Abstract

Green supplier evaluation and selection plays a crucial role in the green supply chain management of any organization to reduce the purchasing cost of materials and increase the flexibility and quality of products. An interval neutrosophic set (INS)—which is a generalization of fuzzy sets, intuitionistic fuzzy sets (IFS) and neutrosophic sets (NS)—can better handle the incomplete, indeterminate and inconsistent information than the other sets. This paper proposes a new integrated Quality Function Deployment (QFD) in support of the green supplier evaluation and selection process. In the proposed approach, INS is used to assess the relative importance of the characteristics that the purchased product should have (internal variables “WHATs”) in order to satisfy the company’s needs, the relevant supplier assessment criteria (external variables “HOWs”), the “HOWs”-“WHATs” correlation scores, the resulting weights of the “HOWs” and the impact of each potential supplier. The normalized weighted rating is then defined and the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) method is developed to obtain a final ranking of green suppliers. A case study is applied to demonstrate the efficiency and computational procedure of the proposed method.

1. Introduction

The selection of the right suppliers is among the important supply chain issues for making company operations efficient [1]. Owing to the recently escalated changes in the world’s climate, green supplier selection is considered a key element for companies to help protect the world environment and to maintain their competitive advantages in the global market. Traditional approaches have considered economic criteria such as cost, quality, flexibility, technology and delivery in supplier evaluation policy. In the sustainable approach to supplier evaluation and selection, environmental and social criteria—such as environmental commitment, recyclable packages, social responsibility, ethical issues and legal compliance and commitment to health and safety of employees—should also be considered when measuring supplier performance [2]. Therefore, green supplier evaluation and selection can be regarded as a multiple criteria decision-making (MCDM) problem [3,4].

Despite the growing work of green supplier selection, existent studies have focused on aspects of supplier selection in terms of some internal criteria in general. External criteria, such as customer opinions or requirements (CRs), have not been considered [1]. Additionally, most studies have focused only on the economic efficiency of suppliers rather than the environmental issues in the supplier selection process [5]. However, considering environmental and social criteria has become critical due to the increasing awareness of environmental issues and governmental regulations in supply chain management. Table 1 shows the most commonly used criteria to evaluate the performance of green supplier selection.

Table 1.

Green supplier selection and evaluation criteria.

Many researchers and practitioners have proposed various MCDM models to evaluate and choose appropriate supplier. Among them, analytic hierarchy process (AHP) [32,33,34,35], Analytic Network Process (ANP) [36], Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) [37,38,39], Quality Function Deployment (QFD) [10,40,41,42,43]; AHP-TOPSIS combined approach [44,45,46], QFD and Step-wise Weight Assessment Ratio Analysis (SWARA) [1], AHP and VlseKriterijuska Optimizacija I Komoromisno Resenje (VIKOR) [47], AHP and QFD [2,48], QFD and MCDM [49]; AHP-TOPSIS-QFD [50] have been successfully applied to optimize the supplier evolution process.

In the supplier selection model, the majority of the criteria are generally evaluated by personal judgment and therefore might be subjective. To solve this problem, Zadeh [51] proposed fuzzy sets theory, which is one of the most effective tools for processing vague information. However, this theory is disadvantaged by its membership and inability to express non-membership. Atanassov [52,53] introduced the intuitionistic fuzzy sets (IFSs) by adding a non-membership function. The IFSs can only handle incomplete information and not indeterminate and inconsistent information. On the basis of IFSs, Smarandache [54,55] proposed the neutrosophic set (NS) by adding an independent indeterminacy-membership. The NS, a generalization of fuzzy set and IFSs, can handle incomplete, indeterminate and inconsistent information. Given that the practical application of NS is difficult, Wang [56] proposed a single valued neutrosophic set (SVNS), which is an instance of the NS. The concept of SVNS has been widely applied to various problems in decision-making, education, artificial intelligence, medical diagnosis and so on. In certain real-life situations, using exact numbers to describe the degree of truth, falsity and indeterminacy about a particular statement is infeasible. Therefore, Wang [57] and Zhang [58] proposed interval neutrosophic sets (INSs) and presented the set-theoretic operators of INSs. The theoretical and practical work in INSs has rapidly progressed. Chi and Liu [59] extended the TOPSIS method for multiple attribute decision-making problems using INSs and the maximizing deviation method. Ye [60] defined the Hamming and Euclidean distances and proposed the similarity measures between INSs based on the relationship between similarity measures and distances. Zhang [58] defined the improved operations for INSs. A method for MCDM problems was explored after applying aggregation operators. Şahin [61] proposed the concept of interval neutrosophic cross-entropy, which was then established in an MCDM problem in which the alternative criteria are characterized by INS.

Ye [60] proposed the concept of an interval neutrosophic linguistic set and developed some new aggregation operators for the interval neutrosophic linguistic information. A decision-making method was then presented to manage decision-making problems. Broumi [62] extended the TOPSIS method to deal with the interval neutrosophic uncertain linguistic information.

Quality function deployment (QFD) recently became a widely used quality management tool in product design and development. The QFD is used to receive customer feedback throughout the product planning, development, engineering and manufacturing stages of any product [41]. This technique helps organizations allocate resources and coordinate skills based on customer needs and thus, it decreases production costs and reduces the cycle [63]. The traditional QFD is only used for decision-making problems with crisp numbers and many extended versions of QFD were proposed to deal with fuzzy information. Various QFD approaches using crisp and fuzzy numbers have been presented in the literature [2,10,40,41,42,43,48,49,50]. However, there exist few studies on the application of the QFD technique in a neutrosophic environment [64] and, thus far, no research has extended QFD for INS.

As a result, this study proposes a new integrated QFD-based INS for supporting the green supplier evaluation and selection process. In the proposed approach, the relative importance of the “WHATs,” the “HOWs”-“WHATs” correlation scores, the resulting weights of the “HOWs,” and the impact of each potential green supplier are assessed in INS. The technique for order performance by similarity to ideal solution (TOPSIS) is developed based on INS to obtain a final ranking of alternatives. A case study is further used to illustrate the computational procedure of the proposed approach.

The rest of this paper is organized as follows: Basic notions of NSs, INSs and their operations are discussed in Section 2; the QFD procedures on INSs are demonstrated in Section 3; an application of the procedures for green supplier evaluation and selection in a real case study is illustrated in Section 4; and conclusions of this research and recommendations for further studies are explained in Section 5.

2. Preliminary

Definition 1.

Neutrosophic Set (NS)

Let U be a universe of discourse and a set N ⊂ U, such that

where TA(x), IA(x), FA(x) ⊆ [0, 1] are real subsets, for all x ∈ U, is called a neutrosophic set (NS) [65]. If TA(x), IA(x), FA(x) ∈ [0, 1] are real (crisp) numbers, for all x ∈ U, then N is called a single-valued neutrosophic set (SVNS).

N = {x( TA(x), IA(x), FA(x) ), x ∈ U },

If TA(x), IA(x), FA(x) ⊆ [0, 1] are real intervals, for all x ∈ U, then N is called a interval-valued neutrosophic set [57].

Definition 2.

Operational Rules of the Interval Neutrosophic Value

Let and be two interval neutrosophic value. The operational rules of interval neutrosphic value are then defined as follows:

The complement of x is

Definition 3.

Distance between two Neutrosophic Values

Let and be two INVs. The Hamming and Euclidian distances between x and y are defined respectively as follows:

3. QFD Model Development Using Interval Neutrosophic Sets

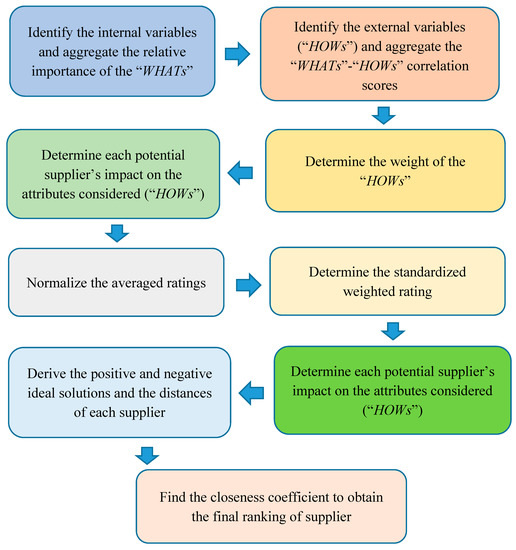

In this section, the QFD model is developed for green supplier selection and evaluation using INSs (as shown in Figure 1).

Figure 1.

The procedure of the proposed Quality Function Deployment (QFD) model.

The steps of the proposed QFD model are as follows:

3.1. Identify the Characteristics That the Product Being Purchased Must Have (Internal Variables or “WHATs”) to Meet the Company’s Needs and Aggregate the Relative Importance of “WHATs”

The characteristics that the products or services being purchased must have (internal variables or “WHATs”) can be identified from the literature review and experts’ opinions (or decision-makers). After determining the “WHATs” factors, the decision-makers further identify their importance weights.

Let be the weight assigned by decision-maker to criterion With the operational rules of the INS, the average weight can be evaluated as:

where

3.2. Identify the Criteria Relevant to Supplier Assessment (External Variables or “HOWs”) and Aggregate the “WHATs”-“HOWs” Correlation Scores

The supplier assessment criteria are defined from a careful review of the supply management literature and expert opinion. The “WHATs”-“HOWs” correlation scores are then defined.

Let be the suitability rating assigned by decision-maker for “WHATs” criteria and “HOWs” criteria With the operational rules of the INS, the averaged suitability rating, can be evaluated as:

where

3.3. Determine the Weights of the “HOWs” Criteria

The weights of the “HOWs” are calculated by averaging the aggregate ratings correlation scores with the aggregate weights of the “WHATs” as follows:

3.4. Determine Each Potential Supplier Impact on the Attributes Considered “HOWs”

Let be the suitability rating assigned to supplier by decision-maker for “HOWs” criteria The averaged suitability rating, can be evaluated as:

where

3.5. Normalize the Averaged Ratings

The “HOWs” criteria are generally classified into two types. The benefit type is characterized as “the larger the better,” whereas the cost type is characterized as “the smaller the better.” To eliminate the influence of the criteria, we need to convert cost to benefit type.

Suppose the standardized matrix is expressed by where then we have

3.6. Determine the Standardized Weighted Rating

The standardized weighted ratings are calculated by multiplying the standardized averaged suitability rating with its associated weights as follows:

where,

3.7. Derive and

The positive and negative ideal solutions are obtained respectively as follows:

The distances of each alternative from and are calculated as:

where is the shortest distance of alternative and is the farthest distance of alternative

3.8. Find the Closeness Coefficient and Ranking Order of Alternatives

The closeness coefficient of each alternative with respect to interval neutrosophic ideal solutions is calculated as:

According to descending order of the closeness coefficient value, the raking order of each alternative can be identified.

4. Application of the Proposed Model for Green Supplier Evaluation and Selection

This section applies the proposed QFD method for green supplier evaluation and selection to the case of Transportation Parts Company Limited in northern Vietnam.

After preliminary screening, four green suppliers (A1–A4) are chosen for further evaluation. A committee of four company managers (D1–D4) conducts the evaluation and selection of green suppliers. As a result of discussions with the company, six fundamental characteristics required in products or services purchased from green suppliers are determined. The committee members were carefully selected from the company’s top managers and the head of the supply chain management department. These characteristics can be listed as: “affordable price (W1),” “product conformity (W2),” “availability and accessibility (W3),” “amount of emission of pollution and hazardous material (W4),” “eco-design (W5),” and “social responsibility (W6).” The six criteria relevant to supplier assessment are identified as: “financial stability (H1),” “quality (H2),” “delivery time (H3),” “corporate social responsibility (H4),” “environmental management systems (H5),” and “pollution control (H6).” The computational procedure is summarized as follows:

4.1. Aggregate the Importance Weights of the “WHATs”

After determining the internal variables or “WHATs” criteria, the decision-makers are asked to determine the level of importance of each criterion using INS, V = {UI, OI, I, VI, AI}, where UI = Unimportant = ([0.1, 0.2], [0.4, 0.5], [0.6, 0.7]), OI = Ordinary Important = ([0.2, 0.4], [0.5, 0.6], [0.4, 0.5]), I = Important = ([0.4, 0.6], [0.4, 0.5], [0.3, 0.4]), VI = Very Important = ([0.6, 0.8], [0.3, 0.4], [0.2, 0.3]) and AI = Absolutely Important = ([0.7, 0.9], [0.2, 0.3], [0.1, 0.2]). Table 2 displays the importance weights of the “WHATs” criteria from the decision-makers. The aggregated weights of the “WHATs” criteria are obtained by Equation (8), as shown in the last column of Table 2.

Table 2.

Aggregated weights of the “WHATs” criteria.

4.2. Aggregate the “HOWs”-“WHATs” Correlation Scores

Assume that the decision-makers use the linguistic rating set S = {VL, L, M, H, VH} where VL = Very Low = ([0.1, 0.2], [0.6, 0.7], [0.6, 0.7]), L = Low = ([0.2, 0.3], [0.5, 0.6], [0.6, 0.7]), M = Medium = ([0.3, 0.5], [0.4, 0.6], [0.4, 0.5]), H = High = ([0.5, 0.6], [0.4, 0.5], [0.3, 0.4]) and VH = Very High = ([0.6, 0.7], [0.2, 0.3], [0.2, 0.3]) to evaluate the ratings of “HOWs”-“WHATs” correlation scores. Table 3 presents the aggregated ratings of “HOWs”-“WHATs” correlation scores from the decision-makers using Equation (9).

Table 3.

Aggregated ratings of “HOWs”-“WHATs” correlation scores.

4.3. Aggregate the Importance Weights of the “HOWs”

The value for weight of each attribute “HOWs” can be obtained using Equation (10), as shown in Table 4.

Table 4.

Aggregated importance weights of “HOWs.”

4.4. Determine Each Potential Supplier’s Impacts on the Attributes Considered the “HOWs”

Using Equation (11), the suitability rating of each “HOWs” factor on four suppliers, based on four participants and its averaged value, can be obtained as shown in Table 5.

Table 5.

Aggregated ratings of each “HOWs” factors in four suppliers.

4.5. Normalize the Averaged Ratings and Weights of the “HOWs”

For simplicity and practicality, all the fuzzy numbers in this paper are defined on the closed interval [0, 1]. Consequently, the normalization procedure is no longer needed.

4.6. Determine the Standardized Weighted Rating

Using Equation (12), the standardized weighted ratings can be obtained as shown in Table 6.

Table 6.

Normalized weighted ratings of each supplier.

4.7. Derive and

As shown in Table 7, the distance of each alternative from and can be calculated by Equations (13)–(16).

Table 7.

Distance measurement.

4.8. Find the Closeness Coefficient and Ranking Order of Each Supplier

The closeness coefficients of a supplier can be calculated by Equation (17), as shown in Table 8. Results show that supplier A1, with the largest closeness coefficient value, is defined as the best supplier for this company. Therefore, the ranking order of the four suppliers is

Table 8.

Closeness coefficients of alternatives.

The INSs are a further generalization of fuzzy, intuitionistic fuzzy and NSs. Hence, the proposed approach in this paper is more typical in applications than the existing QFD approaches [2,40,41,42,43,44,49,50,51]. Furthermore, the proposed approach can be used to solve not only decision-making problems with incomplete information but also those with indeterminate or inconsistent information.

5. Discussion and Conclusions

Neutrosophic value can better express uncertain, imprecise, incomplete and inconsistent information than other types of fuzzy sets. The main objective of this research is to propose the new integrated QFD approach in INS and to apply it to green supplier selection and evaluation. In the proposed approach, the relative importance of the “WHATs,” the “HOWs”-“WHATs” correlation scores, the weights of the “HOWs,” and the impact of each potential supplier were assessed in INS. The normalized and standardized weighted ratings were then defined and the TOPSIS technique based on INS was presented to rank the alternatives. Finally, the proposed integrated QFD approach was applied to supplier selection and evaluation in the case of Transportation Parts Company Limited in northern Vietnam. Four decision-makers, six “WHATs” and six “HOWs” evaluation and selection criteria—which include not only the economic criteria but also environmental and social criteria—were used in the decision process. It was demonstrated throughout the detailed calculation in the application that the proposed integrated approach is efficient and is also more generally compared with the approaches of relevant studies.

Future work should use the AHP method to define the importance weight of “WHATs” and apply the proposed QFD approach to solve more complex problems in real life.

Acknowledgement

This research is funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 502.01-2015.16.

Author Contributions

Luu Huu Van and Vincent. F. Yu have mainly contributed to write the “Application of the Proposed Model for Green Supplier Evaluation and Selection” and the “Introduction” section and checking the typos for this manuscript. Luu Quoc Dat and Shuo-Yan Chou have mainly contributed to write the “QFD Model Development Using Interval Neutrosophic Sets” and “Discussion and Conclusions” section. Canh Chi Dung and Nguyen Viet Loc have contributed to write the “Abstract” and “Preliminary” section and collected data for the application section.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yazdani, M.; Hashemkhani Zolfani, S.; Zavadskas, E.K. New integration of MCDM methods and QFD in the selection of green suppliers. J. Bus. Econ. Manag. 2016, 17, 1097–1113. [Google Scholar] [CrossRef]

- Tavana, M.; Yazdani, M.; Caprio, D.D. An application of an integrated ANP-QFD framework for sustainable supplier selection. Int. J. Logist. Res. Appl. 2017, 20, 254–275. [Google Scholar] [CrossRef]

- Hashemkhani Zolfani, S.; Maknoon, R.; Zavadskas, E.K. An introduction to prospective multiple attribute decision making (PMADM). Technol. Econ. Dev. Econ. 2016, 22, 309–326. [Google Scholar] [CrossRef]

- Hashemkhani Zolfani, S.; Maknoon, R.; Zavadskas, E.K. Multiple attribute decision making (MADM) based scenarios. Int. J. Strateg. Prop. Manag. 2016, 20, 101–111. [Google Scholar] [CrossRef]

- Kumar, A.; Jain, V.; Kumar, S. A comprehensive environment friendly approach for supplier selection. Omega 2014, 42, 109–123. [Google Scholar] [CrossRef]

- Grisi, R.M.; Guerra, L.; Naviglio, G. Supplier performance evaluation for green supply chainmanagement. In Business Performance Measurement and Management; Springer: Berlin/Heidelberg, Germany, 2010; Chapter 10; pp. 149–163. [Google Scholar]

- Abdollahi, M.; Arvan, M.; Razmi, J. An integrated approach for supplier portfolio selection: Lean or agile. Exp. Syst. Appl. 2015, 42, 679–690. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Heidarzade, A.; Mahdavi, I.; Mahdavi-Amiri, N. Supplier selection using a clustering method based on a new distance for interval Type-2 fuzzy sets: A case study. Appl. Soft Comput. 2016, 38, 213–231. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Carpinetti, L.C.R. A multicriteria approach based on fuzzy QFD for choosing criteria for supplier selection. Comput. Ind. Eng. 2016, 101, 269–285. [Google Scholar] [CrossRef]

- Wang, K.-Q.; Liu, H.-C.; Liu, L.; Huang, J. Green supplier evaluation and selection using cloud model theory and the QUALIFLEX method. Sustainability 2017, 9, 688. [Google Scholar] [CrossRef]

- Mafakheri, F.; Breton, M.; Ghoniem, A. Supplier selection order allocation: A two-stage multiple criteria dynamic programming approach. Int. J. Prod. Econ. 2011, 132, 52–57. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. Evaluation of the green supply chain management practices: A fuzzy ANP approach. Prod. Plan. Control 2012, 23, 405–418. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Memon, M.S.; Lee, Y.H.; Mari, S.I. Group multi-criteria supplier selection using combined grey systems theory and uncertainty theory. Exp. Syst. Appl. 2015, 42, 7951–7959. [Google Scholar] [CrossRef]

- Wang, W.P. A fuzzy linguistic computing approach to supplier evaluation. Appl. Math. Model. 2010, 34, 3130–3141. [Google Scholar] [CrossRef]

- Chen, Y.J. Structured methodology for supplier selection and evaluation in a supply chain. Inf. Sci. 2011, 181, 1651–1670. [Google Scholar] [CrossRef]

- Zhu, Q.; Dou, Y.; Sarkis, J. A portfolio-based analysis for green supplier management using the analytical network process. Supply Chain Manag. Int. J. 2010, 15, 306–319. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.F.S. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 4, 22–31. [Google Scholar] [CrossRef]

- Punniyamoorthy, M.; Mathiyalagan, P.; Parthiban, P. A strategic model using structural equation modeling and fuzzy logic in supplier selection. Exp. Syst. Appl. 2011, 38, 458–474. [Google Scholar] [CrossRef]

- Shen, C.Y.; Yu, K.T. Enhancing the efficacy of supplier selection decision-making on the initial stage of new product development: A hybrid fuzzy approach considering the strategic and operational factors simultaneously. Exp. Syst. Appl. 2009, 36, 11271–11281. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Green supplier development: Analytical evaluation using rough set theory. J. Clean. Prod. 2010, 18, 1200–1210. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.Y.; Hsu, C.F.; Hung, H.C. A green supplier selection model for high-tech industry. Exp. Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Tuzkaya, G.; Ozgen, A.; Ozgen, D.; Tuzkaya, U.R. Environmental performance evaluation of suppliers: A hybrid fuzzy multi-criteria decision approach. Int. J. Environ. Sci. Technol. 2009, 6, 477–490. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J. Environ. Manag. 2007, 85, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Yeh, W.C.; Chuang, M.C. Using multi-objective genetic algorithm for partner selection in green supply chain problems. Exp. Syst. Appl. 2011, 38, 4244–4253. [Google Scholar] [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A fuzzy multicriteria approach for evaluating environmental performance of suppliers. Int. J. Prod. Econ. 2010, 126, 370–378. [Google Scholar] [CrossRef]

- Tsai, W.H.; Hung, S.J. A Fuzzy Goal Programming Approach for Green Supply Chain Optimisation Under Activity-based Costing and Performance Evaluation with a Value-chain Structure. Int. J. Prod. Res. 2009, 47, 4991–5017. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Ghadimi, P.; Saman, M.Z.M.; Wong, K.Y.; Heavey, C. An Integrated Approach for Sustainable Supplier Selection Using Fuzzy Logic and Fuzzy AHP. Appl. Int. J. Mech. Mater. Des. 2013, 315, 206–210. [Google Scholar] [CrossRef]

- De Brito, M.P.; Carbone, V.; Blanquart, C.M. Towards a Sustainable Fashion Retail Supply Chain in Europe: Organisation and Performance. Int. J. Prod. Econ. 2008, 114, 534–553. [Google Scholar] [CrossRef]

- Deng, A.Y.; Hu, Y.; Deng, Y.; Mahadevan, S. Supplier selection using AHP methodology extended by D numbers. Expert Syst. Appl. 2014, 41, 156–167. [Google Scholar] [CrossRef]

- Kilincci, O.; Onal, S.A. Fuzzy AHP approach for supplier selection in a washing machine company. Expert Syst. Appl. 2011, 38, 9656–9664. [Google Scholar] [CrossRef]

- Lu, L.Y.Y.; Wu, C.H.; Kuo, T.C. Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. Int. J. Prod. Res. 2007, 45, 4317–4331. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. A fuzzy multi-attribute framework for supplier selection in an e-procurement environment. Int. J. Logist. Res. Appl. 2005, 8, 249–266. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Applying hazardous substance management to supplier selection using analytic network process. J. Clean. Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Yazdani, M.; Payam, A.F. A comparative study on material selection of micro electromechanical systems electrostatic actuators using Ashby, VIKOR and TOPSIS. Mater. Des. 2015, 65, 328–334. [Google Scholar] [CrossRef]

- Kannan, D.; Jabbour, A.B.L.D.S.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Dursun, M.; Karsak, E. A QFD-based fuzzy MCDM approach for supplier selection. Appl. Math. Model. 2013, 37, 5864–5875. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Geraghty, J.; Young, P. Supplier selection paradigm: An integrated hierarchical QFD methodology under multiple-criteria environment. Appl. Soft Comput. 2010, 10, 1013–1027. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Feyzioğlu, O.; Ruan, D. Fuzzy group decision-making to multiple preference formats in quality function deployment. Comput. Ind. 2007, 58, 392–402. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. A fuzzy-QFD approach to supplier selection. J. Purch. Supply Manag. 2006, 12, 14–27. [Google Scholar] [CrossRef]

- Jain, V.; Sangaiah, A.K.; Sakhuja, S.; Thoduka, N.; Aggarwal, R. Supplier selection using fuzzy AHP and TOPSIS: A case study in the Indian automotive industry. Neural Comput. Appl. 2016, 1–10. [Google Scholar] [CrossRef]

- Beikkhakhian, Y.; Javanmardi, M.; Karbasian, M.; Khayambashi, B. The application of ISM model in evaluating agile suppliers selection criteria and ranking suppliers using fuzzy TOPSIS-AHP methods. Expert Syst. Appl. 2015, 42, 6224–6236. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2016, 140, 1686–1698. [Google Scholar] [CrossRef]

- Ho, W.; Dey, P.K.; Martin, L. Strategic sourcing: A combined QFD and AHP approach in manufacturing. Supply Chain Manag. 2011, 6, 446–461. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Hashemkhani Zolfani, S. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Pramanik, D.; Haldar, A.; Mondal, S.C.; Naskar, S.K.; Ray, A. Resilient supplier selection using AHP-TOPSIS-QFD under a fuzzy environment. Int. J. Manag. Sci. Eng. Manag. 2017, 12, 45–54. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inform. Contract 1965, 8, 338–356. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Atanassov, K.T. More on intuitionistic fuzzy sets. Fuzzy Sets Syst. 1989, 33, 37–46. [Google Scholar] [CrossRef]

- Smarandache, F. A Unifying Field in Logics. Neutrosophy: Neutrosophic Probability, Set and Logic; American Research Press: Rehoboth, DE, USA, 1999. [Google Scholar]

- Smarandache, F. A generalization of the intuitionistic fuzzy set. Int. J. Pure Appl. Math. 2005, 24, 287–297. [Google Scholar]

- Wang, H.; Smarandache, F.; Zhang, Y.; Sunderraman, R. Single valued neutrosophic sets. In Proceedings of the 10th International Conference on Fuzzy Theory and Technology, Salt Lake City, UT, USA, 21–26 July 2005. [Google Scholar]

- Wang, H.; Smarandache, F.; Sunderraman, R.; Zhang, Y.Q. Interval Neutrosophic Sets and Logic: Theory and Applications in Computing, Logic in Computer Science; Neutrosophic book Series, No. 5; Hexis: Vernignon, France, 2005. [Google Scholar]

- Zhang, H.Y.; Wang, J.Q.; Chen, X.H. Interval neutrosophic sets and their application in multicriteria decision making problems. Sci. World J. 2014, 2014, 645953. [Google Scholar] [CrossRef] [PubMed]

- Chi, P.P.; Liu, P. An extended TOPSIS method for the multiple attribute decision making problems based on interval neutrosophic set. Neutrosphic Sets Syst. 2013, 1, 63–70. [Google Scholar]

- Ye, J. Some aggregation operators of interval neutrosophic linguistic numbers for multiple attribute decision making. J. Intell. Fuzzy Syst. 2014, 27, 2231–2241. [Google Scholar]

- Şahin, R. Cross-entropy measure on interval neutrosophic sets and its applications in multicriteria decision making. Neutral Comput. Appl. 2017, 28, 1177–1187. [Google Scholar] [CrossRef]

- Broumi, S.; Ye, J.; Smarandache, F. An extended TOPSIS method for multiple attribute decision making based on interval neutrosophic uncertain linguistic variables. Neutrosophic Sets Syst. 2015, 8, 22–31. [Google Scholar]

- Karsak, E.E.; Dursun, M. An integrated fuzzy MCDM approach for supplier evaluation and selection. Comput. Ind. Eng. 2015, 82, 82–93. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.Q.; Zhang, H.Y. Hybrid single-valued neutrosophic MCGDM with QFD for market segment evaluation and selection. J. Intel. Fuzzy Syst. 2018, 34, 177–187. [Google Scholar] [CrossRef]

- Smarandache, F. Neutrosophy: Neutrosophic Probability, Set, and Logic, ProQuest Information and Learning; American Research Press: Ann Arbor, MI, USA, 1998. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).