1. Introduction

The issue of sustainable development is a fast developing area of surveys that represent the interests of business, academia and societies. It is defined and interpreted in various ways and contexts. This concept increasingly points out the direction of the development of economic activity, and that more enterprises are including social and environmental criteria in their activities. However, an effective implementation of the sustainable development idea demands new methods for permanent set-up and tools that enable the integration of different spheres that are so far considered separately [

1].

Initiatives for sustainable development in supply chains have been most probably initiated by pioneering organizations (not necessarily concentrating enterprises), and they are expanded into the remaining cells of the supply chain. For example, an organization acting more proactive in the given supply chain starts initiatives towards its sustainable development, and carries out even more tempered practices, which will be later exported to other parts of the supply chain. Having in mind Silvestre’s deliberations [

2], it is noted that the proliferation and acquisition of knowledge can be realized at different rates in individual parts of the supply chain. The process of “disseminating” is not automatic, but rather requires deliberate effort from both the disseminator (i.e., pioneering organization, which initiated action within the supply chain) and the remaining enterprises in supply chains, which will later consume the knowledge and absorb it as long-lasting practices [

3].

The concept of the balanced supply chain assumes that all links are involved in creating the added value, which is not only the value given to the participants in the chain; this value also contributes to the common wealth of present and future generations [

4]. The balanced supply chain can be determined as “the system of connected business activities, including the entire product life cycle, which allows for the value creation for all stakeholders, simultaneously ensuring the commercial success, which contributes to the increase of the social welfare and the improvement of the environmental status” [

5]. The sustainability of supply chain results relate to managing the environmental, social, and business influences, as well as encouraging the application of the best ruling practices in the entire life cycle of products and services. Such a chain is aimed to create, protect, and increase the long-term advancement of the environmental, social, and economic values of all of the stakeholders involved in delivering the products and services into the market [

6,

7].

Sustainable development initiatives are undertaken by supply chains because of the threats and possibilities that they meet; these are the two main factors affecting the development of sustainable supply chains [

8]. It is possible to include crucial factors associated with their outside and inside contexts of functioning among the barriers for the development of sustainable supply chains [

9].

Keeping this in mind, the above studies also show the threats and possibilities that arise while implementing the concept of sustainable development in supply chain management (SCM) for small and medium-sized enterprises (SMEs). The purpose of this article is to present the current state of the research in the area of managing the supply chains of small and medium-sized enterprises in the context of their sustainable development, and to present the empirical findings within this area.

3. Supply Chain Management in Small and Medium Companies and the Sustainable Development as the Research Background

The small and medium enterprises (SMEs) sector plays a key practical role in economies in all parts of the world. This subject constitutes the foundation for the development of national economies and the global economy, and their impact is already obvious. In the meanwhile, up until the late 1970s, the majority of economists undermined their role, even claiming that entrepreneurship would be more and more strongly driven by large enterprises, and that the impact of SMEs would be more and more marginal.

Despite the great economic significance and the interest of numerous researchers, we have not seen a unitary, widely accepted definition for small and medium enterprises. Therefore, it is possible to find different perspectives of this issue in the literature, the legal documents of various countries, and the recommendations of international organizations. Generally speaking, definitions of small and medium enterprises can be based on qualitative criteria, quantitative criteria, or mixed criteria. Qualitative criteria have a non-measurable character; however, these criteria are mainly decided on by the specificity of enterprises in the SMEs’ sector, simultaneously constituting the determinant of the development of these enterprises.

For the purpose of this study, we accept the SME definition that was established by the Commission in 1996, and subsequently updated through a new recommendation in 2003, which has been in force since January 2005. Furthermore, an external evaluation of the definition was performed in 2012. Based on these studies, it is concluded that a major revision of the definition is not required currently. The main factors determining whether an enterprise is an SME are (

Table 1):

It is without doubt that in order to compete effectively on the global market, companies from the SMEs’ sector must have effective supply chains [

20,

21]. Dissonant goals and a lack of coordination between partners in the supply chain can cause uncertainties in supply and demand. Therefore, an effective management of the supply chain is needed that can be most briefly characterized as integrating suppliers, producers, distributors, and customers in order to guide the long-term action of companies. It is unusually essential to share the information with all of the partners in the supply chain in order to improve the coordination and the absorbency of the chain. This coordination is based on fast and visible up-to-date information for all of the partners in the chain, and it is possible to improve it through close partnership with the customers and the suppliers, who can help in the joint development of new products. However, a joint effort in reducing the lead time and multi-directional training of the workforces are also needed.

Arend and Wisner [

22] discuss the relationship between managing the supply chain and companies from the SMEs’ sector, and emphasize the benefits that companies can reach through SCM. These are mainly include the high quality of products, lowest costs, better customer service, and lowered risk. Other benefits from managing the supply chain include increased market participation, reductions in the property, an improved service in relation to the supply, an improved quality, and a shorter product development [

23]. Additionally, Grove [

24] underlines that other advantages of implementing an effective supply chain include increased competitiveness for all customers, implementing medium/long-term planning actions, increased profitability, the perfection of the design, and corrected self-understanding of the supplier, all of which can be achieved thanks to the calm functioning of better management of the supply chain. Implementing effective SCM practices also have a direct effect on increasing the operational activity of companies from the SMEs’ sector. Hong and Jeong [

25] examined the influence that companies from the SMEs’ sector have on the implementation of the supply chain through performing the roles of the suppliers, distributors, producers, and customers. They state that the integration of these roles is essential in order to be sure that the SMEs keep their competitive edge and can remain competitive in the global market in general; SMEs require a correctly integrated decision-making system in a coordinated strategic supply chain.

Unfortunately, current surveys connected with supply chain management in small and medium enterprises do not concentrate on the subject of sustainable development in both Polish and world literature. In regard to the literature analyzing supply chain management in small and medium enterprises in Poland, it is possible to find Haan’s et al. [

26] study, which researched 127 Polish enterprises from the SMEs’ sector. The objective of the examination was the decision-making processes of supporting IT systems. Polish companies from the SMEs’ sector demonstrated an awareness of the requirements of the competitive market, although the majority of them still acted in the traditional way, and did not attempt to concentrate on managing relations in the supply chain [

27]. It is also been noted that Polish companies from the SMEs’ sector use IT systems, such as supporting decisions and specialist systems, in order to improve decision-making processes and management in logistic areas and databases for supporting customer service.

However, the results of Malys’ [

28] questionnaire surveys present that over 70% of SMEs cooperate with subcontractors, and over 80% of these entities cooperate with customers and suppliers. Fewer than 10% of respondents do not declare cooperation with any partner. According to the author, such a common cooperation between supply chain parts suggests that this factor should not be treated as an indication of increasing competitiveness among small and medium enterprises.

The author also underlines how it is essential that the managers of small and medium enterprises are aware that the present success of their companies is not from individual struggles against competitors, but rather from the efficient functioning and success of whole supply chain, because competing takes place just on the level of supply chains, rather than among individual companies.

Therefore, it is possible to accept that while this is a crucial characteristic of companies from the SMEs’ sector and their supply chains, they can be aware of the matter, which is poorly examined and present in literature. It is within the scope of the activities undertaken by companies from the SMEs’ sector, in which some parts base all of their business arguments on principles of sustainable development [

29], as well as the methods through which these activities are being managed in the supply chain. The characteristics of companies from the SMEs’ sector include translating their integrated commitment into principles, and using ethical and moral arguments in to involve these principles in responsible practice [

30]. This should enable them to achieve sustainable development in a simpler way than large enterprises, who attach great significance to profitability and put their shareholders higher than crucial stakeholders.

The priority of increasing the profit is a characteristic of large firms. Current studies that have examined the sustainable development of supply chain management argue that this characteristic has the tendency to emphasize the economic dimension. As a result, cooperation between economic and environmental results is developed better than cooperation between economic results and the social dimension [

31]. However, the review of studies of small and medium enterprises has shown that many owners and managers of subjects from this sector are not running businesses in order to increase financial results. In contrast, their solid convictions, including those associated with environmental and social responsibility, tend to agree with those of the company founders, who are seen as firmly culturally involved. Both the environmental and social practices of entities from the SMEs’ sector can be subjected to the strong impacts of the priorities of the owners, and as a consequence are base on strong relationships between the supply chain and created social capital [

32].

It is often been assumed that the companies from the SMEs’ sector are simply a “smaller version of large firms” [

33]. However, in the literature it is assumed that the size of company is significant with reference to sustainable development. Therefore, we need deeper insight into the issues of sustainable development surrounding the relationships among companies from the SMEs’ sector. However, examinations concerning this area from the perspective of companies within the SMEs’ sector are still limited [

34]. Meanwhile, small and medium enterprises do not experience the legal pressure to increase the value of shareholders [

35] in the same way as large firms. Instead, they have a more free hand in regard to having the funds of the company at their disposal when they notice any threat, which can enable flexibility in performing environmentally and socially responsible activities [

36].

Their tendency of applying a reduced focus on increasing the profit stands in contrast to the approach of large organizations towards sustainable development, which in practice aspires toward superior economic performance. The literature on sustainability has focused on the environmental performance of SMEs, which is also known as the green supply chain [

37], as well as their role in creating more sustainable forms of food supply [

38]. Some companies from the SMEs’ sector base their business principles specifically on the principles of sustainable development. In these instances, the business is considered not only a profit stream, but also as a driving force behind public and environmental change [

39]. Due to this, companies from the SMEs’ sector are more willing to be environmentally and socially responsible for their own good [

40].

The well-known heterogeneity of the SMEs’ sector also applies to the varied relationships that small and medium enterprises have with the concept of sustainable development. These relationships can be different due to cultural differences that arise because of different property structures, as well as the differing strategies and characteristics of the owner-managers. Therefore, initiatives must recognize the diversity of characteristics among companies from the SMEs’ sector [

41]. Studying the sustainable development of entities from the SMEs’ sector is mainly descriptive when it comes to the scope of changeable characteristics of companies from this sector, and is not cohesive. There is a need to pass from the “what” level to the “why” level in the scope of examining the environmental and public practices of companies from the SMEs’ sector, and developing essential theoretical categories for the relationships within the structure [

42].

In the past, the majority of the supporters of sustainable development concentrated on environmental aspects [

43]. Environmental issues were also the main subject of many of the research studies [

44]; for many organizations in today’s world, these issues have become a major problem [

45].

In order to examine the importance of individual SSCM areas in SMEs’, the following research hypotheses are formulated:

Hypothesis 1. The SMEs’ economic, environmental, and social areas of sustainable supply chain management are equally important.

Hypothesis 2. There is a connection between the size of the company that is measured in relation to the number of employers, and the level of importance of the particular elements in the sustainable supply chain management.

Hypothesis 3. There is a connection between the duration of the functioning of the enterprises on the employment market and the level of the importance of particular elements in the sustainable supply chain management.

When analyzing the importance of individual SSCM areas, determining the particular indicators that should be evaluated is crucial. This approach is particularly appropriate when the empirical fieldwork parallels the theoretical conceptualization of the research by Asby et al. [

31]. While the current literature review focuses on environmental and social aspects, the business area cannot be forgotten; its analysis is also necessary.

3.1. Business Dimension of SSCM

Therefore, in the analysis of the business elements of the sustainable management of supply chains, the flows—which include the flows of materials, information, and capital—should be considered. In order to increase the efficiency of the supply chain, members of the chain jointly manage the logistics and storing of these flows. Alternatively, they hand these functions over to other members. Either way, the promptness of supplies is essential within sustainable supply chain management. The effective flow of products within the supply chain can be achieved well in relation to adaptation of the production, logistics, and marketing of the products, as well as other related activities. Members of the supply chain should develop new products, as well as share typical parts and processes, with the aim of quickly reacting to changes in the size and the specification of the products on offer. The flow of information is equally essential for business success, and includes information concerning the order and the status of delivering the products. For that purpose, information technology (IT) tools are used, which create effective communication between members of the supply chain. Factors (which include IT tools) concerning the agreement to share appropriate information connect management relations in the supply chain with the process of information flow. The flow of the resources includes financial aspects—such as payments, credit rules, or the instrument of ownership—as well as non-financial aspects, such as people and equipment, which both improve the effectiveness of the functioning of the supply chain. Referring to the process of managing relations in the supply chain, J.T. Mentzer [

46] argued that its members must have a clear view of managing the supply chain and building long-standing relations with defined objectives in mind. Support from senior management is also necessary for the development of relations between organizations in the supply chain. Finally, members of the supply chain should establish relations that are based on trusting one another, and fairly divide the benefits that are achieved from managing the supply chain well.

In order to achieve progress in relation to the management and production of permanent resources , managers of the supply chain should have a clear benchmarks by which they measure the effectiveness of their functioning. Next, these visions should be implemented within the supply chain by allocating adequate financial means and supporting the senior management. One should implement guaranteed quality programs for both products and processes through supply chain management in order to improve the effectiveness of the organization. A flow of resources also happens in the product development and commercialization processes. D.M. Lambert [

47] has suggested that the supply chain should have guidelines concerning the participation of both suppliers and customers in the development of products and their commercialization. These guidelines should be multifunctional and apply to both internal and external procedures. H.L. Lee [

48] explained that the effectiveness of the supply chain depends on the conceptual plans that relate to products, processes, and packages. Taking the above literature review into consideration, this study endeavored to examine how the following business elements of the sustainable management of supply chains are important for small and medium enterprises:

Cooperation in inventory and logistics management

Use of information technologies to increase the efficiency of communication

Building long-term relationships based on established guidelines

Common clear vision of supply chain management

Use of the “Just in Time” concept/as a tool for enhancing competiveness

Exchange of production information on a regular basis, e.g., through sales and operations planning meetings

Common introduction of benchmarking and performance metrics

Standardization of quality policy for both products and processes with established guidelines

Aligned product strategies, supply, and distribution within the supply chain strategy

Information sharing about customer requirements and design plans

Usage of the supply chain concept within the design of products, processes, and packaging

Common procedures to obtain feedback from customers, who are involved in product development

3.2. Environmental Dimension of SSCM

The environment is a key element of the sustainable development; climate changes, global warming, and the rising cost of energy are central points of interest [

49]. Sustainable development in the scope of the environment relates to maintaining ongoing access to natural resources, i.e., minerals and the atmosphere, without which mankind cannot exist. In this scope, sustainable development relates to the protection of sources of raw materials that are needed for satisfying human needs. Therefore, as Tsoulfas and Pappis, as well as Min and Kim indicate, the environmental dimension of sustainable development should contain environmentally-friendly production processes and actions for reducing the quantity of waste [

50,

51]. The commitment to sustainable production processes frees companies from the release of pollutants. Applying renewable sources in production and re-using materials, whether processing defective or consumed products, are equally essential [

52]. Crucial elements of the environmental dimension of sustainable development include organizational activities such as the selection of partners in the supply chain based on ecological guidelines, and the commitment of employees to environmental protection programs [

53]. Taking the above studies into consideration, an analytical set of the environmental elements of sustainable development in supply chain management for examinations of small and medium enterprises is established as follows:

Environmentally-friendly production processes

Actions for reducing the quantity of waste

Commitment to production processes that are free from the release of pollutants

Applying renewable sources in production

Re-use of materials

Processing defective and consumed products

Selection of partners in the supply chain based on ecological guidelines

Commitment of employees to environmental protection programs

3.3. Social Dimension of SSCM

Social sustainable development regards numerous relationships between human rights and development, including the impact of a corporation’s actions on individuals and global poverty, ambiguous business operations, and the consumer’s choice without the moral contexts [

54,

55]. Considering the public aspect, it is possible to find a diverse number of elements that relate to sustainable development and are worthy of analysis, e.g., frames of social influence and initiatives connect with the ability to evaluate the social permanence of supply chains. Besides this, the relationships between the business decisions and sustainable development in social areas [

56,

57,

58] are influenced by the company’s ethical code towards employees and contractors, and can include honest principles regarding employing the local community, and even delivering employees equipment ensuring hygiene and job security [

59,

60]. The indirect influence of enterprises on the local community on the macroeconomic scale is equally essential; this influence expresses itself through companies timely and legally paying taxes and associated charges. The transparency of incomes is the base of the tax calculation, and it is also important to apply ethical norms to business and trade, or even invest and/or participate in investments in infrastructure objects that communities use [

61]. Colantonia also gives investments in poverty reduction programs, participation in the charity actions of the local community, and regional and transregional development initiatives as socially crucial elements of sustainable development [

62]. Therefore, for examinations regarding the involvement of small and medium enterprises in managing supply chains that follow the social elements of the sustainable development, the following elements are important:

Applying an ethical code towards employees and contractors

Applying honest principles of employing the local community

Delivering equipment ensuring hygiene and job security

Investments in infrastructure objects

Timely and legally paying taxes and associated charges

Transparency of incomes as the basis of tax calculation

Applying ethical norms of business and trade

Investments in poverty reduction programs

Participation in the charity actions of the local community

Participation in regional and transregional development initiatives

4. Methodology of Research and Study Sample

The research tool was a survey questionnaire that was divided into two parts, with the first identifying the respondents, and the second identifying the important sustainable supply chain management (SSCM) elements in the practices of small and medium enterprises. Polish small and medium enterprises were randomly sampled, with the Polish Statistics Office data serving as the base of the draw. The draw had dependent unrestricted characteristics. The initial sample size that was considered was 500 SMEs in Poland; its structure had been chosen randomly. The data was collected through the direct method between January and March 2017. A total of 383 fully completed questionnaires qualified for final analysis, and were used in this study. The obtained research sample for this study corresponded to the materiality level p = 0.1, at the maximum admissible error of 0.05. It should be noted that some of the respondents did not answer all of the questions; hence, there were a significant number of rejected surveys. Likert’s five-level scale was used to evaluate the SSCM concept in small and medium entities, which measured the average level of the evaluation of elements in the following SSCM areas: business, environmental, and social. Moreover, the study considered the dependence of the business, environmental, and social elements in the small and medium enterprises’ SSCM on the employment size, as well as the period of functioning.

As mentioned, a total of 383 enterprises were studied in the survey, respectively. Small entities with 10 to 49 employees predominated (290), which constituted 75.7% of the research sample, while medium enterprises made up the other 93 (24.3%). Considering the period of the enterprises’ operation in the market, one could observe that slightly more than half of the surveyed enterprises (197) had been in business for more than 15 years. Meanwhile, 86 of the surveyed enterprises had been in the market between eight and 15 years, while 73 entities had been functioning between three and seven years. The smallest category of respondents in the survey was entities that had been operating in the market for less than three years (27). At the same time, it was noted that the longer the activity of the entities in the market, the greater their participation in the survey.

Taking into account the structure of the research sample in relation to industry representation, 13 specific areas of activity of the analyzed companies are considered in

Table 2.

Based on the results,

Table 2 shows a high diversity of the surveyed enterprises according to industrial operations. Taking into account the percentages, the most frequently occurring industries were logistics and transport (14.4%), services (15.9%), wholesale and retail trade (17%), and other industries (11.7%).

The survey also identifies the position of the person who filled out the questionnaire. The majority of respondents (225; 59%) were the either the owners/co-owners or head directors of the surveyed enterprises. Other directors participating in the survey amounted to 14% of the sample: 30 sale directors, 14 logistics directors, six marketing directors, and four supply-chain directors. Less than one-third of respondents (104) occupied a different type of position than those proposed. The presented structure, which gathered that over 63% of the respondents held managerial functions, used the credibility of the obtained research results.

In conclusion, most of the respondents in the survey were from small entities that had been operating in the market for more than 15 years, especially from the wholesale and retail trade industry. Most of answers were given by the owners and the companies’ managing directors.

5. Results and Discussions

A balanced frame of business, environmental, and social considerations is an important aspect of sustainable supply chain management and its implementation.

Therefore, our questionnaire asked about the importance of the aforementioned elements in SMEs practice in supply chain management. The business elements of SCM are first considered, and the calculations were done based on the Likert’s five-level scale, where: 1 = doesn’t matter; 2 = unimportant; 3 = neutral; 4 = important; and 5 = very important (

Table 3,

Table 4 and

Table 5).

While estimating the importance of the business elements of SSCM, the respondents mostly presented SSCM as important to their practice (

Table 3). The most willingly surveyed companies built long-term relationships with other members of their supply chain, as directed by established guidelines, and used information technologies to increase the effectiveness of communication within the cooperation framework. The standardization of quality policy for both products and processes with established guidelines, as well as information sharing regarding customer requirements and design plans, were also important to their practice. Only the common introduction of benchmarking and performance metrics were considered neutral for business practice.

All of the proposed environmental elements in SSCM were frequently estimated as important (

Table 4). It is worth noticing that acting towards reducing the amount of waste and engaging in production processes that were free from harmful substances emissions were estimated as very important in the majority of answers in the studied enterprises practice.

Despite the literature results [

39,

40], social elements were estimated as very important in relation to six analyzed elements, and four were frequently considered important (

Table 5). For further estimation of the importance of other elements, detailed statistics calculations were prepared, as shown below.

The dominant ratings are marked as “important”, while their percentage structures (on average 40%) indicate large disparities in relation to the level of the importance of the individual SSCM elements in the surveyed enterprises; this is also confirmed by the high values of the standard deviations (

Table 6). This means that the level of importance of the SSCM business elements in practice differentiated the surveyed entities.

An important aspect of sustainable supply chain management in the literature is environmental elements. Therefore, it is the second area of SSCM that was investigated, and the calculations based on the Likert’s five-level scale, as previously mentioned, are shown in

Table 7.

The average rating indicates that the proposed environmental elements of SSCM are usually important for a surveyed companies’ practice. At the same time, measures to reduce waste and involvement in production processes free of harmful emissions have been identified as most important. Both the percentage structure of dominant assessments and the large values of standard deviations mean a high diversity of responses, and different levels of perceptions of environmental elements on the concept of SSCM are identified.

Social factors are also acknowledged as an important aspect of sustainable supply chain management, even more than previous considerations (

Table 8).

The average results of the assessments show that the indicated social elements are perceived as important for the concept of SCCM. The highest-rated factors are the timely and lawful payment of taxes and fees, as well as transparency of income being the basis for calculating taxes. In contrast, participation in regional and supraregional development initiatives seems neutral. Among the dominant assessments, those demonstrating the important and very important impacts of social elements were used by the surveyed entities on sustainable development. At the same time, their percentage structure indicated a large decisiveness among the majority of respondents (assessments of 4 and 5 were over 50%) regarding the validity of most of the factors for the correct implementation of SSCM.

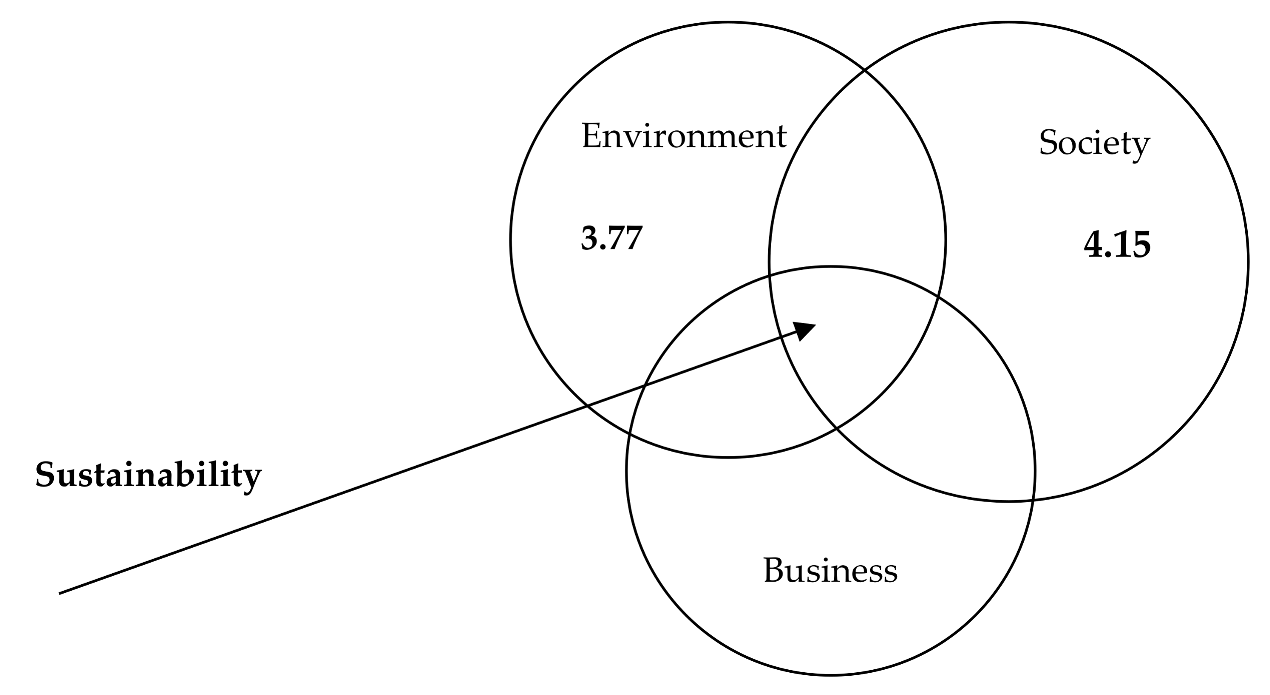

Based on average values for the elements of the business, social, and environmental areas and the Triple Bottom Line (3BL) concept of sustainability elaborated by C.R. Carter and D.S. Rogersa [

63], the following model of the SSCM in studied SMEs are presented in

Figure 1.

It is visible that there is an imbalance in the sustainability areas in the supply chain practice of SMEs, where the social area is acknowledged as more important (4.15) than the environmental (3.77) and business (3.54) areas. Due to this situation, the common area of “sustainability” has shrunk in relation to fully balanced sustainability model.

Table 9 presents the materiality level of the relationship between the size of the entity, the length of its functioning in the market, and the particular business, environmental, and social dimensions of sustainable development.

The majority of the studies reported a relations materiality level of p > 0.005 (almost 90% of all values). This means that statistically, there are no essential relations between the size of the examined enterprises, the period of their operation in the market, and the specified areas of sustainable management. The remaining 10% of the relations, due to a low r-Pearson’s indicator (below 0.05; values are put in brackets in the table), can be possibly regarded as unimportant in the forming of the examined phenomenon. The χ2 test results are statistically unimportant, so there are grounds for rejecting the H2 and H3 hypotheses. It is possible to assume that a link between the analyzed variables does not exist. The number of the employees and the period of operation of the enterprises in the market do not influence the level of the evaluation of importance of the particular SSCM elements.

In order to verify the significant relationships between the sample data sheets and the particular SSCM areas, the non-parametric Chi-square independence test is used for the adopted significance level of

p < 0.005. To check the linear relationship between these pairs, a Pearson’s

r correlation coefficient is also estimated. Its value can range from −1 to 1, where a value closer to the unity shows a stronger degree of dependence between the studied variables (

Table 10).

As the result of the independence test, eight pairs of factors were identified as mutually dependent for p < 0.005 (four pairs) and p < 0.001 (four pairs). At the same time, the r-Pearson coefficient indicated that there was only one negative case; the remaining pairs showed a weak positive correlation. Such low values showed that only a small part of the observation showed a dependency between the variables. So, the following conclusion can be assumed:

There was a slight negative correlation of less than 0.2 between the operating period and the common clear vision of supply chain management, which means that a longer operating period caused a less significant common clear vision of supply chain management.

There was a slight positive correlation at the level of less than 0.2 between the operating period and the following SSCM elements: environmentally-friendly production processes, acting towards reducing the amount of waste and engaging in production processes free from harmful substances emissions. This meant that the significance of those SSCM elements increased along with the increase in the length of the operating period, which could be because higher amounts of financial means in enterprises could then be devoted to environmentally-friendly development.

There was a slight positive correlation at the level of less than 0.2 between the studied enterprises’ employment size and the exchange of production information on a regular basis, such as for instance through sales and operations planning meetings, as well as environmentally-friendly production processes. It means that as the level of employment increased, the importance of information exchange and environmentally-friendly production processes rose in SSCM practice.

There was a slight positive correlation at the level of less than 0.2 between the position of the respondent and applying the ethical code conducts to the employees and contractors, as well as the clearance of taxable income. This means that with the level of position held, the importance of applying the ethical code conducts to the employees and contractors and clearance of taxable income rose in the SSCM of the studied SMEs.

At the same time, only the significance of one dependent variable, which was environmentally-friendly production processes, resulted from the interaction of two independent variables, i.e., operating period and employment size.

These research results did not confirm to the notion that small and medium enterprises seem to avoid environmental responsibility [

64], and are less willing to take actions associated with initiatives for the environment. It was also possible to notice that entities from the SMEs’ sector applied stronger pressure to the social elements of the sustainable management of supply chains than was presented in the more comprehensive literature devoted to the sustainable development of supply chains. The social elements of the sustainable management of supply chains reflected the importance of charity and commitment to the community in small organizations, and that the priorities of the owner-manager have a strong impact on how small enterprises face sustainable development in their actions.

6. Conclusions

The presented theoretical considerations, methodology, and research results pointed to the broad perspective of the current priorities of SMEs in the field of SSCM. The literature reviews of the previous studies extended the scope of knowledge of the enterprises from the SMEs’ sector. It shows that problems related to the sustainable management of supply chains are still insufficiently examined. The limitation of applying a single theory to a concept as broad and dynamic as sustainable supply chain management was well known, while the use of multi-faceted theoretical perspectives resulted in valuable views and beneficial research possibilities. At present, larger firms are attracting more media attention and scrutiny regarding SSCM practices [

65]. Bearing this in mind, a significant number of studies are devoted to large enterprises; this paper identified research gaps in the current literature concerning enterprises from the SMEs’ sector in the context of supply chains. The perspectives of enterprises from the SMEs’ sector of sustainable development opened new opportunities for formulating questions and new areas of research regarding sustainable supply chain management. The characteristics of the functioning of SMEs seem to coincide with the company’s approach to sustainable development within the supply chain. SMEs are more likely to rely on informal and often personal relationships in the supply chain, which is strongly influenced by the owner-manager’s priorities. These priorities are also reflected in the approach to sustainable development and the specific treatment of environmental and social aspects in the supply chain.

Findings have shown that enterprises from the SMEs’ sector acts much better than large units. They understand the social dimension of their own activity and take initiatives in this area. They identify the need of long-standing relations that are based on confidence. Both of these aspects are crucial gaps in the literature on sustainable supply chains management.

The most important business elements in the SSCM of the studied SMEs relate to building long-term relationships in accordance with established guidelines, which contributes to shortening delivery times and increasing the level of customer satisfaction due to meeting specified or anticipated dates of deliveries and ordered quantities of products. It can be noticed that acting towards reducing the amount of waste is the most important environmental element in SSCM; it is worth pointing out that this element can have a crucial impact on the financial and positive results of a business. The social elements of the SSCM of the studied SMEs on the whole are more important than the previous literature indicated. The timely and lawful payment of taxes and fees, clearance of taxable income, provision of health and safety equipment, and application of ethical business and trade standards are acknowledged as the most important elements.

The examined enterprises consciously influence the degree of importance of the particular elements on SSCM; hence, their evaluation is high. Simultaneously, the character of their opinion does not result from the size of examined entities, nor the period of subject’s operation in the market. Both small and medium enterprises start their activity and realize their goals in the market for a few years, while also paying attention to the important factors that relate to the sustainable development in SCM. It means that these companies observe similar phenomena in the economy. They are identically mature in noticing the weight of the sustainable development in increasing the effectiveness of SSCM.

Detailed analysis of the sustainable development in supply chain management in the SMEs’ sector is currently underdeveloped. A limited number of studies in this specific field have been conducted at present. However, the examination shows that small and medium enterprises are involved more in environmental and socially responsible practices of the supply chain, which are strongly connected with managers’ priorities. The research findings also show that the social dimension of SSCM is potentially much more fully developed, so the elaboration can fill the determined gaps in the current state of research on sustainable development in supply chain management. Research results also indicate how to achieve the full cooperation with all three dimensions of the sustainable development equally.

The study suggests a close connection among all of the dimensions of the sustainable supply chain management, and has encouraged a comprehensive understanding of the decision-making results. The progress towards the sustainability of potential solutions needs to be assessed with their real sustainability effects [

66]. For managers, it will mean the need for an analysis of decisions connected with sustainable development on the organizational level or in specific relation to supply chains, because the failure to manage the supply chain in a socially and environmentally responsible manner can have significant implications for a firm’s cooperative reputation [

67].

Certainly, the research results may have a limited level of representation in relation to the whole population of SMEs, due to the relatively small sample used in the study. Another limitation is that this study indicates only Polish SMEs’ engagement in environmental and social responsibility. These results most likely differ from those that could be obtained within European developed economies, as well as in developing economies in Asia or Africa.

Basic statistical measures, which enable general conclusions to be drawn, were also used in this examination. It is possible to treat these examinations as the base for further analysis; however, the performed observations did not explore the issue fully. There is a plan to look for other factors that determine the choices of important components of sustainable development in the studied subjects.

Moreover, the research that was carried out did not exhaust the topic. These concepts will be developed in the future with a much more detailed analysis of the implementation of the sustainable development concept in SCM in small and medium enterprises, as well as in large companies.