2.1. Dynamic Modeling

In order to further study the inherent characteristics of the powertrain mounting system of hybrid electric vehicles and analyze its vibration response characteristics under transient conditions (such as engine start–stop) and steady-state conditions (such as road excitation), so as to improve the vibration isolation performance of the whole vehicle, this paper regards the powertrain as a rigid body and establishes a 6-degree-of-freedom dynamic model. Compared with common 2-DOF or 3-DOF models, 6-DOF models can more comprehensively describe the motion state of the powertrain in space, including three translation directions (longitudinal, transverse, and vertical) and three rotation directions (roll, pitch, and yaw). This modeling method is of great significance for accurately reflecting the vibration transmission characteristics between the powertrain and the vehicle body under actual working conditions.

In this paper, the vibration differential equation of the system is derived by Lagrange method, the translation and rotation displacement of the powertrain are selected as generalized coordinates, and the generalized force expression of the system is constructed by considering the elastic force, damping force, and external exciting force. Based on this model, the following three aspects of research are carried out in this paper: (1) intrinsic characteristic analysis, which involves identifying the resonant frequency range of the system; (2) transient response analysis, which is carried out to evaluate the dynamic response of the engine under conditions such as start and stop; and (3) steady-state response analysis, in which the vibration isolation performance under steady-state conditions such as road excitation is studied.

On this basis, by optimizing the stiffness and damping parameters of the suspension system, the vibration isolation effect of the system is improved. The introduction of the 6-DOF model not only improves the accuracy of the system analysis, but also captures the multidimensional vibration behavior of the powertrain under complex excitation conditions, so as to provide more comprehensive data support and a theoretical basis for the optimal design of the suspension system.

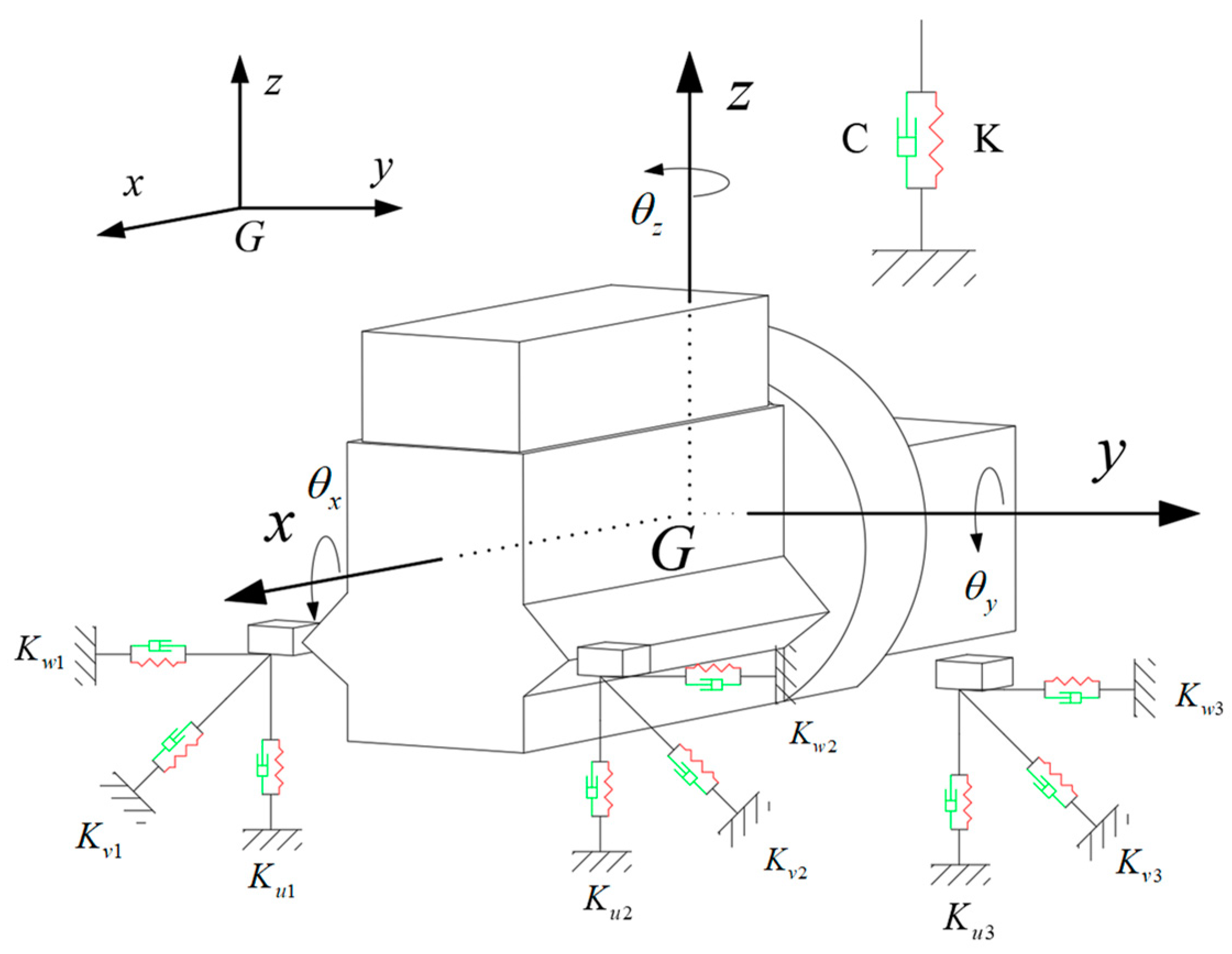

The powertrain mounting system usually adopts a 3-point arrangement or a 4-point arrangement, and the engine layout is divided into two types: horizontal and vertical. The suspension system studied in this paper is a 3-point horizontal arrangement. Since the vibration natural frequency of the powertrain mounting system is generally lower than 30 Hz, the engine and transmission assembly and the frame are usually regarded as absolute rigid bodies, and each mounting is simplified into elastic damping elements in three vertical directions along the space, ignoring the torsional elastic effect between the support elements. Therefore, the powertrain mount system can be equivalent to a spatial 6-DOF vibration system, as shown in

Figure 1, below.

In this system, the origin represents the position of the center of mass of the powertrain at rest. The associated parameters Kui, Kvi, and Kwi for the ith suspension represent the spindle stiffness corresponding to the u, v, and w directions of the elastic spindle of the rubber suspension, respectively. The freedom of motion of a rigid body consists of three linear displacements (longitudinal x, transverse y, vertical z) and rotations around three axes (roll angle pitch angle , and yaw angle ).

Let the generalized displacement vector of the powertrain mounting system be

:

The generalized displacement vector

q includes three translational displacements (Cartesian coordinates

,

,

) and three rotational angles (Euler angles

,

,

), representing the rigid-body motion of the powertrain in 6-DOF space [

22].

The vibration equation of the powertrain mounting system is

where

is the system mass matrix;

is the system damping matrix;

is the stiffness matrix of the system. The mass matrix

M and damping matrix

are constant under small vibration assumptions, while the stiffness matrix

is the primary optimization variable.

is the exciting force;

is six generalized acceleration vectors. The vector

explicitly depends on time

t, governed by the dynamic interaction between inertial, damping, and stiffness forces.

In the design of powertrain mounting systems, the installation position and angle are usually considered in the early stage of design, along with structural layout, manufacturing process, performance requirements, and other factors, so they are difficult to change significantly in practical engineering applications. Therefore, the optimal design of the suspension system mainly focuses on the adjustment of the stiffness matrix, and improves the vibration isolation performance of the system by changing the stiffness characteristics of the suspension. This method can not only effectively improve the decoupling degree of the system in theory, but also provide a feasible optimization scheme in engineering practice. Therefore, the stiffness matrix is derived in detail in order to realize vibration decoupling and performance optimization of the suspension system.

2.2. Derivation of Stiffness Matrix K

According to the mechanical analysis, after the suspension is moved and rotated, the values of the deformation caused by the stiffness direction of the three main axes of the ith suspension are

. Consequently, the potential energy of the system on the elastic main axes

,

,

of the rubber suspension is

Equation (3) is derived from the potential energy analysis of elastic deformation, following the Lagrangian mechanics principles [

10]. The stiffness matrix formulation (Equation (5)) aligns with the methodology proposed by Hu et al. [

10] for multi-axis decoupling.

Equation (3) is decomposed:

Therefore, the stiffness matrix is

where

,

,

, are the centroid coordinates;

,

, are the angle between the suspension elastic spindle coordinate system and the vehicle coordinate system. Matrix

is the direction cosine matrix, where

,

, and

define the orientation of the

th mount’s elastic axes relative to the vehicle coordinate system.

Because adjusting the mounting position and angle usually involves high design and manufacturing costs, optimizing the stiffness of the suspension can be achieved by adjusting the material characteristics or the internal structure of the suspension without changing the existing structural layout. This method is not only low in cost, but also easy to implement, and has significant advantages in engineering applications. Therefore, the research focus of this paper is to improve the vibration isolation performance by optimizing the suspension stiffness parameters, so as to achieve significant improvement in the system performance.

2.3. Energy Decoupling Method

Energy decoupling is a widely used method in the design of mounting parameters. The method assumes that the system is in the state of small vibration (ignoring the damping effect), and optimizes the vibration isolation performance of the system through reasonable configuration of the stiffness matrix. The six-degree-of-freedom linear free vibration differential equation of powertrain mounting system can be expressed as

Equation (2) describes the forced vibration of the system under general excitation, while Equation (6) focuses on free vibration analysis by omitting damping effects, which is essential for energy decoupling studies.

For Equation (6), let the theoretical solution be

where

is the amplitude of the theoretical solution;

is the phase angle.

Bringing this into Equation (6), we can obtain

where

is the natural frequency of the system.

The circular frequency and mode of vibration of the suspension system can be obtained from Equation (7). When the suspension system vibrates at the

order, the percentage

of the total energy of the suspension system distributed at the

generalized degrees of freedom (representing the degree of decoupling) is

where

is the

th column

element of

;

is the

order principal mode of the system;

and

are the

th and

th elements of

respectively.

2.4. Suspension Dynamic Reaction Calculation

The dynamic reaction force of the suspension system refers to the reaction force transmitted to the frame or body through the suspension system when the powertrain is vibrating or under external excitation. This force comes from the excitation force and torque generated by the engine during operation, and is transmitted to the frame or body by the suspension system. It is a direct response to the body imposed by the suspension system in the process of supporting and constraining the powertrain, and also a direct reflection of the vibration isolation and support performance of the suspension system. The magnitude and direction of the dynamic reaction directly affect the vibration comfort and driving stability of the vehicle body, so optimizing the dynamic reaction is an important step to improve the NVH performance of the vehicle in the design of the suspension system.

Under idle conditions, the vibration differential equation of the engine mounting system is as follows:

where

represents the harmonic exciting force vector received by the system under idle conditions.

In the calculation process for suspension dynamic reaction and centroid acceleration, the system damping matrix has a great influence on the calculation results, which cannot be ignored.

The steady-state solution of the system under forced vibration is

The dynamic reaction

transmitted by the

th suspension to the body can be expressed as

where

is the ith stiffness matrix suspended in the global coordinate system;

is the antisymmetric matrix of the

th suspension position coordinates.

The sum of the dynamic reaction force transmitted by the suspension system to the body under idle condition is

where

,

,

are the three components of the dynamic reaction of the

th suspension under idle conditions.

2.5. Natural Characteristic Calculation

The calculation of natural frequency and decoupling ratio of powertrain mounting system is based on the data for mounting stiffness, mounting angle, mounting position, and inertia parameters of powertrain. These key parameters can be obtained by relevant testing means, and the initial data are shown in

Table 1,

Table 2 and

Table 3. In the test, the mounting angle of the suspension was 0°, and all three suspensions were placed horizontally. In addition, the powertrain suspension of the model studied in this paper is made of rubber material, and its stiffness/dynamic ratio is 1.4 [

24].

According to the above theoretical calculation, the natural frequencies and decoupling rates of each order of the prime powertrain mounting system can be obtained, as shown in

Table 4, below.

The data in

Table 4 show that the decoupling rate of the prime powertrain mounting system in the

X direction is only 77%, and the coupling with the

Y direction is serious. The decoupling rate for

Rx direction is only 59.1%, and the coupling with

Rz direction is serious. The decoupling rate for

Ry direction is only 75.2%, and the coupling with

X direction is serious. The decoupling rate for

Rz direction is only 55.4%, and the coupling with

Rx direction is serious. Only the decoupling rates of

Y and

Z, which are 99.7% and 96.3%, meet the design requirements. According to the above analysis, the decoupling rate for the four directions in the original 6-DOF system is low, and there is serious coupling with other directions, which will lead to excessively wide resonance band and slow vibration energy attenuation, thus affecting the vibration isolation performance of the entire suspension system. Therefore, the original suspension system must be optimized.