1. Introduction

The advent of permanent magnet materials in the previous century has significantly enhanced the operational performance of motors due to their amalgamation of a high core flux density, high coercivity, and a substantial magnetic energy product [

1,

2,

3]. These materials are typically integrated into either the rotor or the stator of motors, leading to the design of rotor-type or stator-type permanent magnet motors, respectively. The specific configurations of these motors vary according to the shape and positioning of the permanent magnet materials. Over the last decade, research has demonstrated that the fundamental structure of permanent magnet motors significantly impacts their thermal behavior and electromagnetic properties, despite the advent of various control technologies [

4,

5]. This paper aims to provide a detailed review and comprehensive analysis of the Special Issue titled “Temperature Field, Electromagnetic Field, and Operation Control of Permanent Magnet Motor for Electric Vehicles”, which focuses on cutting-edge technologies and theories pertinent to the use of permanent magnet motors in electric vehicles.

Electric vehicles, characterized by multimodal operation demands such as starting, accelerating, and climbing, require permanent magnet motors that exhibit the following performance characteristics [

6,

7,

8,

9]:

Compact size and a light weight;

High efficiency throughout the whole speed spectrum;

Low speed and high torque characteristics;

Constant power within a wide speed range;

High safety and reliability;

High voltage;

High speed;

High mechanical stress;

Low temperature rises;

High power density.

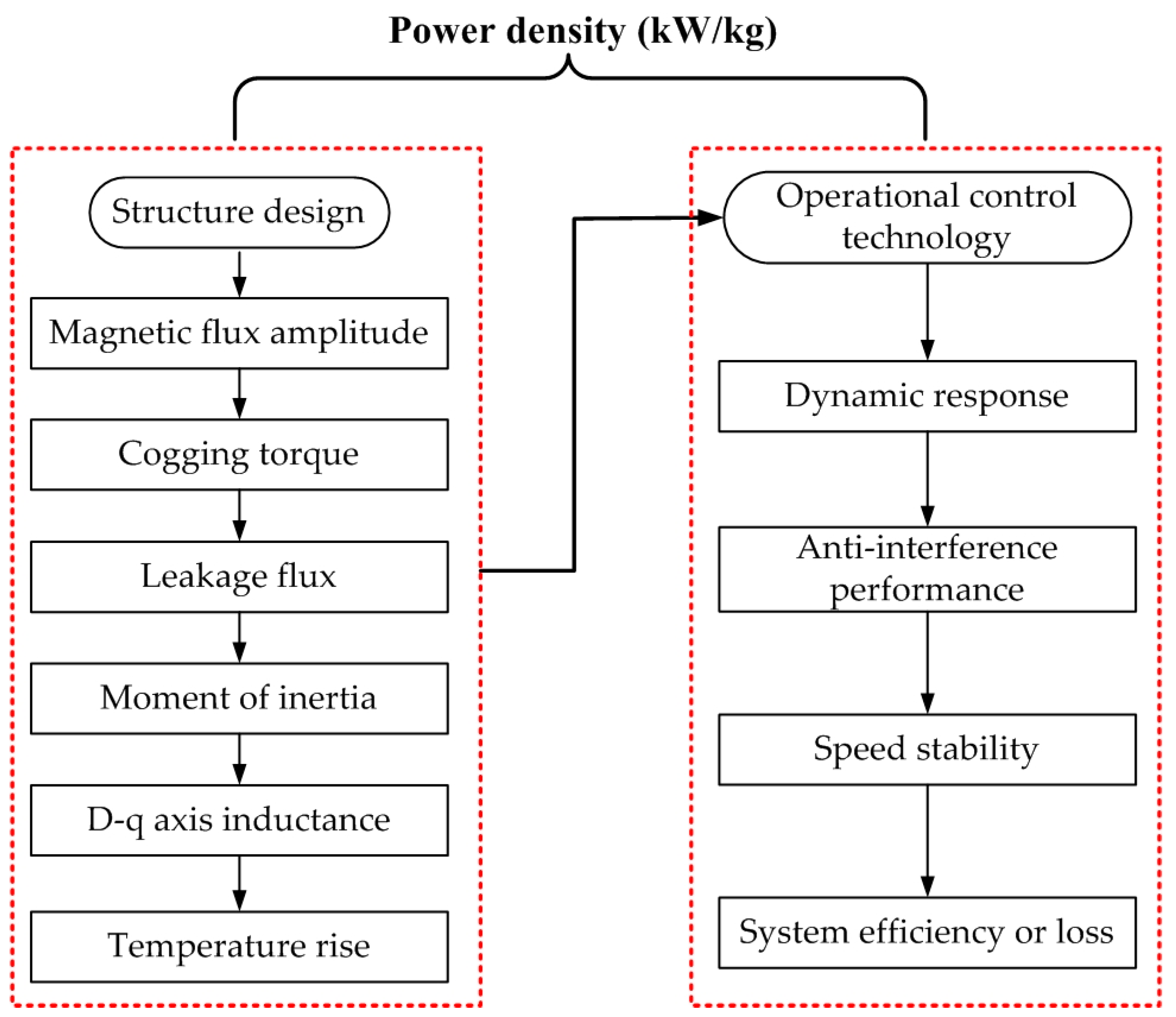

These performance traits underscore the importance of structural design and operational control technology as fundamental elements in the research on the use of permanent magnet motors for electric vehicles, as illustrated in

Figure 1. From

Figure 1, it is evident that the structural design is not only crucial for optimizing the magnetic flux amplitude, cogging torque, leakage flux, moment of inertia, and

d-

q axis inductance, but also influences the dynamic performance of the motor. Concurrently, operational control technology governs the dynamic response, anti-interference capability, speed stability, and system efficiency of the motor. The power density (kW/kg) of the motor is a function of both the structural design and operational control technology, with a high power density facilitating cost reductions and efficiency enhancements in practical applications.

Despite many scholars and experts focusing on structural design and operational control technology in the context of permanent magnet motors for electric vehicles, the issue of temperature rises has been largely overlooked. For instance, a review of publications across all MDPI (Multidisciplinary Digital Publishing Institute) journals over the past decade (2014–2024) reveals a significant disparity in research focus:

Given this research landscape, the objective of this Special Issue is to encourage scholars and experts to intensify their investigations into the drive motors of electric vehicles. This Special Issue welcomes submissions that explore structural design within the constraints of electric vehicles, electromagnetic modeling, computational methods, operational control technologies, and temperature rises. Additionally, contributions on new and emerging topics relevant to the drive motors of electric vehicles are encouraged. While theoretical analyses form the core of the submissions, there is a particular emphasis on practice-oriented research that builds on theoretical foundations.

Fifteen manuscripts were submitted for review in this Special Issue, with ten manuscripts accepted for publication. The principal topics addressed in each paper are summarized in

Table 1.

2. Structural Design of Permanent Magnet Motors

Permanent magnet motors used in electric vehicles are characterized by their high-speed operation, ranging from a base speed of 4000 RPM to an extended speed of 12,000 RPM. At high speeds, centrifugal forces become a critical constraint, particularly in the rotor section of permanent magnet motors, which lacks additional mechanical containment. Consequently, the structural design phase of the permanent magnet motor necessitates the simultaneous consideration of both centrifugal forces and electromagnetic characteristics.

Paper 1 utilizes a linear elastic model within ANSYS software to analyze the centrifugal forces in the rotor section of a permanent magnet motor, alongside an examination of the motor’s electromagnetic characteristics. This model facilitated the optimal structural design of the rotor section, resulting in a final rotor diameter of 165 mm and a shaft length of 103 mm. Moreover, the optimized design concerning electromagnetic characteristics and centrifugal forces enabled the motor to achieve a high power density of 2.4 kW/kg.

During the design of rotor sections with varying diameters, the simulation results indicated that increased power and torque densities in the permanent magnet motor corresponded to an increased leakage flux between the adjacent regions of individual magnet poles. Leakage fluxes are indicative of reduced efficiency in the permanent magnet motor. Consequently, an optimum rotor diameter of 165 mm was determined through a comparative analysis of speed, centrifugal forces, and current density.

Paper 1 also explores the impact of the rotor diameter and shaft length on the hub diameter. For a hub-type permanent magnet motor with a rotor diameter of 165 mm, the calculated electromagnetic torque significantly increases once the hub diameter exceeds 115 mm. This phenomenon is primarily attributed to the magnetic saturation of the leakage flux path in the rotor as the hub diameter increases, thereby enhancing the effective air gap flux and electromagnetic torque between the rotor and stator sections.

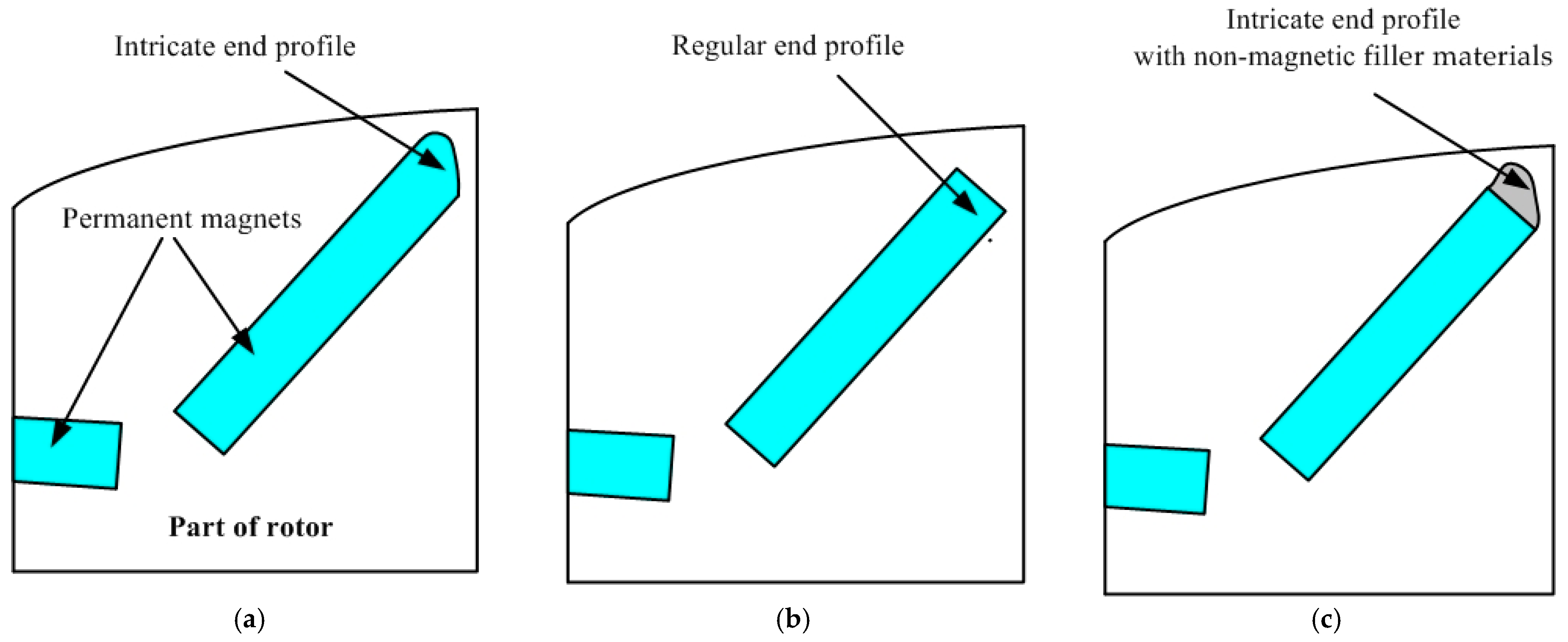

Furthermore, an important finding of Paper 1 is that the permanent magnet profile influences the rotor section on both the electromagnetic torque and the maximum localized stress within the motor. Under consistent conditions of speed, dimensions, materials, etc., the simulation results for electromagnetic torque and maximum localized stress with various permanent magnet profiles are detailed in

Table 2, and specific rotor section profiles are illustrated in

Figure 2. Considering factors such as manufacturing difficulty, cost, and performance requirements, a suitable rotor structure for the permanent magnet motor can be determined using the analytical models and methods.

3. Temperature Rises in Permanent Magnet Motors

The high torque density and speed inherent in permanent magnet motors lead to a temperature rise in certain internal components. Consequently, developing effective temperature regulation or cooling systems for drive motor systems of electric vehicles has become a crucial research topic.

The conventional method for calculating the temperature rises in permanent magnet motors primarily uses finite element software integrated with computational fluid dynamics (CFD). However, this method has significant drawbacks: it is time-consuming and requires high-performance computing capabilities. Paper 2 introduces a highly efficient method called the equivalent thermal network, which calculates the thermal resistance at each node of the permanent magnet motor. The results validate that the proposed method’s calculation error is less than 5%, and it significantly reduces the calculation time to 194 s. Furthermore, Paper 2 offers a detailed analysis of the sources of calculation error, primarily attributing them to the low thermal conductivity of the potting material in the equivalent thermal network model being overlooked.

Paper 3 outlines the design of an automotive cooling system equipped with an adequately structured fan to effectively manage the thermal conditions of permanent magnet motors in electric vehicles. The experimental findings indicate that the internal temperature of the motor increases gradually during the initial operation phase (from 0 to 3300 s) and subsequently stabilizes. Extended operation within the temperature range of 120 °C to 160 °C markedly reduces the motor’s operational efficiency. Thus, an active cooling system is indispensable for managing the heat in high-torque and high-speed scenarios in electric vehicle motors.

Moreover, appropriate control technology not only ensures reasonable management of the motor’s temperature rise but also helps regulate the battery’s temperature to prevent it from exceeding safe limits. Paper 3 proposes a novel space vector pulse width modulation (SVPWM) algorithm with dead zone regulation, termed dSVPWM, to adjust the temperature rises in both the permanent magnet motor and the battery. The simulation results demonstrate that the dSVPWM algorithm effectively maintains the battery’s minimum temperature and affirms the feasibility of the motor’s speed control. Additionally, compared to the conventional SVPWM algorithm, the dSVPWM algorithm maintains the sinusoidal fluctuations in the phase current and phase difference at consistent levels.

Looking ahead, research on temperature rises in permanent magnet motors should focus on developing a comprehensive analytical model that incorporates both operational and heating efficiencies. This model would facilitate the exploration of temperature-sensitive parameters in permanent magnet motors, thereby enabling the swift and efficient regulation of temperature based on these parameters.

4. Operational Control of Permanent Magnet Motor

The primary operating characteristics of permanent magnet motors, such as the speed stability, dynamic response, and anti-disturbance performance, are significantly influenced by the control methods employed. To enhance these characteristics, it is essential to explore and implement two closed-loop control processes: current closed-loop control and speed closed-loop control. Paper 5 introduces an internal model control (IMC) method combined with inverter switching frequency to improve the

dq-axis current response time. Both the simulation and the experimental results demonstrate that the inverter’s switching frequency critically affects the

dq-axis current response time, as detailed in

Table 3. The parameter “Tpwm” represents the inverter switching period. Furthermore, data from

Table 3 also indicate that the IMC-PI method offers substantial advantages in terms of the control parameter settings and remains unaffected by the inverter switching period.

Indeed, the operational performance of permanent magnet motors is determined by the comprehensive application of both current closed-loop and speed closed-loop controls. Papers 6 and 7 adopted the vector control method and direct torque control method, respectively, incorporating these two closed-loop processes to enhance motor performance. In Paper 6, a direct torque control model with a primary–secondary virtual vector was developed and validated, reducing the fluctuations in electromagnetic torque and flux linkages in the permanent magnet motor and significantly decreasing high-order harmonics in the phase current by 69.4%. Paper 7 introduced an extended state observer (ESO) based on sliding mode control (SMC) to improve the speed stability and anti-interference performance of the motor. Compared with the traditional SMC method and linear SMC-ESO method, the experimental results from this paper reveal that only the nonlinear SMC-ESO method effectively enhances both speed stability and anti-interference performance.

In the operational control of permanent magnet motors, dynamic characteristic parameters play a pivotal role in the motors’ performance. Consequently, Papers 8 and 9 focus on the online detection or identification of these parameters. Paper 8 proposes a comprehensive detection method that combines open-phase faults (OPF) and open-switching faults (OSF) to enhance the dynamic response capability and anti-disturbance performance of dual three-phase permanent magnet motors. The test results confirm the validity of the proposed method, with an accuracy rate of 97%. Paper 9 utilizes the recursive least squares algorithm and particle swarm optimization to identify the d-axis and q-axis inductances. The accurate identification of these inductances allows for the stable and precise speed regulation of the motor using the sensorless control method.

5. Future Research of Drive Motor for Electric Vehicles

The total drive system of electric vehicles encompasses the inverter, controller, drive motor, sensors, and software. While this Special Issue focuses on the structural design, temperature rises, and operational control of permanent magnet motors, it is imperative to extend research to other related areas, such as power quality, battery charging efficiency, and energy feedback devices [

10,

11].

For instance, Paper 10 investigates the wireless power transmission performance used for powering the drive system of electric vehicles. Through the structural design of the coil, the study elucidates the mechanism by which the coupling coefficient can enhance the transmission efficiency of wireless power. The simulation and hardware test results demonstrate that, for coils with an equal area or perimeter, the performance of circular coils surpasses that of rectangular coils.

Table 4 presents the hardware test results of a comparison of the wireless power transmission performance (coupling coefficient) of circular and rectangular coils. However, a significant finding from

Table 4 is that the optimal coupling coefficient for a given type of coil predominantly depends on the coil spacing. Additionally, as all simulation and hardware tests were conducted under the same conditions of wireless power transmission, future research should explore other vital variable characteristics, such as frequency and magnetic interference.

6. Conclusions

These papers have analyzed a broad spectrum of topics pertaining to the structural design, temperature rises, and operational control of permanent magnet motors in electric vehicles. The findings underscore the pivotal role of structural design technology in advancing research on various aspects of permanent magnet motors, including temperature regulation, operational control, and energy feedback devices. Despite the significant theoretical analyses and related technical applications explored in this Special Issue, numerous challenges remain to be addressed to meet the growing demands for safety, stability, and dynamic response in electric vehicles.

The focus of the papers in this Special Issue was predominantly on the normal operating speed conditions of permanent magnet motors. Therefore, a primary technical challenge that requires further investigation is the operational performance of these motors at higher speeds exceeding 14,000 rpm. At such high speeds, factors such as the controller’s processing speed, rotor position detection, inverter switching frequency, and control algorithms play crucial roles in influencing the electromagnetic performance and temperature regulation of the motor. Additionally, the introduction and application of advanced silicon steel sheets in the rotor and stator cores have facilitated their lightweight design, which is emerging as a key development direction for permanent magnet motors. Moreover, it is imperative to conduct comprehensive research and analyses to identify an optimal balance among cost investment, temperature rises, mechanical stress, power density, speed stability, and anti-disturbance performance in permanent magnet motors.