1. Introduction

The proportion of CO

2 emissions from road transport to overall energy-related CO

2 emissions is 15.9%, 27.8%, and 16.9% in Japan, the US, and worldwide, respectively [

1]. The introduction of effective technologies and policies to reduce CO

2 emissions from road transport is thus critical for automotive manufacturers and policy makers to contribute to sustainable development.

Life cycle assessment (LCA) is a useful methodology to evaluate technologies that contribute to lower environmental loads. Specifically, vehicle assessment is among the most important subjects in the LCA community given its impact on economy, policy, and environment [

2,

3]. Extensive LCA research has been devoted to compare conventional and alternative fuel vehicles (recent publications include [

4,

5]). Together with colleagues [

6], I conducted techno-economic analysis based on LCA of advanced vehicles.

In general, the LCA procedure, especially life cycle inventory (LCI) analysis, that is part of LCA, can be summarized as follows. First, assumptions are established and fed into the LCA model. Then, results from the model are obtained as outputs, which are interpreted to finally draw conclusions. However, the obtained results depend on the stated assumptions and vary if assumptions are altered. Therefore, a major challenge for LCA is determining general insights from objective assumptions.

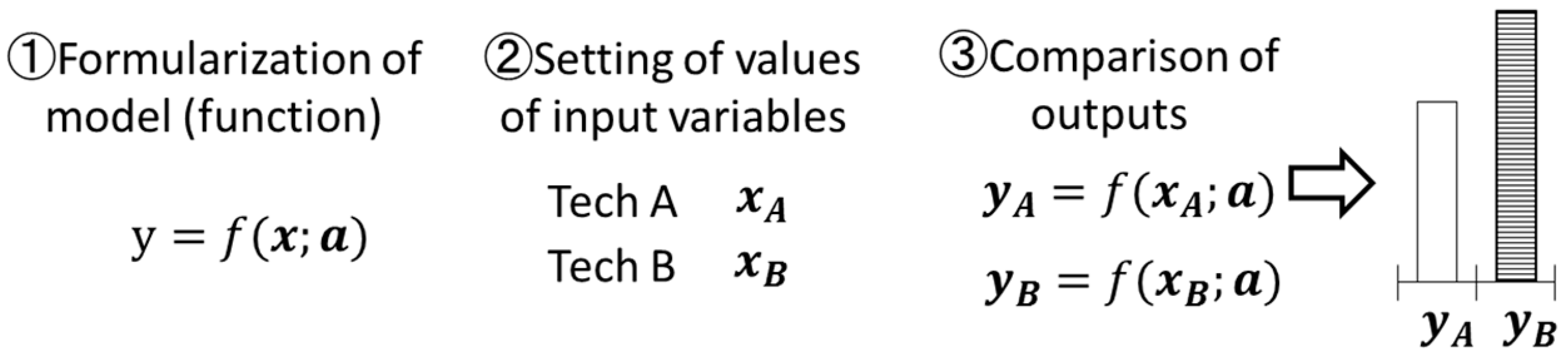

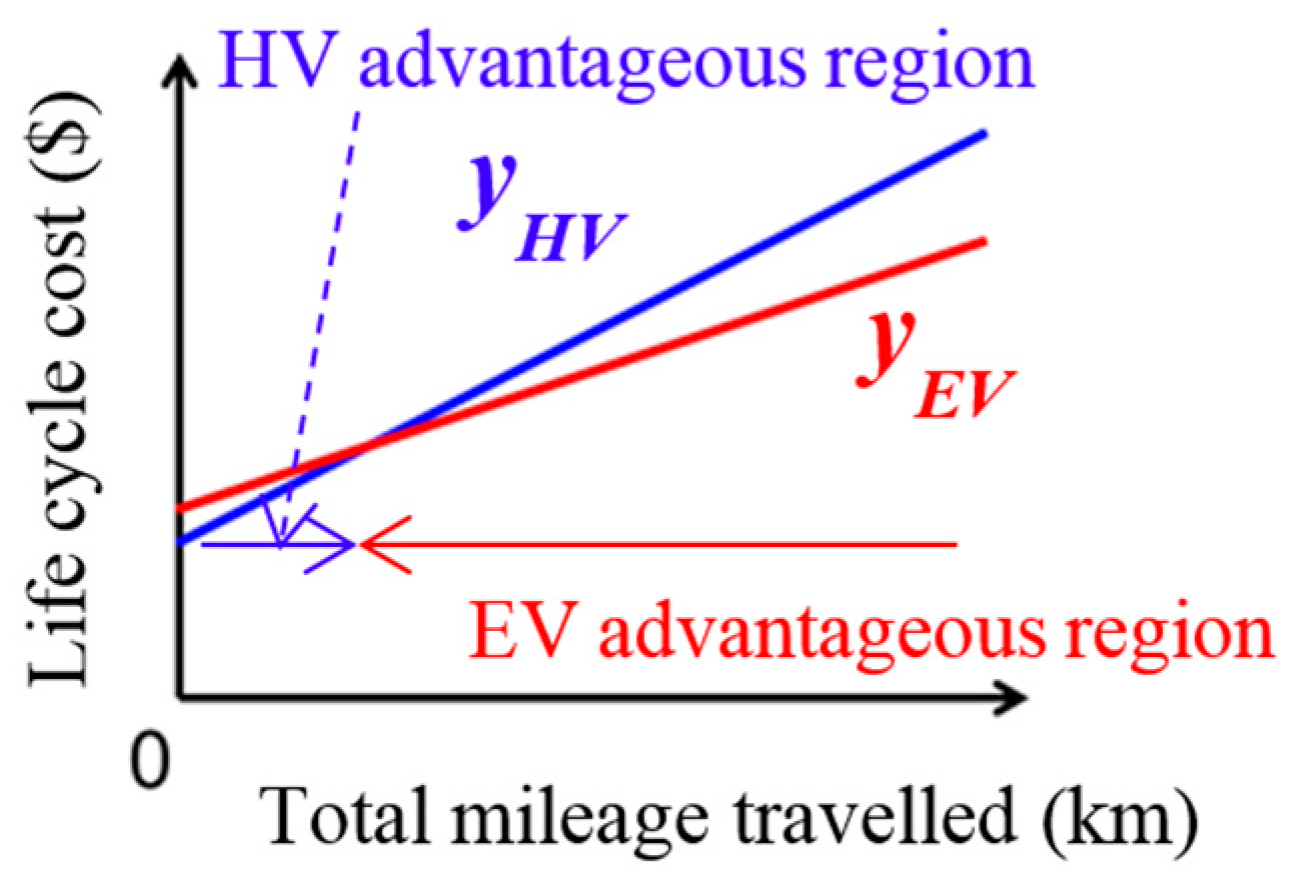

One approach to address this challenge is sensitivity analysis, which is used in a wide variety of fields besides LCA and aims to observe the change in one output variable (result) according to the change in one input variable (assumption), i.e., to find the coefficient of partial differentiation of the function describing the model. Nevertheless, comprehensive sensitivity analysis used to fully unveil the relationship between inputs and outputs has not yet been sufficiently explored.

Fukushima et al. [

7] proposed the separation of LCI into lifecycle and scenario models, with the former describing the relationships between variables and the latter determining the values of variables. This method can improve transparency of the LCI process and the reusability of models and data. It also contributes to systematizing the LCA for analyses. More notably, this study devised LCI as a model representing relationships between variables.

LCA research has also developed a visualization methodology to comprehensively show relationships between assumptions and results for aiding understanding and interpretation. Barter et al. [

8] developed a model to evaluate future scenarios for the road transport sector by unveiling relationships between inputs (required pay-back time for consumers, carbon price, energy price) and outputs (e.g., share of electric vehicles, decreasing ratio of average fuel economy) using contour diagrams. Likewise, Chen et al. [

9] developed a visualization methodology for LCA to show the CO

2 reduction potential by the introduction of renewable energies into the road transport sector. Braff et al. [

10] evaluated the value of energy storage technologies for wind and solar power under different conditions, showing results in two-dimensional by two-dimensional diagrams (nine contour diagrams with different combinations of other two variables with three different values, respectively). None of these studies, however, provided comprehensive visualization because only a limited number of variables was selected.

In this study, I developed a visualization methodology called a multi-dimensional techno-economic assessment diagram to comprehensively illustrate the relationship between assumptions (sets of input parameters) and results (corresponding sets of output variables). Appling this methodology to compare life cycle cost (LCC) and total CO2 emissions (LCCO2) of hybrid vehicles (HVs) and electric vehicles (EVs), I constructed an eight-dimensional interactive diagram showing advantageous areas for HV or EV in the input space consisting of eight parameters: HV fuel efficiency, EV energy efficiency, total mileage travelled, gasoline price, electricity price, battery price, gasoline CO2 intensity, and electricity CO2 intensity.

3. Results

3.1. LCC

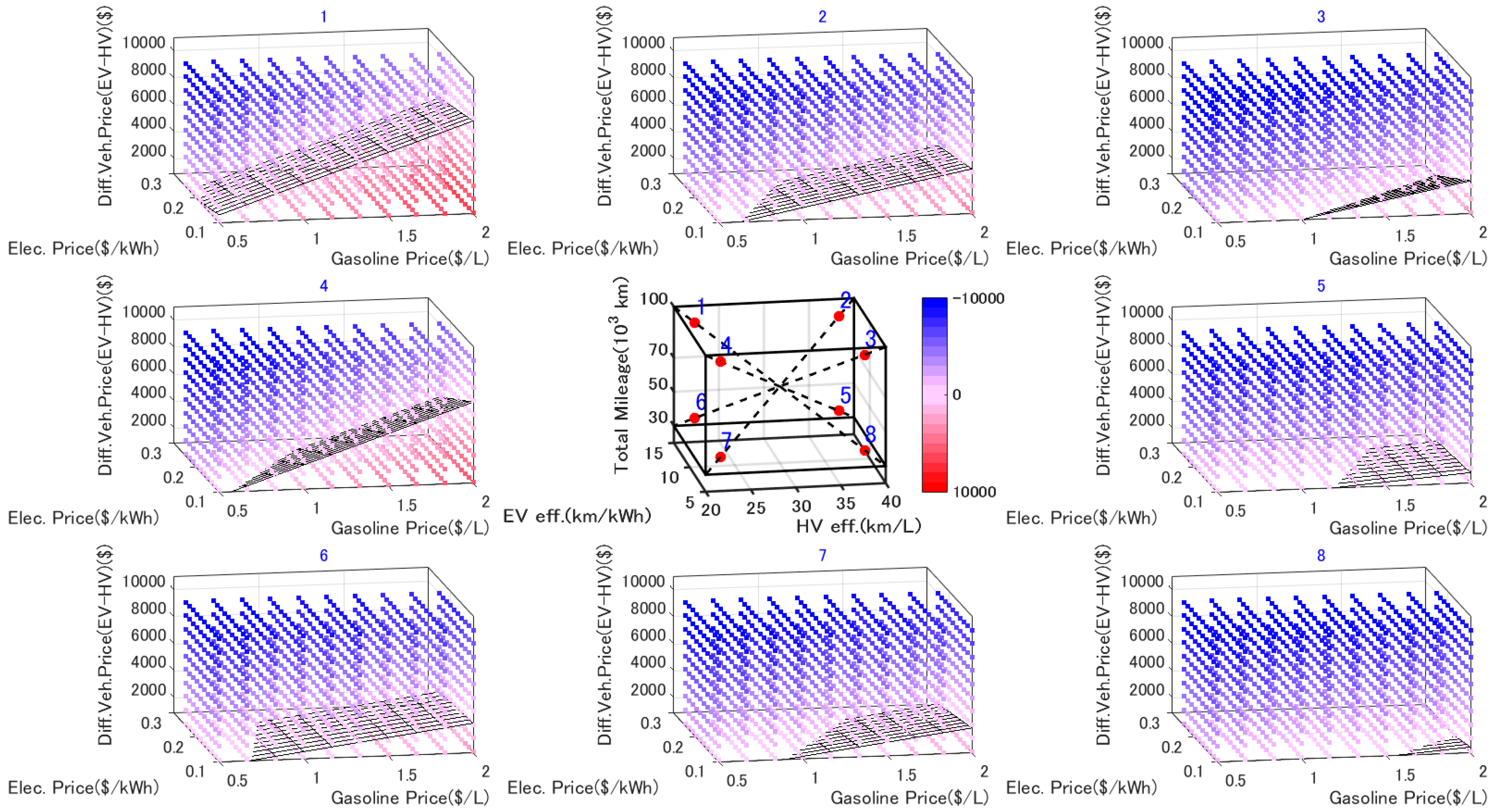

Figure 4 shows the result of the comprehensive comparison of LCC between HV and EV, or a visualization of Equation (3). Different combinations of values of the six input variables, i.e., HV fuel efficiency, EV energy efficiency, total mileage, gasoline price, electricity price, and difference in vehicle price, are considered. The settings of the first three variables are shown in the center as a cube with eight points within it. Each point corresponds to the settings of the three variables of each of eight 3D diagrams around the center.

These eight 3D diagrams around the center show the corresponding relationships between difference of LCC, , and the last three variables with fixed values of the first three variables. Different values of are represented by different colors; a negative value, indicating that the LCC of HV is lower (i.e., HV is advantageous) is represented in blue, while a positive value, indicating that the LCC of EV is lower, is represented in red. Near zero values are shown in magenta. Black planes represent thresholds at which the LCC of HV and EV is equal.

It is apparent that the blue colored region is larger than the red one, indicating that the advantageous region of HV is larger than that of EV in terms of LCC. Based on a comparison of 3D diagrams nos. 1 and 4, the better the EV energy efficiency, the larger the advantageous EV region. Similarly, the worse the HV fuel efficiency or the longer the total mileage, the better the EV energy efficiency. However, even taking these conditions into account, HV is advantageous if EV price is $8000 or more than that of HV.

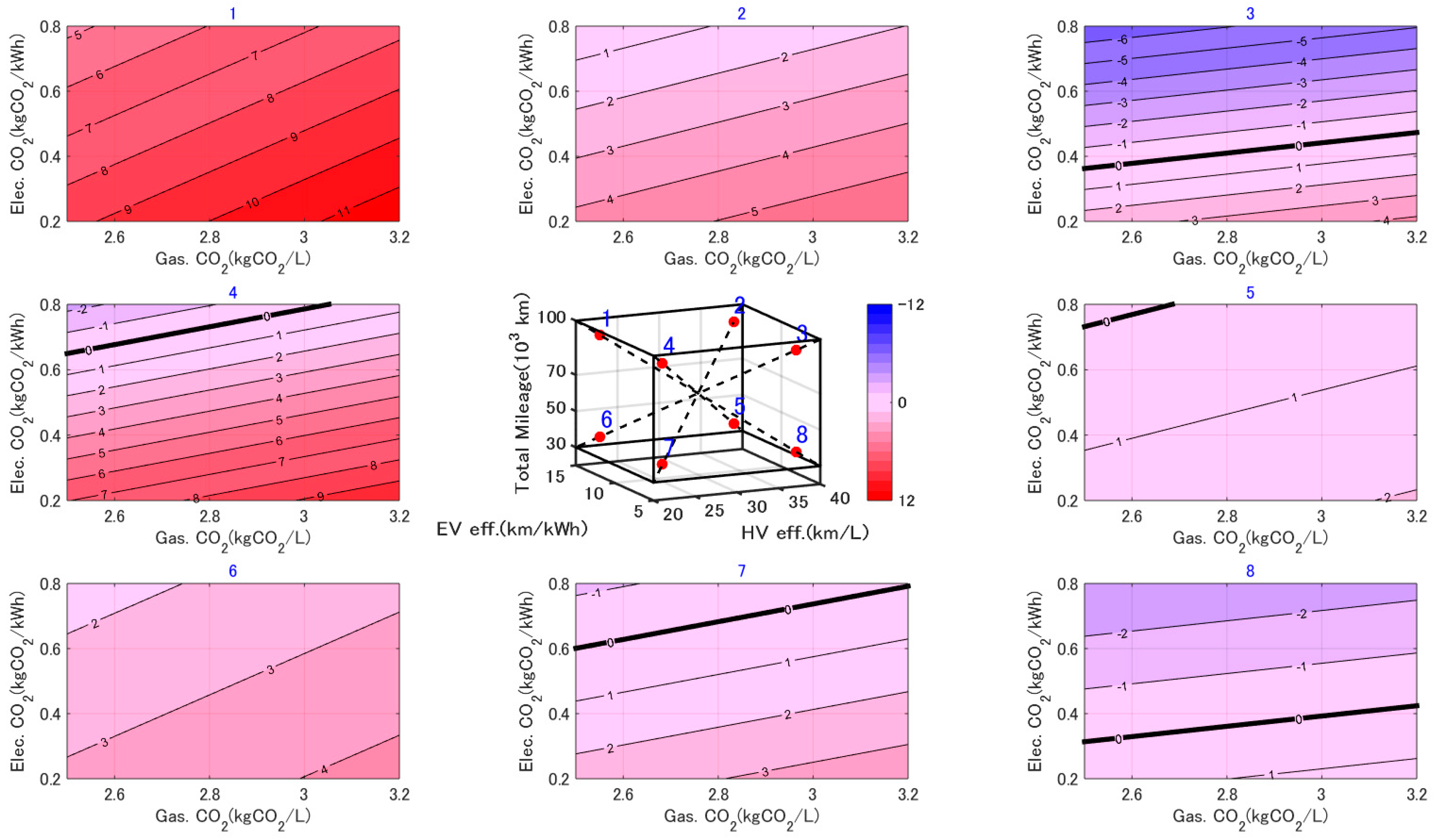

3.2. LCCO2

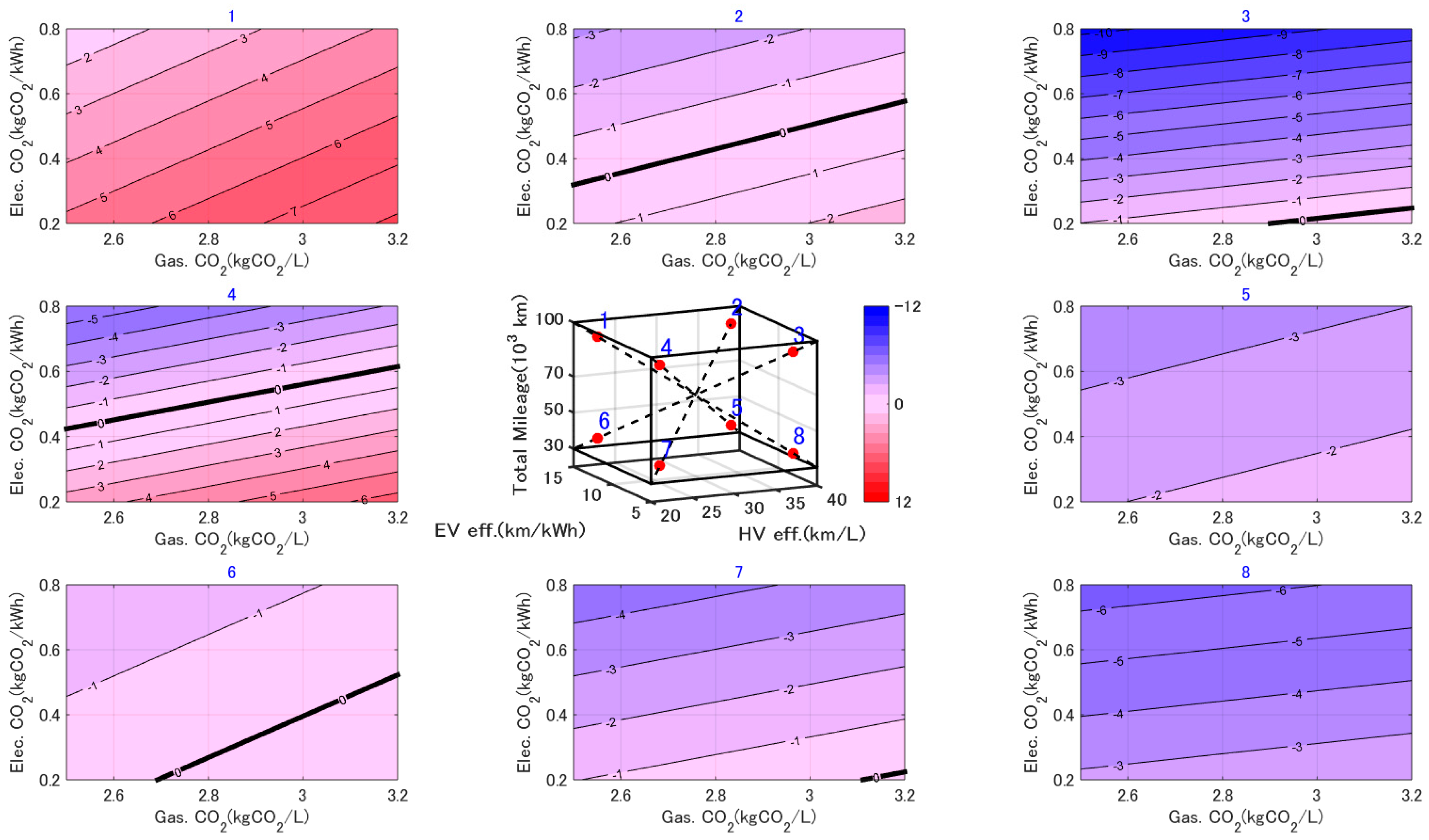

Figure 5 and

Figure 6 show the result of the comprehensive comparison of LCCO

2 between HV and EV, or a visualization of Equation (5). Different from the case of

Figure 4, the difference in vehicle CO

2,

, is treated as constant, and two cases (lower and higher case) are shown in

Figure 5 and

Figure 6, respectively. The figure thus consists of a combination of a 3D diagram representing three common variables (HV fuel efficiency, EV energy efficiency, and total mileage) in the center, and 2D contour diagrams showing the relationships between difference in LCCO

2,

, and the other two input variables (gasoline and electricity CO

2 intensity). For ease of understanding, the dimension of diagrams around the center is reduced to 2D by treating

as constant. The colors used to indicate the relative advantages of HV and EV are the same as in

Figure 4; blue represents the HV advantageous region, while red indicates advantageous EV. The ranges of gasoline and electricity CO

2 intensities are the same in the eight 2D diagrams.

The coloring of 2D diagrams evidently differs depending on the combination of values of three common variables and the difference in vehicle CO

2. The key conclusions that can be drawn from

Figure 5 and

Figure 6 are summarized as follows.

- (1)

EV is advantageous in almost all areas (combinations of the ranges of gasoline and electricity CO

2 intensity) of 2D diagrams Nos. 1, 2, 5, and 6 in

Figure 5, and No. 1 in

Figure 6. That means:

- (1)

when EV energy efficiency is better (about 15 km/kWh or more) and total mileage is adequate, EV is advantageous regardless of HV fuel efficiency, and

- (2)

the extent of EV’s advantage is increased when gasoline CO2 intensity is greater, or when electricity CO2 intensity is lower.

- (2)

Comparing

Figure 5 and

Figure 6, or the diagrams with different settings of

, the coloring of each diagram differs but the width of contours remains the same. This is because the difference between the two figures is an intercept of the comparison of LCCO

2 of HV and EV.

- (3)

When assuming HV and EV efficiency at current levels (No. 4 in

Figure 3 and

Figure 4), then HV is advantageous in the region of larger electricity CO

2 intensity (about 0.8 kgCO

2/kWh or more).

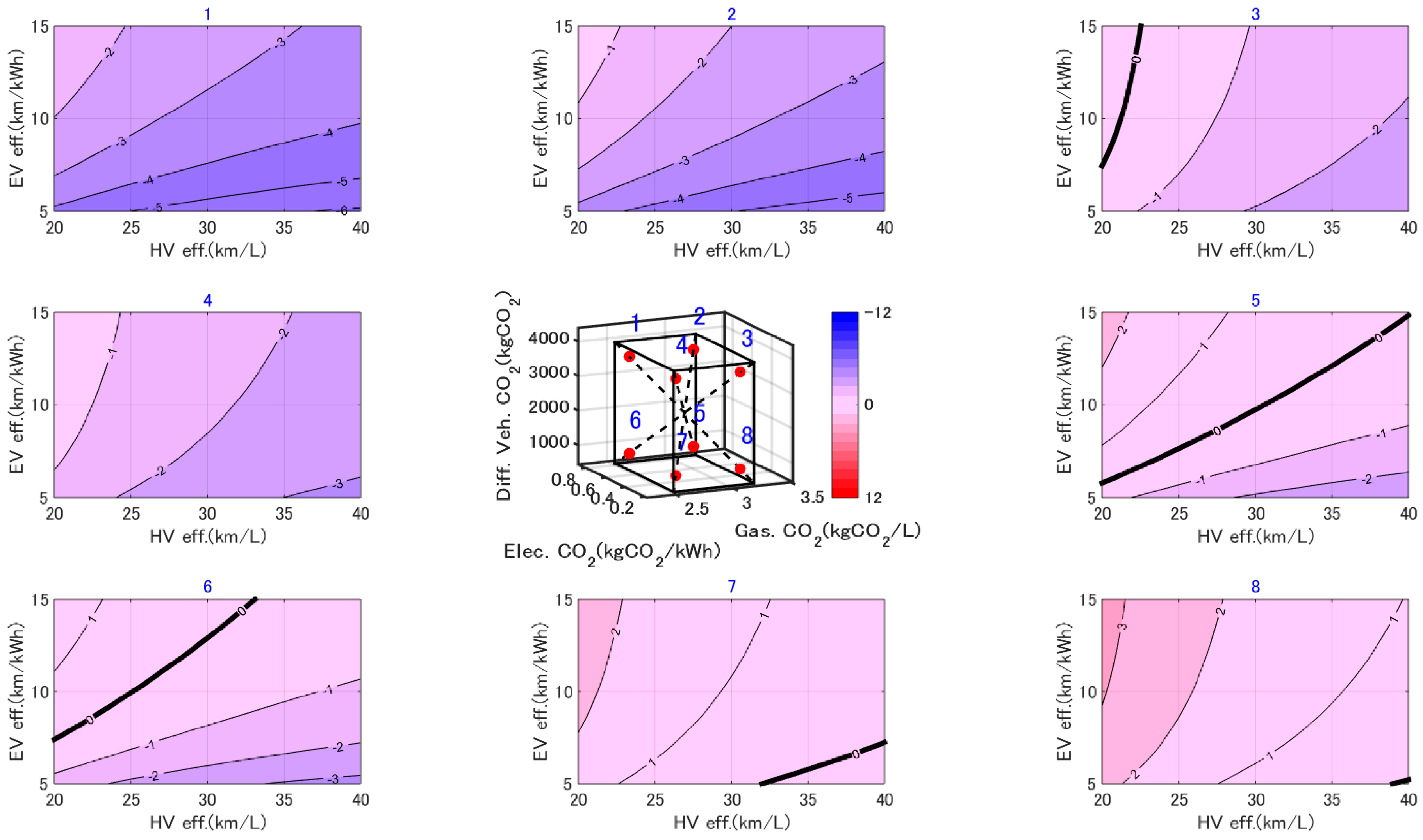

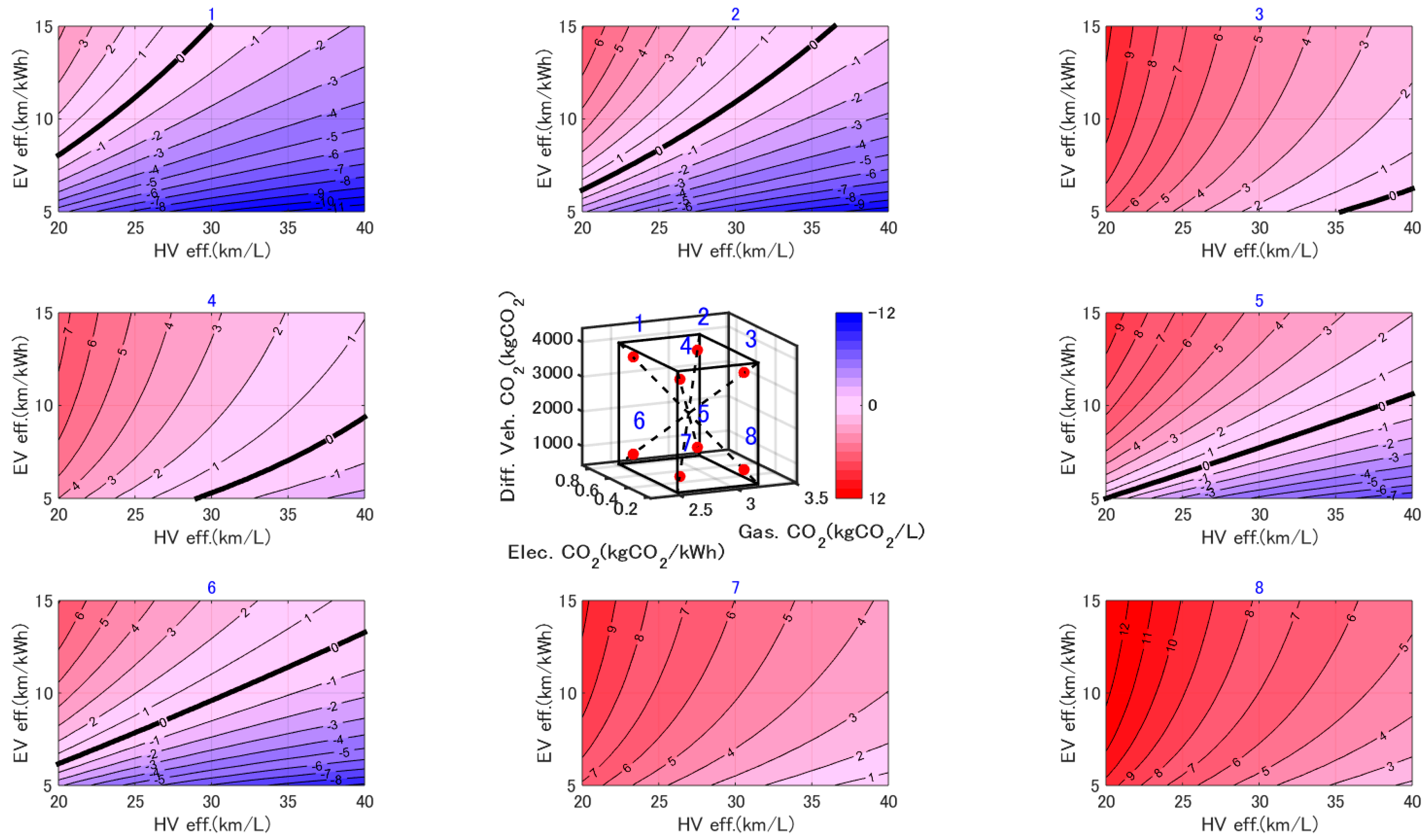

3.3. LCCO2 Analysis on Different Axes

Figure 7 and

Figure 8 show different variable combinations. The three variables in the central graph represent gasoline CO

2 intensity, electricity CO

2 intensity, and difference of vehicle CO

2 emissions during production, and the axes of the 2D contour diagrams show HV and EV efficiency. In the figures, the total mileage travelled is constant, respectively considering 30,000 and 100,000 km for

Figure 7 and

Figure 8.

Unlike

Figure 5 and

Figure 6, the contour curves do not exhibit a linear trend. In the region where electricity CO

2 intensity is higher, the coloring of diagrams varies, indicating that the relative advantage of the vehicles is highly dependent on both HV and EV efficiency.

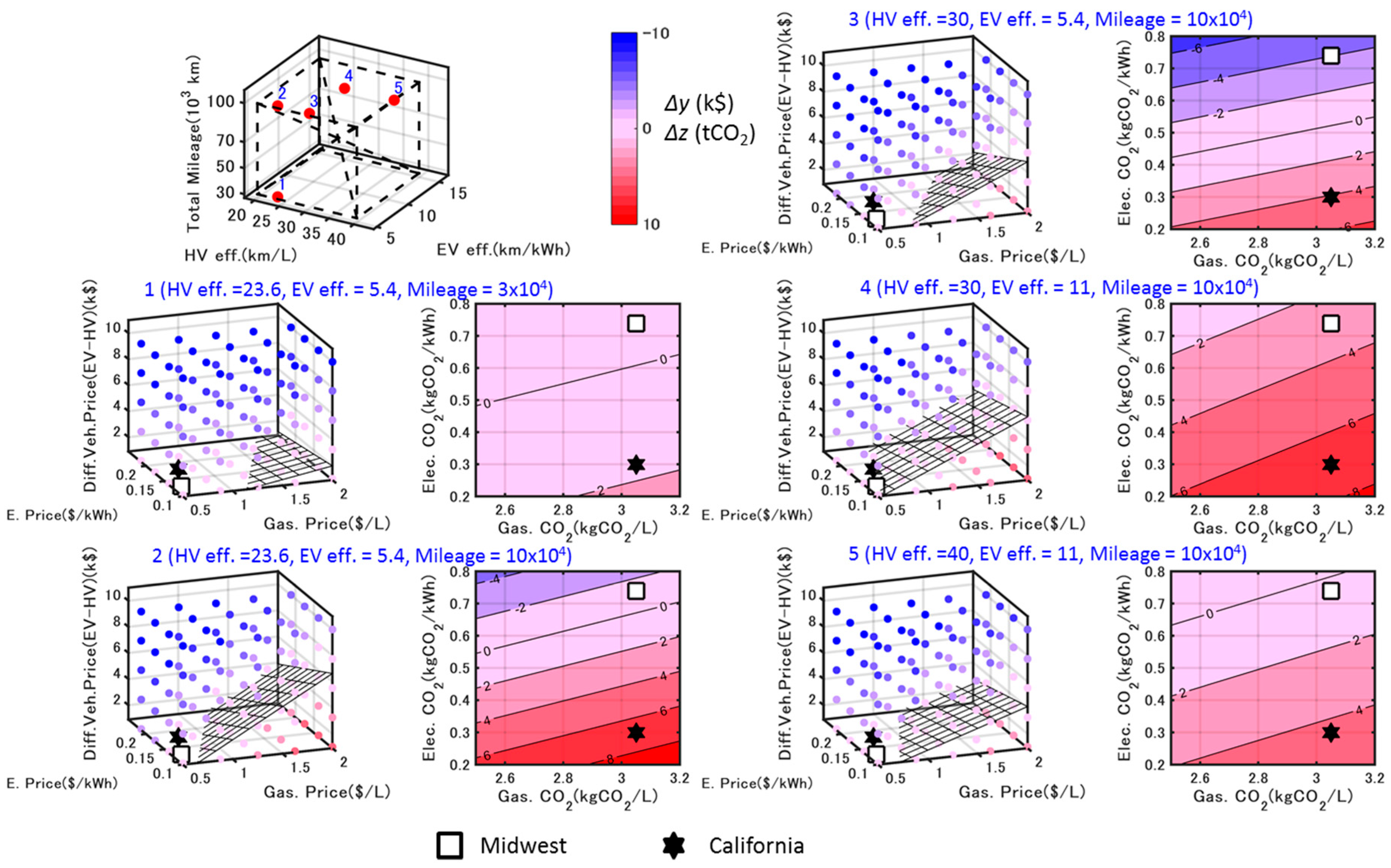

3.4. Application to Regional Scenario Analyses

As gasoline and electricity prices and CO2 intensities generally differ among regions, the comparisons would also differ among regions, even under the same technological assumptions. This methodology, which represents specific values of regions as points plotted on the diagrams, enables a comprehensive understanding of the extent to which a given vehicle is advantageous under any combination of assumptions.

Two regions in the United States with different properties, California and the Midwest, are considered as an example. Coal power is the main source of energy in the Midwest whereas renewables are extensively deployed in California.

Table 2 shows the settings of energy prices and CO

2 intensities for the two regions.

By combining the two diagrams for LCC and LCCO

2, I constructed an eight-dimensional diagram with three common variables, three price variables, and two CO

2 intensity variables. Plotting the points representing the two regions and considering different combinations of the common variables illustrate the variation of techno-economic outcomes among regions, as shown in

Figure 9. For simplicity, the difference in vehicle price at these two regions was considered to be

$1000 for LCC, and the difference in vehicle CO

2 emissions during production was considered low (500 kg) for LCCO

2.

The top left graph in

Figure 9 depicts HV fuel efficiency, EV energy efficiency, and total mileage travelled. Points 1 to 5 within the figure correspond to the settings of the variables of each pair of 3D and 2D diagrams for LCC and LCCO

2, respectively.

Point 1 (in the top left graph) shows the initial setting for HV fuel efficiency and EV energy efficiency for the corresponding diagrams. The mileage travelled was set to 30,000 km, assuming a total cost and CO2 emissions over three years with annual mileage travelled of 10,000 km. The diagram at the left of the second row indicates that HVs are advantageous for both regions in terms of LCC, whereas the Midwest and California are the most advantageous for HVs and EVs, respectively, for LCCO2.

Point 2 (in the top left graph) changes the total mileage travelled to 100,000 km. The corresponding diagram at the left of third row indicates that for the LCC, HVs are still advantageous for both regions, although the distance to the threshold plane is closer than that at point 1. In addition, the width of contour in the LCCO2 diagram is narrower than that at point 1, suggesting that the difference in LCCO2 increases for HVs and EVs at the same setting.

The HV fuel efficiency improves from diagram 2 to 3, whereas the EV energy efficiency improves from diagram 3 to 4. Diagram 4 shows that the two regions are almost on the threshold for LCC (i.e., EVs become cost competitive with HVs), whereas for LCCO2, the Midwest also becomes advantageous for EVs. HV fuel efficiency further improves from diagram 4 to 5. For LCC, both regions are again advantageous for HVs, but both regions are advantageous for EVs regarding LCCO2.

Overall, HVs exhibit advantage in terms of LCC (see

Figure 10, which summarizes the LCC results shown in

Figure 9). For LCCO

2, the advantage of either type of vehicle depends on the combination of the settings, but EVs are advantageous if their energy efficiency is high, even in a region with CO

2 intensive electricity like the Midwest.

4. Discussion

In this paper, I proposed a multi-dimensional techno-economic assessment diagram to comprehensively visualize the relationships between assumptions and results. I then demonstrated the application of the methodology to compare the LCC and LCCO2 between HVs and EVs.

The results exhibit complicated relationships between assumptions and results even for simple functions, making it difficult to completely understand these relationships intuitively. Therefore, this methodology applied to relatively simple problems may facilitate the comprehensive understanding of relationships among variables.

Several studies compare conventional and alternative energy vehicles from economic and environmental viewpoints, such as life cycle assessment, techno-economic analysis, well to wheel analysis, and total cost of ownership (e.g., [

2,

3,

4,

5,

13]). However, understanding the relationships between inputs and outputs is usually more important than focusing on the results of such evaluations, because the relationships depend on inputs (assumptions). In this context, the methodology presented here can contribute to comparing studies by summarizing meta-analyses of LCA studies and suggesting a procedure to create diagrams with points representing the results of different studies.

Furthermore, the presented methodology can be beneficial to finding critical factors or variables in such assessments. In the application example detailed in

Section 3.4, EV energy efficiency was found to be key to LCCO

2. By visualizing specific settings as plots and dividing advantageous regions for HVs and EVs into threshold lines or planes, results under different conditions vary (e.g., the extent to which energy prices or CO

2 intensities change the advantageous type of vehicle). The distance between a point on the diagrams and the threshold might point toward targets for technology research and development or policy design that would render a specific technology advantageous.

The presented diagram can be extended to include other vehicle types (e.g., plug-in hybrid and fuel cell vehicles) and performance variables by including additional information, such as that considered by Hara et al. [

14], who conducted a techno-economic analysis of alternative energy vehicles including solar hybrid vehicles.