Abstract

Microbial electrochemical cells (MxCs) offer a sustainable approach for wastewater treatment and energy recovery by harnessing the electroactive properties of microorganisms. This study explores the enrichment of Geobacter species on anode biofilms in single-(S-MxCs) and double-chambered (D-MxCs) MxCs, using domestic wastewater without an external anode potential. Stable current densities were achieved within 10 days for S-MxCs (9.52 ± 0.8 A/m2) and 14 days for D-MxCs (4.28 ± 0.9 A/m2), with S-MxCs showing a superior electrochemical performance. Hydrogen production rates were higher in D-MxCs (14.93 ± 0.66 mmol H2/L/day) compared to S-MxCs (9.46 ± 0.8 mmol H2/L/day), with cumulative production rates of 12.9 ± 1.3 mmol H2/g COD and 6.48 ± 1.4 mmol H2/g COD, respectively. Cyclic voltammetry confirmed enhanced bioelectrocatalytic activity in S-MxCs, while SEM imaging showed denser biofilms on S-MxC anodes. The novelty of this study lies in its demonstration of efficient biofilm development and microbial community resilience under non-potentialized conditions, providing insights that advance the practical application of MxCs in environmental biotechnology.

1. Introduction

MxCs are a widely developing environmental technology, which integrates bioelectrochemistry, microbiology, molecular biology, material science, engineering, and others [1,2,3]. A better environmental understanding of microbial electrochemistry offers a flexible platform to develop different engineering functions. MxCs have a wide range of applications, but they work on a common anodic principle that utilizes organic or inorganic electron donation by microorganisms. These cells can be used in different ways; for example, microbial electrolysis cells (MECs) are used for the production of H2, CH4, and value-added chemicals; microbial fuel cells (MFCs) are directly used for electricity; microbial recycling cells (MRCs) are used in cathode chambers for contaminant remediation; and microbial desalination cells (MDCs) are used for organic compound synthesis [4,5,6,7,8]. This multifunctional technology is commonly known as MxCs, where the ‘x’ stands for the platform of different applications.

An ideal anodic reaction of MxCs employs a specific group of microorganisms that can actively play a role in extracellular electron transfer (EET), e.g., exoelectrogens, anode respiring bacteria (ARB), or electrochemically active bacteria (EAB) [9]. The mechanism of the EET of electroactive biofilms has been studied; however, more research is still needed. Currently, the most persuasive concepts of EET mechanisms are firstly, direct electron transfers from microbes to the electrode; secondly, soluble electron shuttles (e.g., melanin, flavis, quinones, and phenazines) that can carry electrons from microbes to the electrode; and thirdly, via conductive pili (nanowires) or conductive biofilms [10]. The Geobacter sp. has been proven to be one of the more promising exoelectrogens that take part in cell-to-cell electron transfer using its unique feature of conductive pili (nanowires). However, the microbial activity and electroactive efficiency of bioanodes/cathode dramatically influence the overall performance of MxCs.

The start-up time, abundance of electroactive biofilm, and steady-state performance directly depend on the environmental conditions and start-up procedure like pH, temperature, microbial diversity of inoculum, reactor configuration, and imposed anode potential. The enrichment of an anode with a high abundance of electroactive bacteria (e.g., Geobacter sp.) accelerates the electrochemical reactions of MxCs, especially in MFCs and MECs. The growth of electroactive biofilms depends on the energy gained by transferring the electrons to the solid electrode (anode) [11]. It has been reported that by imposing the Nernst–Monod potential (close to −0.2 V vs. SHE) to the anode, many electroactive bacteria, including Geobacter, can enhance their efficiency by using different outer membrane proteins [12,13].

The applied potential in MxCs plays a significant role in microbial enrichment. The potential affects the performance of current production and the composition of the microbial communities [14]. The effect of the potential on current production decreases over time, indicating a shift in the anode biofilm from accepting electrons to producing electrons [15]. Additionally, the amount of energy available for bacterial growth is another key factor that influences the populations of electrochemically active bacteria [16]. A high potential also affects the corrosion of the electrodes [17]. It is important to investigate the implications of the enrichment process of electroactive biofilms on the electrochemical performance and microbial community dynamics of MxCs without applying anode potential.

In this study, we examined the enrichment of particular electroactive bacteria (Geobacter) on anode biofilms without posing anode potential in single- and double-chambered MxCs using domestic wastewater. The study provides a thorough investigation into the enrichment process by combining multiple analytical techniques such as cyclic voltammogram, EIS, microbiological communities, biofilm imaging, current density, hydrogen production rate, and COD removal rate. This multi-faceted approach offers deep insights into the electrochemical behavior, microbial community dynamics, and biofilm morphology, contributing to a more holistic understanding of MxCs.

2. Materials and Methods

2.1. Reactor Configuration and Operation

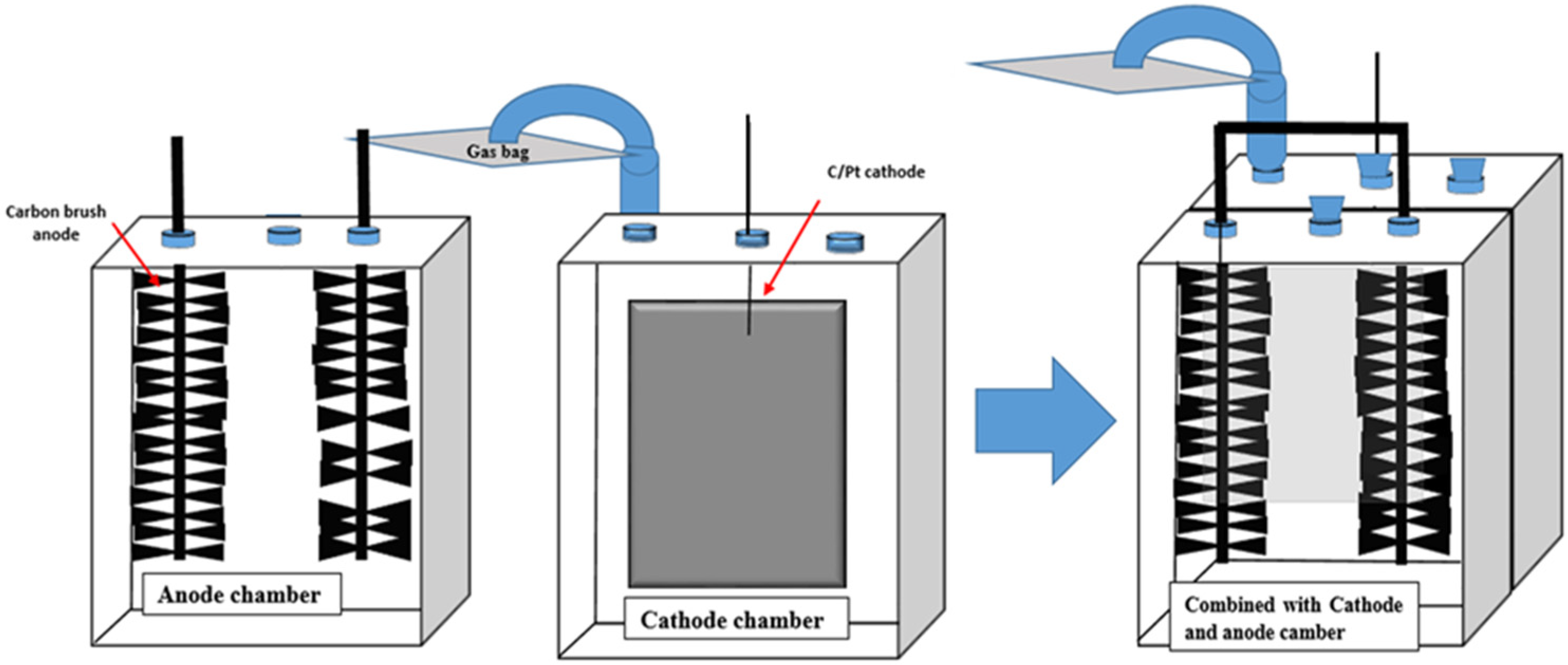

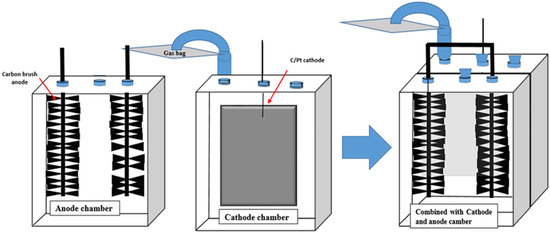

A set of single- and dual-chamber MxCs were constructed with Plexiglas (6 cm × 6 cm × 3 cm) with a working volume of 200 mL for the S-MxCs or 100 mL for each (anode and cathode) chamber in the D-MxCs. A cation exchange membrane (CEM) was used in dual-chamber MECs to separate the anode and cathode chamber, as described in Figure 1.

Figure 1.

Schematic diagram of the microbial electrolysis cell used for the experiments. Separate anode and cathode chambers are assembled into MECs; a CEM is placed between the anode and cathode chambers to make a single chamber into a dual chamber.

Two carbon fiber brushes (3 cm diameter × 4 cm length, each) were used for anodes, and stainless-steel mesh (25 cm2) was employed for cathodes. We pretreated the carbon fiber brush by soaking it in 100% acetone for 24 h to remove impurities and then dried the brush at 450 °C for 30 min in a muffle oven [18]. The anodes and cathodes were connected via Cu wires, with an inserted 10 Ω resistor, and electrical signals were monitored during the experiment.

The domestic wastewater used for inoculating the anode biofilms in both MxCs was collected from the sewage treatment plant at Harbin Institute of Technology campus II (Harbin, China). The wastewater was transported to the laboratory under ambient conditions to preserve its microbial contents. No additional processing was performed on the wastewater to maintain its natural composition and microbial diversity. Using untreated domestic wastewater allows for a more accurate exploration of the natural enrichment potential of Geobacter and other electroactive bacteria under conditions that closely resemble the actual wastewater treatment environment [2,4,19,20,21,22]. The domestic wastewater mixed with growth medium (with a wastewater-to-medium ratio of 1:2 v/v) was fed to the anode chambers of the MxCs. The chemical composition of the medium includes CH3COONa (2 g/L), KCl (0.13 g/L), NaH2PO4·2H2O (3.32 g/L), Na2HPO4·12H2O (10.32 g/L), NH4Cl (0.31 g/L), vitamin solution (5 mL/L), and trace mineral solution (12.5 mL/L). The literature details the chemical compositions of vitamin and trace mineral solutions [23]. During the experiments, the MxCs were operated in batch mode (48 h of reaction time per batch cycle). When the current density decreased ≥20 A/m3, the anolyte was entirely replaced with a fresh mixture of the domestic wastewater and the medium, while the cathode chamber of the D-MxCs was filled with a medium (50 mM PBS) without a carbon source and inoculum. We started a new batch operation after sparging the MxCs with nitrogen gas for 15 min. During the experiments, a fixed applied voltage of 0.8 V was consistently supplied to the MxCs using a power supply (Input A.C: 220 ± 20%, Output D.C: 0–12 V, Shanghai, Fudan, Tianxian Science and Education Instrument Co., Ltd., Shanghai, China). The MxCs were maintained at a constant temperature of 30 ± 1 °C throughout the experiments.

2.2. Measurements and Analysis

The electrical current generated from the MxCs was recorded every 30 min using a data acquisition system (PISO-813, ICI DAS Co., Ltd., Taiwan, China). The current density (j) was calculated based on the working volume of the MxCs (200 mL for S-MECs and 100 mL for D-MxCs). Biogas was collected in a gas bag and was analyzed using gas chromatography (GC) (7890B, Agilent Ins., Santa Clara, CA, USA). The total amount of moles of H2 produced in MECs was calculated using the following formula: . P is the atmospheric pressure (1 atm), V is the volume of produced gas (L), T is the temperature (K), and R is the gas constant (0.08206 L-atm/K-mol). We performed statistical analysis to determine the variation in degradation. Standard deviations were calculated for each set using OriginLab 2021 (9.8) software. The data were plotted with mean values, and error bars represented the standard deviations. COD concentration was measured with Hach vials (TNTplus COD Reagent, HACH Company, Ames, IA, USA) using a spectrophotometer (DR/3900 HACH Co., CO., USA). pH and conductivity were measured using a pH and conductivity meter (PH7110 and cond7110, WTW, Weilheim, Germany). The morphologies of the biofilms were examined using scanning electron microscopy (SEM, FEI Sirion, Thermo Fisher, Columbus, OH, USA). The performance of the MxCs was assessed in terms of current density and hydrogen production rate, as well as total Geobacter accumulation. The electrochemical analysis of the anode was examined using turnover cyclic voltammetry (CV) (PMC2000A, Advanced Measurement Technology, Richfield, WI, USA) from −0.8 V to 0.3 V at a scan rate of 1 mVs−1. The internal resistance of the system was examined using electrochemical impedance spectroscopy (EIS) (PMC2000A, Advanced Measurement Technology, Richfield, WI, USA) of full-cell MxCs.

2.3. Biofilm Community Analysis

The anode biofilm samples were collected from the two MxCs using sterilized scissors and tweezers at day 23 after current–time profiles were replicated 5 times in fed-batch cycles. To improve representative biofilm samples, we took samples from the both anode carbon fibers in each MxC in a laminar flow chamber to stop cross-contamination. The sampled carbon fibers were cut into small pieces and placed in lysate solution. DNA extraction was performed using the E.Z.N.ATM Mag-Bind Soil DNA Kit (Omega Bio-Tech, Norcross, GA, USA), according to the manufacturer’s instructions. DNA extraction was confirmed using agarose gel electrophoresis, and DNA extracts were sent out for pyrosequencing (Illumina Miseq sequencer, Sangon Boitech, Shanghai, China). Microbial community analysis focused on the V3–V4 region of the 16s rRNA gene, and these regions were amplified using barcode primers 341F and 805R. The raw data were scrutinized using ‘Prinseq 0.20.4’ and filtered out >10 bps homopolymers, <200 bps, primer mismatches, or average quality scores < 20. The operational taxonomic units (OTUs) were picked by the Greengenes 16S rRNA gene database with ‘R’ based on 97% identity [24,25]. Chimeric sequences were identified by ‘uchime’ and were removed using ‘Usearch’. Phylogenetic tree diversity was analyzed with ‘MEGA 5.05’. OTUs were assigned a taxonomy using a 60% identity threshold. Functional gene analysis was conducted using a BLAST search against the Clusters of Orthologous Groups (COGs) database for proteins (http://www.ncbi.nlm.nit.gov/COG/) accessed on 22 February 2020.

3. Results and Discussions

3.1. Current Density and COD Removal

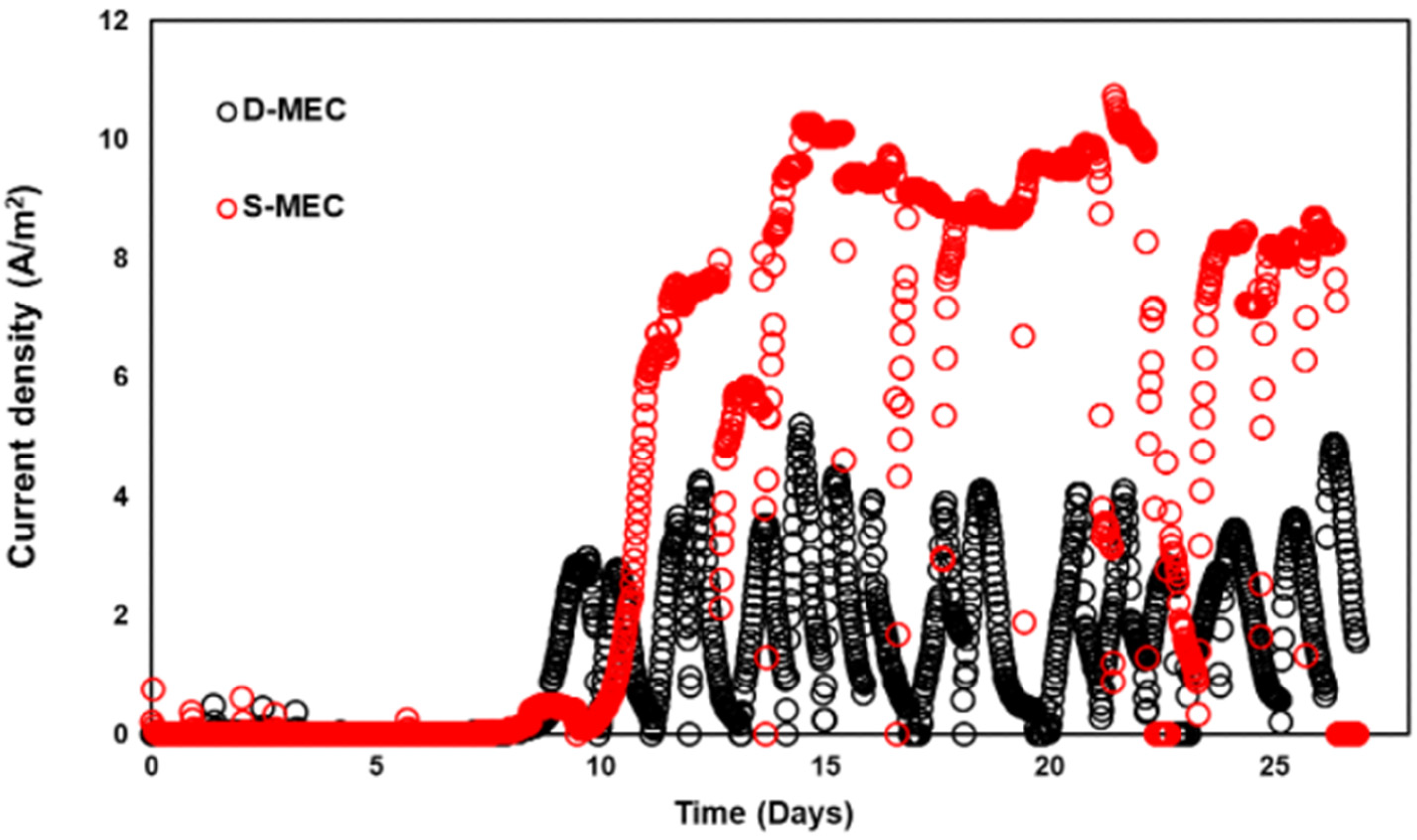

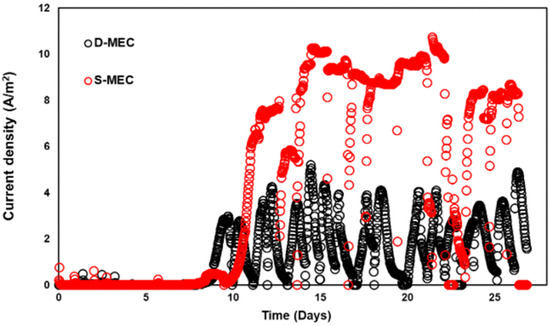

The current density reached a steady state only at 10 and 14 days after inoculation in D-MxCs and S-MxCs, respectively. It reached values as high as 4.28 ± 0.9 and 9.52 ± 0.8 A/m2 in D-MxCs and S-MxCs, respectively. The maximum current density was repeatedly obtained until the end of this experiment. Figure 2 shows the profiles of current density with time.

Figure 2.

Current density of S-MxCs and D-MxCs.

The current density in single-chamber MxCs was higher than has been previously reported in studies that pose a potential on the anode in MxCs [20,21,26,27,28]. In our MxCs, the activity of the electroactive microorganisms started to increase following 9 to 10 days of inoculation, as indicated by the current density (Figure 2). This time range meets the requirements reported by Escapa et al. (2015), whereby a minimum of 7 and a maximum of 25 days was needed to start current generation in acetate-fed MECs (acetate as an electron donor; inoculated by domestic wastewater; and an applied voltage of 0.7 V), as well as the maximum current density being much lower than reported in this study [29]. Anode biofilm enrichment using air cathodes (MFCs) is one of the popular enrichment processes of MECs; however, it takes more time than the process used in this study to enrich the biofilm. Lu et al. (2016) have reported a 15–17day acclimation period using domestic wastewater as an inoculum, acetate as an electron donor, and oxygen as ab electron accepter; Mei et al. (2017) reported a 2month acclimation period using similar operational conditions [30,31]. Sim et al. (2015) obtained a maximum current density of 8 A/m2 after two weeks of enrichment using pre-enriched MEC effluent as an inoculum by posing a −0.4 V potential on the anode of double-chamber MxCs, which is much higher than the current density used on D-MxCs in this study. Compared to those studies, we obtained a much higher current density in a comparable enrichment period to reach steady state without posing a potential on the anode (Table 1).

Table 1.

Comparison of the maximum current density or power density, acclimation time, and Geobacter population in biofilm anodes of MXCs.

The acetate concentration in the influent was 25 ± 0.6 mM (2 g/L), with a COD of 1650 ± 20 mg COD/L. After 15 cycles, the average COD removal was 77.85 ± 1% and 56 ± 2.5% in S-MxCs and D-MxCs, respectively, in 24 h of reaction time. It shows that the current density is totally proportional to substrate utilization [21]. Effluent pH was stable at 7.3 ± 0.2 in S-MxCs, while D-MxCs had a pH of 5.9 ± 0.1 in the anode chamber and 7.8 ± 0.1 in the cathode chamber during the experiments. The method’s reliance on wastewater adds value by integrating waste treatment with energy production, potentially offsetting the costs associated with wastewater management.

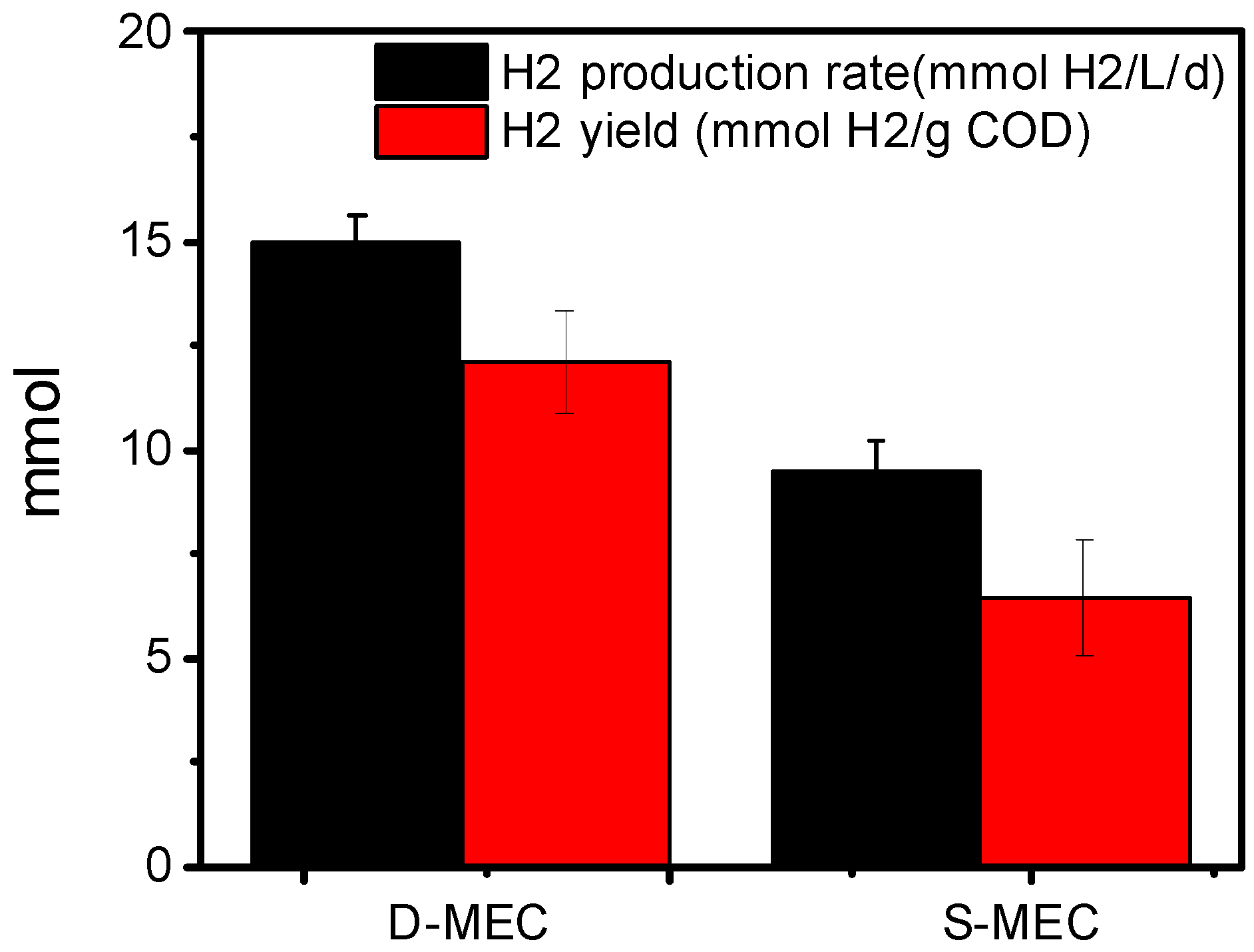

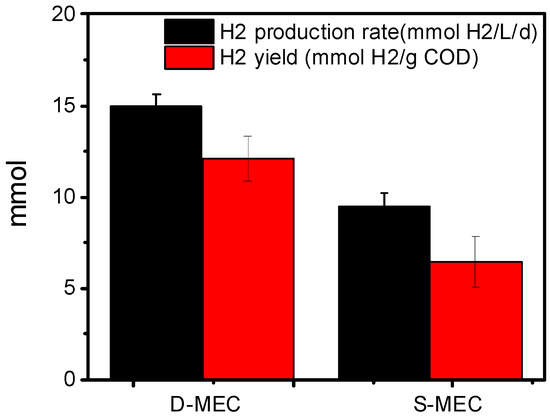

3.2. Hydrogen Production

The average hydrogen production rate in S-MxCs and D-MxCs was 9.46 ± 0.8 and 14.93 ± 0.66 mmol H2/L/D, respectively (Figure 3). The total H2 yield in S-MxCs and D-MxCs was 6.48 ± 1.4 and 12.9 ± 1.3 mmol H2/g COD, respectively, which is an average of those previous studies using anode potential [9,26,35]. This suggests that the enrichment process based on the presence/absence of a posing potential on the anode does not affect the hydrogen production of MECs.

Figure 3.

Hydrogen production rate and total hydrogen yield in single- and dual-chamber MxCs.

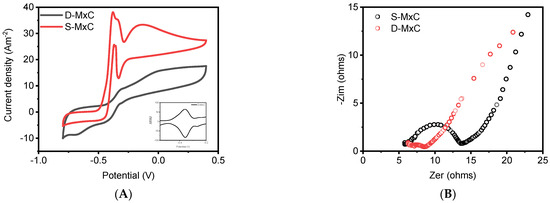

3.3. Electrochemical Analysis

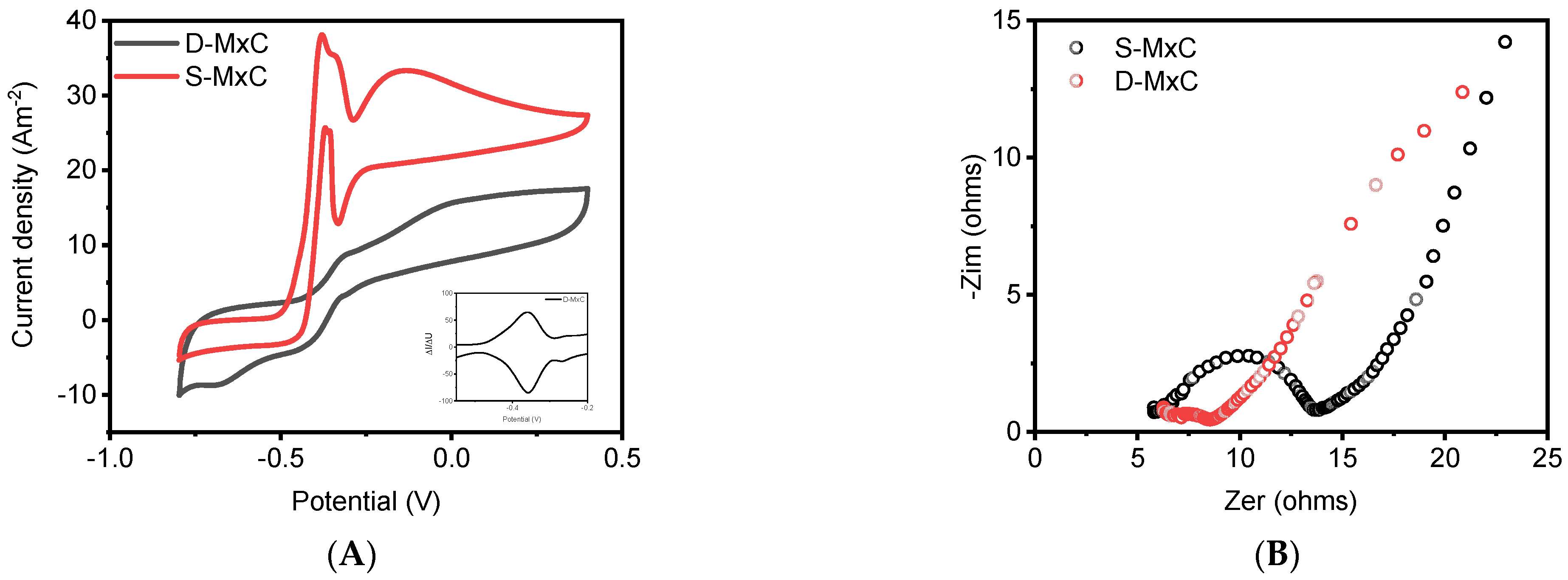

To investigate the effect of the enrichment process without posing an anode potential on the catalytic activity of the biofilms of S-MxCs and D-MxCs, CV of the bioanodes at a scan rate of 1 mV/s was executed. From the shape of the cyclic voltammograms (Figure 4A), two major redox peaks can be distinguished at the formal potential, at −0.383 V and −0.154 V (vs. Ag/AgCl) in S-MxCs, which contribute to the bioelectrocatalytic anodic electron transfer. In D-MxCs, a typical sigmoidal shape was observed with one single underlying redox center; the actual EET sites (−0.368 V) indicate the derivatives of the voltammetry curve (Figure 4A (inset)). Xinlei Qian et al. reported that the electron transfers from Geobacter via direct electron transfer (DET) are accomplished by outer membrane cytochromes [36]. For cytochrome OmcB, a formal potential of –0.387 V vs. Ag/AgCl has been reported [37], which is similar to the redox peaks in this study.

Figure 4.

Cyclic votammograms (A) and Nyquist plots of full-cell MxCs (single and dual-chamber MxCs) (B).

Figure 4B shows the Nyquist plots of the full-cell MEC system of both MECs (S-MxCs and D-MxCs). The charge transfer resistance of D-MxCs (13 Ω) was higher than that of S-MECs (8.6 Ω), which shows that the presence of a cation exchange membrane in D-MxCs increased the internal resistance, causing a lower current density than S-MECs; this is a general phenomenon and shows no adverse effect of anode potential abortion on the internal resistance of either anode’s electrochemical activities in S-MECs and D-MxCs. Since the method does not require complex equipment for applying and maintaining an external potential, it is easier to scale up. This simple design and operation enhance the feasibility of deploying MxCs in larger, real-world settings such as municipal wastewater treatment plants.

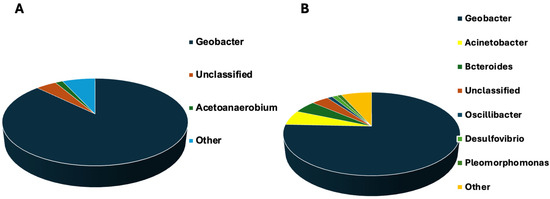

3.4. Microbial Community Analysis

Over time, microbial communities begin to colonize the anode surface, forming a biofilm. This biofilm developed as the microorganisms adhered to the anode and started utilizing the electrode as an electron acceptor during the oxidation of the organic matter present in wastewater. The biofilm formation process was monitored by regularly measuring the current density. Once current density reached a steady state, microbial communities were sampled for further analysis. From the pyrosequencing of the 16s rRNA of D-MxC and S-MxC anode biofilms, the average reads were 55,413 and 57,646 with an average length of 427bps. The operational taxonomic units (OTUs) were determined at 97% nucleotide identity, and 277 and 407 were counted, respectively. The obtained OTUs, Ace and Chao1 (Table 2), showed that the anode biofilm of S-MECs had a higher richness than that of D-MxCs. Mei, X. X., et al. stated that a high richness indicated a low diversity or low species evenness [30], which was also verified by the that total relative abundance at the genus level.

Table 2.

Illumina sequencing analysis for species richness and diversity analyses of anode biofilms.

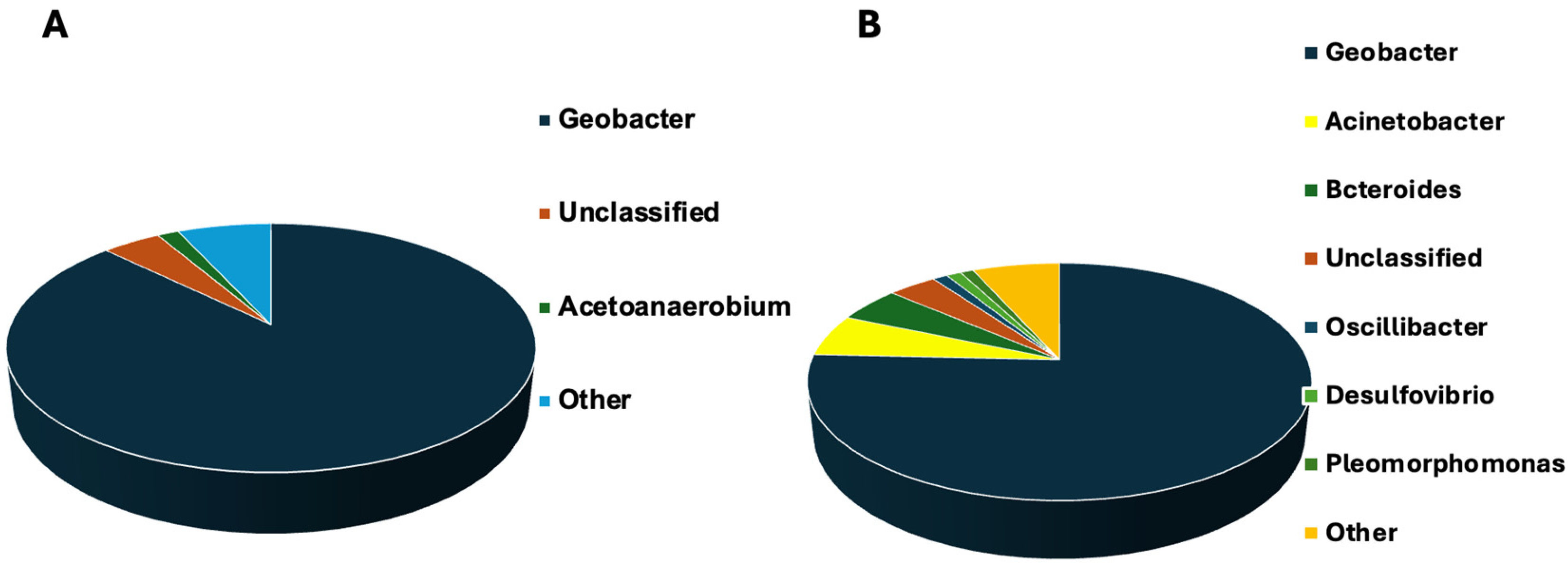

The relative abundance of anodic microbial communities is shown in Figure 5 at the genus level. The dominant bacteria belonged to Geobacter sp. in both S-MECs and D-MxCs, with a relative abundance of 87.31% and 75.7%, respectively, which is much higher than the value reported by Mei, X. X., et al. (2017), but is comparable with that reported by Lu, et al. (2011), who reported an 11% and 73% abundance of Geobacter, respectively, enriched by domestic wastewater as an inoculum and acetate as a substrate-using air-cathode [30,32]. The diversity of the microbial community was higher in D-MxCs than S-MxCs. Two other major genus, Acinetobacter (5.75%) and Bacteroides (4.87%), were present in D-MxCs. These genera, with a lower abundance than Geobacter, are noteworthy for their potential role in the electrochemical processes within MxCs. As mentioned earlier, the current density was low, and the COD removal efficiency was over 55% in D-MxCs. This suggests that Acinetobacter and Bacteroides play a role as fermentative bacteria responsible for producing metabolites for exoelectrogens and hydrolyzing complex organics from wastewater [38].

Figure 5.

The average anode microbial community distribution (relative abundance ≥ 1%) at the genus levels of S-MxCs (A) and D-MxCs (B).

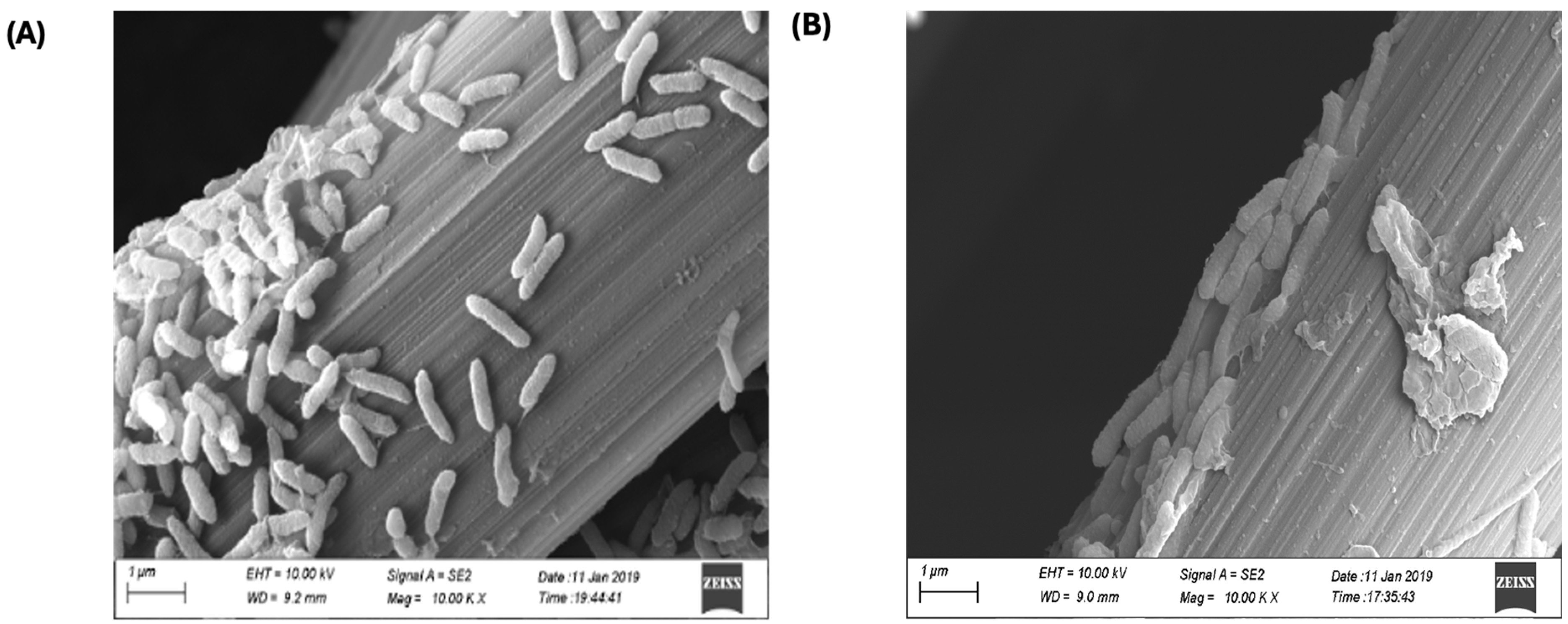

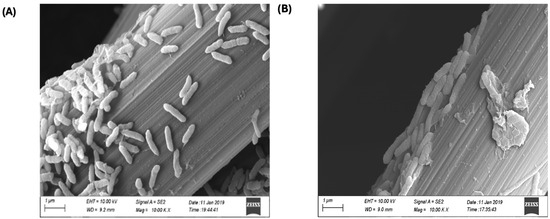

3.5. Anode Biofilm Imagining

The presence of biofilm in the MEC system is crucial. The thickness and integrity of the biofilm indicate the quantity of bacterial activity, while any damage to the biofilm can decrease the bacteria’s ability to survive in harsh conditions. A prolonged electrical current has the potential to harm the integrity of the biofilm’s structure. SEM (Figure 6) was used to examine the surface morphology of the electrode.

Figure 6.

Scanning electron microscopy image of anode biofilms (A) in double-chamber and (B) single-chamber MxCs.

The SEM image of the anode biofilm in the S-MxCs (Figure 6A) displays a fully developed and thick biofilm with an elevated density of microbial cells, suggesting the presence of a robust and mature microbial community. The high concentration of extracellular polymeric substances (EPSs) indicates an intense biofilm structure, which enhances stability and promotes microbial interactions. The well-developed biofilm structure is likely responsible for the increased hydrogen output found in S-MxCs. This is because the biofilm’s physical and chemical features improve the efficiency of hydrogen evolution reactions.

On the other hand, the biofilm in the D-MxCs (Figure 6B) is characterized by being thinner and less dense. It is mostly composed of rod-shaped bacteria, notably Geobacter species, which are well known for their ability to generate electrons. The significant prevalence of Geobacter in the D-MxCs is directly correlated with the increased hydrogen attained in this particular setup. A biofilm with a smoother surface and a lower EPS content indicates a less developed conductive biofilm, emphasizing the importance of microbial composition in enhancing electron transfer activities.

4. Conclusions

This study provides a comprehensive examination of the enrichment of electroactive bacteria, particularly Geobacter species, on anode biofilms in MxCs using domestic wastewater without the application of anode potential. The successful enrichment in both S-MxCs and D-MxCs highlights the potential for optimizing MxCs without the need for external voltage, thereby simplifying the system and reducing operational costs. The findings underscore the resilience and efficiency of the microbial community, particularly in S-MxCs, which achieved higher current densities and a well-developed biofilm structure. This indicates that Geobacter-dominated biofilms can be effectively utilized for bioelectrocatalysis without imposing anode potential, offering a sustainable approach to enhance MxCs performance.

The implications of this work are significant for advancing the practical applications of MxCs in the environmental and energy sectors. By demonstrating the feasibility of enriching Geobacter species without anode potential, this study opens avenues for developing cost-effective and scalable MxC systems for applications such as wastewater treatment, bioenergy production, and resource recovery. The insights gained from this research lay the groundwork for future studies aimed at optimizing enrichment strategies, exploring the genetic and metabolic pathways of key microbial species, and evaluating the long-term stability of biofilms under various environmental conditions. It contributes to the growing body of knowledge on MxCs and their potential for sustainable environmental applications, paving the way for their commercialization and broader adoption.

Author Contributions

R.S.Y.: conceptualization, methodology, writing—original draft, and formal analysis. W.H.: visualization, investigation, and supervision. D.L.: conceptualization and methodology. C.L.: software and validation. Y.Y.: validation. Y.F.: supervision and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research, and the research was also supported by the Fundamental Research Funds for the Central Universities (RFCU5710010122), the Natural Science Foundation of Heilongjiang Province—Outstanding Youth Foundation (YQ2022E033), the National Natural Science Foundation Youth Fund (No. 42207257), the State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology) (No. 2022TS07, ES202224 and ES202310), the China Postdoctoral Science Foundation (2022M710952 and 2023T160170), Heilongjiang Postdoctoral Science Foundation (LBH-Z22179), and the Fundamental Research Funds for Postdoctoral fellow (Harbin Institute of Technology). The authors also acknowledge the support of the Innovation Team in Key Areas of the Ministry of Science and Technology and the Innovation Team in Key Areas of the Ministry of Science and Technology and Heilongjang Touyan Team.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Deng, P.; Wang, L.; Li, X.; Zhang, J.; Jiang, H. Geobacter grbiciae—A New Electron Donor in the Formation of Co-Cultures via Direct Interspecies Electron Transfer. Microbiol. Res. 2023, 14, 1774–1787. [Google Scholar] [CrossRef]

- Lee, H.S. Electrokinetic analyses in biofilm anodes: Ohmic conduction of extracellular electron transfer. Bioresour. Technol. 2018, 256, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, R.K.; Sarangi, P.K.; Vivekanandm, V.; Nidhi, P.; Khasim, B.S.; Sanjukta, S. Microbial fuel cells for waste nutrients minimization: Recent process technologies and inputs of electrochemical active microbial system. Microbiol. Res. 2022, 265, 127216. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Juan, A.Z.; Bian, Y.; Sun, D.; Yan, Y.; Chen, X.; Zhu, J.; Harold, D.M. Scale-up and techno-economic analysis of microbial electrolysis cells for hydrogen production from wastewater. Water Res. 2023, 241, 120139. [Google Scholar] [CrossRef]

- Mohammad, H.K.M.; Sepehr, D.; Seyed, A.M.R.; Ana, M.B. Optimal 4E evaluation of an innovative solar-wind cogeneration system for sustainable power and fresh water production based on integration of microbial desalination cell, humidification–dehumidification, and reverse osmosis desalination. Energy 2024, 297, 131256. [Google Scholar]

- Ao, T.; Zhao, X.; Muhammad, A.M.; Wang, N.; Zhu, H.; Liu, C.; Bai, F. A double-chamber microbial electrolysis cell improved the anaerobic digestion efficiency and elucidated the underlying bio-electrochemical mechanism. Chem. Eng. J. 2023, 471, 144228. [Google Scholar] [CrossRef]

- Oscar, G.; Juan, A.B.; Albert, G. Enhancing bioelectrochemical hydrogen production from industrial wastewater using Ni-foam cathodes in a microbial electrolysis cell pilot plant. Water Res. 2024, 256, 121616. [Google Scholar]

- He, K.; Li, W.; Tang, L.; Li, W.; Lv, S.; Xing, D. Suppressing Methane Production to Boost High-Purity Hydrogen Production in Microbial Electrolysis Cells. Environ. Sci. Technol. 2022, 56, 11931–11951. [Google Scholar] [CrossRef]

- Tahseena, N.; Ankit, K.; Anusha, V.; Nupur, S.; Soumya, P.; Pankaj, G.; Sokhee, P.J. Recent advances in biological approaches towards anode biofilm engineering for improvement of extracellular electron transfer in microbial fuel cells. Environ. Eng. Res. 2023, 28, 220666. [Google Scholar]

- Jiang, J.; He, P.C.; Luo, Y.; Peng, Z.; Jiang, Y.; Hu, Y.; Qi, L.; Dong, X.; Dong, Y.; Shi, L. The varied roles of pilA-N, omcE, omcS, omcT, and omcZ in extracellular electron transfer by Geobacter sulfurreducens. Front. Microbiol. 2023, 14, 1251346. [Google Scholar] [CrossRef]

- Hu, L.; Yang, Y.; Fu, Q.; Zhang, L.; Zhu, X.; Li, J.; Liao, Q. In Situ Probing the Mass Transport Property Inside an Imitated Three-Dimensional Porous Bioelectrode. Environ. Sci. Technol. 2023, 57, 6159–6168. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Xia, X.; Nie, W.; Qin, B.; Hou, Y.; Lin, A.; Yao, S.; Zhuang, L. Bidirectional extracellular electron transfer pathways of Geobacter sulfurreducens biofilms: Molecular insights into extracellular polymeric substances. Environ. Res. 2024, 245, 118038. [Google Scholar] [CrossRef] [PubMed]

- Torres, C.I.; Krajmalnik-Brown, R.; Parameswaran, P.; Marcus, A.K.; Wanger, G.; Gorby, Y.A.; Rittmann, B.E. Selecting Anode-Respiring Bacteria Based on Anode Potential: Phylogenetic, Electrochemical, and Microscopic Characterization. Environ. Sci. Technol. 2009, 43, 9519–9524. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-C.; Chen, Y.-C.; Yu, C.-P. Microbial community dynamics in electroactive biofilms across time under different applied anode potentials. Sustain. Environ. Res. 2022, 32, 19. [Google Scholar] [CrossRef]

- De La Fuente, M.J.; Daille, L.K.; De la Iglesia, R.; Walczak, M.; Armijo, F.; Pizarro, G.E.; Vargas, I.T. Electrochemical bacterial enrichment from natural seawater and its implications in biocorrosion of stainless-steel electrodes. Materials 2020, 13, 2327. [Google Scholar] [CrossRef]

- Lim, S.S.; Kim, B.H.; Li, D.; Feng, Y.; Daud, W.R.W.; Scott, K.; Yu, E.H. Effects of applied potential and reactants to hydrogen-producing biocathode in a microbial electrolysis cell. Front. Chem. 2018, 6, 318. [Google Scholar] [CrossRef]

- Szydlowski, L.; Sorokin, A.; Vasieva, O.; Fedorovich, V.; Goryanin, I. Evolutionary dynamics of microbial communities in bioelectrochemical systems. BioRxiv 2019, 13, 725580. [Google Scholar]

- Feng, Y.; Yang, Q.; Wang, X.; Logan, B.E. Treatment of carbon fiber brush anodes for improving power generation in air–cathode microbial fuel cells. J. Power Sources 2010, 195, 1841–1844. [Google Scholar] [CrossRef]

- Dhar, B.R.; Ren, H.; Chae, J.; Lee, H.S. Recoverability of electrical conductivity of a Geobacter-enriched biofilm. J. Power Sources 2018, 402, 198–202. [Google Scholar] [CrossRef]

- Dhar, B.R.; Ryu, H.; Ren, H.; Domingo, J.W.S.; Chae, J.; Lee, H.S. High Biofilm Conductivity Maintained Despite Anode Potential Changes in a Geobacter-Enriched Biofilm. ChemSusChem 2016, 9, 3485–3502. [Google Scholar] [CrossRef]

- Lee, H.S.; Torres, C.I.; Rittmann, B.E. Effects of Substrate Diffusion and Anode Potential on Kinetic Parameters for Anode-Respiring Bacteria. Environ. Sci. Technol. 2009, 43, 7571–7577. [Google Scholar] [CrossRef] [PubMed]

- Dhar, B.R.; Park, J.H.; Park, H.D.; Lee, H.S. Hydrogen-based syntrophy in an electrically conductive biofilm anode. Chem. Eng. J. 2019, 359, 208–216. [Google Scholar] [CrossRef]

- Cheng, S.; Xing, D.; Call, D.F.; Logan, B.E. Direct Biological Conversion of Electrical Current into Methane by Electromethanogenesis. Environ. Sci. Technol. 2009, 43, 3953–3958. [Google Scholar] [CrossRef] [PubMed]

- Alrashed, W.; Lee, J.; Park, J.; Rittmann, B.E.; Tang, Y.; Neufeld, J.D.; Lee, H.S. Hypoxic Methane Oxidation Coupled to Denitrification in a Membrane Biofilm. Chem. Eng. J. 2018, 348, 745–753. [Google Scholar] [CrossRef]

- Lusk, B.G.; Colin, A.; Parameswaran, P.; Rittmann, B.E.; Torres, C.I. Simultaneous fermentation of cellulose and current production with an enriched mixed culture of thermophilic bacteria in a microbial electrolysis cell. Microb. Biotechnol. 2018, 11, 63–73. [Google Scholar] [CrossRef]

- Cheng, S.; Logan, B.E. High hydrogen production rate of microbial electrolysis cell (MEC) with reduced electrode spacing. Bioresour. Technol. 2011, 102, 3571–3574. [Google Scholar] [CrossRef]

- Commault, A.S.; Lear, G.; Weld, R.J. Maintenance of Geobacter -dominated biofilms in microbial fuel cells treating synthetic wastewater. Bioelectrochemistry 2015, 106 Pt A, 150–158. [Google Scholar] [CrossRef]

- Chung, T.H.; Meshref, M.N.; Dhar, B.R. A review and roadmap for developing microbial electrochemical cell-based biosensors for recalcitrant environmental contaminants, emphasis on aromatic compounds. Chem. Eng. J. 2021, 424, 130245. [Google Scholar] [CrossRef]

- Escapa, A.; San-Martin, M.I.; Mateos, R.; Moran, A. Scaling-up of membraneless microbial electrolysis cells (MECs) for domestic wastewater treatment: Bottlenecks and limitations. Bioresour. Technol. 2015, 180, 72–78. [Google Scholar] [CrossRef]

- Mei, X.X.; Xing, D.F.; Yang, Y.; Liu, Q.; Zhou, H.H.; Guo, C.H.; Ren, N.Q. Adaptation of microbial community of the anode biofilm in microbial fuel cells to temperature. Bioelectrochemistry 2017, 117, 29–33. [Google Scholar] [CrossRef]

- Lu, L.; Hou, D.; Wang, X.; Jassby, D.; Ren, Z.J. Active H2 Harvesting Prevents Methanogenesis in Microbial Electrolysis Cells. Environ. Sci. Technol. Lett. 2016, 3, 286–290. [Google Scholar] [CrossRef]

- Lu, L.; Ren, N.; Zhao, X.; Wang, H.; Wu, D.; Xing, D. Hydrogen production, methanogen inhibition and microbial community structures in psychrophilic single-chamber microbial electrolysis cells. Energy Environ. Sci. 2011, 4, 1329–1336. [Google Scholar] [CrossRef]

- Sim, J.; An, J.; Elbeshbishy, E.; Ryu, H.; Lee, H.S. Characterization and optimization of cathodic conditions for H2O2 synthesis in microbial electrochemical cells. Bioresour. Technol. 2015, 195, 31–36. [Google Scholar] [CrossRef] [PubMed]

- Ullery, M.L.; Logan, B.E. Anode acclimation methods and their impact on microbial electrolysis cells treating fermentation effluent. Int. J. Hydrog. Energy 2015, 40, 6782–6791. [Google Scholar] [CrossRef]

- Call, D.; Logan, B.E. Hydrogen production in a single chamber microbial electrolysis cell lacking a membrane. Environ. Sci. Technol. 2008, 42, 3401. [Google Scholar] [CrossRef]

- Qian, X.L.; Reguera, G.; Mester, T.; Lovley, D.R. Evidence that OmcB and OmpB of Geobacter sulfurreducens are outer membrane surface proteins. FEMS Microbiol. Lett. 2007, 277, 21–27. [Google Scholar] [CrossRef]

- Fricke, K.; Harnisch, F.; Schröder, U. On the use of cyclic voltammetry for the study of anodic electron transfer in microbial fuel cells. Energy Environ. Sci. 2008, 1, 144–147. [Google Scholar] [CrossRef]

- Abdullah, A.; Akintunde, O.B.; Mishari, K.; Gordon, W.; Mohammad, A. Microbial community structure of anode electrodes in microbial fuel cells and microbial electrolysis cells. J. Water Process Eng. 2020, 34, 101140. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).