Plain and Ultrafine Fly Ashes Mortars for Environmentally Friendly Construction Materials

Abstract

:1. Introduction

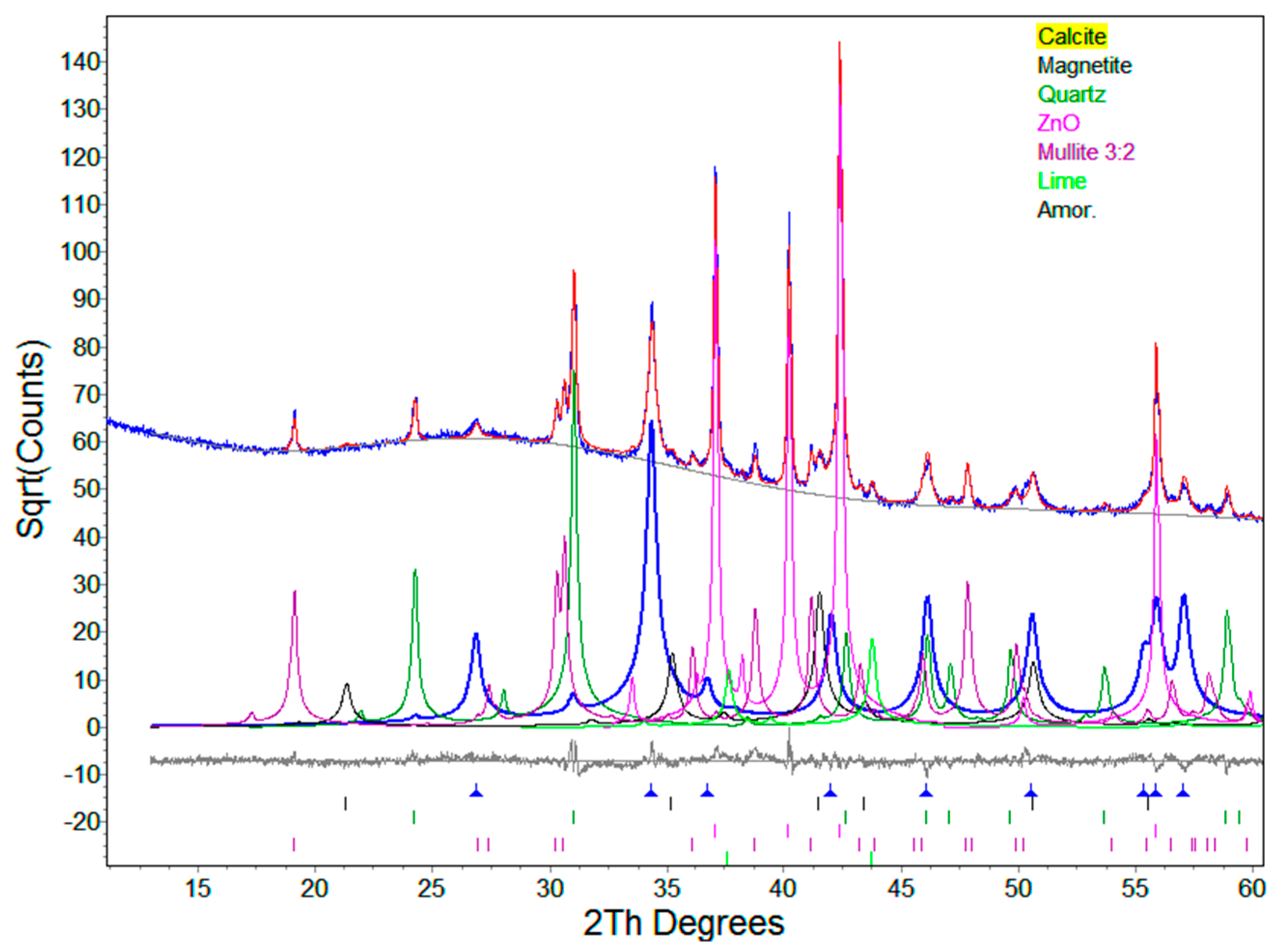

2. Materials

3. Experimental Procedure

4. Results and Discussion

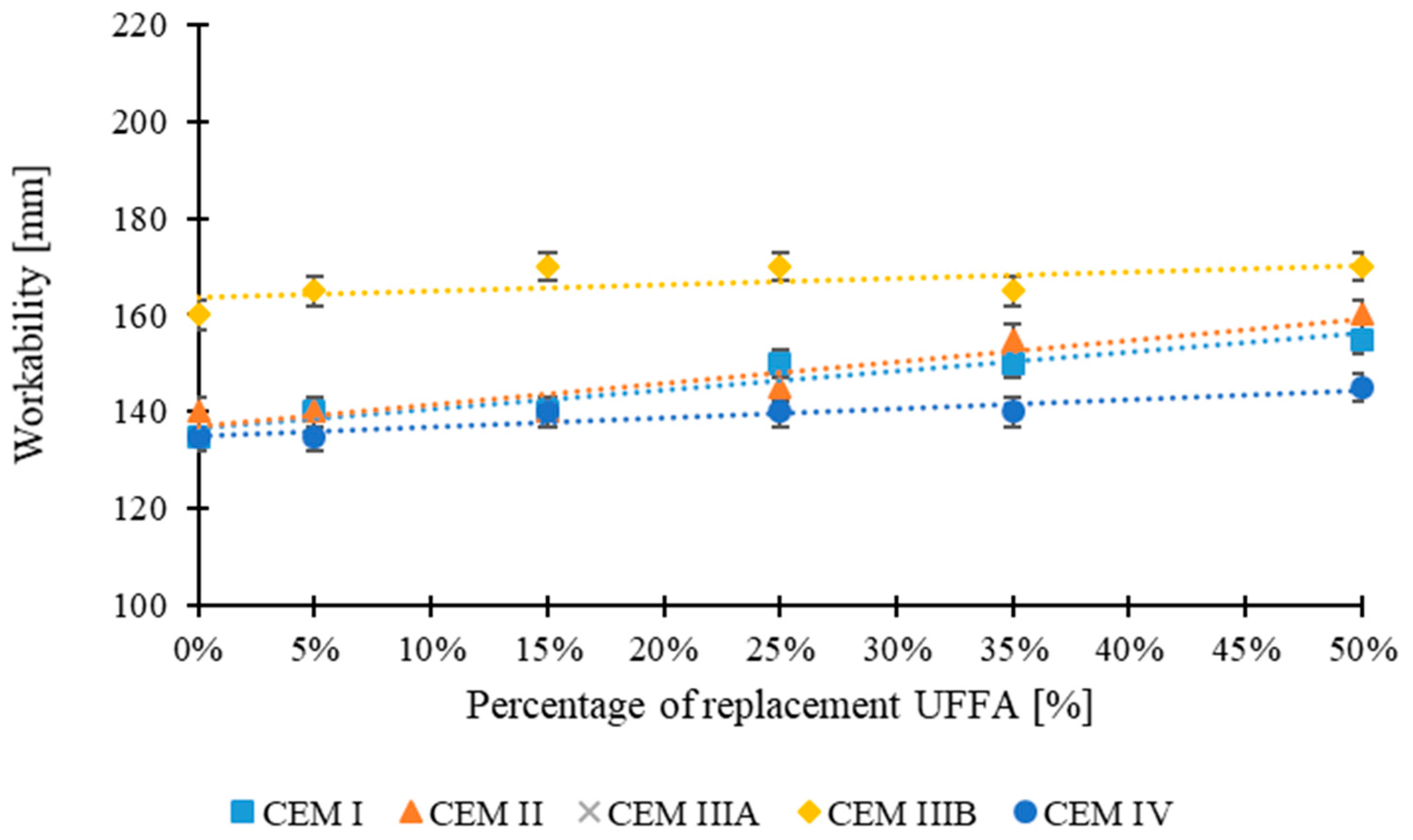

4.1. Rheological Properties

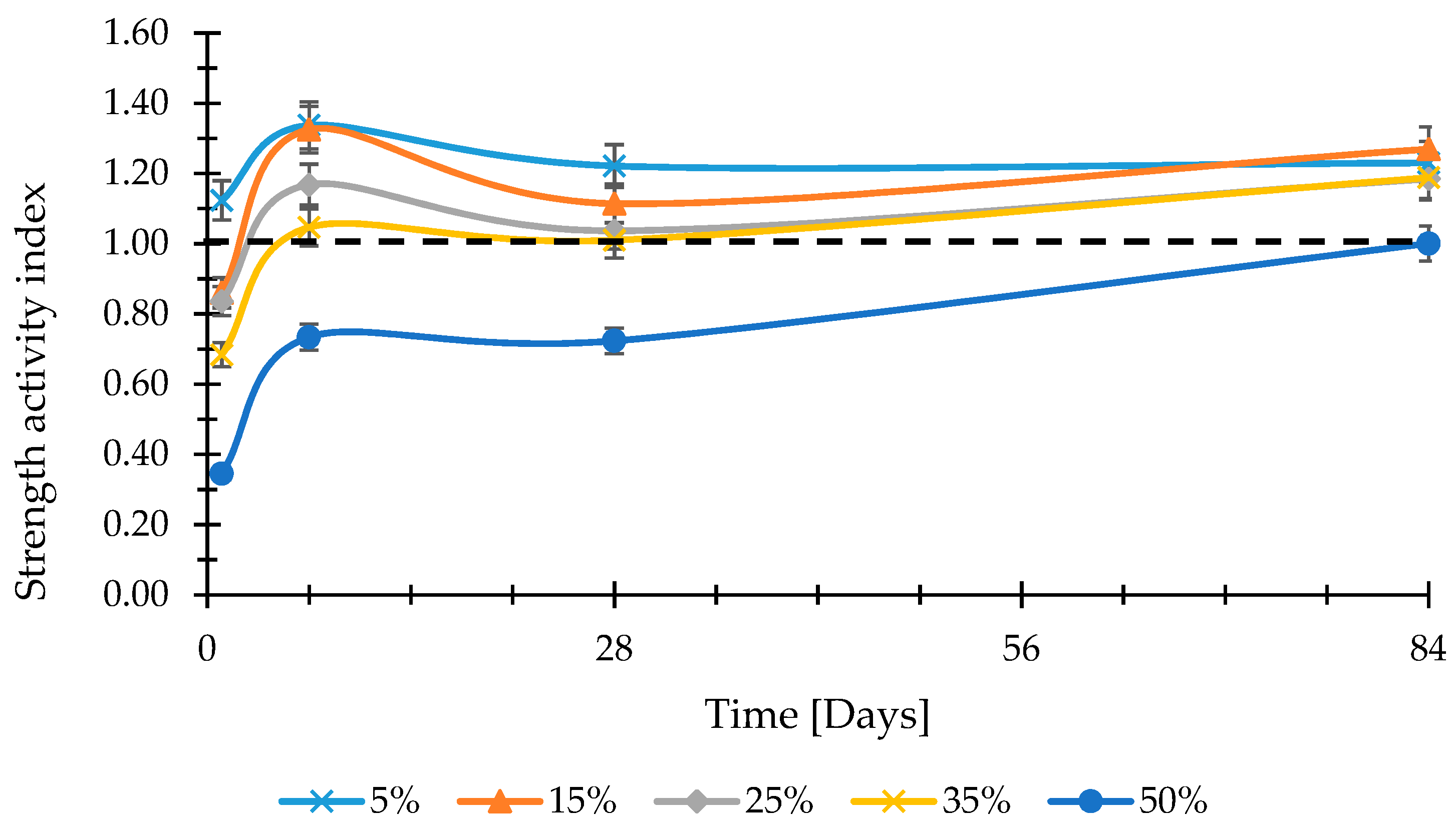

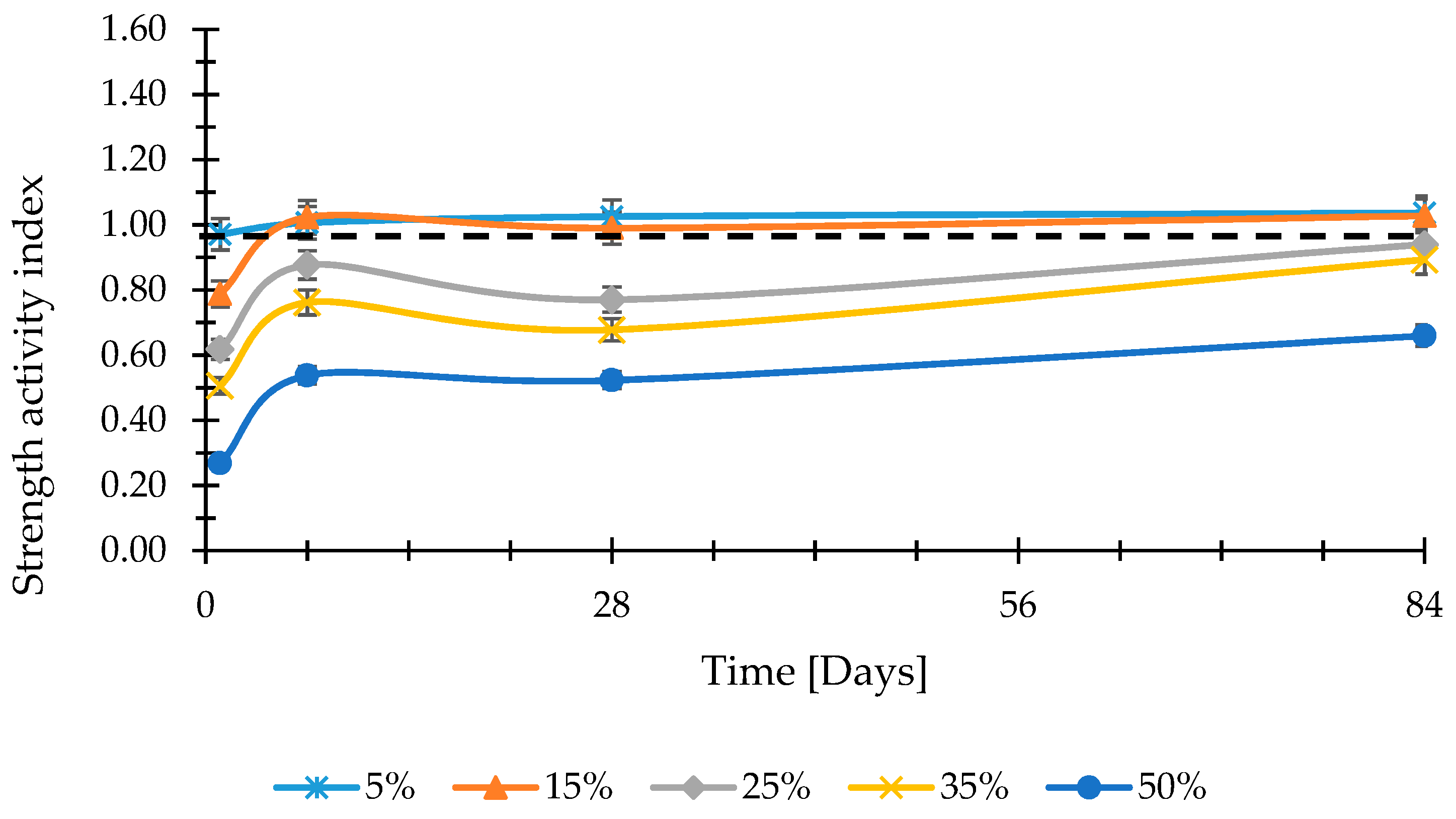

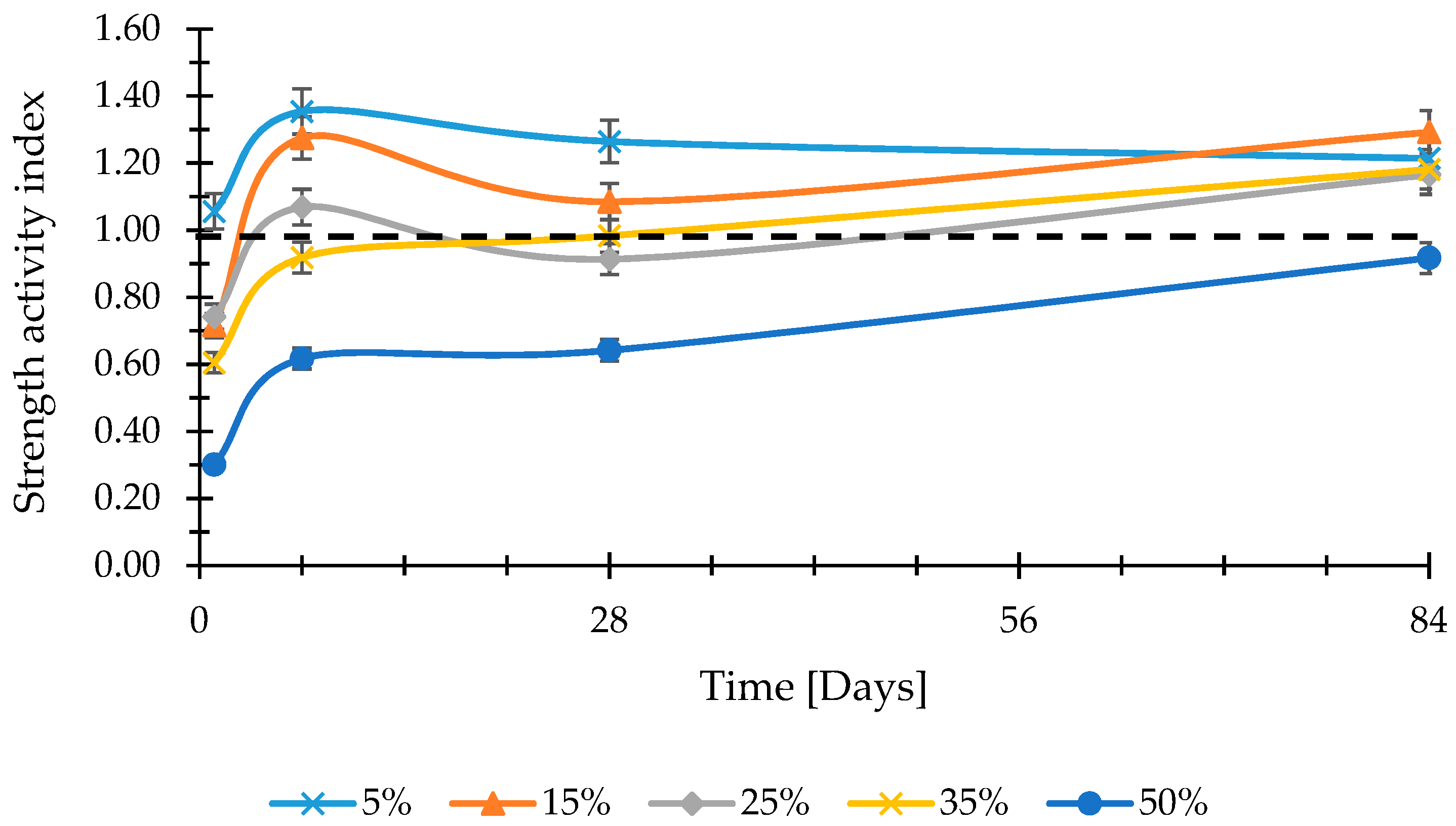

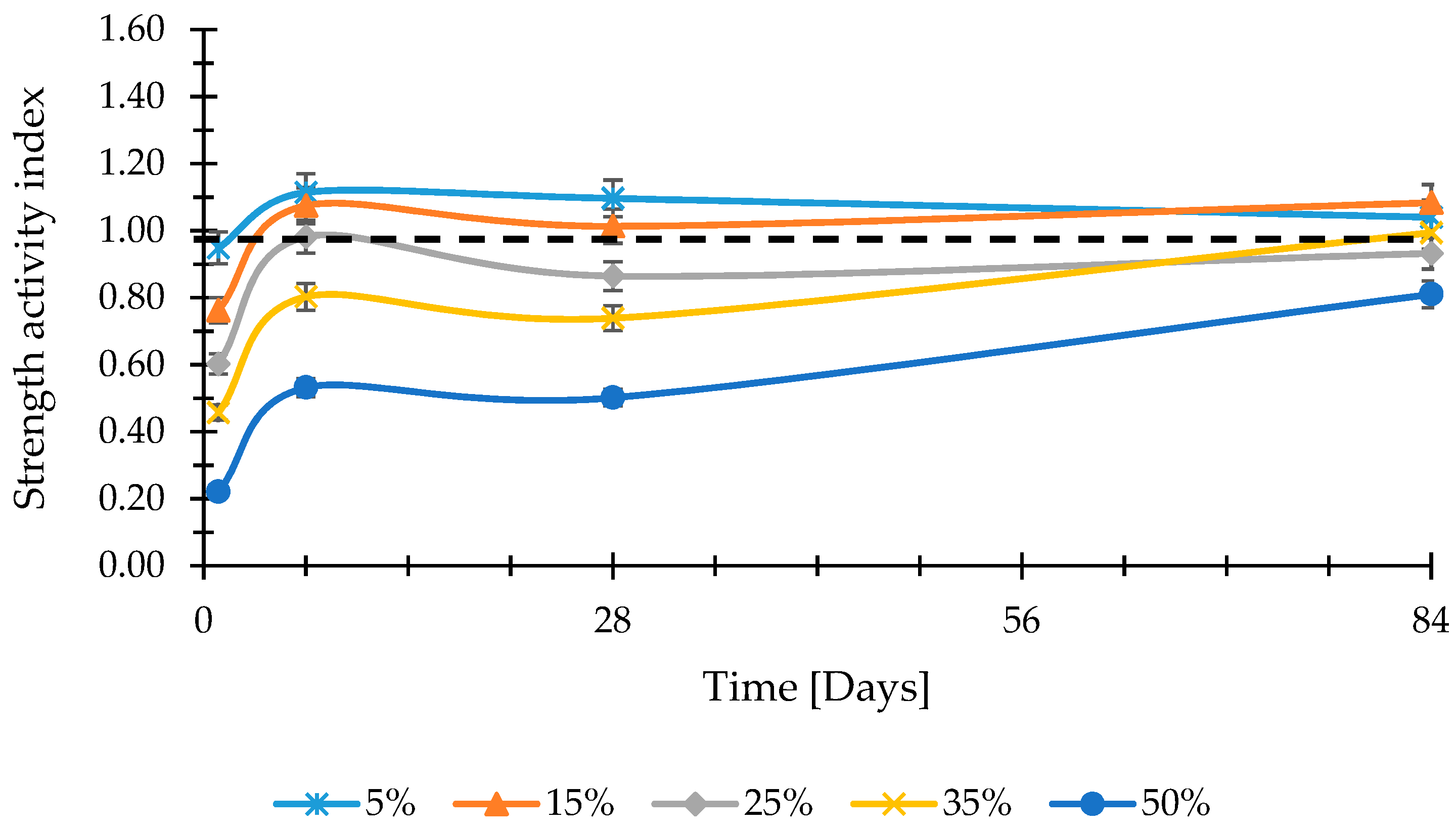

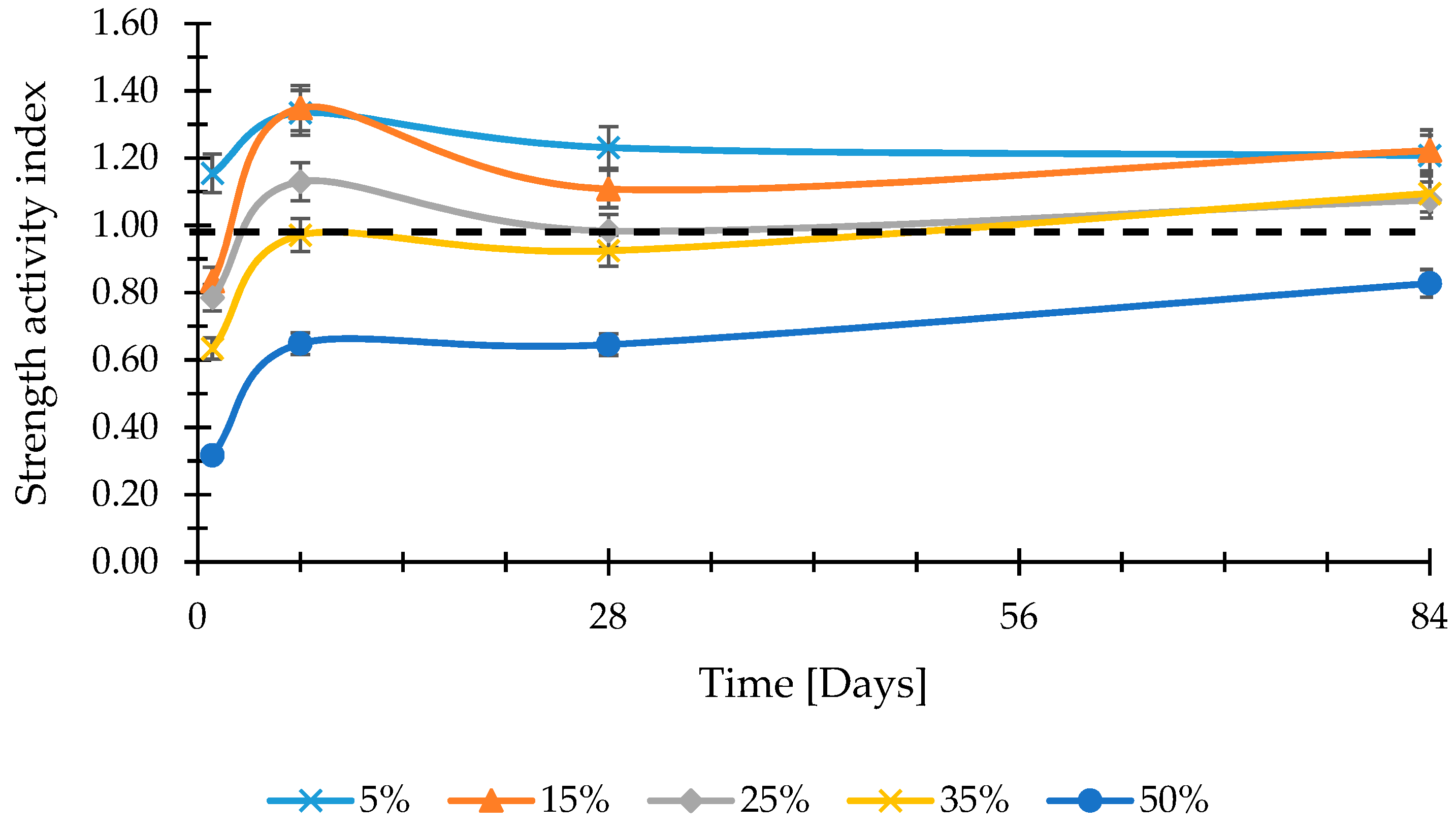

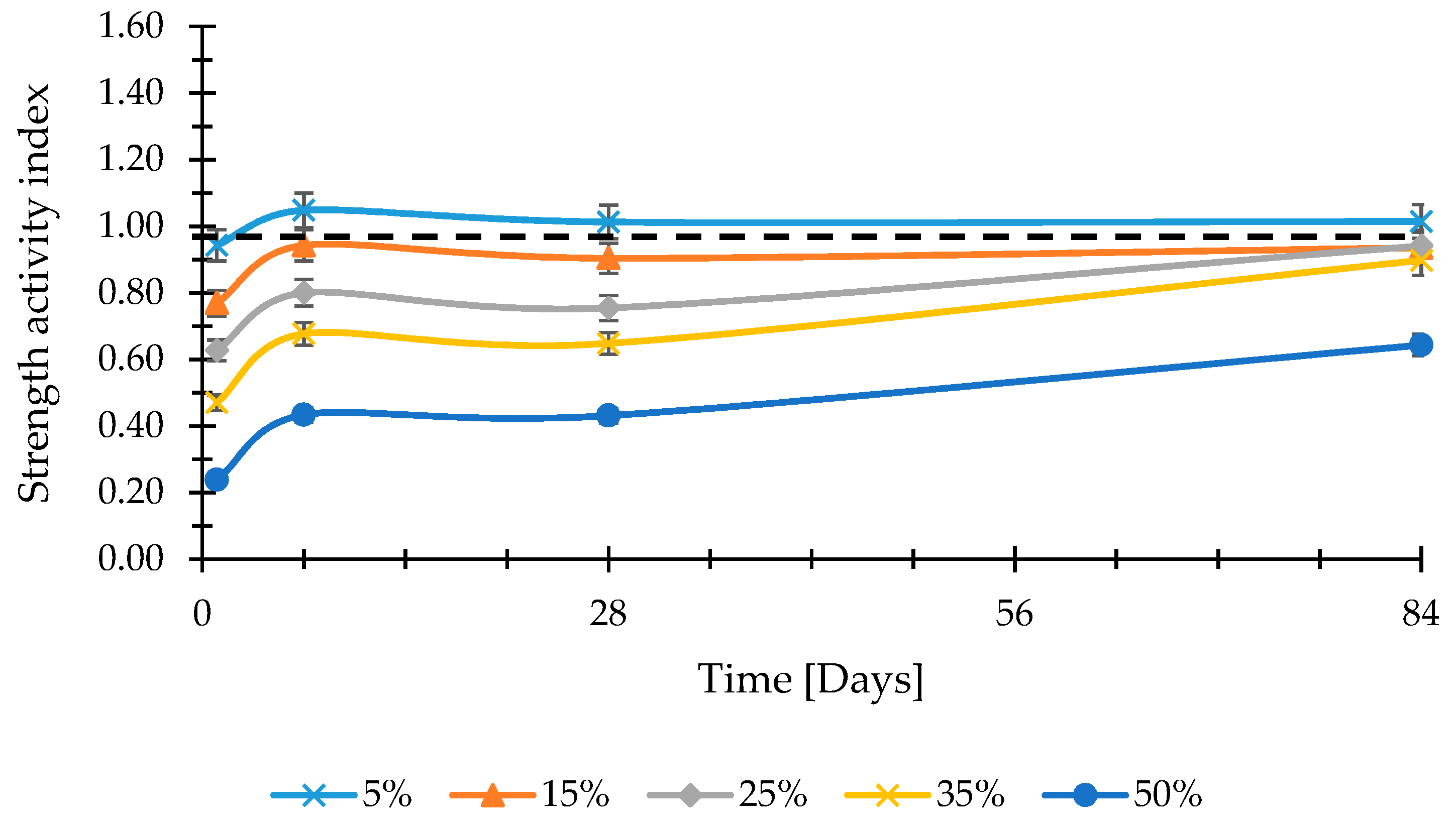

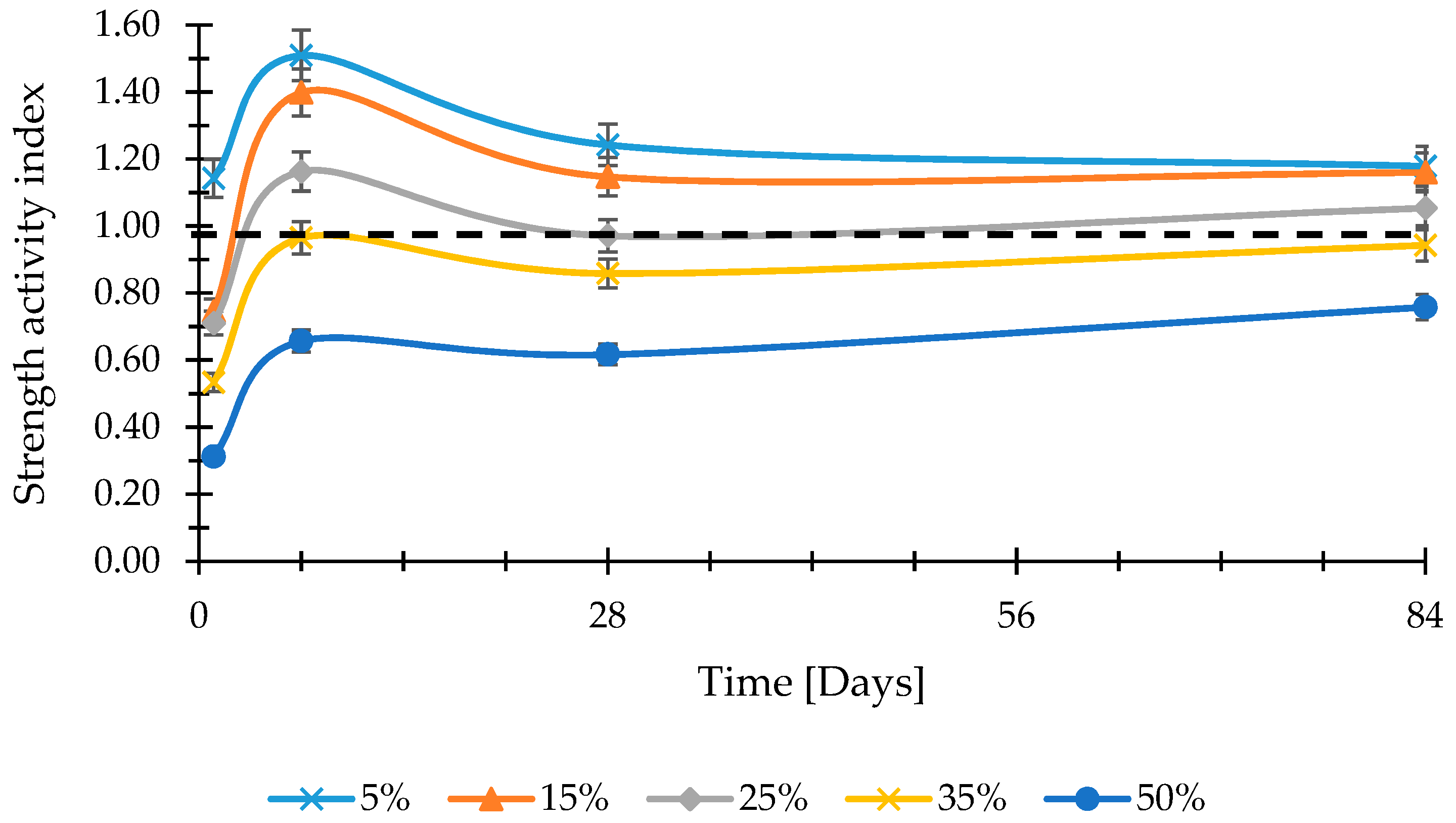

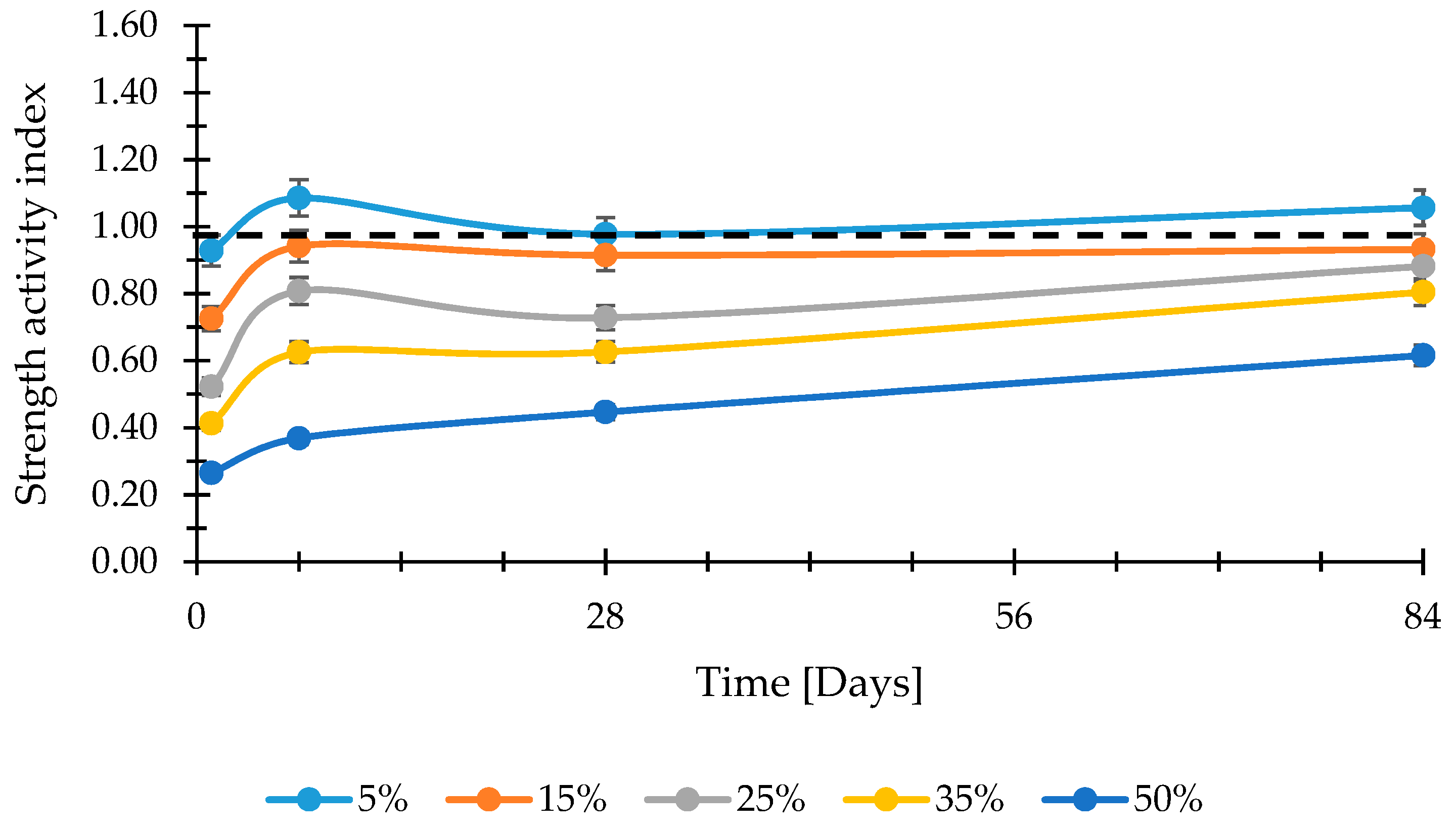

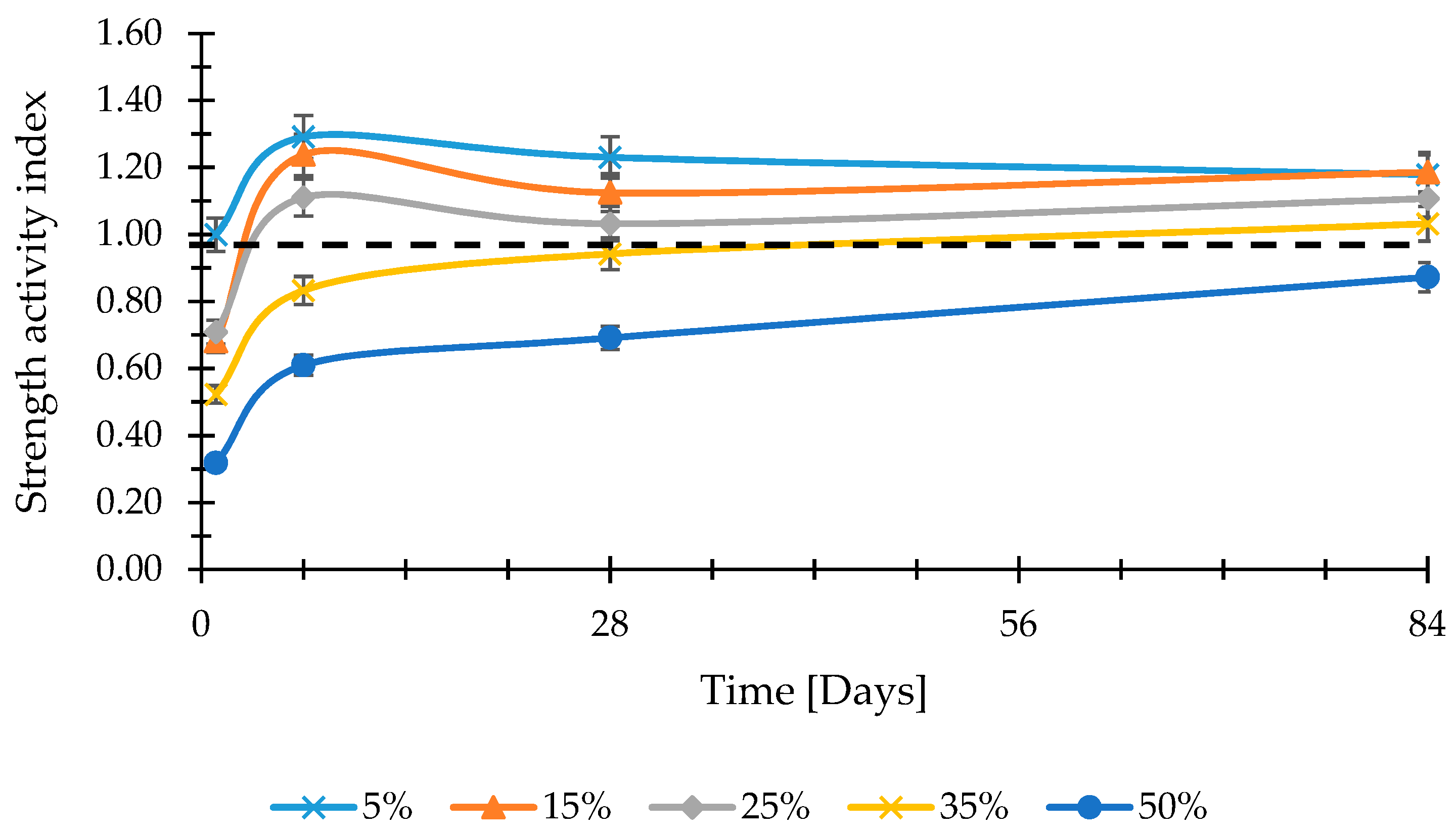

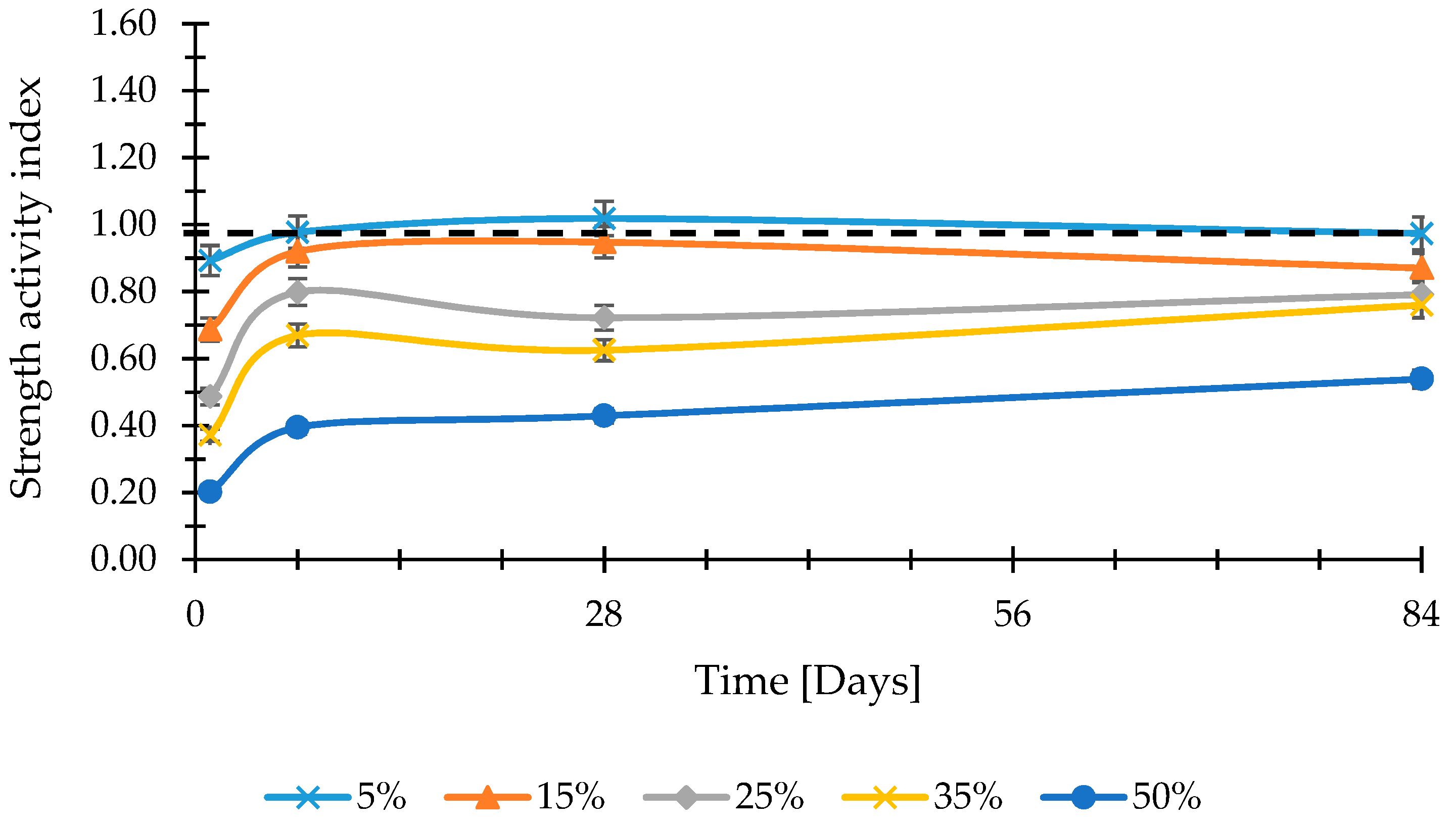

4.2. Mechanical Properties

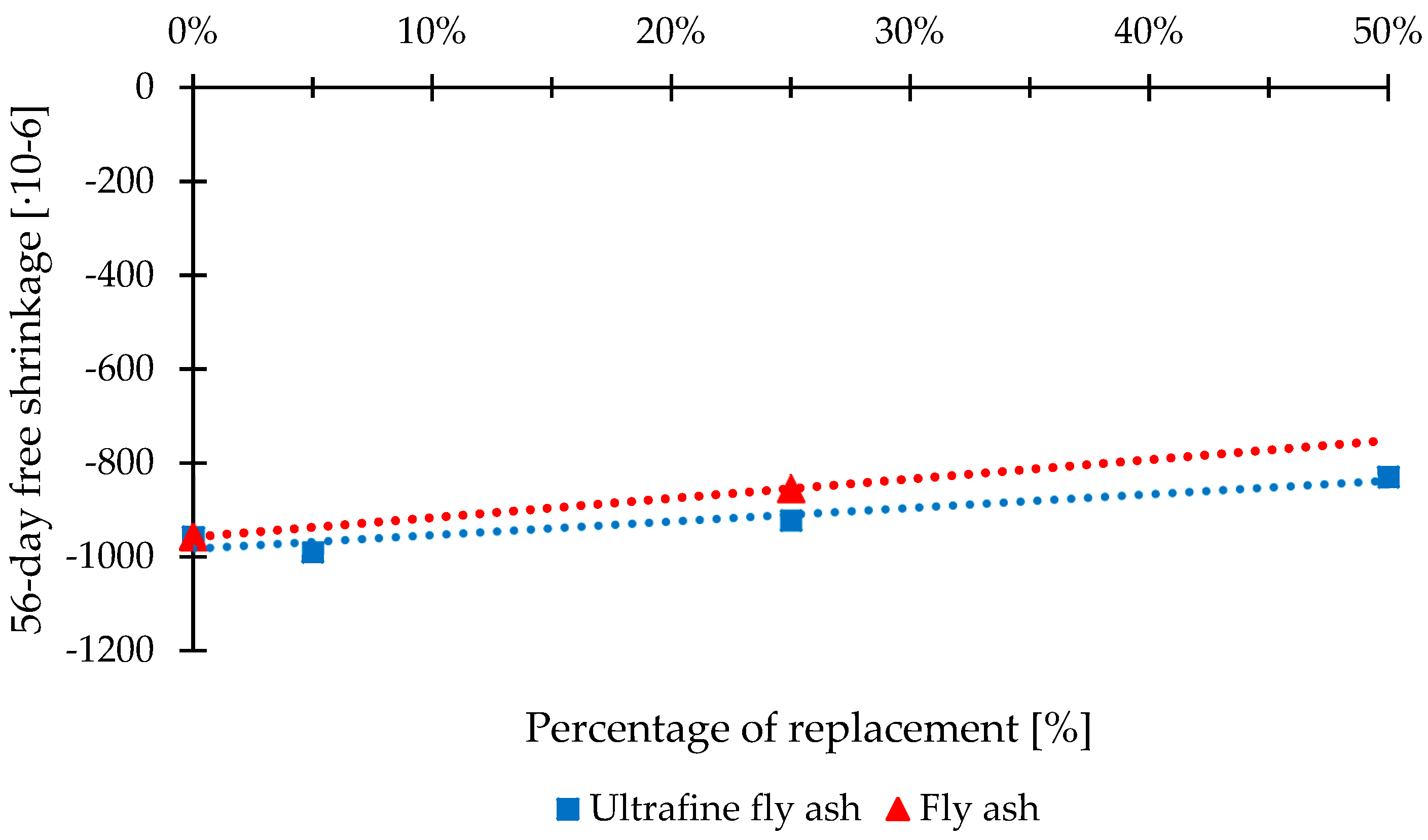

4.3. Shrinkage

4.4. Sustainability Parameters

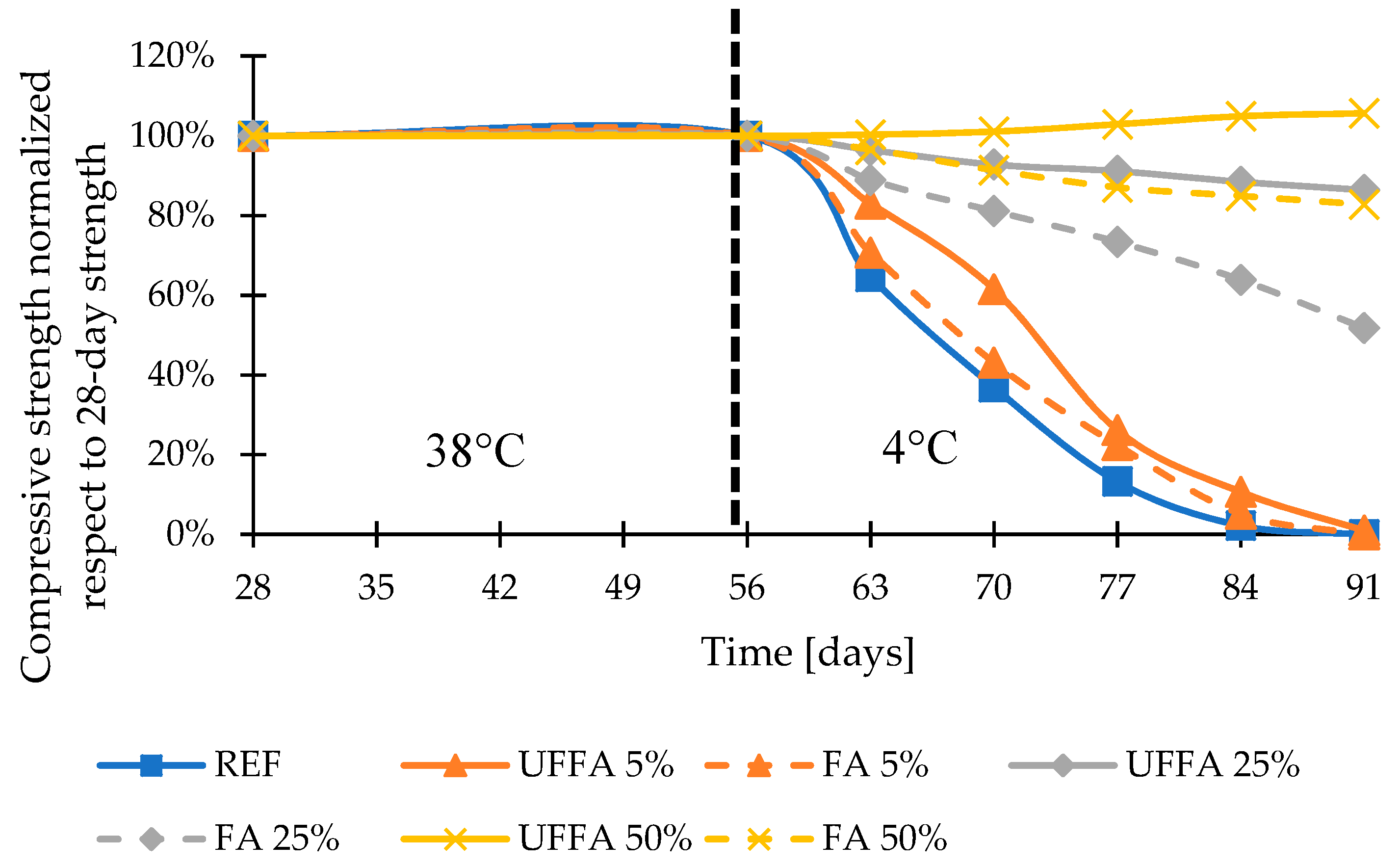

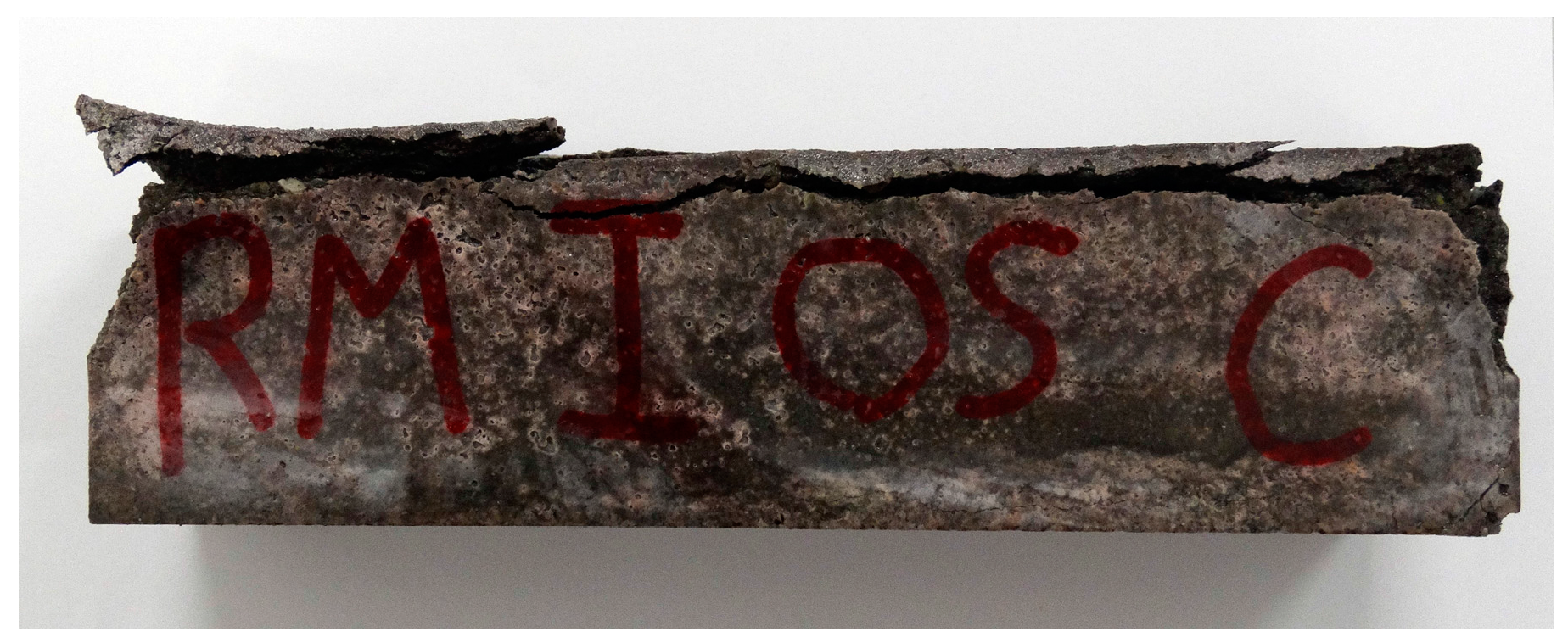

4.5. Calcium Chloride Resistance

5. Conclusions

- As a consequence of the grinding process, UFFA evidenced a reduction of average particle size (16.69 μm and 11.29 μm is the D50 for FA and UFFA, respectively), and an increase in the specific surface area (4500 cm2/g and 6800 cm2/g for FA and UFFA, respectively).

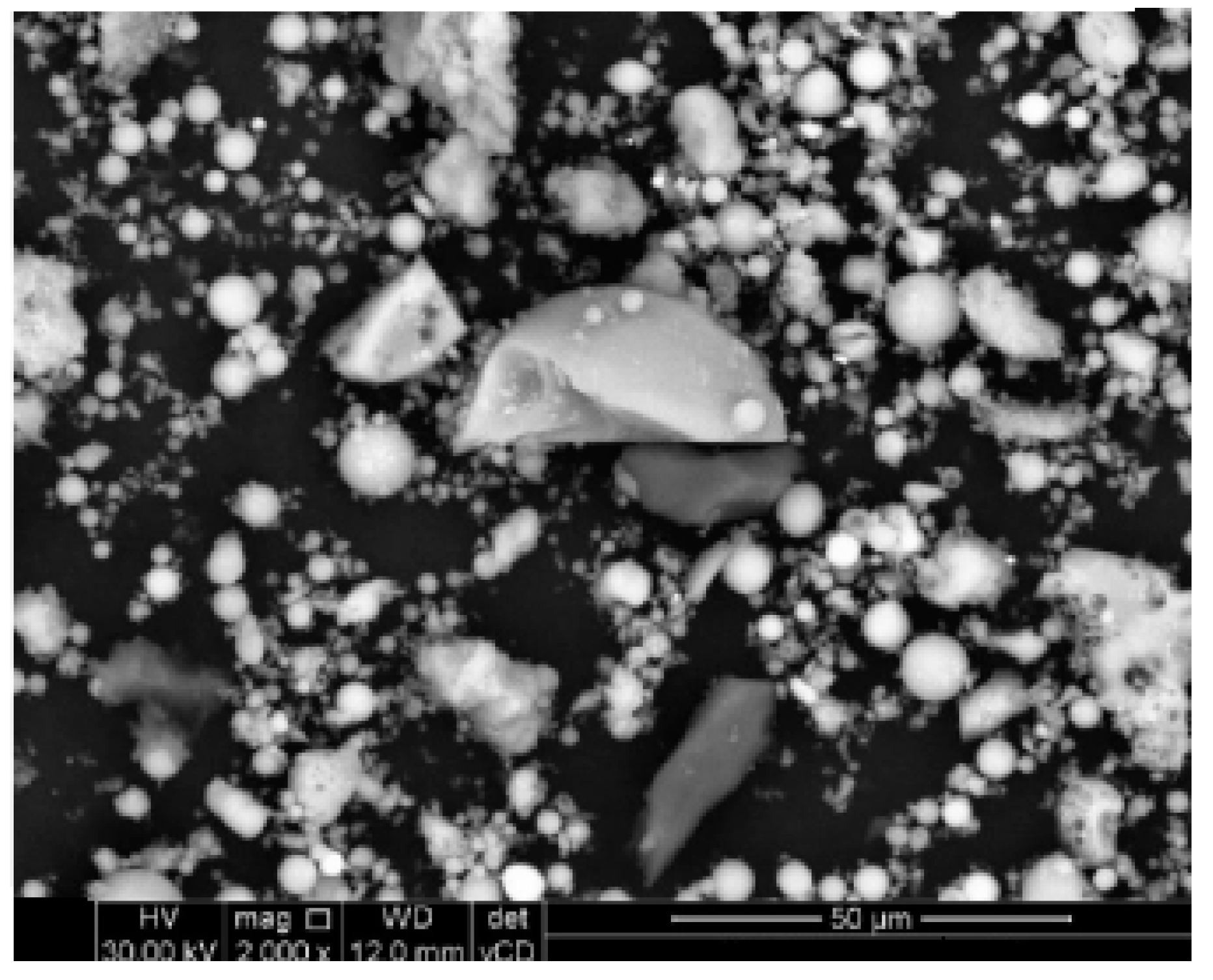

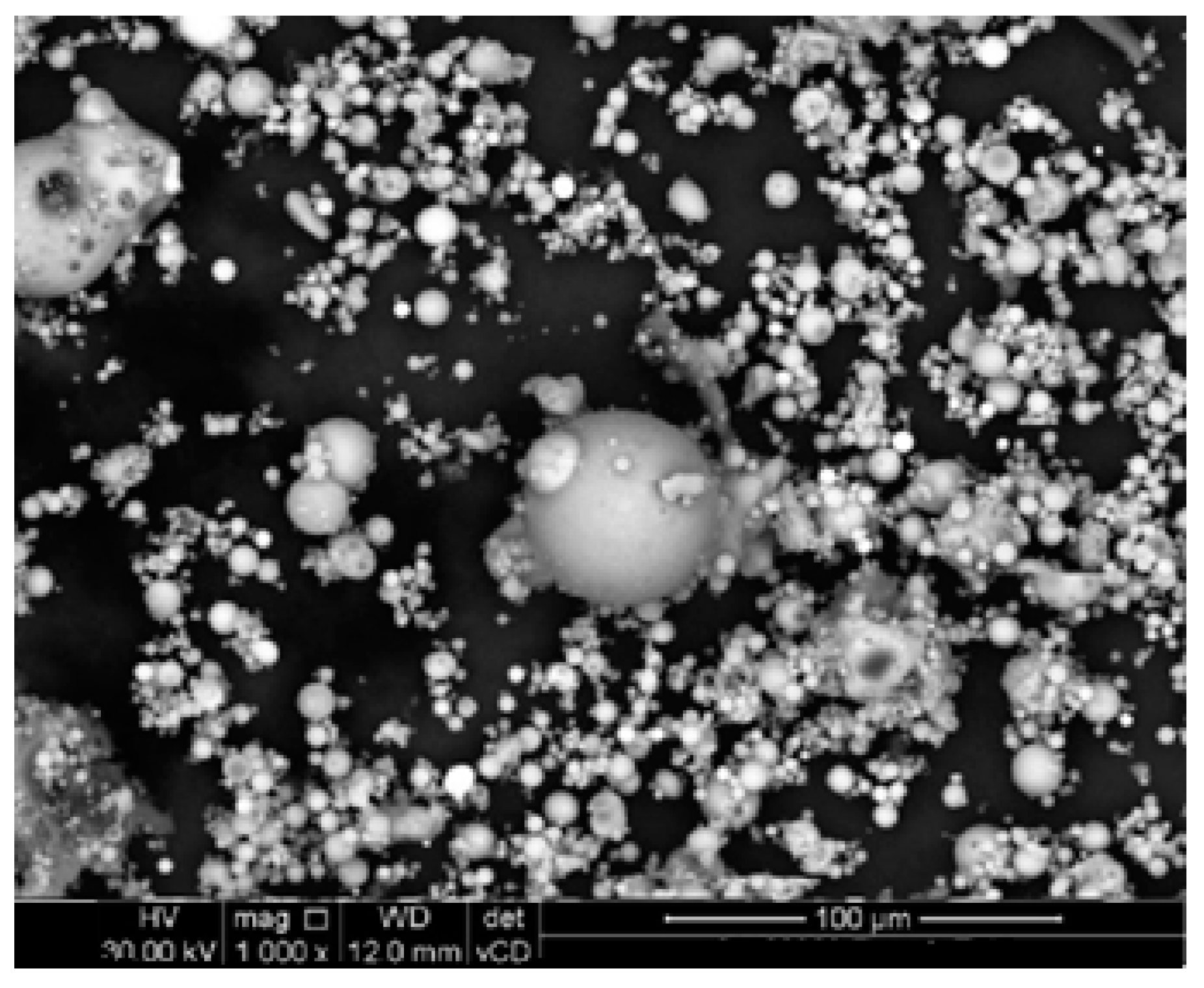

- The partial replacement of Portland with the FA determines an increase in the workability of the mortars, at the same amount of water. Data shows a linear relationship between the increase in fluidity of the fresh mixtures along the percentage of FA replacing the cement, independently of the type of cement used. This behavior could be ascribed the spherical shape of FA particles. The grinding process, on the contrary, involves a general damage of particles, an increase in the number of irregular shaped particles, and a larger specific surface area responsible for a mitigation of the superplasticizing effect of UFFA compared to that shown by the (unground) fly ash.

- The strength pozzolanic activity index (K)-ratio of the compressive strength of mortar containing either UFFA or FA and the corresponding value of the reference mortar containing cement only, is generally higher for UFFA mortars compared to FA mixtures, regardless of the type of cement used and the percentage of replacement. Moreover, the mixtures containing up to 25% of UFFA exhibited higher compressive strength at 7, 28, and 84 days than reference mortars (cement only), independently of the type of cement used. On the other hand, compressive strength at 7 and 28 days of mortars with 35% of UFFA depends on the type of cement used. In fact, only mortars containing 35% of UFFA manufactured with CEM I 42.5 R and CEM II/A-LL 42.5 R show a K-value higher than 1. However, it can be observed that at 84 days, regardless of the type of cement used, the compressive strength of mortars containing 35% of UFFA replacing cement is higher than that of mixtures manufactured exclusively with cement. Mortars manufactured with 50% of UFFA show values of K equal to 0.70 and 0.87 at 28 and 84 days, respectively.

- Replacement of Portland cement with FA or UFFA does not determine significant changes in hydraulic shrinkage. The shrinkage values of UFFA or FA based mortars are similar to those of cement-based mixtures.

- The GWP of the mortar manufactured with the UFFA is, at equal 28-day strength level, 35–40% lower with respect reference mortar (and about 20–35% lower than the FA-based mortars having the same strength). Furthermore, the GER is reduced in UFFA-based mortars production of about 20–35% vs. reference mortar (and % lower than the FA-based mortars having the same strength).

- The use of ultrafine fly ash in partial substitution of cement for manufacturing mortars allows to attain a better behavior in CaCl2-rich environments in respect to that exhibit by unmilled fly-ash-based mortars or reference mixtures containing only cement.

Author Contributions

Conflicts of Interest

References

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Gartner, E.; Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem. Concr. Res. 2015, 78, 126–142. [Google Scholar] [CrossRef]

- Mehta, P.K.; Walters, M. Road map to a sustainable concrete construction industry. Constr. Specif. 2008, 61, 45–57. [Google Scholar]

- Coppola, L.; Coffetti, D.; Lorenzi, S. Cement-Based Renders Manufactured with Phase-Change Materials: Applications and Feasibility. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Loganathan, B.G.; Lam, P.K.S. Global Contamination Trends of Persistent Organic Chemicals; CRC Press: Boca Raton, FL, USA, 2012; 638p. [Google Scholar]

- Kodavanti, P.R.S.; Senthil Kumar, K.; Loganathan, B.G. Organohalogen pollutants and human health. In The International Encyclopedia of Public Health; Academic Press: Oxford, UK, 2008; Volume 5, pp. 686–693. [Google Scholar]

- Atmaca, A.; Kanoglu, M. Reducing energy consumption of a raw mill in cement industry. Energy 2012, 42, 261–269. [Google Scholar] [CrossRef]

- Katsioti, M.; Tsakiridis, P.E.; Giannatos, P.; Tsibouki, Z.; Marinos, J. Characterization of various cement grinding aids and their impact on grindability and cement performance. Constr. Build. Mater. 2009, 23, 1954–1959. [Google Scholar] [CrossRef]

- Coppola, L.; Kara, P.; Lorenzi, S. Concrete manufactured with crushed asphalt as partial replacement of natural aggregates. Mater. Constr. 2016, 66, 101. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Coffetti, D.; Kara, P.; Lorenzi, S. Electric arc furnace granulated slag for sustainable concrete. Constr. Build. Mater. 2016, 123, 115–119. [Google Scholar] [CrossRef]

- Coppola, L.; Lorenzi, S.; Buoso, A. Electric arc furnace granulated slag as a partial replacement of natural aggregates for concrete production. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Coppola, L.; Cerulli, T.; Salvioni, D. Sustainable development and durability of self-compacting concretes. In Proceedings of the 11th International Conference on Fracture, Turin, Italy, 20–25 March 2005. [Google Scholar]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- González, A.; Navia, R.; Moreno, N. Fly ashes from coal and petroleum coke combustion: Current and innovative potential applications. Waste Manag. Res. 2009, 27, 976–987. [Google Scholar] [CrossRef] [PubMed]

- Bilodeau, A.; Mohan Malhotra, V. High-volume fly ash system: Concrete solution for sustainable development. ACI Struct. J. 2000, 97, 41–48. [Google Scholar]

- Bouzoubaâ, N.L. Self Compacting Concrete Incorporating High-Volumes of Class F Fly Ash: Preliminary Results. Cem. Concr. Res. 2001, 31, 413–420. [Google Scholar] [CrossRef]

- Siddique, R. Performance characteristics of high-volume Class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The influence of high-calcium fly ash on the properties of fresh and hardened self-compacting concrete and high performance self-compacting concrete. J. Clean. Prod. 2014, 72, 212–221. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The effect of high-calcium fly ash on selected properties of self-compacting concrete. Arch. Civ. Mech. Eng. 2014, 14, 455–465. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Gołaszewski, J. The Rheological and Mechanical Properties of High-performance Self-compacting Concrete with High-calcium Fly Ash. Procedia Eng. 2013, 65, 33–38. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A.; Booth, A.P.P.G. Characteristics of the ultrafine component of fly ash. Fuel 2006, 85, 2250–2259. [Google Scholar] [CrossRef]

- Yazici, S.; Arel, H.S. Effects of fly ash fineness on the mechanical properties of concrete. Sadhana 2012, 37, 389–403. [Google Scholar] [CrossRef]

- ASTM International. ASTM C618—Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- British Standards Institute Staff, British Standards Institution. Cement. Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; BSI: London, UK, 2004. [Google Scholar]

- European Committee for Standardization. Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria; EN 450-1; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Supit, S.W.M.; Shaikh, F.U.A.; Sarker, P.K. Effect of ultrafine fly ash on mechanical properties of high volume fly ash mortar. Constr. Build. Mater. 2014, 51, 278–286. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–458. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive strength and durability properties of high volume fly ash (HVFA) concretes containing ultrafine fly ash (UFFA). Constr. Build. Mater. 2015, 82, 192–205. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Sinsiri, T.; Teeramit, P.; Jaturapitakkul, C.; Kiattikomol, K. Effect of finenesses of fly ash on expansion of mortars in magnesium sulfate. Sci. Asia 2006, 32, 63–69. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life—Cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- British Standards Institute Staff, British Standards Institution. Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table); EN 1015-3; British Standards Institution: London, UK, 1999. [Google Scholar]

- British Standards Institute Staff, British Standards Institution. Methods of Test for Mortar for Masonry. Determination of Bulk Density of Fresh Mortar; EN 1015-6; British Standards Institution: London, UK, 1999. [Google Scholar]

- British Standards Institute Staff, British Standards Institution. Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11; British Standards Institution: London, UK, 1999. [Google Scholar]

- British Standards Institute Staff, British Standards Institution. Concrete. Specification, Performance, Production and Conformity; EN 206-1; British Standards Institution: London, UK, 2013. [Google Scholar]

- Metrology and Testing Czech Office for Standards. Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Determination of Shrinkage and Expansion; EN 12617-4; British Standards Institution: London, UK, 2002. [Google Scholar]

- Suraneni, P.; Azad, V.J.; Isgor, B.O.; Weiss, W.J. Calcium oxychloride formation in pastes containing supplementary cementitious materials: Thoughts on the role of cement and supplementary cementitious materials reactivity. RILEM Tech. Lett. 2016, 1, 24. [Google Scholar] [CrossRef]

- Farnam, Y.; Washington, T.; Weiss, J. The Influence of Calcium Chloride Salt Solution on the Transport Properties of Cementitious Materials. Adv. Civ. Eng. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

| Cement Type | Clinker Content (%) | Specific Surface (cm2/g) | Specific Mass (Kg/m3) | L.O.I. 950 °C (%) | GER (MJ/kg) | GWP (kg CO2,/kg) | |

|---|---|---|---|---|---|---|---|

| CEM I 42.5 R | Portland cement | 95–100 | 3200 | 2900 | 1.1 | 5.50 | 0.98 |

| CEM II/A-LL 42.5 R | Portland-limestone cement | 80–94 | 3650 | 3000 | 4.0 | 3.60 | 0.88 |

| CEM III/A 42.5 R | Blast furnace cement | 35–64 | 3950 | 2900 | 1.4 | 3.31 | 0.34 |

| CEM III/B 42.5 N LH-SR | Blast furnace cement | 20–34 | 4100 | 2900 | 1.5 | 2.15 | 0.27 |

| CEM IV/A-P 42.5 R | Pozzolanic cement | 65–89 | 4000 | 2800 | not available | 2.98 | 0.53 |

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | Na2O (%) | K2O (%) | |

|---|---|---|---|---|---|---|---|

| Fly ash | 53.87 | 24.18 | 5.11 | 7.04 | 1.35 | 0.63 | 2.16 |

| Ultrafine fly ash | 54.00 | 25.00 | 5.21 | 7.50 | 1.90 | 0.68 | 2.55 |

| D50 (μm) | Specific Surface (cm2/g) | Specific Mass (kg/m3) | L.O.I. 950 °C (%) | |

|---|---|---|---|---|

| Fly ash | 16.69 | 4500 | 2200 | 2.98 |

| Ultrafine fly ash | 11.29 | 6800 | 2200 | 3.01 |

| Grinding | Preheating and Kiln | Total * | ||||

|---|---|---|---|---|---|---|

| GHG Emissions (kg CO2/kg) | Energy Requirement (MJ/kg) | GHG Emissions (kg CO2/kg) | Energy Requirement (MJ/kg) | GHG Emissions (kg CO2/kg) | Energy Requirement (MJ/kg) | |

| CEM I 42.5 R | 9.06 × 10−3 | 0.32–0.36 | 9.7 × 10−1 | 5.10 | 9.8 × 10−1 | 5.50 |

| FA | -- | -- | -- | -- | 5.3 × 10−3 | 0.10 |

| UFFA | 2.10 × 10−3 | 0.09–0.11 | -- | -- | 7.4 × 10−3 | 0.20 |

| Composition | REF | FA 5% | FA 15% | FA 25% | FA 35% | FA 50% | UFFA 5% | UFFA 15% | UFFA 25% | UFFA 35% | UFFA 50% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement (kg/m3) | 500 | 475 | 425 | 375 | 325 | 250 | 475 | 425 | 375 | 325 | 250 |

| Fly Ash (kg/m3) | / | 25 | 75 | 125 | 175 | 250 | / | / | / | / | / |

| Ultrafine fly ash (kg/m3) | / | / | / | / | / | / | 25 | 75 | 125 | 175 | 250 |

| Aggregates (kg/m3) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Water (kg/m3) | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Superplasticizer (kg/m3) | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 |

| w/c ratio * | 0.50 | 0.53 | 0.59 | 0.67 | 0.77 | 1.00 | 0.53 | 0.59 | 0.67 | 0.77 | 1.00 |

| w/b ratio ** | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Replacement (%) | GER (MJ/m3) | GER (% vs. REF) | GWP (kg CO2/m3) | GWP (% vs. REF) | ||

|---|---|---|---|---|---|---|

| CEM I 42.5 R | REF | -- | 2945 | -- | 494 | -- |

| FA | 5% | 2810 | 95.4% | 469 | 94.9% | |

| UFFA | 40% | 1885 | 64.0% | 299 | 60.5% | |

| CEM II/A-LL 42.5 R | REF | -- | 1995 | -- | 444 | -- |

| FA | 15% | 1733 | 86.9% | 378 | 85.1% | |

| UFFA | 35% | 1400 | 70.0% | 291 | 65.5% | |

| CEM III/A 42.5 R | REF | -- | 1850 | -- | 176 | -- |

| FA | 5% | 1770 | 95.7% | 167 | 94.9% | |

| UFFA | 25% | 1461 | 79.0% | 134 | 76.1% | |

| CEM III/B 42.5 N | REF | -- | 1270 | -- | 140 | -- |

| FA | 5% | 1219 | 96.0% | 134 | 95.7% | |

| UFFA | 25% | 1026 | 80.8% | 107 | 76.4% | |

| CEM IV/A-P 42.5 R | REF | -- | 1685 | -- | 269 | -- |

| FA | 5% | 1613 | 95.7% | 256 | 95.2% | |

| UFFA | 25% | 1338 | 79.4% | 203 | 75.5% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coppola, L.; Coffetti, D.; Crotti, E. Plain and Ultrafine Fly Ashes Mortars for Environmentally Friendly Construction Materials. Sustainability 2018, 10, 874. https://doi.org/10.3390/su10030874

Coppola L, Coffetti D, Crotti E. Plain and Ultrafine Fly Ashes Mortars for Environmentally Friendly Construction Materials. Sustainability. 2018; 10(3):874. https://doi.org/10.3390/su10030874

Chicago/Turabian StyleCoppola, Luigi, Denny Coffetti, and Elena Crotti. 2018. "Plain and Ultrafine Fly Ashes Mortars for Environmentally Friendly Construction Materials" Sustainability 10, no. 3: 874. https://doi.org/10.3390/su10030874

APA StyleCoppola, L., Coffetti, D., & Crotti, E. (2018). Plain and Ultrafine Fly Ashes Mortars for Environmentally Friendly Construction Materials. Sustainability, 10(3), 874. https://doi.org/10.3390/su10030874