Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review

Abstract

1. Introduction

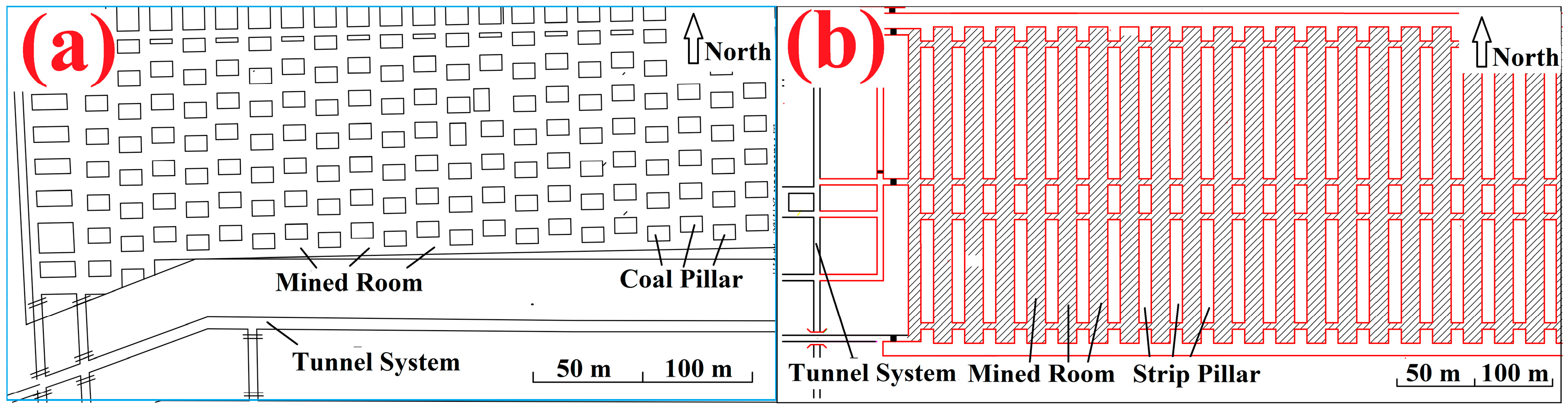

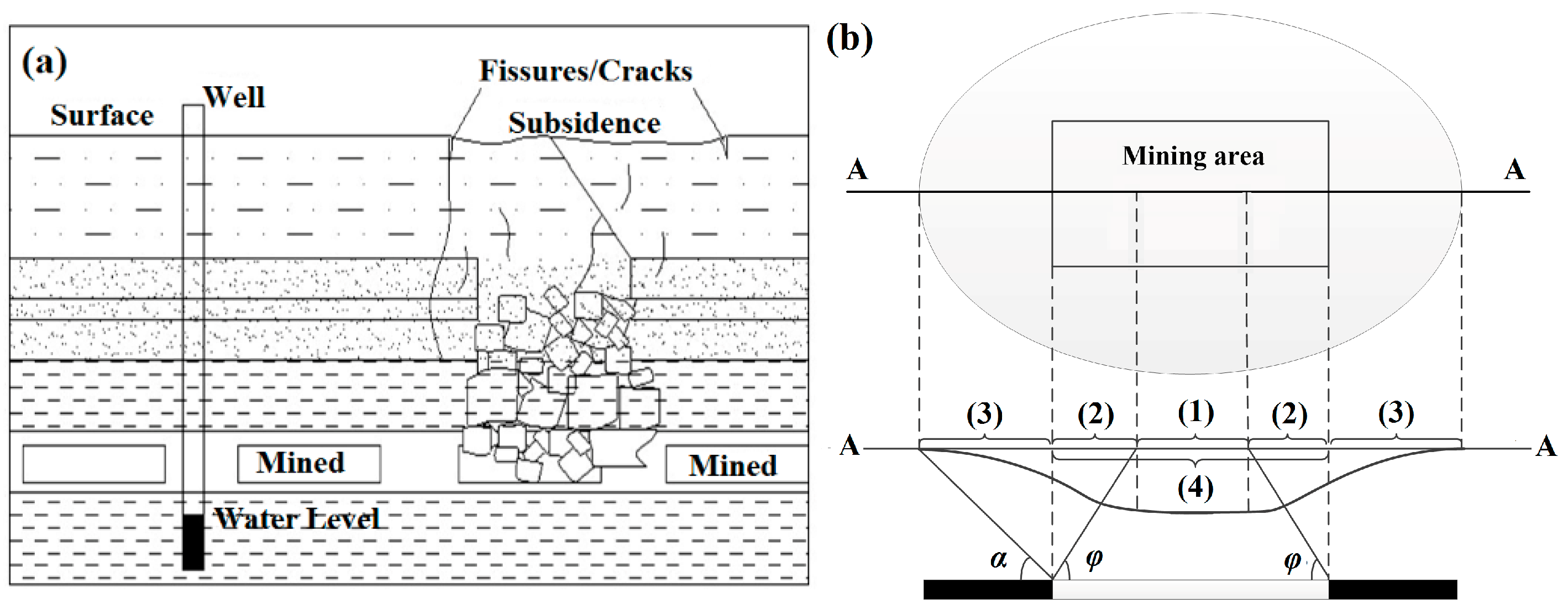

2. Abandoned Mine Stability Assessment Methods for Partial Extraction

2.1. The Classic Methods

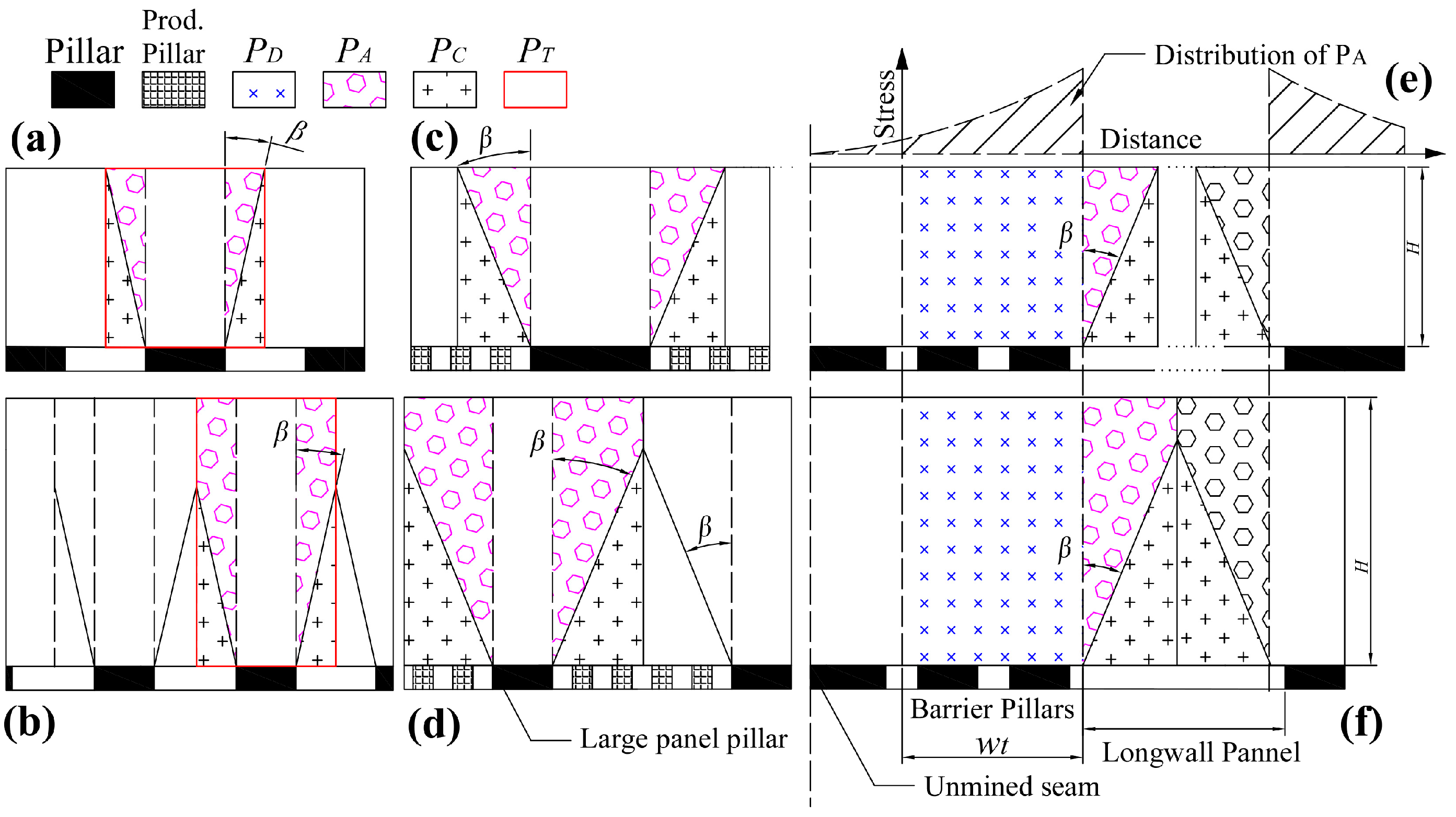

2.1.1. Pillar Load

2.1.2. Coal Pillar Strength

2.1.3. Pillar Yielding Area

2.2. Numerical Simulation Methods

2.3. Physical Simulation Methods

2.4. Other Methods

3. Discussion of Influence Factors on Mine Stability

3.1. Influence of Coal and Mine Structures

3.2. Influence of Weathering

3.3. Influence of Spontaneous Combustion of Coal

3.4. Influence of Roof and Floor Properties

3.5. Influence of Pillar Shape and Other Factors

4. Discussion of Improving Stability Assessment Methods

5. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bureau of Land Management of U.S. Available online: http://www.abandonedmines.gov (accessed on 5 October 2017).

- Bian, Z.; Miao, X.; Lei, S.; Chen, S.; Wang, W.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Land and Resources of China. 2008. Available online: http://www.mlr.gov.cn/xwdt/jrxw/200805/t20080507_102527.htm (accessed on 5 October 2017). (In Chinese)

- Shaanxi Earthquake Information Network. Available online: http://www.eqsn.gov.cn/ (accessed on 7 December 2017).

- Yin, Y.; Ren, H. Turning “Waste” into Wealth—The Recovery Ratio of Coal Resource Is Doubled Due to the Improvement of Pillar Recovery Technique. 2007. Available online: http://jjckb.xinhuanet.com/cjxw/2007-08/14/content_61914.htm (accessed on 7 December 2017). (In Chinese).

- Li, C.; Ren, J.; Wen, H.; Xu, W.; Gong, T.; Wang, M. Impact of coal mining subsidence on loss of soil moisture and nutrients and ecological environment. J. Anhui Agric. Sci. 2013, 40, 4343–4344. (In Chinese) [Google Scholar]

- Wang, J.; Du, H.; Wang, S. Analysis of damage process and mechanism for plant community and soil properties at northern Shenmu subsidence mining area. J. China Coal Soc. 2017, 42, 17–25. (In Chinese) [Google Scholar]

- He, W.; Xiang, M.; Liu, H.; Li, Y.; Peng, J. Ground subsidence and its environment problems in Yushenfu mining area. Coal Geol. Explor. 2016, 44, 131–135. (In Chinese) [Google Scholar]

- Zhang, F.; Zhao, H.; Song, Y.; Chen, L. The effect of coal-mining subsidence on water environment in the Shenfu-Dongsheng mining area. ACTA Geosci. Sin. 2007, 28, 521–527. (In Chinese) [Google Scholar]

- Kivinen, S. Sustainable post-mining land use: Are closed metal mines abandoned or re-used space? Sustainability 2017, 9, 1705. [Google Scholar] [CrossRef]

- He, G.Q.; Yang, L.; Ling, G.D.; Jia, F.C.; Hong, D. Mine Subsidence Science; China University of Mining and Technology Press: Xuzhou, China, 1994. (In Chinese) [Google Scholar]

- Bell, F.G.; Genske, D.D. The influence of subsidence attributable to coal mining on the environment, development and restoration: Some examples from Western Europe and South Africa. Environ. Eng. Geosci. 2001, 7, 81–99. [Google Scholar] [CrossRef]

- Mark, C. Analysis of Longwall Pillar Stability. Ph.D. Thesis, Pennsylvania State University, University Park, PA, USA, 1987. [Google Scholar]

- Mark, C. Science of empirical design in mining ground control. Int. J. Min. Sci. Technol. 2016, 26, 461–470. [Google Scholar] [CrossRef]

- Hauquin, T.; Deck, O.; Gunzburge, Y. Average vertical stress on irregular elastic pillars estimated by a function of the relative extraction ratio. Int. J. Rock. Mech. Min. 2016, 83, 122–134. [Google Scholar] [CrossRef]

- Poulsen, B.A. Coal pillar load calculation by pressure arch theory and near field extraction ratio. Int. J. Rock Mech. Min. 2010, 47, 1158–1165. [Google Scholar] [CrossRef]

- Yu, Y.X.; Huang, R.B.; Wang, B.Q. Analysis on limit equilibrium zone of coal pillar in mining roadway based on mechanical model of elastic foundation beam. J. Eng. Mech. 2016, 142. Available online: https://doi.org/10.1061/(ASCE)EM.1943-7889.0001032 (accessed on 4 January 2018). [CrossRef]

- Wilson, A.H. The stability of underground workings in the soft rocks of the coal measures. Int. J. Min. Eng. 1983, 1, 91–187. [Google Scholar] [CrossRef]

- Heasley, K.A. The forgotten denominator, pillar loading. In Proceedings of the 4th North American Rock Mechanics Symposium, Seattle, WA, USA, 31 July–3 August 2000. [Google Scholar]

- Heasley, K.A. Some thoughts on calibrating LaModel. In Proceedings of the 27th International Conference on Ground Control in Mining, Morgantown, WV, USA, 29–31 July 2008. [Google Scholar]

- Singh, A.K.; Singh, R.; Maiti, J.; Kumar, R.; Mandal, P.K. Assessment of mining induced stress development over coal pillars during depillaring. Int. J. Rock Mech. Min. 2011, 48, 805–818. [Google Scholar] [CrossRef]

- Rezaei, M.; Hossaini, M.F.; Majdi, A. Determination of longwall mining-induced stress using the strain energy method. Rock Mech. Rock Eng. 2015, 48, 1–13. [Google Scholar] [CrossRef]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Mine Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010. (In Chinese) [Google Scholar]

- Hatzor, Y.H.; Benary, R. The stability of a laminated Voussoir beam: Back analysis of a historic roof collapse using DDA. Int. J. Rock Mech. Min. Sci. 1988, 35, 165–181. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, C.; Yetilmezsoy, K.; Zhang, B.; Zhang, S. Fractural structure of thick hard roof stratum using long beam theory and numerical modeling. Environ. Earth Sci. 2017, 76, 751. [Google Scholar] [CrossRef]

- Wu, L.; Wang, J.; Guo, Z. Foundation for Coal Pillar Design and Monitoring; China University of Mining and Technology Press: Xuzhou, China, 2000. (In Chinese) [Google Scholar]

- Salamon, M.D.G. Elastic analysis of displacements and stress induced by the mining of seam or reef deposits, Part II. J. S. Afr. Inst. Min. Metall. 1964, 64, 197–218. [Google Scholar]

- Majdi, A. The Stability of Face Access Tunnel in the Deep Soft Rocks of Coal Mining. Ph.D. Thesis, McGill University, Montreal, QC, Canada, 1988. [Google Scholar]

- Griffith, W.A.; Becker, J.; Cione, K.; Miller, T.; Pan, E. 3D topographic stress perturbations and implications for ground control in underground coal mines. Int. J. Rock Mech. Min. 2014, 70, 59–68. [Google Scholar] [CrossRef]

- Molinda, G.M.; Heasley, K.A.; Oyler, D.C.; Jones, J.R. Effects of Horizontal Stress Related to Stream Valleys on the Stability of Coal Mine Openings; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1992.

- Mark, C.; Mucho, T.P.; Dolinar, D. Horizontal stress and longwall headgate ground control. Min. Eng. 1998, 50, 61–68. [Google Scholar]

- Xu, W.Y.; Zhang, J.C.; Wang, W.; Wang, R.B. Investigation into in situ stress fields in the asymmetric V-Shaped river valley at the Wudongde Dam site, Southwest China. Bull. Eng. Geol. Environ. 2014, 73, 465–477. [Google Scholar] [CrossRef]

- Hustrulid, W.A. A review of coal pillar strength formulas. Rock Mech. 1976, 8, 115–145. [Google Scholar] [CrossRef]

- Lunder, P.J. Hard rock pillar strength estimation—An applied empirical approach. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 1994. [Google Scholar]

- Mathey, M.; Van der Merwe, J.N. Critique of the South African squat coal pillar strength formula. J. S. Afr. Inst. Min. Metall. 2016, 116, 291–299. [Google Scholar] [CrossRef]

- Rastiello, G.; Federico, F.; Screpanti, S. New soft rock pillar strength formula derived through parametric FEA using a critical state plasticity model. Rock Mech. Rock Eng. 2015, 48, 2077–2091. [Google Scholar] [CrossRef]

- Verma, A.K. A comparative study of various empirical methods to estimate the factor of safety of coal pillars. Am. J. Min. Metall. 2014, 2, 17–22. [Google Scholar]

- Bunting, D. Chamber-pillars in deep anthracite mines. Trans. Am. Inst. Min. Eng. 1911, 42, 739–748. [Google Scholar]

- Van Heerden, W.L. In-Situ Determination of Complete Stress-Strain Characteristics of 1.4 m Square Specimens with Width to Height Ratios up to 3.4; Council for Scientific and Industrial Research: Pretoria, South Africa, 1974. [Google Scholar]

- Sorenson, W.K.; Pariseau, W.G. Statistical analysis of laboratory compressive strength and Young’s modulus data for the design of production pillars in coal mines. In Proceedings of the 19th U.S. Symposia on Rock Mechanics, Reno, NV, USA, 1–3 May 1978. [Google Scholar]

- Overt, L.; Duvall, W.I. Rock Mechanics and the Design of Structures in Rock; John Wiley & Sons: New York, NY, USA, 1967. [Google Scholar]

- Bieniawski, Z.T. The effect of specimen size on the compressive strength of coal. Int. J. Rock Mech. Min. Sci. 1968, 5, 325–335. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; van Heerden, W.L. The significance of in situ tests on large rock specimen. Int. J. Rock Mech. Min. Sci. 1975, 12, 101–113. [Google Scholar] [CrossRef]

- Zern, E.N. Coal Miner’s Pocketbook; McGraw Hill: New York, NY, USA, 1928. [Google Scholar]

- Steart, F.A. Strength and stability of pillars in coal mines. J. Chem. Metall. Min. Soc. S. Afr. 1954, 54, 309–325. [Google Scholar]

- Salamon, M.D.G.; Munro, A.H. A study of the strength of coal pillars. J. S. Afr. Inst. Min. Metall. 1967, 68, 55–67. [Google Scholar]

- Holland, C.T. The strength of coal in mine pillars. In Proceedings of the 6th U.S. Symposia on Rock Mechanics, Rolla, MO, USA, 28–30 October 1964. [Google Scholar]

- Hedley, D.G.F.; Grant, F. Stope and pillar design for the Elliot Lake uranium mines. Can. Inst. Min. Metall. Bull. 1972, 65, 37–44. [Google Scholar]

- Logie, C.V.; Matheson, G.M. A critical review of the current state-of-the-art design of mine pillar. In Proceedings of the 1st International Conference on Stability in Underground Mining, Vancouver, BC, Canada, 16–18 August 1982. [Google Scholar]

- Maleki, H. In situ pillar strength and failure mechanisms for US coal seams. In Proceedings of the Workshop on Coal Pillar Mechanics and Design, Santa Fe, NM, USA, 7 June 1992. [Google Scholar]

- Sheorey, P.R. Pillar strength considering in situ stresses. In Proceedings of the Workshop on Coal Pillar Mechanics and Design, Santa Fe, NM, USA, 7 June 1992. [Google Scholar]

- Galvin, J.M. Ground Engineering—Principles and Practices for Underground Coal Mining; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Salamon, M.D.G.; Wagner, H. Practical experience in the design of coal pillars. In Proceedings of the 21st International Conference of Safety in Mines Research Institutes, Sydney, Australia, 21–25 October 1985. [Google Scholar]

- Mark, C. The evolution of intelligent coal pillar design: 1981–2006. In Proceedings of the 25th International Conference on Ground Control in Mining, Morgantown, WV, USA, 1–3 August 2006. [Google Scholar]

- Zhu, Q.Z.; Shao, J.F. A refined micromechanical damage–friction model with strength prediction for rock-like materials under compression. Int. J. Solids Struct. 2015, 60–61, 75–83. [Google Scholar] [CrossRef]

- Yang, J.P.; Chen, W.Z.; Yang, D.S.; Yuan, J.Q. Numerical determination of strength and deformability of fractured rock mass by FEM modeling. Comput. Geotech. 2015, 64, 20–31. [Google Scholar]

- Wang, M.; Kulatilake, P.H.S.W. Understanding of hydraulic properties from configurations of stochastically distributed fracture networks. Hydrol. Process. 2008, 22, 1125–1135. [Google Scholar] [CrossRef]

- Zhang, T.T.; Yan, E.C.; Hu, X.M.; Cao, Y.B. Fractal description of rock mass structure representative elementary volume. Adv. Mater. Res. 2012, 594–597, 439–445. [Google Scholar] [CrossRef]

- Khani, A.; Baghbanan, A.; Hashemolhosseini, H. Numerical investigation of the effect of fracture intensity on deformability and REV of fractured rock masses. Int. J. Rock Mech. Min. 2013, 63, 104–112. [Google Scholar] [CrossRef]

- Xia, L.; Zheng, Y.; Yu, Q. Estimation of the REV size for blockiness of fractured rock masses. Comput. Geotech. 2016, 76, 83–92. [Google Scholar] [CrossRef]

- Esmaieli, K.; Hadjigeorgiou, J.; Grenon, M. Estimating geometrical and mechanical REV based on synthetic rock mass models at Brunswick mine. Int. J. Rock Mech. Min. 2010, 47, 915–926. [Google Scholar] [CrossRef]

- Wu, Q.; Kulatilake, P.H.S.W. REV and its properties on fracture system and mechanical properties, and an orthotropic constitutive model for a jointed rock mass in a dam site in china. Comput. Geotech. 2012, 43, 124–142. [Google Scholar] [CrossRef]

- Riyadh, A. Change in microstructure parameters of porous media over repre-sentative elementary volume for porosity. Part. Sci. Technol. 2012, 30, 1–16. [Google Scholar]

- Li, J.H.; Zhang, L.M. Geometric parameters and REV of a crack network in soil. Comput. Geotech. 2010, 37, 466–475. [Google Scholar] [CrossRef]

- Bai, M.; Liu, T. Study on pillar size and mining width for partial mining. J. China Coal Soc. 1983, 4, 19–26. (In Chinese) [Google Scholar]

- Wu, L.; Wang, J. Calculation of width of yield zone of coal pillar and analysis of influence factors. J. China Coal Soc. 1995, 20, 625–631. (In Chinese) [Google Scholar]

- Jaiswal, A.; Shrivastva, B.K. Numerical simulation of coal pillar strength. Int. J. Rock Mech. Min. 2009, 46, 779–788. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. A numerical study of stress changes in barrier pillars and a border area in a longwall coal mine. Int. J. Coal Geol. 2013, 106, 39–47. [Google Scholar] [CrossRef]

- Kostecki, T.; Spearing, A.J.S. Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- He, L.; Zhang, Q.B. Numerical investigation of arching mechanism to underground excavation in jointed rock mass. Tunn. Undergr. Space Technol. 2015, 50, 54–67. [Google Scholar] [CrossRef]

- Wei, X.Q.; Bai, H.B.; Rong, H.R.; Jiao, Y.; Zhang, B.Y. Research on mining fracture of overburden in close distance multi-seam. Procedia Earth Planet. Sci. 2011, 2, 20–27. [Google Scholar] [CrossRef]

- Li, C.; Xu, J.; Wang, Z.; Qin, S. Domino instability effect of surrounding rock-coal pillars in a room-and-pillar gob. Int. J. Min. Sci. Technol. 2013, 23, 913–918. [Google Scholar] [CrossRef]

- Gao, W.; Ge, M. Stability of a coal pillar for strip mining based on an elastic-plastic analysis. Int. J. Rock Mech. Min. Sci. 2016, 87, 23–28. [Google Scholar] [CrossRef]

- Li, G.; Cao, S.; Li, Y.; Zhang, Z. Load bearing and deformation characteristics of granular spoils under unconfined compressive loading for coal mine backfill. Adv. Mater. Sci. Eng. 2016, 2016, 8530574. [Google Scholar] [CrossRef]

- Ghabraie, B.; Ghabraie, K.; Ren, G.; Smith, J.V. Numerical modelling of multistage caving processes: Insights from multi-seam longwall mining-induced subsidence. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 959–975. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, B. Coal mining under aquifers in China: A case study. Int. J. Rock Mech. Min. Sci. 2004, 41, 629–639. [Google Scholar] [CrossRef]

- Fama, M.E.D.; Trueman, R.; Craig, M.S. Two- and three-dimensional elasto-plastic anaylsis for coal pillar design and its application to highwall mining. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 215–225. [Google Scholar] [CrossRef]

- Peng, S.S. Topical areas of research needs in ground control–a state of the art review on coal mine ground control. Int. J. Min. Sci. Technol. 2015, 25, 1–6. [Google Scholar] [CrossRef]

- Bidgoli, M.N.; Jing, L. Water pressure effects on strength and deformability of fractured rocks under low confining pressures. Rock Mech. Rock Eng. 2015, 48, 971–985. [Google Scholar] [CrossRef]

- Mortimer, L.; Aydin, A.; Simmons, C.T.; Love, A.J. Is in situ stress important to groundwater flow in shallow fractured rock aquifers? J. Hydrol. 2011, 399, 185–200. [Google Scholar] [CrossRef]

- Benmebarek, N.; Benmebarek, S.; Kastner, R. Numerical studies of seepage failure of sand within a cofferdam. Comput. Geotech. 2005, 32, 264–273. [Google Scholar] [CrossRef]

- Ma, D.; Miao, X.; Bai, H.; Huang, J.; Pu, H.; Wu, Y.; Zhang, G.; Li, J. Effect of mining on shear sidewall groundwater inrush hazard caused by seepage instability of the penetrated Karst collapse pillar. Nat. Hazards 2016, 82, 73–93. [Google Scholar] [CrossRef]

- Kline, S.J. Similitude and Approximation Theory; McGraw-Hill Book Company: New York, NY, USA, 1965. [Google Scholar]

- Butterfield, R. Dimensional analysis for geotechnical engineering. Geotechnique 1999, 49, 357–366. [Google Scholar] [CrossRef]

- Wu, K.; Cheng, G.; Zhou, D. Experimental research on dynamic movement in strata overlying coal mines using similar material modeling. Arab. J. Geosci. 2015, 8, 6521–6534. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.; Zhang, J.; Xing, H.; Wang, H. Low-strength similar materials for backfill mining: Insight from experiments on components and influence mechanism. Geotech. Test. J. 2015, 38, 929–935. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, K.; Zhou, D.; Li, L.; Xu, Y. Experimental study on displacement field of strata overlying goaf with sloping coal seam. Geotech. Geol. Eng. 2016, 34, 1–10. [Google Scholar] [CrossRef]

- Zha, J.; Li, h.; Guo, G.; Wang, J. Influence of temperature and humidity on similar material and its control measures. Environ. Earth Sci. 2017, 76, 740. [Google Scholar] [CrossRef]

- Li, H.; Guo, G.; Zha, J. Study on time-varying characteristics of similar material model strength and the regulation measures. Environ. Earth Sci. 2017, 76, 518. [Google Scholar] [CrossRef]

- Ghabraie, B.; Ren, G.; Zhang, X.; Smith, J. Physical modelling of subsidence from sequential extraction of partially overlapping longwall panels and study of substrata movement characteristics. Int. J. Coal Geol. 2015, 140, 71–83. [Google Scholar] [CrossRef]

- Sun, Z.V. Reliability-Based Method for Stability of Mine Entry Design and Evaluation. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 2000. [Google Scholar]

- Wattimena, R.K.; Kramadibrata, S.; Sidi, I.D.; Azizi, M.A. Developing coal pillar stability chart using logistic regression. Int. J. Rock Mech. Min. 2013, 58, 55–60. [Google Scholar] [CrossRef]

- Deb, D.; Choi, S.O. Analysis of sinkhole occurrences over abandoned mines using Fuzzy reasoning: A case study. Geotech. Geol. Eng. 2006, 24, 1243–1258. [Google Scholar] [CrossRef]

- Ghasemi, E.; Ataei, M.; Shahriar, K. An intelligent approach to predict pillar sizing in designing room and pillar coal mines. Int. J. Rock Mech. Min. 2014, 65, 86–95. [Google Scholar] [CrossRef]

- Hu, Y.X.; Li, X.B. Bayes discriminant analysis method to identify risky of complicated goaf in mines and its application. Trans. Nonferrous Metals Soc. China 2012, 22, 425–431. [Google Scholar] [CrossRef]

- Tang, S.L.; Tang, H.; Guo, H. Stability evaluation of empty mine goaf based on BP neural network. J. Xian Univ. Sci. Technol. 2012, 32, 234–238. (In Chinese) [Google Scholar]

- Zhou, J.; Li, X.; Mitri, H.S.; Wang, S.; Wei, W. Identification of large-scale goaf instability in underground mine using particle swarm optimization and support vector machine. Int. J. Min. Sc. Technol. 2013, 23, 701–707. [Google Scholar] [CrossRef]

- York, G.; Canbulat, I.; Jack, B.W. Coal Pillar Design Procedures. 2000. Available online: http://researchspace.csir.co.za/dspace/handle/10204/1419 (accessed on 5 October 2017).

- Ramamurthy, T.; Rao, G.V.; Singh, J. A strength criterion for anisotropic rocks. In Proceedings of the 5th Australia-New Zealand Conference on Geomechanics, Sydney, Australia, 22–26 August 1988. [Google Scholar]

- Esterhuizen, G.S. Investigations into the effect of discontinuities on the strength of coal pillars. J. S. Afr. Inst. Min. Metall. 1997, 97, 57–61. [Google Scholar]

- Biswas, K. Study of Weathering Actions on Partings and Its Effects on Long Term Stability of Coal Pillar. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 1997. [Google Scholar]

- Hill, D. Coal pillar design criteria for surface protection. In Proceedings of the Coal Operators’ Conference, Wollongong, Australia, 26–28 April 2005; pp. 31–38. [Google Scholar]

- Salamon, M.D.G.; Ozbay, M.U.; Madden, B.J. Life and design of bord-and-pillar workings affected by pillar scaling. J. S. Afr. Inst. Min. Metall. 1998, 98, 135–145. [Google Scholar]

- Van der Merwe, J.N. Predicting coal pillar life in South Africa. J. S. Afr. Inst. Min. Metall. 2003, 5, 293–301. [Google Scholar]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock. Mech. Min. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Van der Merwe, J.N. Revised strength factor for coal in the Vaal Basin. J. S. Afr. Inst. Min. Metall. 1993, 93, 71–77. [Google Scholar]

- Salmi, E.F.; Nazem, M.; Karakus, M. The effect of rock mass gradual deterioration on the mechanism of post-mining subsidence over shallow abandoned coal mines. Int. J. Rock Mech. Min. 2017, 91, 59–71. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.E.; Deng, K.Z.; Fan, H.D. Long-term stability evaluation and pillar design criterion for room-and-pillar mines. Energies 2017, 10, 1644. [Google Scholar] [CrossRef]

- Peng, S.S. Ground Control Failures: A Pictorial View of Case Studies; West Virginia University Press: Morgantown, WV, USA, 2007. [Google Scholar]

- Nara, Y.; Morimoto, K.; Hiroyoshi, N.; Yoneda, T.; Kaneko, K.; Benson, P.M. Influence of relative humidity on fracture toughness of rock: Implications for subcritical crack growth. Int. J. Solids Struct. 2012, 49, 2471–2481. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Maruvanchery, V.; Liu, G. Water effects on rock strength and stiffness degradation. Acta Geotech. 2016, 11, 713–737. [Google Scholar] [CrossRef]

- Shi, X.; Cai, W.; Meng, Y.; Li, G.; Wen, K.; Zhang, Y. Weakening laws of rock uniaxial compressive strength with consideration of water content and rock porosity. Arab. J. Geosci. 2016, 9, 369. [Google Scholar] [CrossRef]

- Vásárhelyi, B.; Ván, P. Influence of water content on the strength of rock. Eng. Geol. 2006, 84, 70–74. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of water content on the strength and deformability of gypsum. Int. J. Rock Mech. Min. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Vergara, M.R.; Triantafyllidis, T. Influence of water content on the mechanical properties of an argillaceous swelling rock. Rock Mech. Rock Eng. 2016, 49, 2555–2568. [Google Scholar] [CrossRef]

- Khamrat, S.; Archeeploha, S.; Fuenkajorn, K. Pore pressure effects on strength and elasticity of ornamental stones. Scienceasia 2016, 42, 121–135. [Google Scholar] [CrossRef]

- Masoumi, H.; Horne, J.; Timms, W. Establishing empirical relationships for the effects of water content on the mechanical behavior of Gosford sandstone. Rock Mech. Rock Eng. 2017, 50, 2235–2242. [Google Scholar] [CrossRef]

- Pellet, F.L.; Keshavarz, M.; Boulon, M. Influence of humidity conditions on shear strength of clay rock discontinuities. Eng. Geol. 2013, 157, 33–38. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.Y.; Wang, H.L.; Wang, R.B.; Wang, W. Experimental studies on hydro-mechanical properties of metamorphic rock under hydraulic pressures. Eur. J. Environ. Civ. Eng. 2016, 20, 45–59. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock Mech. Min. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Kuenzer, C.; Stracher, G.B. Geomorphology of coal seam fires. Geomorphology 2012, 138, 209–222. [Google Scholar] [CrossRef]

- Kuenzer, C.; Zhang, J.; Tetzlaff, A.; Dijk, P.V.; Voigt, S.; Mehl, H.; Wagner, W. Uncontrolled coal fires and their environmental impacts: Investigating two arid mining regions in north-central China. Appl. Geogr. 2007, 27, 42–62. [Google Scholar] [CrossRef]

- Song, Z.; Kuenzer, C. Coal fires in China over the last decade: A comprehensive review. Int. J. Coal Geol. 2014, 133, 72–99. [Google Scholar] [CrossRef]

- Qi, L.M.; Chen, X.X. Theory analysis on spontaneous combustion zone width in the middle of goaf. Procedia Earth Planet. Sci. 2009, 1, 322–327. [Google Scholar]

- Ray, S.K.; Panigrahi, D.C.; Udayabhanu, G.; Saxena, V.K. Assessment of spontaneous heating susceptibility of Indian coals—A new approach. Energy Sources Part A 2016, 38, 59–68. [Google Scholar] [CrossRef]

- Kim, J.; Lee, Y.; Ryu, C.; Park, H.Y.; Lim, H. Low-temperature reactivity of coals for evaluation of spontaneous combustion propensity. Korean J. Chem. Eng. 2015, 32, 1297–1304. [Google Scholar] [CrossRef]

- Tang, Y.; Xue, S. Laboratory study on the spontaneous combustion propensity of lignite undergone heating treatment at low temperature in inert and low-oxygen environments. Energy Fuel 2015, 29, 4683–4689. [Google Scholar] [CrossRef]

- Huang, X.H. Research on Fire Control Technology of Residual Pillar Mining with Spontaneous Combustion in Mine. Ph.D. Thesis, China University of Mining and Technology (Beijing), Beijing, China, 2015. (In Chinese). [Google Scholar]

- Wang, S.; Li, X.; Wang, D. Void fraction distribution in overburden disturbed by longwall mining of coal. Environ. Earth Sci. 2016, 75, 1–17. [Google Scholar] [CrossRef]

- Wang, G.; Luo, H.Z.; Liang, Y.T.; Wang, J.R. Temperature field simulation of gob influenced by atmospheric pressure. J. Cent. South Univ. 2015, 22, 4366–4371. [Google Scholar] [CrossRef]

- Wang, H.; Chen, C. Experimental study on greenhouse gas emissions caused by spontaneous coal combustion. Energy Fuel. 2015, 29, 5213–5221. [Google Scholar] [CrossRef]

- Voigt, S.; Tetzlaff, A.; Zhang, J.; Künzer, C.; Zhukov, B.; Strunz, G.; Oertel, D.; Roth, A.; Dijk, P.V.; Mehl, H. Integrating satellite remote sensing techniques for detection and analysis of uncontrolled coal seam fires in North China. Int. J. Coal Geol. 2004, 59, 121–136. [Google Scholar] [CrossRef]

- Xia, T.; Zhou, F.; Liu, J.; Kang, J.; Gao, F. A fully coupled hydro-thermo-mechanical model for the spontaneous combustion of underground coal seams. Fuel 2014, 125, 106–115. [Google Scholar] [CrossRef]

- Lu, Y.; Qin, B. Identification and control of spontaneous combustion of coal pillars: A case study in the Qianyingzi mine, China. Nat. Hazards 2015, 75, 2683–2697. [Google Scholar] [CrossRef]

- Qin, S.; Jiao, J.J.; Tang, C.A.; Li, Z. Instability leading to coal bumps and nonlinear evolutionary mechanisms for a coal-pillar-and-roof system. Int. J. Solids Struct. 2006, 43, 7407–7423. [Google Scholar] [CrossRef]

- Ma, H.; Wang, J.; Wang, Y. Study on mechanics and domino effect of large-scale goaf cave-in. Saf. Sci. 2012, 50, 689–694. [Google Scholar] [CrossRef]

- Qi, Q.X.; Dou, L.M. Coal Bump Theories and Technologies; China University of Mining and Technology Press: Xuzhou, China, 2008. (In Chinese) [Google Scholar]

- Poulsen, B.A.; Shen, B. Subsidence risk assessment of decommissioned bord-and-pillar collieries. Int. J. Rock Mech. Min. 2013, 60, 312–320. [Google Scholar] [CrossRef]

- Zhou, Q.C. Study on the Mechanical Property of a Sandstone under Geothermal-Mechanical and Hydraulic-Mechanical Coupling. Ph.D. Thesis, Chinese Academy of Science, Beijing, China, 2006. (In Chinese). [Google Scholar]

- Funatsu, T.; Kuruppu, M.; Matsui, K. Effects of temperature and confining pressure on mixed-mode (I–II) and mode II fracture toughness of Kimachi sandstone. Int. J. Rock Mech. Min. 2014, 67, 1–8. [Google Scholar] [CrossRef]

- Nara, Y.; Yamanaka, H.; Oe, Y.; Kaneko, K. Influence of temperature and water on subcritical crack growth parameters and long-term strength for igneous rocks. Geophys. J. Int. 2013, 193, 47–60. [Google Scholar] [CrossRef]

- Castellanza, R.; Gerolymatou, E.; Nova, R. An attempt to predict the failure time of abandoned mine pillars. Rock Mech. Rock Eng. 2008, 41, 377–401. [Google Scholar] [CrossRef]

- Peyras, L.; Rivard, P.; Breul, P.; Millet, A.; Ballivy, G. Characterization of rock discontinuity openings using acoustic wave amplitude—Application to a metamorphic rock mass. Eng. Geol. 2015, 193, 402–411. [Google Scholar] [CrossRef]

- Moradian, Z.; Einstein, H.H.; Ballivy, G. Detection of cracking levels in brittle rocks by parametric analysis of the acoustic emission signals. Rock Mech. Rock Eng. 2016, 49, 785–800. [Google Scholar] [CrossRef]

- Wieser, C.; Käsling, H.; Raith, M.; Richter, R.; Moser, D.; Gemander, F.; Grosse, C.; Thuro, K. Acoustic emission technique to detect micro cracking during uniaxial compression of brittle rocks. Eng. Geol. Soc. Territ. 2015, 6, 465–468. [Google Scholar]

- Yu, Q.; Yang, S.; Ranjith, P.G.; Zhu, W.; Yang, T. Numerical modeling of jointed rock under compressive loading using x-ray computerized tomography. Rock Mech. Rock Eng. 2016, 49, 877–891. [Google Scholar] [CrossRef]

- Pini, R.; Madonna, C. Moving across scales: A quantitative assessment of X-ray CT to measure the porosity of rocks. J. Porous Mater. 2016, 23, 325–338. [Google Scholar] [CrossRef]

- Feng, X.; Wang, E.; Shen, R.; Wei, M.; Chen, Y.; Cao, X. The dynamic impact of rock burst induced by the fracture of the thick and hard key stratum. Procedia Eng. 2011, 26, 457–465. [Google Scholar]

- Ju, J.; Xu, J.; Zhu, W. Longwall chock sudden closure incident below coal pillar of adjacent upper mined coal seam under shallow cover in the Shendong coalfield. Int. J. Rock Mech. Min. 2015, 77, 192–201. [Google Scholar] [CrossRef]

- Gong, W.; Peng, Y.; He, M.; Wang, J. Thermal image and spectral characterization of roadway failure process in geologically 45° inclined rocks. Tunn. Undergr. Space Technol. 2015, 49, 156–173. [Google Scholar] [CrossRef]

- Abellán, A.; Oppikofer, T.; Jaboyedoff, M.; Rosser, N.J.; Lim, M.; Lato, M.J. Terrestrial laser scanning of rock slope instabilities. Earth Surf. Process. Landf. 2014, 39, 80–97. [Google Scholar] [CrossRef]

- Sousa, J.J.; Bastos, L. Multi-temporal SAR interferometry reveals acceleration of bridge sinking before collapse. Nat. Hazards Earth Syst. 2013, 13, 659–667. [Google Scholar] [CrossRef]

- Lazecký, M.; Çomut, F.C.; Hlaváčová, I.; Gürboğa, S. Practical application of satellite-based SAR interferometry for the detection of landslide activity. Procedia Earth Planet. Sci. 2015, 15, 613–618. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Li, L.; Wang, L.; Liang, R.Y. A case study integrating numerical simulation and GB-InSAR monitoring to analyze flexural toppling of an anti-dip slope in Fushun open pit. Eng. Geol. 2015, 197, 20–32. [Google Scholar] [CrossRef]

- Huang, J.; Deng, K.; Fan, H.; Yan, S. An improved pixel-tracking method for monitoring mining subsidence. Remote Sens. Lett. 2016, 7, 731–740. [Google Scholar] [CrossRef]

- Fan, H.; Gao, X.; Yang, J.; Deng, K.; Yu, Y. Monitoring mining subsidence using a combination of phase-stacking and offset-tracking methods. Remote Sens. 2015, 7, 9166–9183. [Google Scholar] [CrossRef]

- Chen, B.; Deng, K.; Fan, H.; Yu, Y. Combining SAR interferometric phase and intensity information for monitoring of large gradient deformation in coal mining area. Eur. J. Remote Sens. 2015, 48, 701–717. [Google Scholar] [CrossRef]

- Pone, J.D.N.; Hein, K.A.A.; Stracher, G.B.; Annegarn, H.J.; Finkleman, R.B.; Blake, D.R.; McCormack, J.K.; Schroeder, P. The spontaneous combustion of coal and its by-products in the Witbank and Sasolburg coalfields of South Africa. Int. J. Coal Geol. 2007, 72, 124–140. [Google Scholar] [CrossRef]

| Type | Formula Name | a | b | Application Condition & Parameter Instruction | ||

|---|---|---|---|---|---|---|

| TAT | TAT [13,16,26] | 2D | 0 | 0 | - | The TAT method can be used for stress calculation of production pillars when the roof is intact, and mine size is large. |

| 3D | 1 | 0 | ||||

| PAT | King (1970) [13,26] | 2D | 0 | 1 | 31° |

|

| 3D | 1 | 1 | ||||

| Wilson (1970) [13,26] | 2D | 0 | 1 | 16.7° | ||

| 3D | 1 | 1 | ||||

| Choi & McCain (1980) [13] | 2D | 0 | 1 | 18° | ||

| 3D | 1 | 1 | ||||

| Mark (1987) [13] | 2D | 0 | 1 | 21° | ||

| 3D | 1 | 1 | ||||

| Poulsen (2010) [16] | 2D | 0 | 1 | |||

| 3D | 1 | 1 |

| Formula Name | Formula & Parameter Instruction |

|---|---|

| Salamon (1964) [21,27] | |

| Pillar stress at location x can be calculated; the origin of x is located at the center of longwall panel. for unit weight of overburden, N/m3; H for the mining depth, m; L for panel length, m. | |

| Mark (1987) [13] | |

| The abutment load on pillar group is calculated (Figure 4); for abutment load; H for the mining depth, m for width of pillar group. | |

| Majdi (1988) [22,28] | |

| for unit weight of overburden, N/m3; H for the mining depth, m; h for pillar height, m; Ep and EO for elastic modulus of coal seam and overburden respectively, GPa; L for panel length, m. | |

| Heasley (2000) [19,20] | |

| Pillar stress at location x can be calculated; the origin of x is located at the center of longwall panel. for unit weight of overburden, N/m3; H for the mining depth, m; L for panel length, m; Ep and EO for elastic modulus of coal seam and overburden respectively, GPa; is the laminated constant; h for pillar height, m; for Poisson’s ratio of overburden; for width of yield zone of pillar. | |

| A.K. Singh et al. (2011) [21] | |

| ; ; | |

| for ultimate vertical stress of coal pillar, MPa; H for the mining depth (H < 200), m; for UCS of caved roof, MPa; for length of roof sample core, cm; for thickness of strong roof bed, m; n = 1.2 if RQD of rock ≥80%, or n = 1; is the influence range of abutment stress, m. | |

| Rezaei et al. (2015) [22] | |

| Pillar stress at location x can be calculated; the origin of x is located at the edge of longwall panel; for unit weight of overburden, N/m3; H for the mining depth, m; for height of “destressed zone” (similar to height of pressure arch), m; h for pillar height, m; k for bulk factor of roof; for Poison’s ratio of overburden; for UCS of caved roof, MPa. |

| Formula Name | K | A | B | C | D | ||

|---|---|---|---|---|---|---|---|

| Linear | Bunting (1911) [26,34,38] | = 7 MPa | 0.7 | 0.3 | 1 | 1 | 0.5–3.4 |

| Van Heerden (1974) [34,39] | |||||||

| Sorenson (1978) [34,40] | |||||||

| Obert-Duvall/Wang (1967) [13,26,36,37,41] | 0.778 | 0.222 | 1 | 1 | 1–8 | ||

| Bieniawski (1975) [13,26,34,35,36,37,42,43] | 0.64 | 0.36 | 1 | 1 | <5 | ||

| Power | Zern (1928) [26,34,37,44] | 0 | 1 | 0.5 | 0.5 | - | |

| Steart (1954) [34,45,46] | or | 0 | 1 | 0.5 | 1 | 2–8 | |

| Holland-Gaddy (1962) [13,26,34,47] | |||||||

| Greenwald (1941) [34,37,46] | 0.67 | 0 | 1 | 0.5 | 5/6 | ||

| Salamon and Munro (1967) [26,34,35,36,37,46] | 7.176 MPa | 0 | 1 | 0.46 | 0.66 | <5 | |

| Hedley & Grant (1972) [34,36,48] | 0 | 1 | 0.5 | 0.75 | |||

| Merwe and Mathey Squat pillar (2013) [35] | 6.61 MPa | 0 | 1 | 0.5 | 0.7 | <12 | |

| 5.47 MPa | 0 | 1 | 0.8 | 1 | |||

| Parameter Explanation | |||||||

| for in-situ coal stress, MPa; for in-situ UCS (uniaxial compressive strength) of a cubic specimen with a critical size, m; for UCS of a 30 cm long cubic specimen; d for specimen size, cm; for strength of coal cube (d = 2.5 cm). | |||||||

| Formula Name | Formula & Parameter Instruction | |

|---|---|---|

| Logie and Matheson (1982) [37,49] | >5 | |

| for UCS of a 30 cm long cubic specimen; for pillar width, m; h for pillar height, m. | ||

| Maleki (1992) [35,50] | 10–15 | |

| for pillar width, m; h for pillar height, m. | ||

| Sheorey (1992) [35,37,51] | <6.7 | |

| for strength of coal cube (specimen size d = 2.5 cm); h for pillar height, m; H for mining depth, m; for pillar width, m. | ||

| Mark-Bieniawski (1997) [20,37,52] | ||

| for in-situ coal stress, MPa; h for pillar height, m; for pillar width, m; for pillar length, m. | ||

| Salamon Squat Pillar (1982) [35,53] | >5 | |

| for in-situ coal stress, MPa; for critical width-height ratio of pillar and = 5; for rate of strength increase and = 2.5; for pillar volume; for width-height ratio of pillar. | ||

| Lunder (1997) (rock) [34] | ||

| for pillar width, m; h for pillar height, m; for UCS of intact sample of pillar material (5 cm), MPa. |

| Formula Name | Formula | Parameter Explanation |

|---|---|---|

| Wilson (1972) [26] | h for pillar height, m; H for mining depth, m | |

| Wilson (1983) [18] | Yield only occur in coal seam | h for pillar height, m; H for mining depth, m; ; ; p for restraint stress at pillar rib, MPa; for unit weight of overburden, N/m3 |

| Yield occur in roof, coal seam and floor | ||

| Bai (1983) [65] | for unit weight of overburden, N/m3; H for mining depth, m; for mining width, m; for coal yield stress, MPa; = (0.595 + 0.875)(0.9831 + 0.0106N), N for strip pillar number; | |

| Wu (1995) [66] | h for pillar height, m; d = 1.5–3 for stress disturbance factor (damages on pillar rib); for coal ultimate strength, MPa; for pillar average compressive strength, MPa; for coefficient of horizontal stress at yield/elastic plate. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Chen, S.-E.; Deng, K.-Z.; Wang, P.; Fan, H.-D. Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review. Sustainability 2018, 10, 113. https://doi.org/10.3390/su10010113

Yu Y, Chen S-E, Deng K-Z, Wang P, Fan H-D. Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review. Sustainability. 2018; 10(1):113. https://doi.org/10.3390/su10010113

Chicago/Turabian StyleYu, Yang, Shen-En Chen, Ka-Zhong Deng, Peng Wang, and Hong-Dong Fan. 2018. "Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review" Sustainability 10, no. 1: 113. https://doi.org/10.3390/su10010113

APA StyleYu, Y., Chen, S.-E., Deng, K.-Z., Wang, P., & Fan, H.-D. (2018). Subsidence Mechanism and Stability Assessment Methods for Partial Extraction Mines for Sustainable Development of Mining Cities—A Review. Sustainability, 10(1), 113. https://doi.org/10.3390/su10010113