Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca)

Abstract

:1. Introduction

2. Life Cycle Cost Analysis

2.1. US Federal LCCA Process for Highway Construction

2.2. Life-Cycle Cost Analysis Existing Literature

3. Research Objectives and Methods

3.1. Choosing a Project: SR-91 Corridor Improvement Project

3.2. LCCA Process in California Practice

- Step 1:

- Define Pavement Alternatives: the LCCA begins with the selection of pavement alternatives that will accomplish the same performance objectives for a project. The Caltrans LCCA manual includes decision tree flowcharts to guide selection of pavement alternatives but are not shown here as it is outside the purview of this research.

- Step 2:

- Analysis Period is the duration in which the initial and future costs for project alternatives will be evaluated. FHWA’s Policy recommends at least 35 years [14]. Caltrans uses 20 years for Capital Preventive Maintenance (CAPM) projects, 35 years for a 20-year design life and 55 years for any design life longer than 20 years with the analysis period chosen based on the longest design life of alternatives.

- Step 3:

- Traffic Data needed to conduct LCCA are as follows: construction year AADT, total truck percentage, 2-axle percentage truck AADT, annual growth rate of traffic percentage, traffic index and lane closure chart. The Caltrans Traffic Data Branch website is used for the traffic demand and truck percentage for the calculation of the Traffic Index (TI) for the pavement design [31].

- Step 4:

- Step 5:

- Future Maintenance and Rehabilitation (M&R) Schedules identify the sequence and timing of future activities that are required to maintain and rehabilitate the pavement over the analysis period. For Caltrans, the M&R schedules are pre-defined within their manual and chosen based on the project and maintenance characteristics. Interim maintenance treatments between each scheduled major activity are converted into an annualized routine maintenance cost in dollars per lane mile for step 6.

- Step 6A:

- Agency Costs are initial, maintenance, rehabilitation, support and service life costs. There is an Agency Cost module in the CA4PRS program which is used to validate cost estimates for initial costs and future maintenance and rehabilitation costs.

- Step 6A.1:

- Initial Construction Costs: for each design alternative, the initial construction costs are determined from the engineer’s estimate. Construction costs for mainline and shoulder pavement, base and subbase, joint seals, earthwork and time-related overhead should be included. All non-pavement (i.e., traffic, drainage, specialty, storm water protection), add-on (i.e., minor, supplemental, mobilization, contingencies) and project support costs are not included in the LCCA per policy. Construction costs that will not change between alternatives may be excluded if those costs can be separated from the rest of the estimate.

- Step 6A.2:

- Maintenance Costs include costs for routine, preventative and corrective maintenance. Caltrans uses annualized maintenance costs per historical, project-backed data and maintenance activities based on “Pavement M&R Decision Trees” prepared by each district and depicted in the LCCA manual.

- Step 6A.3:

- Rehabilitation Costs include costs for all the necessary appurtenance work for drainage, safety and other features.

- Step 6A.4:

- Future Support Costs should be estimated based on the costs identified in the proposed future activity for each alternative. The RealCost Version 2.5-CA program has a default Agency Support Cost Multiplier for these costs.

- Step 6A.5:

- Remaining Service Life Costs is activities whose service life exceed the analysis period and are calculated by prorating the user/agency costs of the activity.

- Step 6B:

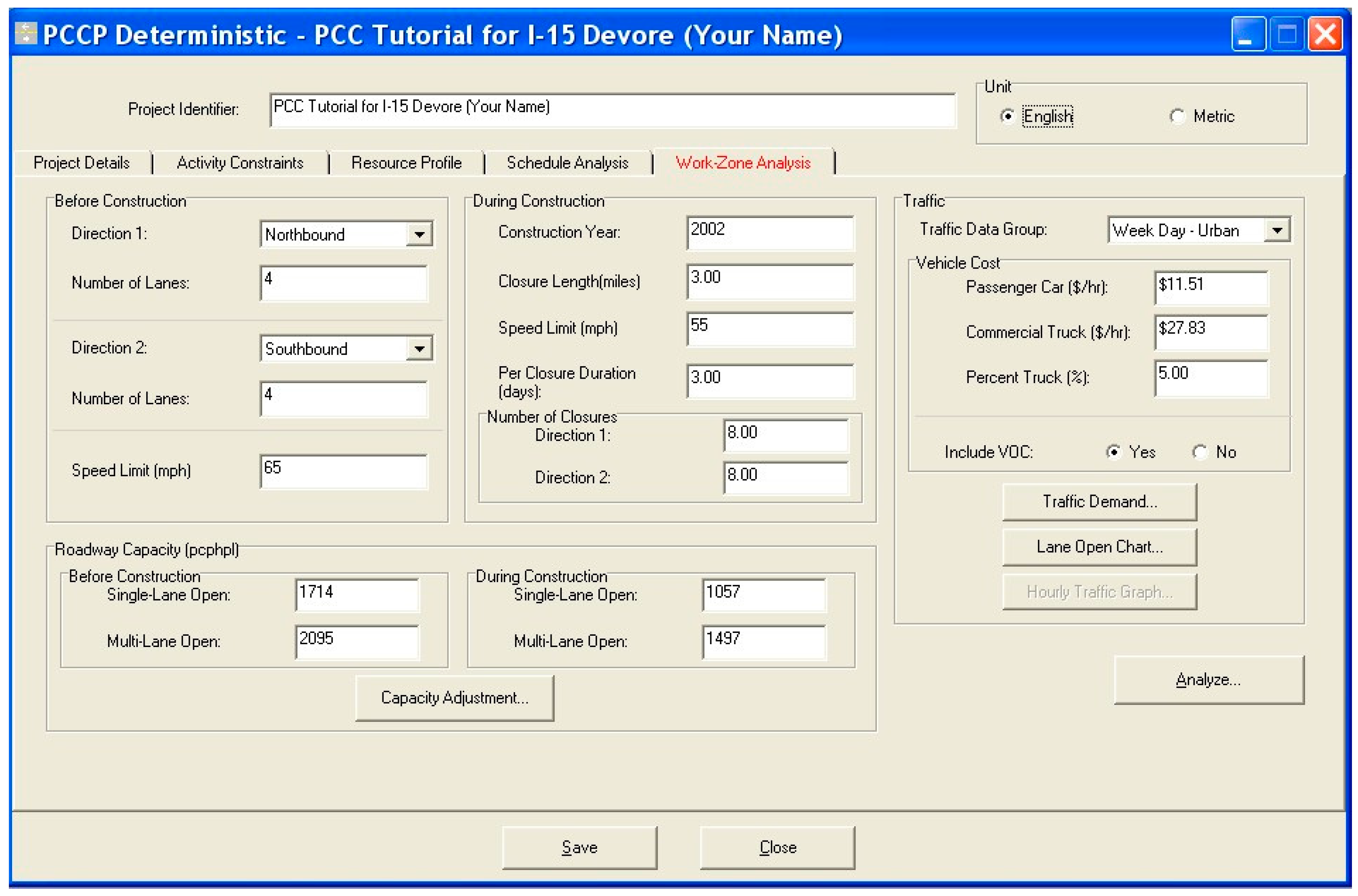

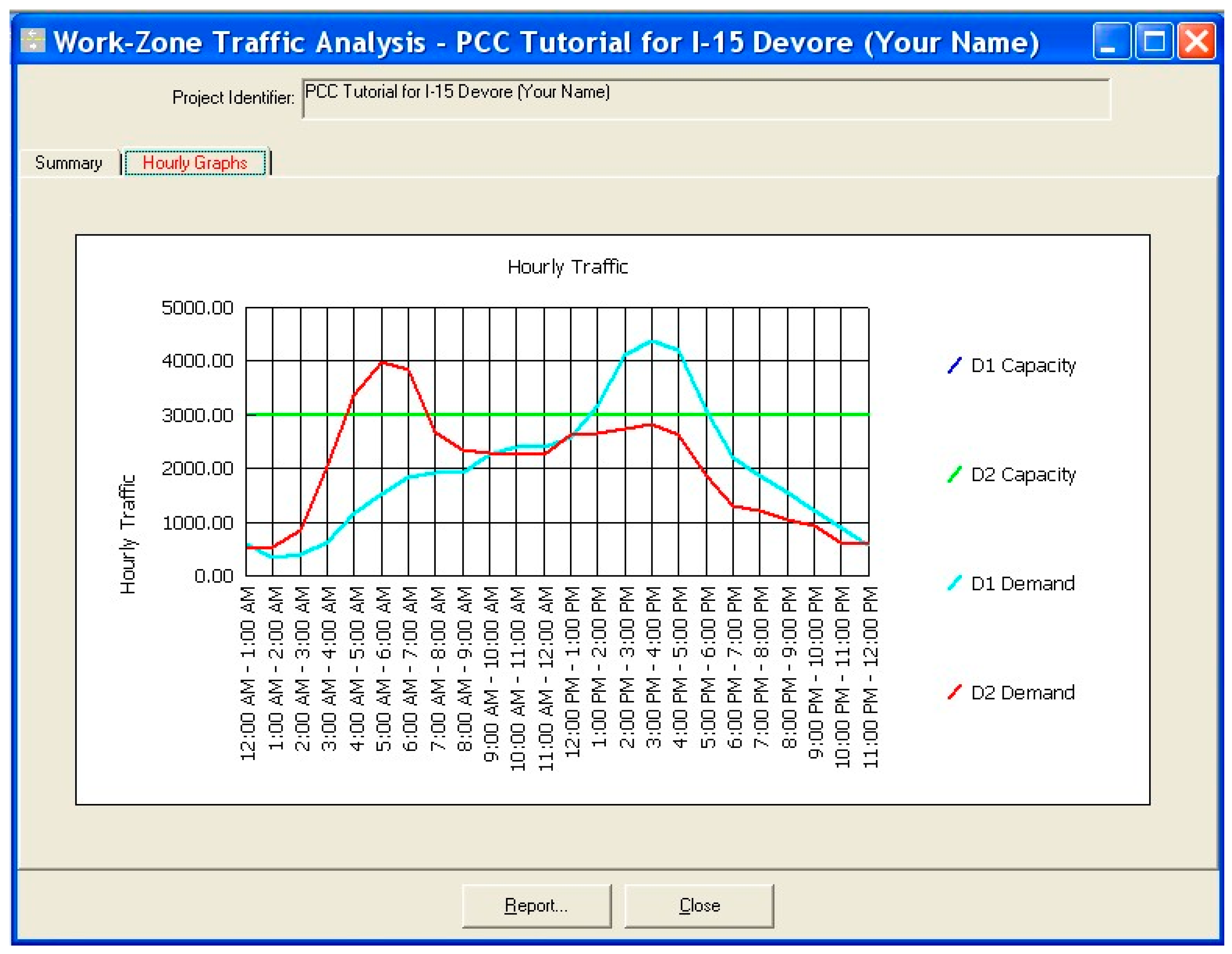

- RUC are costs associated with additional travel time and vehicle operating costs incurred by the traveling public through work-zone due to construction traffic delays with lane closures. There are several RUC models and significant literature dedicated to accurate RUC calculations. This paper and Caltrans, use the CA4PRS program (Work-zone module) which is defined below.

- Step 6C:

- Calculating Life-Cycle Costs involves direct comparison of the total life-cycle costs of each alternative at the present value. Future monies are brought to present values through a process called discounting. Caltrans uses the net present value (NPV) approach, shown below:where F = future cost at the end of nth years i = discount rate n = number of years.

- Step 7:

- LCCA through Software (RealCost): due to the large quantity of variables and robust data sets from which said variables come from, a program is required for final LCCA. Caltrans uses a California-specific modified form of FHWA RealCost called “RealCost Version 2.5-CA”, which is described below along with detailed reasoning and defense of its use [30].

3.3. Life-Cycle Cost Analysis Tools Incorporated

3.3.1. Pavement Design Tools: CalFP and CalAC Software

3.3.2. LCCA Calculation Tool: RealCost Software

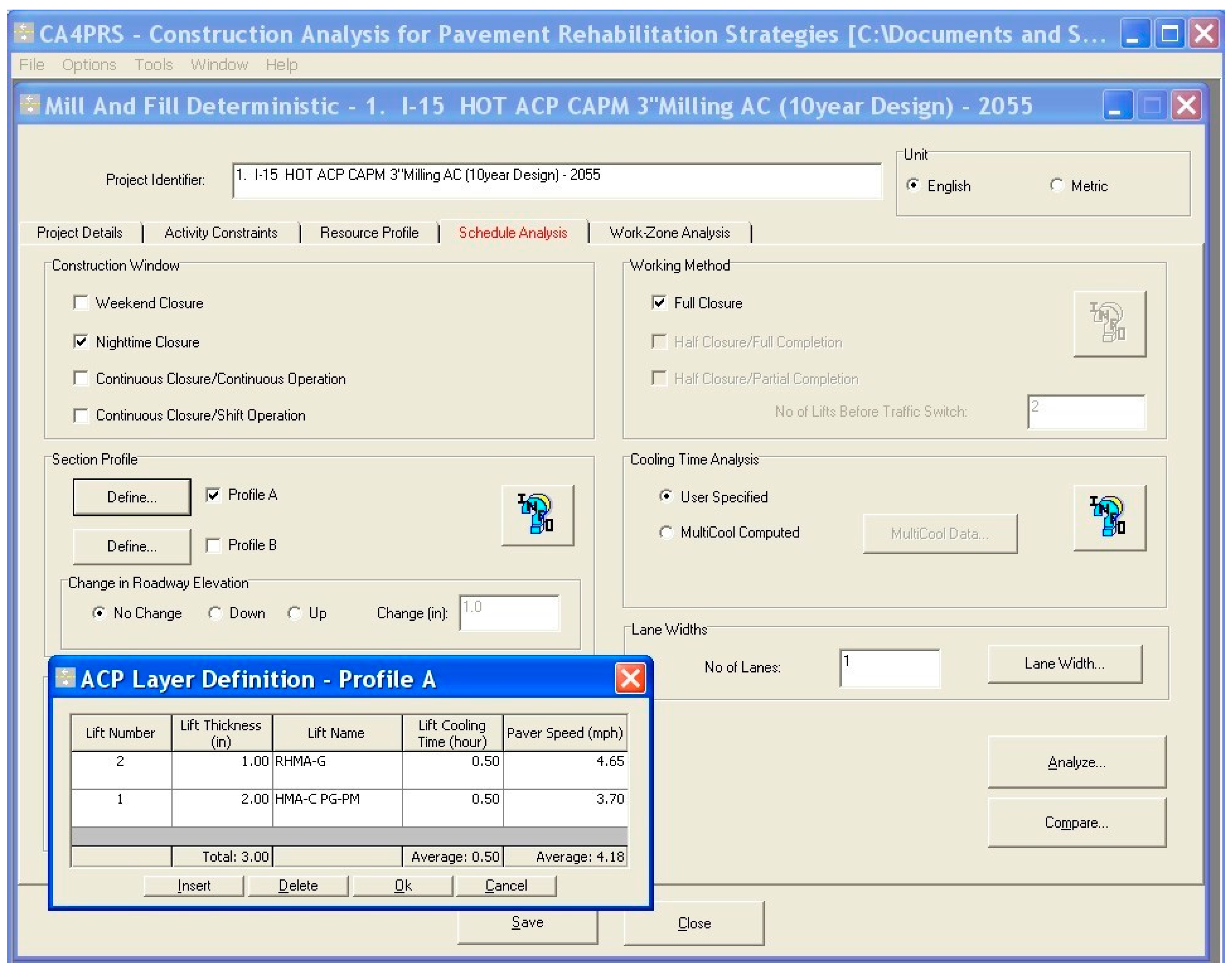

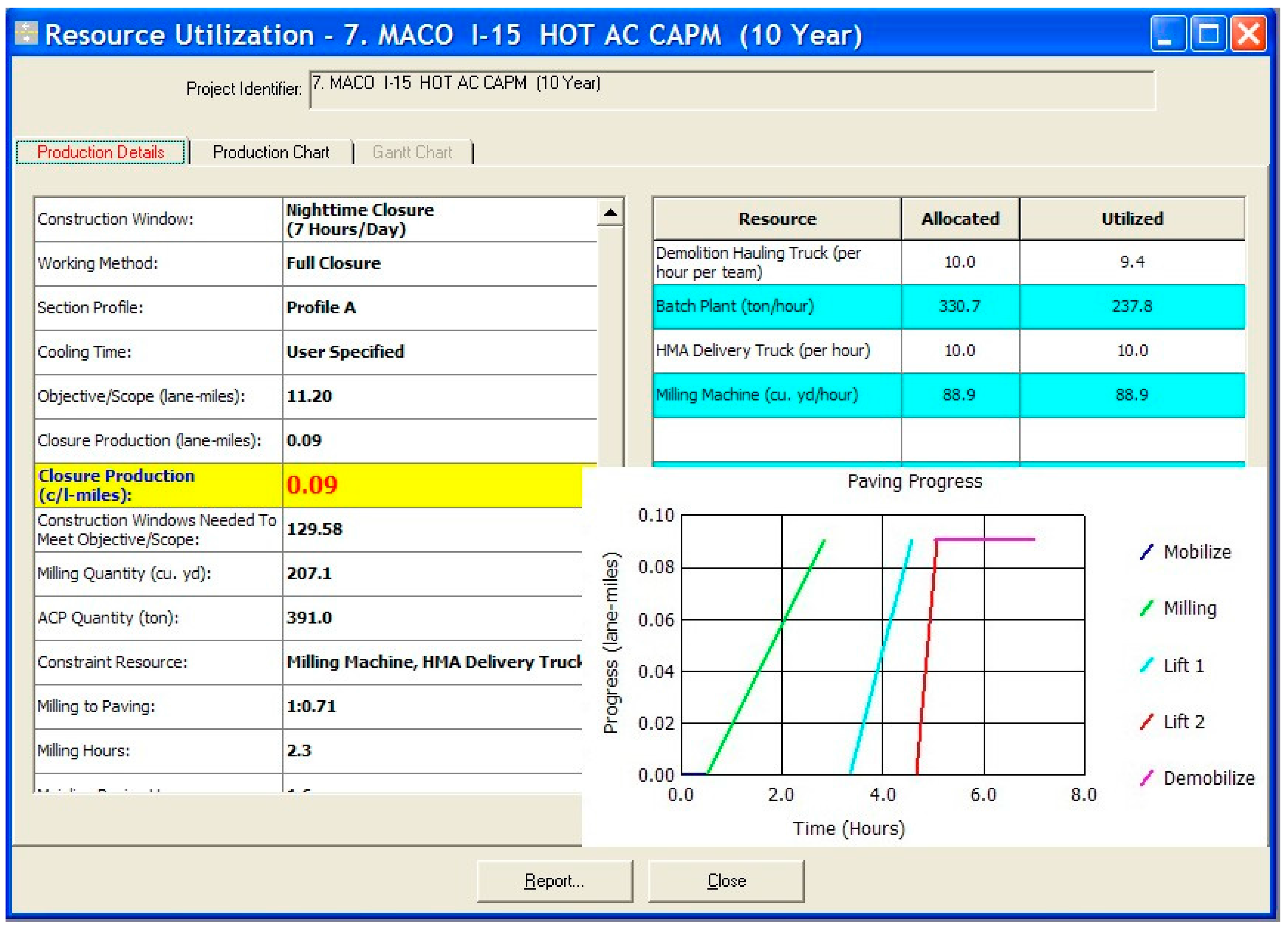

3.3.3. Schedule—Traffic-Cost Estimate Tool: CA4PRS Software

3.4. Validation of Proposed LCCA Processes

4. SR-91 CIP Life-Cycle Cost Analysis: Step-by-Step Process

4.1. Step 1: Define Pavement Alternatives

4.2. Step 2: Analysis Period

4.3. Step 3: Traffic Data

4.4. Step 4: Discount Rate

4.5. Step 5: Future M&R Schedules

4.5.1. Pavement Alternative 1

4.5.2. Pavement Alternative 2

4.5.3. Summary of M&R Activities

4.6. Step 6: Total Life-Cycle Cost Estimate and Analysis

4.6.1. Step 6A.1 Initial Improvement Construction Costs

4.6.2. Step 6A.2 Maintenance Costs

4.6.3. Step 6A.3 Pavement Rehabilitation Costs

4.6.4. Step 6A.4 Agency Support Costs for Future Rehabilitation

4.6.5. Step 6A.5 Remaining Service Life Costs

4.6.6. Step 6B RUCs and Toll Fee Revenue Loss during M&R

4.6.7. Step 6C: Calculating Life-Cycle Costs

4.7. STEP 7: LCCA Comparison and Alternative Selection

4.8. LCCA Conclusions and Recommendation for SR-91 CIP

5. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| LCCA | Life-Cycle Cost Analysis |

| SR-91 CIP | SR-91 Corridor Improvement Project |

| CA4PRS | Construction Analysis for Pavement Rehabilitation Strategies |

| TEA-21 | Transportation Equity Act for the 21st Century |

| FHWA | Federal Highway Administration |

| AADT | Annual Average Daily Traffic |

| GP | General Purpose |

| HOV | High Occupancy Vehicle |

| HDM | Highway Design Manual |

| PA/ED | Project Approval/ Environmental Document |

| CAPM | Capital Preventive Maintenance |

| TI | Traffic Index |

| M&R | Maintenance and Rehabilitation |

| NPV | Net Present Value |

| HMA | Hot Mix Asphalt |

| PCCP | Portland Cement Concrete Pavement |

| ACP | Asphalt Concrete Pavement |

| CRCP | Continuously Reinforced Concrete Pavement |

| RUC | Road User Costs |

References

- American Society of Civil Engineers (ASCE). 2017 Infrastructure Score Card; ASCE: Reston, VA, USA, 2017. [Google Scholar]

- Ozbay, K.; Jawad, D.; Parker, N.; Hussain, S. Life Cycle Cost Analysis: State-Of The-Practice vs. State-Of-The-Art; Transportation Research Record: Washington, DC, USA, 2004. [Google Scholar]

- Flannery, A.; Manns, J.; Venner, M. NCHRP Synthesis of Highway Practice 494: Life-Cycle Cost Analysis for Management of Highway Assets; Transportation Research Board of the National Academies: Washington, DC, USA, 2016. [Google Scholar]

- Papagiannakis, T.; Delwar, M. Computer model for life-cycle cost analysis of roadway pavements. J. Comput. Civ. Eng. 2001, 15, 152–156. [Google Scholar] [CrossRef]

- Zheng, N.; Liu, A.G.X.; Jin, Y. Evaluation of tools for incorporating road user costs in pavement rehabilitation decision making on rural highways in Saskatchewan. In Proceedings of the Seventh International Conference on Traffic and Transportation Studies, Kunming, China, 3–5 August 2010; pp. 522–534. [Google Scholar]

- Yu, J.; Huang, X.; Liao, G. Expressway work zone life cycle user costs model. In Proceedings of the ICCTP 2010 10th International Conference of Chinese Transportation Professionals, Beijing, China, 4–8 August 2010; pp. 1415–1420. [Google Scholar]

- Lee, E.B.; Kim, C.; Harvey, J.T. Pavement Type Selection for Highway Rehabilitation Based on a Life-Cycle Cost Analysis: Validation of California Interstate 710 Project (Phase 1); Transportation Research Record: Washington, DC, USA, 2011; pp. 23–32. [Google Scholar]

- US Department of Transportation (USDOT). Life-Cycle Cost Analysis Primer; FHWA Report No. FHWA-IF-02-047; FHWA: Washington, DC, USA, 2002.

- Wilde, W.; Walkes, S.; Harrison, R. Life Cycle Cost Analysis of Portland Cement Concrete Pavements; FHWA: Washington, DC, USA, 1999.

- Winfrey, R. Economics Analysis for Highways; International Textbook Company: Scranton, PA, USA, 1969. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1983. [Google Scholar]

- Peterson. NCHRP Synthesis of Highway Practice 122: Life-Cycle Cost Analysis of Pavements; Transportation Research Board of the National Academies: Washington, DC, USA, 1985. [Google Scholar]

- US Department of Transportation. Life Cycle Cost Analysis in Pavement Design, Demonstr; Project No. 115; Office of Asset Management, FHWA: Washington, DC, USA, 1998.

- FHWA. Life-Cycle Cost Analysis in Pavement Design—Interim Technical Bulletin; FHWA-SA-98-079; U.S. DOT, Federal Highway Administration: Washington, DC, USA, 1998.

- Hallin, J. NCHRP Report 703: Guide to Pavement-Type Selection; Transportation Research Board of the National Academies: Washington, DC, USA, 2011. [Google Scholar]

- Hawk, H. NCHRP Report 483: Bridge Life-Cycle Cost Analysis; Transportation Research Board of the National Academies: Washington, DC, USA, 2003. [Google Scholar]

- Zimmerman, K.; Smith, K.; Grogg, M. Applying Economic Concepts from Life-Cycle Cost Analysis to Pavement Management Analysis; Transportation Research Record: Washington, DC, USA, 2000. [Google Scholar]

- Rangaraju, P.R.; Amirkhanian, S.; Guven, Z. Life Cycle Cost Analysis for Pavement Type Selection; FHWA, South Carolina Department of Transportation: Clemson, SC, USA, 2008.

- Babashamsi, P.; Yusoff, N.I.M.; Ceylan, H.; Nor, N.G.H.; Jenatabadi, H.S. Evaluation of pavement life cycle cost analysis: Review and analysis. Int. J. Pavement Res. Technol. 2016, 9, 241–254. [Google Scholar] [CrossRef]

- Abaza, K.A. Optimum flexible pavement life-cycle analysis model. J. Transp. Eng. 2002, 128, 542–549. [Google Scholar] [CrossRef]

- Tighe, S. Guidelines for Probabilistic Pavement Life Cycle Cost Analysis; Transportation Research Record: Washington, DC, USA, 2001. [Google Scholar]

- Reigle, J.A.; Zaniewski, J.P. Risk-Based Life-Cycle Cost Analysis for Project-Level Pavement Management; Transportation Research Record: Washington, DC, USA, 2002. [Google Scholar]

- Salem, O.; AbouRizk, S.; Ariaratnam, S. Risk-based life-cycle costing of infrastructure rehabilitation and construction alternatives. J. Infrastruct. Syst. 2003, 9, 6–15. [Google Scholar] [CrossRef]

- Zhang, H.; Keoleian, G.A.; Lepech, M.D.; Kendall, A. Life-cycle optimization of pavement overlay systems. J. Infrastruct. Syst. 2010, 16, 310–322. [Google Scholar] [CrossRef]

- Morgado, J.; Neves, J. Work zone planning in pavement rehabilitation: Integrating cost, duration and user effects. J. Constr. Eng. Manag. 2014, 140, 04014050. [Google Scholar] [CrossRef]

- Heravi, G.; Esmaeeli, A.N. Fuzzy multicriteria decision-making approach for pavement project evaluation using life-cycle cost/performance analysis. J. Infrastruct. Syst. 2014, 20, 04014002. [Google Scholar] [CrossRef]

- California Department of Transportation (Caltrans). Draft Project Report—91 Project. Available online: http://sr91project.info/environmental/_pdf/SR-91_CIP_DPR_EA_0F540_(th-Attachments-1-18).pdf (accessed on 20 June 2017).

- Caltrans. SR-91 Corridor Improvement Project: Final Draft Traffic Study Report. Available online: http://sr91project.info/environmental/_pdf/Tech_Studies/Traffic%20Study%20Report/SR%2091%20Traffic%20Study%20July%202010.pdf (accessed on 8 December 2017).

- Caltrans. Caltrans Highway Design Manual. Available online: http://www.dot.ca.gov/hq/oppd/hdm/hdmtoc.htm (accessed on 20 June 2017).

- Caltrans. Caltrans Life-Cycle Cost Analysis Procedures Manual. Available online: http://www.dot.ca.gov/hq/maint/Pavement/Offices/Pavement_Engineering/LCCA_Docs/LCCA_25CA_Manual_Final_Aug_1_2013_v2.pdf (accessed on 18 June 2017).

- Caltrans. Traffic Census. Available online: http://www.dot.ca.gov/trafficops/census/ (accessed on 18 June 2017).

- Caltrans. Pavement Software. Available online: http://www.dot.ca.gov/hq/maint/Pavement/Offices/Pavement_Engineering/Software.html (accessed on 18 June 2017).

- USDOT. Life-Cycle Cost Analysis RealCost User Manual. Office of Asset Management. Available online: https://www.fhwa.dot.gov/infrastructure asstmgmt/rc210704.pdf (accessed on 20 June 2017).

- Kim, C.; Lee, E.-B.; Harvey, J.T.; Fong, A.; Lott, R. Automated sequence selection and cost calculation for maintenance and rehabilitation in highway Life-Cycle Cost Analysis (LCCA). Int. J. Transp. Sci. Technol. 2015, 4, 61–75. [Google Scholar] [CrossRef]

- Flintsch, G.W.; Kuttesch, J. Application of engineering economic analysis tools for pavement management. In Proceedings of the 83rd Annual TRB Meeting, Washington, DC, USA, 11–15 January 2004. [Google Scholar]

- Lee, E.B.; Ibbs, C.W. A computer simulation model: Construction analysis for highway rehabilitation strategies CA4PRS. J. Constr. Eng. Manag. 2005, 131, 449–458. [Google Scholar] [CrossRef]

- Collura, Work Zone Safety Data Collection and Analysis Guide, USDOT/FHWA. Available online: https://www.workzonesafety.org/files/documents/training/fhwa_wz_grant/atssa_wz_safety_data_collection.pdf (accessed on 8 March 2017).

- Federal Highway Administration (FHWA). Construction Analysis for Pavement Rehabilitation Strategies. Available online: https://www.fhwa.dot.gov/research/deployment/ca4prs.cfm (accessed on 8 March 2017).

- Lee, E.B.; Thomas, D.K. State-of-practice technologies on accelerated urban highway rehabilitation: I-15 California experience. J. Constr. Eng. Manag. 2007, 133, 105–113. [Google Scholar] [CrossRef]

- Transportation Research Board, National Research Counsel. Highway Capacity Manual (HCM) 2000; Transportation Research Board, National Research Counsel: Washington, DC, USA, 2000.

- Lee, E.-B.; Thomas, D.K.; Bloomberg, L. Planning urban-highway reconstruction with traffic demand affected by construction schedule. J. Transp. Eng. 2005, 11, 752–761. [Google Scholar] [CrossRef]

- Caltrans. SR-91 Corridor Improvement Project Draft EIR/EIS. Available online: http://sr91project.info/_pdf/Chapter%202%20Project%20Alternatives.pdf (accessed on 20 June 2017).

- USDOT. Continuously Reinforced Concrete Pavement Design & Construction Guidelines. FHWA. Available online: http://crcpavement.org/wp-content/uploads/2014/12/CRCP-Design-and-Construction-Guidelines.pdf (accessed on 20 June 2017).

- Caltrans. Contract Cost Database. Available online: http://sv08data.dot.ca.gov/contractcost/ (accessed on 18 June 2017).

- Riverside County Transportation Commission (RCTC). SR-91 Project. Available online: http://rctcdev.info/projects/state-route-91/sr-91-corridor-improvement-project (accessed on 5 July 2017).

| Segments | No-Build Alternative | Alternative 1 | Alternative 2 |

|---|---|---|---|

| SR-91 Design | PCCP | PCCP | CRCP |

| I-15 Design | PCCP | PCCP | ACP |

| SR-91: SR-241 to the Orange/Riverside County line | 2 tolled express lanes | 2 tolled express lanes | 2 tolled express lanes |

| 5 general-purpose lanes | 6 general-purpose lanes | 6 general-purpose lanes | |

| 1 express auxiliary lane | |||

| SR-91: Orange/Riverside County line to SR-71 | 2 HOV lanes | 2 HOV lane | 2 tolled express lanes |

| 5 general-purpose lanes | 6 general-purpose lanes | 6 general-purpose lanes | |

| 1 express auxiliary lane | |||

| SR-91: SR-71 to I-15 | 1 HOV lane | 1 HOV lane | 2 tolled express lanes |

| 4 general-purpose lanes | 5 general-purpose lanes | 5 general-purpose lanes | |

| 1 auxiliary lane | 1 auxiliary lane | ||

| SR-91: I-15 to Pierce Street | 1 HOV lane | 1 HOV lane | 1 tolled express lanes |

| 3 general-purpose lanes | 4 general-purpose lanes | 4 general-purpose lanes | |

| I-15: Cajalco Road to Ontario Avenue | 3 general-purpose lanes | 3 general-purpose lanes | 1 tolled express lane |

| 3 general-purpose lanes | |||

| I-15: Ontario Avenue to SR-91 | 4 general-purpose lanes | 1 HOV lane | 1 tolled express lane |

| 4 general-purpose lanes | 4 general-purpose lanes | ||

| I-15: SR-91 Interchange to Hidden Valley Parkway | 4 general-purpose lanes | 4 general-purpose lanes | 1 tolled express lane |

| 4 general-purpose lanes |

| Location | AADT | Truck AADT | Truck % |

|---|---|---|---|

| SR-91 at County Line | 280,000 | 15,100 | 5.5 |

| SR-91 west of I-15 | 271,500 | 14,500 | 5.3 |

| SR-91 east of I-15 | 223,500 | 16,300 | 7.3 |

| I-15 north of SR-91 | 170,800 | 17,900 | 10.5 |

| I-15 south of SR-91 | 200,800 | 10,300 | 5.1 |

| SR-91 Ramps (56 EA) Average | 11,381 | N/A | N/A |

| I-15 Ramps (24 EA) Average | 8856 | N/A | N/A |

| Location | 2035 AADT (a) | 40-Year ESAL (b) | 40-Year TI (a) |

|---|---|---|---|

| SR-91 at County Line | 409,100 | 169,000,000 | 16.1 |

| SR-91 west of I-15 | 390,700 | 155,000,000 | 16.0 |

| SR-91 east of I-15 | 273,200 | 149,000,000 | 15.9 |

| I-15 north of SR-91 | 323,800 | 64,000,000 | 12.2 |

| I-15 south of SR-91 | 336,900 | 32,000,000 | 11.2 |

| SR-91 Ramps (60 EA) Average | 15,505 | 9,000,000 | 11.6 |

| I-15 Ramps (27 EA) Average | 13,267 | 10,000,000 | 11.8 |

| Alternative | Pavement Item | Thickness (ft.) | Unit-Price (sf) | Unit-Price ($/sf) |

|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | PCCP | 1.1 | $6.37 | $7.02 |

| HMA BB | 0.1 | $6.85 | $0.69 | |

| LCB | 0.5 | $4.37 | $2.19 | |

| AS (Class 2) | 0.7 | $1.11 | $0.78 | |

| Average Unit-Price $/sf = | $10.66 | |||

| SR-91 Pavement Cost (Alternative 1) = | $69,616,918 | |||

| Alt. 2 (CRCP Long-life) | CRCP | 0.95 | $6.37 | $6.05 |

| Rebar | 3.44 lb./sf | $0.65/lb. | $2.24 | |

| ACP (HMA) | 0.5 | $6.26 | $3.10 | |

| AS (Class 2) | 0.7 | $1.11 | $0.80 | |

| Average Unit-Price $/sf = | $12.20 | |||

| SR-91 Total Pavement Cost (Alternative 2) = | $79,696,819 | |||

| Alternative | Pavement Item | Thickness (ft.) | Unit-Price (sf) | Unit-Price ($/sf) |

|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | PCCP | 0.96 | $6.37 | $6.14 |

| HMA BB | 0.1 | $6.85 | $0.69 | |

| LCB | 0.5 | $4.37 | $2.19 | |

| AS (Class 2) | 0.7 | $1.11 | $0.78 | |

| Average Unit-Price $/sf = | $9.79 | |||

| I-15 Pavement Cost (Alternative 1) = | $19,691,841 | |||

| Alternative 2 (Long-life ACP) | RHMA-G | 0.10 | $7.23 | $0.72 |

| HMA-C PG-PM (long-life) | 0.20 | $6.48 | $1.30 | |

| HMA-C PG-PM (a) | 1.46 | $6.48 | $9.45 | |

| AB (Class 2) | 0.5 | $1.15 | $0.60 | |

| Average Unit-Price $/sf = | $12.05 | |||

| I-15 Total Pavement Cost (Alternative 2) = | $24,221,347 | |||

| Alternative | Pavement Item | Thickness (ft.) | Unit-Price (sf) | Unit-Price ($/sf) |

|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | PCCP (a) | 0.80 | $6.37 | $5.11 |

| HMA BB | 0.1 | $6.85 | $0.69 | |

| LCB (a) | 0.43 | $4.37 | $1.86 | |

| AS (Class 2) (a) | 0.63 | $1.11 | $0.69 | |

| Average Unit-Price $/sf = | $8.35 | |||

| SR-91 Ramp Cost (Alternative 1) = | $9,739,931 | |||

| Alternative 2 (Long-life ACP) | RHMA-G | 0.10 | $7.23 | $0.72 |

| HMA-C PG-PM (long-life) | 0.20 | $8.80 | $1.76 | |

| HMA-C PG-PM (a) | 1.15 | $6.48 | $7.48 | |

| AB (Class 2) | 0.5 | $1.15 | $0.58 | |

| Average Unit-Price $/sf = | $10.53 | |||

| SR-91 Ramp Cost (Alternative 2) = | $12,287,219 | |||

| LCCA Alternative | Construction Activity | Service Life (Years) | Construction (Year) | Annual Maint. ($/Lane-Mile) | |

|---|---|---|---|---|---|

| SR-91 GP Lanes | Alt. 1 (Long-life PCCP) | PCCP GP Widening | 45 (a) | 2015 | $800 |

| 1st PCCP CAPM | 5 | 2060 | $1500 | ||

| 2nd PCCP CAPM | 10 | 2065 | $1500 | ||

| Alt. 2 (Long-life CRCP) | CRCP GP Widening | 50 (b) | 2015 | $200 | |

| 1st CRCP CAPM | 5 | 2065 | $1400 | ||

| 2nd CRCP CAPM | 5 | 2070 | $1400 | ||

| SR-91 Ramps and I-15 Lanes | Alt. 1 (Long-life PCCP) | PCCP Widening | 45 (c) | 2015 | $800 |

| 1st PCCP CAPM | 5 | 2060 | $1500 | ||

| 2nd PCCP CAPM | 10 | 2065 | $1500 | ||

| Alt. 2 (Long-life ACP) | ACP Widening | 40 | 2015 | $7200 | |

| RHMA-G | 10 (d) | 2025 2035 2045 | $3700 | ||

| 1st ACP CAPM | 10 | 2055 | $3700 | ||

| 2nd ACP CAPM | 10 | 2065 | $3700 |

| Alternative | Activity | Pavement Item | Unit-Price (/sf) | Area (sf) | Price ($) |

|---|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | 1st PCCP CAPM | CPR “C” (2% Slab-replace) | $16.6 | 130,665 | $2,171,946 |

| Grinding (100% of surface) | $0.4 | 6,533,260 | $2,874,634 | ||

| Seal Joint (100% of joints) | $3.0 | 1,633,315 | $4,899,945 | ||

| 1st CAPM Total Pavement Cost (yr. 2060) = | $9,946,525 | ||||

| 1st CAPM Total Pavement and Agency Cost (yr. 2060) = | $20,821,097 | ||||

| 2nd PCCP CAPM | CPR “B” (5% Slab-replace) | $16.6 | 326,663 | $5,429,865 | |

| Grinding (25% of surface) | $0.4 | 1,633,315 | $718,659 | ||

| Seal Joint (15% of joints) | $3.0 | 244,997 | $734,992 | ||

| 2nd CAPM Total Pavement Cost (yr. 2065) = | $6,883,515 | ||||

| 2nd CAPM Total Pavement and Agency Cost (yr. 2065) = | $14,409,287 | ||||

| Alt. 2 (CRCP Long-life) | 1st CRCP CAPM | CPR “C” (2% CRCP Slab-replace) | $14.4 | 130,665 | $1,875,772 |

| Grinding (100% of surface) | $0.4 | 6,533,260 | $2,874,634 | ||

| Rebar (Random-slab rebar) | $4.5 | 1,633,315 | $2,874,634 | ||

| 1st CAPM Total Pavement Cost (yr. 2065) = | $5,335,786 | ||||

| 1st CAPM Total Pavement and Agency Cost (yr. 2065) = | $11,169,420 | ||||

| 2nd CRCP CAPM | CPR “B” (2% CRCP Slab-replace) | $14.4 | 326,663 | $4,689,429 | |

| Grinding (25% of surface) | $0.4 | 1,633,315 | $718,659 | ||

| Rebar (Random-slab rebar) | $4.5 | 244,997 | $1,463,450 | ||

| 2nd CAPM Total Pavement Cost (yr. 2070) = | $6,152,879 | ||||

| 2nd CAPM Total Pavement and Agency Cost (yr. 2070) = | $12,879,843 | ||||

| Alternative | Activity | Pavement Item | Unit-Price (/sf) | Area (sf) | Price ($) |

|---|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | 1st PCCP CAPM | CPR “C” (2% Slab-replace) | $14.6 | 40,215 | $586,423 |

| Grinding (100% of surface) | $0.4 | 2,010,747 | $884,729 | ||

| Seal Joint (100% of joints) | $3.0 | 502,687 | $1,508,060 | ||

| 1st CAPM Total Pavement Cost (yr. 2060) = | $2,979,212 | ||||

| 1st CAPM Total Pavement and Agency Cost (yr. 2060) = | $6,236,395 | ||||

| 2nd PCCP CAPM | CPR “B” (5% Slab-replace) | $14.6 | 100,537 | $1,466,058 | |

| Grinding (25% of surface) | $0.4 | 502,687 | $221,182 | ||

| Seal Joint (15% of joints) | $3.0 | 75,403 | $226,209 | ||

| 2nd CAPM Total Pavement Cost (yr. 2065) = | $1,913,449 | ||||

| 2nd CAPM Total Pavement and Agency Cost (yr. 2065) = | $4,005,430 | ||||

| Alt. 2 (Long-life ACP) | 1st, 2nd and 3rd RHMA-G | RHMA-G & Cold-plane | $0.91 | 2,010,747 | $1,835,108 |

| 1st CAPM Pavement/Agency Cost (yr. 2025, 2035, 2045) = | $3,841,439 | ||||

| 1st and 2nd ACP CAPM | RHMA-G & Milling | $1.1 | 2,010,747 | $2,211,822 | |

| HMA-C PG-PM | $1.3 | 2,010,747 | $2,613,971 | ||

| 1st CAPM Total Pavement Cost (yr. 2055 and 2065) = | $4,823,682 | ||||

| 1st CAPM Pavement/Agency Cost (yr. 2055 and 2065) = | $10,097,429 | ||||

| Alternative | Activity | Pavement Item | Unit-Price (/sf) | Area (sf) | Price ($) |

|---|---|---|---|---|---|

| Alt. 1 (Long-life PCCP) | 1st PCCP CAPM | CPR “C” (2% Slab-replace) | $12.12 | 23,328 | $282,661 |

| Grinding (100% of surface) | $0.4 | 1,166,400 | $513,216 | ||

| Seal Joint (100% of joints) | $3.0 | 291,600 | $874,800 | ||

| 1st CAPM Total Pavement Cost (yr. 2060) = | $1,670,677 | ||||

| Agency Support Cost Multiplier ≈ | 2.09 | ||||

| 1st CAPM Total Pavement and Agency Cost (yr. 2060) = | $3,491,718 | ||||

| 2nd PCCP CAPM | CPR “B” (5% Slab-replace) | $12.12 | 58,320 | $706,656 | |

| Grinding (25% of surface) | $0.4 | 1,166,400 | $513,216 | ||

| Seal Joint (15% of joints) | $3.0 | 43,740 | $131,220 | ||

| 2nd CAPM Total Pavement Cost (yr. 2065) = | $1,351,092 | ||||

| Agency Support Cost Multiplier ≈ | 2.09 | ||||

| 2nd CAPM Total Pavement and Agency Cost (yr. 2065) = | $2,823,782 | ||||

| Alt. 2 (Long-life ACP) | 1st, 2nd and 3rd RHMA-G | RHMA-G & Cold-plane | $0.91 | 1,166,400 | $1,061,424 |

| Agency Support Cost Multiplier ≈ | 2.09 | ||||

| 1st CAPM Pavement/Agency Cost (yr. 2025, 2035, 2045) = | $2,224,836 | ||||

| 1st and 2nd ACP CAPM | RHMA-G & Milling | $1.0 | 1,166,400 | $1,166,400 | |

| HMA-C PG-PM | $1.3 | 1,166,400 | $1,516,320 | ||

| 1st CAPM Total Pavement Cost (yr. 2055 and 2065) = | $2,682,720 | ||||

| Agency Support Cost Multiplier ≈ | 2.09 | ||||

| 1st CAPM Pavement/Agency Cost (yr. 2055 and 2065) = | $5,616,514 | ||||

| Route | LCCA Alternative | M&R Activity | Year | Pavement Cross-Section | Closure Number |

|---|---|---|---|---|---|

| SR-91 GP Lanes | Alt. 1 (PCCP Long-life) | 1st PCCP CAPM | 2060 | CPR “C” (2% Slab-replace) | 131 |

| 2nd PCCP CAPM | 2065 | CPR “B” (5% Slab-replace) | 336 | ||

| Alt. 2 (CRCP Long-life) | 1st CRCP CAPM | 2065 | CPR “C” (2% Slab-replace) | 170 (a) | |

| 2nd CRCP CAPM | 2070 | CPR “B” (5% Slab-replace) | 437 (a) | ||

| I-15 Express Lanes | Alt. 1 (PCCP Long-life) | 1st PCCP CAPM | 2060 | CPR “C” (2% Slab-replace) | 41 |

| 2nd PCCP CAPM | 2065 | CPR “B” (5% Slab-replace) | 105 | ||

| Alt. 2 (ACP Long-life) | 1st RHMA-G | 2025 | 0.1′ Milling and AC Overlay | 42 | |

| 2nd RHMA-G | 2035 | 0.1′ Milling and AC Overlay | 42 | ||

| 3rd RHMA-G | 2045 | 0.1′ Milling and AC Overlay | 42 | ||

| 1st ACP CAPM | 2055 | 0.3′ Milling and AC Overlay | 143 | ||

| 2nd ACP CAPM | 2065 | 0.3′ Milling and AC Overlay | 143 |

| LCCA Alternative | Construction | Life | Year | Agency Cost (Discounted Value) ($k) | Agency Cost (Undiscounted Value) ($k) |

|---|---|---|---|---|---|

| Alternative1 (Long-life PCCP) | PCCP GP Widening | 45 | 2015 | 69,617 | 69,617 |

| 1st PCCP CAPM | 5 | 2060 | 3565 | 20,821 | |

| 2nd PCCP CAPM | 10 | 2065 | 2028 | 14,410 | |

| Annual Maintenance | 2004 | 6033 | |||

| Total | 60 | 77,213 | 110,881 | ||

| Alternative2 (Long-life CRCP) | CRCP GP Widening | 50 | 2015 | 79,697 | 79,697 |

| 1st ACP CAPM | 5 | 2065 | 1572 | 11,169 | |

| 2nd ACP CAPM | 5 | 2070 | 1490 | 12,880 | |

| Annual Maintenance | 608 | 2475 | |||

| Total | 60 | 83,366 | 106,221 | ||

| Cost Difference (Alt 1–Alt 2) | (6153) | (4659) | |||

| LCCA Alternative | Construction | Life | Year | Discounted Value | Undiscounted Value | ||

|---|---|---|---|---|---|---|---|

| Agency ($k) | Toll Loss ($k) | Agency ($k) | Toll Loss ($k) | ||||

| Alternative 1 (Long-life PCCP) | PCCP Lane Widening | 45 | 2015 | 19,692 | 19,692 | ||

| 1st PCCP CAPM | 5 | 2060 | 1068 | 36 | 6236 | 36 | |

| 2nd PCCP CAPM | 10 | 2065 | 564 | 98 | 4005 | 98 | |

| Annual Maintenance | 617 | 1857 | |||||

| Total | 60 | 22,075 | 135 | 31,925 | 135 | ||

| Alternative 2 (Long-life ACP) | ACP Lane Widening | 40 | 2015 | 24,221 | 24,221 | ||

| 1st RHMA-G | 10 | 2025 | 2595 | 32 | 3841 | 32 | |

| 2nd RHMA-G | 10 | 2035 | 1753 | 35 | 3841 | 35 | |

| 3rd RHMA-G | 10 | 2045 | 1184 | 32 | 3841 | 32 | |

| 1st ACP CAPM | 10 | 2055 | 2103 | 121 | 10,097 | 121 | |

| 2nd ACP CAPM | 10 | 2065 | 1421 | 133 | 10,097 | 133 | |

| Annual Maintenance | 4856 | 11,491 | |||||

| Total | 60 | 38,486 | 352 | 67,783 | 352 | ||

| Cost Difference (Alt 1–Alt 2) | (16,412) | (217) | (35,858) | (217) | |||

| LCCA Alternative | Construction | Life | Year | Discounted Value | Undiscounted Value | ||

|---|---|---|---|---|---|---|---|

| Agency ($k) | RUC ($k) | Agency ($k) | RUC ($k) | ||||

| Alternative 1 (Long-life PCCP) | PCCP Ramps Widening | 45 | 2015 | 9740 | 9740 | ||

| 1st PCCP CAPM | 5 | 2060 | 598 | 75 | 3492 | 438 | |

| 2nd PCCP CAPM | 10 | 2065 | 397 | 83 | 2824 | 593 | |

| Annual Maintenance | N/A | N/A | 357 | 1075 | |||

| Total | 60 | 11,092 | 158 | 17,131 | 1031 | ||

| Alternative 2 (Long-life ACP) | ACP Ramps Widening | 40 | 2015 | 12,287 | 12,287 | ||

| 1st RHMA-G | 10 | 2025 | 1503 | 174 | 2225 | 258 | |

| 2nd RHMA-G | 10 | 2035 | 1015 | 122 | 2225 | 268 | |

| 3rd RHMA-G | 10 | 2045 | 686 | 86 | 2225 | 278 | |

| 1st ACP CAPM | 10 | 2055 | 1170 | 182 | 5617 | 876 | |

| 2nd ACP CAPM | 10 | 2065 | 790 | 128 | 5617 | 908 | |

| Annual Maintenance | N/A | N/A | 2812 | 6654 | |||

| Total | 60 | 20,264 | 692 | 36,849 | 2587 | ||

| Cost Difference (Alt 1–Alt 2) | (9172) | (534) | (19,718) | (1556) | |||

| LCCA Alternative | Construction | Net Present Value | |||

|---|---|---|---|---|---|

| Agency ($k) | Toll Loss ($k) (a) | RUC ($k) | Total | ||

| Alternative 1 (Long-life PCCP) | SR-91 Lanes Total | 77,213 | 77,213 | ||

| I-15 Lanes Total | 22,075 | 135 | 22,210 | ||

| SR-91 Ramps Total | 11,092 | 158 | 11,250 | ||

| Total | 110,380 | 135 | 158 | 110,673 | |

| Alternative 2 (Long-life CRCP/ACP) | SR-91 Lanes Total | 83,366 | 83,366 | ||

| I-15 Lanes Total | 38,486 | 352 | 38,838 | ||

| SR-91 Ramps Total | 20,264 | 692 | 20,956 | ||

| Total | 142,116 | 352 | 692 | 143,160 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, E.-B.; Thomas, D.K.; Alleman, D. Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca). Sustainability 2018, 10, 179. https://doi.org/10.3390/su10010179

Lee E-B, Thomas DK, Alleman D. Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca). Sustainability. 2018; 10(1):179. https://doi.org/10.3390/su10010179

Chicago/Turabian StyleLee, Eul-Bum, David K. Thomas, and Douglas Alleman. 2018. "Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca)" Sustainability 10, no. 1: 179. https://doi.org/10.3390/su10010179

APA StyleLee, E.-B., Thomas, D. K., & Alleman, D. (2018). Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca). Sustainability, 10(1), 179. https://doi.org/10.3390/su10010179