; Duran, İ.U.; Tuna, R.; Sayin, C. Experimental study and prediction of performance and emission in an SI engine using alternative fuel with artificial neural network. Int. J. Automot. Eng. Technol. 2018, 7, 58–64. [Google Scholar]

- Ovando-Medina, I.; Espinosa-García, F.; Núñez-Farfán, J.; Salvador-Figueroa, M. Does biodiesel from Jatropha Curcas represent a sustainable alternative energy source? Sustainability 2009, 1, 1035–1041. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships derived from physical properties of vegetable oil and biodiesel fuels. Fuel 2008, 87, 1743–1748. [Google Scholar] [CrossRef]

- Altun, Ş. Effect of the degree of unsaturation of biodiesel fuels on the exhaust emissions of a diesel power generator. Fuel 2014, 117, 450–457. [Google Scholar] [CrossRef]

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste Cooking Oil as an Alternate Feedstock for Biodiesel Production. Energies 2008, 1, 3–18. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Lin, C.W.; Opricovic, S. Multi-criteria analysis of alternative-fuel buses for public transportation. Energy Policy 2005, 33, 1373–1383. [Google Scholar] [CrossRef]

- Kumar, N.; Varun; Chauhan, S.R. Performance and emission characteristics of biodiesel from different origins: A review. Renew. Sustain. Energy Rev. 2013, 21, 633–658. [Google Scholar] [CrossRef]

- Anish Kumar, K.; Senthil Kumar, P.; Madhusudanan, S.; Pasupathy, V.; Vignesh, P.R.; Sankaranarayanan, A.R. A simplified model for evaluating best biodiesel production method: Fuzzy analytic hierarchy process approach. Sustain. Mater. Technol. 2017, 12, 18–22. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F.; Shi, G.H.; Zhang, X.T. A fuzzy multi-criteria decision-making model for trigeneration system. Energy Policy 2008, 36, 3823–3832. [Google Scholar] [CrossRef]

- Durairaj, S.; Sathiya Sekar, K.; Ilangkumaran, M.; Rammanohar, M.; Thyalan, B.; Yuvaraj, E.; Ramesh, S. Multi-Criteria Decision Model for Biodiesel Selection in an Electrical Power Generator Based on Fahp-Gra-Topsis. IJRET Int. J. Res. Eng. Technol. 2014, 2319–2363. [Google Scholar]

- Bagočius, V.; Zavadskas, E.K.; Turskis, Z. Multi-person selection of the best wind turbine based on the multi-criteria integrated additive-multiplicative utility function. J. Civ. Eng. Manag. 2014, 20, 590–599. [Google Scholar] [CrossRef]

- Baležentis, T.; Zeng, S. Group multi-criteria decision making based upon interval-valued fuzzy numbers: An extension of the MULTIMOORA method. Expert Syst. Appl. 2013, 40, 543–550. [Google Scholar] [CrossRef]

- Dahooie, J.H.; Zavadskas, E.K.; Abolhasani, M.; Vanaki, A.; Turskis, Z. A novel approach for evaluation of projects using an interval-valued fuzzy additive ratio assessment (ARAS) method: A case study of oil and gas well drilling projects. Symmetry 2018, 10, 45. [Google Scholar] [CrossRef]

- Debbarma, B.; Chakraborti, P.; Bose, P.K.; Deb, M.; Banerjee, R. Exploration of PROMETHEE II and VIKOR methodology in a MCDM approach for ascertaining the optimal performance-emission trade-off vantage in a hydrogen-biohol dual fuel endeavour. Fuel 2017, 210, 922–935. [Google Scholar] [CrossRef]

- Eghbali-Zarch, M.; Tavakkoli-Moghaddam, R.; Esfahanian, F.; Sepehri, M.M.; Azaron, A. Pharmacological therapy selection of type 2 diabetes based on the SWARA and modified MULTIMOORA methods under a fuzzy environment. Artif. Intell. Med. 2018. [Google Scholar] [CrossRef] [PubMed]

- Godiganur, S.; Suryanarayana Murthy, C.; Reddy, R.P. Performance and emission characteristics of a Kirloskar HA394 diesel engine operated on fish oil methyl esters. Renew. Energy 2010, 35, 355–359. [Google Scholar] [CrossRef]

- Behçet, R.; Oktay, H.; Çakmak, A.; Aydin, H. Comparison of exhaust emissions of biodiesel-diesel fuel blends produced from animal fats. Renew. Sustain. Energy Rev. 2015, 46, 157–165. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a di diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Keršuliene, V.; Turskis, Z. Integrated fuzzy multiple criteria decision making model for architect selection. Technol. Econ. Dev. Econ. 2011, 17, 645–666. [Google Scholar] [CrossRef]

- Keršuliene, V.; Zavadskas, E.K.; Turskis, Z. Selection of rational dispute resolution method by applying new step-wise weight assessment ratio analysis (Swara). J. Bus. Econ. Manag. 2010, 11, 243–258. [Google Scholar] [CrossRef]

- Brauers, W.K.M.; Zavadskas, E.K. The MOORA method and its application to privatization in a transition economy. Control Cybern. 2006, 35, 445–469. [Google Scholar]

- Brauers, W.K.M.; Zavadskas, E.K. Robustness of MULTIMOORA: A Method for Multi-Objective Optimization. Informatica 2012, 23, 1–25. [Google Scholar]

- Karlin, S.; Studden, W.J. Tchebycheff Systems: With Applications in Analysis and Statistics; Interscience Publishers: New York, NY, USA, 1966; Volume 9. [Google Scholar]

- Hafezalkotob, A.; Hafezalkotob, A. Extended MULTIMOORA method based on Shannon entropy weight for materials selection. J. Ind. Eng. Int. 2015, 12. [Google Scholar] [CrossRef]

- Brauers, W.K.M.; Zavadskas, E.K. Multimoora Optimization Used to Decide on a Bank Loan to Buy Property. Technol. Econ. Dev. Econ. 2011, 17, 174–188. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A combined fuzzy AHP and fuzzy TOPSIS based strategic analysis of electronic service quality in healthcare industry. Expert Syst. Appl. 2012, 39, 2341–2354. [Google Scholar] [CrossRef]

- Biodiesel Standards & Properties. Available online: https://www.dieselnet.com/tech/fuel_biodiesel_std.php (accessed on 10 April 2018).

- Ge, J.; Yoon, S.; Kim, M.; Choi, N. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Appl. Sci. 2016, 7, 34. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Wan Ghazali, W.N.M.; Mamat, R.; Masjuki, H.H.; Najafi, G. Effects of biodiesel from different feedstocks on engine performance and emissions: A review. Renew. Sustain. Energy Rev. 2015, 51, 585–602. [Google Scholar] [CrossRef]

- Knothe, G.; Matheaus, A.C.; Ryan, T.W. Cetane numbers of branched and straight-chain fatty esters determined in an ignition quality tester. Fuel 2003, 82, 971–975. [Google Scholar] [CrossRef]

- Sayin, C.; Gumus, M.; Canakci, M. Effect of fuel injection pressure on the injection, combustion and performance characteristics of a DI diesel engine fueled with canola oil methyl esters-diesel fuel blends. Biomass Bioenergy 2012, 46, 435–446. [Google Scholar] [CrossRef]

- Abedin, M.J.; Kalam, M.A.; Masjuki, H.H.; Sabri, M.F.M.; Rahman, S.M.A.; Sanjid, A.; Fattah, I.M.R. Production of biodiesel from a non-edible source and study of its combustion, and emission characteristics: A comparative study with B5. Renew. Energy 2016, 88, 20–29. [Google Scholar] [CrossRef]

- Barabas, I.; Todoru, I.-A. Biodiesel Quality, Standards and Properties. In Biodiesel-Quality, Emissions and By-Products; InTech: Pleasanton, CA, USA, 2011. [Google Scholar] [CrossRef]

- Yoon, S.H.; Lee, C.S. Experimental investigation on the combustion and exhaust emission characteristics of biogas-biodiesel dual-fuel combustion in a CI engine. Fuel Process. Technol. 2011, 92, 992–1000. [Google Scholar] [CrossRef]

- Aydin, H. Scrutinizing the combustion, performance and emissions of safflower biodiesel-kerosene fueled diesel engine used as power source for a generator. Energy Convers. Manag. 2016, 117, 400–409. [Google Scholar] [CrossRef]

- Selvam, D.J.P.; Vadivel, K. An experimental investigation on performance, emission, and combustion characteristics of a diesel engine fueled with methyl esters of waste pork lard and diesel blends. Int. J. Green Energy 2013, 10, 908–923. [Google Scholar] [CrossRef]

- Grabowski, M.S.; McCormick, R.; Alleman, T.L.; Herring, A.M. The Effect of Biodiesel Composition on Engine Emissions from a DDC Series 60 Diesel Engine: Final Report; Report 2 in a Series of 6 (NREL/SR-510-31461); National Renewable Energy Laboratory: Golden, CO, USA, 2003; NREL/SR-51.

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- U.S. Department of Energy Alternative Fuels Data Center: Fuel Price. Available online: https://www.afdc.energy.gov/fuels/prices.html (accessed on 10 April 2018).

- EIA Daily Prices—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/todayinenergy/prices.php (accessed on 13 May 2018).

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Hung, Y.T. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef]

- Biodiesel Prices. Available online: https://www.neste.com/en/corporate-info/investors/market-data/biodiese-prices-sme-fame (accessed on 10 April 2018).

- Tate, R.E.; Watts, K.C.; Allen, C.A.W.; Wilkie, K.I. The viscosities of three biodiesel fuels at temperatures up to 300 °C. Fuel 2006, 85, 1010–1015. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M. Characterization of the key fuel properties of methyl ester-diesel fuel blends. Fuel 2009, 88, 75–80. [Google Scholar] [CrossRef]

- Yasar, F.; Altun, S.; Adin, H. Fuel properties of biodiesels produced from blends of canola oil and animal tallow. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2011, 27, 199–208. [Google Scholar]

- Altun, Ş.; Rodríguez-Fernández, J. Biofuels derived from Turkish industry wastes—A study of performance and emissions in a diesel engine. Environ. Prog. Sustain. Energy 2016, 35, 847–852. [Google Scholar] [CrossRef]

- Bart, J.C.J.; Palmeri, N.; Cavallaro, S. Sustainability and use of biodiesel. Biodiesel Sci. Technol. 2010, 625–712. [Google Scholar] [CrossRef]

- Canakci, M.; Gerpen, J. Van Comparison of engine performance and emissions for petroleum diesel fuel, yellow grease biodiesel, and soybean oil biodiesel. Trans. ASAE 2003, 46, 937–944. [Google Scholar] [CrossRef]

- Knothe, G.; Sharp, C.A.; Ryan, T.W. Exhaust emissions of biodiesel, petrodiesel, neat methyl esters, and alkanes in a new technology engine. Energy Fuels 2006, 20, 403–408. [Google Scholar] [CrossRef]

- Brauers, W.K.M.; Zavadskas, E.K. Multi-Objective Decision Making With A Large Number of Objectives. An Application For Europe 2020. Int. J. Oper. Res. 2013, 10, 67–79. [Google Scholar]

| Alternatives | Density (kg/m3) | Kinematic Viscosity (mm2/s) | Cetane Number | Flashpoint (°C) | Iodine Value (gI/100 g) | Water (mg/kg) | Calorific Value (kj/g) |

|---|---|---|---|---|---|---|---|

| ULSD | 840 | 2.80 | 52 | 78 | ~0 | ~0 | 43.3 |

| VOB5 | 842.20 | 3.01 | 52 | 83.5 | 5.8 | 10.1 | 43.1 |

| VOB20 | 848.78 | 3.14 | 52.1 | 100 | 23.2 | 40.4 | 42.4 |

| VOB50 | 861.95 | 3.52 | 52.3 | 133 | 58 | 101 | 41 |

| VOB100 | 883.90 | 4.01 | 52.6 | 188 | 116 | 202 | 38.6 |

| AFB5 | 842.15 | 3.11 | 52.3 | 82.2 | 2 | 19.4 | 43.1 |

| AFB20 | 848.58 | 3.79 | 53.0 | 94.7 | 8 | 77.6 | 42.8 |

| AFB50 | 861.45 | 4.98 | 54.5 | 119.8 | 20 | 194 | 41.7 |

| AFB100 | 882.90 | 9.81 | 57 | 161.5 | 40 | 388 | 40 |

| Standards [29] | 860–900 kg/m3 1 | 3.5–5.0 mm2/s 1; 1.9–6.0 mm2/s 2 | 51, min 1; 47, min 2 | 101 °C, min 1; 93 °C, min 2 | 120 gI/100 g, max 1 | 500 mg/kg 1 | - |

| Criteria | sj | kj | qj | wj |

|---|---|---|---|---|

| C1—Calorific value | 1.000 | 1.000 | 0.219 | |

| C2—Cetane number | 0.30 | 1.300 | 0.769 | 0.168 |

| C3—Oxygen content rate | 0.20 | 1.200 | 0.641 | 0.140 |

| C4—Fuel price | 0.20 | 1.200 | 0.534 | 0.117 |

| C5—Flash point | 0.10 | 1.100 | 0.486 | 0.106 |

| C6—Viscosity | 0.40 | 1.400 | 0.347 | 0.076 |

| C7—Lubricity | 0.05 | 1.050 | 0.330 | 0.072 |

| C8—Iodine number | 0.40 | 1.400 | 0.236 | 0.052 |

| C9—Water content | 0.05 | 1.050 | 0.225 | 0.049 |

| 1.000 |

| Criteria | wj of 1st DM | wj of 2nd DM | wj of 3rd DM | wj of 4th DM | wj of 5th DM | Geometric Average | Normalized Weights of Criteria |

|---|---|---|---|---|---|---|---|

| C1 | 0.219 | 0.257 | 0.232 | 0.268 | 0.232 | 0.241 | 24.2% |

| C2 | 0.168 | 0.146 | 0.166 | 0.129 | 0.166 | 0.154 | 15.5% |

| C3 | 0.140 | 0.160 | 0.150 | 0.168 | 0.107 | 0.144 | 14.5% |

| C4 | 0.117 | 0.086 | 0.116 | 0.107 | 0.118 | 0.108 | 10.9% |

| C5 | 0.106 | 0.095 | 0.085 | 0.083 | 0.102 | 0.094 | 9.4% |

| C6 | 0.076 | 0.104 | 0.089 | 0.072 | 0.079 | 0.083 | 8.4% |

| C7 | 0.072 | 0.062 | 0.058 | 0.065 | 0.065 | 0.064 | 6.5% |

| C8 | 0.052 | 0.047 | 0.061 | 0.052 | 0.072 | 0.056 | 5.6% |

| C9 | 0.049 | 0.043 | 0.044 | 0.057 | 0.059 | 0.050 | 5.0% |

| Alternatives | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| ULSD | 43.3 | 52.0 | 100.00 | 0.78 | 78.0 | 2.80 | 1.00 | 100.0 | 100.0 |

| VOB5 | 43.1 | 52.0 | 100.55 | 0.79 | 83.5 | 3.01 | 4.00 | 105.8 | 110.1 |

| VOB20 | 42.4 | 52.1 | 102.21 | 0.83 | 100.0 | 3.14 | 6.00 | 123.2 | 140.4 |

| VOB50 | 41.0 | 52.3 | 105.52 | 0.90 | 133.0 | 3.52 | 7.00 | 158.0 | 201.0 |

| VOB100 | 38.6 | 52.6 | 111.04 | 1.02 | 188.0 | 4.01 | 9.00 | 216.0 | 302.0 |

| AFB5 | 43.1 | 52.3 | 100.55 | 0.78 | 82.2 | 3.11 | 4.00 | 102.0 | 119.4 |

| AFB20 | 42.8 | 53.0 | 102.22 | 0.80 | 94.7 | 3.79 | 6.00 | 108.0 | 177.6 |

| AFB50 | 41.7 | 54.5 | 105.54 | 0.83 | 119.8 | 4.98 | 7.00 | 120.0 | 294.0 |

| AFB100 | 40.0 | 57.0 | 111.08 | 0.87 | 161.5 | 9.81 | 9.00 | 140.0 | 488.0 |

| Max. | Max. | Max. | Min. | Max. | Min. | Max. | Min. | Min. | |

| wj | 24.2% | 15.5% | 14.5% | 10.9% | 9.4% | 8.4% | 6.5% | 5.6% | 5.0% |

| Alternatives | RS | Rank | RP | Rank | FMF | Rank | MULTIMOORA Final Ranking |

|---|---|---|---|---|---|---|---|

| ULSD | 0.13334 | 8 | 0.02843 | 8 | 7.79952 | 9 | 8 |

| VOB5 | 0.14158 | 4 | 0.02701 | 6 | 8.45322 | 2 | 4 |

| VOB20 | 0.14538 | 1 | 0.02275 | 4 | 8.56300 | 1 | 1 |

| VOB50 | 0.14206 | 3 | 0.01422 | 1 | 8.42104 | 4 | 3 |

| VOB100 | 0.13841 | 6 | 0.01604 | 2 | 8.25594 | 6 | 6 |

| AFB5 | 0.14121 | 5 | 0.02736 | 7 | 8.41822 | 5 | 5 |

| AFB20 | 0.14279 | 2 | 0.02412 | 5 | 8.42710 | 3 | 2 |

| AFB50 | 0.13557 | 7 | 0.01764 | 3 | 8.23115 | 7 | 7 |

| AFB100 | 0.10846 | 9 | 0.04161 | 9 | 7.84806 | 8 | 9 |

| Scenarios | Weights of Cluster | Weights of Criteria | The Rank of Alternatives |

|---|---|---|---|

| Set 1 | CPE (100%), S&CoC (0%), EL&MP (0%) | C1, C2, C3, C8 (25%); Others (0%) | ULSD > AFB5 > AFB20 |

| Set 2 | CPE (0%), S&CoC (0%), EL&MP (100%) | C6, C7, C9 (33.3%); Others (0%) | VOB20 > VOB5 > VOB50 |

| Set 3 | CPE (0%), S&CoC (100%), EL&MP (0%) | C4, C5 (50%); Others (0%) | AFB100 > VOB100 > VOB50 |

| Set 4 | CPE (50%), S&CoC (0%), EL&MP (50%) | C1, C2, C3, C8 (12.5%); C4, C5 (0%); C6, C7, C9 (16.7%) | VOB20 > VOB5 > AFB5 |

| Set 5 | CPE (50%), S&CoC (50%), EL&MP (0%) | C1, C2, C3, C8 (12.5%); C4, C5 (25%); C6, C7, C9 (0%) | AFB100 > AFB50 > VOB100 |

| Set 6 | CPE (0%), S&CoC (50%), EL&MP (50%) | C1, C2, C3, C8 (0%); C4, C5 (25%); C6, C7, C9 (16.7%) | VOB100 > VOB50 > VOB20 |

| Set 7 | CPE (33.3%), S&CoC (33.3%), EL&MP (33.3%) | C1, C2, C3, C8 (8.3%); C4, C5 (16.7%); C6, C7, C9 (11.1%) | VOB20 > VOB50 > VOB100 |

| Set 8 | CPE (44.4%), S&CoC (22.2%), EL&MP (33.3%) | C1-9 (11.1%) weighted equally | VOB20 > VOB5 > AFB5 |

| Group Decision | CPE (58.6%), S&CoC (20.2%), EL&MP (21.2%) | C1 (23.4%), C2 (15.5%), C3 (13.7%), C8 (6.0%); C4 (10.5%), C5 (9.7%); C6 (8.8%), C7 (7.0%), C9 (5.4%) | VOB20 > AFB20 > VOB50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdogan, S.; Sayin, C. Selection of the Most Suitable Alternative Fuel Depending on the Fuel Characteristics and Price by the Hybrid MCDM Method. Sustainability 2018, 10, 1583. https://doi.org/10.3390/su10051583

Erdogan S, Sayin C. Selection of the Most Suitable Alternative Fuel Depending on the Fuel Characteristics and Price by the Hybrid MCDM Method. Sustainability. 2018; 10(5):1583. https://doi.org/10.3390/su10051583

Chicago/Turabian StyleErdogan, Sinan, and Cenk Sayin. 2018. "Selection of the Most Suitable Alternative Fuel Depending on the Fuel Characteristics and Price by the Hybrid MCDM Method" Sustainability 10, no. 5: 1583. https://doi.org/10.3390/su10051583

APA StyleErdogan, S., & Sayin, C. (2018). Selection of the Most Suitable Alternative Fuel Depending on the Fuel Characteristics and Price by the Hybrid MCDM Method. Sustainability, 10(5), 1583. https://doi.org/10.3390/su10051583