1. Introduction

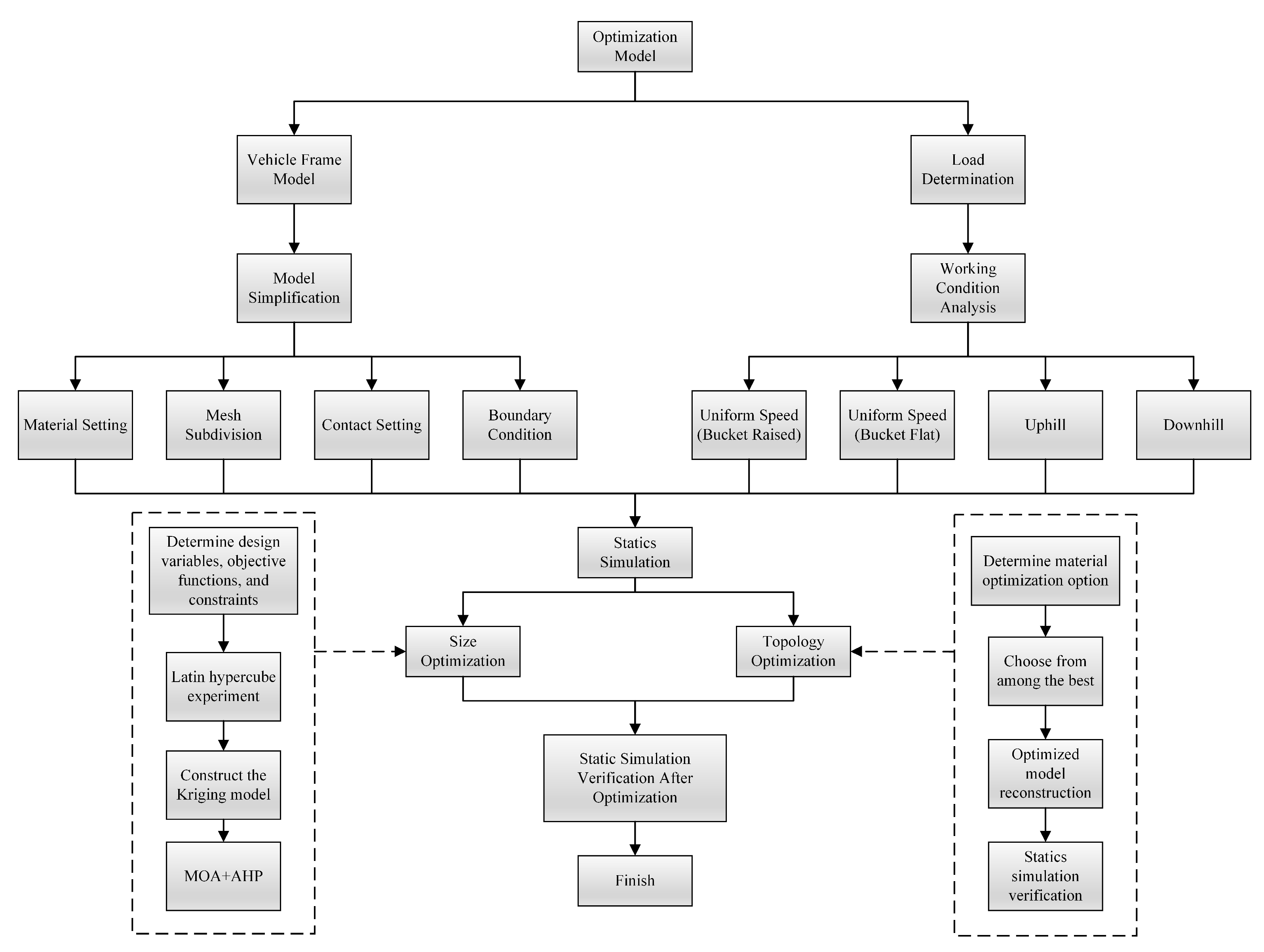

A vehicle’s frame is the vehicle’s skeleton and support system, and it has a significant effect on both performance and safety. The traditional method of designing frames is primarily based on expertise and trial and error, so it is less effective and cannot provide an optimal frame design. The application of finite element analysis (FEA) technology to the design of the best vehicle frames has become a research hotspot with the advancement of FEA technology. However, the current frame optimization design mainly focuses on size optimization or topology optimization and ignores the method of combining the two, which makes the frame optimization design process have certain limitations and shortcomings. Thus, this study will investigate how to combine dimensional optimization and topology optimization to optimize a mixer truck frame’s design and enhance the frame’s performance and safety, all based on the ANSYS Workbench 2020R2 software.

Size optimization belongs to one kind of parametric optimization technique; it is a very classical and frequently used structural optimization technique. It can reduce the system’s overall weight and energy consumption and make the whole system more compact by changing the size and shape of the parts and components in the system. For instance, it can optimize the structure’s thickness, beam and rod cross sections, the moment of inertia, the stiffness of elastic elements, and other parameters. At present, the main size optimization techniques are the mathematical planning method and the optimality criterion method [

1]. Sensitivity analysis is a highly effective method of performing size optimization for large and complex engineering problems.

In academic research, topology optimization is a mathematical technique. The material distribution within a designated area is optimized by taking into account specific loading conditions, constraints, and performance metrics. Finding the best material distribution path inside a predetermined design space is the main goal. This is carried out to satisfy several performance requirements and produce the lightest design possible. Homogenization, the variable thickness method, variable density method, level set method, evolutionary structural optimization (ESO), and the independent continuous mapping method (ICM) are currently widely used topology optimization techniques [

2]. The variable density method, which was developed from the basis of density-based topology optimization techniques, is the most often used method. To obtain a more optimized result, the core concept is to use different density parameters in different areas of the structure.

Size optimization and topology optimization have been widely researched in recent years, with significant applications in engineering design, materials science, and other fields. Abroad, the research and application of size optimization and topology optimization are highly advanced. Currently, major foreign research institutions and scholars are employing topology optimization and size optimization methods for the design and optimization of aerospace structures, mechanical manufacturing, architectural structures, and automotive engineering. This ongoing trend continually propels the application and development of size optimization and topology optimization. Michell first proposed the concept of topology optimization in truss theory in 1904 [

3], and the optimal design of structural topology, based on the homogenization theory published by Bendsoe and Kikuchi in 1988, opened a new situation in the study of optimal designs for the topology of continuum structures [

4]. Soon after the homogenization theory was developed, Bendsoe introduced a density function of continuous design variables, which is also referred to as Solid Isotropic Materials with Penalties (SIMP) [

5]; this allowed for the elimination of the discrete nature of the problem in many ways. The evolutionary structural optimization method was proposed by Steven GP and Xie YM in 1993 [

6]. The intermediate density values in the SIMP model were properly physically interpreted by Bendsoe and Sigmund in 1999. This meant that the stiffness that could be obtained from the SIMP model could actually be realized as the stiffness of a microstructure made up of the number of solid materials corresponding to the voids and the corresponding densities. This demonstrated that density-based approaches have physical significance [

7]. Many academics have been researching topology optimization in various domains in recent years. For instance, Cetin B. Dilgen et al. applied topology optimization to fluid system turbulence in 2018 and introduced the use of the automatic differentiation method for exact sensitivity in large-scale two- and three-dimensional turbulence topology optimization problems. The findings demonstrated the significance of exact sensitivity analysis and opened up new avenues for the design of turbulence-related large-scale multi-physics field problems [

8]. In order to achieve design results comparable to those obtained using free-form topology optimization techniques, Julián A. Norato (2018) proposed a continuum-based structural topology optimization method, which was demonstrated to be effective by numerical examples [

9]. In 2019, I. Sosnovik and I. Oseledets proposed a neural network as an efficient tool for accelerating the topology optimization process that significantly reduces the optimization time consumption [

10]. Pedro Gomes and Rafael Palacios (2020) investigated the use of topology optimization in the elastic and aerodynamic design of flexible wings. They used a geometrically nonlinear finite element structural solver in conjunction with a Reynolds-averaged Navier–Stokes finite volume solver [

11].

The history of size optimization development can be traced back to the 1960s. With the development of computer technology and finite element analysis methods, size optimization methods have been gradually introduced into the engineering field and have been widely applied and studied. In the late 1960s and early 1970s, the earliest size optimization methods mainly used some direct optimization methods, such as the variable load, stiffness matrix, direct deformation method, and so on. The main advantage of these methods is that they are easy to understand and implement, but they are limited by computational power and accuracy. By the mid-1970s, with the development of digital computers and the application of the finite element method, size optimization methods began to enter a new stage of theory and practical application. Currently, the majority of size optimization techniques are based on finite element methods and are optimized through mathematical planning techniques, like strength assumptions, as demonstrated by Koiter [

12]; optimization methods for elastic structures, as demonstrated by Pian and Sumihara [

13]; as well as feasible domain methods, as demonstrated by Rozvany [

14]. After the 1980s, size optimization methods were further developed, and methods based on variable transformation and sensitivity analysis appeared; these techniques include the Lagrangian method, the proposed Newton method, the coefficient optimization method, and others. The main advantages of these methods are their high efficiency and flexibility, which can effectively solve some practical engineering problems. Also, there are some important works in this phase, such as the finite element substructure and spatial lattice grid methods proposed by Arora and Cheng [

15], and the multi-objective optimization methods proposed by Svanberg and Sobieszczanski-Sobieski et al. [

16]. From the 1990s to the present, size optimization methods have been widely used, especially in industry. With the rapid development of computer technology, the speed of size optimization calculation has been significantly improved. In addition, cross-research with the fields of mechanics of materials, engineering mechanics, and computer science has also received extensive attention. At this stage, the research focus shifted to multi-objective optimization, structural optimization, optimal design, and multidisciplinary optimization. Meanwhile, with the development of advanced computer technology and optimization algorithms, the application prospect of size optimization will become broader and provide strong support for practical engineering applications.

In addition, in recent years, electric vehicles, as part of renewable energy, have become important components of energy sustainability. The rise of electric vehicles brings new challenges and opportunities for energy management. In a multi-energy hybrid system, more intelligent, flexible, and sustainable energy utilization can be achieved by effectively integrating resources such as combined heat and power (CHP), green energy, fuel cells, and plug-in electric vehicles (PEVs). Some advanced adaptive control strategies, such as the proposed Optimal Self-Tuning Fractional Order Fuzzy Controller (OSTFOF), offer new possibilities for the performance of electric vehicles in terms of resource savings. This controller optimally tunes its parameters by means of a path-finding algorithm (PFA) to adaptively obtain proportional, integral, and derivative gain values to account for nonlinearities, such as governor dead zones and power generation rate constraints, in a combined heat and power system. The simulation results show that the proposed OSTFOF controller exhibits excellent performance metrics in various scenarios compared to the conventional PI, PID, and FOPID controllers, and it provides strong support for the sustainable development of electric vehicles in the energy system [

17]. In addition, with the wide application of electric vehicles, the bidirectional power control of EV aggregators is not only regarded as an innovation, but also as an intelligent choice for distributed energy storage. This control strategy not only flexibly adjusts the energy flow in the grid, but also effectively reduces frequency and power fluctuations, providing a reliable and effective solution for the stable operation of power systems [

18]. Another way to save energy is to rationally schedule the energy consumption of electric vehicles. In order to explore the impact of electric vehicle charging/discharging decisions on energy scheduling, the problem is modeled as a two-stage optimization problem. In the first stage, the main demand of EV owners is introduced as the objective function; in the second stage, the total energy cost and emission factor are considered as the main criteria. The decision variables include the generation schedules of distributed generation (DG) technologies and the charging/discharging schedules of EVs, for which some effective modeling methods are introduced for the uncertainty of these variables. The results of the study show that it is possible to strike an effective balance between emission factors and system energy costs, emphasizing the importance of this integrated energy dispatch framework [

19]. From an integrated perspective, electric vehicles play active roles in energy management and resource utilization, contributing not only to the achievement of energy sustainability but also to the construction of a more environmentally friendly and sustainable energy future. This all-encompassing impact demonstrates the enormous potential of electric vehicles to contribute to sustainable development.

Compared with foreign countries, domestic research on size optimization and topology optimization has had a late start. However, with the rapid development of China’s manufacturing industry in recent years, the application of size optimization and topology optimization in engineering design and manufacturing has gradually increased, and related research and application in China has also gradually emerged. Currently, some domestic research institutions and universities have begun to carry out research on size optimization and topology optimization, involving aerospace, automotive engineering, building structures, and other fields. At the same time, some enterprises have begun to use these methods for product design and manufacturing, which promotes the development of size optimization and topology optimization technology. The development of domestic topology optimization can be traced back to the late 1980s and early 1990s, when it was mainly engaged in the research of structural topology design. In the late 1980s and early 1990s, this stage was mainly led by scholars at home and abroad, and the theoretical foundation of structural topology optimization was gradually established, but it was mainly based on the research of a two-dimensional model, which was relatively simple and rough. By the early 2000s, a period of rapid development of topology optimization research began in China. Drawing from the results of advanced research conducted abroad, domestic scholars started conducting a great deal of research using techniques like the MMA method, SIMP method, LP planning, etc. [

20]. At this point, domestic researchers also started looking into the use of topology optimization in engineering applications, including ship structures, mechanical parts, automotive parts, and other areas. Between 2000 and 2010, researchers in the country started using topology optimization for more intricate structural designs, consisting of microscale, nonlinear, and multi-physics field optimization. Furthermore, a few topology optimization programs, including TOGO and TOMO, started to surface in China [

21]. In China, topology optimization finally reached the stage of multidisciplinary integration since 2010 [

22]. This includes applications in the fields of construction, subterranean engineering, electronic circuits, and machinery in addition to aerospace, aviation, and other fields. Additionally, some new topology optimization methods, like Hybrid Element Topology Optimization (HETOP) [

23], have emerged in recent years, which are expected to provide better solutions for more complex structural designs.

It is evident from the aforementioned analysis that most current research on vehicle frame optimization is conducted in one of two directions: size optimization or topology optimization. However, very few studies take into account both of these factors in their entirety. Topology optimization focuses on the rationality of shape and the efficient use of materials, yet it frequently encounters the issue of insufficient structural stiffness in real-world engineering applications. Size optimization seeks structural compactness and stiffness; nevertheless, pursuing only stiffness may result in an unneeded increase in weight. Performance trade-offs can easily result from the two being optimized separately. To create a lightweight vehicle frame that still maintains adequate stiffness and strength, this study tries to investigate the natural fusion of size optimization and topology optimization. The ultimate goal is to offer a more creative and effective solution for the long-term advancement of automotive engineering. This paper’s primary research involves the following:

(1) An automatic loading and unloading mixer truck is used as an example to thoroughly examine a mixer truck’s overall load-bearing performance; to carry out a multi-case stress analysis and static finite element analysis; to identify the riskiest operating circumstances; and to study structural modal characteristics before vehicle frame optimization.

(2) A sensitivity analysis is used to filter out the important structural parameters and design variables that significantly affect a vehicle’s frame weight; structural static characteristics as well as structural modal characteristics are chosen. The Kriging method is used to create an approximate model of the vehicle’s frame weight and maximum stress. After that, the multi-objective genetic algorithm is combined with the hierarchical analysis method to optimize the vehicle frame with the goals of minimum mass and maximum stress.

(3) The size and topology optimization techniques are combined to fully optimize the vehicle frame’s structural parameters. Ultimately, the optimized frame’s simulation and experiments confirm its dependability under a range of operating conditions and show off the frame’s outstanding performance under a load.

8. Topology Optimization of Mixer Truck Frame

Through the above optimization of the frame size, the reduction in the thickness of the frame bracket arm is realized. However, the frame structure obtained by size optimization only reduces the thickness of some parts in the frame and cannot be used as the result of the final design. Therefore, it is also necessary to carry out topology optimization on the structure based on the frame size optimization.

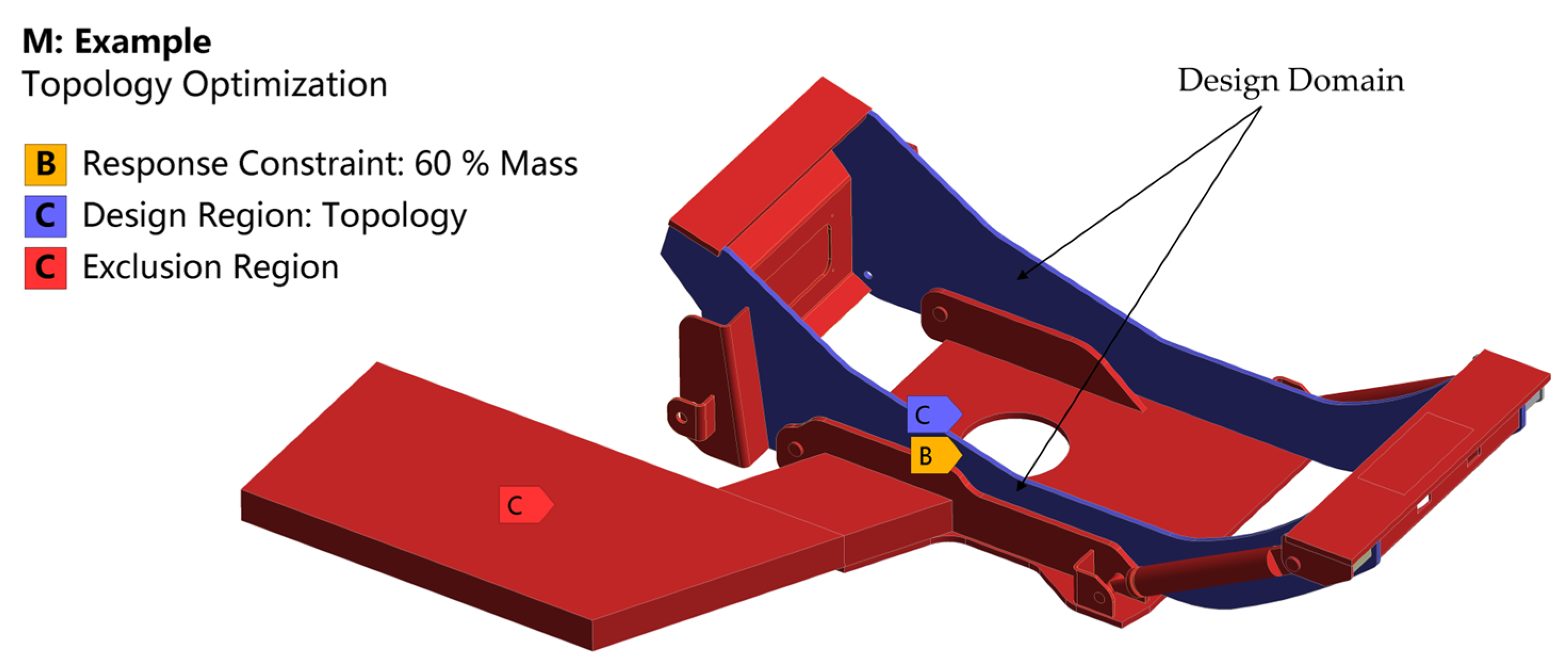

Topology optimization can further optimize the structure of the frame and find the optimal material distribution scheme in the optimization space of uniform materials. The scheme is reflected as a “maximum stiffness” design in topology optimization. On the basis of size optimization, it is made more lightweight with higher strength and better stiffness while reducing material waste and manufacturing costs. In addition, topology optimization can also reduce noise and vibration and improve the comfort and stability of the frame, thereby improving the performance and safety of the vehicle. After considering the structural performance requirements, weight optimization manufacturing feasibility, cost, etc., this paper uses three schemes for topology optimization; compares the material density change thresholds of 0.2, 0.4, and 0.5; and then selects the best among them. The division results of the frame optimization design domain are shown in

Figure 15, where the tank arm on both sides of the frame is the design domain, and the rest of the area is the non-design domain.

The topology optimization results for setting the material density change thresholds to 0.2, 0.4, and 0.5 are shown in

Figure 16,

Figure 17 and

Figure 18. Considering the feasibility and performance of the frame, the topology optimization with a threshold of 0.4 results in a balance between feasibility and performance. Lower thresholds may lead to excessive material removal, resulting in structural fragility or instability, while higher thresholds may retain too much material, limiting performance gains. Selecting a threshold of 0.4 can achieve a higher level of optimization performance while maintaining structural feasibility.

According to the topology optimization results with a threshold of 0.4, and considering the processing property of the frame, the optimized area is reasonably removed, and the frame structure of the automatic loading and unloading mixer truck after topology optimization is obtained, as shown in

Figure 19. The comparison reveals that the topology-optimized frame structure has achieved weight reduction by digging some polygonal holes in the non-assembled areas. After the optimization, the bracket arm on both sides of the frame is reduced by 76.207 Kg compared with that before optimization, and the overall weight of the frame is reduced by 11.96% compared with that before optimization.

After the optimization of the frame of the first 15 orders of modes, shown in

Table 7, it can be seen that 1~6 orders are also rigid body modes, the frequency of the first 10 orders is lower than the frequency of the engine idling, and the frequency of the last 5 orders is also lower than the frequency of the engine that commonly used. Additionally, it can be seen in

Table 7 that the frequency of the frame of the various orders of changes in the stability of the phenomenon does not have prominence. Based on the above analysis, the design of the frame is reasonable and meets the requirements of the vehicle.

After size optimization and topology optimization, the overall optimized frame performance was significantly changed, as shown in

Table 8, where the weight, maximum stress, factor of safety, maximum strain, and first-order intrinsic frequency of the frame were again changed.

By comparing the data in

Table 8, it can be seen that the topology optimization had a significant impact on the performance of the frame. After size optimization, the total weight of the frame was reduced from 1214.4 kg to 1138.2 kg, which is a 6.27% reduction. In addition, the maximum stress of the frame increased from 177.07 Mpa to 183.39 Mpa, which is a 3.57% increase, but it still stays within the permissible stress of the frame, which is not more than 235 Mpa. The minimum safety factor of the frame also decreased slightly, from 1.33 to 1.28, which is a 3.76% decrease. Meanwhile, the maximum strain of the frame is increased from 0.00086195 to 0.00092352 after topology optimization, which is a significant increase of 7.14%. In terms of the structural dynamic characteristics, the first-order intrinsic frequency of the frame is slightly increased from 9.08 Hz before optimization to 9.17 Hz, which is an increase of 0.99%.

The results of this series of optimizations show that the structure of the frame is effectively improved through topology optimization. The maximum stress is still within the allowable stress range of the structure, the mass is reduced, and the dynamic response of the structure is also improved. This not only provides a feasible way to improve the performance of the vehicle, but also provides a useful reference for the optimization of the structure of similar electric vehicles in the design stage.

The optimized frame was assembled to the mixer truck and tested again for working condition b, or bucket lift.

Figure 20a presents the results of the size-optimized test, representing the scenario where the mixer truck is on a 15-degree slope with the bucket in a flat position. The optimized chassis demonstrated excellent performance under this condition, showing no signs of bending or fracture.

Additionally, the independent test depicted in

Figure 20b involves rotating the upper part of the mixer truck by 90 degrees with the bucket in a flat position, and similarly, no failure was observed. Meanwhile,

Figure 20c illustrates the comprehensive test of the mixer truck chassis after size and topology optimizations, simulating the scenario where the bucket is full and in a flat position during operation. In this comprehensive test, neither structural nor material failure occurred, laying a solid foundation for the reliability of future lightweight electric chassis. These test results strongly validate the credibility of our optimization strategy, providing robust support for future chassis design.

9. Conclusions

Taking the frame of the automatic loading and unloading mixer truck as the research example, this paper proposes the design optimization of the structural parameters of the frame based on the combination of the Kriging model and hierarchical analysis method, and on this basis, the material distribution of the frame is optimized by using topology optimization, which provides an efficient optimization design method to make the frame of the electric vehicle lightweight. The following conclusions can be drawn:

(1) On the basis of the in-depth analysis of the overall load-bearing performance of the automatic loading and unloading mixer truck, the frame was subjected to a multi-case stress analysis and static finite element analysis so as to identify the most dangerous working conditions. Secondly, the structural modal characteristics of the frame were studied before optimization, which paved the way for the subsequent refined size optimization and optimization strategy with topological features.

(2) In order to improve the efficiency and accuracy of the optimization of the frame’s structural parameters, the structural parameters that have significant influences on the frame’s weight, structural static characteristics, and structural modal characteristics are screened out as design variables through a sensitivity analysis. An approximate model of the frame’s weight and maximum stress is constructed by using the Kriging model, and a hybrid model based on the combination of the Kriging model and hierarchical analysis is used to optimize the frame with the objectives of a minimum frame mass and maximum stress. By comparing the iterative curves of the hybrid model and the single model in terms of the frame’s weight, it can be concluded that the initial optimization efficiency of the hybrid model is about double compared with that of the AHP model, and the final optimization result of the hybrid model is about 3.6% higher compared with that of the Kriging model, which proves that this method can be used as an effective tool for the multi-objective optimization of electric vehicle frames and can provide higher efficiency and accuracy.

(3) The structural parameters of the frame are comprehensively improved by integrating the two methods of size optimization and topology optimization. This integrated optimization method significantly improves the optimization efficiency and accuracy. The results show that during the size optimization stage, the thickness of the key components of the frame is reduced by 78.4 Kg, and although the maximum stress of the frame rises from 152.28 MPa to 177.07 MPa, it is still within the allowable stress range (235 MPa). The correctness of the size optimization was verified in subsequent frame experiments. Subsequently, through topology optimization, the weight of the bracket arms on both sides of the frame was reduced by 76.2 Kg. The maximum stress of the frame increased from 177.07 MPa to 183.39 MPa, which, again, did not exceed the allowable stress of the material. Through the field experiments of the frame under working condition b, it was found that the frame shows good performance under load conditions, which further verifies its reliability under actual working conditions. In summary, this method not only provides a new idea for the optimization design of electric vehicle components, but also has a wide application potential and provides a useful reference for engineering practice and technical research in the field of electric vehicles.