Critical Mineral Security in China: An Evaluation Based on Hybrid MCDM Methods

Abstract

1. Introduction

- (1)

- How should mineral security be defined under the background of sustainable development?

- (2)

- How should national mineral security be measured and tracked?

- (3)

- How did the energy security performance change during the past years?

- (4)

- How can China enhance its national mineral security and minimize the related risks?

2. Materials and Methods

2.1. Dimensions and Metrics

2.1.1. Availability

2.1.2. Accessibility

2.1.3. Technology Efficiency

2.1.4. Sociability and Governance

2.1.5. Environmental Sustainability

2.2. Methods

2.2.1. Fuzzy AHP

- Step 1: Pairwise comparisons of the criteria are made according to their relative importance with respect to the overall goal, and the importance of the alternatives with respect to each criterion using fuzzy numbers. In this study, we relied on the linguistic term and corresponding fuzzy numbers (as presented in Table 2) to make pairwise comparisons.

- Step 2: The comparison matrix is established based on the pairwise comparison in Step 1. Let us assume that a total of n criteria are included in the decision unit, with the criteria represented by . Then, the fuzzy comparison matrix can be obtained as shown below.where is the triangular fuzzy number, represents the lowest possible value, represents the most likely value, and represents the highest possible value.

- Step 3: The value of fuzzy synthetic extent is computed with respect to the criterion, which is defined aswhere

- Step 4: The degree of possibility of ≥ is calculated, which is defined as follows:

- Step 5: The possibility matrix is determined, which is used to describe the relative significance of each pair of criteria using the corresponding value of the fuzzy synthetic extent as shown in Equation (6).

- Step 6: The degree of possibility for the fuzzy synthetic extent is obtained with respect to each criterion to be greater than that for all the other criteria. For instance, the degree of possibility for the fuzzy synthetic extent with respect the criterion is greater than that with respect to all the other criteria, and can be defined as follows:where and .

- Step 7: The weight vectors are normalized, which are written aswhere

2.2.2. PROMETHEE

- Step 1: The decision matrix is established and normalized. Let us assume that there are a total of alternatives and criteria in the decision problem, and donates the attribute value of the alternative with respect to the criterion; then, the decision matrix can be represented by . In order to eliminate the dimensional effect of the metrics, the benefit and cost type criteria are normalized by Equations (11) and (12), respectively; then, the normalized decision matrix can be donated by , where is the normalized value of the alternative with respect to the criterion.where and represent the maximum and minimum values of all the alternatives with respect to the criterion.

- Step 2: The deviations are computed based on pairwise comparisons according to Equation (13), which donates the preference for alternative a over b for the criterion.

- Step 3: The preference function for each criterion is selected. According to Equation (14), the preference function can transform the difference between two alternatives into a preference degree that ranges from zero to one. Usually, six types of generalized preference functions can be used: (1) usual criterion, (2) U-shaped criterion, (3) V-shaped criterion, (4) level criterion, (5) V-shaped with indifference criterion, and (6) Gaussian criterion, as shown in Equations (15)–(20). Among them, the V-shaped criterion is more widely used in practice.

- Step 4: The global preference index for all alternatives is determined by Equation (21); then, their positive and negative outranking flows and are calculated by Equations (22) and (23), respectively.where , and .

- Step 5: The net outranking flow, which represents the final rank of the alternatives, can be determined by Equation (24), where a greater value is better.

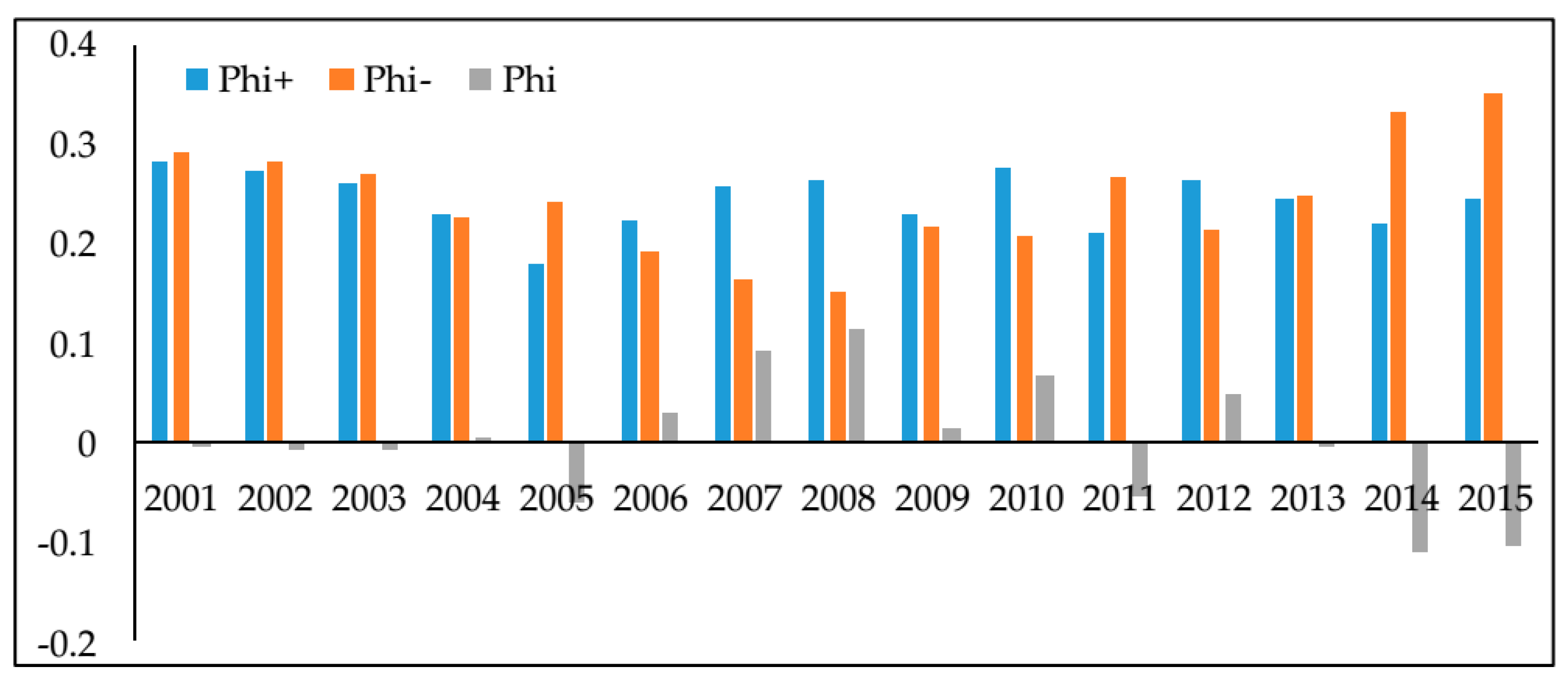

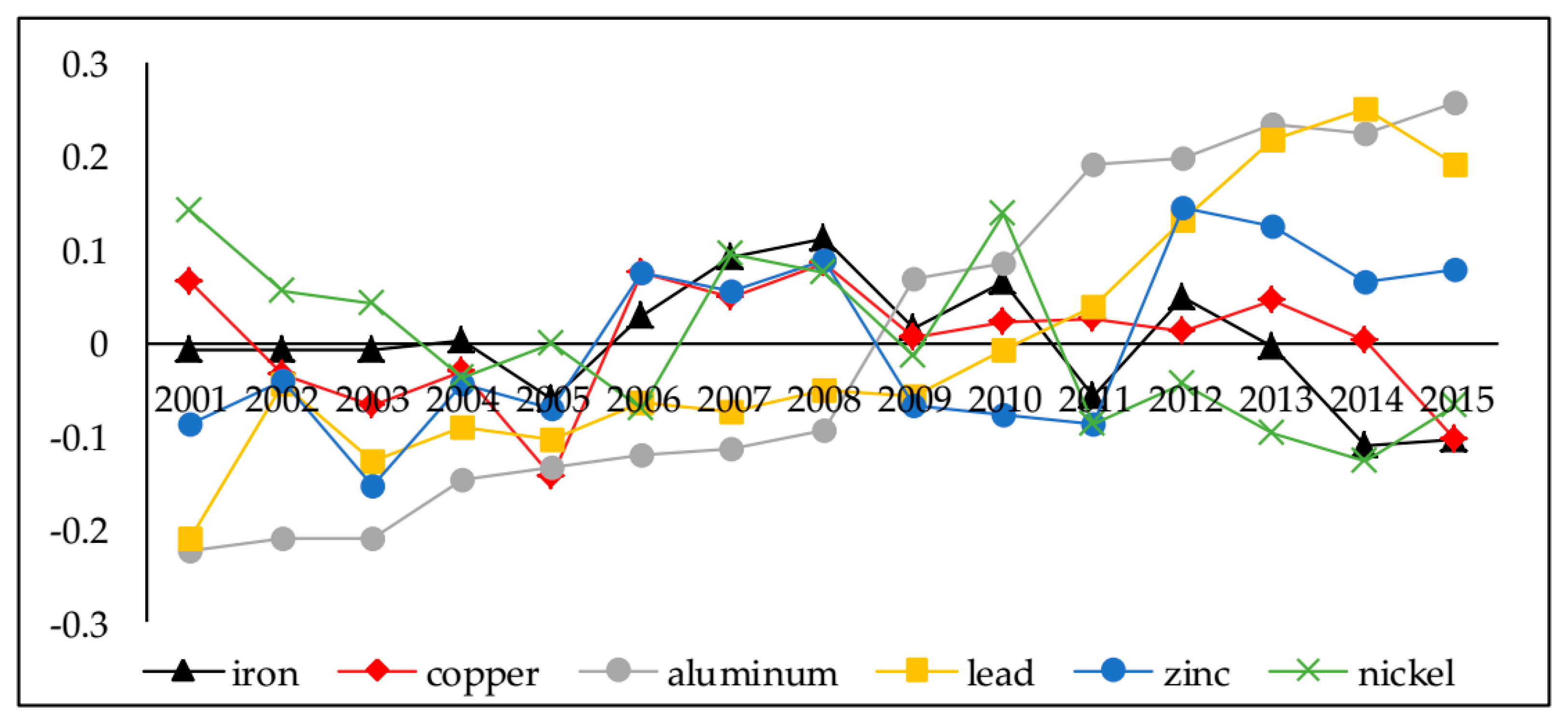

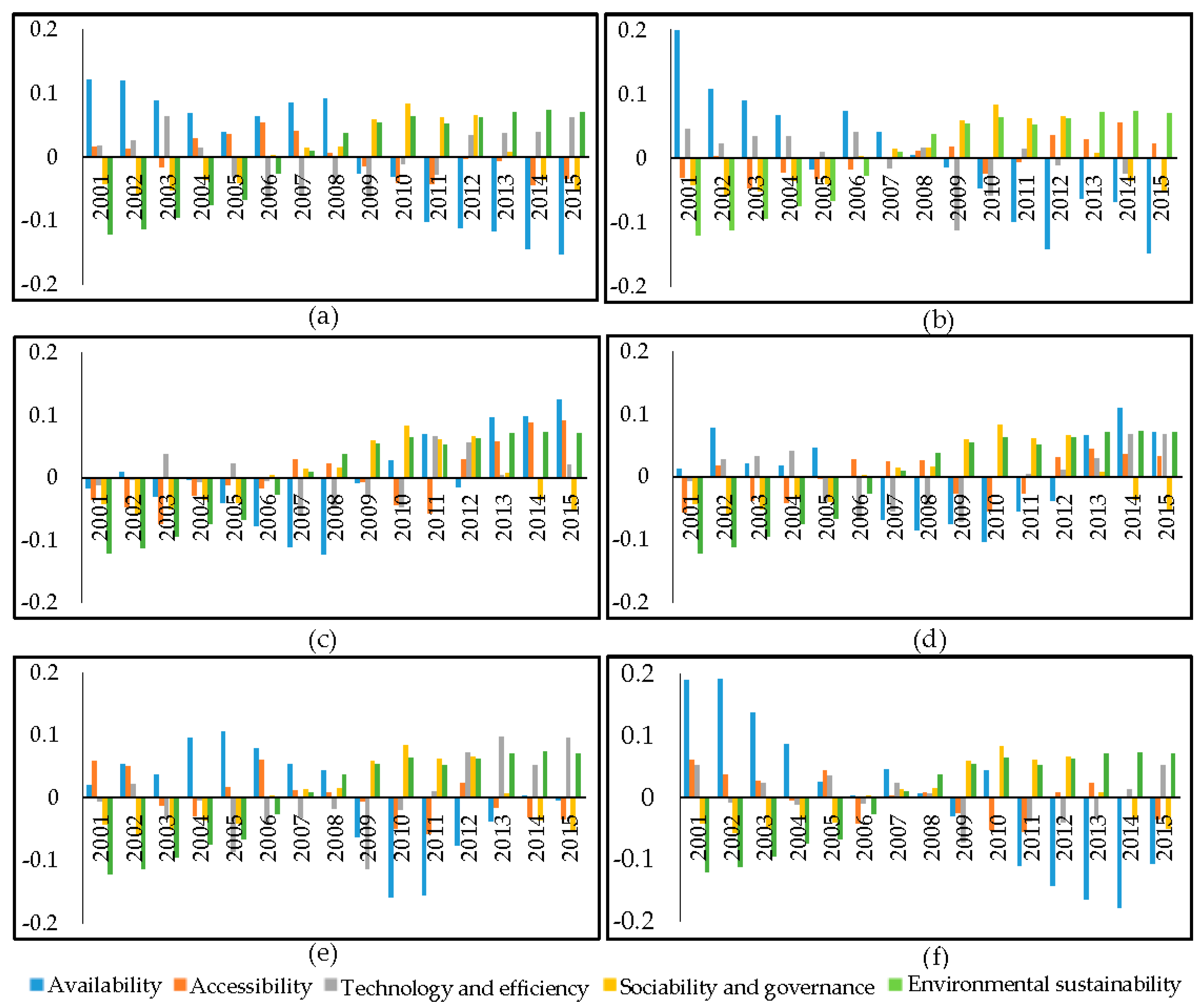

3. Results

4. Policy Implications

5. Conclusions and Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Availability (A1) | Accessibility (A2) | Technology and Efficiency (A3) | Sociability and Governance (A4) | Environmental Sustainability (A5) | |

|---|---|---|---|---|---|

| A1 | E | M | W | V | F |

| A2 | RM | E | RW | W | M |

| A3 | RW | W | E | F | W |

| A4 | RV | RW | RF | E | RM |

| A5 | RF | RM | RW | M | E |

| I1: Reserve to Production Ratio | I2: Per Capita Mineral Reserves | I3: Ratio of Domestic Mineral Reserves to World Total | I4: Self-Sufficiency | I5: Production Centralization | I6: Ratio of Domestic Mineral Production to World Total | |

|---|---|---|---|---|---|---|

| I1 | E | M | W | W | A | V |

| I2 | RM | E | RM | RW | M | M |

| I3 | RW | M | E | W | V | F |

| I4 | RW | W | RW | E | F | F |

| I5 | RA | RM | RV | RF | E | W |

| I6 | RV | RM | RF | RF | RW | E |

| I7: Concentration of Importing Sources | I8: Mineral Price in International Market | I9: Safety of Transport Routes | |

|---|---|---|---|

| I7 | E | F | W |

| I8 | RF | E | RM |

| I9 | RW | M | E |

| I10: Mining Technology Innovations | I11: Newly Discovered Reserves | I12: Mineral Intensity | I13: Comprehensive Utilization of Minerals | |

|---|---|---|---|---|

| I10 | E | M | RW | M |

| I11 | RM | E | RV | RW |

| I12 | W | V | E | M |

| I13 | RM | W | RM | E |

| I14: Proportion of Mining Industry in Total Employment | I15: Wage Level of Mining Industry | I16: Investment on Exploration | I17: Investment on Mining Environment Restoration | I18: Cases of Illegal Mining Activities | |

|---|---|---|---|---|---|

| I14 | E | RW | RV | RA | RW |

| I15 | W | E | RM | RV | M |

| I16 | V | M | E | E | V |

| I17 | A | V | E | E | V |

| I18 | W | RM | RV | RV | E |

| I19: Intensity of Industrial Solid Waste Emissions | I20: Ratio of Industrial Solid Waste Utilized | I21: Intensity of Industrial Waste Water Emissions | I22: Intensity of Industrial COD Emissions | I23: Intensity of Industrial NH3–N Emissions | I24: Intensity of Industrial SO2 Emissions | I25: Intensity of Industrial Soot and Dust Emissions | I26: Intensity of NOx Emissions | |

|---|---|---|---|---|---|---|---|---|

| I19 | E | A | E | F | F | M | W | F |

| I20 | RA | E | RV | RM | RM | RF | RV | RM |

| I21 | E | V | E | F | M | M | W | M |

| I22 | RF | M | RF | E | W | RW | RM | W |

| I23 | RF | M | RM | RW | E | RM | RM | E |

| I24 | RM | F | RM | W | M | E | RW | W |

| I25 | RW | V | RW | M | M | W | E | W |

| I26 | RF | M | RM | RW | E | RW | RW | E |

| Availability (A1) | Accessibility (A2) | Technology and Efficiency (A3) | Sociability and Governance (A4) | Environmental Sustainability (A5) | |

|---|---|---|---|---|---|

| A1 | (1,1,1) | (1,3/2,2) (1,3/2,2) (3/2,2,5/2) | (1/2,1,3/2) (1,3/2,2) (1,3/2,2) | (2,5/2,3) (3/2,2,5/2) (5/2,3,7/2) | (3/2,2,5/2) (1,3/2,2) (3/2,2,5/2) |

| A2 | (1/2,2/3,1) (1/2,2/3,1) (2/5,1/2,2/3) | (1,1,1) | (2/3,1,2) (2/5,1/2,2/3) (1/2,2/3,1) | (1/2,1,3/2) (2/3,1,2) (1,3/2,2) | (1,3/2,2) (1/2,1,3/2) (1/2,1,3/2) |

| A3 | (2/3,1,2) (1/2,2/3,1) (1/2,2/3,1) | (1/2,1,3/2) (3/2,2,5/2) (1,3/2,2) | (1,1,1) | (3/2,2,5/2) (1/2,1,3/2) (3/2,2,5/2) | (1/2,1,3/2) (1,1,1) (1,3/2,2) |

| A4 | (1/3,2/5,1/2) (2/5,1/2,2/3) (2/7,1/3,2/5) | (2/3,1,2) (1/2,1,3/2) (1/2,2/3,1) | (2/5,1/2,2/3) (2/3,1,2) (2/5,1/2,2/3) | (1,1,1) | (1/2,2/3,1) (2/3,1,2) (2/3,1,2) |

| A5 | (2/5,1/2,2/3) (1/2,2/3,1) (2/5,1/2,2/3) | (1/2,2/3,1) (2/3,1,2) (2/3,1,2) | (2/3,1,2) (1,1,1) (1/2,2/3,1) | (1,3/2,2) (1/2,1,3/2) (1/2,1,3/2) | (1,1,1) |

| A1 | A2 | A3 | A4 | A5 | |

|---|---|---|---|---|---|

| A1 | (1.000,1.000,1.000) | (1.167,1.667,2.167) | (0.833,1.333,1.833) | (2.000,2.500,3.000) | (1.333,1.833,2.333) |

| A2 | (0.467,0.611,0.889) | (1.000,1.000,1.000) | (0.522,0.722,1.222) | (0.722,1.167,1.833) | (0.667,1.167,1.667), |

| A3 | (0.556,0.778,1.333) | (1.000,1.500,2.000) | (1.000,1.000,1.000) | (1.167,1.67,2.167) | (0.833,1.167,1.500) |

| A4 | (0.340,0.411,0.522) | (0.556,0.889,1.500) | (0.489,0.667,1.111) | (1.000,1.000,1.000) | (0.611,0.889,1.667) |

| A5 | (0.433,0.556,0.778) | (0.611,0.889,1.667) | (0.722,0.889,1.333) | (0.667,1.167,1.667) | (1.000,1.000,1.000) |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| S1 | - | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| S2 | 0.5277 | - | 0.7893 | 1.0000 | 1.0000 |

| S3 | 0.7277 | 1.0000 | - | 1.0000 | 1.0000 |

| S4 | 0.4028 | 0.8651 | 0.6577 | - | 0.8890 |

| S5 | 0.5027 | 0.9732 | 0.7631 | 1.0000 | - |

| Weight of Dimensions | Metrics | Local Weight of Metrics | Global Weight of Metrics | |

|---|---|---|---|---|

| A1 | 0.3164 | I1 | 0.2527 | 0.0799 |

| I2 | 0.1865 | 0.0590 | ||

| I3 | 0.2108 | 0.0667 | ||

| I4 | 0.2199 | 0.0696 | ||

| I5 | 0.0587 | 0.0186 | ||

| I6 | 0.0714 | 0.0226 | ||

| A2 | 0.1669 | I7 | 0.4629 | 0.0773 |

| I8 | 0.1925 | 0.0321 | ||

| I9 | 0.3446 | 0.0575 | ||

| A3 | 0.2302 | I10 | 0.2652 | 0.0611 |

| I11 | 0.1492 | 0.0344 | ||

| I12 | 0.3488 | 0.0803 | ||

| I13 | 0.2368 | 0.0545 | ||

| A4 | 0.1274 | I14 | 0.0409 | 0.0052 |

| I15 | 0.1213 | 0.0155 | ||

| I16 | 0.3687 | 0.0470 | ||

| I17 | 0.3687 | 0.0470 | ||

| I18 | 0.1004 | 0.0128 | ||

| A5 | 0.1591 | I19 | 0.2027 | 0.0322 |

| I20 | 0.0070 | 0.0011 | ||

| I21 | 0.2027 | 0.0322 | ||

| I22 | 0.1211 | 0.0193 | ||

| I23 | 0.0959 | 0.0153 | ||

| I24 | 0.1248 | 0.0198 | ||

| I25 | 0.1351 | 0.0215 | ||

| I26 | 0.1107 | 0.0176 | ||

References

- Tse, P.K. The mineral industry of China. In US Geological Survey Minerals Yearbook; United States Geological Survey: Reston, VA, USA, 2010. [Google Scholar]

- Singh, M.A.; Nabar, M.M.; N’Diaye, M.P.M. China’s Economy in Transition: From External to Internal Rebalancing; International Monetary Fund: Washington, DC, USA, 2013. [Google Scholar]

- United States Geological Survey. Mineral Commodity Summary. Available online: https://minerals.usgs.gov/minerals/pubs/mcs/2017/mcs2017.pdf (accessed on 27 March 2017).

- Who Holds the Lifeblood of China? Whose Throat Does China Hold? 2017. Available online: http://futures.jrj.com.cn/2017/04/24131622371528.shtml (accessed on 31 July 2018). (In Chinese).

- Editorial Department of China Mining Yearbook. China Mining Yearbook 2013; Seismological Press: Beijing, China, 2014. (In Chinese)

- Chopin, E.I.B.; Alloway, B.J. Distribution and mobility of trace elements in soils and vegetation around the mining and smelting areas of Tharsis, Riotinto and Huelva, Iberian Pyrite Belt, SW Spain. Water Air Soil Pollut. 2007, 182, 245–261. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, H.J.; Cheong, H.K.; Choi, K.; Jang, J.Y.; Jeong, W.C.; Kim, D.S.; Yu, S.; Kim, W.Y.; Lee, K.Y.; et al. Investigation on health effects of an abandoned metal mine. J. Korean Med. Sci. 2008, 23, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Pusapukdepob, J.; Sawangwong, P.; Pulket, C.; Satraphat, D.; Saowakontha, S.; Panutrakul, S. Health risk assessment of villagers who live near a lead mining area: A case study of Klity village, Kanchanaburi Province, Thailand. Southeast Asian J. Trop. Med. Public Health 2009, 38, 168–177. [Google Scholar]

- Zhang, X.; Yang, L.; Li, Y.; Li, H.; Wang, W.; Ye, B. Impacts of lead/zinc mining and smelting on the environment and human health in China. Environ. Monit. Assess. 2012, 184, 2261–2273. [Google Scholar] [CrossRef] [PubMed]

- He, B.J.; Zhao, D.X.; Zhu, J.; Darko, A.; Gou, Z.H. Promoting and implementing urban sustainability in China: An integration of sustainable initiatives at different urban scales. Habitat Int. 2018. [CrossRef]

- He, B.; Zhu, J. Constructing community gardens? Residents’ attitude and behaviour towards edible landscapes in emerging urban communities of China. Urban For. Urban Green. 2018, 34, 154–165. [Google Scholar] [CrossRef]

- Prior, T.; Giurco, D.; Mudd, G.; Mason, L.; Behrisch, J. Resource depletion, peak minerals and the implications for sustainable resource management. Glob. Environ. Change 2012, 22, 577–587. [Google Scholar] [CrossRef]

- Kesler, S.E.; Simon, A.C. Mineral Resources, Economics and the Environment; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Moran, C.J.; Lodhia, S.; Kunz, N.C.; Huisingh, D. Sustainability in mining, minerals and energy: New processes, pathways and human interactions for a cautiously optimistic future. J. Clean. Prod. 2014, 84, 1–15. [Google Scholar] [CrossRef]

- Yu, J.; Yao, S.; Chen, R.; Zhu, K.; Yu, L. A quantitative integrated evaluation of sustainable development of mineral resources of a mining city: A case study of Huangshi, Eastern China. Resour. Policy 2005, 30, 7–19. [Google Scholar] [CrossRef]

- Hatayama, H.; Tahara, K. Evaluating the sufficiency of Japan’ s mineral resource entitlements for supply risk mitigation. Resour. Policy 2015, 44, 72–80. [Google Scholar] [CrossRef]

- Chen, R.H.; Lin, Y.; Tseng, M.L. Multicriteria analysis of sustainable development indicators in the construction minerals industry in China. Resour. Policy 2015, 46, 123–133. [Google Scholar] [CrossRef]

- Ray, G.F. Mineral reserves: Projected lifetimes and security of supply. Resour. Policy 1984, 10, 75–80. [Google Scholar] [CrossRef]

- Anderson, D.L. Implications of the Canada-USA Free Trade Agreement for the Canadian minerals industry. Resour. Policy 1988, 14, 121–134. [Google Scholar] [CrossRef]

- Harker, R.I.; Lutz, T.M. Securities of mineral supplies. Resour. Policy 1990, 16, 115–127. [Google Scholar] [CrossRef]

- Humprheys, D. Whatever happened to security of supply? Minerals policy in the post-Cold War world. Resour. Policy 1995, 21, 91–97. [Google Scholar] [CrossRef]

- Pereira, J.J. Mineral security through landuse planning–case study of rock aggregates in Eastern Selangor. Bull. Geol. Soc. Malays. 2007, 53, 89–93. [Google Scholar]

- Lusty, P.A.J.; Gunn, A.G. Challenges to global mineral resource security and options for future supply. Geol. Soc. Lond. Spec. Publ. 2015, 393, 265–276. [Google Scholar] [CrossRef]

- Hilson, G.; Basu, A.J. Devising indicators of sustainable development for the mining and minerals industry: An analysis of critical background issues. Int. J. Sust. Dev. World 2003, 10, 319–331. [Google Scholar] [CrossRef]

- Petrie, J.; Cohen, B.; Stewart, M. Decision support frameworks and metrics for sustainable development of minerals and metals. Clean Technol. Environ. 2007, 9, 133–145. [Google Scholar] [CrossRef]

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Lehtonen, M. The environmental–social interface of sustainable development: Capabilities, social capital, institutions. Ecol. Econ. 2004, 49, 199–214. [Google Scholar] [CrossRef]

- Pearce, D.; Barbier, E.; Markandya, A. Sustainable Development: Economics and Environment in the Third World; Routledge: Landon, UK, 2013. [Google Scholar]

- McLellan, B.C.; Corder, G.D.; Ali, S.H. Sustainability of rare earths—An overview of the state of knowledge. Minerals 2013, 3, 304–317. [Google Scholar] [CrossRef]

- Petterson, M.G. Minerals sustainability, emerging economies, the developing world, and the ‘truth‘ behind the rhetoric. Est. J. Earth Sci. 2008, 57, 57–74. [Google Scholar] [CrossRef]

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

- Cooper, C.; Giurco, D. The Mineral Resources Landscape—An Expanded Conceptualisation of Minerals Sustainability; Australasian Institute of Mining & Metallurgy: Carlton, Australia, 2009. [Google Scholar]

- Giurco, D.; Cooper, C. Mining and sustainability: Asking the right questions. Miner. Eng. 2012, 29, 3–12. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Mukherjee, I. Conceptualizing and measuring energy security: A synthesized approach. Energy 2011, 36, 5343–5355. [Google Scholar] [CrossRef]

- Liu, G. Development of a general sustainability indicator for renewable energy systems: A review. Renew. Sustain. Energy Rev. 2014, 31, 611–621. [Google Scholar] [CrossRef]

- Bambawale, M.J.; Sovacool, B.K. China’s energy security: The perspective of energy users. Appl. Energy 2011, 88, 1949–1956. [Google Scholar] [CrossRef]

- Von Hippel, D.; Suzuki, T.; Williams, J.H.; Savage, T.; Hayes, P. Energy security and sustainability in Northeast Asia. Energy Policy 2011, 39, 6719–6730. [Google Scholar] [CrossRef]

- Ren, J.; Sovacool, B.K. Quantifying, measuring, and strategizing energy security: Determining the most meaningful dimensions and metrics. Energy 2014, 76, 838–849. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, J.; Sovacool, B.K.; Ren, J. Measuring energy security performance within China: Toward an inter-provincial prospective. Energy 2017, 125, 825–836. [Google Scholar] [CrossRef]

- Shields, D.J.; Blengini, G.A.; Solar, S.V. Integrating life cycle assessment and other tools for ex ante integrated sustainability assessment in the minerals industry. Am. J. Appl. Sci. 2011, 8, 1214–1227. [Google Scholar] [CrossRef]

- Govindan, K. Application of multi-criteria decision making/operations research techniques for sustainable management in mining and minerals. Resour. Policy 2015, 46, 1–5. [Google Scholar] [CrossRef]

- Kabir, G.; Sumi, R.S. Power substation location selection using fuzzy analytic hierarchy process and PROMETHEE: A case study from Bangladesh. Energy 2014, 72, 717–730. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, X.B.; Yang, J.B. Evidential reasoning-based nonlinear programming model for MCDA under fuzzy weights and utilities. Int. J. Intell. Syst. 2010, 25, 31–58. [Google Scholar] [CrossRef]

- Leung, L.C.; Cao, D. On consistency and ranking of alternatives in fuzzy AHP. Eur. J. Oper. Res. 2000, 124, 102–113. [Google Scholar] [CrossRef]

- Kilincci, O.; Onal, S.A. Fuzzy AHP approach for supplier selection in a washing machine company. Expert Syst. Appl. 2011, 38, 9656–9664. [Google Scholar] [CrossRef]

- Razmi, J.; Sangari, M.S. A hybrid multi-criteria decision making model for ERP system selection. In Proceedings of the 4th International Conference on Information and Automation for Sustainability, Colombo, Sri Lanka, 12–14 December 2008; pp. 489–495. [Google Scholar]

- Liu, P.; Jin, F. Methods for aggregating intuitionistic uncertain linguistic variables and their application to group decision making. Inf. Sci. 2012, 205, 58–71. [Google Scholar] [CrossRef]

- Brans, J.P. Lingenierie de la decision. Elaboration dinstrumentsdaide a la decision. Methode PROMETHEE. In Laide a la Decision: Nature, Instrument Set Perspectives Davenir; Nadeau, R., Landry, M., Eds.; Presses de Universite Laval: Quebec, QC, Canada, 1982; pp. 183–214. [Google Scholar]

- Brans, J.P.; Vincke, P.h.; Mareschal, B. How to select and how to rank projects: The PROMETHEE method. Eur. J. Oper. Res. 1986, 24, 228–238. [Google Scholar] [CrossRef]

- Ren, J.; Lützen, M. Fuzzy multi-criteria decision-making method for technology selection for emissions reduction from shipping under uncertainties. Transp. Res. D Transp. Environ. 2015, 40, 43–60. [Google Scholar] [CrossRef]

- World Bank. The World Bank in China. Available online: http://www.worldbank.org/en/country/china/overview#1 (accessed on 27 July 2018).

- Nozomu, K. Where Is the Excess Capacity in the World Iron and Steel Industry?—A Focus on East Asia and China. Available online: https://www.rieti.go.jp/jp/publications/dp/17e026.pdf (accessed on 27 July 2018).

- Lu, Z. China’s Excess Capacity in Steel: A Fresh Look. Peterson Institute for International Economics. Available online: https://piie.com/blogs/china-economic-watch/chinas-excess-capacity-steel-fresh-look (accessed on 27 July 2018).

- The Proposition of the Scientific Outlook on Development. Available online: http://www.hprc.org.cn/gsgl/dsnb/zdsj/201001/t20100109_40258.html (accessed on 27 July 2018).

- Gulley, A.L.; Nassar, N.T.; Xun, S. China, the United States, and competition for resources that enable emerging technologies. Proc. Natl. Acad. Sci. USA 2018, 115, 4111–4115. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.R.; Zhang, T.; Zhou, P.; Zheng, R.R. An analysis of mineral resources distribution and investment climate in the “One Belt, One Road” countries. Geol. Bull. China 2015, 34, 1918–1928. [Google Scholar]

- Farooki, M. China’s Mineral Sector and the Belt & Road Initiative. Available online: http://stradeproject.eu/fileadmin/user_upload/pdf/STRADE_PB_02-2018_One_Belt_One_Road.pdf (accessed on 30 July 2018).

- Fitch Solutions. One Belt One Road: Central Asia As Largest Mining Beneficiary. Available online: https://www.fitchsolutions.com/corporates/metals-mining/one-belt-one-road-central-asia-largest-mining-beneficiary-10-07-2018 (accessed on 30 July 2018).

- Mangino, E.; Carruthers, J.; Pitarresi, G. The future use of structural composite materials in the automotive industry. Int. J. Veh. Des. 2007, 44, 211–232. [Google Scholar] [CrossRef]

- Ramirez-Vazquez, I.; Hernández-Corona, R.; Salgado-Talavera, J.E. Composite Materials as an Alternative to Replace Steel Members on Lattice Power Transmission Towers. J. Mater. Civ. Eng. 2015, 28, 04015151. [Google Scholar] [CrossRef]

- DuPont. Innovative Ideas for Metal Replacement. Available online: http://www.dupont.co.uk/products-and-services/plastics-polymers-resins/articles/innovative-ideas-for-metal-replacement.html (accessed on 30 July 2018).

- Jaroslaw, B.; Barbara, S.; Patryk, J. The comparison of low-velocity impact resistance of aluminum/carbon and glass fiber metal laminates. Polym. Compos. 2016, 37, 1056–1063. [Google Scholar] [CrossRef]

- Gibson, R. Using Polymers as an Alternative to Metals. Available online: http://www.dieselduck.info/library/01%20articles/polymers.htm (accessed on 30 July 2018).

- Barker, C. The Feasibility of Fiber Reinforced Polymers as an Alternative to Steel in Reinforced Concrete. Available online: http://digitool.library.mcgill.ca/webclient/StreamGate?folder_id=0&dvs=1532919621675~183 (accessed on 30 July 2018).

- Yang, J.; Lu, B.; Xu, C. WEEE flow and mitigating measures in China. Waste Manag. 2008, 28, 1589–1597. [Google Scholar] [CrossRef] [PubMed]

- Bigum, M.; Brogaard, L.; Christensen, T.H. Metal recovery from high-grade WEEE: A life cycle assessment. J. Hazard. Mater. 2012, 207, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Sovacool, B.K.; Ren, J.; Ely, A. The Dragon awakens: Innovation, competition, and transition in the energy strategy of the People’s Republic of China, 1949–2017. Energy Policy 2017, 108, 634–644. [Google Scholar] [CrossRef]

- The European Union Chamber of Commerce in China. Overcapacity in China: An Impediment to the Party’s Reform Agenda. 2016. Available online: https://static1.squarespace.com/static/5537b2fbe4b0e49a1e30c01c/t/56cc3017cf80a1fc057c84e4/1456222242257/Overcapacity_in_China_An_Impedim.pdf (accessed on 30 July 2018).

- Smil, V. China’s Environmental Crisis: An Enquiry into the Limits of National Development: An Enquiry into the Limits of National Development; Routledge: London, UK, 2016. [Google Scholar]

- Chan, R.Y. Environmental attitudes and behavior of consumers in China: Survey findings and implications. J. Int. Consum. Mark. 1999, 11, 25–52. [Google Scholar] [CrossRef]

| Dimensions | Components | Metrics | Explanation | Data source |

|---|---|---|---|---|

| A1: Availability | A11: Mineral potential | I1: Reserve to production ratio | Mineral reserves/mineral production | China Mining Yearbook |

| I2: Per capita mineral reserves | Mineral reserves/total population | China Mining Yearbook | ||

| I3: Ratio of domestic mineral reserves to world total | Domestic mineral reserves/world total mineral reserves | Mineral Commodity Summary | ||

| A12: Mineral production | I4: Self-sufficiency | Total mineral production/total mineral consumption | China Mineral Resources | |

| I5: Production centralization | Number of middle–large mineral companies/number of total mineral companies | China Mining Yearbook | ||

| I6: Ratio of domestic mineral production to world total | Domestic mineral production/world total mineral production | Mineral Commodity Summary | ||

| A2: Accessibility | A21: Import security | I7: Concentration of importing sources | China Mining Yearbook | |

| I8: Mineral prices | Mineral prices in the international mineral market | London Metal Exchange | ||

| A22: Transport security | I9: Safety of transport routes | Actual and attempted piracy attacks around the world | International Maritime Organization | |

| A3: Technology and efficiency | A31: Mining technologies | I10: Mining technology innovations | Scientific and technological achievements registered in Ministry of Land and Resources | China Gazette of Land and Resources |

| I11: Newly discovered reserves | Newly discovered reserves/yearly mineral production | China Gazette of Land and Resources | ||

| A32: Mineral utilization | I12: Mineral intensity | Volume of mineral consumption/Gross Domestic Product | China Mining Yearbook | |

| I13: Comprehensive utilization of minerals | Output from comprehensive utilization of minerals/total mining output | China Mining Yearbook | ||

| A4: Sociability and governance | A41: Employment | I14: Ratio of mining workers in total employment | Number of mining workers/total social employment | China National Bureau of Statistics |

| I15: Wage level of mining workers | Average wages of mining workers/average wages of total social employment | China National Bureau of Statistics | ||

| A42: Investment and expenditure | I16: Government investment on mining exploration | Government investment on mining exploration/Gross Domestic Product | China Mining Yearbook | |

| I17: Expenditure on mining environment restoration | Expenditure on mining environment restoration/total government expenditure | China Mineral Resources Report | ||

| A43: Governance efficiency | I18: Cases of illegal mining activities | Illegal cases of mining investigation and exploitation | China Mining Yearbook | |

| A5: Environmental sustainability | A51: Land environment | I19: Intensity of industrial solid waste emissions | Volume of industrial solid waste emissions/Gross Domestic Product | China National Bureau of Statistics |

| I20: Ratio of industrial solid waste utilized | Volume of utilized industrial solid waste/volume of industrial solid waste emissions | China National Bureau of Statistics | ||

| A52: Water environment | I21: Intensity of industrial waste water emissions | Volume of industrial waste water emissions/Gross Domestic Product | China National Bureau of Statistics | |

| I22: Intensity of industrial COD emissions | Volume of industrial COD emissions/Gross Domestic Product | China National Bureau of Statistics | ||

| I23: Intensity of industrial NH3–N emissions | Volume of industrial ammonia nitrogen emissions/Gross Domestic Product | China National Bureau of Statistics | ||

| A53: Air environment | I24: Intensity of industrial SO2 emissions | Volume of industrial SO2 emissions/Gross Domestic Product | China National Bureau of Statistics | |

| I25: Intensity of industrial soot and dust emissions | Volume of industrial soot and dust emissions/Gross Domestic Product | China National Bureau of Statistics | ||

| I26: Intensity of NOx emissions | Volume of industrial solid wastes emissions/Gross Domestic Product | China National Bureau of Statistics |

| Linguistic Scales | Triangular Fuzzy Scales |

|---|---|

| Equally important (E) | (1,1,1) |

| Weakly important (W) | (1/2,1,3/2) |

| Moderately important (M) | (1,3/2,2) |

| Fairly strongly important (F) | (3/2,2,5/2) |

| Very strongly important (V) | (2,5/2,3) |

| Absolutely important (A) | (5/2,3,7/2) |

| Reciprocals of these | Reciprocals of the fuzzy numbers |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Bai, W.; Yu, J.; Ma, L.; Ren, J.; Zhang, W.; Cui, Y. Critical Mineral Security in China: An Evaluation Based on Hybrid MCDM Methods. Sustainability 2018, 10, 4114. https://doi.org/10.3390/su10114114

Zhang L, Bai W, Yu J, Ma L, Ren J, Zhang W, Cui Y. Critical Mineral Security in China: An Evaluation Based on Hybrid MCDM Methods. Sustainability. 2018; 10(11):4114. https://doi.org/10.3390/su10114114

Chicago/Turabian StyleZhang, Long, Wuliyasu Bai, Jing Yu, Linmao Ma, Jingzheng Ren, Weishi Zhang, and Yuanzheng Cui. 2018. "Critical Mineral Security in China: An Evaluation Based on Hybrid MCDM Methods" Sustainability 10, no. 11: 4114. https://doi.org/10.3390/su10114114

APA StyleZhang, L., Bai, W., Yu, J., Ma, L., Ren, J., Zhang, W., & Cui, Y. (2018). Critical Mineral Security in China: An Evaluation Based on Hybrid MCDM Methods. Sustainability, 10(11), 4114. https://doi.org/10.3390/su10114114