BIM-Based Incremental Cost Analysis Method of Prefabricated Buildings in China

Abstract

1. Introduction

2. Brief Literature Review

- Variables such as building structure and component’s positions have a great impact on the accuracy of incremental cost calculation, and there will be a large difference in these variables in two different buildings, so it is hard to guarantee the accuracy of the incremental cost comparison results of two similar but different PFB and TRB. Additionally, there is a large difference (i.e., PFC types, construction location, etc.) in study cases, and the incremental analysis results cannot present the overall situation of the prefabricated industry.

- There is no suitable method to obtain accurate and reliable cost data of the PFC production stage. Therefore, it is hard to quantitatively analyze the whole construction stage incremental cost (including the PFC production and on-site assembly stages).

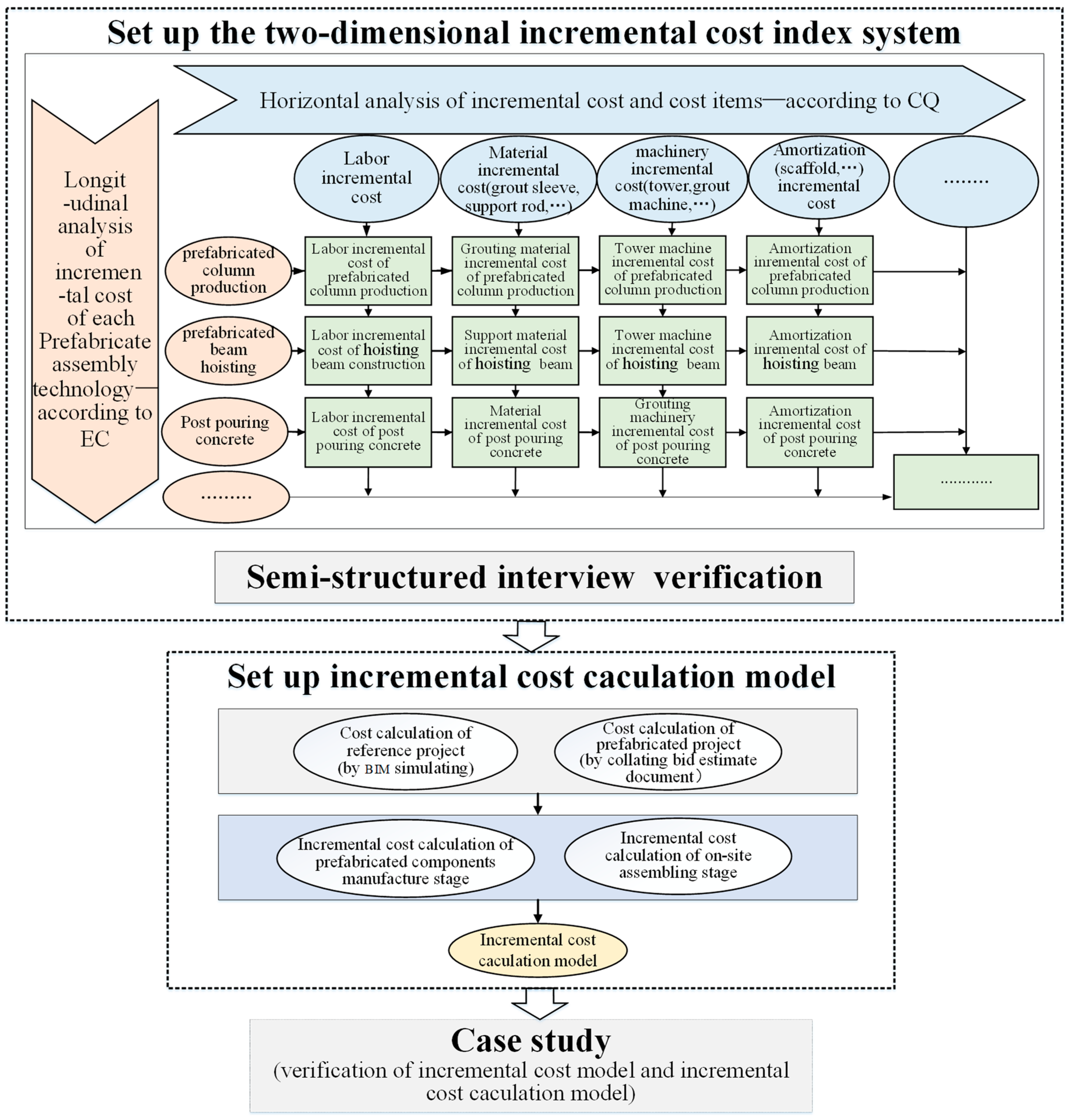

3. Research Approach

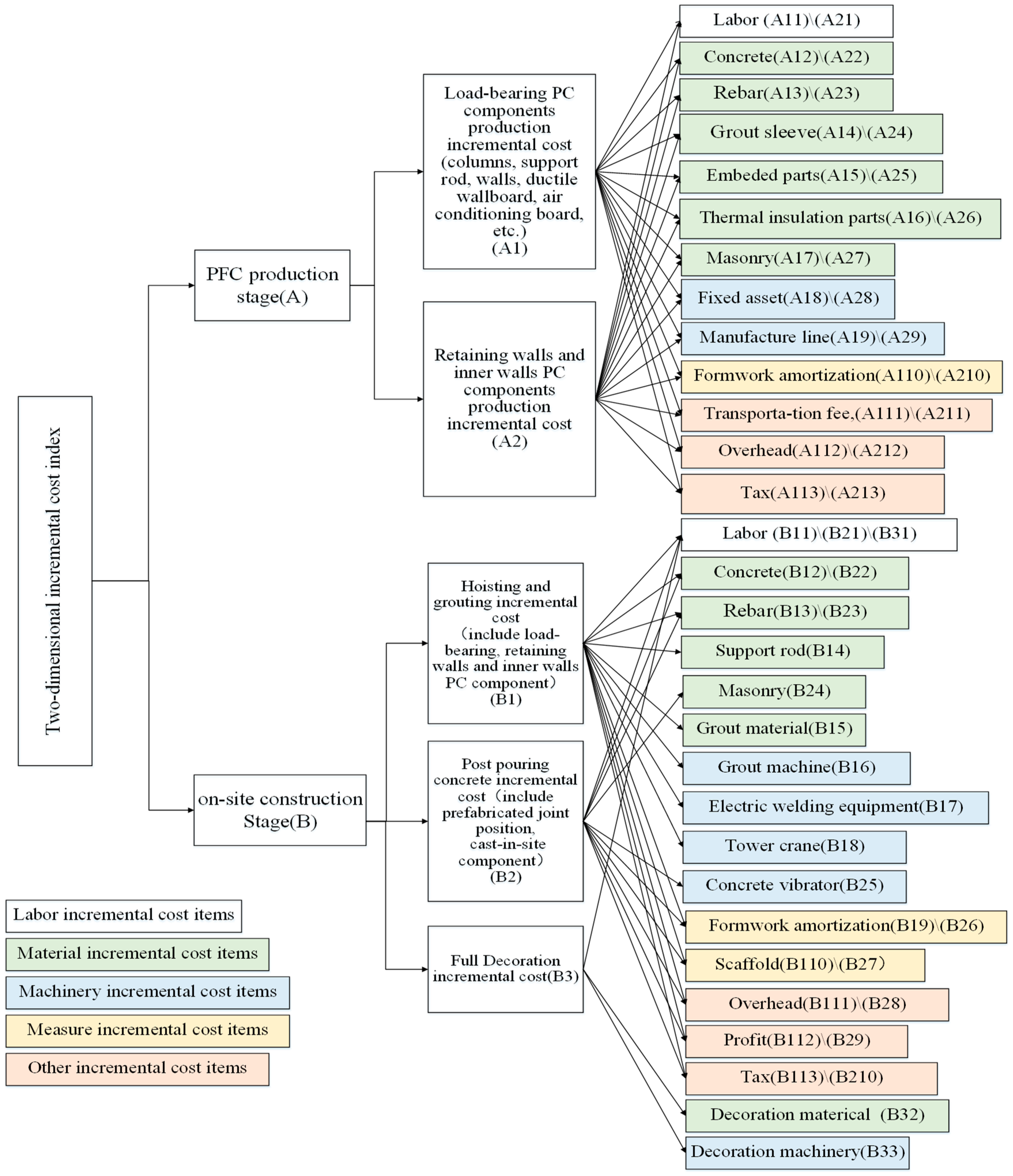

3.1. Two-Dimensional Incremental Cost Index System

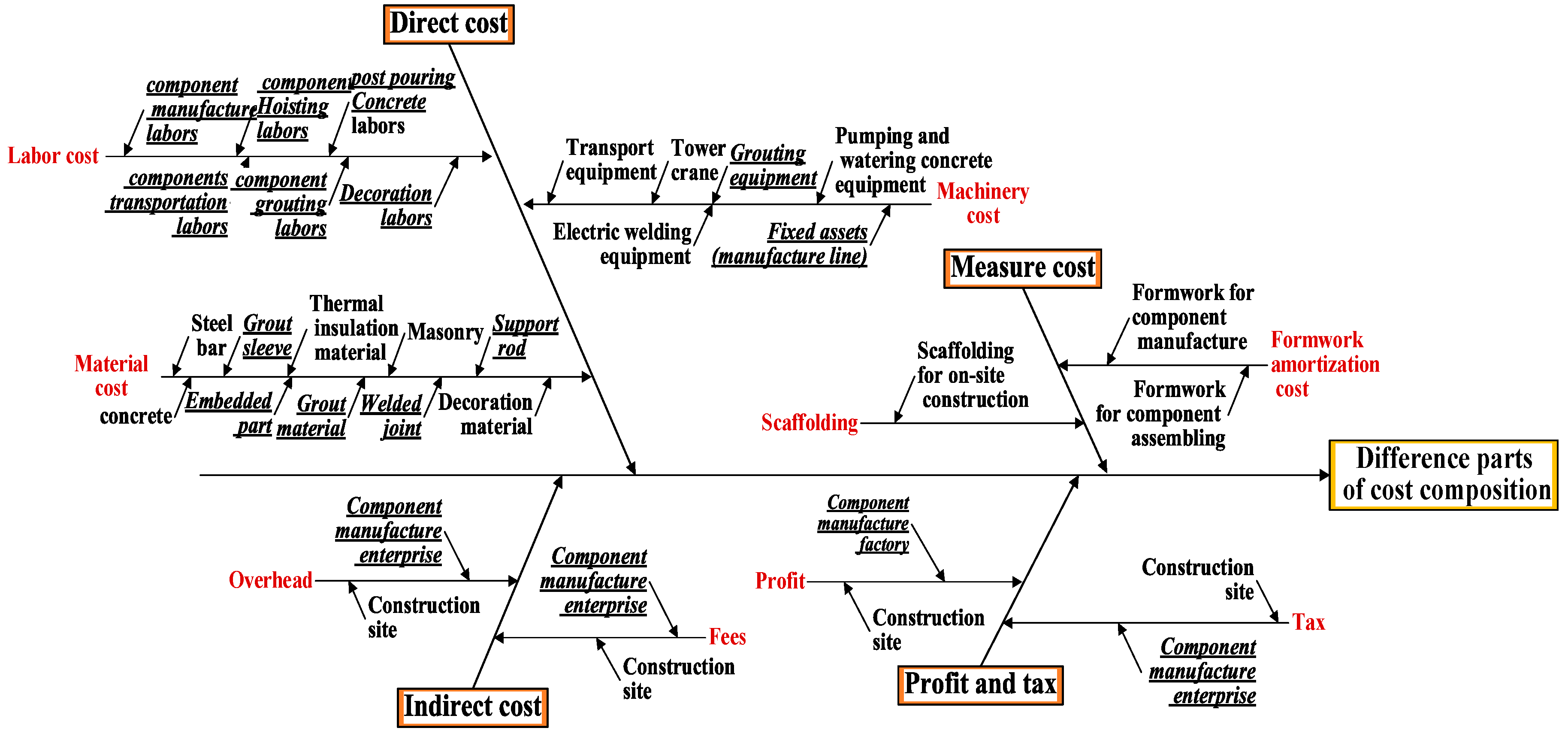

3.1.1. Identification of PRBs Incremental Cost Items

3.1.2. Classification of PRBs Incremental Cost Items

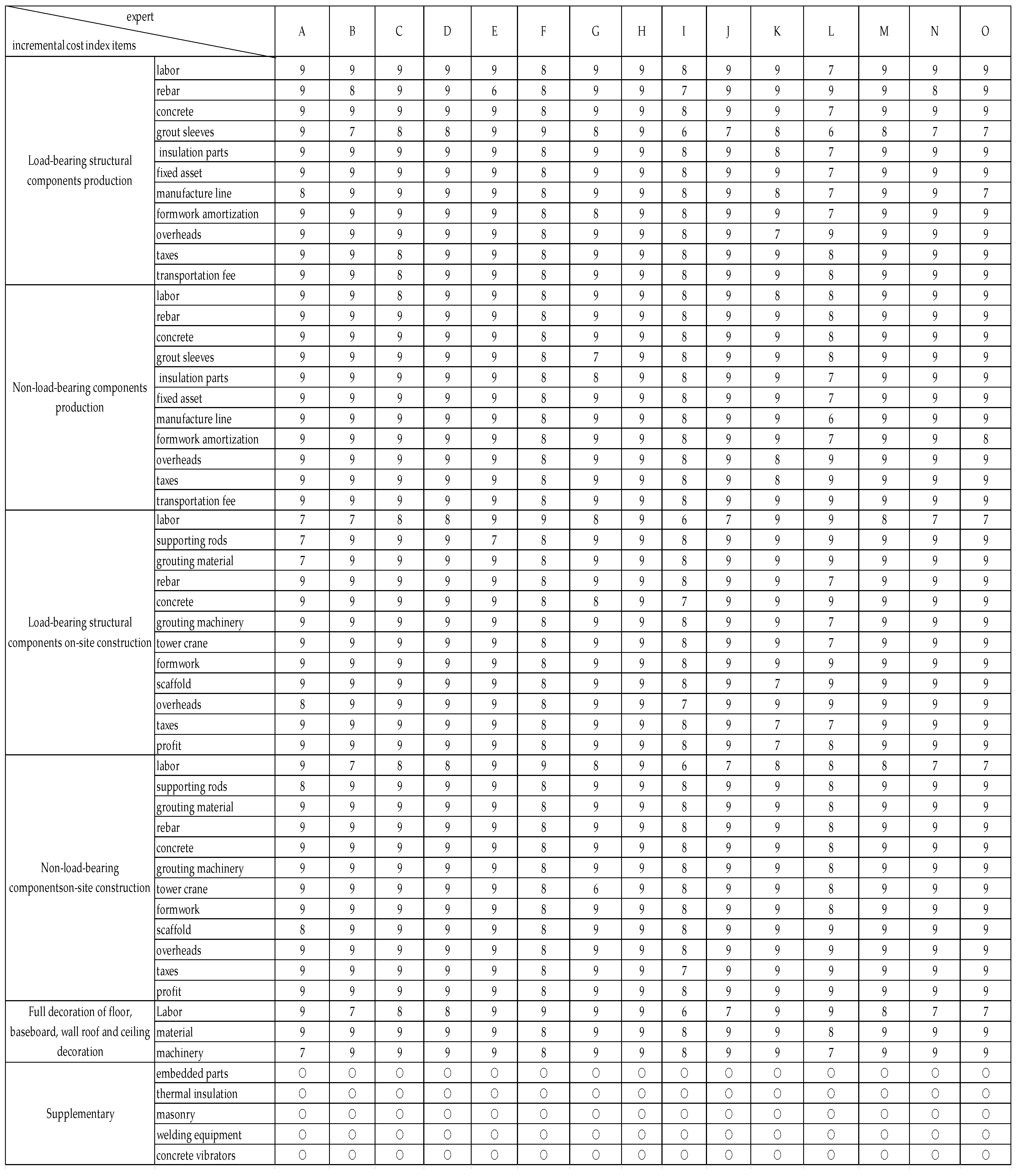

3.1.3. Verification and Correction of Two-Dimensional Incremental Index System

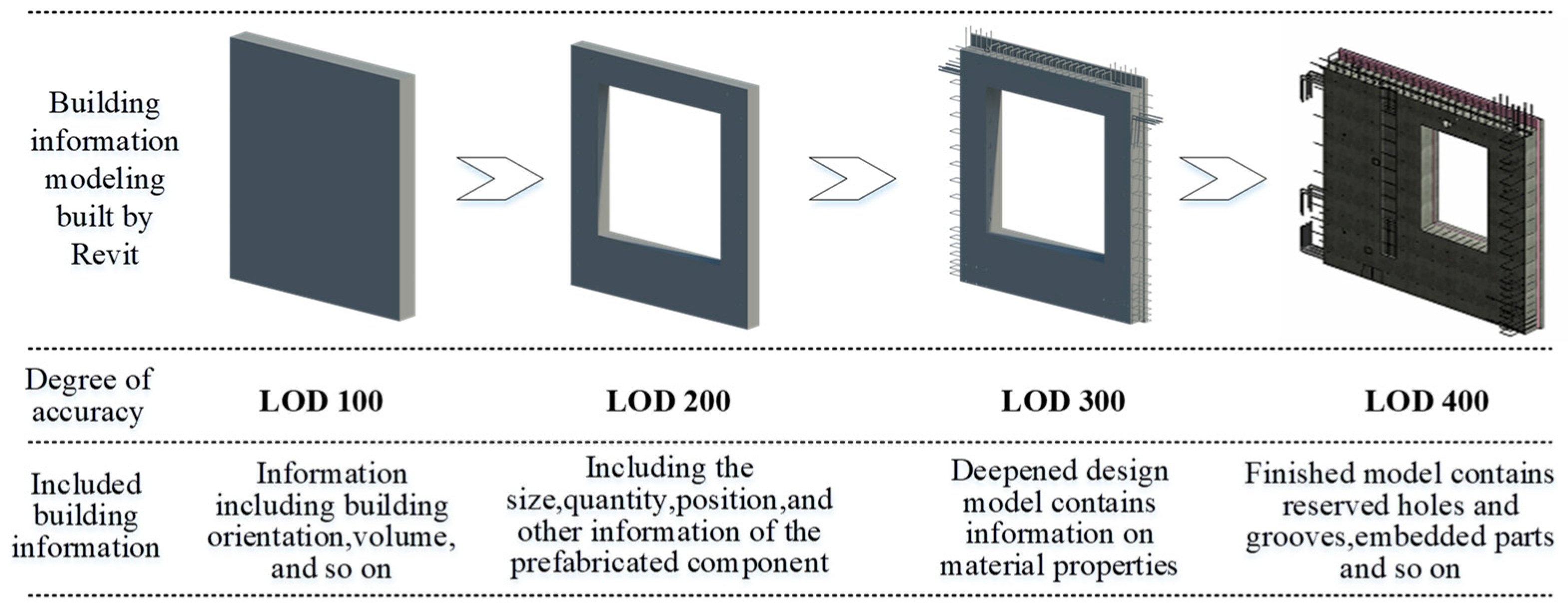

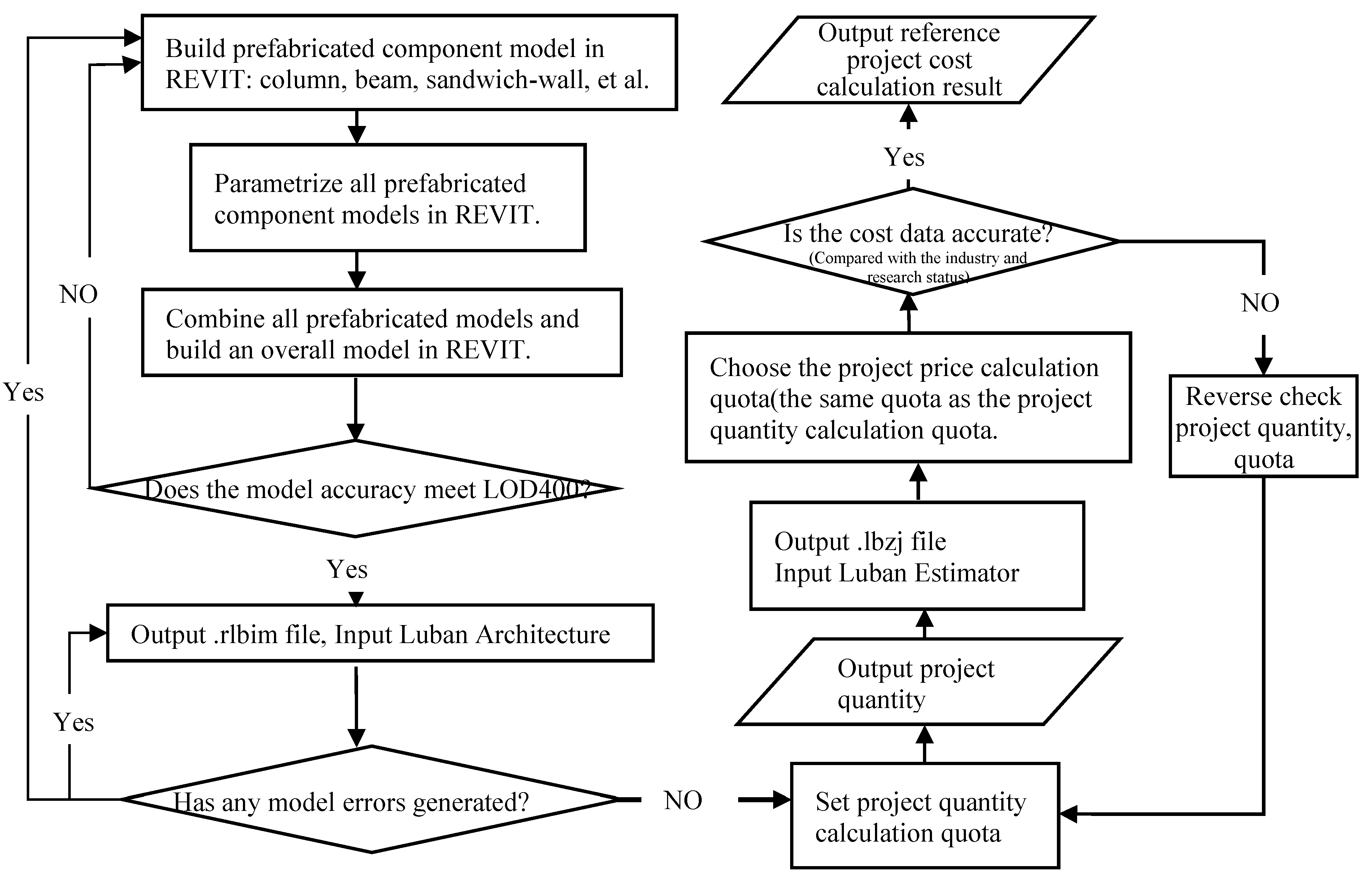

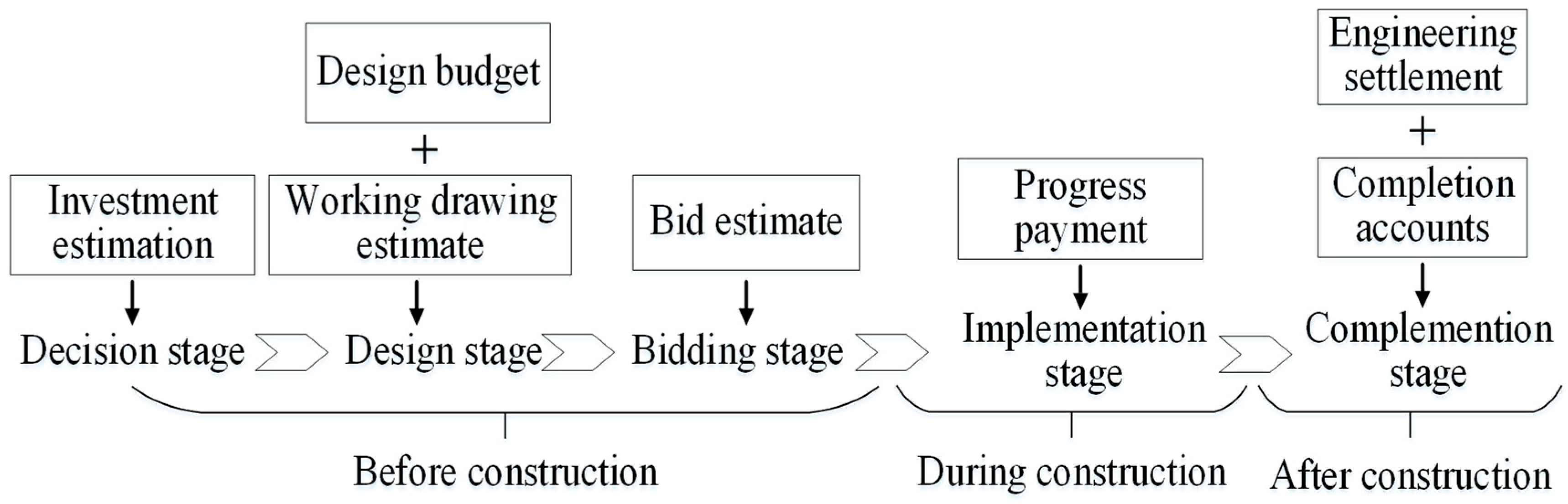

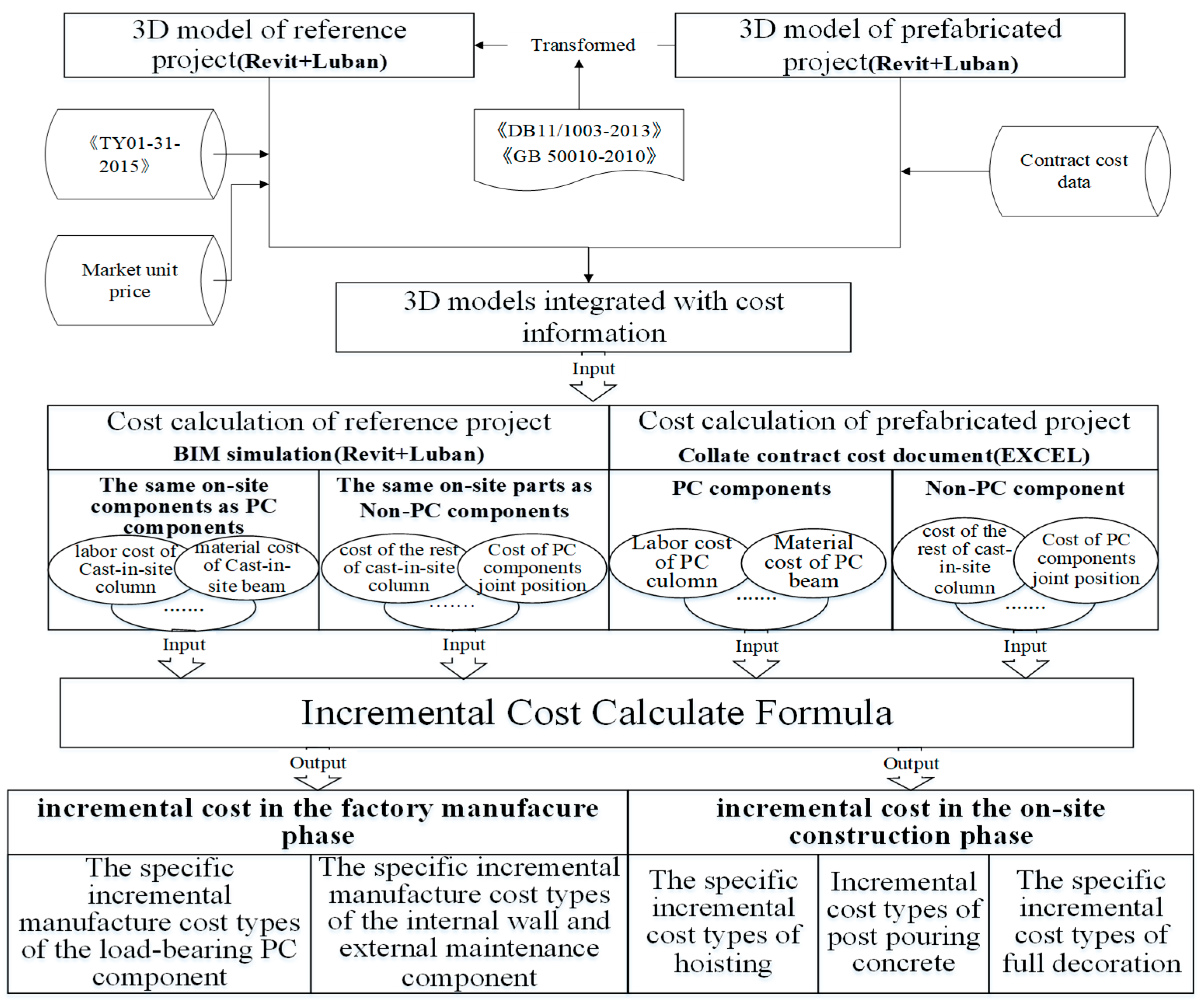

3.2. Incremental Calculation Model Based on BIM Simulation

3.2.1. Cost Calculation for Reference Project

3.2.2. Cost Calculation for Prefabricated Project

3.2.3. Incremental Cost Calculation Model

4. Case Study

4.1. Brief Introduction to the Demonstration Project

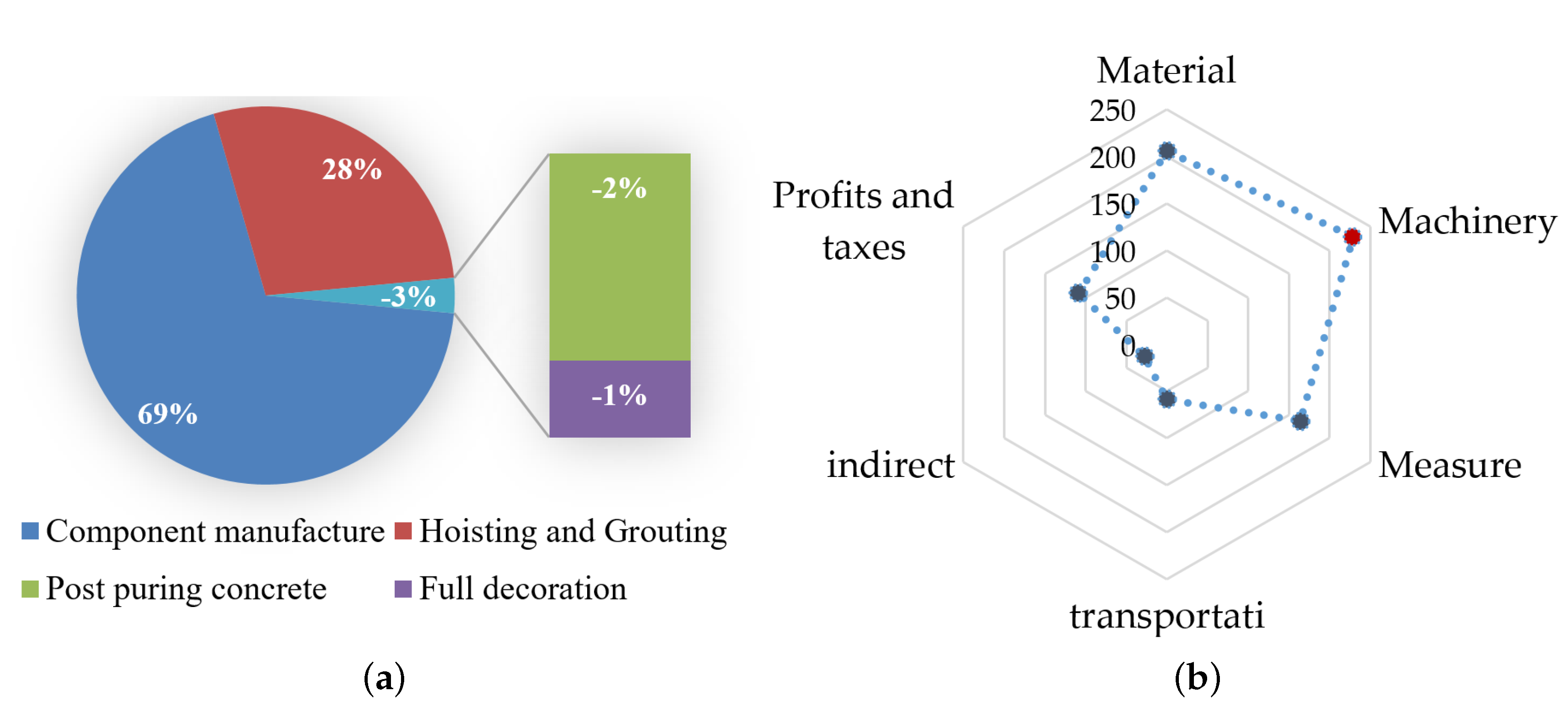

4.2. Incremental Calculation Results of the Whole Construction Period

4.3. Incremental Cost Calculation Results Analysis

4.3.1. Incremental Cost Analysis of the Whole Construction Stage

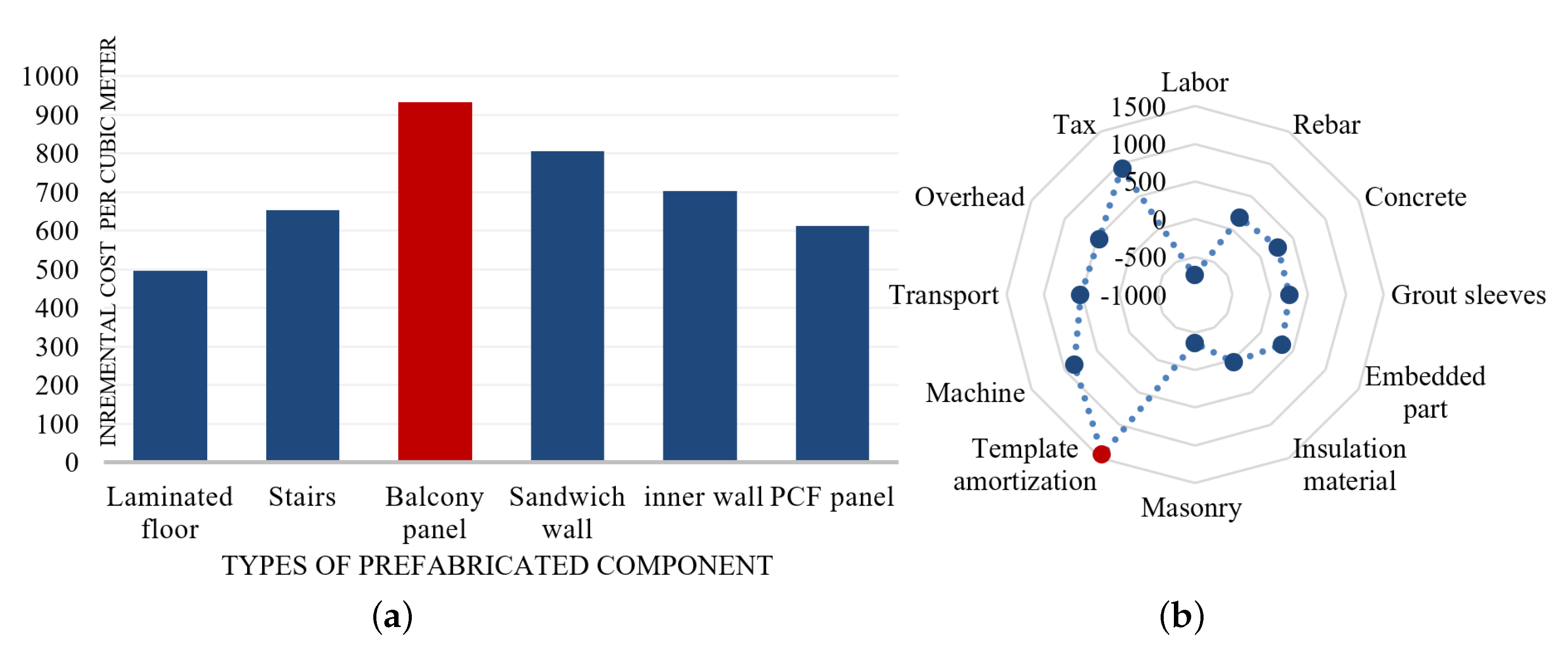

4.3.2. Incremental Cost Analysis of the PFC Production Stage

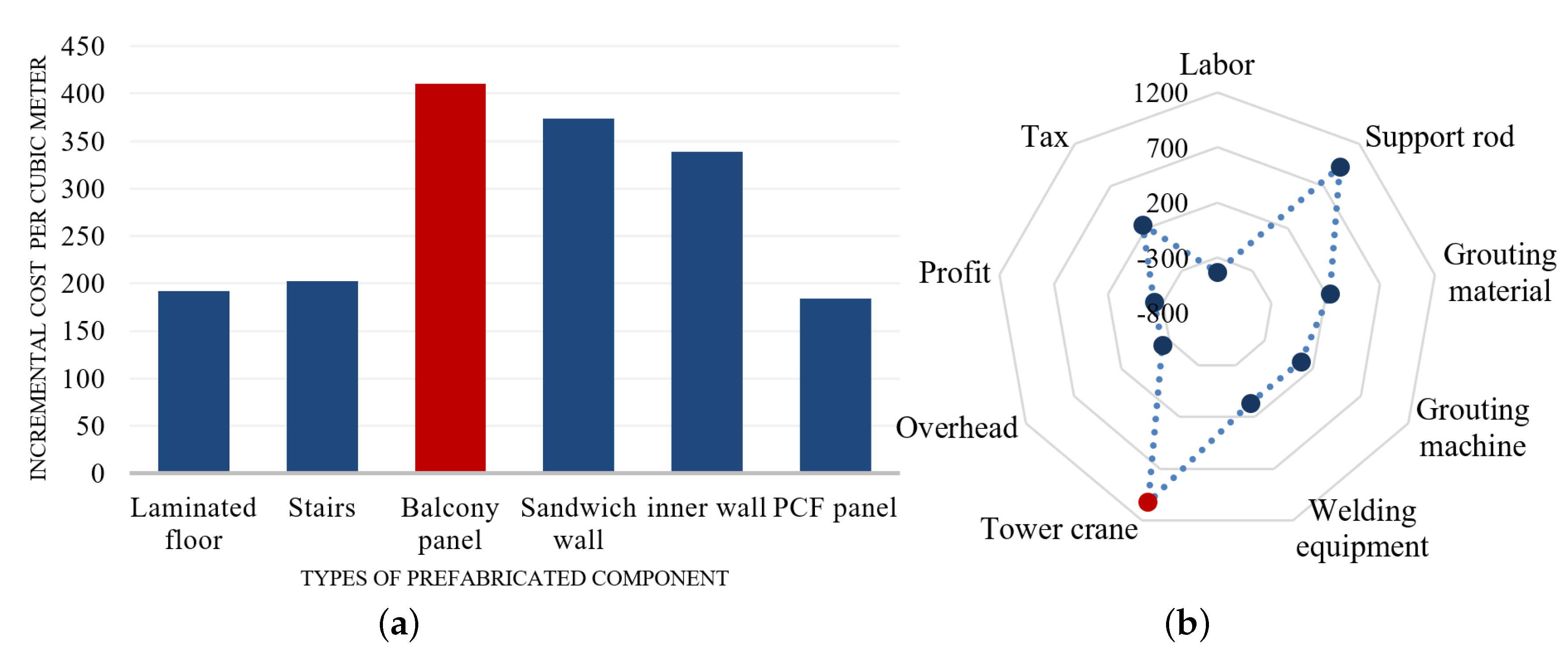

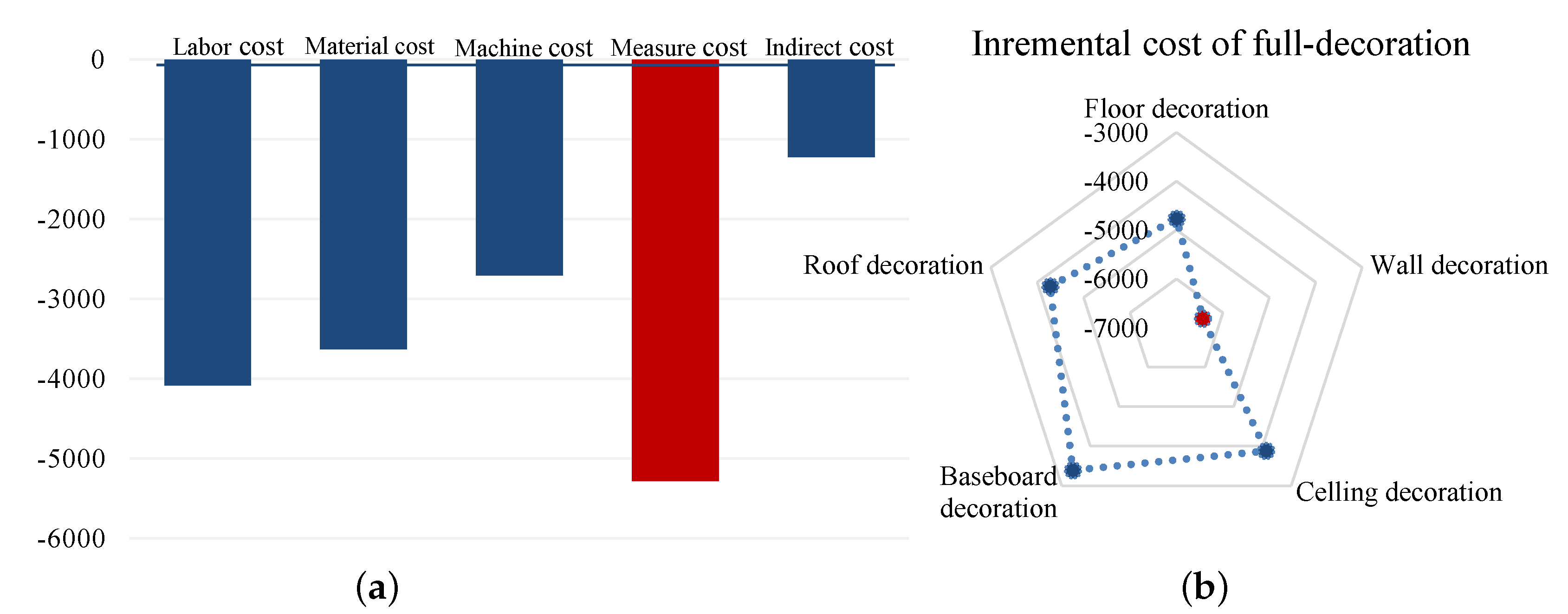

4.3.3. Incremental Cost Analysis of the on-Site Assembly Construction Stage

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Economic and Social Development Statistical Communique of People’s Republic of China. 2017. Available online: http://www.stats.gov.cn/tjsj/zxfb/201802/t20180228_1585631.html (accessed on 28 February 2018).

- Notice of the State Council on Printing and Distributing the National Population Development Plan (2016–2030). Available online: http://www.gov.cn/zhengce/content/2017-01/25/content_5163309.html (accessed on 25 January 2017).

- In August, the National Economy Maintained an Overall Stable, Stable and Positive Development Trend. Available online: http://www.stats.gov.cn/tjsj/zxfb/201809/t20180914_1622877.html (accessed on 14 November 2018).

- Material Waste in the China Construction Industry: Minimization Strategies and Benefits of Recognition. Available online: http://www.ijee.ieefoundation.org/vol5/issue6/IJEE_09_v5n6.pdf (accessed on 30 September 2016).

- Li, J.; Ding, Z.; Mi, X.; Wang, J. A Model for Estimating Construction Waste Generation Index for Building Project in China. Resour. Conserv. Recyc. 2013, 74, 20–26. [Google Scholar] [CrossRef]

- Pedro, S.; Manuela, G.A.; Luís, B.; Vasco, M. Development of prefabricated retrofit module towards nearly zero energy; buildings. Energy Build. 2013, 56, 115–125. [Google Scholar] [CrossRef]

- Guiding Opinions of the General Office of the State Council on Vigorously Developing Prefabricated Buildings. Available online: http://www.gov.cn/zhengce/content/2016-09/30/content_5114118.html (accessed on 30 November 2016).

- Chen, Y.; Cao, X.; Wei, B. Study on the Influence of Value-added Tax on the Project Cost of Prefabricated Buildings. Econ. Bus. Manag. 2017. [Google Scholar] [CrossRef]

- Hong, J.; Shen, Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to Promoting Prefabricated Construction in China: A Cost–Benefit Analysis. J. Clean. Prod. 2018, 172. [Google Scholar] [CrossRef]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Tomas, U.G. Development and Efficiency of Prefabricated Building Components. Smart Home 2016, 10, 85–94. [Google Scholar] [CrossRef]

- Cost Reduction through Cost Effective Construction Techniques. Available online: https://www.ijsr.net/archive/v4i2/SUB151760.pdf (accessed on 3 February 2015).

- Elvira, A.; Jesús, C.; Germán, P.; Guillermo, R.-D. A multi-domain incremental analysis engine and its application to incremental resource analysis. Theor. Comput. Sci. 2015, 585, 91–114. [Google Scholar] [CrossRef]

- Prefabrication: A Lean Strategy for Value Generation in Construction. Available online: https://iglcstorage.blob.core.windows.net/papers/attachment-b2d89667-269f-40cd-a20e-04f2f9082a98.pdf (accessed on 10 July 2006).

- Diana, L.; Thomas, M.F. Analysis of costs and benefits of panelized and modular prefabricated homes. Procedia Eng. 2016, 145, 1291–1297. [Google Scholar] [CrossRef]

- Dorina, N.I.; Sebastian, G.M.; Oana, N. Thermal Analysis of a Structural Solution for Sustainable, Modular and Prefabricated Buildings. Mater. Sci. Eng. 2017, 46, 17–19. [Google Scholar] [CrossRef]

- Qi, L.; Xu, J. Analysis of Incremental Costs of Housing Industrialization and Its Resolution Approach. Build. Econ. 2015, 12, 5–8. [Google Scholar] [CrossRef]

- Yu, W. Discussion on cost control and countermeasure analysis of prefabricated buildings. Low Temp. 2018, 8, 125–128. [Google Scholar] [CrossRef]

- Nick, B.; Ron, W. Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 2013, 9, 72–83. [Google Scholar] [CrossRef]

- Lihong, L.; Zuhai, X.; Xin, F. Cost Analysis of Civil Engineering for Assembled Integral Buildings. Build. Econ. 2014, 35, 63–67. [Google Scholar] [CrossRef]

- Guangming, W.; Zhen, W. Incremental Cost Analysis and Countermeasures of Assembled Concrete Building. Archit. Econ. 2017, 38, 15–21. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Lu, J.; Junbo, R. Research on Incremental Cost Control Method of Assembled Integral Shear Wall Structure. Sci. Technol. 2017, 29, 470–475. [Google Scholar] [CrossRef]

- Talking about the Economics of PC and Related Problems. Available online: https://wenku.baidu.com/view/c695f476a88271fe910ef12d2af90242a895abef.html (accessed on 15 August 2017).

- Zhengdao, L.; Fan, X.; Xiao, L.; Hong, J.; Geoffrey, Q.S. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Fadeyi, O. The role of building information modeling (BIM) in delivering the sustainable building value. Int. J. Sustain. Built Environ. 2017, 6. [Google Scholar] [CrossRef]

- Sungyol, S.; Jeongsam, Y.; Namhyuk, K. Development of a BIM-based structural framework optimization and simulation system for building construction. Comput. Ind. 2012, 63, 895–912. [Google Scholar] [CrossRef]

- Joosung, L.; Jaejun, K. BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects. Sustainability 2017, 9, 426. [Google Scholar] [CrossRef]

- Gulsum, S.B.; Ragip, A. Structured Evaluation of Pre-Construction Cost Alternatives with BIM and Resource Integrated Simulation. Comput. Constr. 2017, 499–506. [Google Scholar] [CrossRef]

- Li, J.; Jarde, A. Integrating Building Information Modelling (BIM), Cost Estimating and Scheduling for Buildings Construction at the Conceptual Design Stage. Master’s Thesis, University of Ottawa, Ottawa, ON, Canada, 2016. [Google Scholar]

- Kim, J.P.; Kwon, O.J.; Shim, H.S.; Kim, R.B.; Kim, J.H.; Woo, S.H. Analysis of Clinical Feature and Management of Fish Bone Ingestion of Upper Gastrointestinal Tract. Clin. Exp. Otorhinolaryngol. 2015, 8, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Chun, L. Cost Analysis and Control of Prefabricated Concrete Building Construction. Master’s Thesis, Liaocheng University, Liaocheng, China, 2016. [Google Scholar]

- Gabriel, L. The incremental cost principle and the conservation of globally important habitats: A critical examination. Ecol. Econ. 2008, 65, 216–224. [Google Scholar] [CrossRef]

- Hadas, G.; Isaac, A.M.; Moshe, S.; Elia, W. Cost-benefit analysis of green buildings: An Israeli office buildings case study. Energy Build. 2014, 76, 558–564. [Google Scholar] [CrossRef]

- Gayatri, V.; Kumar, N.J. What does it cost to convert a non-rated building into a green building? Sustain. Cities Soc. 2017, 36, 107–115. [Google Scholar]

- Dubravka, M.; Jamie, R.; Miloš, E.; Babin, M. NGBS-Certified Single-Family Green Homes: Costs and Benefits. Des. Constr. 2017, 22, 05017001. [Google Scholar]

- Lu, Y.; Wu, Z.; Chang, R.-D.; Li, Y. Building Information Modeling (BIM) for Green Buildings: A Critical Review and Future Directions. Autom. Constr. 2017, 83, 134–148. [Google Scholar] [CrossRef]

- Dubravka, M.; Jamie, R.; Miloš, E.; Babin, M. Economically feasible energy refurbishment of prefabricated building in Belgrade, Serbia. Energy Build. 2014, 98, 74–81. [Google Scholar] [CrossRef]

- Lara, J.; Chi, D.P. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Jeff, H.; Eric, C.G.; He, J.; Gorodetzky, D.; Brown, N. A robust, cross-validation classification method (RCM) for improved mapping accuracy and confidence metrics. Can. J. Remote Sens. 2012, 38, 69–90. [Google Scholar] [CrossRef]

- James, P.S.; Brian, J.R.; Todd, R. Policy Implementation and Cognition: Reframing and Refocusing Implementation Research. Rev. Educ. Res. 2002, 72, 387–431. [Google Scholar] [CrossRef]

- Zhang, X.; Kuchinke, L.; Woud, M.L.; Velten, J.; Margraf, J. Survey Method Matters: Online/Offline Questionnaires and Face-to-Face or Telephone Interviews Differ. Comput. Hum. Behav. 2017, 71. [Google Scholar] [CrossRef]

- Henry, A.; Joseph, H.M.T.; Cheung, F.K.T. BIM in Off-site Manufacturing for Buildings. J. Build. Eng. 2017, 14. [Google Scholar] [CrossRef]

- Research on Engineering Quantity Calculation Method Based on BIM Software. Available online: https://wenku.baidu.com/view/ab6b88b2185f312b3169a45177232f60ddcce78d.html (accessed on 10 May 2018).

- Peter, S. BIM & the 5D Project Cost Manager. Procedia Soc. Behav. Sci. 2014, 119, 475–484. [Google Scholar] [CrossRef]

- Comparison of Cost Comparison between Prefabricated Buildings and Traditional Cast-in-Place Buildings. Available online: https://wenku.baidu.com/view/536ce2a126fff705cc170abb.html (accessed on 4 January 2014).

- Westerweel, B.; Basten, R.J.I.; van Houtum, G.-J. Traditional or Additive Manufacturing? Assessing component design options through lifecycle cost analysis. Eur. J. Oper. Res. 2018, 270. [Google Scholar] [CrossRef]

- Malik, K.; Tayyab, M. Current State of Off-Site Manufacturing in Australian and Chinese Residential Construction. J. Constr. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Catarina, A.; Manuela, A.; Luís, B.; José, A. Cost–benefit analysis method for building solutions. Appl. Energy 2016, 173, 124–133. [Google Scholar] [CrossRef]

| Assembly Technologies (First-Level Indicators) | Incremental Cost Distribution and Classification | ||

|---|---|---|---|

| PFCs Production Stage (Second-Level Indicators) | On-Site Assembly Construction Stage (Second-Level Indicators) | ||

| Load-bearing structural components construction (automatically factory product, | Columns, load-bearing walls, ductile wall panels, etc. vertical load-bearing components | Labor cost: labor cost for structural components production Material cost: rebar, concrete, grout sleeves, insulation parts for bearing structural components production Machinery cost: fixed asset, manufacture line Measure cost: formwork amortization Other costs: overheads, taxes, transportation fee | Labor cost: bearing structural components hoisting, grouting and post-concrete pouring labor Material cost: bearing structural components supporting rods, grouting material, rebar, concrete Machinery cost: grouting machinery, tower crane Measure cost: formwork, scaffold Other cost: overheads, taxes, profit |

| Beams, slabs, stairs, balconies, air conditioning panels and other cover members | |||

| Non-load-bearing components | Outer maintenance components | Labor cost: Non-load-bearing components construction labor Material cost: rebar, concrete, grout sleeves, insulation parts for non-load-bearing components construction Machinery cost: fixed asset, manufacture line Measure cost: formwork amortization; other costs: overheads, taxes, transportation fees | Labor cost: Non-load-bearing components hoisting, grouting and post-concrete pouring labor Material cost: Non-load-bearing components supporting rods, grouting material, rebar, concrete Machinery cost: grouting machinery, tower crane Measure cost: formwork, scaffold Other cost: overheads, taxes, profit |

| Internal wall | |||

| Decoration | Full decoration | —— | Labor, material, machinery costs for floor, baseboard, wall roof and ceiling decoration |

| Letter ID | Title | Workplace |

|---|---|---|

| A | Dean, School of Civil Engineering | North China University of Technology (Beijing, China) |

| B | Deputy Head of the School of Civil Engineering | North China University of Technology |

| C | Assistant/professor of the construction economic evaluation | North China University of Technology |

| D | Lecturer at the School of Smart Construction | North China University of Technology |

| E | Lecturer in project management | North China University of Technology |

| F | Executive vice president (real estate) | Longxin Construction Group Co., Ltd. (Nantong, China) |

| G | Professor-level senior engineer | Zhongjian City Construction Development Co., Ltd. (Beijing, China) |

| H | Director of Intelligent Director of the Intelligent Manufacturing Department | Sanyi Group Co., Ltd. (Beijing, China) |

| I | Senior Engineer | China Construction First Bureau Group Co., Ltd. (Beijing, China) |

| J | Researcher-level Engineer | Nantong Architectural Design and Research Institute Co., Ltd. (Nantong, China) |

| K | Senior engineer | Haimen City Construction Drawing Review Center (Haimen, China) |

| L | Senior engineer | Shanghai Zhongsen Building & Engineering Design Consultant Co., Ltd. (Shanghai, China) |

| M | Assistant/Professor of the project evaluation | Tongji University (Shanghai, China) |

| N | Chief Engineer | Shenyang Wanrong Modern Construction Industry Co., Ltd. (Shenyang, China) |

| O | Lecturer of project economic management | Harbin Institute of Technology (Harbin, China) |

| Formula | Symbolic Interpretation | |

|---|---|---|

| Factory manufacture stage Load-bearing PC components incremental cost (1) | -prefabrication of the i-th load-bearing PC component, j-th cost -simulation of on-site pouring the i-th load-bearing PC component, j-th cost | |

| Factory manufacture stage Internal wall and outer maintenance PC components incremental cost (2) | :-prefabrication of the k-th non-load-bearing PFC, j-th cost :-simulation of on-site pouring the k-th Non- load-bearing PFC, j-th cost | |

| Factory manufacture stage incremental cost (3) | : load-bearing PFC incremental cost : non-load-bearing PFC incremental cost | |

| On-site construction stage-hoisting incremental cost (4) | : g-th hoisting cost of prefabricated construction : g-th hoisting cost of traditional construction | |

| On-site construction stage-Post-concrete pouring incremental cost (5) | : s-th full decoration cost of prefabricated construction. : t-th post-concrete pouring cost of traditional construction | |

| On-site construction stage-Full decoration incremental cost (6) | : s-th full decoration cost of prefabricated construction : s-th full decoration cost of traditional construction | |

| On-site construction stage incremental cost (7) | : incremental cost of hoisting : incremental cost of post-concrete pouring : incremental cost of full decoration | |

| Total incremental cost (8) | : factory manufacture stage incremental cost : on-site construction stage incremental cost |

| Data Sources | Corporate Cost Document (Prefabricated Construction Cost) | BIM Simulation (Reference Construction Cost) | |

|---|---|---|---|

| Index | |||

| Incremental cost of bearing and non-load-bearing PFC production | PFC design drawings PFC manufacture plan PFC cost contract (From components manufacturers) | PFC model(Revit) types; PFC engineering quantity types; (Luban Architecture); Manufacture cost of each type of PFC (Luban Estimator) | |

| Incremental cost of bearing and non-load-bearing PFC hoisting | Structural design drawings Architectural design drawings Construction organization design On-site construction cost documents (from EPC contractor) | Whole building and each type of PFC model (Revit); Engineering quantity of post-concrete pouring parts, decoration and each type of PFC (Luban Architecture); On-site construction cost of post-concrete pouring parts, decoration and each type of PFC (Luban Estimator) | |

| Cost Items | Labor | Material | Machinery | Measure | Transportation | Indirect | Profit and Tax | Total | |

|---|---|---|---|---|---|---|---|---|---|

| Construction Stage | |||||||||

| PFC production | −85.15 | 81.26 | 97.59 | 167.09 | 58.95 | 53.81 | 107.28 | 480.82 | |

| On-site construction | Hoisting and grouting | −48.90 | 132.52 | 133.85 | —— | —— | −25.63 | 2.79 | 194.61 |

| Post-concrete pouring | −2.01 | −5.89 | −1.67 | −3.34 | —— | −1.12 | −1.18 | −15.22 | |

| Full decorati-on | −2.62 | −2.13 | −0.91 | —— | —— | —— | —— | −5.67 | |

| Total | −138.69 | 205.77 | 228.86 | 163.74 | 58.95 | 27.05 | 108.89 | 654.58 | |

| PFC Types | Load-Bearing PFCs | Internal Wall and Outer Maintenance PFCs | Total | |||||

|---|---|---|---|---|---|---|---|---|

| Cost Items | Laminated Floor | Stairs | Balcony | Sandwich Wall | Internal Wall | PCF Panel | ||

| Labor | −192.348 | −64.71 | −172.72 | −138.58 | −29.12 | −147.279 | −744.76 | |

| Material | Steer bar | 115.1854725 | 13.17 | 10.06 | 15.60 | 15.30 | 15.25 | 184.57 |

| Concrete | 119.80 | 14.52 | 52.64 | 15.21 | 45.25 | 15.27 | 262.69 | |

| Grouting sleeve | — | — | — | 84.99 | 170.81 | — | 255.80 | |

| Embedded parts | 39.59 | 59.41 | 35.48 | 56.22 | 62.10 | 80.12 | 332.92 | |

| Insulation material | — | — | — | 12.92 | — | 22.04 | 34.96 | |

| Masonry | — | — | — | −35.95 | −324.22 | — | −360.172 | |

| Formwork amortization | 153.46175 | 184.95 | 369.18 | 300.01 | 252.02 | 201.74 | 1461.36 | |

| Machinery | 51.98 | 113.15 | 297.67 | 142.52 | 154.99 | 93.19 | 853.5 | |

| Transportation | 47.50 | 91.74 | 72.20 | 90.21 | 94.45 | 119.50 | 515.6 | |

| Overhead | 66.75 | 68.96 | 67.44 | 83.87 | 74.09 | 109.55 | 470.66 | |

| Tax | 94.88 | 171.82 | 201.04 | 179.64 | 187.60 | 103.37 | 938.36 | |

| Total | 496.79 | 653.02 | 932.99 | 806.72 | 703.25 | 612.76 | 4205.53 | |

| PFC Types | Load-Bearing PFCs | Internal Wall and Outer Maintenance PFCs | Total | |||||

|---|---|---|---|---|---|---|---|---|

| Cost Items | laminated Floor | Stair | Balcony | Sandwich Wall | Internal Wall | PCF Panel | ||

| Labor | −90.40 | −79.23 | −64.08 | −67.36 | −65.63 | −61.04 | −427.74 | |

| Material | Support rod | 165.76 | 129.19 | 211.48 | 216.61 | 214.28 | 168.28 | 925.60 |

| Grouting material | — | — | — | 114.33 | 119.16 | — | 233.49 | |

| Machinery | Grouting Machinery | — | — | — | 29.70 | 49.35 | — | 79.05 |

| Welding equipment | 37.17 | — | 30.74 | — | — | — | 67.91 | |

| Tower crane | 101.54 | 172.19 | 239.59 | 131.27 | 109.45 | 89.68 | 1023.72 | |

| Overhead | −26.06 | −29.06 | −37.47 | −53.99 | −61.01 | −16.62 | −224.21 | |

| Profit | −23.56 | −20.04 | −29.66 | −50.97 | −75.87 | −22.84 | −222.94 | |

| Tax | 27.96 | 29.42 | 59.60 | 54.33 | 49.25 | 26.77 | 247.33 | |

| Total | 192.41 | 202.47 | 410.20 | 373.92 | 338.98 | 184.23 | 1702.21 | |

| Construction Method | Assembly Construction | Traditional Construction | Total | |

|---|---|---|---|---|

| Cost Items | ||||

| Labor | 63.15 | 65.17 | −2.01 | |

| Material | Rebar | 106.56 | 107.72 | −1.17 |

| Concrete | 101.41 | 102.67 | −1.26 | |

| Masonry | 89.31 | 90.68 | −1.38 | |

| Straight thread Connector | 0.95 | 2.10 | −1.05 | |

| Electro slag pressure welding head | 11.11 | 12.13 | −1.02 | |

| Machinery | Concrete vibrator | 8.72 | 10.39 | −1.67 |

| Measure cost | Formwork amortization | 177.87 | 179.41 | −1.54 |

| Scaffold amortization | 33.36 | 35.168 | −1.81 | |

| Fees | 136.86 | 173.98 | −1.12 | |

| Tax | 99.26 | 100.44 | −1.76 | |

| Total | 828.53 | 843.75 | −15.22 | |

| Construction Method | Assembly Construction | Traditional Construction | Total | |

|---|---|---|---|---|

| Cost Items | ||||

| Labor | Floor decoration | 12.81 | 13.37 | −0.56 |

| Wall decoration | 70.57 | 71.25 | −0.69 | |

| Ceiling decoration | 3.10 | 3.55 | −0.45 | |

| Baseboard decoration | 0.21 | 0.63 | −0.42 | |

| Roof decoration | 7.50 | 8.01 | −0.51 | |

| Material and machinery | Floor decoration | 21.28 | 21.91 | −0.63 |

| Wall decoration | 35.63 | 36.55 | −0.92 | |

| Ceiling decoration | 1.92 | 2.43 | −0.51 | |

| Baseboard decoration | 0.07 | 0.50 | −0.43 | |

| Roof decoration | 16.76 | 17.32 | −0.55 | |

| Total | 169.85 | 175.51 | −5.66 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Y.; Chang, S.; Ji, Y.; Qi, K. BIM-Based Incremental Cost Analysis Method of Prefabricated Buildings in China. Sustainability 2018, 10, 4293. https://doi.org/10.3390/su10114293

Qi Y, Chang S, Ji Y, Qi K. BIM-Based Incremental Cost Analysis Method of Prefabricated Buildings in China. Sustainability. 2018; 10(11):4293. https://doi.org/10.3390/su10114293

Chicago/Turabian StyleQi, Yuan, Siwei Chang, Yingbo Ji, and Kai Qi. 2018. "BIM-Based Incremental Cost Analysis Method of Prefabricated Buildings in China" Sustainability 10, no. 11: 4293. https://doi.org/10.3390/su10114293

APA StyleQi, Y., Chang, S., Ji, Y., & Qi, K. (2018). BIM-Based Incremental Cost Analysis Method of Prefabricated Buildings in China. Sustainability, 10(11), 4293. https://doi.org/10.3390/su10114293