Abstract

In order to solve the problem that electric forklifts are prone to rollover when turning, a coordinated control strategy for anti-rollover of electric forklifts is proposed. A forklift dynamics simulation model with integrated centroid position is constructed, the stability of the forklift is judged by the phase plane area division method, the upper controller, including the active steering controller, and the differential brake controller are designed, the control weight coefficient of the active steering controller and the differential brake controller in different control domains is determined through the coordination controller, so as to obtain the required additional rear wheel rotation angle and additional yaw torque, and the braking force distribution controller exerts braking force to the wheel according to the additional yaw torque. A simulation model is built to verify the effectiveness of this control strategy, and the simulation results show that the control strategy can greatly reduce the risk of rollover when the forklift is cornering and further improve the stability of the forklift.

1. Introduction

In order to solve the problem that electric forklifts are prone to rollover when turning, a coordinated control strategy for anti-rollover of electric forklifts was proposed. Forklifts have short wheelbases and short track widths, large steering wheel turning angles, and their center of mass position is constantly changing due to the load being handled, making them prone to rollover accidents. Forklift accidents caused by forklift rollovers account for as much as 42% [1]. Therefore, it is particularly important to study the anti-rollover control of forklifts.

In recent years, experts and scholars have conducted in-depth research on the lateral stability and rollover prevention control of road vehicles. However, there are relatively few studies on the rollover prevention control of forklifts. Therefore, analyzing the rollover stability and rollover prevention control strategy of road vehicles has important reference significance for research on the rollover prevention control of forklifts. Ghazali [2] used model predictive control to design active steering anti-rollover and path-following integrated control, effectively solving the multi-objective constraint optimization problem, aiming to reduce the vehicle’s lateral acceleration and improve the vehicle’s lateral stability. Termous [3] proposed an anti-rollover coordinated control strategy based on the coordination among active steering, differential braking and active suspension systems. When the controller detects the risk of rollover, the proposed control strategy can effectively reduce the risk of rollover. Akar [4] focused on how the lateral load transfer rate (LTR) as a rollover factor reflects the tendency of a vehicle to roll over during vehicle driving. Considering the time-varying nature and limitations of the traditional lateral load transfer rate (LTR), Zong C [5] proposed a dynamic LTR bus anti-rollover control strategy based on the three-degree-of-freedom model of the bus, which effectively improved the rollover stability of the bus. Qi B [6] proposed a vehicle stability evaluation index by calculating the vehicle instability energy threshold and the vehicle’s real-time instability energy and designed a differential drive sliding mode controller to greatly improve the active safety of electric vehicles. Zhang L [7] analyzed the instability mechanism of hub motor vehicles and proposed a chassis coordinated control method for body yaw and roll stability that integrates differential drive, active steering and active suspension to improve the vehicle’s lateral stability control effect.

As to how to effectively improve the lateral stability of forklifts, researchers have conducted some research on forklift anti-rollover. RINCHI [8] established an electric forklift model based on MATLAB 2022a/Simulink and estimated the center of gravity of the forklift loaded with goods through load sensors and ramp recognition sensors to determine whether the projection of the center of gravity on the driving plane is within the safe area. The stability of the forklift is ensured by limiting the maximum speed and acceleration of the electric wheel. Felez [9] studied the pitch motion of an automatically guided forklift to analyze the stability conditions of the vehicle and designed an anti-rollover controller based on model predictive control, but it is unknown whether it is applicable to counterbalanced forklifts. Rebelle [10] established a dynamic model of a forklift and verified the model. They used the model to analyze the common and critical driving situations of a forklift in a rollover accident. Tao [11] proposed a lateral stability control system with the forklift’s sideslip angle and yaw angular velocity as the desired control targets, adopted a drive torque coordinated distribution control strategy, and solved the forklift’s steering stability problem caused by lateral local loads. Xia G [12] proposed a rollover prevention hierarchical control method based on a T-S fuzzy neural network, which used a neural network to judge the motion state of the forklift and controlled it based on the lateral load transfer rate (LTR). Kasahara [13] studied the effect of changes in the center of gravity on the roll of a forklift, designed a test model with a measurable center of gravity, and studied the lateral stability of the forklift when turning by calculating the LTR. Zhang Z [14] considered the influence of cargo lifting on the synthetic center of gravity during the forklift turning process, and established a vehicle model including cargo weight and cargo-lifting speed. Based on this model, a lateral stability controller based on a simplified chaotic particle swarm algorithm was designed, and active steering and differential braking were used to jointly control the forklift. Xia G [15] analyzed the motion state of all-terrain forklifts on different road surfaces, proposed the roll stability indices HR-LTR and SR-LTR considering different road surfaces, and established an anti-roll control strategy based on road surface recognition. Zhang Y [16] studied the influence of forklift structural parameters and road roughness excitation on forklift roll dynamics and discussed the rationality of evaluating the vehicle roll state by LTR.

Among the existing rollover prevention control strategies, the lateral load transfer rate is a commonly used indicator for judging vehicle stability. It has the characteristics of high real-time performance and strong universality, but its value is affected by the accuracy of sensor measurement and there is no clear standard for determining the threshold [17,18,19]. The phase plane method is less affected by the accuracy of sensor measurement and does not need to consider the threshold value. It can judge the stability of the forklift more accurately [20]. In order to further improve the stability of electric forklifts, in addition to relying on accurate judgment of forklift stability, anti-rollover control methods must be adopted, such as anti-rollover cylinders, active steering and differential braking. Anti-rollover cylinders have good control effects, but the forklift structure is complex and difficult to control [21]. Active steering improves vehicle stability by applying additional steering angles to the steering wheels, but the control function will fail when the tire lateral force is saturated. Differential braking uses the tire longitudinal force to generate additional yaw torque to improve vehicle stability under extreme conditions, but it will affect the driving speed [22]. Active steering and differential braking coordinated control can reasonably and fully utilize tire lateral force and longitudinal force, combining the advantages of both to achieve vehicle stability control. In the anti-rollover coordinated control strategy of electric forklifts, the phase plane area division method is adopted to solve the problem of forklift stability judgment; considering the problem that active steering and differential braking are insufficient to control separately, an active steering and differential braking coordinated control strategy is designed. Finally, the effectiveness of this control strategy is verified by simulation.

The main contributions of this paper include:

- (1)

- In order to explore the impact of cargo on the forklift’s center of mass, a synthetic center of mass position model was constructed.

- (2)

- In order to judge the stability of forklifts, the phase plane area division method was adopted.

- (3)

- Considering the problem of insufficient control of active steering and differential braking alone, a coordinated control strategy of active steering and differential braking was designed.

2. Dynamic Model of an Electric Forklift

2.1. Synthetic Centroid Position Model

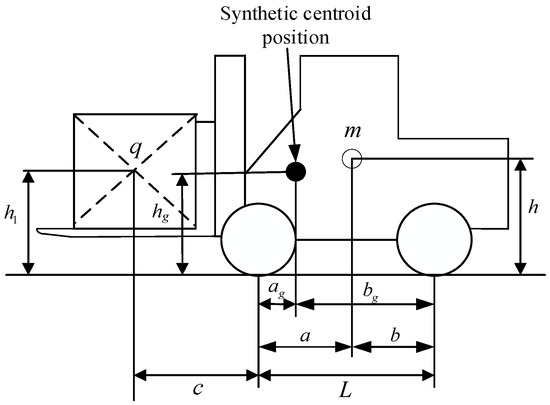

The position of the center of mass of the forklift is constantly changing due to the influence of the transported goods, which, in turn, affects the stability of the forklift; so, when establishing the dynamic model, it is necessary to show the influence of the goods on the center of mass of the forklift, and the position of the synthetic center of mass is shown in Figure 1.

Figure 1.

Synthetic centroid of forklift.

Where a, b is the horizontal distance between the center of mass and the front and rear axles at no load; c is the horizontal distance from the center of cargo to the front wheel grounding point; is the height of the core of the cargo; is the height of the center of mass of the forklift when unloaded; , is the horizontal distance between the synthetic centroid and the front and rear axles; is height of the synthetic centroid; is the quality of the goods to be handled; is the quality of the whole vehicle of the forklift; L is forklift wheelbase.

Synthetic centroid position:

where is the vertical distance from the center of mass of the forklift to the hinged shaft of the steering axle; is the height of the hinged axle of the rear axle.

2.2. Electric Forklift Model

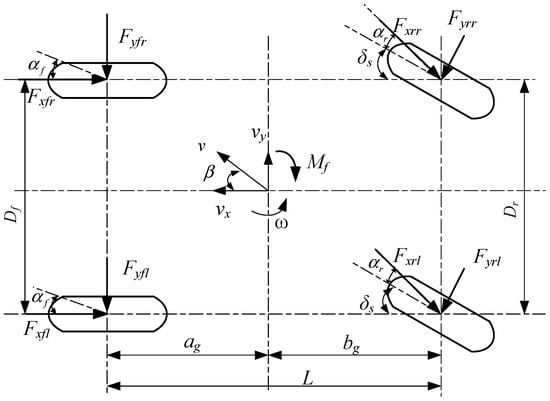

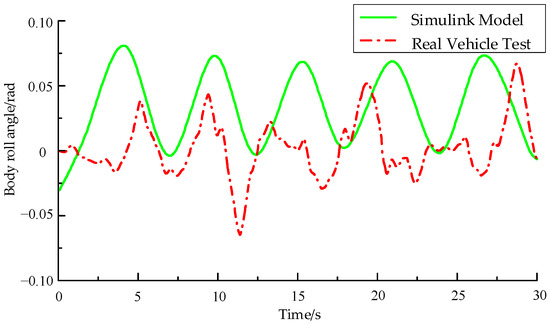

When turning, the forklift will produce a roll motion, and a forklift vehicle model is established to reflect the actual motion state, as shown in Figure 2 and Figure 3. This model assumes that the forklift is traveling on a horizontal road, and since the mass of the steering axle is relatively small compared to the mass of the vehicle body, its influence is not considered.

Figure 2.

Forklift dynamics model.

Figure 3.

Roll dynamics model of forklift truck.

The balance equation of the lateral motion of the forklift along the Y axis is as follows:

The balance equation of the forklift’s yaw motion around the Z axis is as follows:

The balance equation of the forklift’s roll motion around the X-axis is as follows:

where is the body roll angle acceleration; is the lateral force of the tire; is the moment of inertia of the mass of the forklift around the center of roll; is the body roll angle; is the moment of inertia of the forklift around the X-axis. is the lateral acceleration; is the rear wheel corner; is the input for the steering wheel angle; is the input for active steering control corner; is the longitudinal speed of the forklift; is the forklift lateral speed; is the forklift yaw angular velocity; is the centroid side declination; is the moment of inertia of the whole vehicle around the Z-axis.

2.3. Tire Models

In order to reflect the nonlinear characteristics of the forklift, it is necessary to select a reasonable expression of the tire model force. The Dugoff tire model can fully reflect the nonlinear characteristics of the tire model, has a concise form, and meets the requirements of real time [23]. The expression of the Dugoff tire model is as follows:

Let

where is the longitudinal and lateral stiffness of the tire; is the tire side deviation angle; is the vertical load of the tire; is the tire slip rate; is the peak adhesion coefficient of the pavement

Let ; then, the vertical load force of each wheel is as follows:

where are the longitudinal and lateral acceleration; are the front and rear wheel tracks.

The expression for the magnitude of longitudinal and lateral acceleration is as follows:

The side deflection angle of the rear wheel is as follows:

In the same way, the front wheel side deflection angle is as follows:

2.4. Model Validation

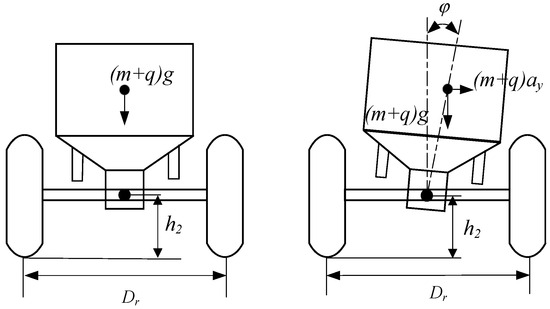

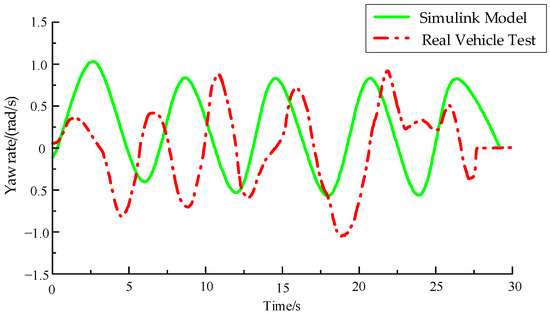

In order to verify the accuracy of the forklift mathematical model, this paper uses a serpentine working condition test to observe the changes in the forklift’s roll angle (Figure 4) and yaw angular velocity (Figure 5), and compares them with the roll angle and yaw angular velocity of the forklift collected in the actual vehicle test under the same working conditions. The simulation vehicle speed is set to 10 km/h.

Figure 4.

Body roll angle under no-load condition.

Figure 5.

Body roll angle under no-load condition.

As shown in Figure 4 and Figure 5, under the 10 km/h serpentine condition, the change trend of the body roll angle and yaw rate reflected by the forklift mathematical model can be consistent with the data of the actual vehicle test, and the change range is also consistent. This verifies the accuracy of the model and provides a control basis for subsequent research [24].

2.5. Expect Control Goals

The 2-DOF model vehicle is used as a reference model to obtain the desired yaw rate and sideslip angle required for stability control.

When a forklift is turning, excessive yaw rate and roll angle will cause it to roll over. Therefore, the selected control target value is the lateral velocity generated by the yaw rate and the sideslip angle of the vehicle body. In order to achieve a good control effect, it is necessary to determine the expected values of the yaw rate and the sideslip angle of the center of mass so that the controller can track them in real time [25].

Expected yaw angular velocity:

where K is the stability factor

Restricted by the adhesion coefficient of the pavement, the upper limit of the yaw angular velocity is as follows:

is used to ensure that the current rotation angle is 0, and the value is 0.

Expected centroid side declination:

Also considering the limitation of the pavement adhesion coefficient , the expected centroid side declination angle is as follows:

The lateral velocity generated by the desired sideslip angle of the forklift can be expressed as follows:

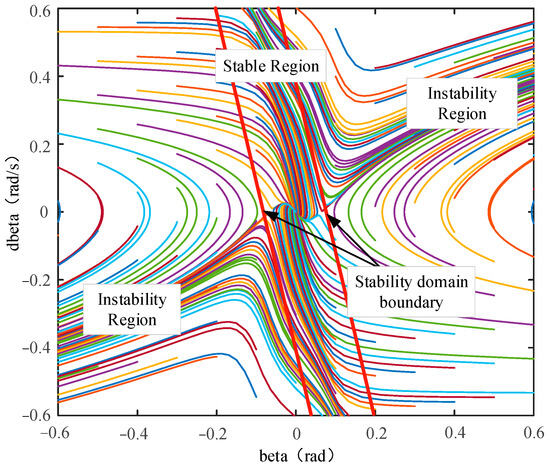

3. Phase Plane

The center of mass sideslip angle–center of mass sideslip angle velocity phase plane is usually used to analyze and judge vehicle stability and has a high judgment accuracy in the case of vehicle instability [26]. Therefore, the center of mass sideslip angle–center of mass sideslip angle velocity phase plane is used to analyze the stability of the forklift. The stability of the forklift can be judged by observing the motion phase trajectory. The motion phase trajectory area that passes through the intermediate stable point is the stable area, and the area that does not pass through is the unstable area.

3.1. Phase Plane Area Division

According to the 2-DOF model of the forklift, the phase plane is established by setting different vehicle speeds and rear wheel angles, as shown in Figure 6. The ordinate is the center of mass sideslip angular velocity, and the abscissa is the center of mass sideslip angle. The vehicle stability domain is divided by two straight lines symmetrical about the origin. These two straight lines are the boundary lines between the stable domain and the unstable domain. The boundary of the stable domain can be expressed as follows:

where is the slope of the boundary line; is the boundary line intercept.

Figure 6.

Phase plane.

3.2. Phase Plane Stability Boundary Equation

The road adhesion coefficient, vehicle speed and wheel angle are the main factors affecting the phase plane stability boundary, but in practical applications, the influence of vehicle speed and wheel angle is generally not considered. According to the phase plane stability boundary determination method, the influence of the road adhesion coefficient on the stability domain boundary of the phase plane is analyzed, and the boundary parameters corresponding to different road adhesion coefficients are obtained, and , as shown in Table 1.

Table 1.

Stable region boundary parameters.

From Table 1, it can be concluded that as the road adhesion coefficient increases, the slope of the stable region boundary line decreases, the intercept of the boundary line increases, and the area of the stable region increases. When a forklift is traveling on a road with a high adhesion coefficient, its stability will increase, which is consistent with the actual situation.

According to the data in Table 1, the equation of the boundary line of the stable region is obtained by fitting with a polynomial:

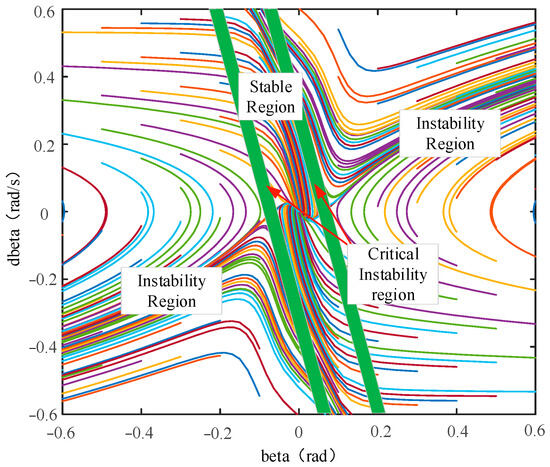

3.3. Coordinated Control Area Division

When the forklift enters the unstable region directly from the stable region, in order to prevent the occurrence of uncoordinated control, the critical stable region is divided in the phase plane stable region, as shown in Figure 7. In this region, the two controllers jointly control and finally realize the smooth transition between the two controllers in different control regions. The mathematical expression of the joint control region is as follows:

Figure 7.

Phase plane area division.

Therefore, the phase plane can be divided as follows:

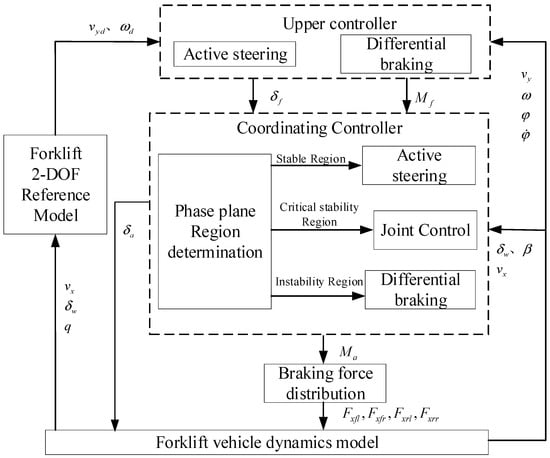

4. Rollover Prevention Coordinated Control Strategy

The anti-rollover coordinated control strategy for electric forklifts consists of an upper controller, a coordinated controller, and a braking force distribution controller, and the structure is shown in Figure 8. The rear wheel steering angle, current vehicle speed, and cargo mass information are calculated by the two-degree-of-freedom model of the forklift to obtain the expected yaw rate and center of mass slip angle. The active steering fuzzy PID controller in the upper controller determines the additional rear wheel steering angle based on the difference between the body roll angle and the expected value and its rate of change; the differential braking MPC controller makes the actual center of mass slip angle, yaw rate, and body roll angle change with the expected value to determine the required additional yaw moment. Then, the coordinated controller determines the control weight coefficients of the active steering controller and the differential braking controller in different control domains. In the stable domain, active steering control is adopted; in the critical stability domain, active steering and differential braking joint control are adopted, and as the degree of instability of the forklift increases, the weight coefficient of the differential braking control action gradually increases; in the instability domain, only differential braking control is adopted. The braking force distribution controller applies braking force to different wheels according to the additional yaw moment to improve the anti-rollover ability of the forklift when turning.

Figure 8.

Coordinated control strategy structure.

4.1. Upper Controller

The upper controller consists of two parts: the active steering fuzzy PID controller determines the additional rear wheel steering angle, and the differential braking MPC controller determines the additional yaw moment.

4.1.1. Active Steering Fuzzy PID Controller

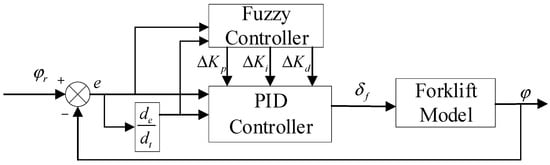

The fuzzy PID algorithm has good robustness and does not rely on mathematical models. Fuzzy rules designed based on expert experience can achieve good control effects. The difference e in the expected value of the body roll angle and the difference change rate ec are used as the input of the fuzzy PID controller, and the active steering rear wheel angle is used as the output. The control structure of the fuzzy PID is shown in Figure 9. The PID controller parameters are adjusted according to the results of fuzzy reasoning. The parameter values of the PID controller are determined as 300, 14, and 10, through simulation experiments.

Figure 9.

Control structure diagram of fuzzy PID.

The domain of error e and the error change rate ec is set to [−3,3]. The fuzzy quantities corresponding to the input changes e and ec are E and EC, and the fuzzy subsets are {NB, NM, NS, ZO, PS, PM, PB}. The definitions of each element of the fuzzy subset are NB (negative large), NM (negative medium), NS (negative small), ZO (almost zero), PS (positive small), PM (positive medium), and PB (positive large). ΔKp, ΔKi, ΔKd domains are set to [−3,3], [−6,6] and [−1,1], respectively, and the fuzzy subsets are {NB,NM,NS,ZO,PS,PM,PB}. Table 2 is the fuzzy rule table.

Table 2.

Fuzzy rule table.

4.1.2. Differential Braking MPC Controller

MPC is a commonly used optimal control method, particularly suitable for solving optimization problems with constraints. It can optimize the control law in real time to adapt to the dynamic change. In vehicle control, state constraints and actuator constraints are often present, making MPC widely used in vehicle stability control [27].

According to the forklift vehicle model, the state variable is selected, the control variable , and the forklift model without control is obtained as follows:

For the convenience of writing, let , ; then, the following formula is obtained:

The state equation of the forklift with differential braking control can be expressed as follows:

Subtracting Equations (27) and (31) above, we obtain the state equation:

Simplifying Equation (32), we can obtain the forklift state space equation used for model predictive control:

Discretization is performed to obtain the state space equation of the discrete state:

where ; ; ; k is the current sampling time; k + 1 is the next sampling time; I is the unit matrix; is the sampling period.

When performing model predictive control, we hope that the controlled output is infinitely close to the expected value. Therefore, the control increment can be used as the state quantity of the objective function, and the objective function can be written as follows:

where is the control output prediction sequence; is the control output reference sequence; is the output error and control increment error weight matrix; is the predict the value at time k + i based on the sampling information at time k; is the control amount and control increment at time k + i.

In control, it is necessary to add constraints to the control quantity, control increment and output quantity:

Considering the system constraints, the following optimization problem is solved in each step:

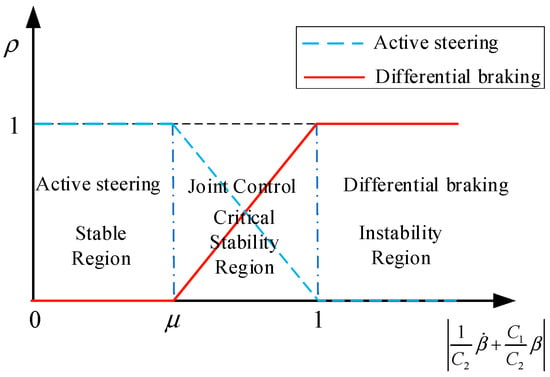

4.2. Coordinating Controller

In order to achieve a good control effect and ensure the coordinated operation of the two controllers, the weight coefficient is introduced to control the two controllers. In the stable domain, due to the small yaw moment required, active steering control is adopted to ensure the driving speed of the forklift. In the critical stable domain, active steering and differential braking are used for joint control. As the instability of the forklift increases, the weight coefficient of differential braking control gradually increases. At this time, in the unstable domain, a large yaw moment is required to ensure the safe driving of the vehicle. Only differential braking control is used. At this time, the relationship between the differential braking weight coefficient and the control area is shown in Figure 10.

Figure 10.

Relationship between weight coefficient and control area.

According to the above analysis, the additional rear wheel steering angle and additional yaw moment after coordinated control distribution can be obtained as follows:

4.3. Brake Force Distributor

The additional yaw moment is independent of the lateral force of the braked wheel and is only generated by the wheel braking force. Therefore, a braking force distribution controller is needed to distribute the braking force required by each wheel, correct the forklift posture, and improve the forklift stability [28]. The selection rules for the differential brake wheel are shown in Table 3.

Table 3.

Brake wheel selection rules.

If the two wheels on the right side of the forklift are braked, according to Figure 3, the following is obtained:

where represent the braking force of the right front and rear wheels, respectively.

When the wheel is not locked, the wheel braking force is approximately proportional to its vertical load. In order to make full use of the road adhesion conditions, the braking force can be dynamically distributed in real time according to the following formula.

Similarly, the braking force on the left wheel is also distributed in the above manner.

5. Simulation Analysis

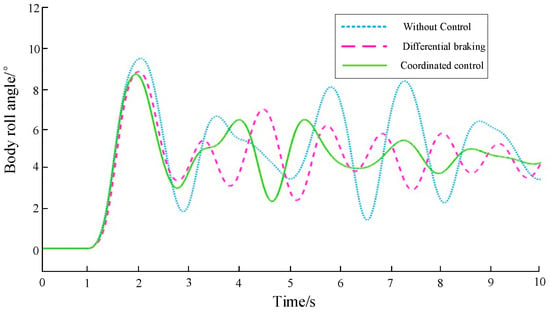

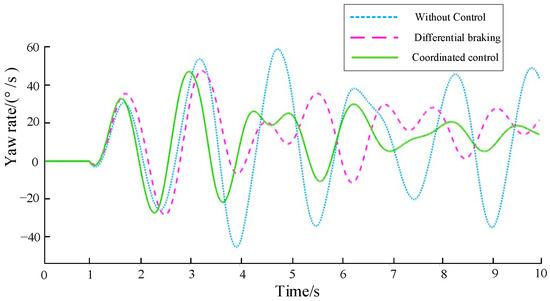

In order to verify the effectiveness of this control strategy for forklift anti-rollover control, a Matlab/Simulink simulation model was built with a 3T electric forklift as a reference. The main parameters of electric forklifts are shown in Table 4. Using the typical working condition of angular step steering, the steering wheel was turned from the initial state of 0° to 250° at a constant speed within 1 s. The forklift speed was 15 km/h. The three states of the forklift, namely, empty, half-loaded, and fully loaded, were analyzed, and the roll angle and yaw angular velocity of the forklift body were compared under no control, differential braking control, and coordinated control. The simulation results are shown in Figure 11, Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16. At the same time, the peak value and stable time are compared and analyzed, as shown in Table 5, Table 6, Table 7 and Table 8.

Table 4.

The main parameters of electric forklifts.

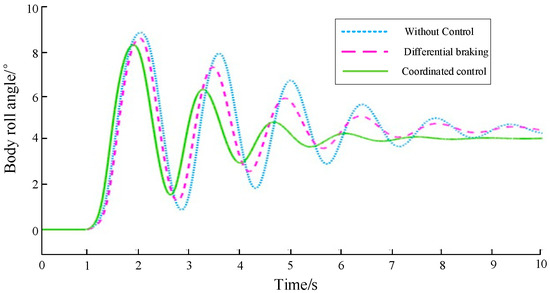

Figure 11.

Unloaded vehicle body roll angle.

Figure 12.

Yaw angular velocity of unloaded vehicle body.

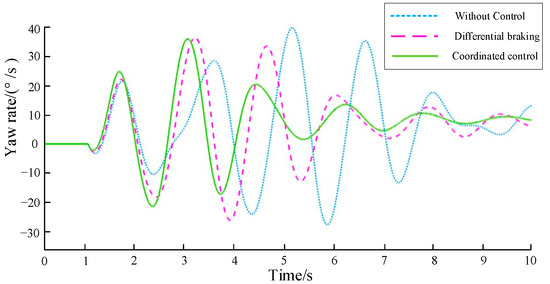

Figure 13.

Half-load body roll angle.

Figure 14.

Half-loaded vehicle body yaw rate.

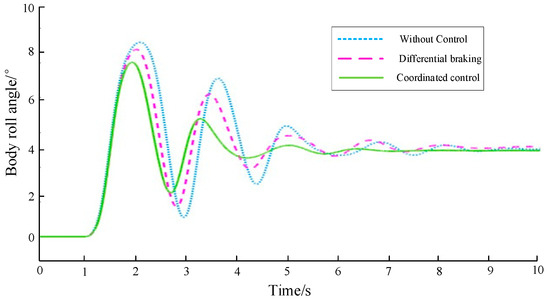

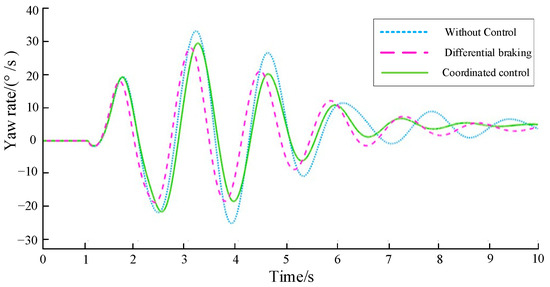

Figure 15.

Fully loaded body roll angle.

Figure 16.

Yaw angular velocity of fully loaded vehicle body.

Table 5.

Simulated vehicle body roll angle peak.

Table 6.

Simulated vehicle yaw rate peak value.

Table 7.

Simulation of vehicle body roll angle stabilization time.

Table 8.

Simulation of vehicle yaw angle stabilization time.

Through simulation analysis, it can be seen that, under no-load conditions, when there is no control, the roll angle and yaw rate of the forklift body increase sharply, and are in a large-amplitude oscillation state without a trend of stabilization. Under differential braking control and coordinated control, the fluctuation in these two parameters is significantly reduced. In particular, the coordinated control has a better effect. The peak values of the body roll angle and yaw rate are controlled within 8.8° and 46°/s, with the maximum improvement of 11.7% and 26.1%, respectively, and the body roll angle and yaw rate quickly reach a stable state. Under half-load conditions, the peak values of the body roll angle and yaw rate under coordinated control are controlled within 8.2° and 35°/s, which is better than the no-control state and differential braking control, with the maximum improvement of 10.5% and 14.3%, respectively, and the maximum reduction in stabilization time is 30.3% and 22.4%, respectively. Under full-load conditions, the peak values of the body roll angle and yaw rate under coordinated control are controlled within 7.6° and 29°/s, with maximum improvements of 9.5% and 14.7%, respectively, and the maximum reductions in stabilization time are 33.5% and 20.2%, respectively. Although the yaw rate under coordinated control is slightly higher than that without control within 2 to 3 s, its peak value is still lower than that without control.

6. Conclusions

In the coordinated control strategy for electric forklift rollover prevention, the phase plane area division method is used to judge the stability of the forklift; considering the problem of insufficient control of active steering and differential braking alone, the coordinated control strategy of active steering and differential braking is designed. Taking a 3T electric forklift as a reference, a MATLAB/Simulink simulation model is built for verification. When unloaded, the peak values of the body roll angle and yaw angular velocity under coordinated control are reduced by 11.7% and 26.1%, respectively compared with those without control, and the stable state is reached quickly; when half-loaded, the peak values of the body roll angle and yaw angular velocity under coordinated control are reduced by 10.5% and 14.3%, respectively, compared with those without control, and the stable speed is increased by 30.3% and 22.4%, respectively; when fully loaded, the peak values of the body roll angle and yaw angular velocity under coordinated control are reduced by 9.5% and 14.7% compared with those without control, and the stable speed is increased by 33.5% and 20.2%, respectively. The simulation results show that this control strategy greatly reduces the risk of rollover when the forklift is turning, and further improves the stability of the forklift. Therefore, it is recommended to introduce an anti-rollover control system based on sensor fusion in future forklift products to monitor the center of mass position and posture changes of the forklift in real time and prevent rollover through active control strategies. At the same time, the chassis design of the forklift should be optimized and the center of mass height should be lowered. The combination of the two can further improve the overall stability of the forklift.

However, there are still some issues that are not discussed in depth in this paper. For example, the working condition set in this paper is that the forklift is driving on an ideal horizontal road surface, which does not take into account the situation of driving on a slope. In addition, this paper only considers the impact of the cargo on the center of mass position in the longitudinal and vertical directions, while, in reality, the mass distribution of the cargo is uneven, which will affect the center of mass position of the forklift in the lateral direction. This will be considered in future research to improve the effect of the ideas explored in this paper.

Author Contributions

Conceptualization, Z.G.; manuscript writing, Y.Y.; image description, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Henan Province University Science and Technology Innovation Team Support Project (24IRTSTHN029).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, Y.; Deng, D.; Li, J. Analysis of causative factors of forklift truck accidents based on text mining. Hois. Conv. Mach. 2024, 13, 46–52. [Google Scholar] [CrossRef]

- Ghazali, M.; Durali, M.; Salarieh, H. Vehicle trajectory challenge in predictive active steering rollover prevention. Int. J. Automot. Technol. 2017, 18, 511–521. [Google Scholar] [CrossRef]

- Termous, H.; Shraim, H.; Talj, R.; Francis, C.; Charara, A. Coordinated control strategies for active steering, differential braking and active suspension for vehicle stability, handling and safety improvement. Veh. Syst. Dyn. 2019, 57, 1494–1529. [Google Scholar] [CrossRef]

- Akar, M.; Dere, A.D. A Switching Rollover Controller Coupled with Closed-Loop Adaptive Vehicle Parameter Identification. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1579–1585. [Google Scholar] [CrossRef]

- Zong, C.; Han, X.; Zhao, W.; Went, Z. Anti-rollover Control of Bus Based on Dynamic LTR. Chin. J. High. Trans. 2016, 29, 136–142. [Google Scholar] [CrossRef]

- Qi, B.; Wang, S.; Ren, C.; Zhang, L. Anti-rollover Control of Distributed Drive Electric Vehicle Based on Energy Method. J. Mech. Eng. 2019, 55, 183–192. [Google Scholar]

- Zhang, L.; Ren, C.; Li, S. Chassis Cooperative Control for Improving Lateral Stability of In-wheel Motors Drive Electric Vehicle. J. Mech. Eng. 2019, 55, 153–164. [Google Scholar]

- Rinchi, M.; Pugi, L.; Bartolini, F. Design of Control System to Prevent Forklift Capsize. Int. J. Veh. Sys. Mode. Test. 2010, 5, 35–48. [Google Scholar] [CrossRef]

- Felez, J.; Bermejo, A. Design of a counterbalance forklift based on a predictive anti-tip-over controller. Integr. Comput.-Aided Eng. 2018, 25, 273–288. [Google Scholar] [CrossRef]

- Rebelle, J.; Mistrot, P.; Poirot, R. Development and validation of a numerical model for predicting forklift truck tip-over. Veh. Syst. Dyn. 2009, 47, 771–804. [Google Scholar] [CrossRef]

- Tao, P.; Jin, X.H. Research on Performance of Wire-controlled Hydraulic Steering System Based on Four-wheel Steering. IOP Conf. Ser. Mater. Sci. 2018, 359, 012004. [Google Scholar] [CrossRef]

- Xia, G.; Li, J.C.; Tang, X.W.; Zhao, L.F.; Sun, B.Q. Layered control of forklift lateral stability based on Takagi-Sugenofuzzy neural network. J. Automot. Eng. 2021, 235, 1767–1780. [Google Scholar] [CrossRef]

- Kasahara, M.; Mori, Y. Relation between overturn and the center of gravity of a forklift truck. In Proceedings of the 2017 56th Annual Conference of the Society of Instrument and Control Engineers of Japan (Sice), Kanazawa, Japan, 19–22 September 2017; pp. 135–140. [Google Scholar]

- Zhang, Z.; Xiao, B. A study on the effeet of cargo lifting on forkliftlateral stability and control strategy. J. Hefei Univ. Technol. (Nat. Sci.) 2020, 43, 1620–1625. [Google Scholar]

- Guang, X.; Zhou, D.; Tang, X.; Zhang, Y.; Zhao, L. Roll stability of all-terrain forklift trucks considering different road types. Procee. Institun. Mech. Eng. Part D- J. Automo. Eng. 2024, 22. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, J.; Xia, G.; Khajepour, A. Roll dynamic model and steering stability analysis of the counterbalance forklift truck with considering hierarchical rollover. J. Autom. Eng. 2024, 238, 1739–1750. [Google Scholar] [CrossRef]

- Li, S.; Du, P.; Feng, X. Integrated anti-rollover control strategy of minibus. J. Jiangsu Univ. (Nat. Sci.) 2022, 43, 131–138. [Google Scholar]

- Kang, X.; Dong, H.; Qi, C.; Wang, H. Anti-Rollover Control of Bus Based on Vehicle State Estimation. Mach. Des. Manu. 2022, 7, 10–13+18. [Google Scholar] [CrossRef]

- Shi, Q.; Li, J. Anti-Rollover Control of Bus Based on Nonlinear Disturbance Estimation. Automot. Eng. 2020, 42, 1224–1231. [Google Scholar] [CrossRef]

- Zheng, L. Coordination Control of Differential Drive Assist Steering and Vehicle Stability Control for Four-Wheel-Independent-Drive EV. Bachelor’s Thesis, Jilin University, Jilin, China, 2019. [Google Scholar]

- Zhang, Y.; Xia, G.; Du, K.; Xie, H.; Tang, X. Research on antirollover control of counterbalanced forklifttruck based on variable universe fuzzy control. J. Hefei Univ. Technol. (Nat. Sci.) 2019, 42, 881–887. [Google Scholar]

- Li, Z.; Pan, S.; Xu, Y. Coordinated Control of AFS and DYC for 8-wheel Distributed Electric Drive Vehicle. Automot. Eng. 2023, 45, 409–420. [Google Scholar] [CrossRef]

- Gao, Y. Stability Control Study Based on the Stability Boundary of Phase Plane for Light Vehicle. Bachelor’s Thesis, Jilin University, Jilin, China, 2013. [Google Scholar]

- Zhang, Y. Research on Anti-rollover Control of Counterbalanced Forklift. Bachelor’s Thesis, Hefei University of Technology, Hefei, China, 2020. [Google Scholar]

- Lu, Y.; Zhuang, W.; Yin, G.; Liang, J.; Ren, Y.; Feng, J. Rollover prevention model predictive control of heavy-duty vehicles considering variable curvature. J. Southeast Univ. (Nat. Sci.) 2022, 52, 990–997. [Google Scholar] [CrossRef]

- Zhong, L.; Peng, Y.; Jiang, M. Stability Control of Distributed Driven Electric Vehicle Based on Phase Plane. Automot. Eng. 2021, 43, 721–729. [Google Scholar] [CrossRef]

- He, Y.; Chu, D.; Wu, C.; Yan, X. Anti-rollover control for heavy-duty vehicles based on model prodictive control. Trans. Syst. Eng. Inform. Technol. 2015, 15, 89–99. [Google Scholar]

- Liao, Z.; Gong, H.; Hu, M. Research on Model Predictive Control of Heavy Dump Truck Against Rollover. Mech. Sci. Technol. Aero. Eng. 2022, 41, 1121–1127. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).