Multidisciplinary Engineering Educational Programme Based on the Development of Photovoltaic Electric Vehicles

Abstract

1. Introduction

- -

- It requires the implementation of a wide range of technologies in industrial engineering, such as electronics, automation, structures, fluids, mechanics, energy, design, graphical expression, manufacturing and projects. This enables their integration in the creation of a tangible and functional prototype.

- -

- It is a constantly evolving, cutting-edge technology that represents a growing trend in urban and sustainable mobility and is having a significant impact on new forms of urban transport. There is a wide range of new designs available for students to develop, such as tricycles and quadricycles with all-wheel drive, highly manoeuvrable vehicles or the integration of renewable energy into power systems. These projects could address real problems in the field of sustainable mobility to improve vehicle autonomy, efficiency, safety and quality of life in cities.

- -

- From an economic point of view, the development of LEVs does not involve high costs, thanks to the wide availability on the market of basic components such as engines, wheels, batteries, brakes, power regulators, processors and displays, which are currently used in electric bicycles and scooters.

- -

- LEVs are excellent for organising competitions between the prototypes developed by different groups of students, where outstanding aspects such as energy efficiency, design or driving ergonomics are rewarded. Participating in such competitions provides an additional stimulus for students, increasing their motivation.

- -

- LEVs have the potential to make a significant impact on society and the economy. Their development can boost sustainable urban mobility, reduce congestion and improve the quality of cities. For all these reasons, LEVs represent a great opportunity for the development of new innovative business models, start-ups and markets related to these issues.

2. Materials and Methods

- -

- Chassis.

- -

- Photovoltaic generator.

- -

- Mechanical systems.

- -

- Electrical systems.

- Chassis

- 2.

- Photovoltaic generator

- 3.

- Mechanical systems

- 4.

- Electrical systems

- -

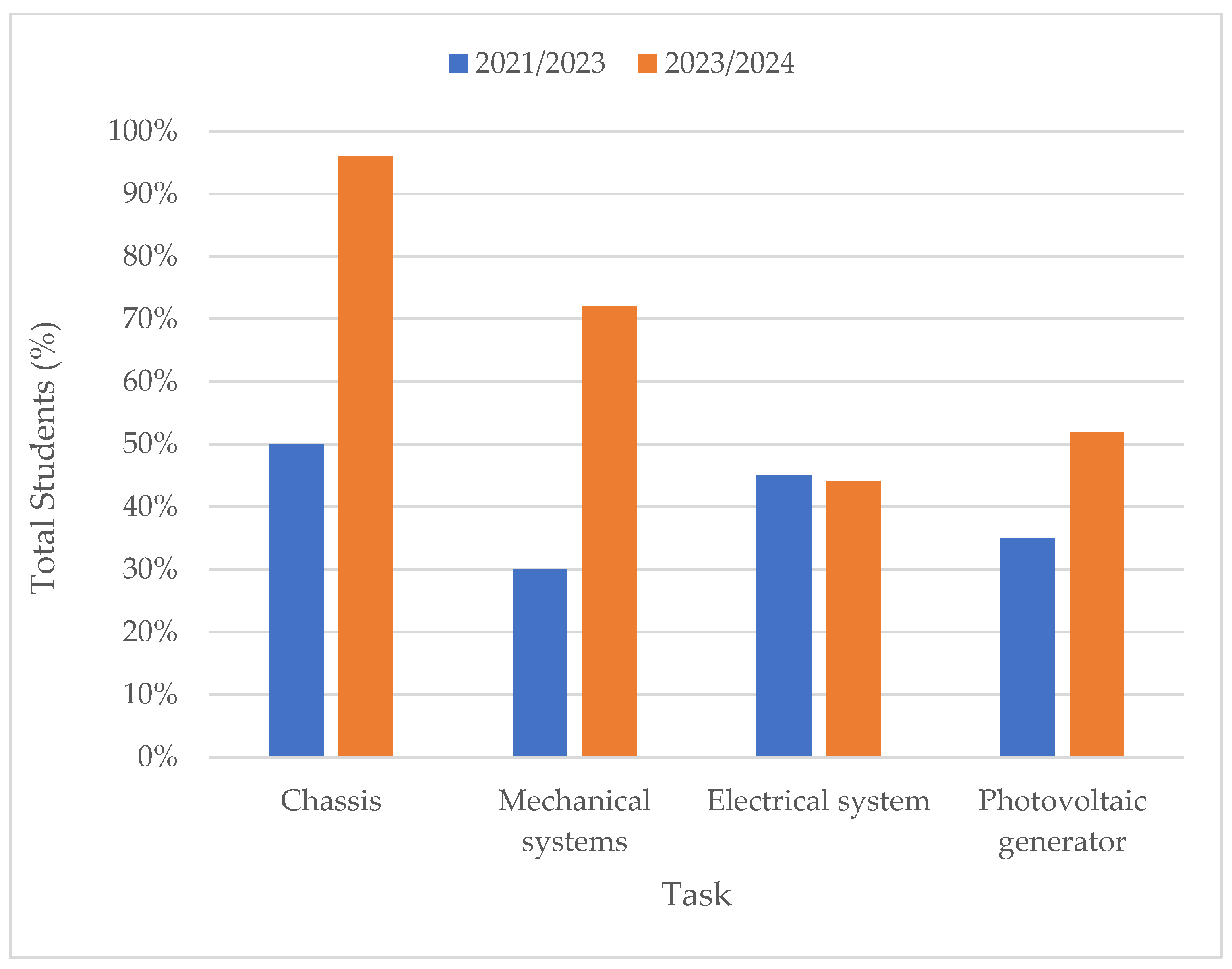

- In the ST methodology, students are only involved in one manufacturing task, so they only experiment with the manufacturing processes related to that task. Students who regularly attend the working sessions are involved in all phases of the task, from the beginning to the end.

- -

- In the EME methodology, students participate in all the manufacturing tasks, so they can experiment with all the manufacturing processes necessary to make the complete vehicle. However, they do not carry out any complete task, only some phases of it, as the activities of each task are distributed among all the working groups.

- -

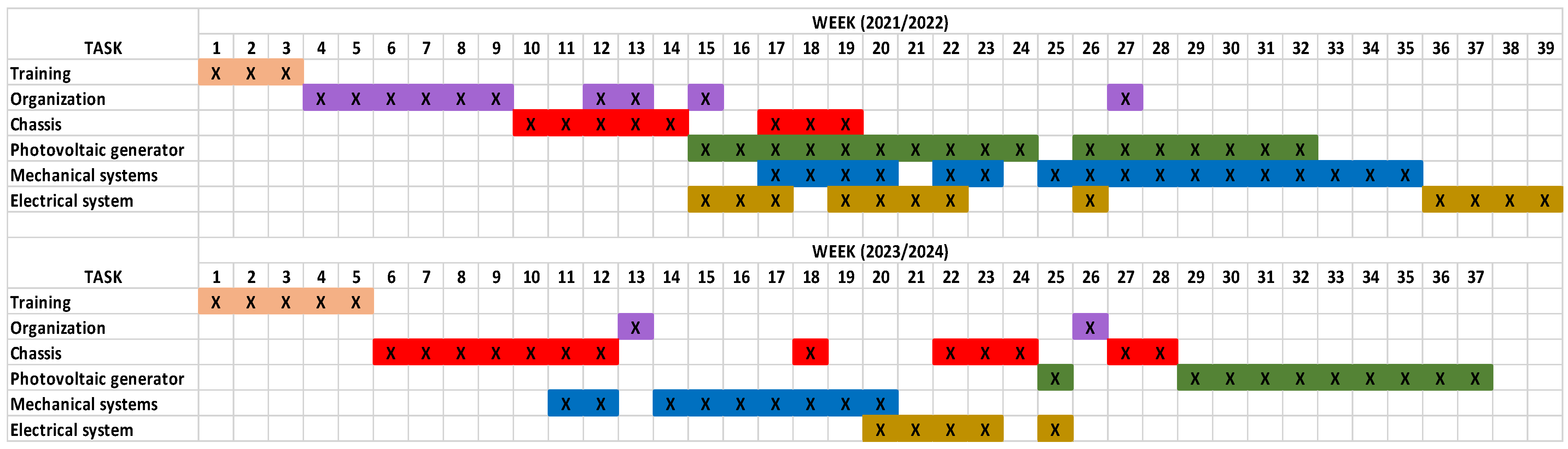

- The ST methodology requires a much more complex planning of activities, allowing an appropriate synchronisation of tasks and a workload that is as balanced as possible over time. The difficulty lies in the fact that on the one hand, the workload associated with each task is different and, on the other hand, there are tasks that cannot be started until others have been completed or are sufficiently advanced.

- -

- In the EME methodology, in contrast, planning is much simpler, as the workload of each group is established in a balanced way by establishing a schedule in which all groups spend the same amount of hours per week on the task that corresponds to them at each moment.

- -

- Documentation and materials used.

- -

- Number of sessions and time required for their execution.

- -

- Students participating in each session.

- -

- Description of problems encountered, actions taken to solve them and suggestions for possible future improvements.

3. Results

3.1. Project Results

3.2. Vehicle Technical Characteristics and Performance

4. Discussion

4.1. The Drop-Out Rate

- -

- The students’ participation was voluntary and free of charge, they had no commitment to remain in the project, so they could leave it whenever they considered it appropriate.

- -

- Both projects spanned two years. From one year to the next, the number of official subjects and the students’ schedules changed significantly, making it impossible for many of them to combine the project with their official studies during the second year.

4.2. The Time Needed to Manufacture the Prototype

4.3. The Complexity of the Organisation

- -

- After the basic training phase, six weeks were devoted to coordination meetings and the development of the online platform, which was not necessary for the second edition.

- -

- The workload was more unevenly distributed, being concentrated during the central weeks of the project: from week 15 to week 26. Most of the work on the 4 tasks was concentrated in this period of time, which required a much greater effort of coordination of schedules and workspace than in the second edition. The reason for this high concentration of work was the need for all students to be active as soon as possible, since it was found that the fact that students were inactive for a long time after the basic training phase caused a great deal of demotivation. This did not happen in the second edition either, as the organisation of the work itself meant that all the students were active during all the weeks of the project.

4.4. The Performance of Students’ Work

- -

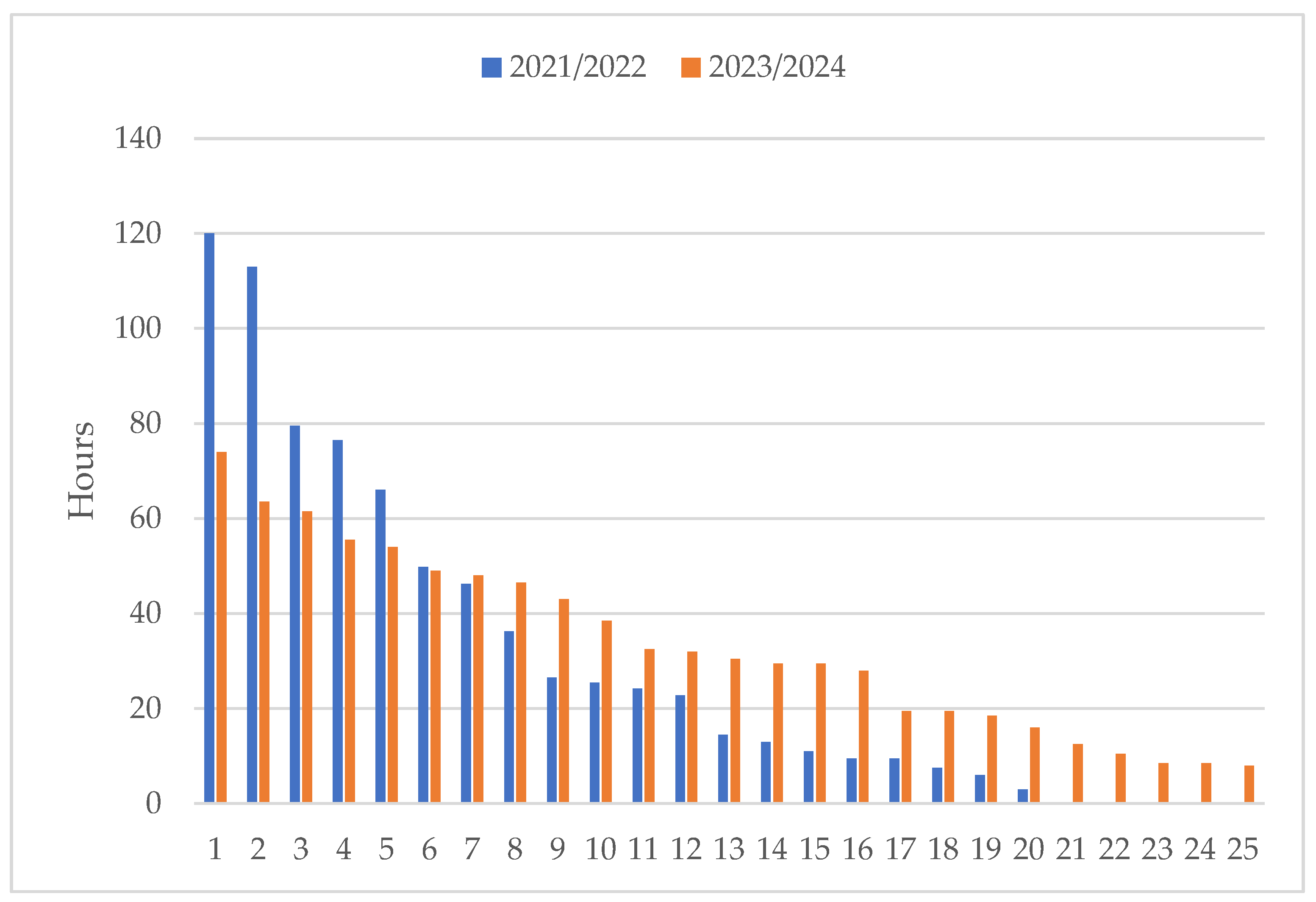

- Due to drop-outs, the number of students at the beginning of the second edition of the project was greater than at the end, so the working groups were also larger at the beginning. The organisation of a group’s work becomes more complicated as the number of group members increases, so that some group members are more likely to be idle for some time during the work session because they have to wait for others to finish a task before they can start their own. These intervals of inactivity are shorter the smaller the number of group members.

- -

- At the beginning, the students often had little or no experience working in the workshop, using tools, etc., so they needed more time to complete the tasks. As the project progressed, they gained more experience and therefore the time spent on tasks decreased, which led to a significant increase in performance.

4.5. The Distribution of Students’ Work

4.6. The Diversity and Depth of the Tasks Undertaken by the Students

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EME | Everyone makes everything |

| EV | Electric vehicle |

| LEV | Light electric vehicle |

| PBL | Project based learning |

| PV | Photovoltaic |

| PV-EV | Photovoltaic electric vehicle |

| STs | Specialized Teams |

References

- SIIU. Datos y Cifras del Sistema Universitario Español. Available online: https://www.universidades.gob.es/wp-content/uploads/2024/05/SIIU_DatosCifras2024.pdf (accessed on 3 March 2025).

- The Organisation for Economic Co-Operation and Development|OECD. Available online: https://www.oecd.org/en.html (accessed on 4 March 2025).

- Inicio—CRUE. Available online: https://www.crue.org/ (accessed on 3 March 2025).

- Bernold, L.E.; Spurlin, J.E.; Anson, C.M. Understanding Our Students: A Longitudinal-Study of Success and Failure in Engineering with Implications for Increased Retention. J. Eng. Educ. 2007, 96, 263–274. [Google Scholar] [CrossRef]

- Meyer, M.; Marx, S. Engineering Dropouts: A Qualitative Examination of Why Undergraduates Leave Engineering: Engineering Dropouts: Why Undergraduates Leave Engineering. J. Eng. Educ. 2014, 103, 525–548. [Google Scholar] [CrossRef]

- Berlanga, V.; Figuera, P.; Pérez-Escoda, N. Academic performance and persistence of study bursary holders. Rev. De Cercet. Si Interv. Soc. 2016, 54, 23–35. [Google Scholar]

- Constate-Amores, A.; Martínez, E.F.; Asencio, E.N.; Fernández-Mellizo, M. Factores asociados al abandono Universitario. Educ. XX1 2021, 24, 17–44. [Google Scholar] [CrossRef]

- Godwin, A.; Kirn, A. Identity-span style = “font-variant:small-caps;” based/span motivation: Connections between span style = “font-variant:small-caps; “first-year/span students’ engineering role identities and future-time perspectives. J. Eng. Educ. 2020, 109, 362–383. [Google Scholar] [CrossRef]

- González-Campos, J.A.; Carvajal-Muquillaza, C.M.; Aspeé-Chacón, J.E.; González-Campos, J.A.; Carvajal-Muquillaza, C.M.; Aspeé-Chacón, J.E. Modelación de la deserción universitaria mediante cadenas de Markov. Uniciencia 2020, 34, 129–146. [Google Scholar] [CrossRef]

- Casanova, J.; Cervero, A.; Núñez, J.; Almeida, L.; Bernardo, A. Factors that determine the persistence and dropout of university students. Psicothema 2018, 30, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Dym, C.L. Learning Engineering: Design, Languages, and Experiences*. J. Eng. Educ. 1999, 88, 145–148. [Google Scholar] [CrossRef]

- Dym, C.L.; Agogino, A.M.; Eris, O.; Frey, D.D.; Leifer, L.J. Engineering Design Thinking, Teaching, and Learning. J. Eng. Educ. 2005, 94, 103–120. [Google Scholar] [CrossRef]

- Zhou, C.; Kolmos, A.; Nielsen, J.D. A problem and Project-Based Learning (PBL) approach to motivate group creativity in engineering education. Int. J. Eng. Educ. 2012, 28, 3–16. [Google Scholar]

- Ercan, M.F.; Khan, R. Teamwork as a fundamental skill for engineering graduates. In Proceedings of the 2017 IEEE 6th International Conference on Teaching, Assessment, and Learning for Engineering (TALE), Hong Kong, China, 12–14 December 2017; IEEE: New York, NY, USA, 2017; pp. 24–28. [Google Scholar] [CrossRef]

- Isaac, T.S.; Kolawole, O.J.; Funsho, A.A.G.; Adesiji, O.J. Reviewing engineering curricula to meet industrial and societal needs. In Proceedings of the 2014 International Conference on Interactive Collaborative Learning, ICL 2014, Dubai, United Arab Emirates, 3–6 December 2014. [Google Scholar] [CrossRef]

- Hsiung, C. The Effectiveness of Cooperative Learning. J. Eng. Educ. 2012, 101, 119–137. [Google Scholar] [CrossRef]

- Martinez, M.L.; Romero, G.; Marquez, J.J.; Perez, J.M. Integrating teams in multidisciplinary project based learning in Mechanical Engineering. In Proceedings of the IEEE EDUCON 2010 Conference, Madrid, Spain, 14–16 April 2010; IEEE: New York, NY, USA, 2010; pp. 709–715. [Google Scholar] [CrossRef][Green Version]

- Cooper, L.A.; Kotys-Schwartz, D.A. Designing the design experience-identifying factors of student motivation in project-based learning and project-based service-learning. In Proceedings of the ASEE Annual Conference and Exposition, Atlanta, GA, USA, 23–26 June 2013. Conference Proceedings. [Google Scholar] [CrossRef]

- MotoStudent. Available online: https://www.motostudent.com/ (accessed on 3 March 2025).

- FSS 25—Formula Student Spain. Available online: https://www.formulastudent.es/ (accessed on 3 March 2025).

- Gadola, M.; Chindamo, D. Experiential learning in engineering education: The role of student design competitions and a case study. Int. J. Mech. Eng. Educ. 2019, 47, 3–22. [Google Scholar] [CrossRef]

- Aguilar, J.J.C.; Vargas, M.G.A.; Fernández, J.P.; García, J.M.V.; Carrillo, J.A.C. UMA Racing Team: Una experiencia en participación en competiciones universitarias (UMA Racing Team: An experience in participation in university competitions). In Innovaciones Docentes en Tiempos de Pandemia; Servicio de Publicaciones Universidad: Zaragoza, Spain, 2021; pp. 268–273. [Google Scholar] [CrossRef]

- Solís, M.; Romero, A. PBL from real projects and students initiative: A case study. Int. J. Eng. Educ. 2017, 33, 1726–1736. Available online: https://www.ijee.ie/latestissues/Vol33-6A/03_ijee3503ns.pdf (accessed on 3 March 2025).

- De-la-Varga-Salto, J.M.; Galindo-Reyes, F.C. Design and Implementation of the Methodology Project Based Learning (PBL). The MART Case. 2023. Available online: https://hdl.handle.net/10630/28245 (accessed on 3 March 2025).

- Hellwig, M.; Ritschel, W. The Electric CafE-Racer Project. In Proceedings of the 2020 21st International Conference on Research and Education in Mechatronics (REM), Cracow, Poland, 9–11 December 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Gonzalez-Rubio, R.; Khoumsi, A.; Dubois, M.; Trovao, J.P. Problem- and Project-Based Learning in Engineering: A Focus on Electrical Vehicles. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016; IEEE: New York, NY, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Gonzalez-Rubio, R.; Khoumsi, A.; Trovao, J.P. Project-Based Learning in Engineering: Illustration by a Capstone Project of an Electric Vehicle. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; IEEE: New York, NY, USA, 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Sekaran, A.; Rodak, C.M. Impact of Physical Model Projects and Multidisciplinary Teams in Fluid Mechanics Education. Educ. Sci. 2024, 14, 658. [Google Scholar] [CrossRef]

- Jaiswal, A.; Karabiyik, T.; Thomas, P.; Magana, A.J. Characterizing Team Orientations and Academic Performance in Cooperative Project-Based Learning Environments. Educ. Sci. 2021, 11, 520. [Google Scholar] [CrossRef]

- Guajardo-Cuéllar, A.; Vázquez, C.R.; Gutiérrez, M.N. Developing Competencies in a Mechanism Course Using a Project-Based Learning Methodology in a Multidisciplinary Environment. Educ. Sci. 2022, 12, 160. [Google Scholar] [CrossRef]

- Kosmanis, T.; Tziourtzioumis, D.; Riel, A.; Reiner, M. Supporting the Growth of Electric Vehicle Market Through the E-DRIVETOUR Educational Program. In Systems, Software and Services Process Improvement; Yilmaz, M., Clarke, P., Riel, A., Messnarz, R., Eds.; Springer Nature: Cham, Switzerland, 2023; Volume 1890, pp. 171–185. [Google Scholar] [CrossRef]

- Hyman, B. From Capstone to Cornerstone: A New Paradigm for Design Education. Int. J. Eng. Educ. 2001, 17, 416–420. Available online: https://www.ijee.ie/articles/Vol17-4and5/IJEE1237.pdf (accessed on 3 March 2025).

- Mills, J.E.; Treagust, D.F. Engineering education: Is problem-based or project-based learning the answer? Australas. J. Eng. Educ. 2003. Available online: https://search.informit.org/doi/10.3316/aeipt.132462 (accessed on 7 February 2025).

- Ramos, J.F.; Lozano, J.J.F.; Calderon, A.G. Design of electric racing vehicles: An experience of interdisciplinary project-based education in engineering. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; IEEE: New York, NY, USA, 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Hosseinzadeh, N.; Hesamzadeh, M.R. Application of Project-Based Learning (PBL) to the Teaching of Electrical Power Systems Engineering. IEEE Trans. Educ. 2012, 55, 495–501. [Google Scholar] [CrossRef]

- Martinez-Rodrigo, F.; Lucas, L.C.H.-D.; De Pablo, S.; Rey-Boue, A.B. Using PBL to Improve Educational Outcomes and Student Satisfaction in the Teaching of DC/DC and DC/AC Converters. IEEE Trans. Educ. 2017, 60, 229–237. [Google Scholar] [CrossRef]

- Kaushik, M. Evaluating a First-Year Engineering Course for Project Based Learning (PBL) Essentials. Procedia Comput. Sci. 2020, 172, 364–369. [Google Scholar] [CrossRef]

- Chen, J.; Kolmos, A.; Du, X. Forms of implementation and challenges of PBL in engineering education: A review of literature. Eur. J. Eng. Educ. 2021, 46, 90–115. [Google Scholar] [CrossRef]

- de Dampierre, M.R.; Gaya-López, M.C.; Lara-Bercial, P.J. Evaluation of the Implementation of Project-Based-Learning in Engineering Programs: A Review of the Literature. Educ. Sci. 2024, 14, 1107. [Google Scholar] [CrossRef]

- Lavado-Anguera, S.; Velasco-Quintana, P.-J.; Terrón-López, M.-J. Project-Based Learning (PBL) as an Experiential Pedagogical Methodology in Engineering Education: A Review of the Literature. Educ. Sci. 2024, 14, 617. [Google Scholar] [CrossRef]

- Sheppard, K.; Dominick, P.; Aronson, Z. Preparing Engineering Students for the New Business Paradigm of International Teamwork and Global Orientation. Int. J. Eng. Educ. 2004, 20, 475–483. [Google Scholar]

- Leite, V. Innovative learning in engineering education: Experimenting with short-term project-oriented research and project-based learning. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; IEEE: New York, NY, USA, 2017; pp. 1555–1560. [Google Scholar] [CrossRef]

- Pérez, B.; Rubio, Á.L. A Project-Based Learning Approach for Enhancing Learning Skills and Motivation in Software Engineering. In Proceedings of the 51st ACM Technical Symposium on Computer Science Education, Portland, OR, USA, 11–14 March 2020; ACM: New York, NY, USA, 2020; pp. 309–315. [Google Scholar] [CrossRef]

- Arcas, A.R.N.; Schenk, J.M.L.; Jara, C.A.; Gadea, I.S. Educational Impacts on Robotic Engineering Students of an International Online Project-Based Learning Course. Educ. Sci. 2024, 14, 1305. [Google Scholar] [CrossRef]

- Kondo, A.; Hayashi, H.; Toyoshi, T. Project-Based Learning of Mechanical Design Utilizing CAE Structural Analyses. Educ. Sci. 2023, 13, 687. [Google Scholar] [CrossRef]

- Ariza, J.A.; Ramos, H.B. An educational experience with PBL in capstone projects: The case of EOLO a Colombian electric vehicle with sustainable energy systems. In Proceedings of the Frontiers in Education Conference, FIE, Cincinnati, OH, USA, 16–19 October 2019. [Google Scholar] [CrossRef]

- Zhang, Z.; Hansen, C.T.; Andersen, M.A.E. Teaching Power Electronics with a Design-Oriented, Project-Based Learning Method at the Technical University of Denmark. IEEE Trans. Educ. 2016, 59, 32–38. [Google Scholar] [CrossRef]

- Heywood, J. Engineering Education: Research and Development in Curriculum and Instruction; Wiley Online Library: Hoboken, NJ, USA, 2006. [Google Scholar] [CrossRef]

- Bøgelund, P.; Nørgaard, B. How Do Engineering Students in a Group-Based Learning Environment Maintain and Build Motivation to Learn? Aalborg University: Aalborg, Denmark, 2018. [Google Scholar]

- Takahashi, Y.; Uda, K. Project based learning using natural energy powered small electric vehicle for sustainable technology education. In Proceedings of the 2013 13th International Conference on Control, Automation and Systems (ICCAS 2013), Gwangju, Republic of Korea, 20–23 October 2013; IEEE: New York, NY, USA, 2013; pp. 788–793. [Google Scholar] [CrossRef]

- Paterson, S.; Vijayaratnam, P.; Perera, C.; Doig, G. Design and development of the Sunswift Eve solar vehicle: A record-breaking electric car. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230. [Google Scholar] [CrossRef]

- Imdoukh, A.; Al-Mannaei, T.; Darweesh, F.; Al-Shammari, S.; Al-Khaldi, M.; Esmaeili, S. Design, Analysis, and Mechanical Assembly of a Three-Wheeled Solar-Powered Electric Vehicle. Int. J. Comput. Digit. Syst. 2020, 9, 515–522. [Google Scholar] [CrossRef]

- Diaz, M. Design and implementation of the first Duoc-UC’s solar energy powered car. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 31 March–2 April 2015; IEEE: New York, NY, USA, 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Esmaeili, S.E.; Aldandan, A.; Dallol, L.; ALdhefeeri, M.; AlSalili, O.; Badreddine, F.; Hussain, G. Design and Implementation of a One-Seater Solar Car. J. Sustain. Dev. Energy Water Environ. Syst. 2024, 12, 1120487. [Google Scholar] [CrossRef]

- Hotaling, N.; Fasse, B.B.; Bost, L.F.; Hermann, C.D.; Forest, C.R. A Quantitative Analysis of the Effects of a Multidisciplinary Engineering Capstone Design Course. J. Eng. Educ. 2012, 101, 630–656. [Google Scholar] [CrossRef]

- Crepeau, J.; Maughan, M.; Beyerlein, S.; Cordon, D.; Swenson, M.; Robertson, D.; Quallen, S. Progress of Student Competencies from Cornerstone to Capstone Design: A Longitudinal Study. Int. J. Eng. Educ. 2022, 38, 836–848. [Google Scholar]

- McDermott, K.J.; Nafalski, A.; Gol, O. Project-based teaching in engineering programs. In Proceedings of the 2007 37th Annual Frontiers in Education Conference—Global Engineering: Knowledge Without Borders, Opportunities Without Passports, Milwaukee, WI, USA, 10–13 October 2007; IEEE: New York, NY, USA, 2007; p. S1D–11–S1D–17. [Google Scholar] [CrossRef]

- Gago-Calderon, A.; Andres-Diaz, J.R.; Gonzalez-Herrera, A.; Contreras-Lopez, M.A.; Fernandez-Ramos, J. Consolidation of an EV project based learning program integrated within a complete Bachelor Engineering Degree. In Proceedings of the EVS 2017—30th International Electric Vehicle Symposium and Exhibition, Stuttgart, Germany, 9–11 October 2017. [Google Scholar]

- María, L.S.J.; José, F.-R.; Alfonso, G.-C. Design, implementation and evaluation of a control system to optimize the performance of a Permanent Magnet Synchronous Motor (PMSM) supplied by a stand-alone Photovoltaic System without batteries. REPQJ 2020, 18, 227–232. [Google Scholar] [CrossRef]

- Gago-Calderón, A.; Clavero-Ordóñez, L.; Andrés-Díaz, J.R.; Fernández-Ramos, J. Hardware Architecture and Configuration Parameters of a Low Weight Electronic Differential for Light Electric Vehicles with Two Independent Wheel Drive to Minimize Slippage. World Electr. Veh. J. 2019, 10, 23. [Google Scholar] [CrossRef]

- Carroll, D.R. The Winning Solar Car: A Design Guide for Solar Race Car Teams; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Rosas-Cervantes, D.; Fernández-Ramos, J.; Gago-Calderón, A. A photovoltaic light electric vehicle for project-based education in engineering. REPQJ 2022, 20, 192–197. [Google Scholar] [CrossRef]

- Rosas-Cervantes, D.; Fernández-Ramos, J. Un enfoque educativo en ingeniería a través del diseño de un vehículo eléctrico fotovoltaico. In Proceedings of the XVI Congreso de Tecnología, Aprendizaje y Enseñanza de la Electrónica: TAEE 2024, Malaga, Spain, 26–28 June 2024; Libro de Actas. Universidad de Málaga (UMA): Malaga, Spain, 2024; pp. 279–284. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=9757958 (accessed on 3 March 2025).

| Edition | 2021/2022 | 2023/2024 | ||||

|---|---|---|---|---|---|---|

| Tasks | Hours/ Session | Hours/ Student | Student/ Session | Hours/ Session | Hours/ Student | Student/ Session |

| Chassis | 47 | 124.5 | 2.65 | 55 | 258 | 4.69 |

| Photovoltaic generator | 51.5 | 127.5 | 2.48 | 49.5 | 119.5 | 2.41 |

| Mechanical systems | 67.5 | 217 | 3.21 | 42 | 167.5 | 3.99 |

| Electrical system | 35.5 | 87.5 | 2.46 | 16 | 46 | 2.88 |

| Total | 201.5 | 556.5 | 2.68 | 162.5 | 591 | 3.64 |

| Edition | 2021/2022 | 2023/2024 | ||||

|---|---|---|---|---|---|---|

| Nº Weeks | Total Nº of Hours | Hours/ Week | Nº Weeks | Total Nº of Hours | Hours/ Week | |

| 17.25 | 57.19 | 3.32 | 26.27 | 45.83 | 1.74 | |

| 7.25 | 32.71 | - | 5.03 | 13.48 | - | |

| Edition | 2021/2022 | 2023/2024 |

|---|---|---|

| Overall dimensions (length/width/height) (m) | 3.00/1.65/0.75 | 2.92/1.62/0.75 |

| Track/wheelbase (m) | 1.35/1.80 | 1.25/1.75 |

| Total weight (kg) | 101.9 | 115.7 |

| Steering system | Rack and pinion steering; Ackermann geometry | Single tie rod and drag link system; Ackermann geometry |

| Braking system | Hydraulic, with four independent circuits and 160 mm disc in each wheel | |

| Propulsion system | Front-wheel drive with a motor in each wheel, Crystalyte G40, in electric differential configuration | Rear-wheel drive with a motor in each wheel, Crystalyte G40, in electric differential configuration |

| Photovoltaic generator | 224 Sunpower C60 cells distributed in two parallel arrays. Power in standard conditions: 715 Wp | |

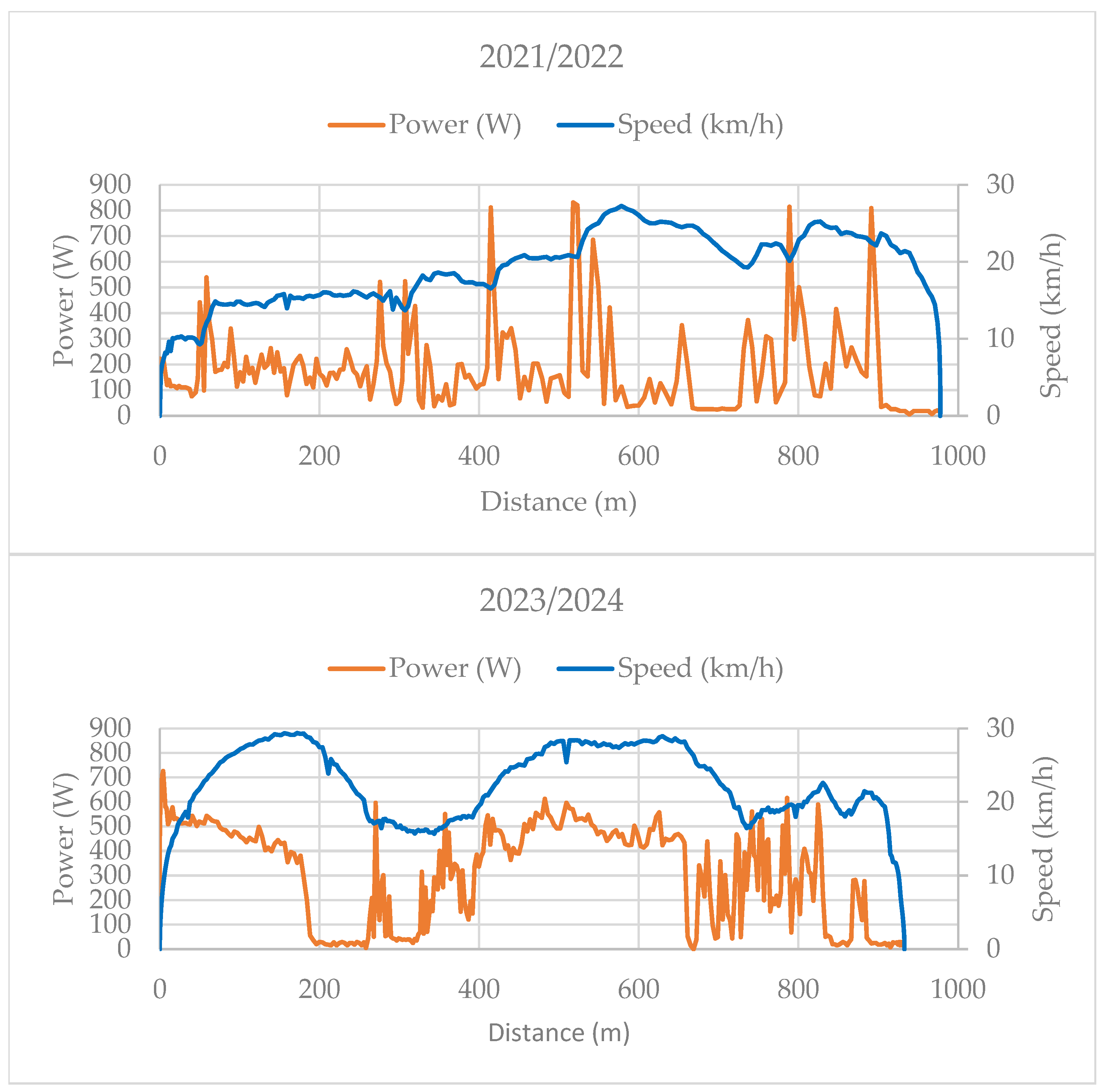

| Edition | 2021/2022 | 2023/2024 |

|---|---|---|

| Average Speed (km/h) | 17.57 | 20.51 |

| Total Time (s) | 207 | 163 |

| Average Power (W) | 178.07 | 292.87 |

| Total Energy (W·h) | 10.29 | 13.34 |

| Efficiency (km/kWh) | 95.02 | 69.92 |

| Methodology | Strengths | Weaknesses |

|---|---|---|

| EME (Everybody Makes Everything) |

|

|

| STs (Specialized Teams) |

|

|

| Methodology | |

|---|---|

| EME (Everybody Makes Everything) |

|

| STs (Specialized Teams) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosas-Cervantes, D.; Fernández-Ramos, J. Multidisciplinary Engineering Educational Programme Based on the Development of Photovoltaic Electric Vehicles. World Electr. Veh. J. 2025, 16, 583. https://doi.org/10.3390/wevj16100583

Rosas-Cervantes D, Fernández-Ramos J. Multidisciplinary Engineering Educational Programme Based on the Development of Photovoltaic Electric Vehicles. World Electric Vehicle Journal. 2025; 16(10):583. https://doi.org/10.3390/wevj16100583

Chicago/Turabian StyleRosas-Cervantes, Daniel, and José Fernández-Ramos. 2025. "Multidisciplinary Engineering Educational Programme Based on the Development of Photovoltaic Electric Vehicles" World Electric Vehicle Journal 16, no. 10: 583. https://doi.org/10.3390/wevj16100583

APA StyleRosas-Cervantes, D., & Fernández-Ramos, J. (2025). Multidisciplinary Engineering Educational Programme Based on the Development of Photovoltaic Electric Vehicles. World Electric Vehicle Journal, 16(10), 583. https://doi.org/10.3390/wevj16100583