A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways

Abstract

:1. Introduction

2. Geomechanical Properties of the Studied Deep Soft Rock Roadway

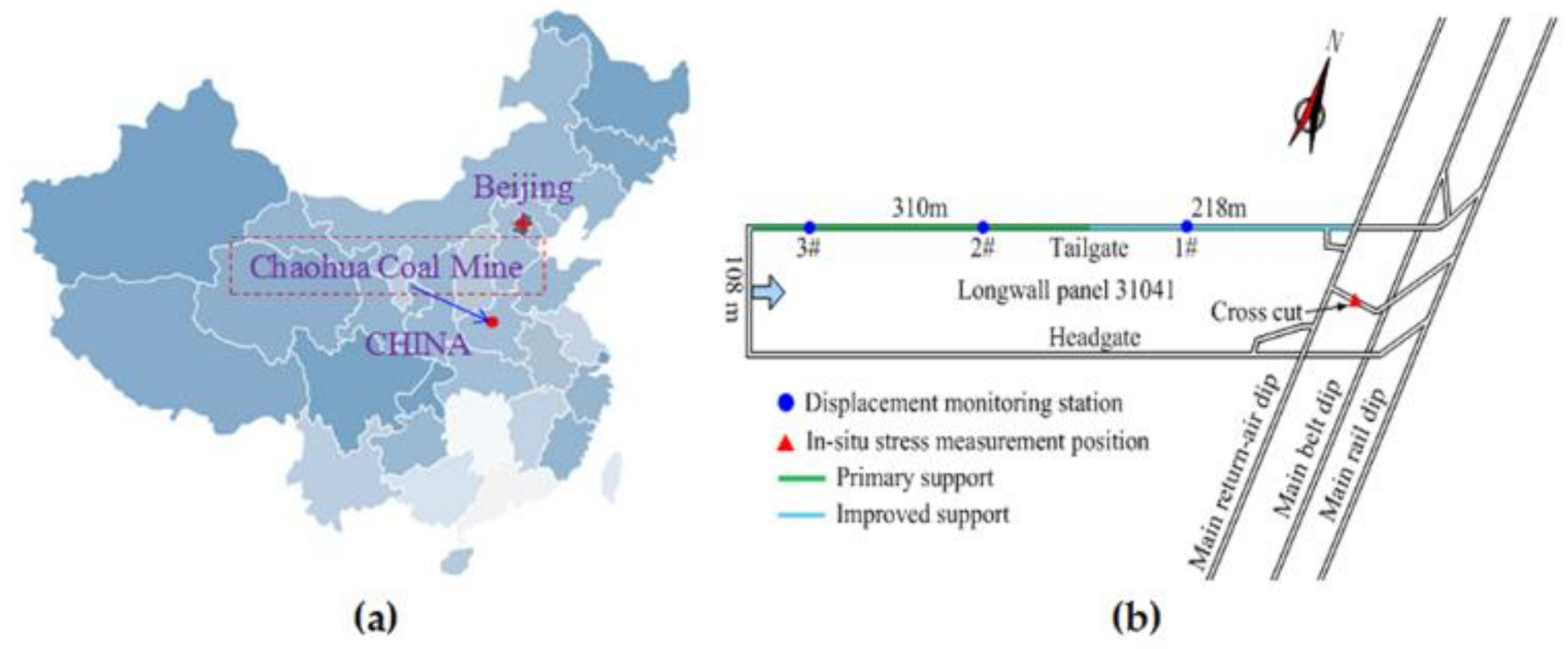

2.1. General Situation of the Studied Mine

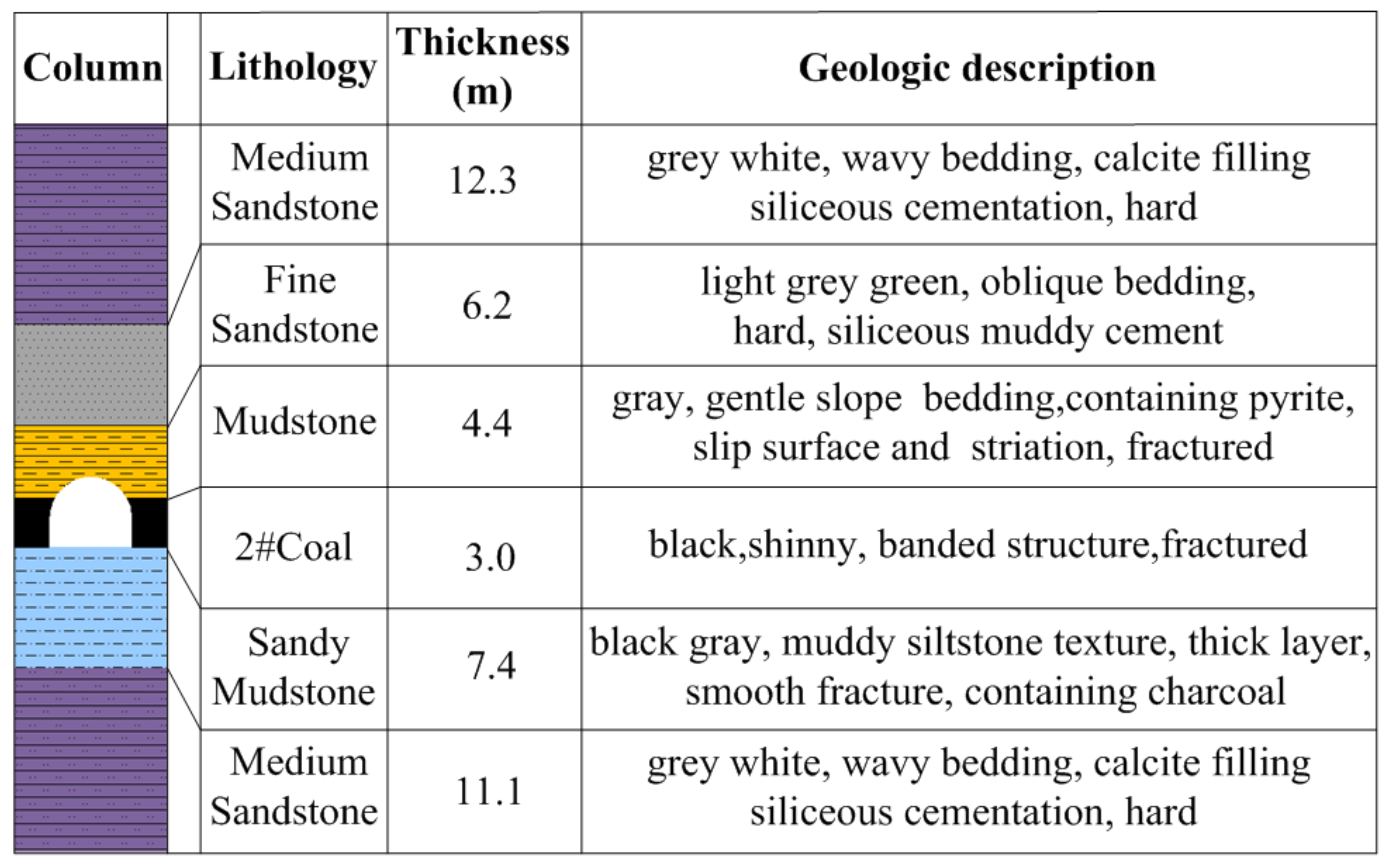

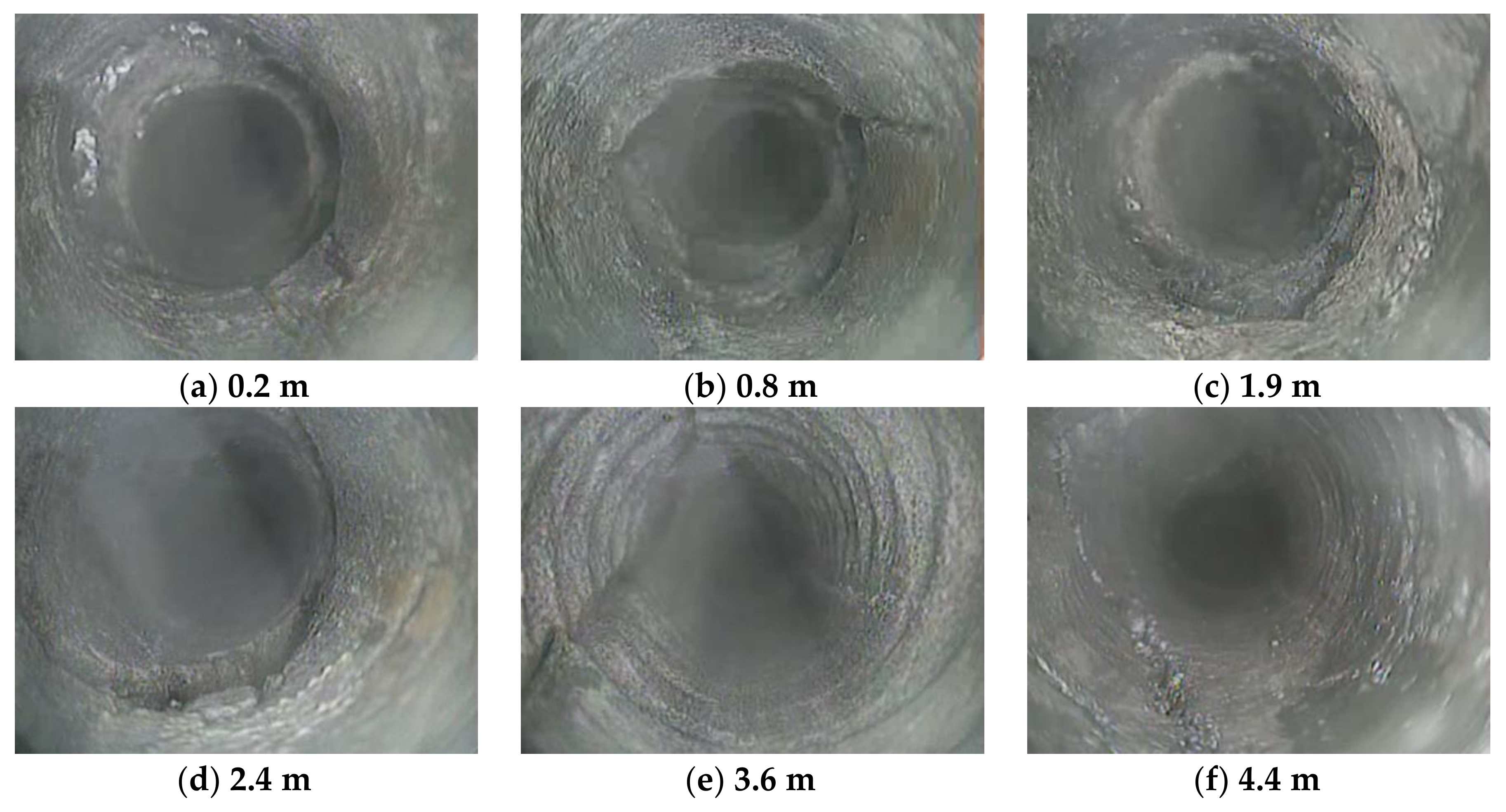

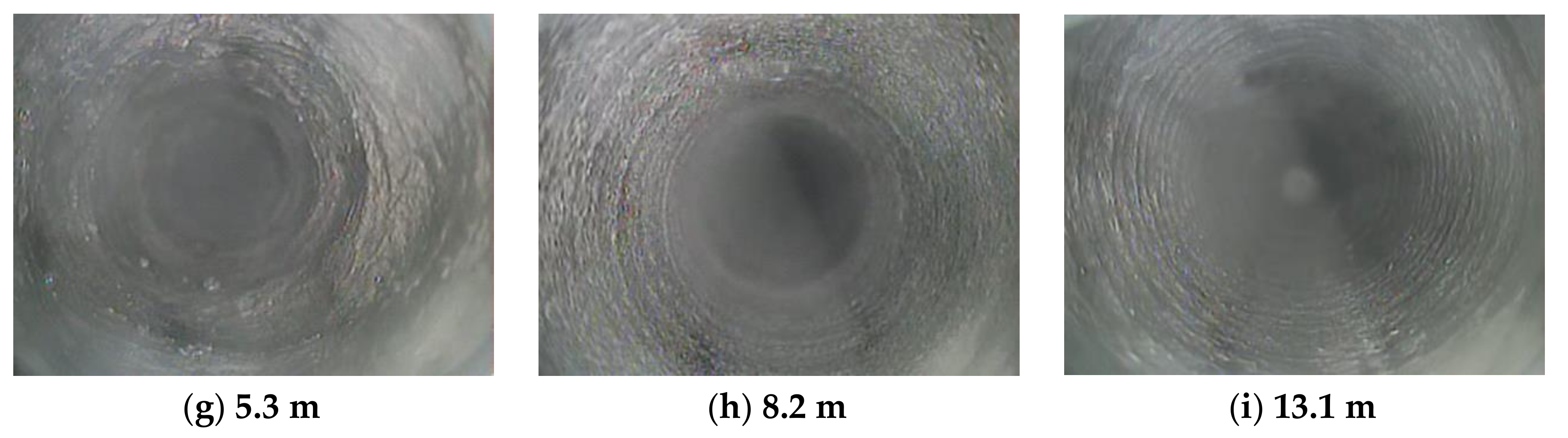

2.2. Physical and Mechanical Properties of Engineering Rock Mass

2.3. Large Deformation Characters of Deep Soft Rock Roadway

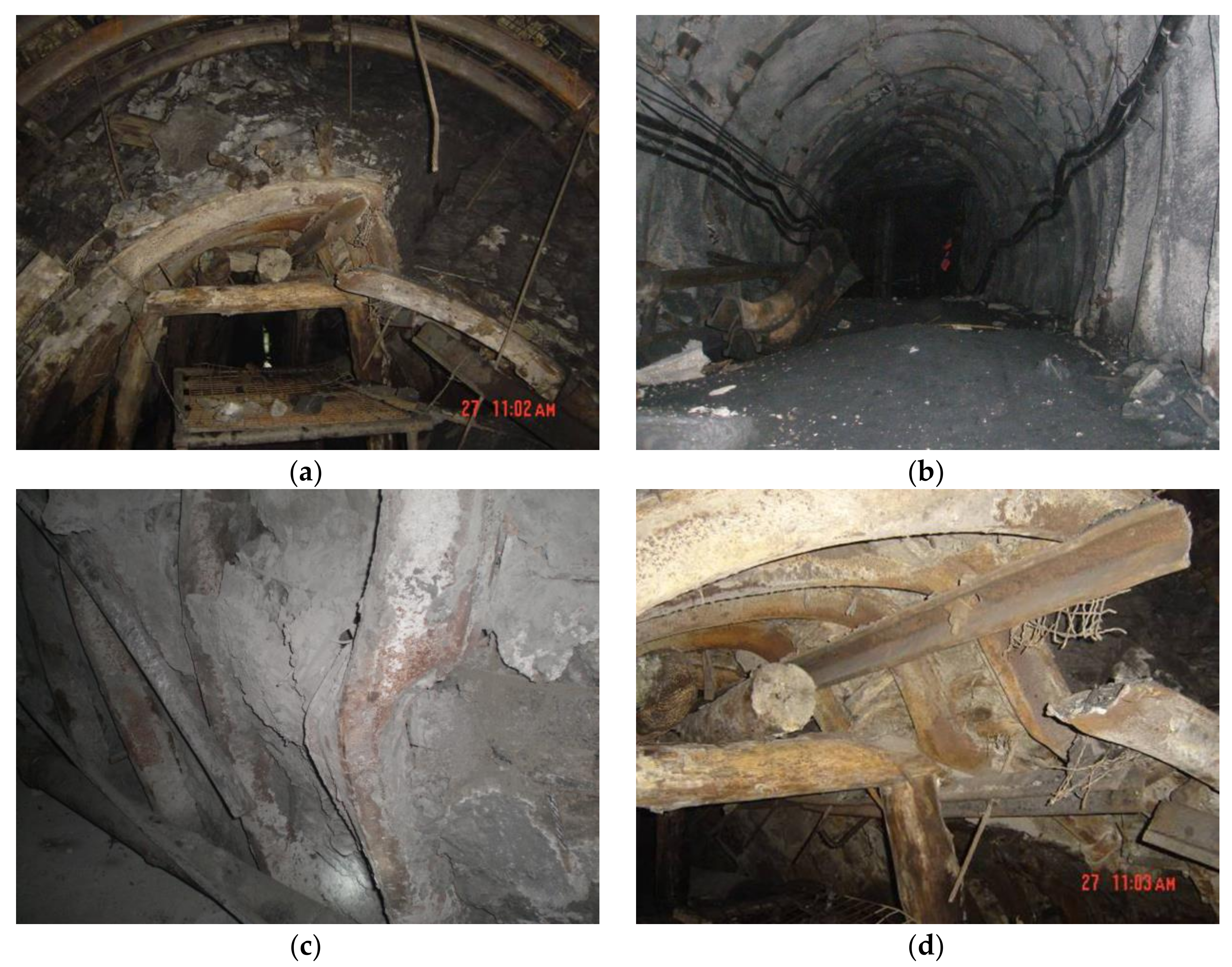

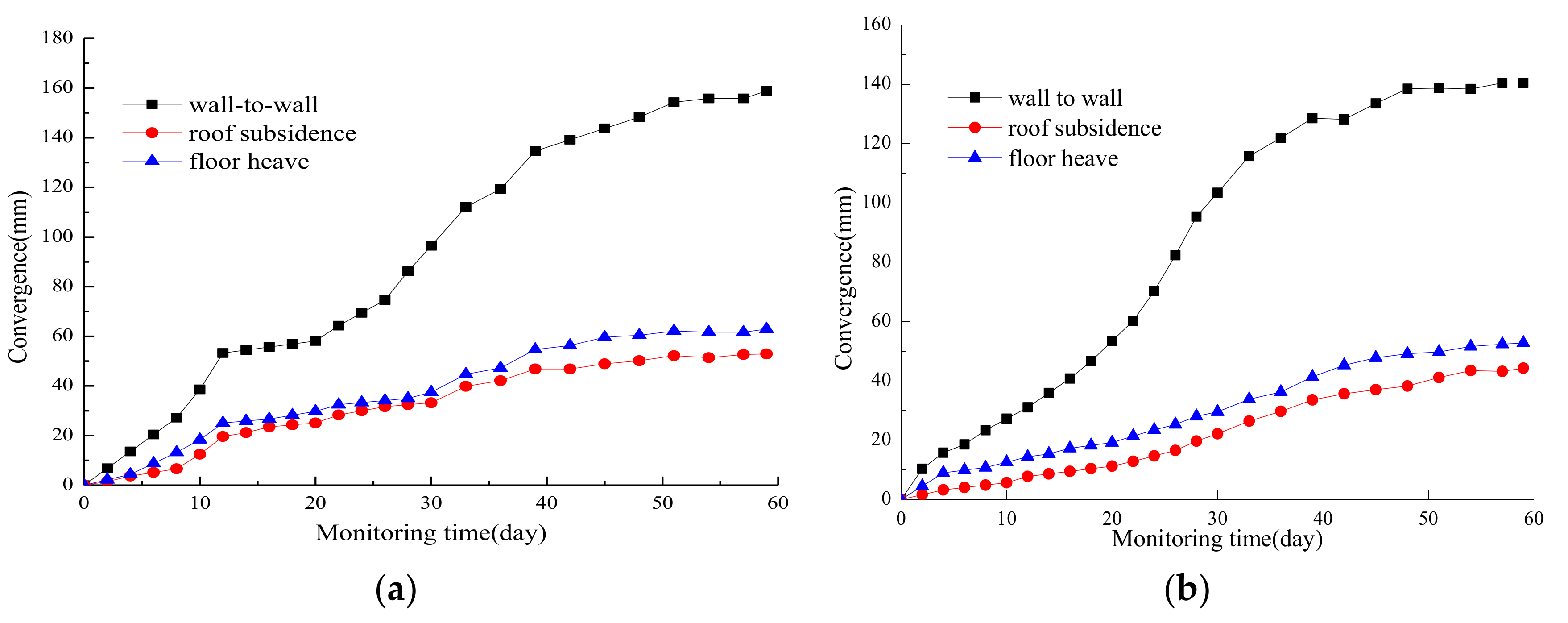

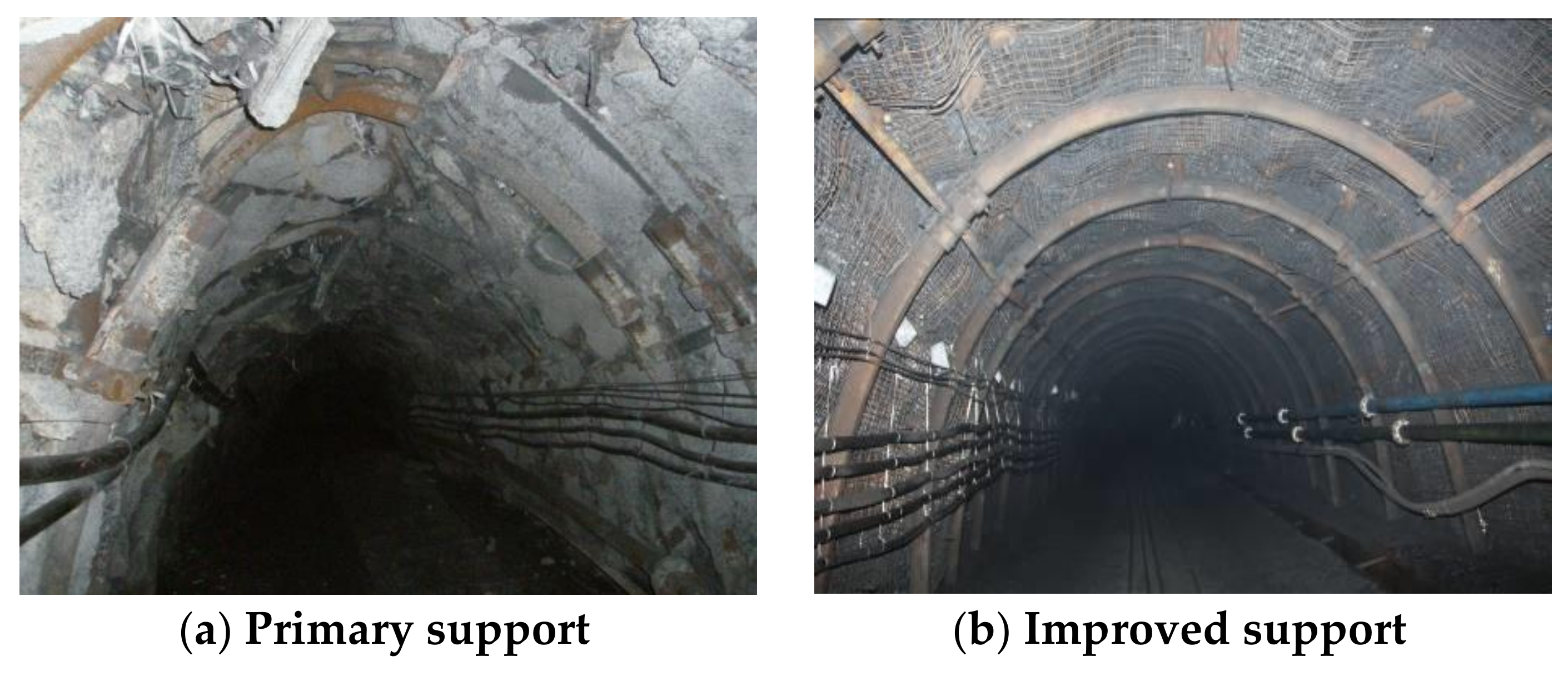

- Large and long-term duration deformation in surrounding rock. After the roadway was excavated, significant deformation occurred in a few days. Skin roof falls and sides spalling made it difficult to obtain the roadway cross section using the road header. The large deformation continued to occur even after U-shaped steel sets were installed, sides were extruded toward the free surface and shrinkage appeared (Figure 4a). Roof subsidence occurred due to stagger and swelling in roof stratums (Figure 4a); Serious floor heave appeared in some places (Figure 4b). Moreover, the phenomena of side shrinkage, roof subsidence and floor heave continued for a long time, which resulted in an extremely weak stability of the surrounding rock. The convergence rate of the roadway was as high as 5–10 mm/day and lasted for 2–3 months, which indicated the potential for an unexpected roof fall and rib spalling. The final reduction percentage of the roadway cross-section could be 30–60%.

- Supporting material failure. Many failures occurred soon after supporting materials were installed and failures still occurred even after several repairs. The failure characters of U-shaped steel sets in different areas of the roadway were significantly different. In the serious roof subsidence places, the U-shaped steel sets broke in the arch shoulder, the top section of the U-shaped steel sets was flattened (Figure 4a), and the leg of the U-shaped steel sets was pressed into the rock of the floor. In the serious side shrinkage places, the top of the U-shaped steel sets became sharpened, and the leg of the U-shaped steel became bent (Figure 4c). A series of U-shaped steel sets became distorted along the direction of the roadway axis (Figure 4d), resulting in the U-shaped steel sets almost losing bearing capacity. The failure of U-shaped steel sets indicates that the strength and stiffness of steel bracket was too low to inhibit the large deformation of the soft surrounding rock. The remaining excavation of the roadway was delayed due to serious deformation and potential instability. An improved support system had to be proposed and performed.

3. Large Deformation Mechanism Analysis Using UDEC

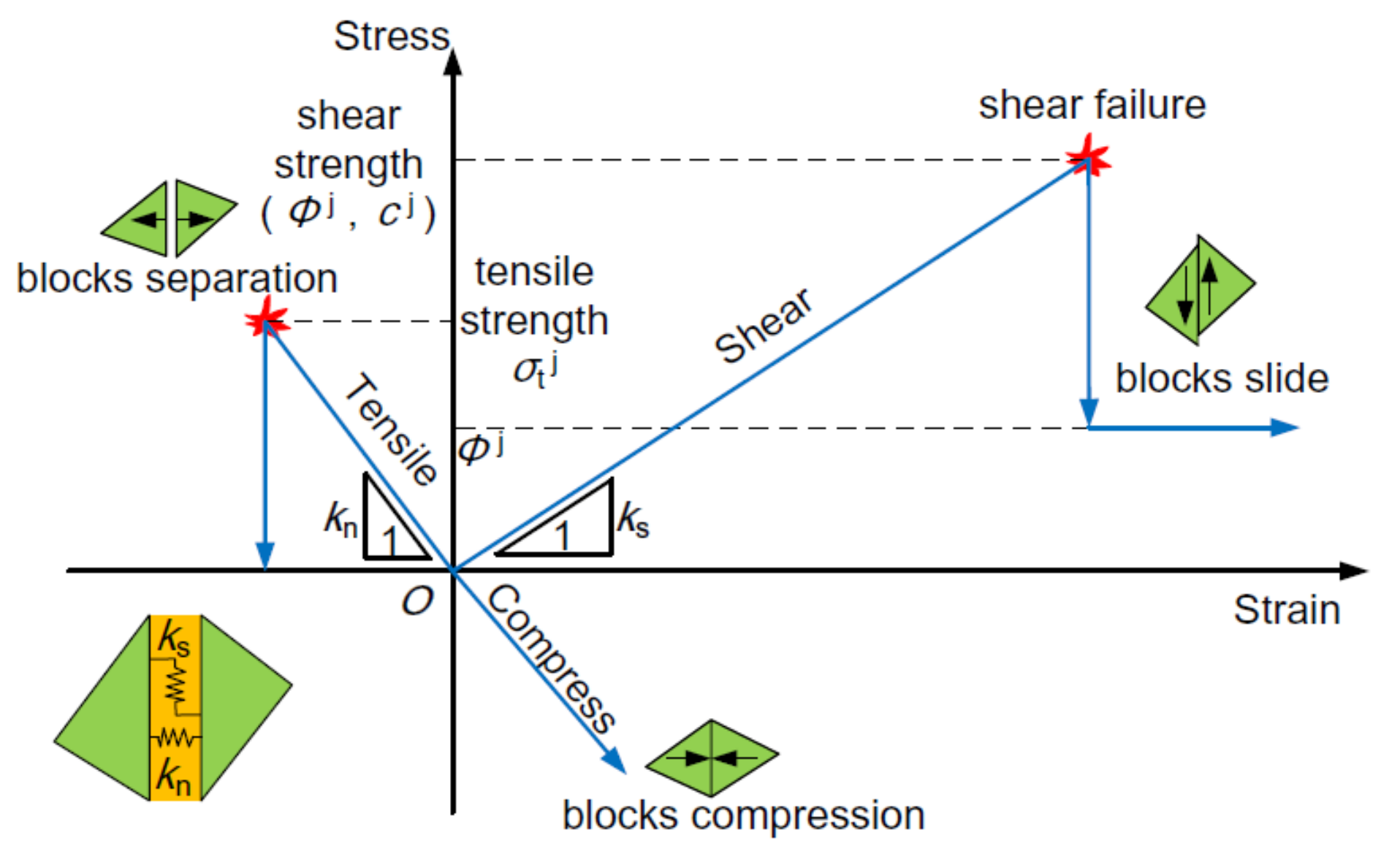

3.1. UDEC Trigon Approach

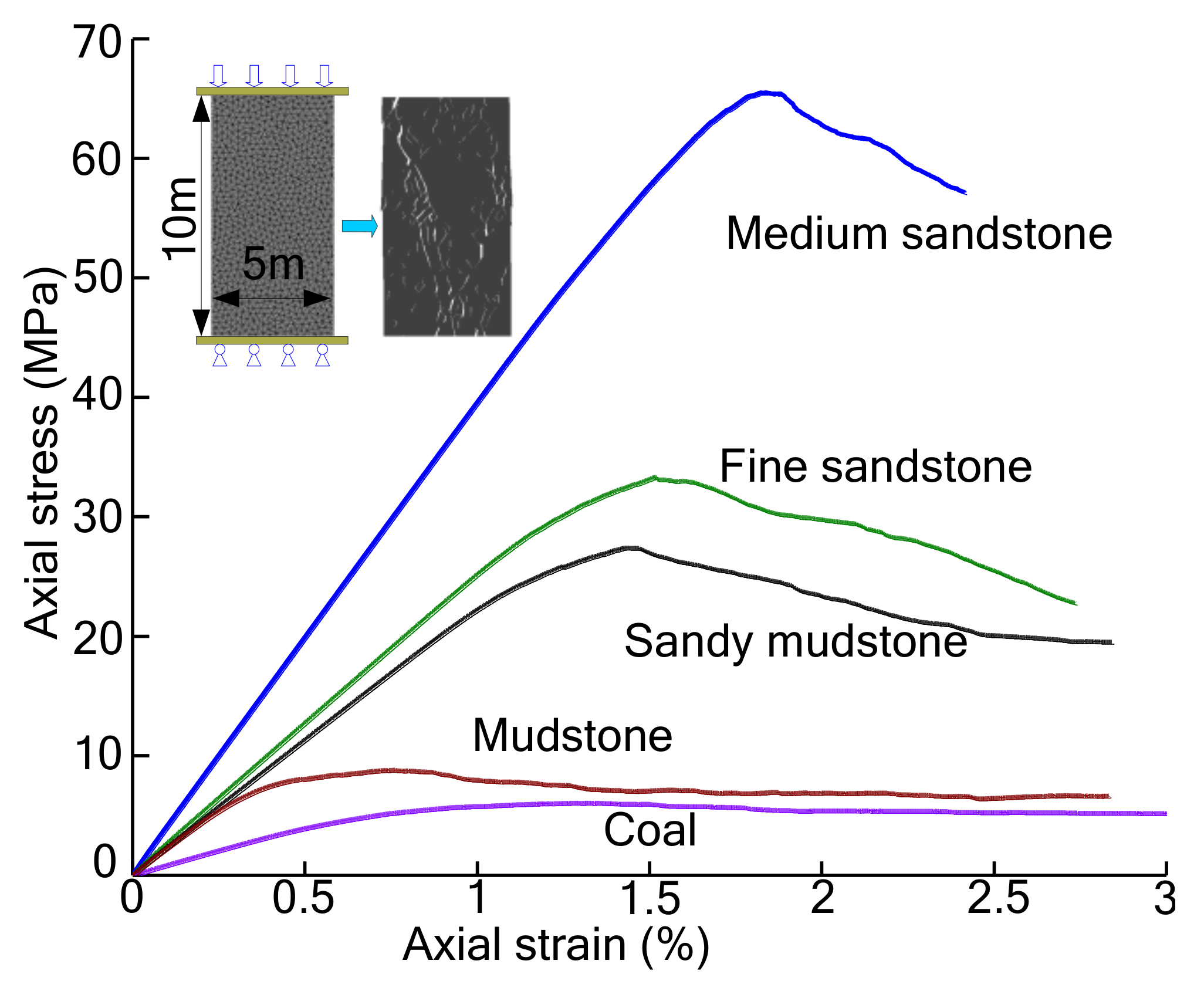

3.2. The Determination of Rock Mass Parameters in UDEC

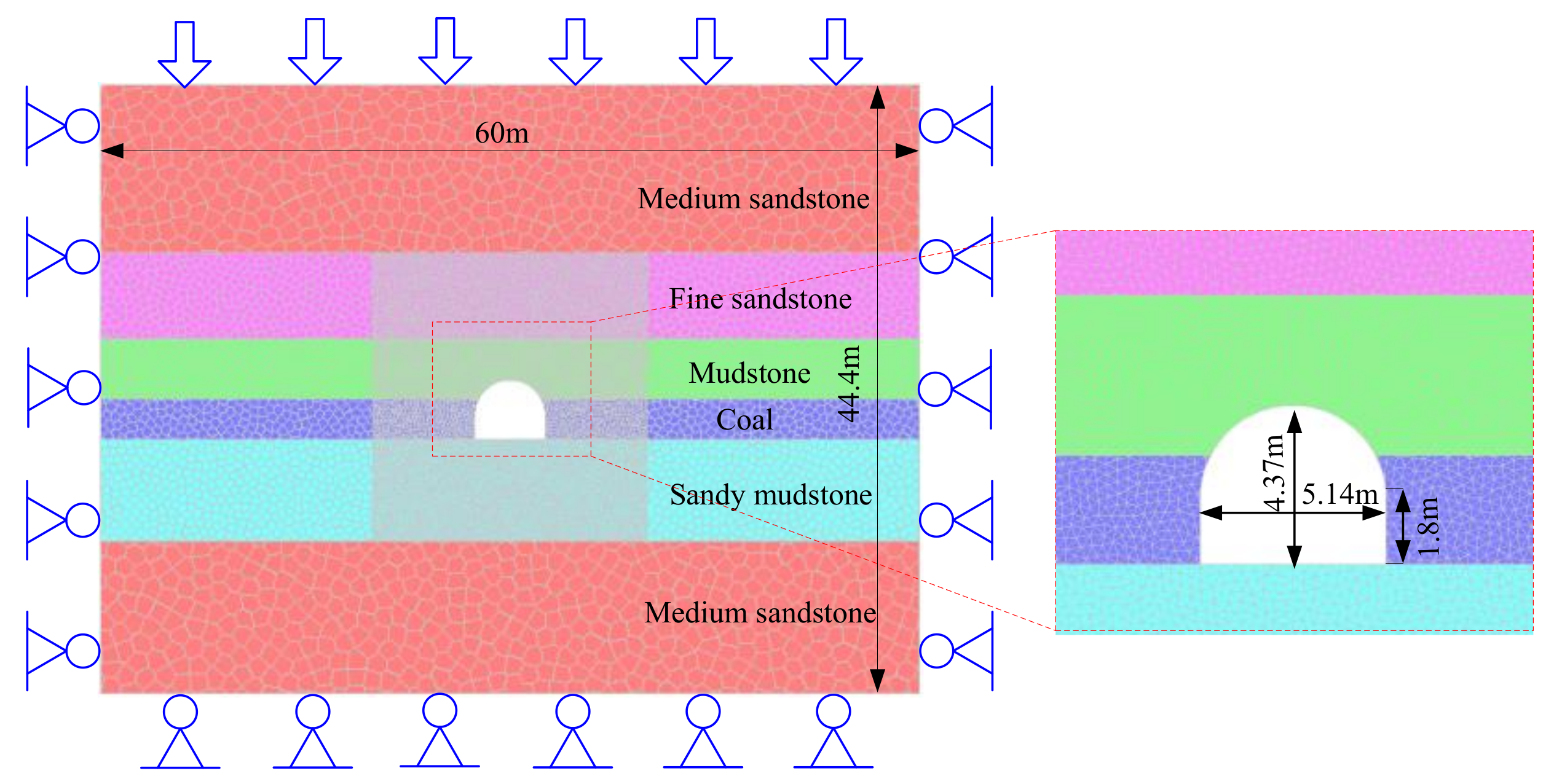

3.3. Discrete Element Model Simulation of Improved Support Scheme

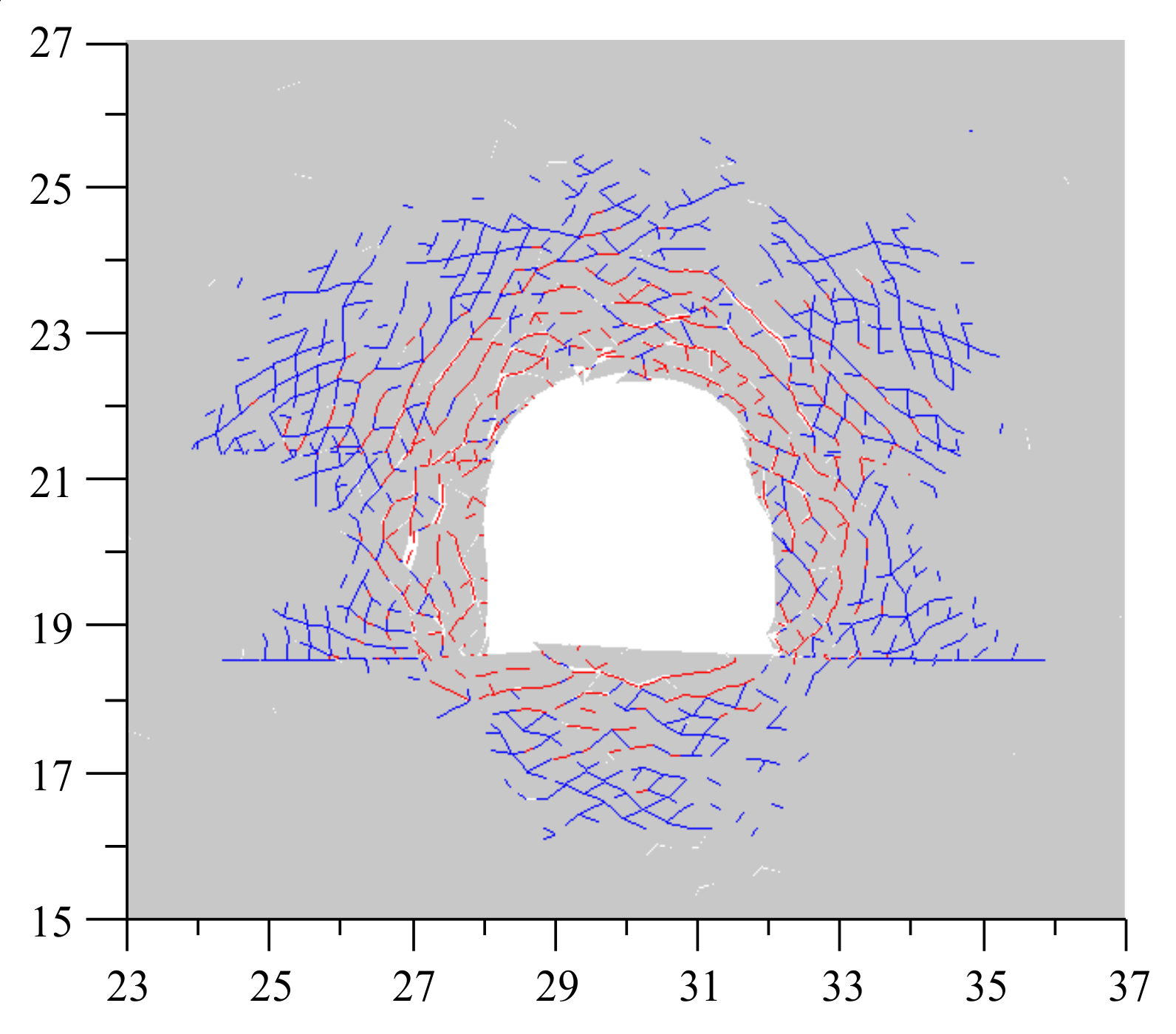

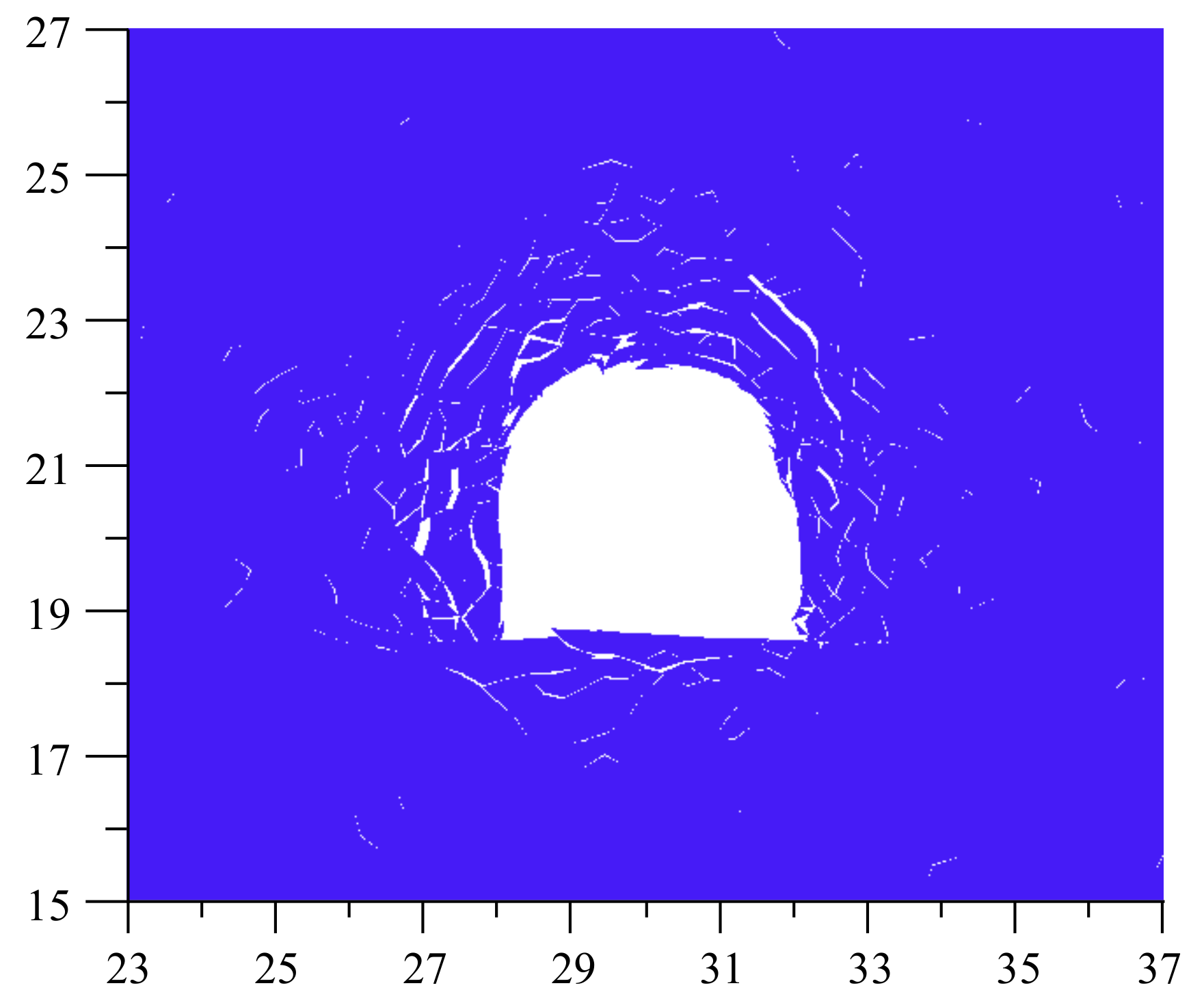

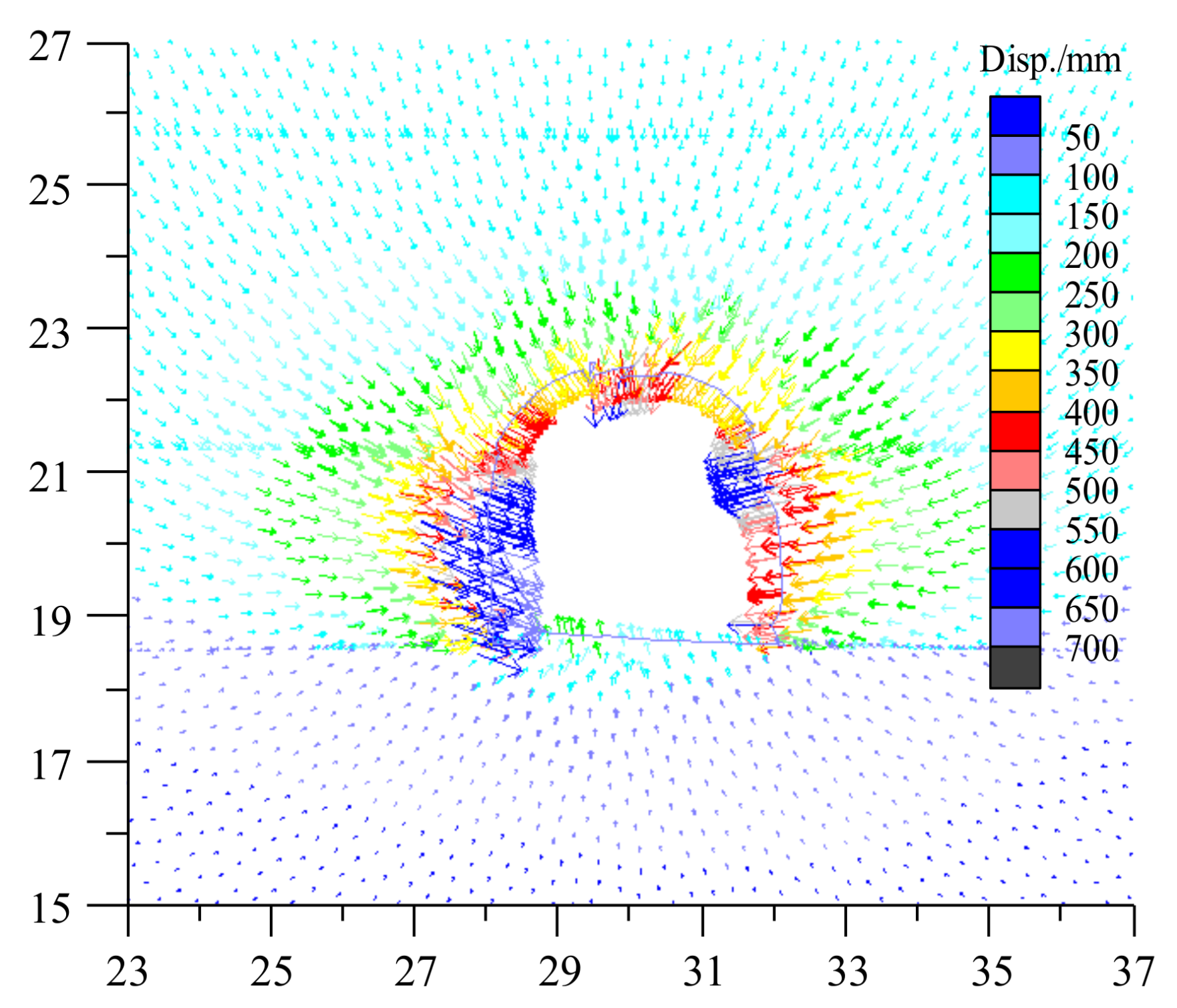

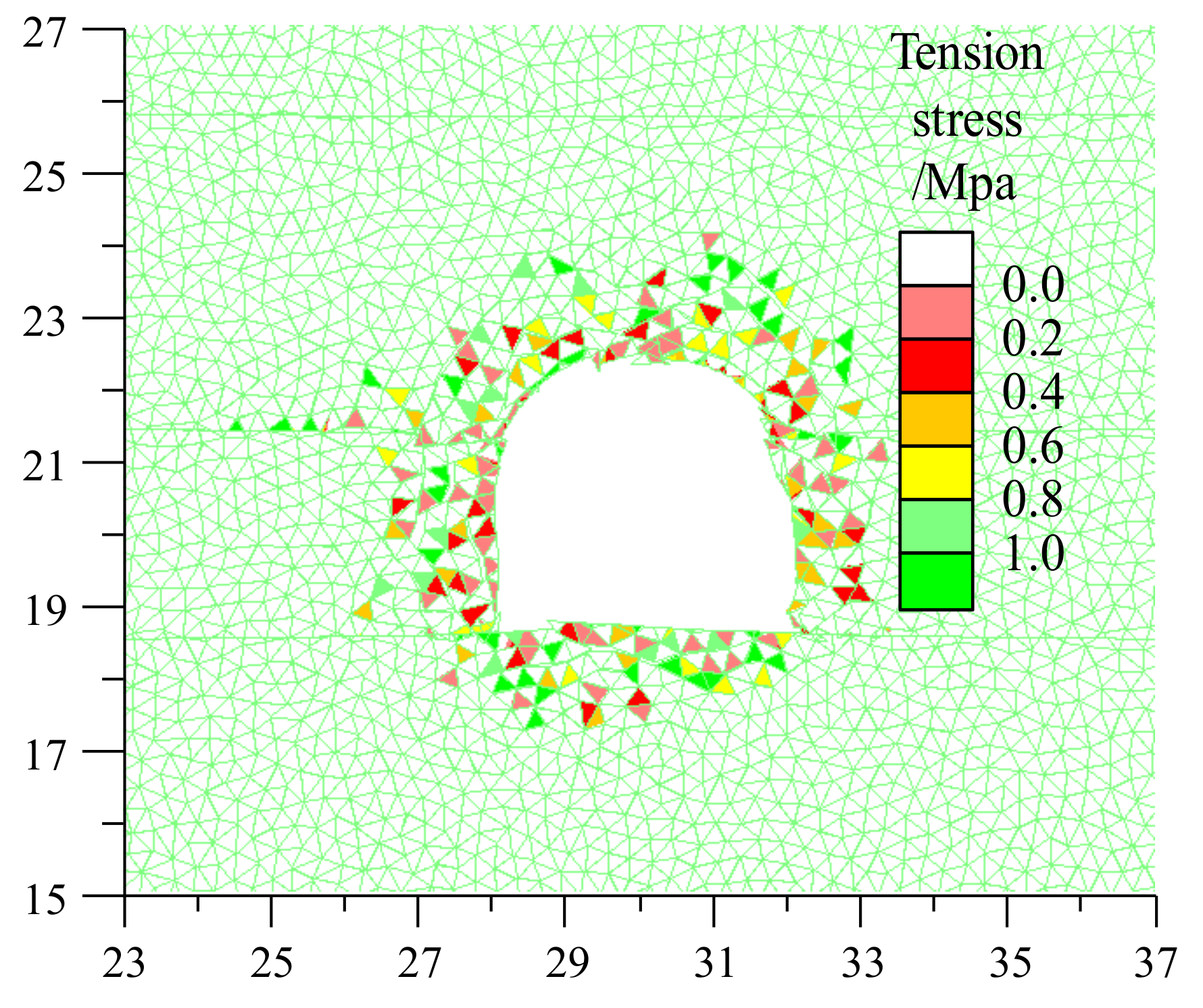

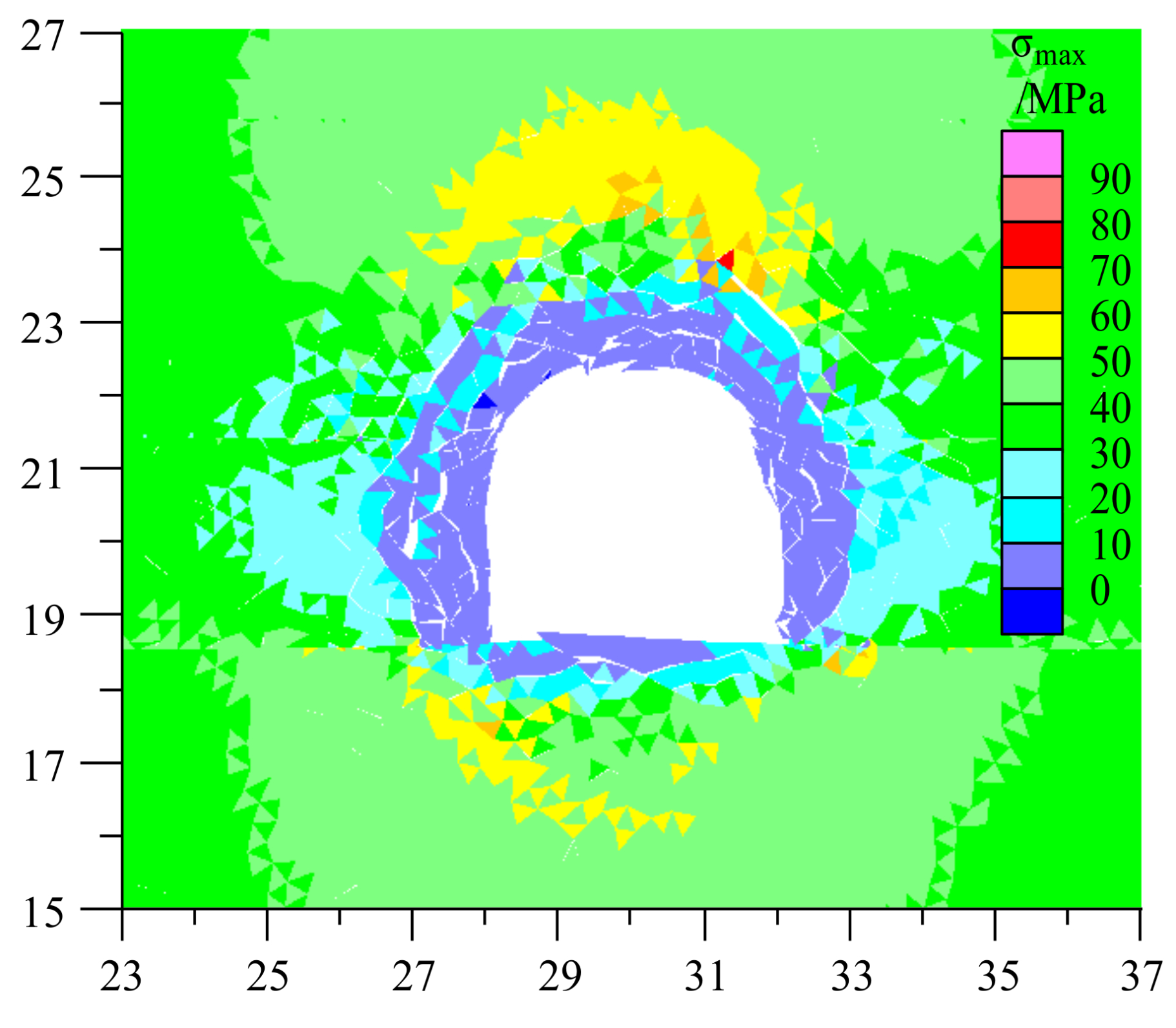

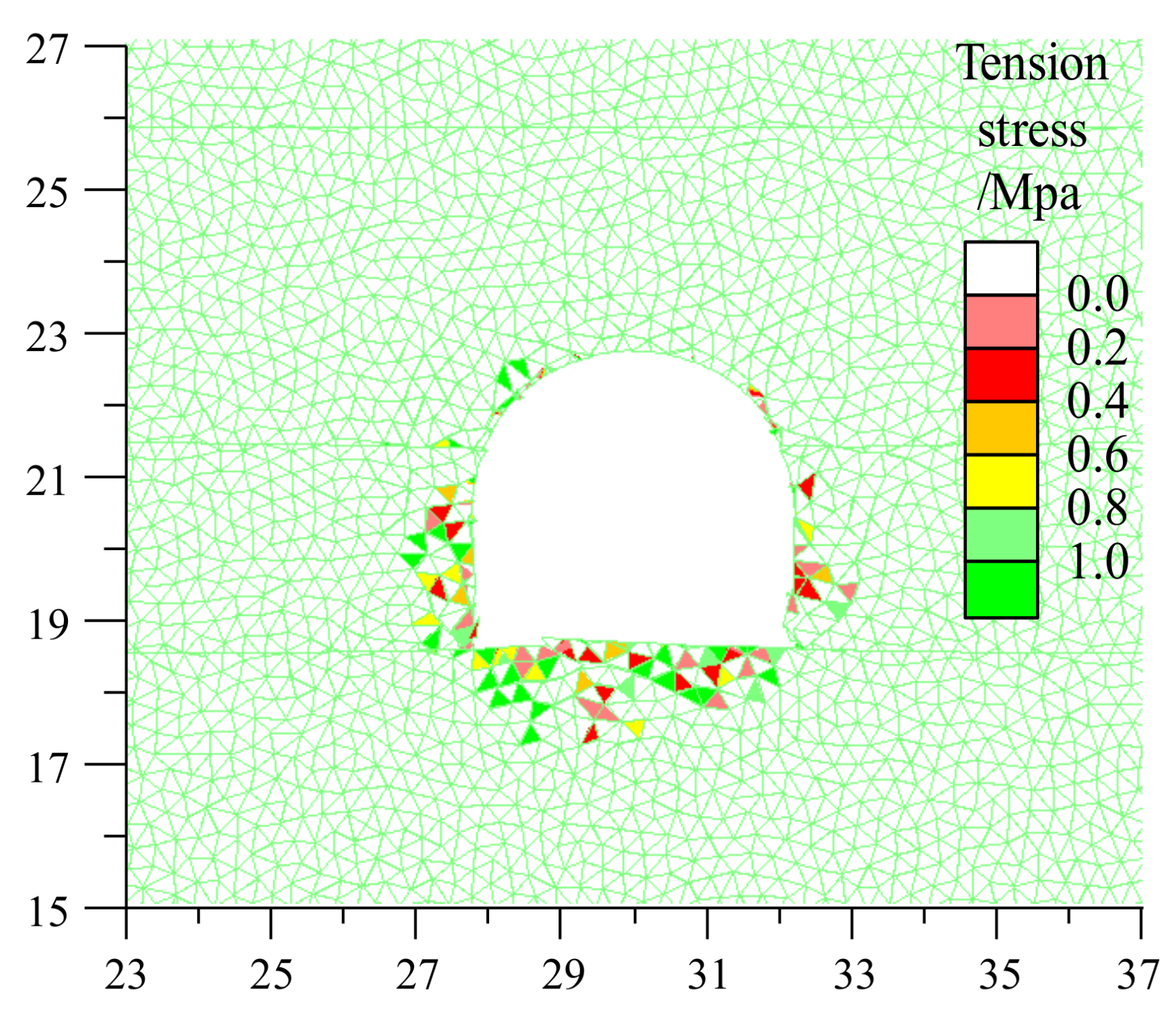

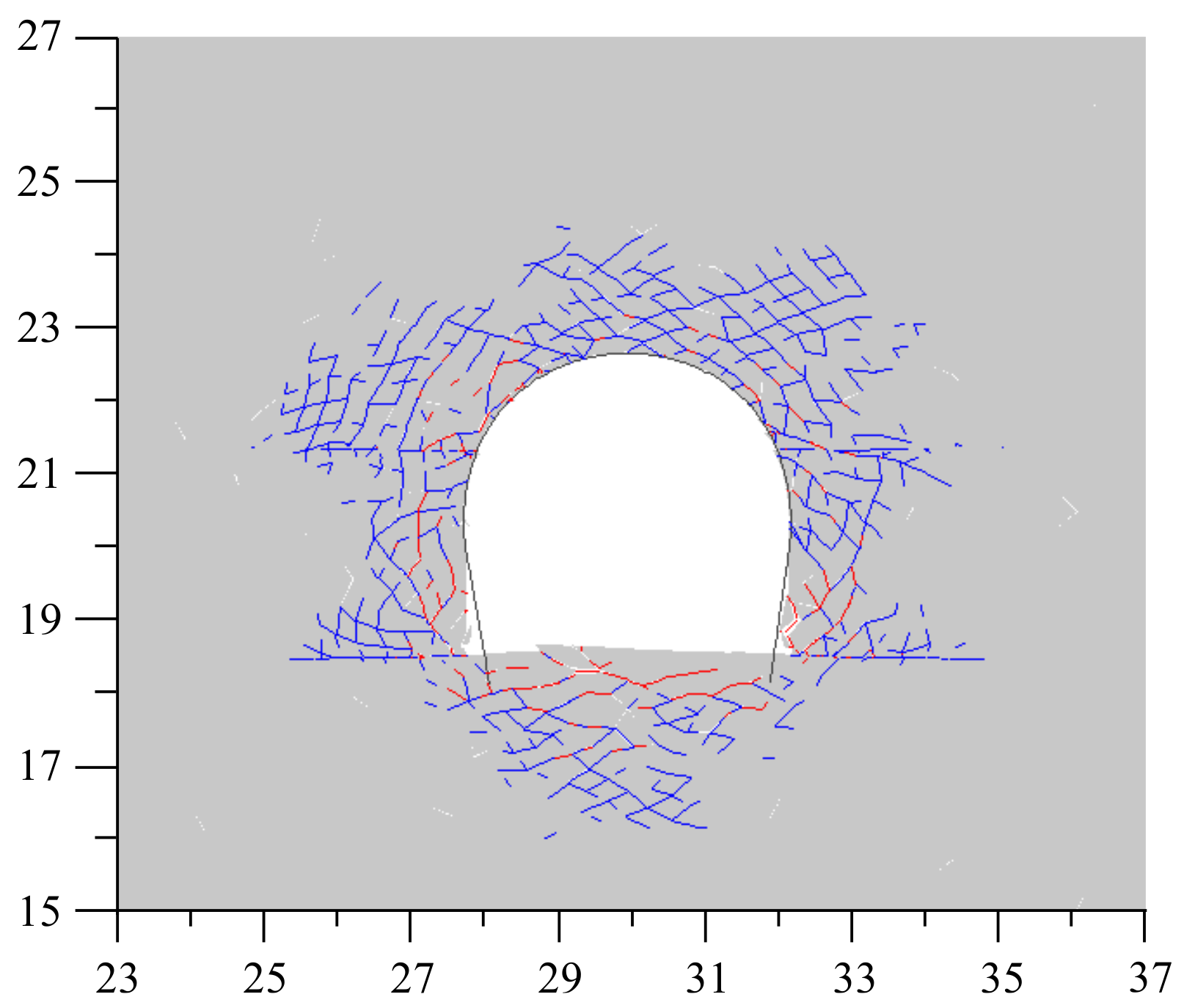

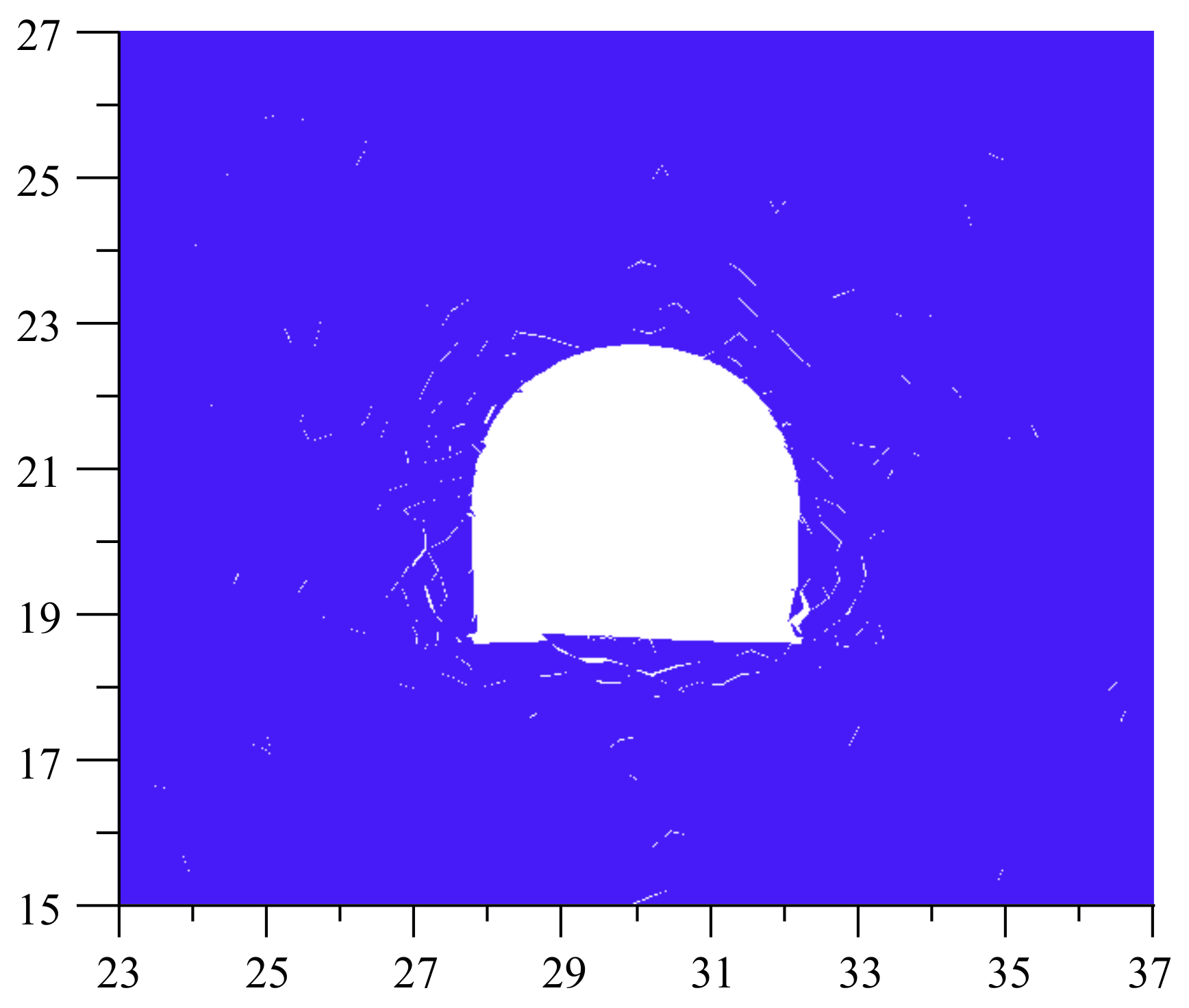

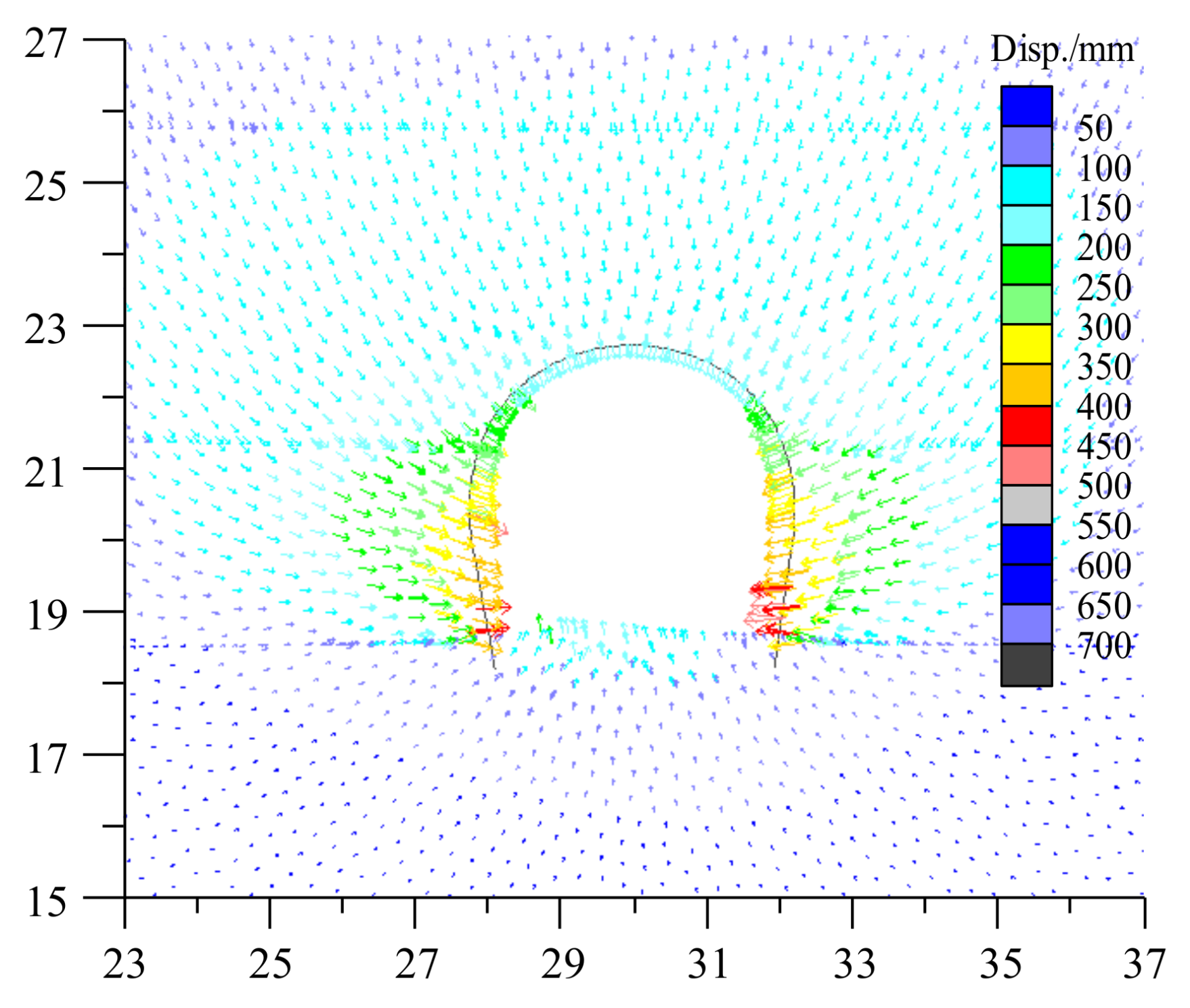

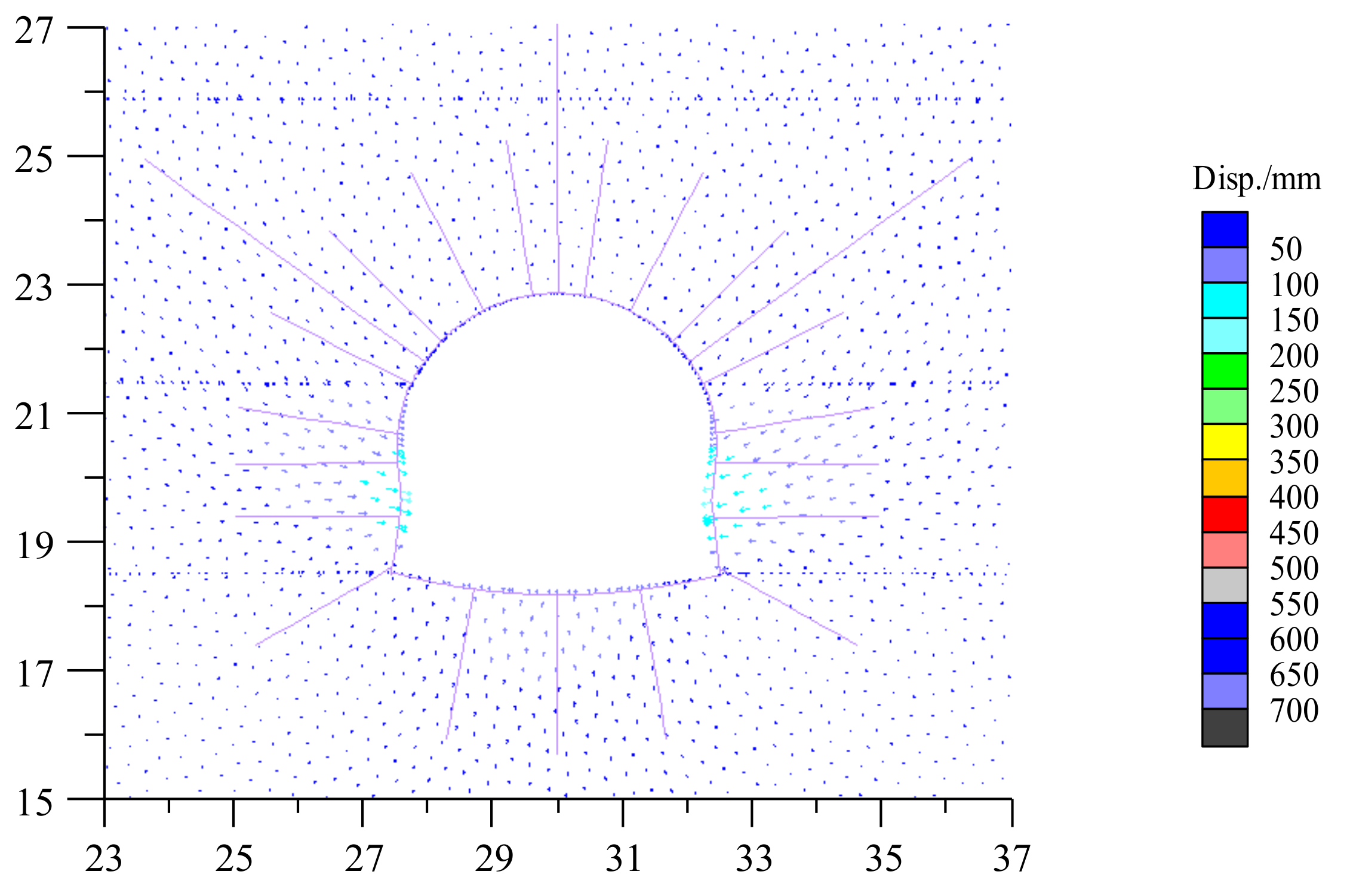

3.4. Large Deformation Mechanism in Deep Soft Rock Roadway

- The interaction between high deviator stress and low strength soft rock. The ground stress distributed around the tailgate was relatively high due to a buried depth of 800 m. The stress relief in the free face due to excavation resulted in high deviator stress and stress concentration, which exceeded the peak strength of soft surrounding rock and caused shallow weak surrounding rock to enter into the post-failure zone with a low residual strength. Tensile cracks then initiated due to tensile stresses and developed around the roadway, which caused the shallow surrounding rock to lose its bearing capacity and formed a large loose zone.

- Contradiction between large deformation and incomplete low-strength supporting structure. The compressive capability of the U-shaped steel sets was too weak to resist the large deformation of lose soft rock, and many broken and curved U-shaped steel sets were found in the roadway. In addition, the U-shaped steel sets were installed with insufficient pretension and shrunk seriously. The bearing capacity of shotcrete was poor and the poured shotcrete made it difficult to remove the grid arch frame during mining activities. The “U-shaped steel -shotcrete” support materials were only installed in the ribs and roof of the roadway, which did not constitute an integrated bearing structure on the roadway surface and led to serious floor bending and heaving.

4. Improvement of the Primary Support System

4.1. Support Principles of the Deep Soft Rock Roadway

4.2. Improved Support Scheme

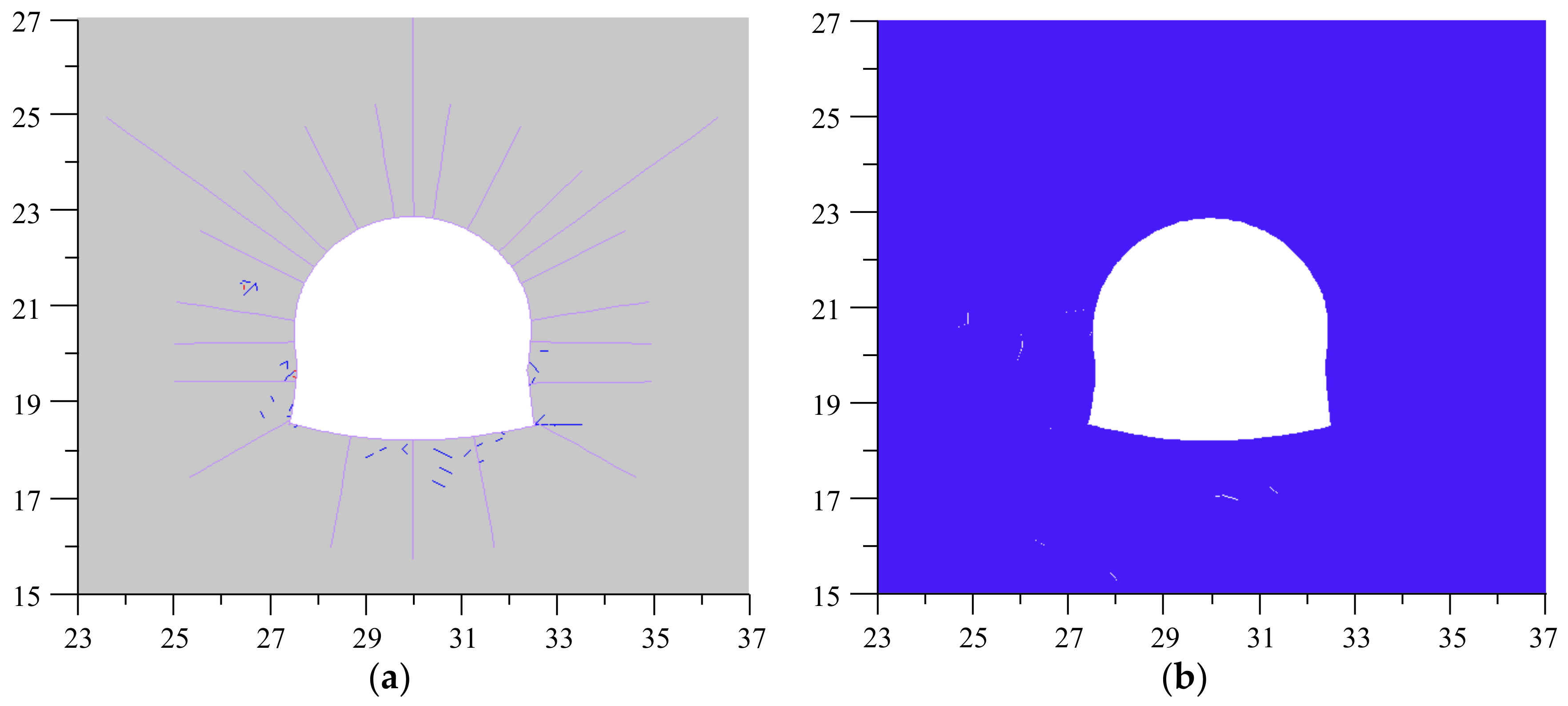

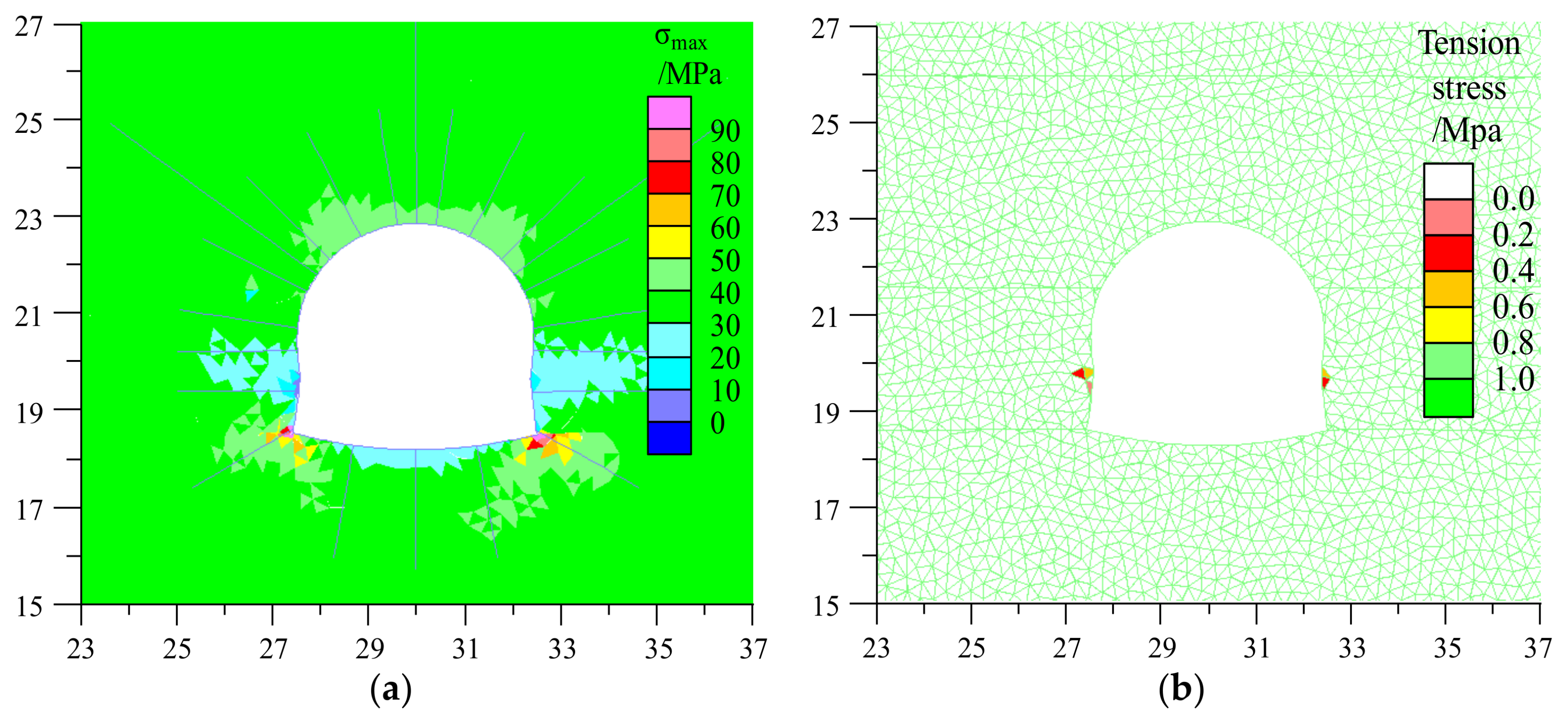

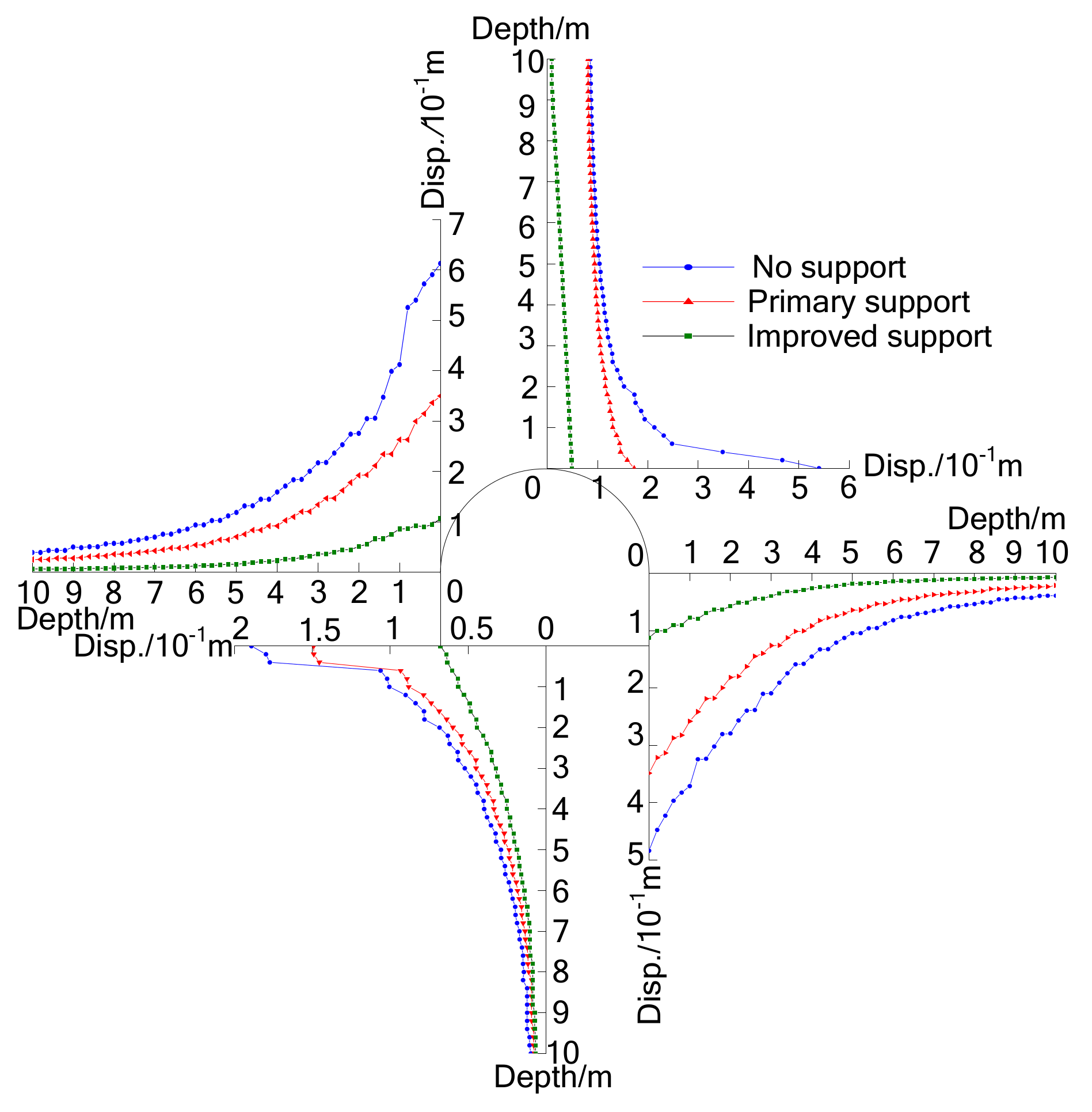

4.3. Simulation Verification of Improved Support Scheme

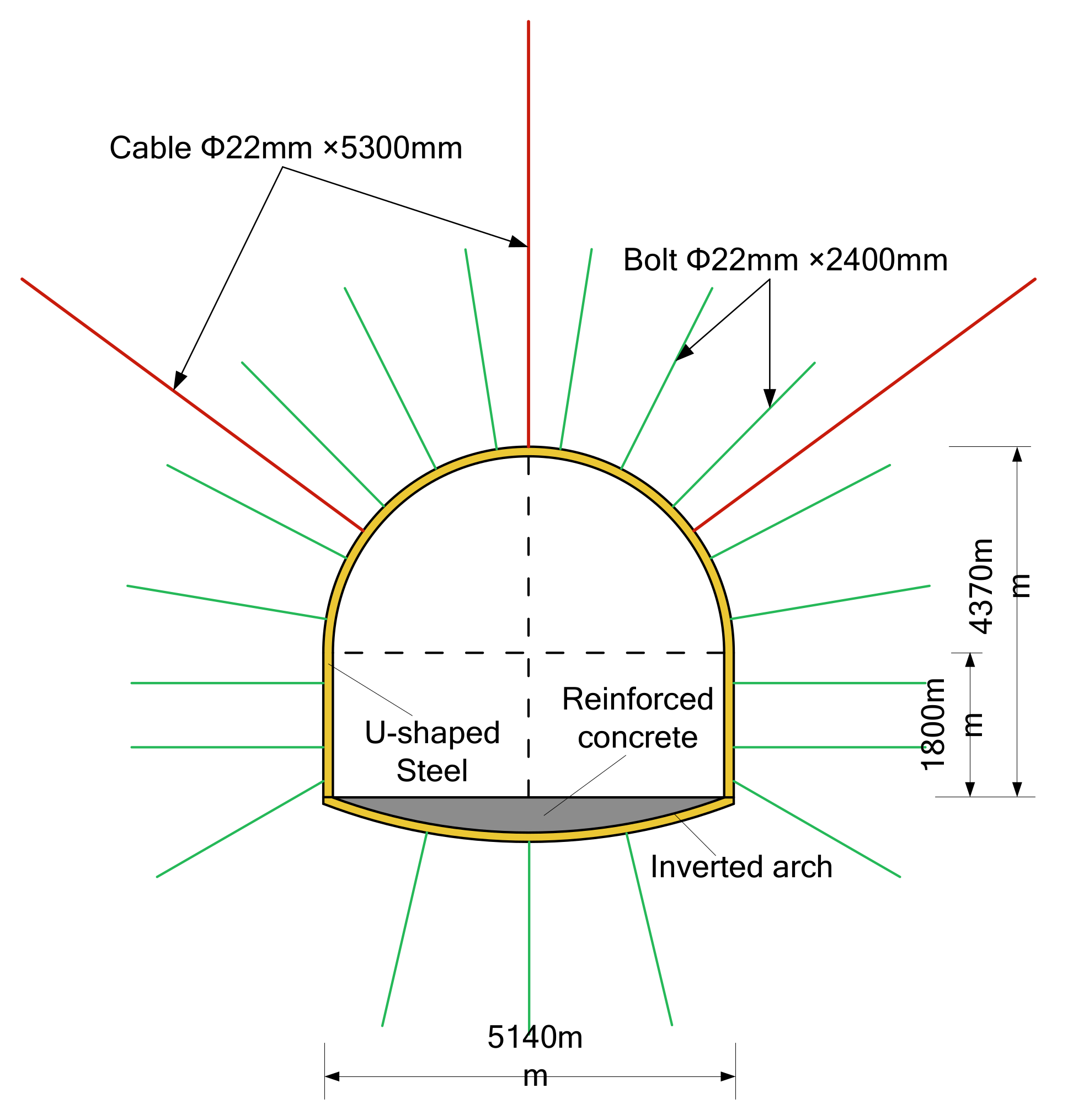

- “Bolt-cable-mesh” flexible support structure. Seventeen Φ22 mm × 2400 mm bolts were installed in the full cross-section with row spacing of 800 mm and column spacing of 900 mm. The tensile resistance of those bolts was not less than 120 kN with a pretension of 80 kN. Three Φ18.9 mm × 5300 mm cables were installed with high strength steel plates that were 450 mm long × 280 mm wide × 4 mm thick in the roof. The row spacing and column spacing of cables were 1600 mm × 2700 mm. The tensile capability of these cables was no less than 300 kN with a pretension of 120 kN. Bolts were designed to be installed with ladder beam 4000 mm long and wire mesh with a grid size of 100 mm × 100 mm.

- “Full-section U-shaped steel sets” rigid support structure. During construction of the yieldable 36 U-shaped steel sets, the inverted arch floor was first constructed. The rise–span ratio and rise of inverted arch floor were 1:12 and 400 mm, respectively. The 36 U-shaped steel sets were connected and fastened by five clamps with a pre-tightening torque of 300 N·m. After setting up the U-shaped steel sets, the shotcrete was poured in the inverted arch floor with a thickness of 350–400 mm. The strength of shotcrete was C20. The final support plan is shown in Figure 18.

4.4. Field application of Improved Support Scheme

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xie, H.P.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar] [CrossRef]

- Xie, H.P. Research Framework and Anticipated Results of Deep Rock Mechanics and Mining Theory. Adv. Eng. Sci. 2017, 49, 1–16. [Google Scholar] [CrossRef]

- He, M.C. Progress and challenges of soft rock engineering in depth. J. China Coal Soc. 2014, 39, 1409–1417. [Google Scholar] [CrossRef]

- Milici, R.C.; Flores, R.M.; Stricker, G.D. Coal resources, reserves and peak coal production in the United States. Int. J. Coal Geol. 2013, 113, 109–115. [Google Scholar] [CrossRef]

- Lechner, A.M.; Kassulke, O.; Unger, C. Spatial assessment of open cut coal mining progressive rehabilitation to support the monitoring of rehabilitation liabilities. Resour. Policy 2016, 50, 234–243. [Google Scholar] [CrossRef]

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar] [CrossRef]

- Gao, Y.B.; Liu, D.Q.; Zhang, X.Y.; He, M.C. Analysis and optimization of entry stability in underground longwall mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef]

- Yang, S.Q.; Chen, M.; Jing, H.W.; Chen, K.F.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2016, 217, 89–101. [Google Scholar] [CrossRef]

- Yang, X.J.; Pang, J.W.; Liu, D.M.; Liu, Y.; Tian, Y.H.; Ma, J.; Li, S.H. Deformation mechanism of roadways in deep soft rock at Hegang Xing’an Coal Mine. Int. J. Min. Sci. Technol. 2013, 23, 307–312. [Google Scholar] [CrossRef]

- Kang, H.P.; Lin, J.; Fan, M.J. Investigation on support pattern of a coal mine roadway within soft rocks—A case study. Int. J. Coal Geol. 2015, 140, 31–40. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, L.S.; Jiang, J.Q.; Zheng, P.Q.; Li, W. Strata behaviors and rock burst–inducing mechanism under the coupling effect of a hard, thick stratum and a normal fault. Int. J. Geomech. 2018, 18, 04017135. [Google Scholar] [CrossRef]

- Jiao, Y.Y.; Song, L.; Wang, X.Z.; Coffi Adoko, A. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam. Int. J. Rock Mech. Min. Sci. 2013, 60, 19–25. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Liu, N.; Zheng, X.G.; Zhang, N. Mechanical model for controlling floor heave in deep roadways with U-shaped steel closed support. Int. J. Min. Sci. Technol. 2015, 25, 713–720. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Lu, S. Deformational behaviour of roadways in soft rocks in underground coal mines and principles for stability control. Int. J. Rock Mech. Min. Sci. 2000, 37, 937–946. [Google Scholar] [CrossRef]

- Kang, H.P. Support technologies for deep and complex roadways in underground coal mines: A review. Int. J. Coal Sci. Technol. 2014, 1, 261–277. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Sarfarazi, V.; Schubert, W.; Blumel, M. A study of the failure mechanism of planar non-persistent open joints using PFC2D. Rock Mech. Rock. Eng. 2012, 45, 677–693. [Google Scholar] [CrossRef]

- Goel, R.K.; Swarup, A.; Sheorey, P.R. Bolt length requirement in underground openings. Int. J. Rock Mech. Min. Sci. 2007, 44, 802–811. [Google Scholar] [CrossRef]

- Karanam, U.M.R.; Dasyapu, S.K. Experimental and numerical investigations of stresses in a fully grouted rock bolts. Geotech. Geol. Eng. 2005, 23, 297–308. [Google Scholar] [CrossRef]

- Peng, S. Roof bolting adds stability to weak strata. Coal Age Mag. 1998, 11, 32–38. [Google Scholar]

- Mark, C. Design of roof bolt system. In Proceeding of New Technology for Coal Mine Roof Support; NIOSH: Washington, DC, USA, 2000; pp. 111–131. [Google Scholar]

- Yang, X.J.; Pang, J.W.; Lou, H.P.; Fan, L.P. Characteristics of in situ stress field at Qingshui coal mine. Int. J. Min. Sci. Technol. 2015, 25, 497–501. [Google Scholar] [CrossRef]

- Fairhurst, C.E.; Hudson, J.A. Draft ISRM suggested method for the complete stress-strain curve for the intact rock in uniaxial compression. Int. J. Rock Mech. Min. 1999, 36, 279–289. [Google Scholar] [CrossRef]

- Zhang, L.; Einstein, H.H. Using RQD to estimate the deformation modulus of rock masses. Int. J. Rock. Mech. Min. Sci. 2004, 41, 337–341. [Google Scholar] [CrossRef]

- Singh, M.; Seshagiri, R.K. Empirical methods to estimate the strength of jointed rock masses. Eng. Geol. 2005, 77, 127–137. [Google Scholar] [CrossRef]

- Gao, F.Q.; Stead, D. The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int. J. Rock Mech. Min. Sci. 2014, 68, 1–14. [Google Scholar] [CrossRef]

- Brady, B.H.G.; Brown, E.T. Rock Mechanics for Underground Mining, 3rd ed.; Springer Science and Business Media: New York, NY, USA, 2006. [Google Scholar]

- Itasca Consulting Group, Inc. UDEC User Manual; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2008. [Google Scholar]

- Yu, W.J.; Wang, W.J.; Chen, X.Y.; Du, S.H. Field investigations of high stress soft surrounding rocks and deformation control. J. Rock Mech. Geotech. Eng. 2015, 7, 421–433. [Google Scholar] [CrossRef]

- Diederichs, M.; Kaiser, P.; Eberhardt, E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int. J. Rock Mech. Min. Sci. 2004, 41, 785–812. [Google Scholar] [CrossRef]

- Gao, F.Q.; Kang, H.P. Effects of pre-existing discontinuities on the residual strength of rock mass–Insight from a discrete element method simulation. J. Struct. Geol. 2016, 85, 40–50. [Google Scholar] [CrossRef]

| Lithology | Intact Rock | Rock Mass | ||||

|---|---|---|---|---|---|---|

| σci (MPa) | Eci (GPa) | RQD | Em (GPa) | σcm (MPa) | σtm (MPa) | |

| Medium sandstone | 103.0 | 6.36 | 87 | 3.25 | 65.66 | 6.57 |

| Fine sandstone | 59.6 | 5.82 | 81 | 2.3 | 31.99 | 3.2 |

| Mudstone | 21.4 | 4.66 | 71 | 1.2 | 8.62 | 0.86 |

| Coal | 19.2 | 2.46 | 62 | 0.43 | 5.97 | 0.6 |

| Sandy mudstone | 54.5 | 5.47 | 78 | 1.9 | 26.84 | 2.68 |

| Lithology | Matrix Properties | Contact Properties | |||||

|---|---|---|---|---|---|---|---|

| Density (kg·m−3) | E GPa | Kn (GPa·m−1) | Ks (GPa·m−1) | Cj (MPa) | φj (°) | σtj (MPa) | |

| Medium sandstone | 2750 | 3.25 | 314.3 | 125.7 | 9.93 | 42 | 6.57 |

| Fine sandstone | 2680 | 2.3 | 237.5 | 95 | 6.8 | 32 | 3.2 |

| Mudstone | 2140 | 1.2 | 172.4 | 69.1 | 1.95 | 21 | 0.86 |

| 2#Coal | 1920 | 0.43 | 94.9 | 38 | 1.45 | 19 | 0.6 |

| Sandy mudstone | 2600 | 1.9 | 214.9 | 86 | 6.29 | 27 | 2.68 |

| Parameters | Elastic Moduli (GPa) | Tensile Strength (MPa) | Compressive Strength (MPa) | Contact Normal Stiffness (GPa·m-1) | Contact Shear Stiffness (GPa·m-1) |

|---|---|---|---|---|---|

| U-shaped steel sets | 200 | 50 | 50 | 4 | 4 |

| Concrete | 30.5 | 2.2 | 16.7 | 2 | 2 |

| Parameters | Density (kg·m−3) | Elastic Moduli (GPa) | Tensile Capability (kN) | Bond Stiffness (N/m2) | Bond Strength (N/m) | Pretension (kN) |

|---|---|---|---|---|---|---|

| Cable | 7500 | 200 | 300 | 2e9 | 4e5 | 120 |

| Bolt | 7500 | 200 | 120 | 2e9 | 4e5 | 80 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wang, E.; Wang, Y.; Gao, Y.; Wang, P. A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways. Sustainability 2018, 10, 1100. https://doi.org/10.3390/su10041100

Yang X, Wang E, Wang Y, Gao Y, Wang P. A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways. Sustainability. 2018; 10(4):1100. https://doi.org/10.3390/su10041100

Chicago/Turabian StyleYang, Xiaojie, Eryu Wang, Yajun Wang, Yubing Gao, and Pu Wang. 2018. "A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways" Sustainability 10, no. 4: 1100. https://doi.org/10.3390/su10041100

APA StyleYang, X., Wang, E., Wang, Y., Gao, Y., & Wang, P. (2018). A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways. Sustainability, 10(4), 1100. https://doi.org/10.3390/su10041100