Evaluating Gravity-Flow Irrigation with Lessons from Yuma, Arizona, USA

Abstract

1. Introduction

Aims and Scope

2. Gravity-Flow and Pressurized Irrigation Technologies

2.1. Gravity-Flow Irrigation Methods

2.2. Pressurized Irrigation Systems

3. Economics and Adoption of Gravity-Flow Irrigation

4. Irrigation Efficiency and Water Use

5. Irrigation in the U.S. Southwest

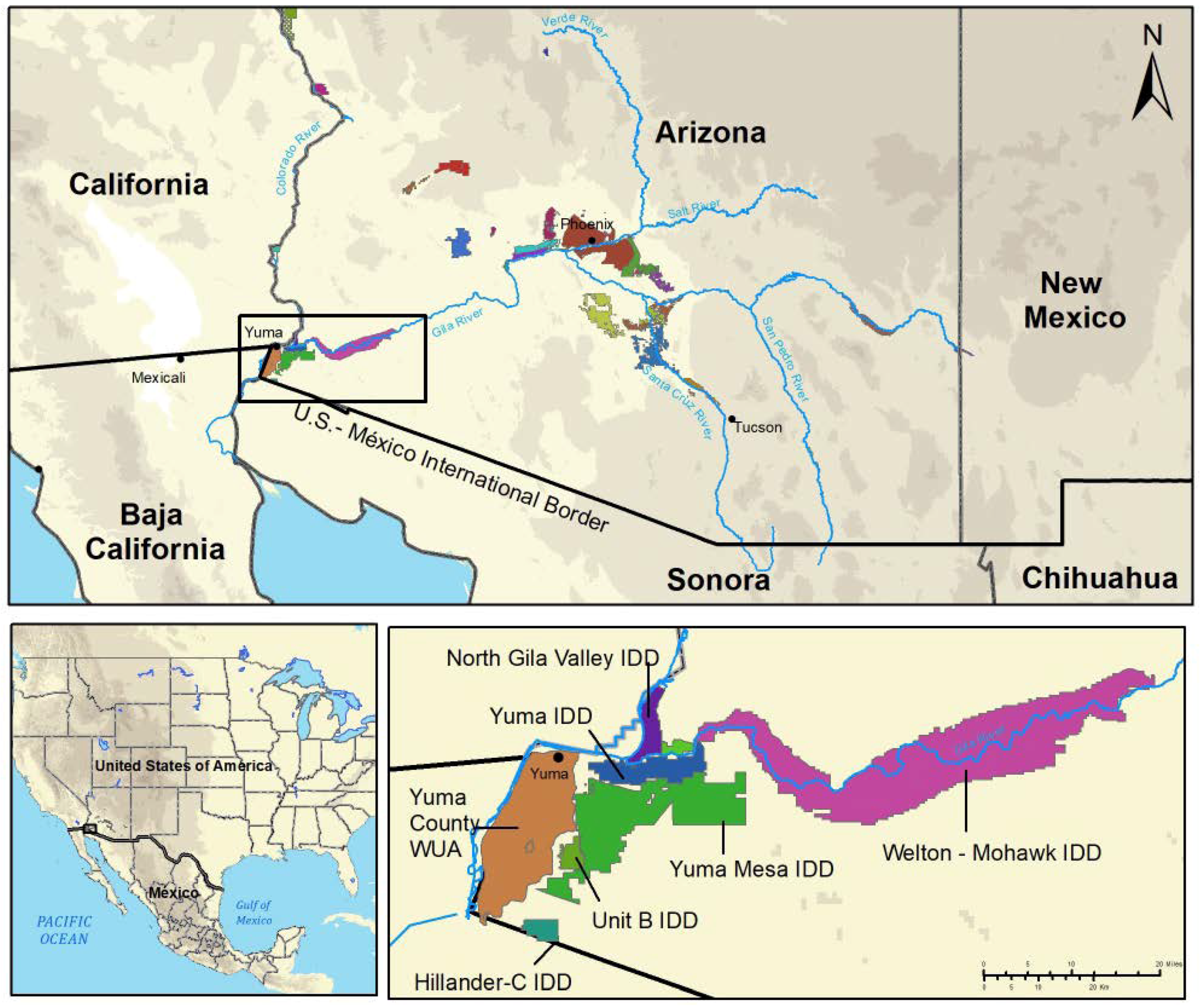

6. A Yuma Case Study

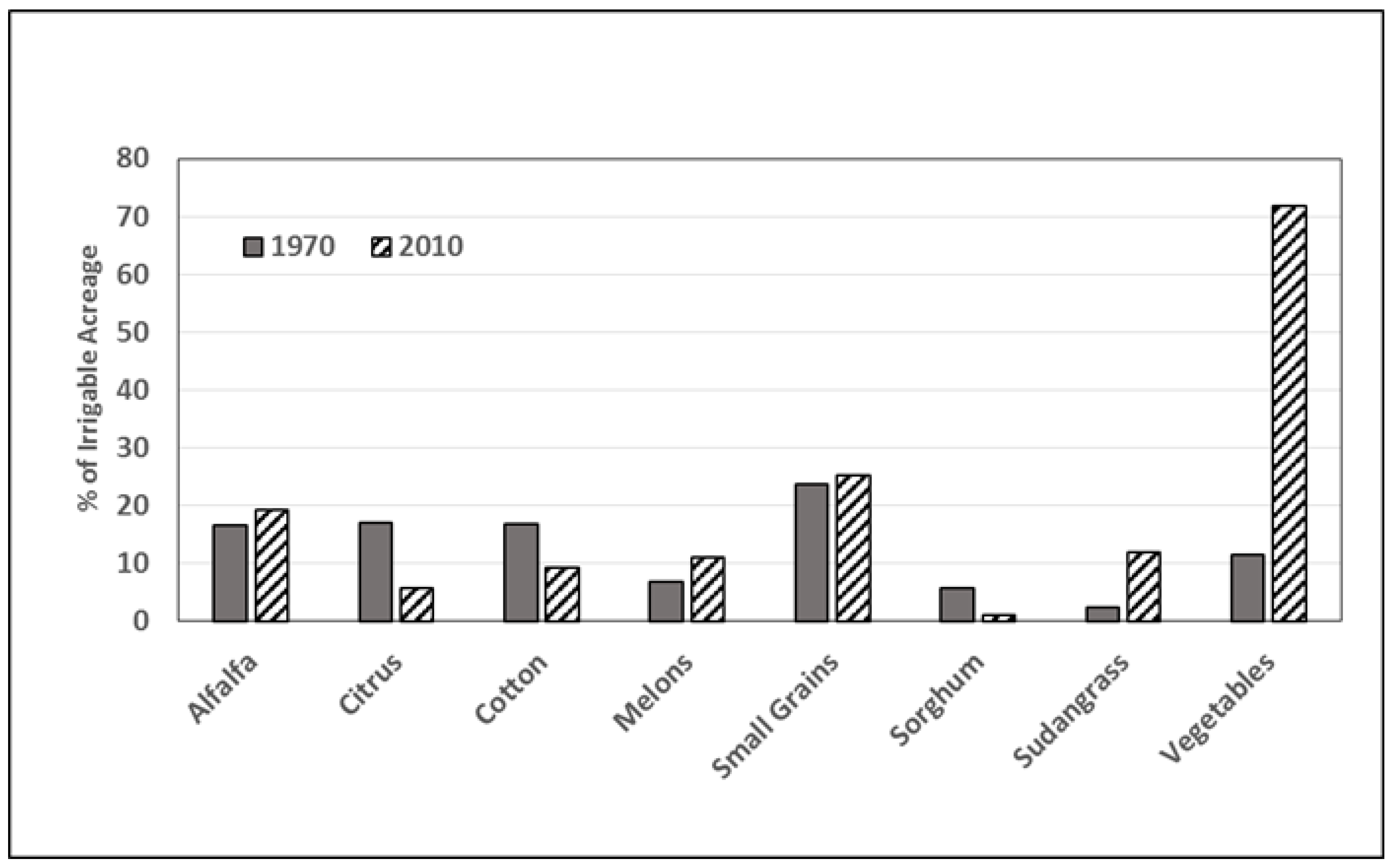

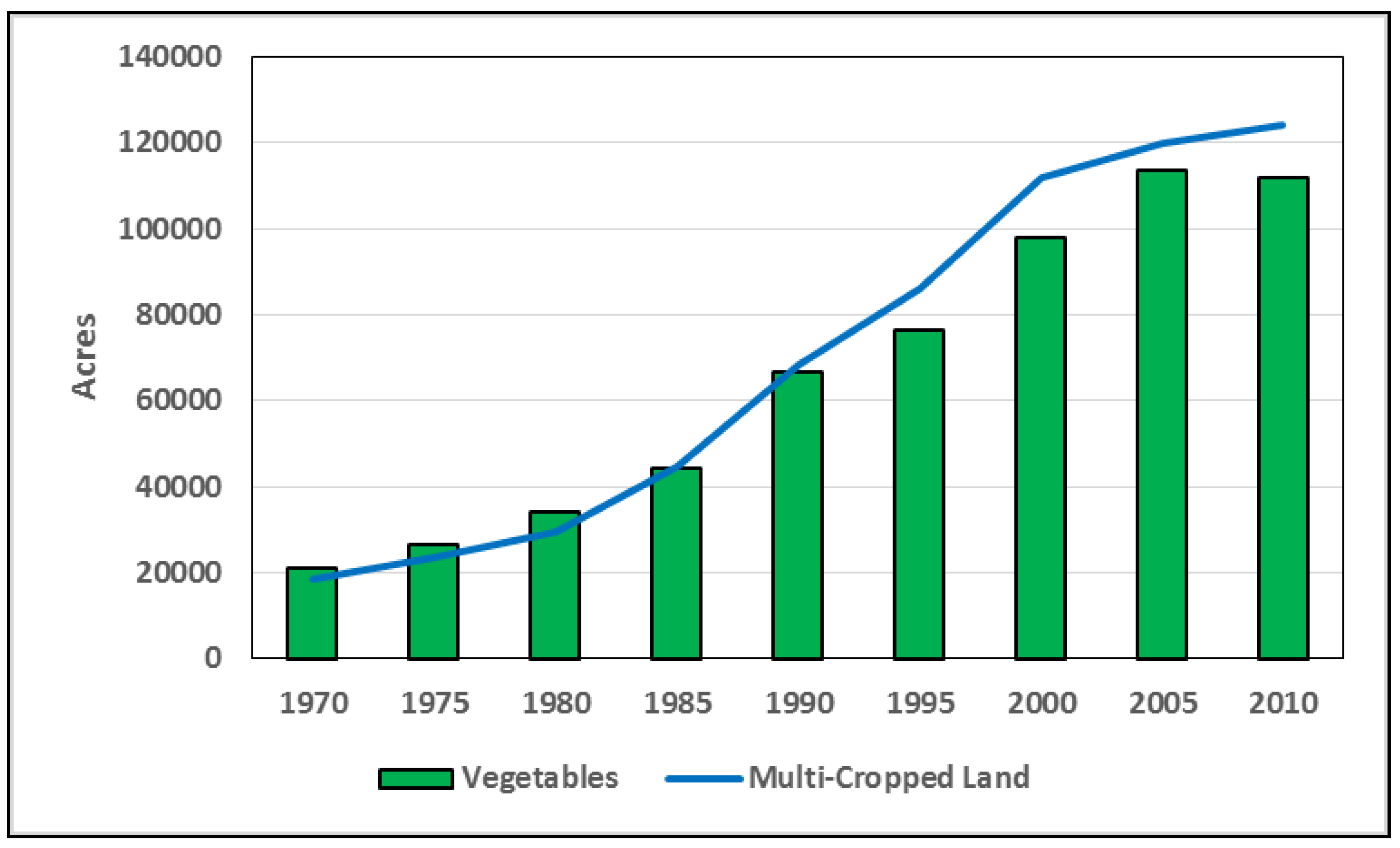

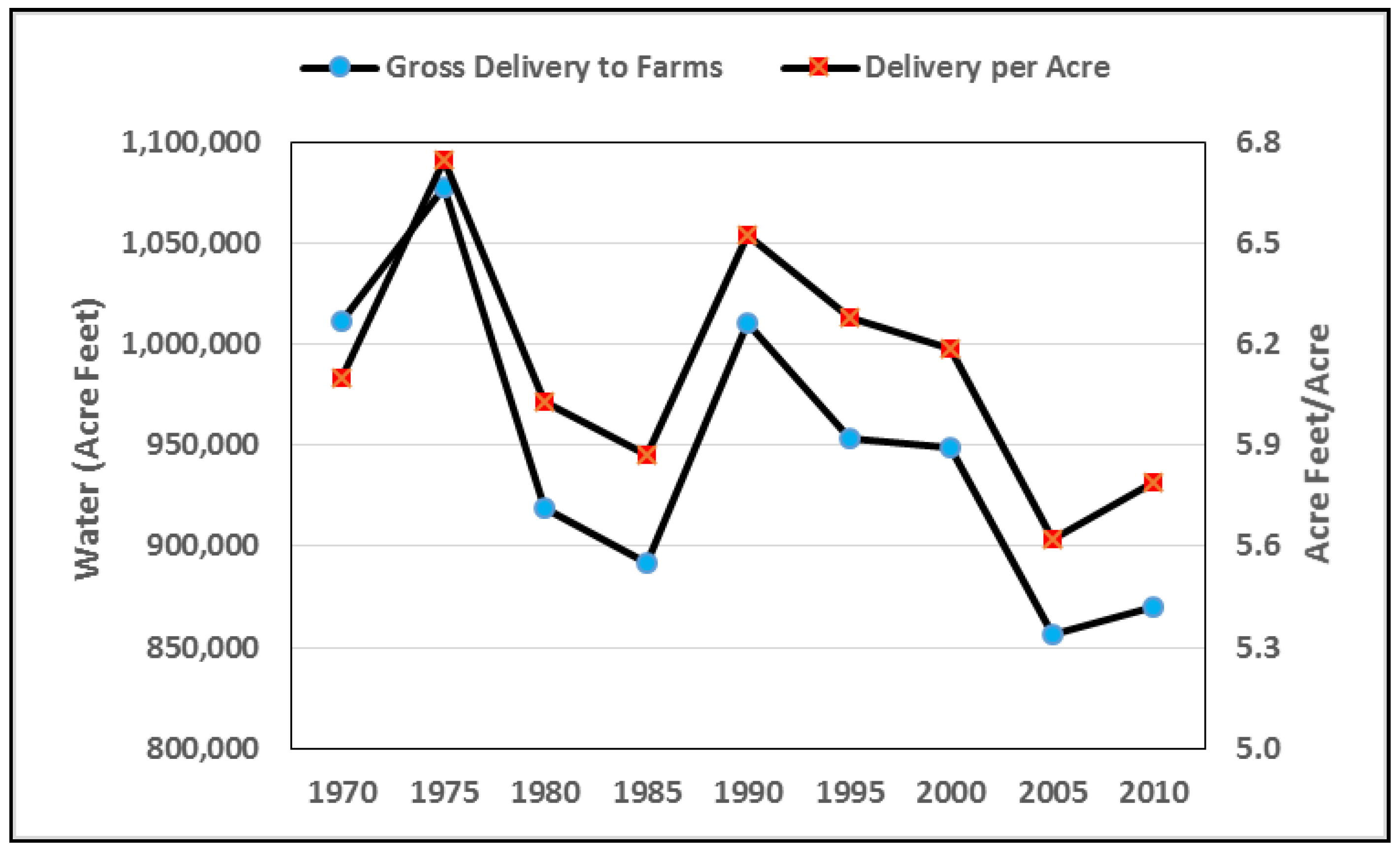

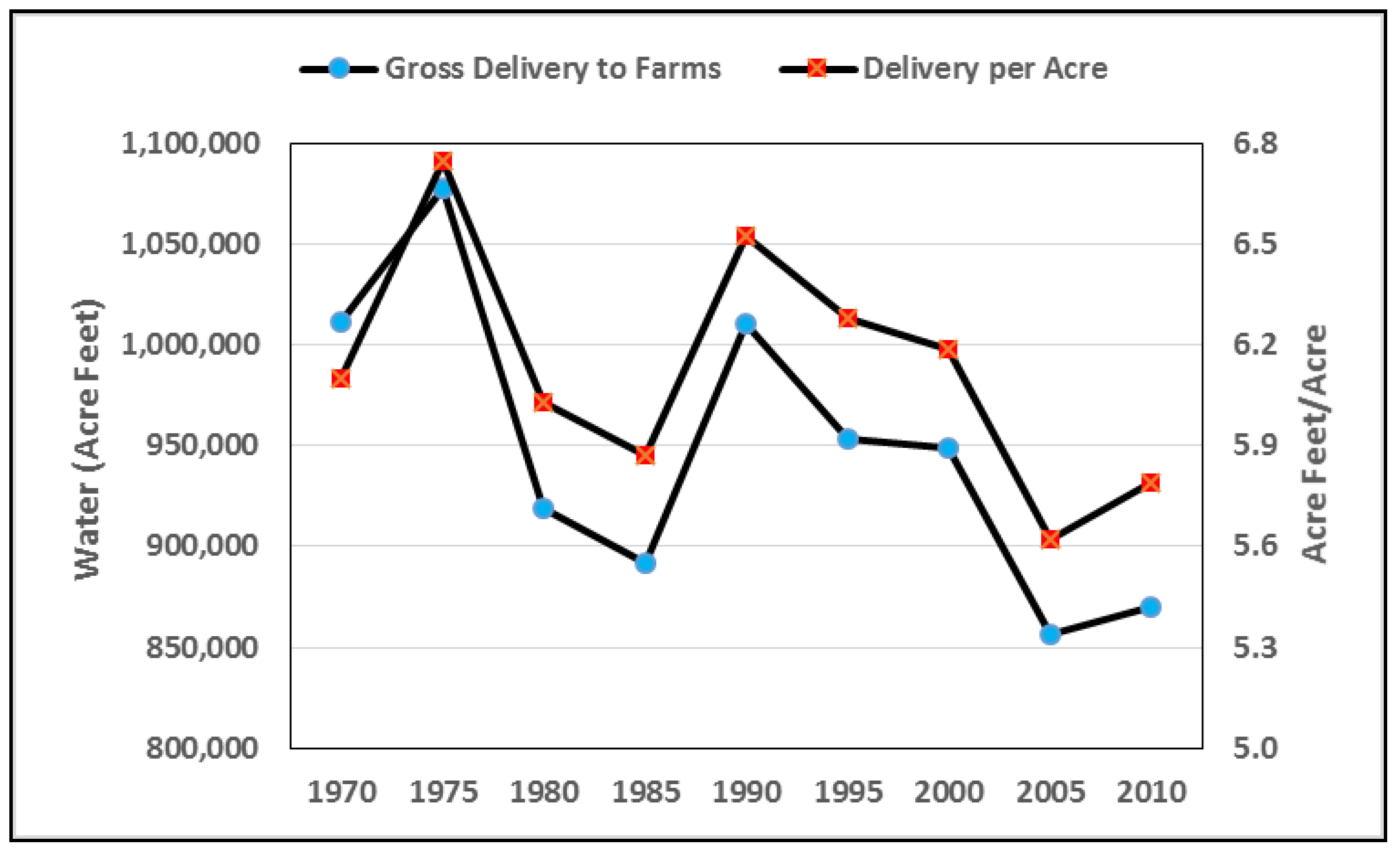

6.1. Yuma Area Agriculture: 1970 versus 2010

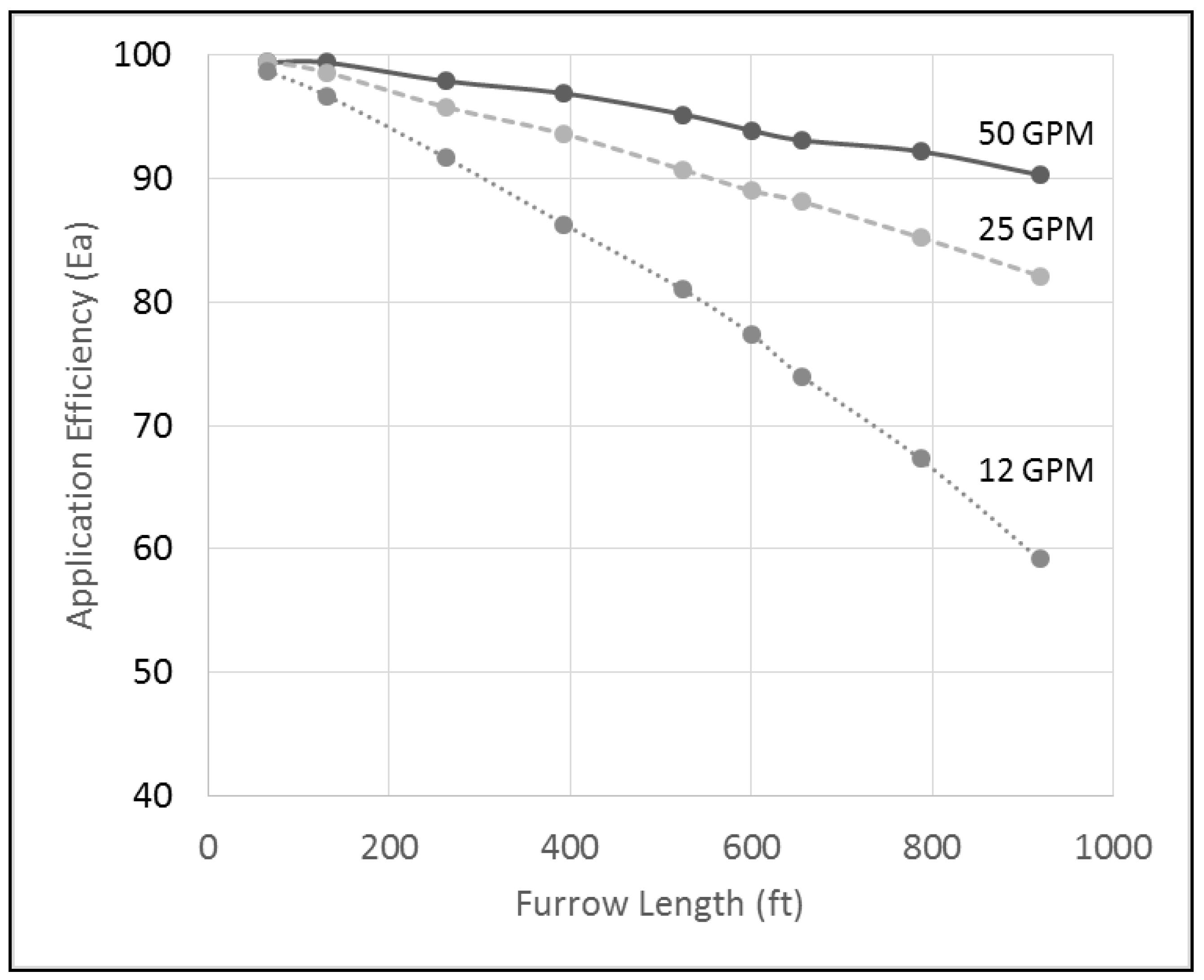

6.2. Field-Level Agricultural Water Use and Irrigation Management

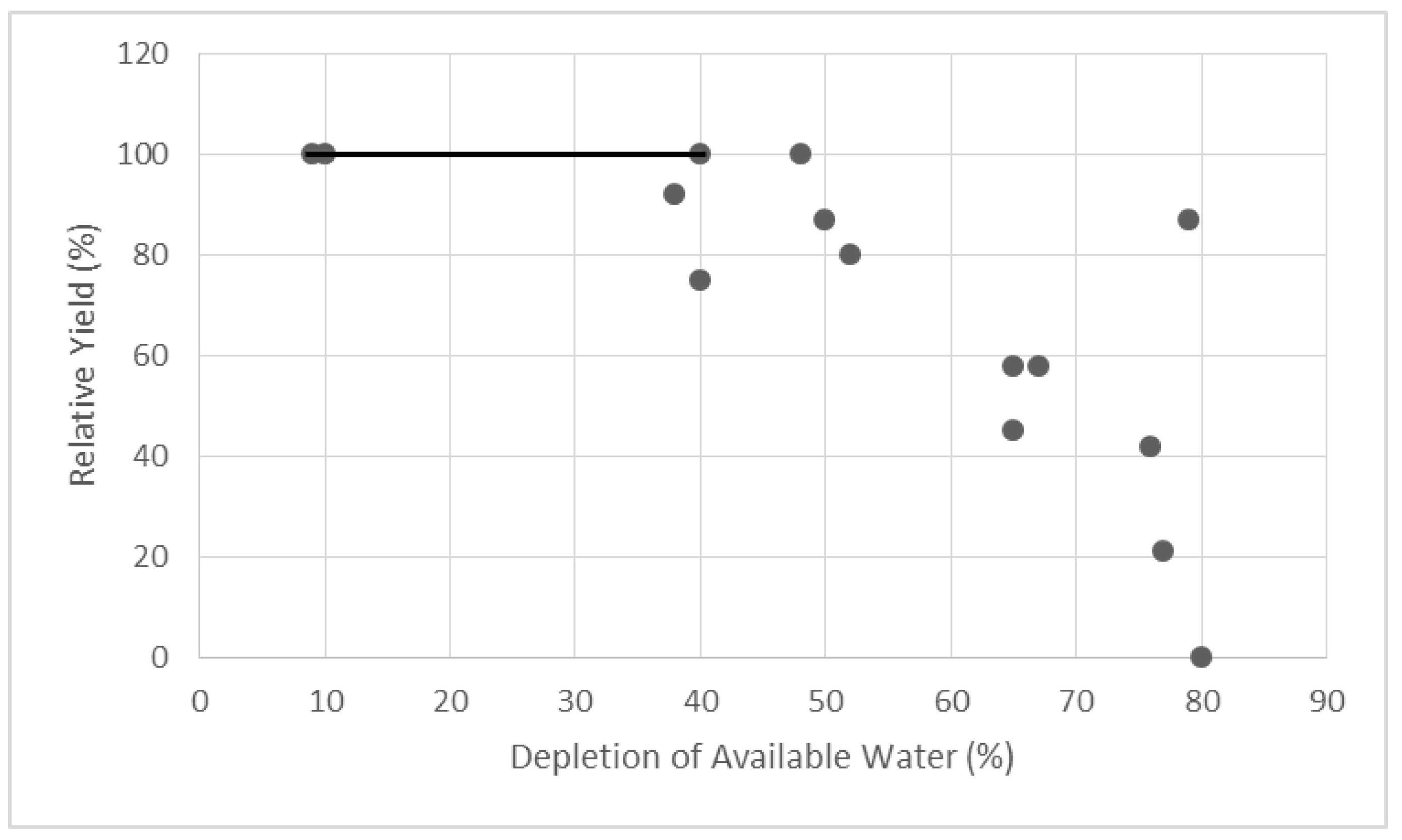

6.3. Components of Irrigation Scheduling

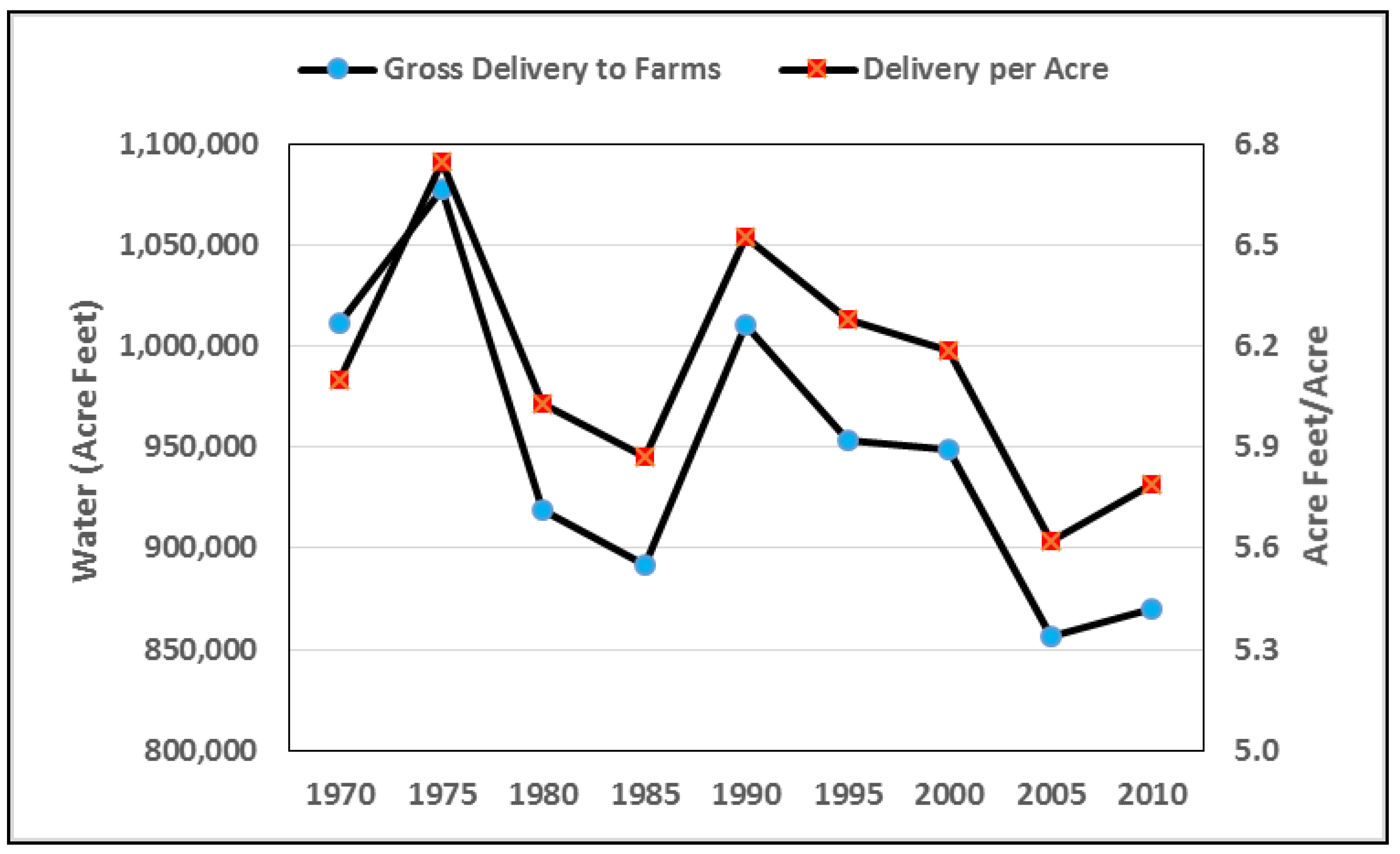

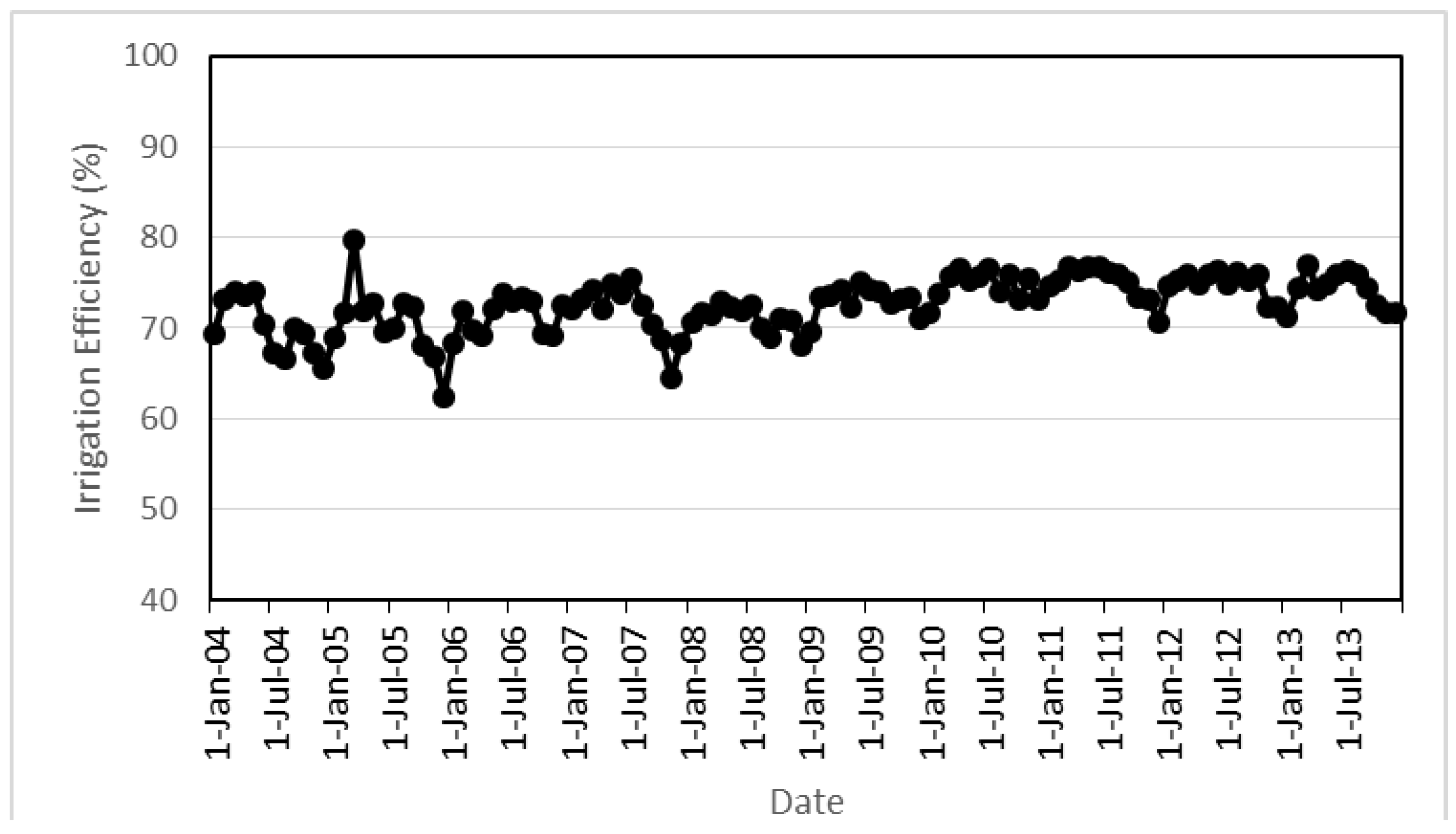

6.4. Basin-Scale Yuma Irrigation Efficiency

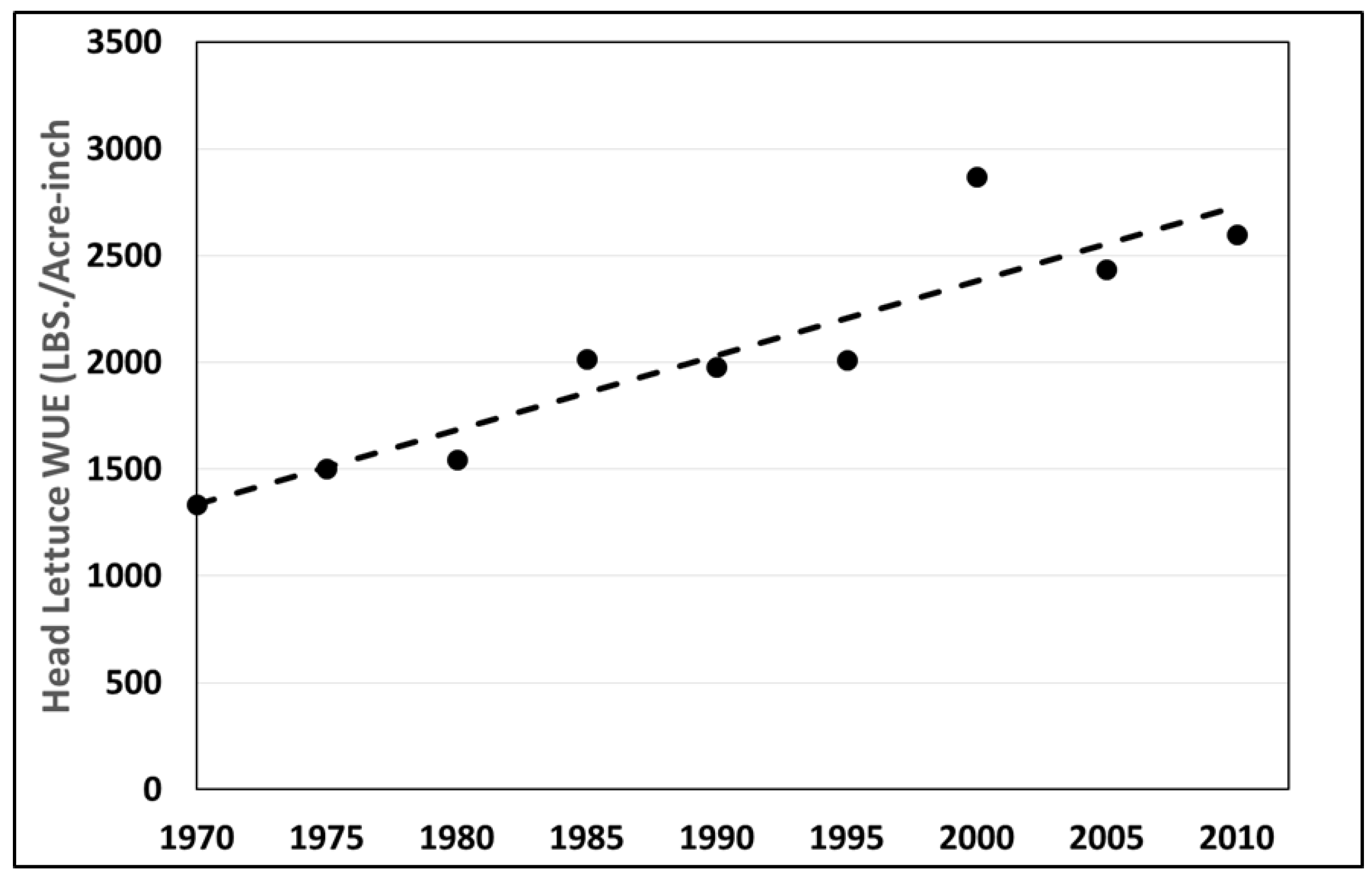

6.5. Water-Use Efficiency (WUE)

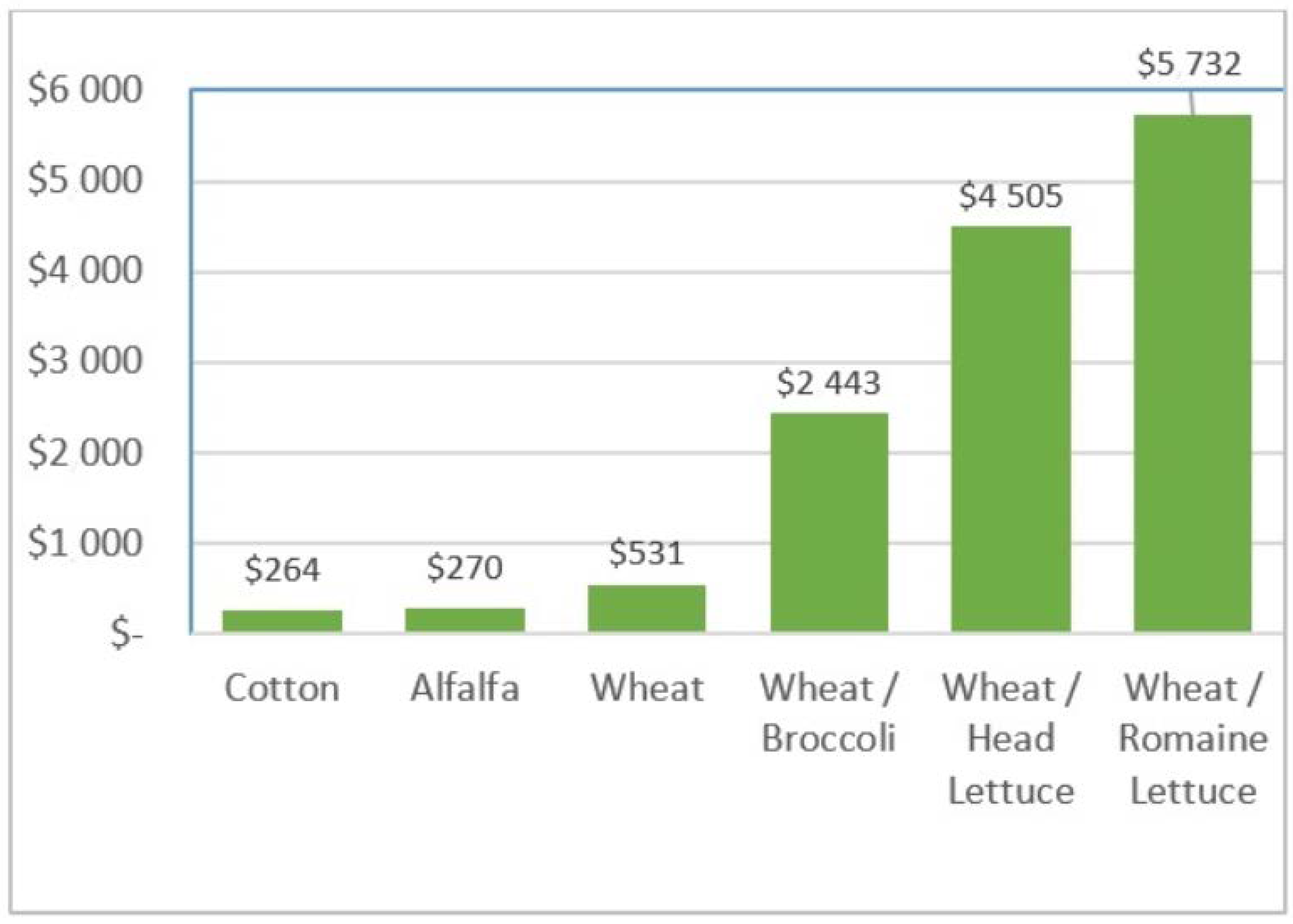

6.6. Economic Water Productivity (EWP)

6.7. Return Flows

7. Discussion

8. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wilkinson, C.F. Perspectives on Water and Energy in the American West and in Indian Country. S Dakota Law Rev. 1981, 26, 393–404. [Google Scholar]

- Lehr, J.H. Increase irrigation efficiency will ultimately silence the water-short blues of the wasteful West. Groundwater 1983, 21, 130–133. [Google Scholar] [CrossRef]

- Radhakrishna, B. Are we utilizing our water resources wisely? Curr. Sci. 1993, 65, 294–300. [Google Scholar]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef] [PubMed]

- O’Mahony, B.; Dalrymple, J.; Levin, E.; Greenland, S. The role of information communications technology in sustainable water management practice. Int. J. Sustain. Agric. Manag. Inform. 2016, 2, 79–92. [Google Scholar]

- Owen, D. Smart Water and Water Megatrend Management and Mitigation. In Assessing Global Water Megatrends; Biswas, A.K., Tortajada, C., Eds.; Springer: Singapore, 2018; pp. 87–104. [Google Scholar]

- Masseroni, D.; Ricart, S.; de Cartagena, F.; Monserrat, J.; Gonçalves, J.; de Lima, I.; Facchi, A.; Sali, G.; Gandolfi, C. Prospects for improving gravity-fed surface irrigation systems in Mediterranean European contexts. Water 2017, 9, 20. [Google Scholar] [CrossRef]

- U.S. Geological Survey (USGS). Estimated Use of Water in the United States County-Level Data for 2010. Available online: https://water.usgs.gov/watuse/data/2010/index.html (accessed on 21 February 2018).

- Smith, R.J.; Raine, S.R.; Minkovich, J. Irrigation application efficiency and deep drainage potential under surface irrigated cotton. Agric. Water Manag. 2005, 71, 117–130. [Google Scholar] [CrossRef]

- Gonçalves, J.M.; Pereira, L.S. Decision support system for surface irrigation design. J. Irrig. Drain. Eng. 2010, 135, 343–356. [Google Scholar] [CrossRef]

- Arbat, G.; Puig-Bargués, J.; Duran-Ros, M.; Barragán, J.; Ramírez de Cartagena, F. Irrigation performance and gross water productivity in furrow-irrigated ornamental tree production. Span. J. Agric. Res. 2011, 9, 627–640. [Google Scholar] [CrossRef]

- Koech, R.K.; Smith, R.J.; Gillies, M.H. A real-time optimization system for automation of furrow irrigation. Irrig. Sci. 2014, 32, 319–327. [Google Scholar] [CrossRef]

- Khatri, K.L.; Smith, R.J. Real-time prediction of soil infiltration characteristics for the management of furrow irrigation. Irrig. Sci. 2006, 25, 33–43. [Google Scholar] [CrossRef]

- Khatri, K.L.; Smith, R.J. Toward a simple real-time control system for efficient management of furrow irrigation. Irrig. Drain. 2007, 56, 463–475. [Google Scholar] [CrossRef]

- Masseroni, D.; Uddin, J.; Tyrrell, R.; Mareels, I.; Gandolfi, C.; Facchi, A. Towards a smart automated surface irrigation management in rice-growing areas in Italy. J. Agric. Eng. 2017, 48, 42–48. [Google Scholar] [CrossRef]

- Masseroni, D.; Moller, P.; Tyrell, R.; Romani, M.; Lasagna, A.; Sali, G.; Facchi, A.; Gandolfi, C. Evaluating performances of the first automatic system for paddy irrigation in Europe. Agric. Water Manag. 2018, 31, 58–69. [Google Scholar] [CrossRef]

- Caswell, M.; Zilberman, D. The effects of well depth and land quality on the choice of irrigation technology. Am. J. Agric. Econ. 1986, 68, 798–811. [Google Scholar] [CrossRef]

- Caswell, M.; Fuglie, K.; Ingram, C.; Jans, S.; Kascak, C. Adoption of Agricultural Production Practices: Lessons Learned from the U.S. Department of Agriculture (USDA) Area Studies Project; Agricultural Economic Report No. AER792; USDA, Economic Research Service: Washington, DC, USA, 2001.

- Caswell, M.; Zilberman, D. The Choices of Irrigation Technologies in California. Am. J. Agric. Econ. 1985, 67, 224–234. [Google Scholar] [CrossRef]

- Negri, D.H.; Brooks, D.H. Determinants of irrigation technology choice. West. J. Agric. Econ. 1990, 15, 213–223. [Google Scholar]

- Dinar, A.; Yaron, D. Influence of Quality and Scarcity of Inputs on the Adoption of Modern Irrigation Technologies. West. J. Agric. Econ. 1990, 15, 224–233. [Google Scholar]

- Dinar, A.; Campbell, M.B.; Zilberman, D. Adoption of improved irrigation and drainage reduction technologies under limiting environmental conditions. Environ. Resour. Econ. 1992, 2, 373–398. [Google Scholar] [CrossRef]

- Green, G.; Sunding, D.; Zilberman, D.; Parker, D. Explaining irrigation technology choices: A microparameter approach. Am. J. Agric. Econ. 1996, 78, 1064–1072. [Google Scholar] [CrossRef]

- Mendelsohn, R.; Dinar, A. Climate, water, and agriculture. Land Econ. 2013, 79, 328–341. [Google Scholar] [CrossRef]

- Frisvold, G.B.; Deva, S. Climate and choice of irrigation technology: Implications for climate adaptation. J. Natl. Res. Policy Res. 2013, 5, 107–127. [Google Scholar] [CrossRef]

- Frisvold, G.; Bai, T. Irrigation Technology Choice as Adaptation to Climate Change in the Western United States. J. Contemp. Water Res. Ed. 2016, 158, 62–77. [Google Scholar] [CrossRef]

- Olen, B.; Wu, J.; Langpap, C. Irrigation decisions for major west coast crops: Water scarcity and climatic determinants. Am. J. Agric. Econ. 2015, 98, 254–275. [Google Scholar] [CrossRef]

- Huang, Q.; Xu, Y.; Kovacs, K.; West, G. Analysis of Factors that Influence the Use of Irrigation Technologies and Water Management Practices in Arkansas. J. Agric. Appl. Econ. 2017, 49, 159–185. [Google Scholar] [CrossRef]

- McLean, R.K.; Ranjan, S.; Klassen, G. Spray evaporation losses from sprinkler irrigation systems. Can. Agric. Eng. 2000, 42, 1–8. [Google Scholar]

- Negri, D.H.; Hanchar, J. Water Conservation through Irrigation Technology; Agriculture Information Bulletin No. 576; U.S. Departmen of Agriculture, Economic Research Service: Washington, DC, USA, 1989.

- Parry, M.; Arnell, N.; Hulme, H.; Nicholls, R.; Livermore, M. Adapting to the inevitable. Nature 1998, 395, 741. [Google Scholar] [CrossRef]

- Ragab, R.; Prudhomme, C. Climate change and water resources management in arid and semi-arid regions: Prospective and challenges for the 21st century. Biosyst. Eng. 2002, 81, 3–34. [Google Scholar] [CrossRef]

- Wallace, J.S. Increasing agricultural water use efficiency to meet future food production. Agric. Ecosyst. Environ. 2000, 82, 105–119. [Google Scholar] [CrossRef]

- Rockstrom, J.; Lannerstad, M.; Falkenmar, M. Increasing water productivity through deficit irrigation: Evidence from the Indus plains of Pakistan. Proc. Natl. Acad. Sci. USA 2007, 104, 6253–6260. [Google Scholar] [CrossRef] [PubMed]

- Jury, W.A.; Vaux, H. The role of science in solving the world’s emerging water problems. Proc. Natl. Acad. Sci. USA 2005, 102, 15715–15720. [Google Scholar] [CrossRef] [PubMed]

- Ward, F.A. Economic impacts on irrigated agriculture of water conservation programs in drought. J. Hydrol. 2014, 508, 114–127. [Google Scholar] [CrossRef]

- Cooley, H.; Christian-Smith, J.; Gleick, P. Sustaining California Agriculture in an Uncertain Future; Technical Report; Pacific Institute: Oakland, CA, USA, 2009. [Google Scholar]

- Evans, R.G.; Sadler, E.J. Methods and technologies to improve efficiency of water use. Water Res. 2008, 44. [Google Scholar] [CrossRef]

- Johnson, N.; Revenga, C.; Echeverria, J. Managing water for people and nature. Science 2001, 292, 1071–1072. [Google Scholar] [CrossRef] [PubMed]

- Zinn, J.A.; Canada, C. (Environmental Quality Incentives Program (EQIP): Status and Issues; Congressional Research Service Report for Congress: Washington, DC, USA, May 2007. [Google Scholar]

- OECD. Environmental Performance of Agriculture in OECD Countries since 1990 (Report); Organisation for Economic Co-operation and Development: Paris, France, 2008. [Google Scholar]

- Ward, F.A.; Pulido-Velazquez, M. Water conservation in irrigation can increase water use. Proc. Natl. Acad. Sci. USA 2008, 105, 18215–18220. [Google Scholar] [CrossRef] [PubMed]

- Viets, F.G. Fertilizers and the efficient use of water. Adv. Agron. 1962, 14, 223–264. [Google Scholar]

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef]

- Scheierling, S.M.; Young, R.A.; Cardon, G.E. Public subsidies for water-conserving irrigation investments: Hydrologic, agronomic, and economic assessment. Water Res. 2006, 42, 1–11. [Google Scholar] [CrossRef]

- Peterson, J.M.; Ding, Y. Economic adjustments to groundwater depletion in the high plains: Do water-saving irrigation systems save water? Am. J. Agric. Econ. 2005, 87, 147–159. [Google Scholar] [CrossRef]

- Huffaker, R.; Whittlesey, N. A theoretical analysis of economic incentive policies encouraging agricultural water conservation. Int. J. Water Res. Dev. 2003, 19, 37–53. [Google Scholar] [CrossRef]

- Khanna, M.; Isik, M.; Zilberman, D. Cost-effectiveness of alternative green payment policies for conservation technology adoption with heterogeneous land quality. Agric. Econ. 2002, 27, 157–174. [Google Scholar] [CrossRef]

- Hanak, E.; Lund, J.; Dinar, A.; Gray, B.; Howitt, R.; Mount, J.; Moyle, P.; Thompson, B.B. Myths of California Water-Implications and Reality; Technical Report; Public Policy Institute of California: San Francisco, CA, USA, 2009. [Google Scholar]

- Frisvold, G.; Emerick, K. Rural-Urban Water Transfers with Applications to the U.S.-Mexico Border Region. In Game Theory and Policy Making in Natural Resources and the Environment (Vol. 10); Dinar, A., Albiac, J., Sánchez-Soriano, J., Eds.; Routledge: London, UK, 2008. [Google Scholar]

- Contor, B.; Taylor, R.G. Why Improving Irrigation Efficiency Increases Total Volume of Consumptive Use. Irrig. Drain. 2013, 62, 273–280. [Google Scholar] [CrossRef]

- Upendram, S.; Peterson, J.M. Irrigation technology and water conservation in the High Plains Aquifer Region. J. Contemp. Water Res. Ed. 2007, 137, 40–46. [Google Scholar] [CrossRef]

- Gutierrez-Martin, C.; Gomez, C.M. Assessing irrigation efficiency improvements by using a preference revelation model. Span. J. Agric. Res. 2011, 9, 1009–1020. [Google Scholar] [CrossRef]

- Lecina, S.; Isidoro, D.; Playán, E.; Aragüés, R. Irrigation modernization and water conservation in Spain: The case of Riegos del Alto Aragón. Agric. Water Manag. 2010, 97, 1663–1675. [Google Scholar] [CrossRef]

- Gómez, C.M.; Pérez-Blanco, C.D. Simple myths and basic maths about greening irrigation. Water Res. Manag. 2014, 28, 4035–4044. [Google Scholar] [CrossRef]

- Jevons, W.S. The Coal Question; Macmillan and Co.: London, UK, 1865. [Google Scholar]

- Dumont, A.; Mayor, B.; López-Gunn, E. Is the rebound effect or Jevons paradox a useful concept for better management of water resources? Insights from the irrigation modernisation process in Spain. Aquat. Procedia 2013, 1, 64–76. [Google Scholar] [CrossRef]

- Golden, B.B.; Peterson, J.M. Evaluation of Water Conservation from More Efficient Irrigation Systems; Staff Paper 06-03; Department of Agricultural Economics, Kansas State University: Manhattan, KS, USA, 2006. [Google Scholar]

- Pfeiffer, L.; Lin, C.Y.C. Does efficient irrigation technology lead to reduced groundwater extraction? Empirical evidence. J. Environ. Econ. Manag. 2014, 67, 189–208. [Google Scholar] [CrossRef]

- Frisvold, G.B. Water, agriculture, and drought in the west under changing climate and policy regimes. Nat. Res. J. 2015, 55, 293–328. [Google Scholar]

- Wallander, S.; Hand, M.S. Measuring the Impact of the Environmental Quality Incentives Program (EQIP) on Irrigation Efficiency and Water Conservation. In Proceedings of the 2011 Annual Meeting, Agricultural and Applied Economics Association, Pittsburgh, PA, USA, 24–26 July 2011. No. 103269. [Google Scholar]

- Fernald, A.G.; Guldan, S.J. Surface water–groundwater interactions between irrigation ditches, alluvial aquifers, and streams. Rev. Fish. Sci. 2006, 14, 79–89. [Google Scholar] [CrossRef]

- Fernald, A.G.; Baker, T.T.; Guldan, S.J. Hydrologic, riparian, and agroecosystem functions of traditional acequia irrigation systems. J. Sustain. Agric. 2007, 30, 147–171. [Google Scholar] [CrossRef]

- Glenn, E.P.; Flessa, K.W.; Pitt, J. Restoration potential of the aquatic ecosystems of the Colorado River Delta, Mexico: Introduction to special issue on “Wetlands of the Colorado River Delta”. Ecol. Eng. 2013, 59, 1–6. [Google Scholar] [CrossRef]

- Kerna, A.; Colby, B.; Zamora, F. Cultural and Recreational Values for Environmental Flows in Mexico’s Colorado River Delta. Water Econ. Policy 2017, 3, 1650035. [Google Scholar] [CrossRef]

- Stromberg, J.C. Restoration of riparian vegetation in the south-western United States: Importance of flow regimes and fluvial dynamism. J. Arid Environ. 2001, 49, 17–34. [Google Scholar] [CrossRef]

- Wiener, J.; Crifasi, R.; Dwire, K.; Skagen, S.; Yates, D. Riparian ecosystem consequences of water redistribution along the Colorado Front Range. Water Res. Impact 2008, 10, 18–21. [Google Scholar]

- U.S. Department of Agriculture. Farm and Ranch Irrigation Survey: 2013; Volume 3, Special Studies, Part 1 of the 2012 Census of Agriculture, AC-12-SS-1; National Agricultural Statistics Service: Washington, DC, USA, 2014.

- Map Prepared by the University of Arizona Water Resources Research Center. March 2018.

- National Agricultural Statistics Service. 2012 Census of Agriculture. County Profile. Yuma County, Arizona. United States Department of Agriculture; 2014. Available online: https://www.agcensus.usda.gov/Publications/2012/Online_Resources/County_Profiles/Arizona/cp04027.pdf (accessed on 8 May 2018).

- National Agricultural Statistics Service. 2012 Census of Agriculture. Volume 1, Chapter 2: County Level Data Arizona. Table 1. County Summary Highlights and Volume 1, Chapter 1: U.S. National Level Data. Historical Highlights. 2004; Total Cropland Data. Available online: https://www.agcensus.usda.gov/Publications/2012/ (accessed on 8 May 2018).

- U.S. Department of Commerce. Bureau of Economic Analysis. Local Personal Income and Employment Interactive Tables. Table CA45: Farm Income and Expenses. 2012; Cash Receipts: Crops Data. Available online: https://www.bea.gov/regional/ (accessed on 8 May 2018).

- Brown, P.W.; Nolte, K.D.; Sanchez, C.A. Irrigation Management in Yuma County. In A Case Study in Efficiency—Agriculture and Water Use in the Yuma; Yuma County Agricultural Water Coalition: Arizona Area, Yuma, AZ, USA, 2015; pp. 17–49. Available online: http://www.agwateryuma.com/ (accessed on 8 May 2018).

- Bureau of Reclamation. Quality of Water: Colorado River Basin; Progress Report No. 22; U.S. Department of Interior, Bureau of Reclamation, Upper Colorado Regional Office: Salt Lake City, UT, USA, 2005; 69p.

- Sadras, V.; Grassini, P.; Steduto, P. 2011: Status of Water Use Efficiency of Main Crops. State of World’s Land and Water Resources for Food and Agriculture (SOLAW) Background Thematic Rep. TR07. p. 41. Available online: www.fao.org/fileadmin/templates/solaw/files/thematic_reports/TR_07_web.pdf (accessed on 8 May 2018).

- Burt, C.M.; Clemmens, A.J.; Strelkoff, T.S.; Solomon, K.H.; Bliesner, R.D.; Hardy, L.A.; Howell, T.A.; Eisenhauer, D.E. Irrigation performance measures: Efficiency and uniformity. J. Irrig. Drain. Eng. 1997, 123, 423–442. [Google Scholar] [CrossRef]

- Erie, L.J.; Dedrick, A.R. Level Basin Irrigation: A Method for Conserving Water and Labor; USDA SEA Farmers’ Bulletin 2261; US Government Printing Office: Washington, DC, USA, 1979; 23p.

- Howell, T.A. Irrigation Efficiency. In Encyclopedia of Water Science; Stewart, B.A., Howell, T.A., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2003; pp. 467–472. [Google Scholar]

- Sanchez, C.A.; Zerihun, D.; Strelkoff, T.S.; Clemmens, A.J.; Farrell-Poe, K.L. Development of management guidelines for efficient irrigation of basins on sandy soils. Appl. Eng. Agric. (ASABE) 2008, 24, 215–224. [Google Scholar] [CrossRef]

- ASCE. The ASCE Standardized Reference Evapotranspiration Equation; Allen, R.G., Elliott, R., Jensen, M.E., Itenfisu, D., Mecham, B., Howell, T.A., Snyder, R., Brown, P., Echings, S., Spofford, T., et al., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2005; 59p. [Google Scholar]

- Brown, P.W. Standardized Reference Evapotranspiration: A New Procedure for Estimating Reference Evapotranspiration in Arizona; Ext. Rpt.1324; College of Agricultural & Life Sciences, University of Arizona: Tucson, AZ, USA, 2005. [Google Scholar]

- Sanchez, C.A.; Zerihun, D.; Farrell-Poe, K.L. Management guidelines for efficient irrigation of vegetables using closed-end level furrows. Agric. Water Manag. 2008, 96, 43–52. [Google Scholar] [CrossRef]

- Sanchez, C.A.; Zerihun, D. Irrigation Management Guidelines for Citrus and Alfalfa Grown on the Sandy Soils of the Yuma Mesa Irrigation Districts; Project Report Submitted to the United States Bureau of Reclamation; Yuma Area Office: Yuma, AZ, USA, 2004.

- Sanchez, C.A.; Zerihun, D. Irrigation Management Guidelines for Furrow Irrigated Vegetable Production Systems in the Yuma Valley; Project Report Submitted to the United States Bureau of Reclamation; Yuma Area Office: Yuma, AZ, USA, 2004.

- Pier, J.W.; Doerge, T.A. Concurrent evaluations of agronomic, economic, and environmental aspects of trickle irrigated water melon production. J. Environ. Qual. 1995, 24, 79–86. [Google Scholar] [CrossRef]

- Thompson, T.L.; Doerge, T.A. Nitrogen and water rates for subsurface trickle irrigated romaine lettuce. HortScience 1995, 30, 1233–1237. [Google Scholar]

- Thompson, T.L.; Doerge, T.A. Nitrogen and water interactions in subsurface trickle irrigated leaf lettuce. II. Agronomic, economic, and environmental outcomes. Soil Sci. Soc. Am. J. 1996, 60, 168–173. [Google Scholar] [CrossRef]

- Roth, R.L.; Sanchez, C.A.; Gardner, B.R. Growth and yield of mature “Valencia” oranges converted to pressurized irrigation. Appl. Eng. Agric. 1995, 11, 101–105. [Google Scholar] [CrossRef]

- Hargreaves, G.H.; Samani, Z.A. Estimating potential evapotranspiration. J. Irrig. Drain. Eng. 1982, 108, 25–230. [Google Scholar]

- AZMET: The Arizona Meteorological Network. Available online: https://cals.arizona.edu/azmet/ (accessed on 2 March 2018).

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration: Guidelines for Computing Crop Water Requirements; FAO Irrigation & Drainage Paper 56; Food and Agriculture Organization of the United Nations: Rome, Italy, 1998; 300p. [Google Scholar]

- ASCE. Agricultural Salinity and Management; ASCE Manuals and Reports on Engineering Practice No. 71; American Society of Civil Engineers (ASCE): Reston, VA, USA, 1990. [Google Scholar]

- Frisvold, G. Developing Sustainability Metrics for Water Use in Arizona Small Grains Production; Final report to the Arizona Grain Research and Promotion Council; Arizona Department of Agriculture: Phoenix, AZ, USA, 2015.

- Frisvold, G.; Caswell, M. Transboundary water management: Game-theoretic lessons for projects on the US–Mexico border. Agric. Econ. 2000, 24, 101–111. [Google Scholar]

- International Boundary and Water Commission (IBWC). Extension of Cooperative Measures and Adoption of a Binational Water Scarcity Contingency Plan in the Colorado River Basin; Minute 323; International Boundary and Water Commission (IBWC): Ciudad Juarez, Mexico, 21 September 2017. [Google Scholar]

- Medellina-Azuara, J.; Lund, J.; Howitt, R. Water supply analysis for restoring the Colorado River delta, Mexico. Water Resour. Plan. Manag. 2007, 133, 462–471. [Google Scholar] [CrossRef]

- Mexicano, L.; Glenn, E.P.; Hinojosa-Huerta, O.; Garcia-Hernandez, J.; Flessa, K.; Hinojosa-Corona, A. Long-term sustainability of the hydrology and vegetation of Cienega de Santa Clara, an anthropogenic wetland created by disposal of agricultural drain water in the delta of the Colorado River, Mexico. Ecol. Eng. 2013, 59, 111–120. [Google Scholar] [CrossRef]

- Brusca, R.C.; Álvarez-Borrego, S.; Hastings, P.A.; Findley, L.T. Colorado River flow and biological productivity in the Northern Gulf of California, Mexico. Earth-Sci. Rev. 2017, 164, 1–30. [Google Scholar] [CrossRef]

- Glennon, R.J.; Culp, P.W. The last green lagoon: How and why the Bush Administration should save the Colorado River Delta. Ecol. Law Q. 2002, 28, 903–988. [Google Scholar]

- Postel, S.L.; Morrison, J.I.; Gleick, P.H. Allocating fresh water to aquatic ecosystems: The case of the Colorado River Delta. Water Int. 1998, 23, 119–125. [Google Scholar] [CrossRef]

- Wichelns, D.; Oster, J.D. Sustainable irrigation is necessary and achievable, but direct costs and environmental impacts can be substantial. Agric. Water Manag. 2006, 86, 114–127. [Google Scholar] [CrossRef]

- Morrison, J.I.; Postel, S.L.; Gleick, P.H. The Sustainable Use of Water in the Lower Colorado River Basin; The Global Water Project; Pacific Institute for Studies in Development, Environment, and Security (PISDES): Oakland, CA, USA, 1996. [Google Scholar]

- Betley, E.C. How the West Was Watered: A Case Study of the Colorado River. Lessons Conserv. 2015, 5, 62–84. [Google Scholar]

- Carrillo-Guerrero, Y.; Glenn, E.P.; Hinojosa-Huerta, O. Water budget for agricultural and aquatic ecosystems in the delta of the Colorado River, Mexico: Implications for obtaining water for the environment. Ecol. Eng. 2013, 59, 41–51. [Google Scholar] [CrossRef]

- Duval, D.; Colby, B. The influence of Colorado River flows on the upper Gulf of California fisheries economy. Ecol. Eng. 2017, 106, 791–798. [Google Scholar] [CrossRef]

| Irrigation Efficiency | Water-Use Efficiency | Blue Water Footprint | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ET/Water Applied | % Change | Yield/(ET/acre) | % Change | (ET/acre)/Yield | % Change | ||||

| Flood | Drip | Flood-to-Drip | Flood | Drip | Flood-to-Drip | Flood | Drip | Flood-to-Drip | |

| Alfalfa | 0.44 | 1 | 127% | 3.6 | 3.7 | 2% | 27.50 | 27.00 | −2% |

| Pima cotton | 0.43 | 1 | 133% | 625.0 | 625.0 | 0% | 0.16 | 0.16 | 0% |

| Upland cotton | 0.43 | 1 | 133% | 833.3 | 833.3 | 0% | 0.12 | 0.12 | 0% |

| Lettuce, Spring | 0.44 | 1 | 127% | 431.8 | 424.1 | −2% | 0.23 | 0.24 | 2% |

| Lettuce, Fall | 0.42 | 1 | 136% | 357.1 | 347.2 | −3% | 0.28 | 0.29 | 3% |

| Onions, Fall | 0.43 | 1 | 135% | 600.0 | 600.0 | 0% | 0.17 | 0.17 | 0% |

| Onions, Midseason | 0.58 | 1 | 74% | 293.5 | 291.0 | −1% | 0.34 | 0.34 | 1% |

| Onions, Spring | 0.56 | 1 | 78% | 305.6 | 303.3 | −1% | 0.33 | 0.33 | 1% |

| Grain sorghum | 0.45 | 1 | 122% | 44.4 | 45.5 | 2% | 2.25 | 2.20 | −2% |

| Wheat | 0.44 | 1 | 127% | 83.6 | 82.1 | −2% | 1.20 | 1.22 | 2% |

| Green chile | 0.43 | 1 | 130% | 5.5 | 5.5 | 0% | 18.18 | 18.12 | 0% |

| Red chile | 0.44 | 1 | 127% | 1590.9 | 1620.4 | 2% | 0.06 | 0.06 | −2% |

| Pecans | 0.43 | 1 | 131% | 445.4 | 452.4 | 2% | 0.22 | 0.22 | −2% |

| Median | 0.44 | 1 | 127% | 357.1 | 347.2 | 0% | 0.28 | 0.29 | 0% |

| Arizona | California | |||

|---|---|---|---|---|

| Farms | Acres | Farms | Acres | |

| Total Irrigation | 4380 | 851,407 | 44,347 | 7,543,928 |

| Base Technology | ||||

| Sprinkler | 37.4% | 28.3% | 30.4% | 22.0% |

| Drip/Low-Flow | 10.8% | 5.9% | 57.3% | 36.9% |

| Gravity | 68.6% | 87.9% | 34.3% | 60.2% |

| Column sum ‡ | 116.8% | 122.0% | 122.0% | 119.1% |

| Arizona | California | |||

|---|---|---|---|---|

| Farms | Acres | Farms | Acres | |

| Gravity water control | ||||

| Down rows or furrows | 33.4% | 51.7% | 36.6% | 32.2% |

| Between borders or in basins | 63.6% | 45.7% | 60.8% | 55.8% |

| Uncontrolled | 7.4% | 1.2% | 5.8% | 5.6% |

| Other (Includes sub-irrigation by controlling water table) | 9.4% | 1.4% | 9.1% | 6.4% |

| Column sum ‡ | 113.8% | 100.0% | 112.3% | 100.0% |

| Gravity water delivery | ||||

| Above ground pipe | 5.7% | 0.5% | 5.0% | 4.8% |

| Poly tubing | 0.8% | 0.2% | 13.6% | 2.3% |

| Lined ditches | 41.9% | 36.9% | 5.5% | 10.6% |

| Unlined ditches | 17.3% | 6.6% | 39.3% | 51.2% |

| Underground pipe | 1.6% | 1.6% | 56.2% | 19.2% |

| Column sum ‡ | 67.2% | 45.7% | 119.7% | 88.0% |

| Arizona | California | |||

|---|---|---|---|---|

| Farms | Acres | Farms | Acres | |

| Sprinkler Systems | ||||

| Center pivot | 23.1% | 46.5% | 18.7% | 9.0% |

| Linear move tower | 8.4% | 1.8% | 5.5% | 5.7% |

| Solid set and permanent | 16.7% | 23.5% | 40.2% | 41.0% |

| Side roll, wheel move | 12.1% | 3.6% | 6.4% | 10.0% |

| Big gun or traveler | 7.6% | 0.4% | 0.8% | 0.4% |

| Hand move | 26.6% | 13.4% | 25.7% | 8.3% |

| Other sprinkler | 13.0% | 10.8% | 14.2% | 25.6% |

| Column sum ‡ | 107.6% | 100.0% | 111.6% | 100.0% |

| Irrigation Timing Methods | Arizona Farms | California Farms |

|---|---|---|

| Traditional Methods | ||

| Condition of crop | 72.4% | 74.8% |

| Feel of soil | 44.8% | 40.8% |

| Scheduled by district | 15.8% | 12.1% |

| Personal calendar schedule | 23.5% | 33.6% |

| When neighbors irrigate | 1.6% | 8.3% |

| Advanced Methods | ||

| Soil moisture sensor | 4.0% | 16.8% |

| Plant moisture sensor | 0.5% | 4.8% |

| Scheduling service | 8.1% | 7.1% |

| Daily ET reports | 6.6% | 11.7% |

| Computer simulation | 0.1% | 1.6% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frisvold, G.; Sanchez, C.; Gollehon, N.; Megdal, S.B.; Brown, P. Evaluating Gravity-Flow Irrigation with Lessons from Yuma, Arizona, USA. Sustainability 2018, 10, 1548. https://doi.org/10.3390/su10051548

Frisvold G, Sanchez C, Gollehon N, Megdal SB, Brown P. Evaluating Gravity-Flow Irrigation with Lessons from Yuma, Arizona, USA. Sustainability. 2018; 10(5):1548. https://doi.org/10.3390/su10051548

Chicago/Turabian StyleFrisvold, George, Charles Sanchez, Noel Gollehon, Sharon B. Megdal, and Paul Brown. 2018. "Evaluating Gravity-Flow Irrigation with Lessons from Yuma, Arizona, USA" Sustainability 10, no. 5: 1548. https://doi.org/10.3390/su10051548

APA StyleFrisvold, G., Sanchez, C., Gollehon, N., Megdal, S. B., & Brown, P. (2018). Evaluating Gravity-Flow Irrigation with Lessons from Yuma, Arizona, USA. Sustainability, 10(5), 1548. https://doi.org/10.3390/su10051548