1. Introduction

Manufacturing in offshore facilities has been apparent since the 1980s and has become one of the most important changes made by companies throughout the world [

1,

2]. In fact, manufacturing offshoring has successfully been used in order to achieve a competitive advantage [

3]. With the development of globally dispersed facilities, manufacturing companies have moved their focus from a single facility to the international manufacturing networks [

4]. Meanwhile, sustainability in the network is a key issue in responding to fierce international competition, and competitive advantage in the global production. It has been accepted that management of international operations gradually becomes an important task for such companies, as it has a considerable impact on long-term performance and profitability [

5,

6]. In order to survive in the growing complexity of the global environment in which companies operate, the coordination of activities in their network facilities has become essential [

5]. In this competitive scenario, a consistent understanding of the right coordination of global manufacturing operation is not explicit. Nonetheless, the ever-present issues of how to integrate so as to be more competitive and to maintain low production and transportation costs persist, and thus network operations need to take aspects of sustainability into account for long-term success [

7]. Accordingly, better coordination mechanisms improve the integration of international operations, which in turn lead to higher performance of the manufacturing network and sustainability in the competitive market of offshore manufacturing.

From an international management perspective, coordination in multinational corporations (MNCs) has focused on the mechanisms to coordinate the activities of subsidiaries based on tasks assigned to the subsidiary. According to Martinez and Jarillo [

8], the use of coordination mechanisms is linked to the integration of a subsidiary’s activities. In this sense, mechanisms of coordination are a plan to coordinate the activities of individual subsidiaries and ‘make the most’ of far-flung activities. Furthermore, due to different priorities of manufacturing ranging from quality, flexibility, delivery lead-time to cost, the coordination of facilities in a network-manufacturing is apparently more encompassing then general activity management of a subsidiary. While it is agreed that coordination mechanisms must be adapted to specific activities in which they are used, this plan has to consider the priorities of network-manufacturing to allocate the benefits from network integration.

Empirical research that includes the mechanisms of coordination with the competitive priorities of network-manufacturing appears to be limited. The main issue here is: how the formal and informal coordination mechanisms foster competitive priorities in network manufacturing, also how they vary across different focuses of offshored facilities. Therefore, this research aims to analyze the activities of intra-firm dispersed facilities and map them according to the dimensions of coordination (formal and informal mechanisms) to understand how they relate to the competitive priorities. Accordingly, we set the following two research questions: How do the mechanisms of coordination relate to the competitive priorities? How are they linked to the focus of the offshore facility?

To achieve the goal, this research focuses on intra-firm network manufacturing through four in-depth case studies in companies from different industry sectors. This article contributes to the extant literature in two ways. Firstly, we show which mechanisms the companies use to coordinate network-manufacturing to facilitate quality, flexibility, delivery lead-time and/or to achieve lower-cost. Secondly, this study explores how the focus of offshored facility acts as a mediator in the choice of mechanisms with respect to different competitive priorities.

The article is structured as follows:

Section 2 first gives a brief overview of recent literature on coordination in network manufacturing, then describes the mechanisms of coordination and competitive priorities. Following the methods section, in

Section 4 the within-case analysis is described to illustrate the coordination practices and competitive priorities of the individual company. Next, based on within-case analysis, formal and informal coordination mechanisms are compared across cases. In

Section 6, we discuss the findings. The article concludes with implications for theory and practice, also indicating the limitations and directions for future research.

2. Literature Review

An international manufacturing network (IMN) is defined as a group of geographically dispersed facilities of a global company that holds the responsibility and control over them, and its management is defined as a coordinated aggregation of facilities located in different places [

9]. Essentially, there are two main issues that have been addressed in the decision-making process of an international manufacturing network: configuration and coordination. Several lines of evidence suggest that the coordination of activities within the network is contingent upon the configuration [

9,

10].

The location of facilities and the inter-facility allocation of resources along the value chain is termed as configuration [

11], which is thought of like the structure of the multi-facility network [

10]. According to the eclectic paradigm (OLI paradigm) of international production, the choice regarding international production is made by asking: why (clarified by ownership advantage), how (internalization of know-how and value-adding activities), and where (the locational issues) [

12]. Ownership advantage refers to the intangible assets of a company, for example, the management model and innovative capacity. Locational advantage relates to the benefits in the input of production regarding price, quality and productivity, as well as the lower cost of transportation and communication. Internalization-incentive advantage indicates the advantage gained from controlling specific activities by the company as its core competence, rather than transferring or outsourcing these activities to others. The final decision on which a firm should locate its production will depend on the character of its advantages and the extent to which one location helps to internalize intermediate product markets better than another [

11] (p. 794).

Dunning highlighted that the network approach to the study of activities of multinational companies is an essential element of international manufacturing [

13]. That is, companies operating their dispersed facilities have potential benefits from individual facilities as well as from the operation of their networks. Shi and Gregory seek to develop new knowledge about IMNs and attempt to integrate the issues of network dispersion and coordination to have an overall view of manufacturing in networks [

14]. The coordination of international manufacturing network comprises the management of worldwide dispersed activities [

15]. Indeed, the extent to which companies may benefit from geographically dispersed facilities depends on how the functions of facilities are coordinated [

16]. It aims to achieve an efficient and effective plan for global production activities. Thought of as an infrastructural process, coordination acts as the link to integrate the facilities in order to ensure the strategic objectives of firms [

17]. Therefore, irrespective of where the facilities are located within a company’s international manufacturing network, the management of manufacturing activities is critical for the success of the international operation. For example, the coordination in purchasing makes it possible to achieve the economies of scale in purchasing, and the transfer of experience can increase the know-how especially within the development centers [

18]. For what concerns the management of international operations to facilitate coordination, Rudberg and Olhager [

9] presented four coordination approaches corresponding to four basic network configurations. Generally, the discussions on coordination seem to focus on the configuration practices and the transfer of technologies and knowledge to the dispersed facilities [

19].

In summary, studies on the intra-firm manufacturing consider coordination aspects either to describe how the companies can manage their operations in order to facilitate the network coordination or to allocate products and volumes to individual facilities. Much attention has been paid to the diffusion of knowledge and production experience focusing on learning from other plants in a network. For example, Ferdows suggests different approaches for transferring production expertise over the distributed network, ranging from the use of manuals and standard practices to the involvement of experts in project workings [

20].

Indeed, coordination in multinational corporations (MNCs) has focused on the mechanisms used to coordinate the activities of the firms’ subsidiaries according to the subsidiary’s directive [

21]. While it is commonly agreed that the coordination mechanisms are adapted to the specific context in which they are used, there is little evidence of the interactions between the coordination of dispersed facilities in a network and the competitive priorities. Meanwhile, the literature recognizes the key success factors through which a company competes are competitive priorities [

22]. In order to address this issue, it is necessary to analyze the coordination practices on the management of dispersed facilities with the aim of understanding their relationship with competitive priorities.

Moreover, in global companies, individual facilities usually differ in their characteristics, e.g., due to their choice for geographic dispersion or history in the company. The facilities contributing to the network are heterogeneous. Thus, they require different levels of integration efforts. Hence, the focus of offshored facilities has an influence on the interplay between the coordination mechanisms to integrate activities and the competitive priorities of international manufacturing.

2.1. Mechanisms of Coordination

Mechanisms of coordination are the plans used to accomplish coordination of activities [

23]. The studies on the organizational management of multinational corporations (MNEs) have analyzed the mechanisms of coordination. In their literature review, Martinez and Jarillo [

8] distinguished four mechanisms that are typical for organizational coordination in MNCs: (i) structure; (ii) centralization vs. decentralization; (iii) formalization; and (iv) other informal mechanisms. Moreover, in the discussion about the evolution of the studies on the mechanisms of coordination, they listed three main streams of research. The first two streams are categorized as formal mechanisms. The third stream of research concentrates on the informal, more subtle mechanism of coordination.

Formal mechanisms of coordination are linked with the basic structuring of organizational units and activities over the networks. These mechanisms are embodied in organizational structures and procedures, in other words, formal coordination builds the structural approach to the interrelations between facilities. In addition, centralization i.e., level and position of decision authority, and the standardization of processes and procedures are included in the formal mechanisms of coordination. A typical example of formal mechanisms of coordination includes the exchange of standard documents. Furthermore, numerous studies have pointed out the control exercised by headquarters, for example, high levels of headquarters’ control are necessary for streamlining the manufacturing [

24], whereas, the centralized control can only be exercised when dispersed facilities are agreed upon a common goal and structure. Therefore, the concept of control exhibits strong elements of formal mechanisms of coordination.

Informal mechanisms of coordination involve activities in which members of multiple units make substantial contributions of resources and know-how to agreed aims [

25]. Informal means of coordination can be achieved through communication within facilities, training and development programs, and the transfer of managers. For example, extensive transfer of executives is the technique for creating a verbal network and making the expatriates a part of it [

8]. As this subtler mechanism is an intangible approach, i.e., this cannot readily be installed in an organization; its success depends on continuous relationships between facilities. Likewise, it has been demonstrated that communication, as a means of informal coordination, between the host facility and the headquarters is crucial for the success of offshore (knowledge-intensive) activities [

18].

2.2. Competitive Priorities

The idea of competitive priorities was first posited by Skinner, who asserted that companies must make choices about which element of competitive priority should take the most significant investment regarding resources and time [

26]. Since the initial development of manufacturing strategy, competitive priorities have been considered as a critical decision variable. This emphasis guides the decision regarding production process, capacity, technology, planning, and control [

27]. Although the idea of competitive priorities in devising manufacturing networks had existed since the early stages, Dubois et al. raised the concern about the differential emphasis on a firm’s competitive priorities, which led to the adoption of different types of global configuration options [

28]. Meanwhile, it enforces manufacturers to choose different tasks, which lead to developing manufacturing capabilities to enhance their position in the marketplace [

29]. Furthermore, it was suggested that multinationals organize themselves to best address the global integration to access to the low-cost versus market proximity, and network flexibility versus economies of scale [

28]. Hence, it has been evident that competitive priorities become an important element for the design and management of international manufacturing.

In this study, we consider four basic elements of competitive priorities, as discussed by [

30,

31]. Cost: the ability to manufacture products at a cost lower than the competitors. The concept of cost has been termed variously in the literature to indicate low cost, low price, cost efficiency, etc. Quality: implies offering products and services with high-performance standards, in other words, offering products that meet pre-set product specifications [

32]. As mentioned in literature, the definition of quality is being viewed from different perspectives. Manufacturing mostly reflects its focus on the conformance and product performance dimensions of quality. Conformance quality is the ability of a company to manufacture products with consistent quality that is durable; hence, the customers can rely upon the products when used. Product performance includes high performance in features, functions, aesthetics, and technology. Flexibility: the ability to be responsive to the changes in production or product design, the ability to react to the changes with little time, effort, cost or performance, the ability to perform different tasks and achieve different objectives with the same set of resources. Typical dimensions of flexibility are product mix, volume, design, and range of products. Delivery lead-time: usually there are two elements that are most often used to describe this competitive priority, delivery speed and delivery dependability. Delivery speed is the ability to deliver products faster than competitors. Delivery dependability refers to the ability to deliver according to promised schedules.

3. Methods

3.1. Research Design

Based on the approach suggested [

33,

34,

35,

36], we employed a multiple case study approach to study the management of network manufacturing of firms from different industries, particularly well suited to the analysis of coordination practices. A case-study approach was chosen to obtain in-depth information on how the competitive priorities and the focus of offshored facilities influence the coordination of network manufacturing. Unconstrained by the rigid limits of questionnaires, case study research is significant in understanding real-life processes, and helps in discovering the relationships between different topics which cannot be obtained through purely quantitative surveys, as they allow for deeper insights into how and why companies choose a specific approach [

36,

37]. Moreover, a multiple case study design ensures the possibility of generalizing findings in an analytic way [

35,

38].

In order to answer the research questions, we searched for companies from different industry sectors and different business orientations. Those companies had already offshored a range of their manufacturing activities and were operating dispersed facilities in their network. The companies were sampled from Swedish origin and had maintained a relationship with our institute. In Sweden, manufacturing has played an important role in the economic growth, and as a high wage country it has witnessed offshoring trends. The final selection was based on accessibility [

37], i.e., we had the best data access regarding coordination of multiple facilities in their networks. In selecting the cases, access to the companies and their particular characteristics were factors taken into consideration. Four companies from different industries were selected for an in-depth analysis to understand the coordination of activities in dispersed facilities and the competitive priorities of manufacturing strategy while ensuring that views were captured from multiple business areas.

Table 1 gives an overview of the studied companies. The first two companies have mainly low-cost focused offshored facilities, and the other two are market-oriented in their manufacturing networks. The unit of analysis is the manufacturing network responsible for a particular product or product group of a company. Company names are undisclosed to maintain anonymity, to comply with their request.

3.2. Data Collection

Empirical data were collected during December 2015 to May 2016 and May–June 2017, using a systematic research plan to ensure the quality of this research [

34]. First, documents from secondary sources, such as company reports and presentation materials for stakeholders, were collected and analyzed to obtain knowledge about the companies as well as their manufacturing networks. Second, in order to improve rigor, a set of semi-structured questionnaires was prepared in advance (please refer to

Supplementary Material). Together with an overview document, the questions were sent to each interviewee before the interview session to make sure they were properly prepared. Third, the information was collected by direct interviews with the most knowledgeable informants (e.g., international operations manager, production manager and business development manager) to obtain the views of activity management in their manufacturing networks. A total of 12 interviews were conducted, in which an individual interview typically lasted from 2 to 4 h. There were two researchers present at each interview to reduce bias and generate a more reliable dataset [

33,

36]. This provided a fine-grained picture of the case companies’ instances of how the manufacturing in intra-firm dispersed facilities was coordinated, and the information about the elements of competitive priorities. Fourth, in order to avoid misinterpretation of facts and figures, written case descriptions were crosschecked with the company managers. After several iterations of correction, the case reports were finalized.

3.3. Data Analysis

Data analysis was carried out simultaneously with the data collection, which provided the flexibility to make relevant adjustments throughout the process [

36]. Extensive pattern matching was used to categorize the data. Each case was analyzed and described in a dedicated report. To analyze the interview data, we followed the approach suggested by Miles and Huberman, with the following key steps: (i) We performed a within-case analysis to highlight the mechanisms through which the network manufacturing was coordinated. This included organizing data through case synopsis, for instance, using the selected dimensions of coordination mechanisms; (ii) Subsequently, a cross-case comparison was done to arrive at the essential mechanisms employed across cases. We tabulated the data to improve the visibility of the outcome; (iii) A last step involved drawing conclusions by looking into explanation and causality. In order to increase the reliability of the findings, the explanation of each case was tested twice by looking into the field notes to see how well supported they were.

3.4. Quality Criteria

The quality of any case study research depends on four different criteria: construct validity, internal validity, external validity, and reliability [

36] (p. 40). Construct validity has been met by the measures for the concept being studied, i.e., coordination mechanisms and elements of competitive priorities from the literature, definition of the unit of analysis, and having key informants review the case report. Internal validity only applies to experimental studies [

38], and the present study’s exploratory purpose was not for addressing the internal validity. External validity of case studies concerns the analytical generalization, not to generalize statistically [

36] (p. 10). A multiple case study design provides breadth, where each case serves as a distinctive experiment and as an analytic unit. Hence, it has higher external validity than single cases [

34]. Reliability is concerned as to whether the same results can be obtained by repeating the data collection procedure [

39]. This has been assured through the use of a case study protocol—to standardize the investigation—and by developing a case study database.

In addition, triangulation—multiple perspectives to converge on the phenomenon—has been met by interviews from different informants with different responsibilities, and by multiple researchers involved in gathering and interpreting the data [

34,

40]. Also, the interview data were supplemented by other sources, such as company presentations, and documents [

34].

4. Within-Case Analysis

4.1. Company A

4.1.1. Configuration of Manufacturing Network

Company-A is a manufacturer of sports and game equipment, produces six categories of products, such as boards and skis, leisure games, sleds, snow racers, street and board games. Most of its products require standardized production processes, and the quality of the mold is important for the desired product quality. Company-A showed a steady increase in turnover, for example, 7025 K€ (in 2007) to 20,104 K€ (in 2015). At present, the company has major customers in more than 30 countries around the world. Company-A’s headquarters were located in Sweden and had two offshore facilities started in the early 2000s: in Lithuania, to manufacture two different winter sports products, and in China, to manufacture a winter sports product and a standard game product. These configurations were made to reduce the total cost of manufacturing because the products were usually distributed from the company’s home facility.

4.1.2. Coordination of Activities in Dispersed Facilities

Formal coordination. Offshore facilities of Company-A can manufacture all the components of selected products. Management of its network manufacturing includes raw material management, machining, assembly, and testing. Host facilities do not have any development center. The knowledge-intensive activities, i.e., design and development of molds for new products as well as the continuous development of products, were specified from the home facility. There were no co-development of the products manufactured in the dispersed facilities. The host facilities have to make the molds under the direct supervision of a manager from the home facility.

Purchasing center of the host facilities was used to work for raw-materials management. According to our interviewee, the center (host’s purchasing) has not able to ensure consistency in the quality of raw materials. The company employed centralized control over purchasing and raw-materials management, for both of its offshore facilities. This involves physical meetings between managers of the home and host facilities and usually placed in the host facilities. It should be noted that the company faced difficulties in managing raw materials mainly at the facility located in the Far-East location, which was mentioned by the production manager, ‘there were some unexpected changes in the raw material inputs’. This complexity was due to the lack of transparency in the procurement process, as well as limitations in the quality assurance practice. Nevertheless, for the host facility located in Lithuania, such type of complexities has been managed by a home facility based sourcing. International operations manager of Company-A stated, ‘it is possible to use the suppliers near the home unit’.

The company had standardized process as well as well-described instructions for production since before the decision it has taken to offshore manufacturing activities. Accordingly, the home facility provides the instructions for production as a means of formal mechanisms. However, there were some problem-oriented complexities which they prefer to solve through direct coordination. That is, managers require physical travel from the home facility to the host to solve a specific problem. It is noted that the company does not set a priori number of visits or physical meetings, for such type of coordination.

Informal coordination. Informal coordination for the material management activities occurred through problem-oriented communication, which was mostly to get insight into the supplier market of offshore locations. Though the home facility has defined the tasks, there was increased communication in the final stages of production. Through this communication, the home facility was able to ensure the quality of final products. Indeed, the informal coordination through unplanned direct travel was unidirectional, that is, from the home to the host facilities.

4.1.3. Competitive Priorities

The network configurations of Company-A were primarily to achieve the lower cost of production inputs, thus offering the product at a competitive price could be considered as an order qualifier for the products. In addition, the company considered the quality of products as a most important priority, that is, quality is the determining factor to why customers are choosing the products. Brand name stands for reliability, e.g., a product that can withstand rough conditions and persist for years, which represents as high-quality standard to its end customer. The company was continually working to improve the design of their products. The ability to make changes in the design and the ability to manufacture an improved product is therefore important for them. Thus, flexibility could be considered an order winner. They also point out the concern regarding delivery speed and reliability. The ability to deliver the highly seasonal products e.g., winter sports product on-time and fast, is a necessary condition for competitiveness in the market. This priority was considered as a factor in winning the orders.

The Company-A does consider cost as the priority in setting offshored facilities; however, the production inputs are still more critical in the trade-off between quality and cost. It is pointed out that, their network coordination efforts, both in formal and informal mechanisms, were most likely to maintain the standard quality and also to make the delivery as expected. For instance, despite setting a standardized production process, Company-A faced complexities with the production process and product quality problems in managing the manufacturing activities in the dispersed facility (in China). Company-A’s management stated, “…ensuring the quality standard is difficult, that is, the durability of stickers, proper positioning of stickers, and color fade offs”. Moreover, the requirements for product quality were not transferred well to employees of the host facility. This is reflected from the comment of international operations manager, “instructions were not interpreted in the same way as we (the home manager) have predicted”. Furthermore, an extended delivery lead-time (six to eight weeks from the Far East facility to its European customers or warehouses) limits its ability to deliver the products on requested and promised time.

4.2. Company B

4.2.1. Configuration of Manufacturing Network

Company-B is a manufacturer of high-tech products specialized in infrared and thermal imaging systems which are used to enhance perception and awareness in surveillance, maritime security and detection activities. This company is a pioneer in developing high-performance, low-cost thermal imaging systems for airborne application. Company-B has several acquisition-lead offshore manufacturing facilities located in different regions around the world. This case study concerns the operation of two manufacturing networks for two different products. These were selected based on the importance of the products in the portfolio. The first product, specialized camera, requires strict regulations imposed by the key customers such as universities and R&D departments of large companies. This offshore manufacturing was mainly to extend the capacity as well as get the low-cost advantages. The second manufacturing network, producing the product characterized as a ball with sensor functionality, is focused on the advantage of low-cost production inputs. Products were distributed via a warehouse located in the Netherlands, to have the proximity to a larger European customer base.

4.2.2. Coordination of Activities in Dispersed Facilities

Formal coordination. Raw materials, light-weight metals and selected graded plastic, were sourced mostly from the suppliers near to the offshore facilities. The sourcing department of the home facility was responsible for ensuring the quality standards. In addition, the development department used to provide additional support, e.g., the detailed requirements of the product. The management has a planned formal meeting per month in order to coordinate this activity.

Offshore facilities of studied networks were equipped with production machinery. Product development activities were located at the home facility; this is because some of its critical components need specialization. Accordingly, the home facility engaged in the development activities and defined the product architecture for all facilities. Sufficient checking has been performed before the product concept is ready to transfer to the host facilities for manufacturing. Hence, as a means of formal coordination, the home facility decides about the product architecture and provides detailed requirements to network facilities. The host facilities were responsible for manufacturing according to the specifications. All the facilities follow the same guidelines for production. The plant managers of the home and host facilities were responsible for managing respective production activities. The management structure was designed to report to the vice-president of production at the home facility. There were few formal meetings among the production peoples of the home and host facilities. Quality control at the host facility was more frequent than to make some unplanned checking at the home facility before sending to the customers.

Informal coordination. According to the network structure, with product standardization by the home facility and the significant responsibility of the home-based managers, the coordination was mostly formally oriented. However, there was informal coordination occurring mainly through virtual communications as well as (unplanned) physical meeting. This informal coordination was to transfer the requirements of product development to the production stages, hence to maintain the quality standard. The communication, in the later stages of the manufacturing, also allowed the home facility to focus on continuous improvement opportunities.

4.2.3. Competitive Priorities

Company-B has made clear that their objective in locating the offshore facility in their (studied) manufacturing networks, was to extend the capacity and keep the cost at a lower level while maintaining the quality standards. We have interpreted the reasons as follows. First, transferring the products to the dispersed facilities allows the company to reduce the total cost of production. This means that having the final products at a lower cost makes them to be competitive in the market. Second, according to the characteristics of the products offshored, the capability to maintain the accuracy vis-à-vis the product quality has been considered as an order qualifier. Third, being closer to its key customer base allows Company-B to accept the customer requirements in a shorter period. This signaled that the network facilities were also intended to focus on reducing the lead-time. Fourth, the company stated the preference of continuous development as one of its key success factors. This preference requires the company to have the flexibility to improve at the host facility, with minimum levels of coordination effort. Moreover, an analysis clarifying the company’s network coordination suggested that the company needed to set a reasonable trade-off between the development possibilities in the host facilities versus the advantages of lower cost of production. Hence, the flexibility priority has also been reinforced in the coordination of activities in dispersed facilities.

4.3. Company C

4.3.1. Configuration of Manufacturing Network

Established in the 1990s, Company-C is a manufacturer of specialized control systems e.g., digital computer controller, communication devices, instrument gauges and sensors for advanced industrial machinery and vehicles. The company usually develops its products according to the customer requirements. When a customer (i.e., machine manufacturer) develops a new series or next-generation machine, this is the point of sales for Company-C. That is, the company’s product development has been linked to the development requirements of the machine manufacturer. According to the operations manager, ‘…we sell our products to their development department; we have the joint-development system for the guidance and development of their machine’. In 2005, the company decided to expand its manufacturing footprint in Malaysia to be closer to its customer base. The company has transferred the production of specialized cable in the offshore location. The raw materials were sourced mostly from the European markets.

4.3.2. Coordination of Activities in Dispersed Facilities

Formal coordination. According to the development requirement, the offshore facility heavily engaged in the development activities. This involves transferring the information from the machine manufacturer (the customer of Company-C) to the company’s home-based development center.

Depending upon the requirements for final products to the individual customer, the home facility-based R&D department decides about the product architecture and detailed development. Moreover, the home facility has the responsibility for the system integration. The host facility was equipped with production machinery and has the responsibility to manufacture according to the given requirements. Coordination of production activities enjoyed more autonomy than the development stages; here, a few planned meetings among top managers act as the formal mechanisms for coordination.

Furthermore, the home facility maintains the purchasing activities for its offshore facility, in which the centralized management was responsible for the standard and quality of raw materials. Coordination of purchasing and material management was mainly focused on formal structure, for instance, writing reports in case of missing items or any changes. These procedures usually require extra administrative tasks. For the time being, the host personnel considered this structure as routine; moreover, it assumes they do not have the responsibility for material management.

Informal coordination. Both the home and host personnel share a common understanding of the product development. This is essential to participate in the development activities of the customer site. In the coordination of development activities, there was increased communication mostly in a virtual format. Also, in order to coordinate the in-process activities and to ensure quality standards, there was some unplanned travel from the home to the host facility.

4.3.3. Competitive Priorities

Company-C aims to become preferred in providing exclusive and customized components to its customers. The home facility intended to serve the European customers, whereas the offshore facility was designed to serve the regional customers. Accordingly, the host facility focuses on on-site cooperation in the customers’ product development activities and the production processes in its facility according to the specification provided by the home facility. Thus, flexibility along with the quality comes as the most important priorities of its network manufacturing. Having an acceptable production lead-time, the offshoring decision to be closer to the customer allows the company to reduce the delivery lead time. That is, the company also intended to maintain the lead time to a minimum, which in turns acts as their order-winning criteria.

A large part of development activities was coordinated by the home-based management. Moreover, there were coordination efforts to transfer the product development knowledge to the production employees, such as instructions on the drawings. It is important to highlight the relevance of the coordination with target priorities. As acknowledged by the management of Company-C, “we have to increase the number as well of the duration of (mostly informal) coordination. Otherwise, the host facility was unable to send the finished product to its customers”. Besides, efforts have been evident to solve the misunderstandings of tacit versus formal responsibilities of the host personnel. On the other hand, the detailed reporting system which acts as a means of formal coordination caused the host facility staff to be overly dependent on centralized management, which in turn increased the administrative tasks and had a detrimental effect on the flexibility.

4.4. Company D

4.4.1. Configuration of Manufacturing Network

Company-D is a manufacturer of home appliances. Established at the beginning of the twentieth century, it has a long record of accomplishment in the manufacturing of electronic and household equipment. In the beginning, the company mainly focused on one product. In the following decades, the company proliferated and had several product families in the household machinery market, where it offers innovative and sustainable solutions. The company aims to become a global manufacturer in order to enhance the image through the consideration of customer-insights. Operational excellence with global optimization of production and modularization is one of the key strategies for reaching its vision, to be the best appliance company in the world as measured by customers, employees and shareholders. Company-D has several experiences in acquisition as well as Greenfield facilities in different regions around the world. This case study concerns the manufacturing network (dispersed facility in the Far-East location) of a laundry machine product. The company has made clear the objective to locate the studied offshore facility, that is, to gain easy access to the regional market as well as the benefits of the host country’s tax policy.

4.4.2. Coordination of Activities in Dispersed Facilities

Formal coordination. Depending upon the requirements of the products and the manufacturability, product development activities were divided into two major stages. First, developing core ideas of the product line, i.e., basic development, was based mainly on the home facility. Note here that the final products manufactured in the home and the host facilities were not the same because both facilities have their assortments of products. Second, the detailed development activities were performed in the development department of the respective facilities. This means that the home facility has implemented the standard development processes for both facilities, and the host facility is responsible for handling the detailed development of the product. These activities were mostly facilitated through the formal mechanisms of coordination, for example, the definition of product architecture and the development frameworks. To ensure the desired level of standards, the company has a global R&D unit comprising people from both facilities. The common agreements were mostly managed through a planned meeting at least once in a year.

Company-D has divided its production or factory management activities into process engineering, and quality control. Both of its facilities have the same capability in managing these activities. Moreover, the production management of the home and host facilities were connected through the global quality department, which serves as a platform to exchange the product requirements and technological information. In that level, coordination was mostly through formal mechanisms, for example, managers and the members of the global quality team meet both personally and virtually on some predetermined schedules. Explicit knowledge transfer through the formalized coordination structure contributed significantly to ensure the product quality.

The purchasing and logistics department of each facility has the responsibility for managing their activities locally. Raw materials were sourced mostly from regional markets. To maintain the quality of raw materials, the same KPIs were used in both facilities, which makes it easy to follow the KPI as well as the progress of facilities. As such, the centralized management maintains only the formal corporate support, and the dispersed facility was responsible for the material management.

Informal coordination. In the product development stage, there was informal coordination to reinforce the common understanding of the home and the host people, which is mostly to enhance the development efficiency. Informal coordination, which is intended to transfer knowledge, involves a virtual exchange between the members. Both the home and host personnel were committed to delivering products according to the promised common vision based on product strategy. In addition, there was a virtual exchange between engineers for transferring production knowledge, as well as to integrate the global quality management practice.

4.4.3. Competitive Priorities

Management of Company-D has made it clear that the objective to locate the manufacturing facility in the Far-East location was to be closer to the customers, and also to save on indirect costs. Hence, a winning strategy beneath this manufacturing network was to serve the regional market with an acceptable lead-time in response to volatile customer demand. Like many other export companies, Company-D mainly focused on the quality criteria for both the home and host products. This is reflected in the statement of an operations manager, ‘the key challenge was to ensure that products coming from the two facilities in the network have equal quality’. Accordingly, to maintain the quality of products from both facilities, the company has chosen to develop a ‘global quality’ department. The ‘global quality’ team is used to support the production activities as well as knowledge transfer for product development. Thus, quality dimension stands as an order qualifier for the products of Company-D.

The company has emphasized the coordination of manufacturing in its network facilities. Formal coordination occurred mainly through the definition of product architecture, and KPIs were built to control the raw materials. As a consequence, both the home and host facilities were able to maintain the quality according to specifications. Moreover, factory management of the host facility was given the flexibility to implement activities, which in turn enabled the host facility to work independently. Through this practice the management of the company was able to transfer responsibilities to the respective facilities, thus helping to maintain the flexibility. Moreover, due to the volatility of customer demand and longer lead-time than planned, there was some unexpected delay. In those instances, they prefer informal coordination to solve the network-level capacity requirements. All of this reinforces the relevance of network-manufacturing coordination with the target priorities.

5. Cross-Case Analysis

Even though the four studied companies are not similar regarding the industry they belong to and their objective and priorities of network-manufacturing, much knowledge can be deducted for this research.

Table 2 summarizes the coordination practices implemented along with the mechanisms of coordination by the studied companies. Matching empirical findings on the mechanisms of coordination with competitive priorities in network-manufacturing generated the following reflections.

5.1. Formal Coordination Mechanism

In the cases of Company-A and -B, network manufacturing was mostly oriented to a low-cost approach in seeking offshoring. The home facilities of this two companies have the responsibilities for product development and the quality of final products. The host facilities hold the responsibilities mostly for the manufacturing of products according to the design and specifications provided by the home facility. Formal coordination in the network manufacturing of Company-A occurred through frame-agreement for purchasing to ensure the standards of materials, direct physical meeting to support the mold formation, and detailed production instructions. These were aiming to get materials with expected cost and to ensure the quality standards. As shown in Company-B, formal coordination occurred mainly through planned meetings to share the development knowledge, and the product architecture with a detailed instruction for the production activities. Using the formal mechanisms of coordination, the home-based management was intended mostly to ensure the quality and flexibility of offshored products.

In the cases of Company-C and -D, the primary objective of network manufacturing was to get closer to the customer. Compared to the Company-A and -B, the Company-C and -D enjoyed a high degree of participation regarding co-development in the product development and autonomy in the production activities. The formal coordination for development activities was achieved through the involvement of both facilities in a standard process. In the control of production activities, the host facility (of Company-D) enjoyed significant autonomy from the home facility. For instance, a few planned meetings of the ‘global quality team’ were adapted to frame the responsibility for product quality. In the management of raw-materials, Company-C practiced centralized purchasing and defined formal reporting structure to resolve the complexities. However, Company-D has well-defined KPIs and therefore does not require significant coordination effort in such activities, i.e., material management. These two companies’ formal coordination approaches were intended to provide the responsibilities to their host facilities. Accordingly, the host facilities possess the distinctive capabilities for development activities, and the know-how on production processes, thus helping to ensure the flexibility and quicker response to customers, while ensuring the standards of products.

5.2. Informal Coordination Mechanisms

The network manufacturing of the companies A, B, and C, heavily engaged in the quality management through a practice of informal mechanisms of coordination. For instance, informal coordination in the Company-A’s manufacturing network, mainly through direct travel, was to support the host facilities in the activities of purchasing to resolve unexpected quality inputs and on the production process to precisely perform the standard checks. Thus, this affected the quality of raw materials as well as the final products. In the case of Company-B, informal coordination of network-manufacturing involves virtual meetings to transfer the development requirements from the home facility-centric development center to the host facilities. These were to update the process-related knowledge and to ensure the understanding of the quality of final products. While in the network management of Company-C, there was increased communication during the initial stages of the product development. Here, they intended to exchange the requirements from the customer’s side, as well as to support the in-process activities. In this case, managers from the home facility have to travel to align the development competencies, which was viewed as a core for providing the right products to the customers. Besides, Company-D’s informal coordination was embodied in a common understanding of both of its facilities on the product strategy. This was mostly accomplished through a virtual exchange among the members of its ‘global quality team’. Though the host facility has responsibilities for their products, the coordination practice through the global quality team helps to assure the prerequisites for the quality.

6. Discussion

In this section, we structure our discussion according to the key aspects of (1) how the mechanisms of coordination are related to each element of competitive priorities; and (2) considering the role of the focus of dispersed facilities in framing the coordination mechanisms. These are described in the following two subsections.

6.1. Coordination Mechanisms and Competitive Priorities

Table 3 summarizes the important practices of formal and informal coordination implemented by the studied companies, along with the competitive priorities.

Quality. It was identified that companies considered quality as an order qualifier, as it is required for the customers to consider their products. In order to manage product quality problems, it was necessary to take into account both the raw materials input and the processing steps. Accordingly, studied companies mostly expressed the concern about the quality of raw materials, and the products meeting the conformance, i.e., reliable products. Regarding raw-materials quality, companies want to ensure the standard of materials according to the design requirements. In addition, to ensure the product’s reliability, the case companies point towards the need to maintain the design specifications.

Drawing from the table (

Table 3), the coordination practices along the formal and informal mechanisms aiming for quality requirements, it has to be underlined that both mechanisms of coordination were almost equally important for the studied firms. It appears that formal mechanisms were designed to ensure the facilities are agreed upon the design requirements and specifications. For instance, defining a set of KPIs in the case of Company-D, and the frame agreement for purchasing in the case of Company-A seems important, especially when dealing with raw materials quality. In all cases, the product architecture and detailed production instructions serve as formal mechanisms of coordination to ensure the products’ quality. On the other hand, studied companies pay lots of attention to the informal mechanisms, such as virtual exchange of process knowledge and informal meetings to enhance the common understanding of product strategy, and to fulfil the specific need for conformance quality.

Flexibility. In the management of network-manufacturing, the coordination concerning flexibility relies on both the formal and informal mechanisms. For instance, at Company-C’s network manufacturing, the participation of the home and the host peoples through a precise task definition works as a vehicle to coordinate formally, which was to carry out the ability to make rapid changes in the design. Furthermore, for both the Company-C and -D, decentralization of decision-making for what concerns increased flexibility in product features, as well as their manufacturing processes, were through formal mechanisms to coordinate their activities. Here, pre-defined work procedures and a few planned meetings among the members of a global team (for system integration) emphasized the transfer of responsibilities, hence enabling the facilities to perform their activities independently. Informal coordination was embodied mainly in the virtual exchange among system sensitive members, and unplanned travels mostly from the home to the host facilities. Virtual exchanges in cases of Company-B, -C and -D, were to share the profound understanding of development knowledge and production competencies, thus helping their facilities to focus on functionality rather than strictly controlling their activities from the home facility.

Delivery lead-time. In the case studies of Company-B and -D, it was found that coordination of network-manufacturing has concerns also for the delivery-dependability and speed. As mentioned earlier, the host facilities of both of these companies were intended to serve regional as well as home-based markets, for which fast and on-time delivery stands as a factor for order winning. In both companies, coordination process is managed only by informal mechanisms. Here, informal coordination mechanisms showed a preference toward problem-oriented communication, where the centralized management of the home facility works for reducing lead-time of products. Formal coordination mechanisms were absent, possibly due to low complexity in delivery as expected.

Cost. In the case studies, according to the design of network manufacturing, Company-A and -B were concerned for low manufacturing cost in the host locations, in which the home-based management focuses only in approval for a reduced cost of production inputs. However, the companies should portray their coordination efforts, both in formal and informal mechanisms, in order to enhance the capabilities of resource access in dispersed location. In contrast, the other two companies do not stress cost as a competitive priority. Accordingly, their coordination efforts have not been apparent in this vein.

6.2. Focus of Offshored Facility and the Mechanisms of Coordination

In the case studies, two out of four companies (Company-A, and -B) offshored their manufacturing, aiming for the benefits of lower cost of production inputs from disperse locations. The other two companies can be characterized as market orientation in their network-manufacturing.

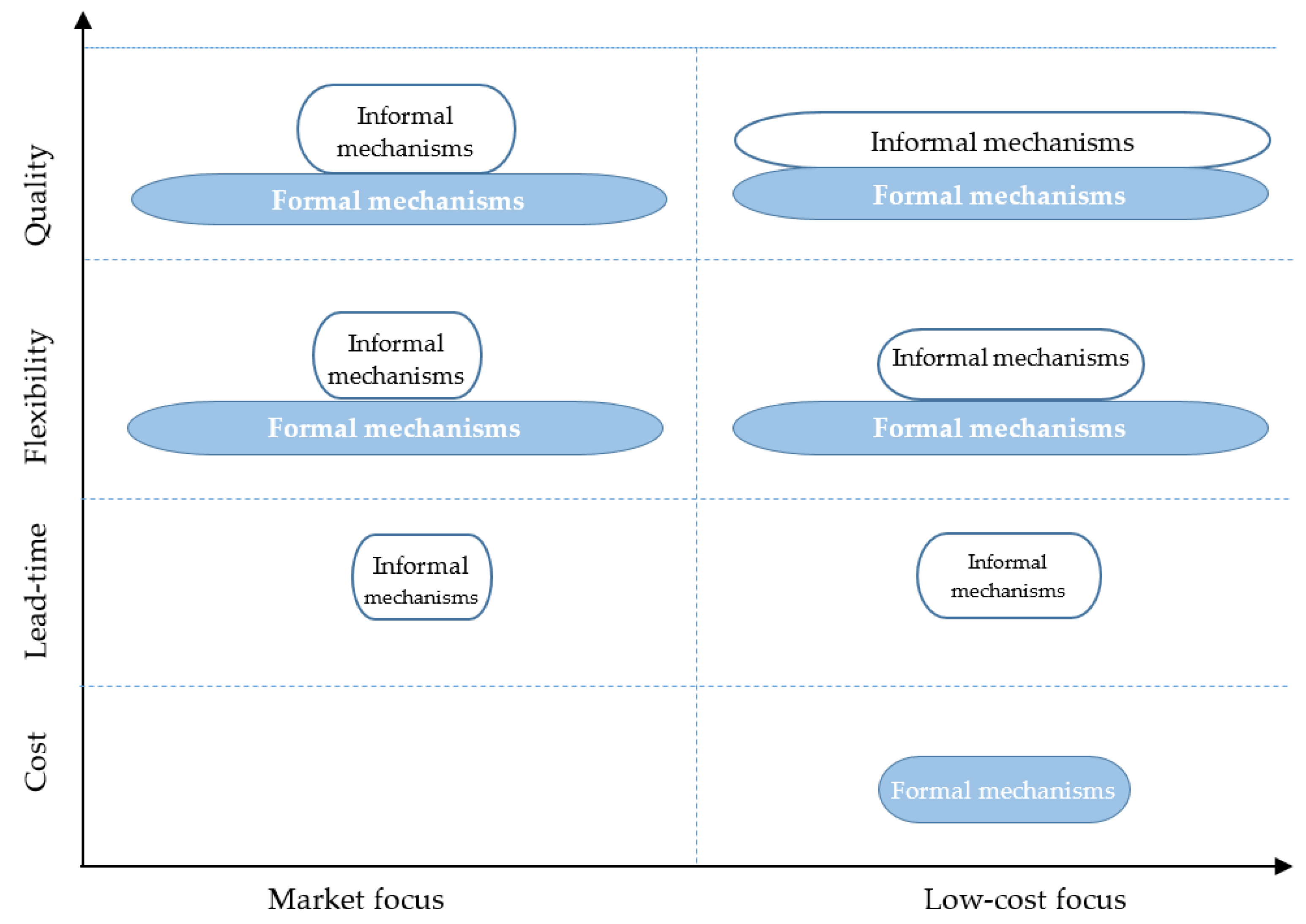

A relationship between the mechanisms of coordination and the focuses of the offshored facilities has been reported in the analysis. In order to visualize the use of formal and informal mechanisms, we plot (

Figure 1) them in the frame of market focused, and low-cost focused against the competitive priorities according to their importance, as highlighted in our analysis. The figure shows the propensity of different coordination mechanisms for each focus type. The amount of formal and informal coordination efforts are illustrated with the horizontal spreading of ovals in the figure. For instance, the equal spreading of formal and informal ovals (right column, top row) indicates their propensity in almost similar levels. In this vein, across the quality dimension, the data suggest that low-cost focused offshored facilities have an intense need at the same level for both the formal and informal coordination mechanisms. In contrast, for the market focused network manufacturing, the coordination is managed in such a way that companies pay much less attention to the informal mechanisms than those of the low-cost focused type. In this way, the findings show that the focus of offshored facilities affects the coordination in intra-firm manufacturing networks at varying levels, which are described in the following.

The dispersed facilities of Company-A, and -B merely looked into simple predefined activities assigned by the home facility. In contrast, at Company-C the host facility was involved in the product development, and the home facility defined the production system but allowed the host facility to perform the production activities independently. Furthermore, at Company-D the host facilities allowed more independence to perform detailed development as well as the production activities. These activities are at the component level of the final products and affect the quality and flexibility requirements. However, irrespective of the focus of offshored facilities, the studied companies pay significant attention to the underlying structure for the coordination of network-manufacturing. Such aspects as product architecture, frame agreement for purchasing, detailed production instructions, and planned physical meeting appear as leading vehicles to formally coordinate the dispersed facilities in a network. Moreover, it seems that formal mechanisms of coordination are viewed as equally necessary for the management of both types (focused) of networks. Thus, based on the conducted study we could infer that formal mechanisms stand as a foundation to coordinate the activities of market-focused and low-cost focused offshore facilities.

On the other hand, the informal coordination mechanisms are not prevalent in the same ways to the different focuses of offshored facilities. In fact, informal mechanisms to coordinate the network manufacturing are related to competitive priorities as well as the focus of offshored facilities. As shown in Company-A and -B, with low-cost focused offshoring, the informal coordination was mostly intended to ensure the quality of raw materials and final products manufactured in dispersed facilities. For example, frequent travel from the home to the host facilities in order to ensure the standards of raw materials as well as to check the final products, and virtual meetings to support the production process were mainly to ensure the product quality. Besides, the informal coordination (at Company-A and -B), such as virtual meetings among the members of the development team, intended for advancing the flexibility, were not as frequent as those aimed towards quality.

Along with this vein, when we look at the network management of Company-C and -D, the informal coordination to ensure the quality was less apparent than it was for the low-cost focused offshored facilities of Company-A and -B. That is, in market-focused network manufacturing, the offshored facility’s production-related technical activities were not subject for integration in a product which was shared between the home and host facilities. The design of the product architecture vis-à-vis their processing are customized allowing the technological competence of host facilities. The reason can be explained as the dispersed facilities mostly operated independently, which were intended to serve the markets via local production [

1]. Furthermore, for both the Company-C and -D, the informal coordination pertaining to the flexibility was reduced relative to that of quality dimension. For instance, in both cases, there was an increased number of unplanned travels and virtual exchanges to support the know-how transfer and in-process activities, which were mostly linked to the product’s quality. Nevertheless, reduced coordination in the issues of flexibility compared to quality was potentially due to the explicitness of design and product variety both at the home and the host facilities. Hence, they are suited through the formal mechanisms of coordination.

Finally, taking together the priorities essential and the mechanisms of network coordination, the findings suggest that low-cost focused network manufacturing has expressed more intensity of the use of both the formal and informal coordination mechanisms, than required by market focused type. Indeed, it appears that though the formal mechanisms are equally crucial for both focus types, coordination of low-cost focused offshored facilities showed more preference towards the informal mechanisms than that of market focused networks.

7. Conclusions

With the current trend of global manufacturing, every company strives to improve its competence to coordinate their facilities in dispersed locations. Without having the right coordination mechanism, manufacturers cannot guarantee long-term sustainability in the network operation. This paper aimed to study the coordination practices and how they relate to the competitive priorities in intra-firm manufacturing networks. Based on extant research we have identified the mechanisms for coordination of international operations. In this way, based on original case studies, this research has mapped the network-manufacturing coordination along the formal and informal mechanisms. The mechanisms are not new; however, what is new is to detail them into the competitive priorities and the specific focus of dispersed facilities.

This study has shown that the use of formal and informal mechanisms of coordination varies with different competitive priorities. The case study analysis showed that the formal and informal mechanisms of coordination in combination could create effects for the competitive priorities (quality, flexibility). Hence, it is necessary to take a holistic view of both mechanisms to improve these two dimensions of competitive priorities. Further, it was shown that formal mechanisms are predominantly used to coordinate the market focused as well as low-cost focused dispersed facilities. Whereas, informal mechanisms are used more to coordinate the dispersed facilities with a low-cost focused than that of a market focused. These preferences were equally relevant for the dimensions of quality and flexibility. Moreover, the findings show that single mechanism type is prevalent for other two dimensions of competitive priorities. Specifically, companies implement informal mechanisms in order to attain the priority of lead-time, and formal mechanisms to compete for the cost.

Our work has decent implications to sustainability at strategic levels as well as operational level. At strategic level, it shows that adoption of competitive priorities and initial objectives of locating abroad contributes to a better understanding of the network coordination. It has been discussed that configuration advantages are not static. In order to realize a full sustainability perspective for international manufacturing, it was suggested to consider the process dimensions, i.e., how companies ensure economic, environmental, social perspectives [

41]. In this, the findings of our research consider the interplay of location objectives and the ways to get the most out of networks. This stresses the importance of integration in order to address rapidly changing environments. Next, this paper shed light on the trade-offs between formal and informal mechanisms of coordination in order to support the priorities ‘quality’ and ‘flexibility’, in the international manufacturing context. These, in turn, contribute to sustainability in the competitive market of international manufacturing. Hence, this research put efforts to connect manufacturing strategy perspective to sustainability aspects. In this respect, we follow the call of Carrahe et al. [

42], to consider a strategic perspective on sustainability.

Moreover, the research contributes to environmental sustainability at the operational level. Our research shows that coordination mechanisms have a significant contribution to improving the delivery lead-time. Past research supports this finding by warranting that pooling resources to improve lead-time through coordination contributes to the betterment of environmental sustainability [

43,

44].

The findings also have valuable implications for managers. First, the description of different coordination mechanisms and the competitive priorities herein illustrated a good picture of potential network management activities. This empirical result provides reference for deciding the coordination mechanisms in global manufacturing. In other words, managers need to know well the mechanisms of coordination to reach the target priorities in international manufacturing. Otherwise, the different facilities in the network can play specific roles in the diffusion of sustainability. In particular, without good coordination, sustainability is left like independent islands. Second, in the coordination of dispersed facilities, in order to be successful, companies should take into account simultaneously the focus of going abroad and point to the importance of competitive priorities.

The findings of this study should be viewed in light of the following limitations. First, because of the obtainability of data, the analysis and discussion of this paper were based on case studies of four Swedish companies (two SMEs and two MNEs). Despite Sweden as being highly involved in the international manufacturing arena, caution is needed in extending the results to companies from other developed countries. Furthermore, it can be interesting to compare the network manufacturing of companies based in two different European countries, since the country of origin might have an impact on the development of a company’s IMN. Second, this study adopted a multiple case study method and performed qualitative data analyses. Despite methodological actions (e.g., multiple interviews and sources of evidence, data collection and analysis conducted by more than one researcher, and case-study protocol) being taken to enhance validity and reliability of our findings, statistical generalization to an extended population is not concerned. Third, the study is based on four case companies entailing different industries. Additional studies on this topic that include a larger sample of companies might be useful to assess the extent to which the relationships derived from this research can be generalized. It would be useful to have additional cases per group of focus of offshore facility; nevertheless, we were not able to achieve more case-companies because of the unwillingness of additional contacted companies to allocate time for our research. Last but not the least, the relational set in the observation for this research is limited to the network formed with only the company’s owned and/or acquired facilities. However, the actors in this relationship also interact with other supply chain members linked to them. This research does not pay attention to the extended network relationships. We recommend considering the interactions among different kinds or extended networks to gain insight into this phenomenon.