Dual-Mode PID Control for Automotive Resolver Angle Compensation Based on a Fuzzy Self-Tuning Divide-and-Conquer Framework

Abstract

1. Introduction

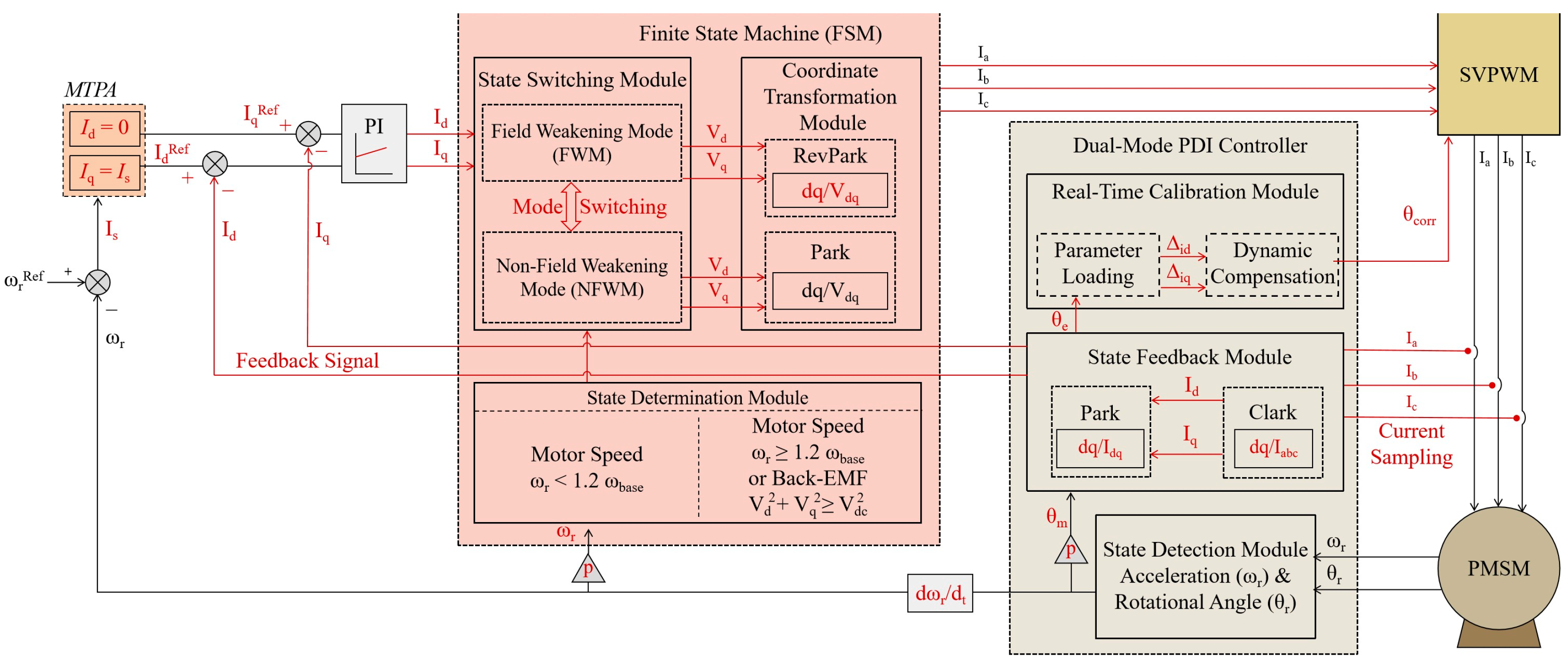

2. Materials and Methods

2.1. Weak Magnetic Field Region Modeling

2.2. Non-Weak Field Region Control

2.3. Fuzzy Logic Parameter Tuning

2.4. Experimental Setup and Procedure

2.4.1. Testbed Configuration

2.4.2. Experimental Methods

2.4.3. Procedure Details

- Operational speed monitoring

- 2.

- Current signal acquisition and transformation

- 3.

- Weak-magnetic field region compensation

- 4.

- Non-weak-magnetic field region compensation

- 5.

- Dynamic angle consistency check

- 6.

- Fault detection and recovery

3. Results

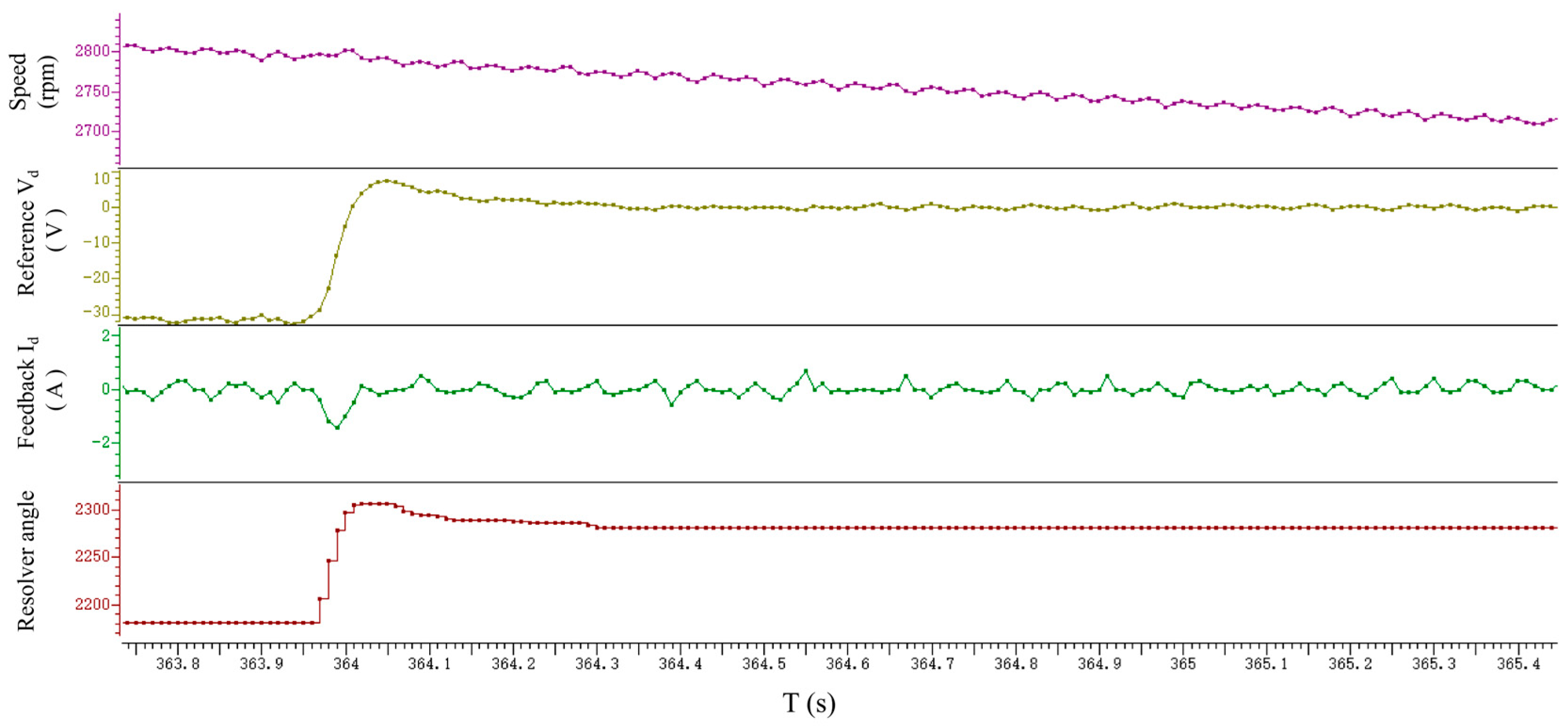

3.1. Parameter Sensitivity Testing

- Overshoot: Proportional gain (Kp) overestimation causes oscillatory divergence, with peak overshoot exceeding 25% in high-speed scenarios.

- Settling Time: Integral gain (Ki) mismatch prolongs settling time by 60% compared to optimized parameters.

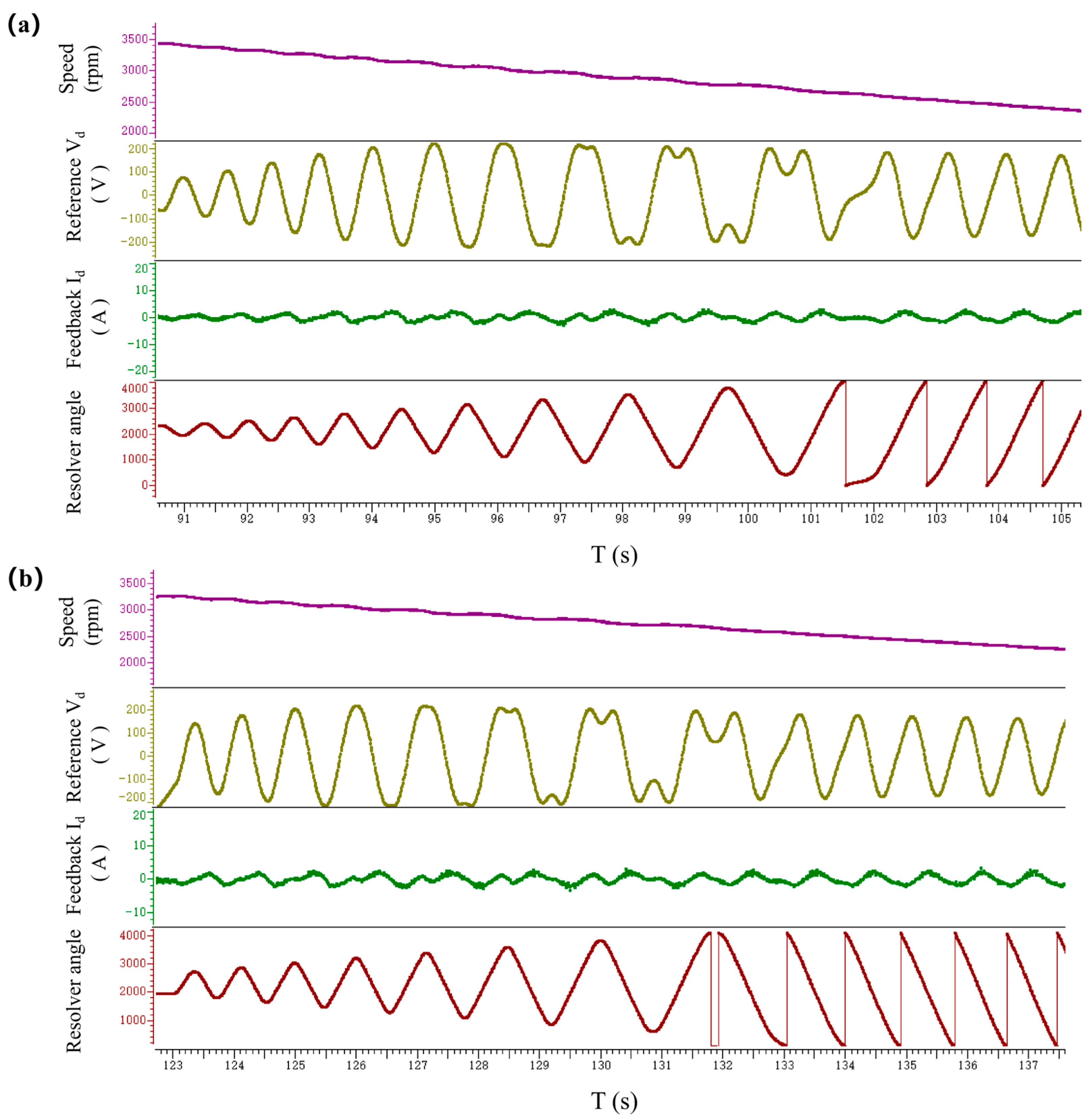

3.2. Parameter Oscillation Testing

3.3. Environmental Robustness

3.3.1. Temperature Cycling Test

3.3.2. Vibration Resistance

3.4. Dynamic Performance Metrics

- The dual-mode controller achieves 42% faster rise time and 52% lower steady-state error versus PID, which is attributed to its real-time gain adaptation.

- A 73% wider bandwidth enables superior disturbance rejection in high-frequency domains (e.g., road-induced vibrations).

- A THD reduction of 53% minimizes electromagnetic interference risks, critical for ASIL-C compliance in EV powertrains.

3.5. Computational Resource Usage

4. Discussion

4.1. Performance Advancements

4.1.1. Dynamic Response Optimization

4.1.2. Torque Ripple Suppression

4.1.3. Robustness Enhancement

4.2. Comparative Analysis

4.3. Enhanced Parameter Tuning via Kangaroo Escape Optimizer (KEO)

4.4. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mao, Y.; Zuo, S.; Cao, J. Effects of Rotor Position Error on Longitudinal Vibration of Electric Wheel System in In-Wheel PMSM Driven Vehicle. IEEE/ASME Trans. Mechatron. 2018, 23, 1314–1325. [Google Scholar] [CrossRef]

- Lara, J.; Xu, J.; Chandra, A. Effects of Rotor Position Error in the Performance of Field-Oriented-Controlled PMSM Drives for Electric Vehicle Traction Applications. IEEE Trans. Ind. Electron. 2016, 63, 4738–4751. [Google Scholar] [CrossRef]

- Tootoonchian, F. Design and Optimization of a Multi-Turn Variable Reluctance Resolver. IEEE Sens. J. 2019, 19, 7275–7282. [Google Scholar] [CrossRef]

- Wu, C.; Ying, W.R.; Zheng, L.H.; Cheng, F.M.; Zhi, E. A Dual-Sampling Differential Position Decoding Method for Resolvers. Trans. China Electrotech. Soc. 2024, 39, 4896–4908. [Google Scholar] [CrossRef]

- Wang, K.; Wu, Z. Oversampling synchronous envelope detection for resolver-to-digital conversion. IEEE Trans. Ind. Electron. 2020, 67, 4867–4876. [Google Scholar] [CrossRef]

- Guo, M.; Wu, Z.; Qin, H. Harmonics reduction for resolver-to-digital conversion via second-order generalized integrator with frequency-locked loop. IEEE Sens. J. 2021, 21, 8209–8217. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Chen, J.; Qu, R. On-Line Compensation of Resolver Periodic Error for PMSM Drives. IEEE Trans. Ind. Appl. 2019, 55, 5990–6000. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, Y.; Qiu, H.; Ren, X. High-precision rotor position correction for high-speed Permanent Magnet Synchronous Motor using resolver. IEEE Trans. Power Electron. 2020, 35, 9716–9726. [Google Scholar] [CrossRef]

- Zhang, H.X.; Fan, T.; Guo, J.; Liu, Z.Y.; Bian, Y.J.; Wen, X.H. Analysis and Elimination of Position Signal Error of Permanent Magnet Synchronous Motor. Proc. CSEE 2020, 40, 294–302. [Google Scholar]

- Cheng, S.W.; Li, X.H.; Wang, D.; Hu, Y.F.; Ji, Z.K. An online method to identify rotor position sensor error forinterior permanent magnet synchronous motors. J. Nav. Univ. Eng. 2022, 34, 1–6. [Google Scholar] [CrossRef]

- Du, C.Q.; Sun, J.H.; Li, W.H.; Ren, W.Q. Integrated Design of Thermal Management System for Pure Electric Vehicles and Research on Multi-Level Fuzzy Control Strategy. Automob. Technol. 2025, 2, 17–25. [Google Scholar] [CrossRef]

- Wang, Q.; Zheng, Y.; Liu, X. Research on Suppression of Motor Vibration and Noise Based on Structural Parameter Optimization. J. Electr. Eng. 2023, 18, 16–25. [Google Scholar] [CrossRef]

- Aranzabal, I.; Gomez-Cornejo, J.; López, I.; Zubiria, A.; Mazón, J.; Feijoo-Arostegui, A.; Gaztañaga, H. Optimal Management of an Energy Community with PV and Battery-Energy-Storage Systems. Energies 2023, 16, 789. [Google Scholar] [CrossRef]

- Da-Silva, C.T.; Dias, B.M.A.; Araújo, R.E.; Pellini, E.L.; Laganá-Armando, A.M. Battery Model Identification Approach for Electric Forklift Application. Energies 2021, 14, 6221. [Google Scholar] [CrossRef]

- Sulaiman, M.H.; Mustaffa, Z.; Saari, M.M.; Daniyal, H.; Daud, M.R.; Razali, S. Barnacles Mating Optimizer: A Bio-Inspired Algorithm for Solving Optimization Problems. In Proceedings of the 2018 19th IEEE/ACIS International Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing (SNPD), Busan, Republic of Korea, 27–29 June 2018; pp. 265–270. [Google Scholar]

- Nasri, R.; Jamii, J.; Mansouri, M.; Affi, Z.; Puig, V. A Novel Data-Driven MPC Framework Using KDE and KPCA for Autonomous Vehicles. IEEE Access 2025, 13, 109638–109656. [Google Scholar] [CrossRef]

- ISO 26262:2018; Road Vehicles—Functional Safety. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Bandur, V.; Pantelic, V.; Tomashevskiy, T.; Lawford, M. A Safety Architecture for Centralized E/E Architectures. In Proceedings of the 2021 51st Annual IEEE/IFIP International Conference on Dependable Systems and Networks Workshops (DSN-W), Tapei, Taiwan, 21–24 June 2021; pp. 67–70. [Google Scholar]

- Zhu, L.; Ma, C.; Li, W. A Novel Structure of Electromagnetic Lead Screw for Wave Energy Converter. Energies 2022, 15, 2876. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, R. Active Disturbance Rejection Control for Flux Weakening in Interior Permanent Magnet Synchronous Motor Based on Full Speed Range. World Electr. Veh. J. 2024, 15, 496. [Google Scholar] [CrossRef]

- Wang, J.C.; Zheng, J.X. Analysis of weak magnetic characteristics on novel variable main flux type outer rotor permanent magnet synchronous motor for electric vehicle drive. Int. J. Electr. Hybrid. Veh. 2024, 16, 329–341. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Qi, R. Flux-Weakening Drive for IPMSM Based on Model Predictive Control. Energies 2022, 15, 2543. [Google Scholar] [CrossRef]

- Xiao, R.X.; Peng, S.; Huang, Z.Q.; Chen, G.S. Deep flux weakening control strategy for IPMSM with variable direct axis current limitations. Electr. Eng. 2022, 104, 3425–3434. [Google Scholar] [CrossRef]

- Elhaj, A.; Alzayed, M.; Chaoui, H. Direct voltage MTPA control of interior permanent magnet synchronous motor driven electric vehicles. Control Eng. Pract. 2025, 156, 106197. [Google Scholar] [CrossRef]

- Wang, H.; Li, C.; Zhang, G.; Geng, Q.; Shi, T. Maximum Torque Per Ampere (MTPA) Control of IPMSM Systems Based on Controller Parameters Self-Modification. IEEE Trans. Veh. Technol. 2020, 69, 2613–2620. [Google Scholar] [CrossRef]

- Heidari, R. Model predictive combined vector and direct torque control of SM-PMSM with MTPA and constant stator flux magnitude analysis in the stator flux reference frame. IET Electr. Power Appl. 2020, 14, 2283–2292. [Google Scholar] [CrossRef]

- Bedetti, N.; Calligaro, S.; Petrella, R. Analytical Design and Autotuning of Adaptive Flux-Weakening Voltage Regulation Loop in IPMSM Drives with Accurate Torque Regulation. Control Engineering Practice. IEEE Trans. Ind. Appl. 2020, 56, 301–313. [Google Scholar] [CrossRef]

- Wang, H.M.; Wang, T.; Zhang, X.F.; Guo, L.Y. Voltage feedback based flux-weakening control of IPMSMs with fuzzy-PI controller. Int. J. Appl. Electromagn. Mech. 2019, 62, 31–43. [Google Scholar] [CrossRef]

- Tidke, R.; Chowdhury, A. Performance analysis of fuzzy logic-sliding mode controlled induction motor drive. Int. J. Electr. Hybrid. Veh. 2023, 15, 352–374. [Google Scholar] [CrossRef]

- Wang, M.; Liu, J.; Jiang, L.; Tan, K.; Wang, Y. Position Sensorless Control of Permanent Magnet Synchronous Motor Based on Improved Model Reference Adaptive Systems. Energies 2025, 18, 2531. [Google Scholar] [CrossRef]

- Luo, Y.; Hu, W.; Jin, G.; Xu, Q. Research on Temperature Control System Based on Cheetah Optimization Fuzzy PID Algorithm; China Automation Congress (CAC): Qingdao, China, 2024; pp. 5624–5629. [Google Scholar] [CrossRef]

- Wen, D.; Yuan, J.; Zhang, Y.; Shi, C. Improved Optimal Duty Model Predictive Current Control Strategy for PMSM. Chin. J. Electr. Eng. 2022, 8, 133–141. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Zidan, M.; Jameel, M.; Abouhawwash, M. Mantis Search Algorithm: A Novel Bio-Inspired Algorithm for Global Optimization and Engineering Design Problems. Comput. Methods Appl. Mech. Eng. 2023, 415, 116200. [Google Scholar] [CrossRef]

| Metric | Traditional PID | Dual-Mode PID |

|---|---|---|

| Settling Time (ms) | 210 | 47 |

| Overshoot (%) | 18 | 8.7 |

| Stability Margin | 0.5° (RMS) | 0.3° (RMS) |

| Indicator | Traditional PID | Dual-Mode PID | Test Conditions |

|---|---|---|---|

| Rise Time (10–90%) | 5.2 ms | 3.0 ms | Step input @ full load |

| Steady-State Error (RMS) | 0.25° | 0.12° | ±10% load disturbance |

| Bandwidth (−3 dB) | 67.3 Hz | 116.7 Hz | Sine sweep (1–500 Hz) |

| THD (Output Current) | 5.1% | 2.4% | 100% load, 50 Hz |

| Metric | Value | Measurement Context |

|---|---|---|

| CPU Load | 18.2% | Worst-case execution time (WCET) per 1 ms cycle |

| RAM Footprint | 4.8 kB | Includes stack, heap, and global variables |

| Flash Usage | 12.1 kB | Algorithm code + lookup tables |

| Interrupt Latency | ≤5 μs | Verified via logic analyzer probes |

| Metric | Conventional PID | Proposed Dual-Mode PID |

|---|---|---|

| Settling Time (12,000 rpm) | 180 ms | 52 ms |

| Torque Ripple (12,000 rpm) | 8.2% | 4.7% |

| Environmental Robustness | Limited | ASIL-C Compliant |

| Parameter Sensitivity | High | Low (fuzzy self-tuning) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, X.; Wang, Y.; Zhu, J.; Chu, Y.; Li, H.; Peng, H. Dual-Mode PID Control for Automotive Resolver Angle Compensation Based on a Fuzzy Self-Tuning Divide-and-Conquer Framework. World Electr. Veh. J. 2025, 16, 546. https://doi.org/10.3390/wevj16100546

Zeng X, Wang Y, Zhu J, Chu Y, Li H, Peng H. Dual-Mode PID Control for Automotive Resolver Angle Compensation Based on a Fuzzy Self-Tuning Divide-and-Conquer Framework. World Electric Vehicle Journal. 2025; 16(10):546. https://doi.org/10.3390/wevj16100546

Chicago/Turabian StyleZeng, Xin, Yongyuan Wang, Julian Zhu, Yubo Chu, Hao Li, and Hao Peng. 2025. "Dual-Mode PID Control for Automotive Resolver Angle Compensation Based on a Fuzzy Self-Tuning Divide-and-Conquer Framework" World Electric Vehicle Journal 16, no. 10: 546. https://doi.org/10.3390/wevj16100546

APA StyleZeng, X., Wang, Y., Zhu, J., Chu, Y., Li, H., & Peng, H. (2025). Dual-Mode PID Control for Automotive Resolver Angle Compensation Based on a Fuzzy Self-Tuning Divide-and-Conquer Framework. World Electric Vehicle Journal, 16(10), 546. https://doi.org/10.3390/wevj16100546