Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels

Abstract

:1. Introduction

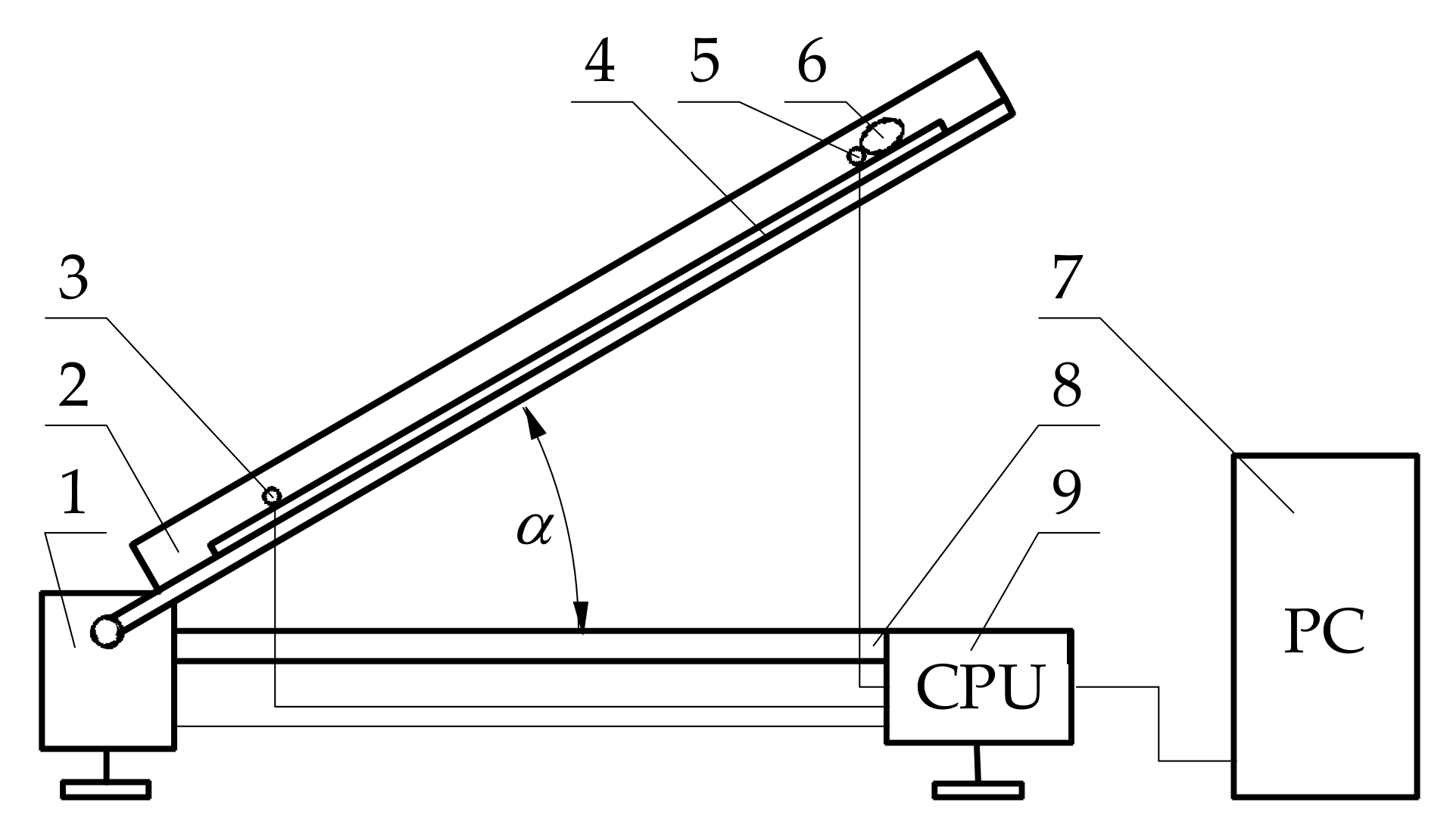

2. Materials and Methods

2.1. Sample Preparation

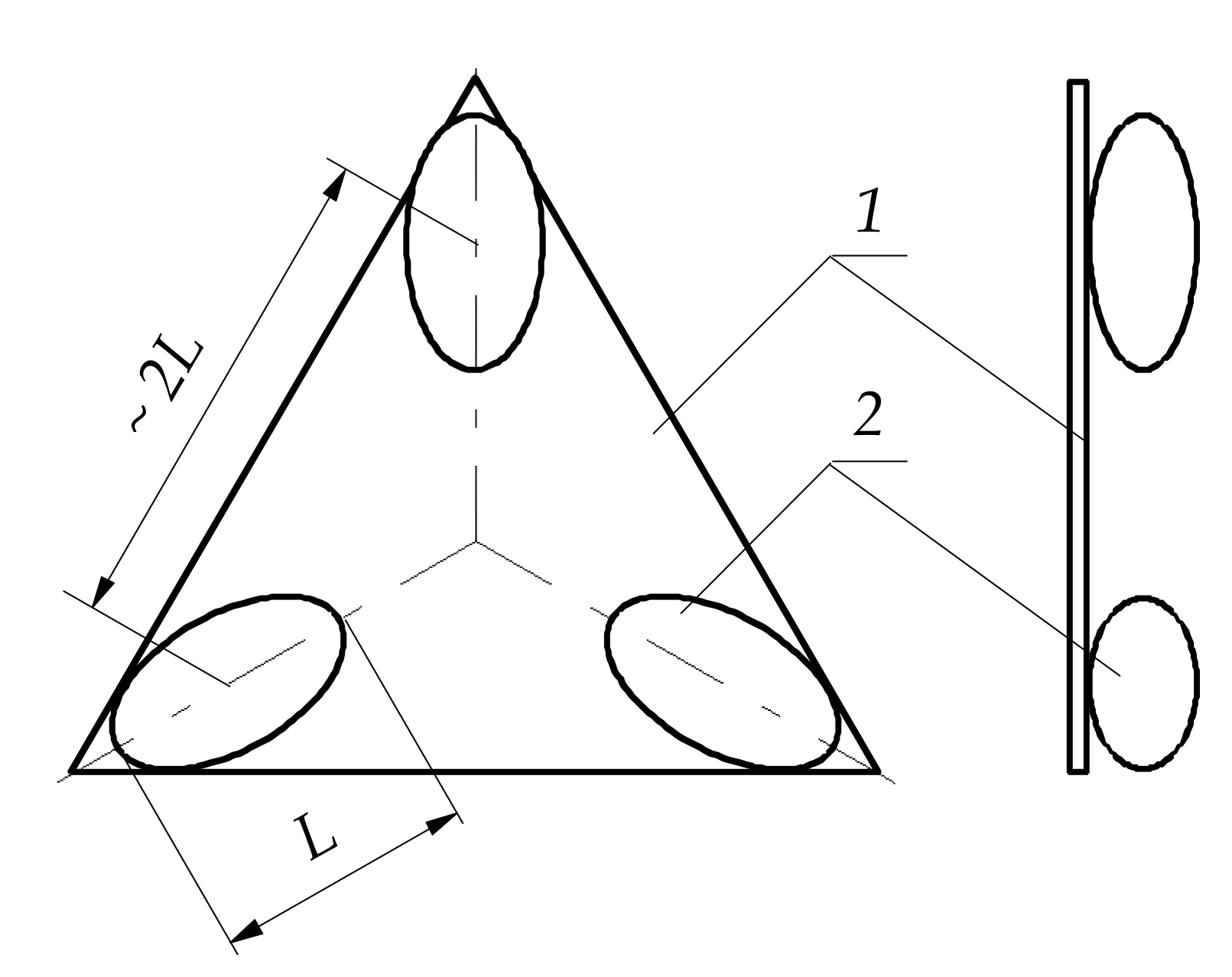

2.2. Physical Properties

- density ρ (on the assumption that kernel shape resembles an ellipsoid):

2.3. Statistical Analysis

3. Results

3.1. Experimental Material

3.2. Angle of External Friction

3.3. Correlation between Plate Roughness and the Angle of External Friction of Cereal Kernels

4. Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Frączek, J. Tarcie Ziarnistych Materiałów Roślinnych [Friction of Granular Materials of Plant Origin]; Akademia Rolnicza: Cracow, Poland, 1999; pp. 1–114. ISSN 12334189. (In Polish) [Google Scholar]

- Frączek, J.; Kaczorowski, J.; Ślipek, Z.; Horabik, J.; Molenda, M. Standaryzacja Metod Pomiaru Właściwości Fizyko-Mechanicznych Roślinnych Materiałów Ziarnistych [Standardization of Methods for the Determination of the Physical and Mechanical Properties of Granular Plant Materials]; Acta Agrophysica: Lublin, Poland, 2003; pp. 1–160. ISSN 12344125. (In Polish) [Google Scholar]

- Afzalinia, S.; Roberge, M. Physical and mechanical properties of selected forage materials. Can. Biosyst. Eng. 2007, 49, 2–23. [Google Scholar]

- Wiącek, J.; Molenda, M.; Horabik, J. Mechanical Properties of Granular Agro-Materials. Cintinuum and Discrete Approach; Acta Agrophysica: Lublin, Poland, 2011; pp. 1–152. ISSN 12344125. [Google Scholar]

- Bridwater, J. Mixing powders and granular materials by mechanical means—A perspective. Particuology 2012, 10, 397–427. [Google Scholar] [CrossRef]

- Mahjoub, M.; Movahhed, S.; Chenarbon, H.A. Effective parameters on angle of repose, internal and external friction coefficient in two wheat varieties (Behrang and Shirudi). Int. J. Biosci. 2014, 5, 117–124. [Google Scholar] [CrossRef]

- Królczyk, J.B. Metrological changes in the surface morphology of cereal grains in the mixing process. Int. Agrophys. 2016, 30, 192–202. [Google Scholar] [CrossRef]

- Paczyński, P. Metrologia Techniczna. Przewodnik do Wykładów, Ćwiczeń i Laboratoriów [Technical Metrology. A Guide Book for Lectures and Workshops]; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 2003; ISBN 8371435320. (In Polish) [Google Scholar]

- Dzierwa, A. Influence of light intensity in optical profilometer on measurement results of surface topography. Aparatura Badawcza i Dydaktyczna 2017, 4, 227–235. (In Polish) [Google Scholar]

- Polish Committee for Standardization. Specyfikacje Geometrii Wyrobów—Struktura Geometryczna powierzchni: Metoda profilowa—Terminy, Definicje i Parametry Struktury Geometrycznej Powierzchni [Geometrical Product Specifications—Geometric Structure of Surfaces: The Profile Method—Terms, Definitions and Parameters of Geometric Surface Structures]; Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish) [Google Scholar]

- Polish Committee for Standardization. Specyfikacje Geometrii Wyrobów (GPS)—Struktura Geometryczna Powierzchni: Przestrzenna—Część 2: Terminy, Definicje i Parametry Struktury Geometrycznej Powierzchni [Geometrical Product Specifications (GPS)—Geometric Structure of Surfaces—Part 2: Terms, Definitions and Parameters of Geometric Surface Structures]; Polish Committee for Standardization: Warsaw, Poland, 2010. [Google Scholar]

- Molenda, M.; Horabik, J.; Grochowicz, M.; Szot, B. Tarcie Ziarna Pszenicy [Friction of Wheat Grain]; Acta Agrophisica: Lublin, Poland, 1995; pp. 1–88. ISSN 12344125. (In Polish) [Google Scholar]

- Horabik, J. Charakterystyka Właściwości Fizycznych Roślinnych Materiałów Sypkich Istotnych w Procesach Składowania [Physical Attributes of Loose Plant Material Which Are Significant during Storage]; Acta Agrophysica: Lublin, Poland, 2001; pp. 1–128. ISSN 12344125. (In Polish) [Google Scholar]

- Molenda, M.; Horabik, J. On applicability of a direct shear test for strength estimation of cereal grain. Part. Part. Syst. Char. 2004, 21, 310–315. [Google Scholar] [CrossRef]

- Bakun-Mazor, D.; Hatzor, Y.H.; Glaser, S.D. Dynamic sliding of tetrahedral wedge: The role of interface friction. Int. J. Numer. Anal. Methods Geomech. 2012, 36, 327–343. [Google Scholar] [CrossRef]

- Sharobeem, Y.F. Apparent dynamic friction coefficients for grain crops. Misr J. Agric. Eng. 2007, 24, 557–574. [Google Scholar]

- Ibrahim, M.M. Determination of dynamic coefficient of friction for some materials for feed pellet under different values of pressure and temperature. Misr J. Agric. Eng. 2008, 25, 1389–1409. [Google Scholar]

- Kaliniewicz, Z.; Anders, A.; Markowski, P.; Jadwisieńczak, K.; Rawa, T. Influence of cereal seed orientation on external friction coefficients. Trans. ASABE 2016, 59, 1073–1081. [Google Scholar] [CrossRef]

- Greń, J. Statystyka Matematyczna. Modele i Zadania [Mathematical Statistics. Models and Tasks]; PWN: Warszawa, Poland, 1984; (In Polish). ISBN 830103699. [Google Scholar]

- Kaliniewicz, Z.; Rawa, T. Laboratorium z Maszyn Rolniczych [Laboratory of Agricultural Machinery]; Uniwersytet Warmińsko-Mazurski: Olsztyn, Poland, 2000; ISBN 8388343181. (In Polish) [Google Scholar]

- Kaliniewicz, Z.; Markowski, P.; Anders, A.; Jadwisieńczak, B.; Rawa, T.; Szczechowicz, D. Basic physical properties of Norway spruce (Picea abies (L.) Karst.) seeds. Tech. Sci. 2016, 19, 103–115. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Gordon and Breach Science Public: New York, NY, USA, 1986; ISBN 9780677213705. [Google Scholar]

- Bakier, S.; Konopka, S.; Lipiński, A.; Anders, A.; Obidziński, S.; Bareja, K.; Bajko, E. Innowacyjne Metody w Badaniach Agrotechnicznych [Innovative Methods in Agricultural Engineering]; Polska Akademia Nauk, Komitet Agrofizyki PAN, Wydawnictwo Naukowe FRNA: Lublin, Poland, 2015; (In Polish). ISBN 9788360489284. [Google Scholar]

- Rabiej, M. Statystyka z Programem Statistica [Statisctics in Statistica Software]; Helion: Gliwice, Poland, 2012; ISBN 9788324641109. (In Polish) [Google Scholar]

- Hebda, T.; Micek, P. Dependences between geometrical features of cereal grain. Inżynieria Rolnicza 2005, 6, 233–241. (In Polish) [Google Scholar]

- Hebda, T.; Micek, P. Geometric features of grain for selected corn varieties. Inżynieria Rolnicza 2007, 5, 187–193. (In Polish) [Google Scholar]

- Horabik, J.; Molenda, M. Właściwości Fizyczne Sypkich Surowców Spożywczych [Physical Properties of Granular Food Materials]; Acta Agrophysica: Lublin, Poland, 2002; pp. 1–96. ISSN 12344125. (In Polish) [Google Scholar]

- Boac, J.M.; Casada, M.E.; Maghirang, R.G.; Harner, J.P., III. Material and interaction properties of selected grains and oilseeds for modeling discrete particles. Trans. ASABE 2010, 53, 1201–1216. [Google Scholar] [CrossRef]

- Kim, K.H.; Shin, S.H.; Park, S.; Park, J.C.; Kang, C.S.; Park, C.S. Relationship between pre-harvest sprouting and functional markers associated with grain weight, TaSUS2-2B, TaGW2-6A, and TaCWI-A1, in Korean wheat cultivars. SABRAO J. Breed. Genet. 2014, 46, 319–328. [Google Scholar]

- Mabille, F.; Abecassis, J. Parametric modelling of wheat grain morphology: A new perspective. J. Cereal Sci. 2003, 37, 43–53. [Google Scholar] [CrossRef]

- Kalkan, F.; Kara, M. Handling, frictional and technological properties of wheat as affected by moisture content and cultivar. Powder Tech. 2011, 213, 116–122. [Google Scholar] [CrossRef]

- Kram, B.B. Research on the coefficient of external friction of corn grain in humidity function. Inżynieria Rolnicza 2006, 3, 175–182. (In Polish) [Google Scholar]

- Kaliniewicz, Z. Analysis of frictional properties of cereal seeds. Afr. J. Agric. Res. 2013, 8, 5611–5621. [Google Scholar] [CrossRef]

- Markowski, M.; Majewska, K.; Kwiatkowski, D.; Malkowski, M.; Burdylo, G. Selected geometric and mechanical properties of barley (Hordeum vulgare L.) grain. Int. J. Food Prop. 2010, 13, 890–903. [Google Scholar] [CrossRef]

- Markowski, M.; Żuk-Gołaszewska, K.; Kwiatkowski, D. Influence of variety on selected physical and mechanical properties of wheat. Ind. Crops Prod. 2013, 47, 113–117. [Google Scholar] [CrossRef]

- Kaczorowski, J.; Ślipek, Z. Modelling of the external friction kinetic process in plant materials. Part II. Determination of the real contact area during kinetic friction of plant materials. Ann. Rev. Agric. Eng. 1996, 1, 87–94. [Google Scholar]

| Plate | Roughness Parameters (μm) | |||||

|---|---|---|---|---|---|---|

| Ra | Rz | Rmax | R3z | Rt | Rq | |

| 1 | 0.36 | 2.8 | 4.1 | 2.0 | 4.2 | 0.49 |

| 2 | 0.47 | 3.2 | 4.2 | 2.6 | 4.4 | 0.61 |

| 3 | 0.90 | 4.6 | 6.5 | 3.9 | 6.5 | 1.10 |

| 4 | 1.28 | 6.9 | 9.1 | 5.4 | 11.3 | 1.62 |

| 5 | 2.45 | 15.4 | 18.3 | 11.7 | 18.4 | 3.28 |

| 6 | 3.70 | 22.7 | 29.1 | 17.0 | 29.1 | 4.90 |

| 7 | 4.78 | 23.6 | 36.8 | 19.3 | 39.1 | 6.48 |

| 8 | 5.66 | 27.4 | 37.8 | 23.2 | 40.8 | 7.38 |

| 9 | 6.72 | 36.9 | 53.9 | 29.2 | 53.9 | 9.11 |

| Physical Parameter a | Cereal Species | ||||

|---|---|---|---|---|---|

| Wheat | Rye | Barley | Oats | Triticale | |

| x ± SD | x ± SD | x ± SD | x ± SD | x ± SD | |

| Moisture (% dry basis) | 9.5 ± 0.02 | 9.7 ± 0.02 | 10.2 ± 0.03 | 9.9 ± 0.03 | 9.7 ± 0.02 |

| Thickness (mm) | 3.09 ± 0.16 | 2.64 ± 0.17 | 3.11 ± 0.14 | 2.71 ± 0.16 | 3.06 ± 0.21 |

| Width (mm) | 3.58 ± 0.23 | 2.76 ± 0.22 | 3.88 ± 0.16 | 3.33 ± 0.21 | 3.33 ± 0.22 |

| Length (mm) | 6.70 ± 0.30 | 7.90 ± 0.41 | 9.28 ± 0.47 | 11.52 ± 0.91 | 8.25 ± 0.39 |

| Mass (mg) | 52.0 ± 6.66 | 35.8 ± 4.52 | 58.3 ± 7.16 | 51.6 ± 9.35 | 53.2 ± 8.52 |

| Geom. mean diam. (mm) | 4.20 ± 0.17 | 3.86 ± 0.19 | 4.81 ± 0.16 | 4.70 ± 0.23 | 4.38 ± 0.21 |

| Aspect ratio (%) | 53.41 ± 2.92 | 35.03 ± 3.07 | 41.83 ± 2.40 | 29.08 ± 2.38 | 40.34 ± 2.62 |

| Sphericity index (%) | 62.64 ± 1.69 | 48.89 ± 2.43 | 51.93 ± 2.07 | 40.94 ± 2.00 | 53.08 ± 2.26 |

| Density (g cm−3) | 1.34 ± 0.05 | 1.19 ± 0.08 | 0.99 ± 0.06 | 0.96 ± 0.19 | 1.21 ± 0.11 |

| Cereal Species | Roughness Parameter Ra (μm) | Angle of External Friction (°) | ||||

|---|---|---|---|---|---|---|

| Value of Parameter | Standard Deviation of Trait | Coefficient of Variation (%) | ||||

| Minimum | Maximum | Average | ||||

| Wheat | 0.36 | 17.58 | 21.06 | 18.99 a,A | 0.78 | 4.12 |

| 0.47 | 19.64 | 28.67 | 22.97 b,C | 2.06 | 8.97 | |

| 0.90 | 17.02 | 25.08 | 19.65 a,C | 1.57 | 8.01 | |

| 1.28 | 18.11 | 28.33 | 22.55 b,B,C | 2.00 | 8.85 | |

| 2.45 | 21.69 | 35.04 | 25.38 c,B | 2.20 | 8.66 | |

| 3.70 | 26.98 | 41.86 | 31.50 e,B | 3.36 | 10.67 | |

| 4.78 | 24.62 | 34.67 | 28.42 d,B,C | 2.86 | 10.07 | |

| 5.66 | 26.33 | 43.65 | 32.67 f,C | 4.04 | 12.36 | |

| 6.72 | 25.52 | 41.01 | 32.52 e,f,B,C | 3.20 | 9.85 | |

| Rye | 0.36 | 16.82 | 22.46 | 19.52 b,B | 1.08 | 5.55 |

| 0.47 | 17.54 | 30.43 | 22.33 d,C | 2.05 | 9.20 | |

| 0.90 | 13.71 | 20.26 | 17.56 a,A | 1.35 | 7.67 | |

| 1.28 | 16.38 | 26.47 | 20.61 c,A | 1.94 | 9.41 | |

| 2.45 | 21.55 | 31.04 | 25.63 e,B | 1.93 | 7.51 | |

| 3.70 | 24.62 | 38.69 | 30.79 f,B | 3.52 | 11.42 | |

| 4.78 | 25.57 | 41.05 | 31.01 f,D | 2.93 | 9.45 | |

| 5.66 | 23.01 | 36.61 | 30.79 f,A,B | 2.91 | 9.43 | |

| 6.72 | 27.86 | 44.53 | 33.11 g,C,D | 3.14 | 9.49 | |

| Barley | 0.36 | 18.31 | 22.72 | 20.21 b,C | 1.01 | 5.02 |

| 0.47 | 15.66 | 24.02 | 20.31 b,A | 1.65 | 8.14 | |

| 0.90 | 14.36 | 24.63 | 18.80 a,B | 2.00 | 10.66 | |

| 1.28 | 16.68 | 29.32 | 22.12 c,B | 3.13 | 14.19 | |

| 2.45 | 22.23 | 34.44 | 26.12 d,B | 2.63 | 10.07 | |

| 3.70 | 22.48 | 35.10 | 28.00 e,A | 3.28 | 11.69 | |

| 4.78 | 19.41 | 33.07 | 26.06 d,A | 3.07 | 11.79 | |

| 5.66 | 23.35 | 38.05 | 30.15 f,A | 3.24 | 10.73 | |

| 6.72 | 24.64 | 33.54 | 28.55 e,A | 2.83 | 9.90 | |

| Oats | 0.36 | 16.47 | 21.14 | 18.99 b,A | 1.00 | 5.29 |

| 0.47 | 17.64 | 26.11 | 21.18 c,B | 1.83 | 8.62 | |

| 0.90 | 15.05 | 20.47 | 17.71 a,A | 1.24 | 7.02 | |

| 1.28 | 18.53 | 29.73 | 23.42 d,C | 2.48 | 10.58 | |

| 2.45 | 20.32 | 32.68 | 24.13 d,A | 2.53 | 10.49 | |

| 3.70 | 26.00 | 41.13 | 30.46 f,B | 3.66 | 12.01 | |

| 4.78 | 22.59 | 36.30 | 29.53 e,C | 3.32 | 11.34 | |

| 5.66 | 24.61 | 44.92 | 31.73 g,B,C | 4.37 | 13.78 | |

| 6.72 | 25.75 | 42.63 | 34.01 h,D | 4.49 | 13.21 | |

| Triticale | 0.36 | 17.29 | 22.35 | 19.09 a,A | 0.87 | 4.58 |

| 0.47 | 19.03 | 27.22 | 22.35 c,C | 1.78 | 7.98 | |

| 0.90 | 15.55 | 23.20 | 18.15 a,A | 1.47 | 8.08 | |

| 1.28 | 16.61 | 25.33 | 20.29 b,A | 2.20 | 10.84 | |

| 2.45 | 18.39 | 29.85 | 23.55 d,A | 2.33 | 9.89 | |

| 3.70 | 24.57 | 41.36 | 30.83 f,B | 3.90 | 12.65 | |

| 4.78 | 24.28 | 37.10 | 27.84 e,B | 2.54 | 9.12 | |

| 5.66 | 27.06 | 43.43 | 32.18 g,B,C | 3.55 | 11.02 | |

| 6.72 | 27.14 | 39.98 | 31.22 f,g,B | 3.20 | 10.24 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaliniewicz, Z.; Żuk, Z.; Krzysiak, Z. Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels. Sustainability 2018, 10, 1003. https://doi.org/10.3390/su10041003

Kaliniewicz Z, Żuk Z, Krzysiak Z. Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels. Sustainability. 2018; 10(4):1003. https://doi.org/10.3390/su10041003

Chicago/Turabian StyleKaliniewicz, Zdzisław, Zbigniew Żuk, and Zbigniew Krzysiak. 2018. "Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels" Sustainability 10, no. 4: 1003. https://doi.org/10.3390/su10041003

APA StyleKaliniewicz, Z., Żuk, Z., & Krzysiak, Z. (2018). Influence of Steel Plate Roughness on the Frictional Properties of Cereal Kernels. Sustainability, 10(4), 1003. https://doi.org/10.3390/su10041003