5.1. Rationale for Evaluating the Materials Si, GaAs, and GaN

Renewed emphasis has been placed on the development of robust solid-state sensors capable of undergoing uncooled operation in harsh environments [

52]. The sensors must not only detect the existence of chemicals, gas, biological substances, or radiation, but also return the corresponding detected signals back to the central monitoring locations [

52]. Although GaN was already evaluated as the most suitable material, it is still worthwhile to discuss the selection process for determining the best-suited material PM2.5 gas sensors. The following discussion shows the detailed rationale for culling the optimal parameters among the three candidate materials: Si, GaAs, and GaN.

The basic building block of MEMS devices is the substrate, which is an object with a macroscopic surface finish [

105]. In semiconductor electronics, the substrate is a slice of single crystal silicon, commonly known as a ‘wafer’ [

105]. Wafers are also made of other crystalline materials, such as quartz, aluminum, or GaAs [

105]. Although these wafers must be made from as high-quality a material as possible, they must be inexpensive enough to fabricate [

105]. Among all types of substrate materials, the most preeminent advantage of choosing a semiconductor (e.g., Si, Ge, or GaAs) as a substrate material lies in its duality of electrical performance. That is, depending on their application in the microelectronic industry [

105], semiconductor substrates can act both as a medium of reasonably low resistance, i.e., a semiconductor, and as a medium of high resistance, i.e., an insulator.

Silicon substrates were among the first to be used in the semiconductor industry. The adoption of silicon substrates in semiconductor processes dates back to the era of 2-inch wafers. Since then, silicon substrates have been widely adopted from the previous 4-, 6-, and 8-inch, to the current 12-inch processes. In general, silicon substrates are the most widely adopted semiconductor technique by major semiconductor firms and research institutes. According to Roy and Sarkar [

105], silicon has already replaced other materials as a popular semiconductor for several reasons: (1) Silicon is mechanically stable and its implementation in the advanced micro fabrication technology has been practiced for a long time; (2) silicon weighs less than aluminum but possesses higher hardness than steel. The Young’s modulus of silicon is tantamount to that of steel (~2 × 10

5 MPa) and the density of silicon is about 2.3 g/cm

3; (3) silicon can be readily used to implement miniature mechanical devices with high precision, a merit that makes it a nearly perfect structural material; (4) the melting point of silicon is as high as 1400 degrees Celsius, almost twice that of aluminum. This high melting temperature makes silicon difficult to reshape even at high temperature and hence endows silicon with a fine dimensional stability temperature-wise; (5) compared to the thermal expansion coefficients of steel and aluminum, silicon has a thermal expansion coefficient that is about 8 and 10 times smaller, respectively. This significantly smaller thermal expansion coefficient makes silicon more immune to shape change due to temperature variations; (6) there is almost no mechanical hysteresis in silicon. Thanks to this characteristic, silicon is considered an ideal material for building sensors and actuators; (7) the extra-thin film layers serving as the integral structural parts of silicon perform the exact desired electromechanical functions; (8) compared with substrates made from other materials, silicon substrates are more lithe and higher flexibility; and (9) existing for such a long time, the silicon processing steps are already well-defined and the related technological details are already carefully researched and concretely standardized. Applications of silicon substrates range widely from logic products, semiconductor memory and sensors, to micro-electromechanical chips and high-frequency communications products. In general, silicon substrates have the broadest application.

According to Jakovenko [

106], contemporary industrial gas sensors adopting the metal-oxide fabrication process normally apply the screen printing skills to small ceramic substrates. This kind of implementation would typically result in a power consumption level between 1 and 2 watts and a response time on the scale of seconds. Unfortunately, this level of performance does not usually meet the demands required by diagnosis systems feeding on batteries. In other words, to better compensate the limitation of electricity provided by externally-connected batteries, the power consumption of the whole sensor system needs to be low and the response time needs to be short. In addition to these concerns, other factors, such as low cost, small size, user-friendly operational interface, high detection sensitivity, stability, and accuracy are all important facets that need to be carefully pondered over when trying to build an optimal gas sensor. The demand for less rated operational power dissipation and increased system complexity on gas sensors can be satisfied through employment of semiconductor free-standing MEMS micro-hotplates. Typical designs of micro-hotplates are based on membranes made of silicon nitride and silicon oxide. The silicon technology is favored for its inexpensiveness and maturity, but it also suffers from a vital shortcoming. In general, to enhance the sensitivity, selectivity, and response time of a gas sensor adopting the metal-oxide fabrication process, the gas absorption layer is preferred to have high operating temperature. However, the maximum operating temperature of the micro-hotplates fabricated by the silicon technology is approximately 300 to 500 degrees Celsius, a deficiency that harms the candidacy of the silicon technology. In addition to silicon carbide (SiC), an excellent candidate for these applications, the group of III-nitrides can also meet these requirements. In fact, MEMS hotplates based on GaAs and GaN can be very attractive for the design of gas sensor micro-hotplates. Hence, except for the advantages of Si-based sensor techniques being low-cost and widely-commercialized applications in the world, the GaAs and GaN could be better alternatives for PM2.5 gas sensors.

Although Si-based sensors offer the advantages of being low-cost and highly-matured techniques, GaAs-based devices can be a better alternative when higher detection sensitivity and shorter response time are required [

107]. The micro-machined thermal converters (MTCs) designed and fabricated with GaAs can be a possible alternative for the thermally-based MEMS sensor devices in the future. The MTC generally integrates GaAs devices on GaAs thermally-isolated micromechanical structures such as membranes, cantilevers, and bridges. Most of the MTC devices fabricated with GaAs serve as RF/microwave power and infrared thermal sensors [

108]. To fully facilitate the chemical reactions between the molecules of the gas to be detected and the exterior of the sensing material, metal-oxide gas sensors are normally requested to operate at high-temperature [

108]. To keep operating temperatures between 200 and 500 degrees Celsius, low power consumption is required [

108]. Besides, the active sensing area is requested to have uniform temperature distribution so as to ensure that the sensing properties are leveled over the entire sensing surface [

108]. The mechanical stability, integrity, and prompt thermal response are very important figures of merit that one must ruminate during designing process [

108]. All of the above requirements can be fulfilled by the structure of MEMS. The sensing layer is located on the top of a suspended thin dielectric membrane fabricated by using the micromachining process. Meanwhile, every design rule for metal-oxide gas sensors mentioned above can be realized by means of the micro-machined concept of the thermal converter based on GaAs.

In recent years, GaN has also emerged as one of the possible alternatives for the construction materials for MEMS. According to Rais-Zadeh, Gokhale [

109], one interesting direction for GaN research, which is largely unexplored, is GaN-based MEMS devices. The integration of GaN and gas sensors is one possible approach to fully unlock the potential of GaN and realize new advanced all-GaN integrated circuits [

109]. The emergence of the GaN was mainly because of the large bandgap (∼3.5 eV), piezoelectric characteristics, as well as the compatibility with 6H-SiC and (111) Si substrates [

110]. Over the past decade, the GaN-based materials have successfully penetrated into various applications, which include light emitting diodes, the semiconductor ultraviolet (UV) light sources, power electronic devices for microwave communications [

53], and highly accurate electrochemical sensors [

111]. As the development of GaN is just beginning, data pertaining to its mechanical properties are sparse [

110]. The GaN materials system is drawing a great deal of attention for its commercial applications [

112] since GaN provides a new approach to improve the performance of gas sensors in terms of the operating temperature and response time [

113]. Owing to the wide bandgap of the material, it is very thermally stable and its electronic devices can operate at up to 500 degrees Celsius [

112]. Moreover, the material is also chemically stable. The only known wet etchant of it is molten NaOH or KOH. Having only two kinds of effective wet etchants perfectly enables this material to work in chemically severe environments or under strong exposure to radiation fluxes [

112]. Due to the high electron sustainability of the nitride-based HEMTs, the operation frequencies of devices being fabricated by using the GaN range from the very high frequency (VHF) to the X-band frequencies. Furthermore, in comparison to the Si or GaAs based devices, the breakdown voltages, thermal conductivity, and the transmission bandwidth of the GaN based devices have better characteristics [

112]. Therefore, the GaN is also an appropriate material for making gas sensors, such as PM2.5 sensors. Because the HEMTs have great potential to become the primordial GaN electronic device that is likely to be commercialized in next-generation radars and wireless communication systems, the gas sensors fabricated by building the metal-oxide semiconductor (MOS) diodes on AlGaN–GaN HEMT layer structures are attracting a lot of attention [

52]. Different from the Schottky diodes built on a GaN layer, these structures enjoy better performance due to their much higher sensitivity resulting from the gains of intrinsic transistors [

52]. In addition, when it comes to thermal stability, the MOS-gate version of the HEMT is significantly superior to the structure of metal gate, and is thus well-suited to perform gas sensing [

52]. When the ambient changes, it causes variations on the sensing surface potential, and the potential difference will bring about a huge alteration on the channel current [

52]. All of the favorable reasons stated above make GaN an appropriate material to implement in gas sensing. Therefore, Köck et al. [

114] predicted that gas sensors will be the next industrial sensor to be commercialized after pressure sensors.

5.2. Prioritization of the Dimensions and the Influence between Dimensions

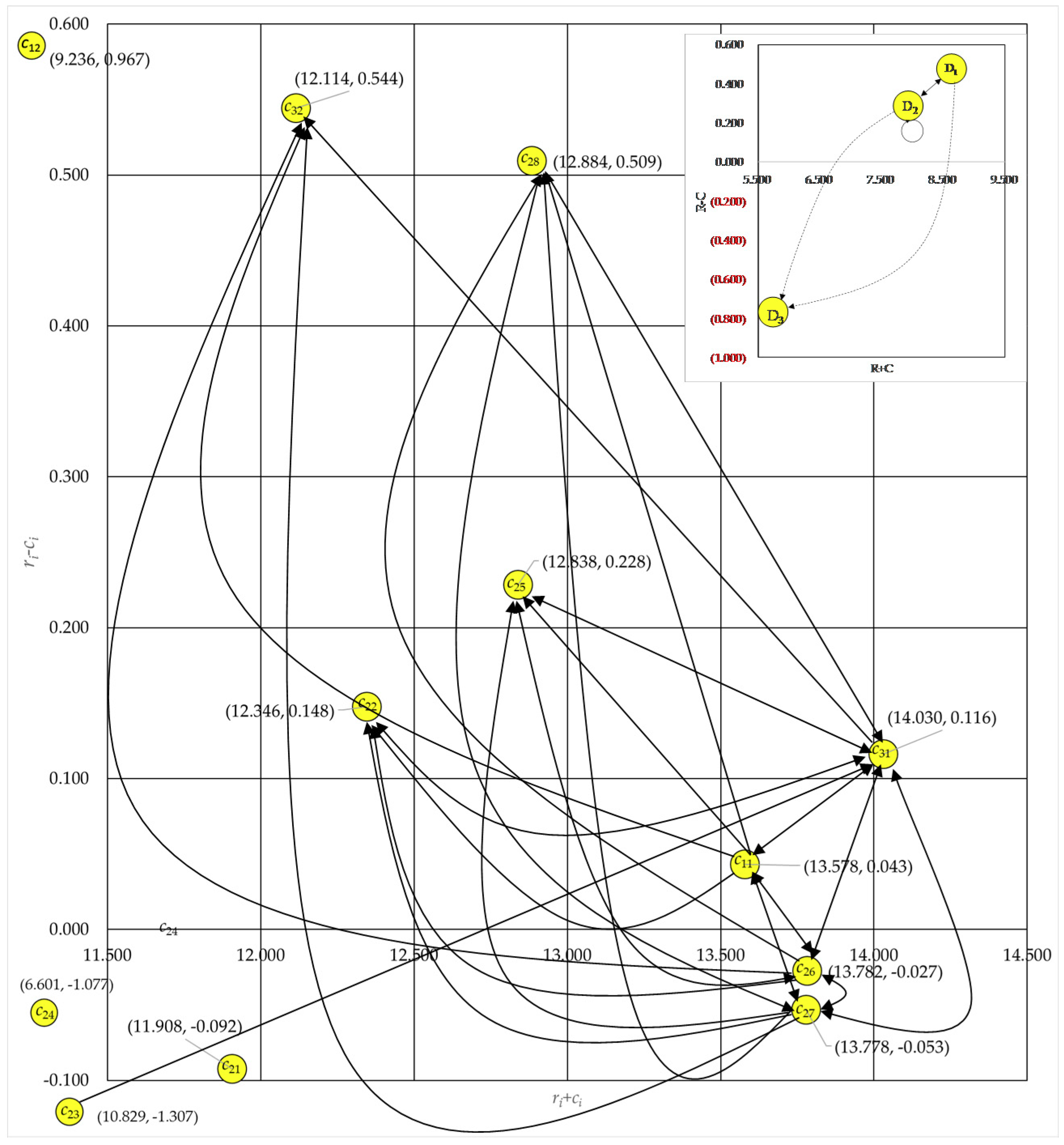

According to the analytical results (

Table 9) derived by the DNP, the process and geometric attributes (

D2) were ranked as the most important dimension. The influence weighs 0.648. The other two dimensions were less important than the process and geometric attributes. Meanwhile, based on the IRM of dimensions demonstrated in the upper right of

Figure 2, the material dimension (

D1) and the process and geometric dimension (

D2) influence each other. The two dimensions influence the economic dimension (

D3). This finding is consistent with earlier works. Tadigadapa and Najafi [

115] argued that at the MEMS scale, at which the thickness of materials is typically a few microns, changes in fabrication processes (

D2) significantly influence their material (

D1) and mechanical properties. According to Gaura and Newman [

116], it is a must to carefully concurrently ponder over the materials (

D1) employed in the fabrication of a particular device and the process flow (

D2), and this coherent planning will form part of the material selection process. It is not rare to find that the ‘best’ material to use based on the quantitative material selection often turns out to be impracticable as a result of processing incompatibility. When faced with such a predicament, a compromise should be ready to come into play as a substitute [

116]. As stated by Tadigadapa and Najafi [

115], the choice of the fabrication process (

D2) is very important in that it defines the overall performance and cost (

D3) of the micromachined part. Burger et al. [

117] also mentioned that technology development teams in MEMS companies work on new concepts to reduce costs (

D3) through miniaturization and a decrease of material consumption (

D1) [

117,

118,

119]. Next, the most influential criteria for each dimension will be discussed.

For the first dimension, namely, the Material Attributes (

D1), the criterion for evaluating the most suitable material for the PM2.5 sensor fabrication was evaluated and selected. Based on the analytical results, suitability for the main structural material (

) is critical from the aspect of material selection and is ranked fourth. The weight associated with the criterion is 9.455%. As the PM2.5 sensor device is directly connected with the substrate, the device material and the structural material for the substrate are closely related. Thus, the fabrication and reliability of the PM2.5 sensor device will be influenced by the main structural material. For the other criteria in this dimension, i.e., suitability for nonstructural purposes (

), the importance to the criterion is comparatively lower, 7.089%, and it is ranked 10th. Applications of materials for nonstructural purposes usually include processes such as metallization and insulation layers [

48]. According to Bali [

53], metallization is the final step in the wafer-processing sequence, and aims to connect the individual devices to form an integrated circuit. As defined by Jones [

54], an insulator is a material that blocks the flow of electric current. As the metallization layer aims to provide connections between devices, and the insulation layer aims to block currents inside the sensor device, the materials are generally independent of the bulk material. That is, no matter which material is selected (e.g., Si, GaAs, or GaN), these metallization and insulation layers are still used. Therefore, independence between the suitability for the main structural material (

) and the suitability for nonstructural purposes (

) is reasonable.

For the second dimension, namely, the Process and Geometric Attributes (

D2), technology readiness (

) and yield (

) are the most influential criteria. Based on the analytical results, technology readiness (

) and yield (

) are critical for the PM2.5 MEMS process and are ranked second and third, respectively. The weights associated with the criteria are 9.556% and 9.542%, respectively. While evaluating the technology readiness (

) of a novel sensor technology, the key decision factor is whether the material can be fabricated using the widely adopted low-cost photolithography and etching equipment. Therefore, the technology’s readiness (

) was assigned a rank of second place (see

Table 10). Whether the device can be successfully commercialized or is technology-ready (

) will further be determined based on three factors: (1) whether the characteristics of the PM2.5 sensors fabricated in the initial stage of the product life cycle are compatible with product specifications; (2) whether the yield (

) will be sufficiently high to achieve economy of scale; and (3) whether the reliability (

) of the sensor meets the requirement of the specification when the sensor is applied under various environments over the long term. The above characteristics for evaluating technology readiness are compatible with the influence relationships demonstrated.

The yield () is of course one of the most important factors in evaluating and selecting the materials. Based on the yield of the PM2.5 sensor, a decision can be made as to whether the materials () should be adjusted. Meanwhile, based on the device structure being finished, whether the precision () of the photolithography alignment is influenced can be further analyzed. Whether the process design can be changed so as to enhance the yield should be considered. If the yield () cannot be improved, then better equipment to enhance the precision () of the photolithography alignment should be adopted.

Good yield () does not imply high reliability (). Reliability depends not only on the characteristics of the device, but also on its operating environment. If a poor operating environment can damage the PM2.5 sensors, then we must consider changing the structure and material of the device to achieve better reliability. Therefore, the yield and reliability are closely interrelated, and neither one can be considered independently. Hence, in the inchoate stages of the product life cycle, before the new PM2.5 sensor products have been commercialized, these two criteria need to be carefully considered and evaluated.

In the third dimension (D3), the capability of the sensor to be mass-produced () will influence future investments (). Based on the analytical results, the capability of the sensor to be mass-produced () is critical from the economic aspect and is ranked first in this research. The weight associated with the criterion is 9.814%. When the technology has reached the mass production stage of the product life cycle, investments in the equipment required for mass production are essential. Equipment, manpower, and thus mass production capacity will be greatly improved. When a new sensor product technology has been proven to be mature and stable after the pilot run of product testing, the mass production process can be initiated. Numerous problems can arise at the mass production stage. Such problems should be overcome although problems will keep emerging. The initiation of mass production may be delayed. Investments in automatic production and measuring equipment and related production analysis management tools can facilitate mass production. Hence, the mass production capability and thus competitive advantages can be improved.

5.3. Mutual Influences between the Most Important Criteria

The mutual influences between the suitability of the main structural material (

), technology readiness (

), yield (

), and capability to be mass-produced (

) are interesting and worthy of further discussion. As introduced in

Section 5.1, MEMS wafers need to be made from as high quality a material as possible; yet, they should be inexpensive to manufacture [

105]. Meanwhile, according to Uttamchandani [

120], high yield (

) of MEMS structures comes from a highly stable and firmly reproducible fabrication process, which is formidable and hard to realize in real-world implementations, and consequently, has remained a grave challenge as well as one of the bottlenecks in MEMS commercialization (

) [

120]. Furthermore, according to the definitions of technology readiness levels (TRLs) (

), the highest level of technology readiness, or the TRL9, can be defined as an actual system proven through successful mission operations [

121]. Based on the report of the Next-generation Low-Cost Multifunctional Web Enabled Ocean Sensor Systems (NeXOS) project [

122], granted by the European Commission, TRL 9 means full commercial application, or that the technology is available for the consumer. Apparently, yield (

) can influence the MEMS commercialization capabilities (

) and thus, the technology readiness level (

).

According to Quinn et al. [

48], the value of MEMS devices often depends on whether or not their mass production is achieved (

). If the MEMS devices have already reached their mass production stage, large capital investments (

) can be paid off over time. The influence relation is consistent with recent works. According to Jiang et al. [

111], the GaN can be produced on a large scale with a mature preparation process. The work by Jiang et al. [

111] is consistent with a recent report mentioning the significant capital and engineering investment in GaN manufacturing capability by TSMC, the industry leader of semiconductor foundries [

123].

As mentioned in

Section 5.2, once the technology has reached the mass production stage (

) of the product life cycle, investments in the equipment required for mass production are essential. Equipment, manpower, and thus mass production capacity will be greatly improved. This is consistent with the work by Bhala [

124], mentioning that businesses prefer not to invest in physical capital equipment for a new product until its features are settled, the exact market identified, and the best way to automate production determined. When a new sensor product technology has been proven to be mature and stable after the pilot run of product testing, the mass production process can be initiated. Numerous problems can arise in the mass production stage. Investments in automatic production, measuring equipment, and related production analysis management tools can resolve these problems, and thus increase the yield (

), technology readiness (

), and facilitate production (

).

Based on the same rationale, the capability to be mass-produced (

) can influence the investment in automatic production, measuring equipment, and related production analysis management tools. Thus, the precision of the MEMS, and thus reliability in terms of the consistency of the MEMS sensor with the specification, can be enhanced. Thus, precision (

) and reliability (

) can be influenced directly by the capability to be mass-produced (

). The capability to be mass-produced (

) can further influence precision (

) and reliability (

) through the material, yield (

), and technology readiness (

). This finding is consistent with the argument by Burkacky et al. [

125] and the yield-learning procedure mentioned by Weber [

126]. Recently, Burkacky et al. [

125] found that the problems do not stop after chips enter the market (

): customers may encounter unexpected performance issues (

and

) and ask semiconductor companies to help resolve them. In many cases, problems arise because important tasks still require frequent manual intervention, despite having some degree of automation. To improve the process, many technology companies are now creating analytical tools that could help fabs replace guesswork and human intuition with fact-based knowledge, pattern recognition, and structured learning [

125]. According to Weber [

126], in order to achieve yields (

) near 100%, i.e., technology readiness (

), a semiconductor manufacturer needs to master a procedure called yield learning, which essentially consists of eliminating one source of faults (

) after another until an overwhelming portion of manufactured units function according to specification (

). By using advanced data analytics, companies can correct errors in physical designs and improve yield (

) and reliability (

) without running a single wafer or making a mask [

125].

5.4. The Independent Criteria

Another criteria belonging to the dimension, the suitability for nonstructural purposes (

), has comparatively lower importance (7.089%), and ranked in 10th place. The applications of materials for nonstructural purposes usually include processes such as metallization or insulation layers [

48]. According to Bali [

53], metallization is the final step in the wafer-processing sequence which aims to connect the individual devices in an integrated circuit. As defined by Jones [

54], an insulator is a material that blocks the flow of electric current. As the metallization layer provides connections between devices and the insulation layer aims to block currents inside the sensor device, the materials are generally independent from the bulk material. That is, no matter which material(s) from the Si, GaAs, or GaN is selected, these metallization or insulation layers are still used. Therefore, the independence between the suitability for main structural material (

) and the suitability for nonstructural purposes (

) is reasonable.

The surface attribute includes the in-plane surface roughness of the beam as well as its out-of-plane/wall roughness [

48]. For the design of mirrors and the reduction of stiction, the roughness is of particular importance [

48]. Besides, the Minimum achievable beam height (

) dimensions play an essential role to help ascertain the compactness, natural frequency, and thermal time constants of the devices. These dimensions also assist in finding the sensitivity limits of the sensors and actuators [

48]. Although the minimum achievable beam height (

) dimensions possess such advantages, they are not applicable in PM2.5 sensor designs. The form factors of PM2.5 sensors are not critical. Meanwhile, the operating frequency is usually only highly critical for communications devices, and is not critical for sensors. Most of the time, PM2.5 sensors operate at ordinary temperatures. Thus, the independence of the surface attribute (

) from other criteria is reasonable.

5.5. Contributions, Limitations, and Future Recommendations

PM2.5 is recognized as one of the most important air pollution issues. Meanwhile, the demand for PM2.5 sensors is surging rapidly in recent years. Most of the newly developed PM2.5 sensors are designed and fabricated by using the MEMS. Selecting an appropriate material for manufacturing an MEMS device or component in general, and for PM2.5 sensors in particular, by considering the material, process, geometric as well as the economic attributes at the same time is not easy. However, very few or no works have tried to investigate what the most appropriate MEMS material is for designing and fabricating future PM2.5 sensors. The evaluation and selection of an MEMS material is, by nature, an MCDM problem. In this work, a HMCDM framework was proposed. Further, the derived influence relationships have been proven to be consistent with prior works. Therefore, we have not only demonstrated the feasibility of the proposed analytic framework but also selected the most suitable MEMS material, GaN, for PM2.5 sensors. The analytic framework and results selected by experts from industry, academic and research institutes are very reasonable and suitable for future applications. In this subsection, we would like to discuss the major contributions, limitations, as well as future recommendations.

5.5.1. Contributions

Firstly, the major contributions will be discussed from three aspects: (1) MEMS material selection; (2) successful integration of TA concepts with MCDM models and successful verification of the models; and (3) the research in sustainability, especially the most up-to-date PM2.5 issue.

From the aspect of MEMS materials selection in general, and the evaluation and selection of MEMS materials for PM2.5 gas sensors in particular, though Za and Du [

51] proposed the concept of evaluating and selecting the manufacturing process and material concurrently, based on the authors’ knowledge and experience of the subject, very limited or no prior works model the concurrent evaluation and selection of MEMS materials. Thus, development and verification of the MCDM-based concurrent evaluation and selection of the MEMS materials will be one of the major research contributions.

The successful integration of TA and advanced MCDM models and the successful verification of models by engineering research results also contribute to the management of technology research and decision analysis. Although the concept of TA emerged in the 1960s [

11], only recently have scholars started to introduce the concept of influence relations between criteria as well as feedbacks. However, very few works have focused on engineering practices, not to mention verification of the influence relationships and analytic results by using engineering analysis results. This study fully verifies the influence relationships between aspects and criteria as well as the alternatives (GaN) selected by engineering research results in this Section. The comparison results are summarized in

Table 12. Such verifications demonstrate the feasibility of the DNP-based HMCDM models based on experts’ opinions.

The selected alternative is consistent with recently published academic works. Rais-Zadeh et al. [

109] argued that GaN-based MEMS is becoming popular. In comparison with other alternatives, such as Si and GaAs, in this work, the comparison results are consistent with the most up-to-date research works. According to Lidow [

127], for the first time in 60 years, a new higher-performance technology is less expensive to produce than its silicon counterpart. According to Tsao et al. [

128], GaN-based transistors had a significant power advantage over GaAs-based transistors; led by GaN-on-Silicon, it is competing to be the next viable alternative to silicon, even as silicon itself continues to evolve towards higher performance (with advances in superjunction MOSFETs, IGBTs, and other devices). Thus, beginning in the 2000s and accelerating in the 2010s, U.S. government investment in GaN electronics research increased within the Department of Defense, especially by DARPA [

128]. Nowadays, the GaN can be produced on a large scale with a mature preparation process [

111]. Meanwhile, according to Reddeppa et al. [

113], GaN provides a new approach to improve the performance of gas sensors in terms of the operating temperature and response time [

113]. Apparently, the GaN will be one of the most suitable materials for future MEMS design.

For the influence relationships between the analytic results and engineering research results, we also verified the consistency between the analytic results derived by the HMCDM methods and those derived by engineering research and published in well-known journals (refer to

Table 12). Based on the authors’ knowledge and experiences, the results derived by MCDM-based analytic models were seldom verified by engineering research results. The consistency between the results derived by both methods further demonstrates the feasibility and the trustworthiness of the expert-opinion based MCDM models.

In terms of the contributions of this research to sustainability, PM2.5 is apparently a very significant problem which is now threatening the sustainable development of human beings. The successful selection of MEMS materials can enable vendors to provide low-cost and high-precision sensors and thus, accelerate the diffusion of PM2.5 gas sensors. The wide distribution of PM2.5 gas sensors, or even connecting these sensors to the Internet and disclosing this air pollution information, can further enhance public awareness and involvement in environmental sustainability [

129]. These sensor technologies enable the capture of environmental data by involving public authorities and the general public, and by making real-time information on environmental conditions available to the wider public [

129].

5.5.2. Limitations

In terms of limitations, in this research, the experts were invited to help determine the aspects, criteria, influence relationships, and the influence weights. Unfortunately, the number of qualified experts is very limited in Taiwan due to the limited number of PM2.5 IC vendors. Therefore, the experts are mainly from research and academic institutes, and the results may seem controversial. To provide results with a wider possibility of interpretation, future research may include studies based on the opinions from foreign institutes and firms.

5.5.3. Future Research Possibilities

In terms of future research possibilities, in the past, the silicon substrate was regarded as the most suitable material for sensor technology; however, by considering the daily complicated operation conditions for future PM2.5 sensors (e.g., smart factories, unmanned aerial vehicles, and unmanned cars), which will operate at higher temperatures, a GaN-on-silicon substrate should be considered. GaN-on-silicon means implementing one epitaxial layer of GaN on the silicon substrate. Such a GaN-on-silicon substrate can be fabricated on 8-inch wafers. The PM2.5 sensors fabricated by GaN substrates can operate at high temperature, whereas the PM2.5 sensors fabricated by other materials cannot fulfill this condition. The environmental impacts on the PM2.5 sensors by GaN will be less. The fabrication cost of the GaN-on-silicon substrate will keep reducing, because various sensor materials can be introduced. Thus, PM 2.5 sensors can also be integrated with other gas sensors that detect such species as carbon monoxide (CO), organic solvents, and sulfides. The functionalities and thus utilities of such integrated sensors can be greatly improved, and thereby also the product values. For system designers, such sensor products can be better leveraged.

Furthermore, because the MCDM methods and HMCDM-based approaches have developed rapidly in recent years, recently developed MCDM methods, such as complex proportional assessment (COPRAS), fuzzy additive ratio assessment method (ARAS-F), multi-objective optimization on the basis of ratio analysis (MOORA), multiple objective optimization on the basis of ratio analysis plus full multiplicative form (MULTIMOORA), step-wise weight assessment ratio analysis (SWARA), and weighted aggregated sum product assessment (WASPAS) [

131], a combination of the dominance-based rough set approach (DRSA) decision-rules with formal concept analysis (FCA) based DANP [

132], etc., can be applied in the future to evaluate suitable materials for sensors or other products in general, and materials for PM gas sensors in particular.