Analysis of the Effect of Wear on Tire Cornering Characteristics Based on Grounding Characteristics

Abstract

1. Introduction

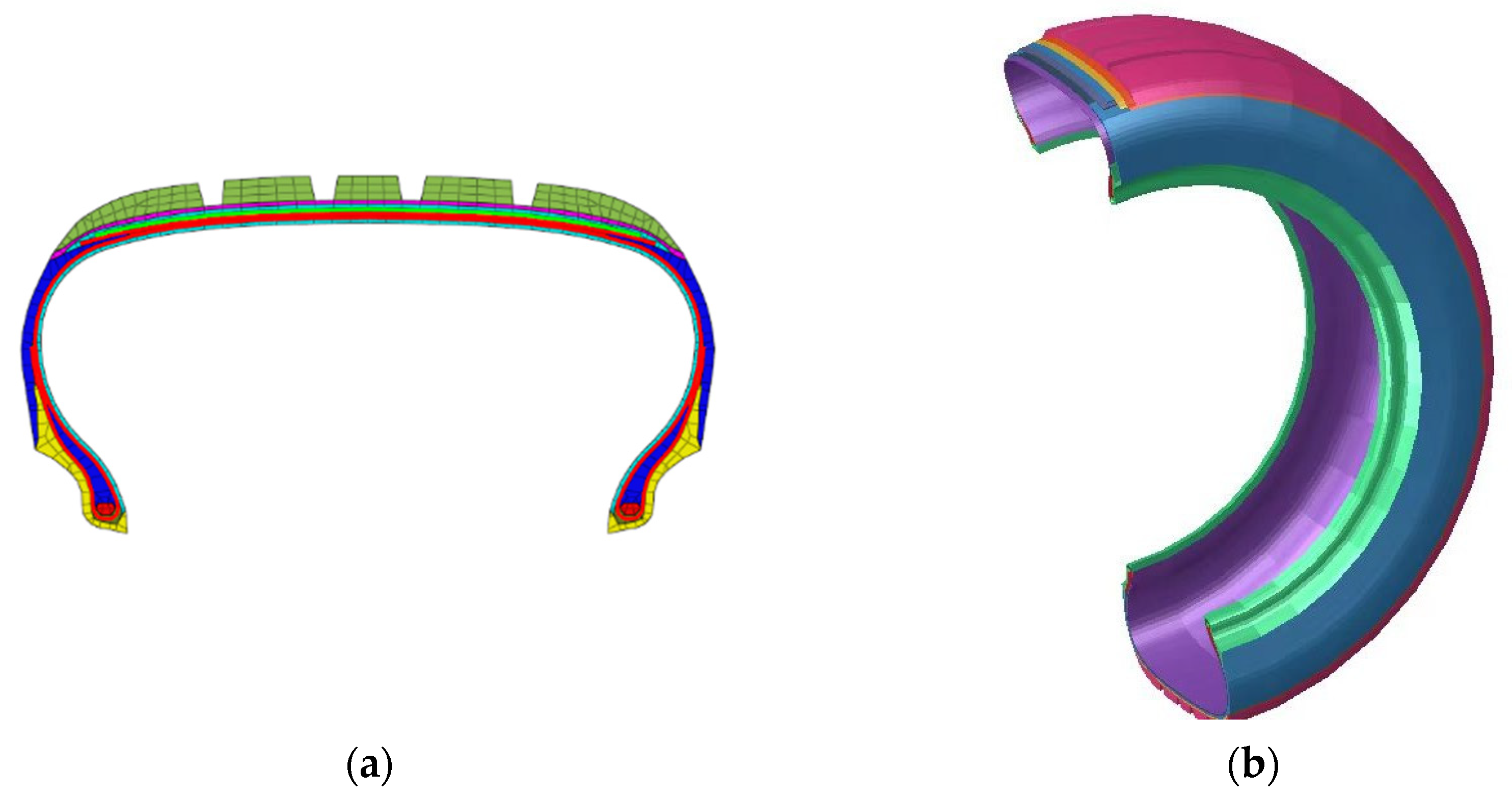

2. Finite Element Model of the Tire

2.1. Finite Element Structural Model

2.2. Verification of Finite Element Model

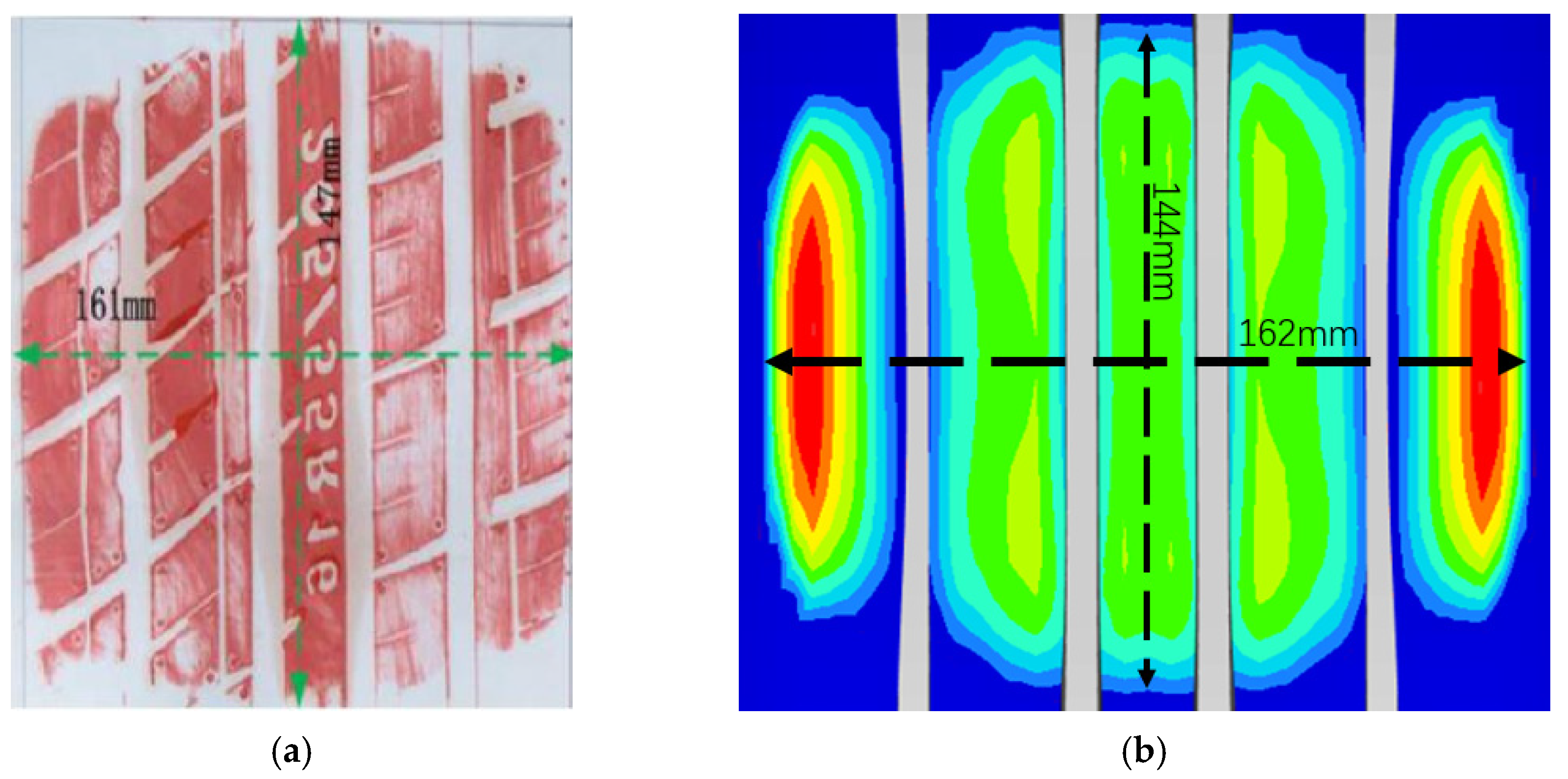

2.2.1. Grounding Footprint Verification

2.2.2. Stiffness Verification

3. Wear Simulation

3.1. Archard’s Wear Law

3.2. ALE and UMESHMOTION Subroutine

3.3. Simulation Operating Condition

3.4. Result

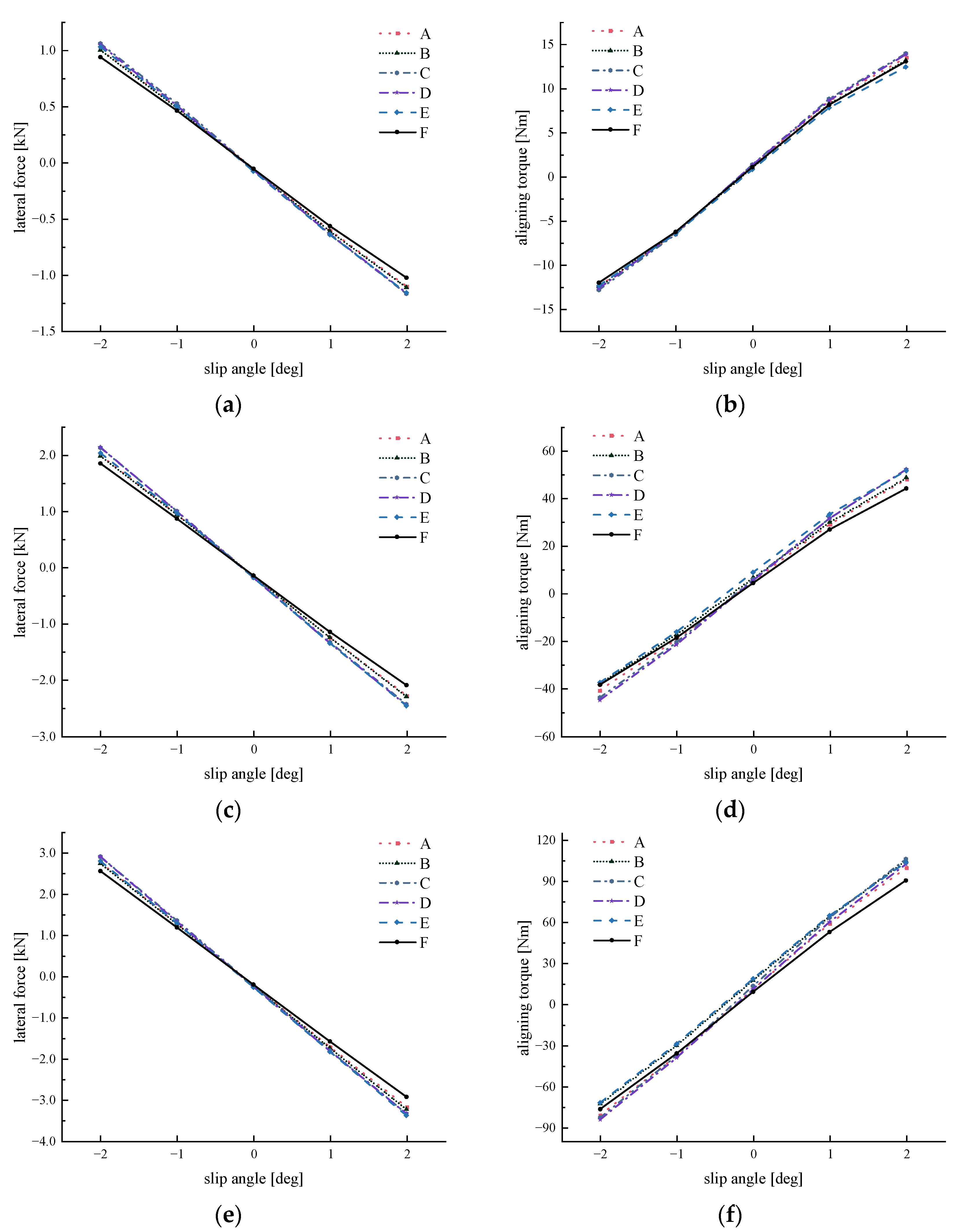

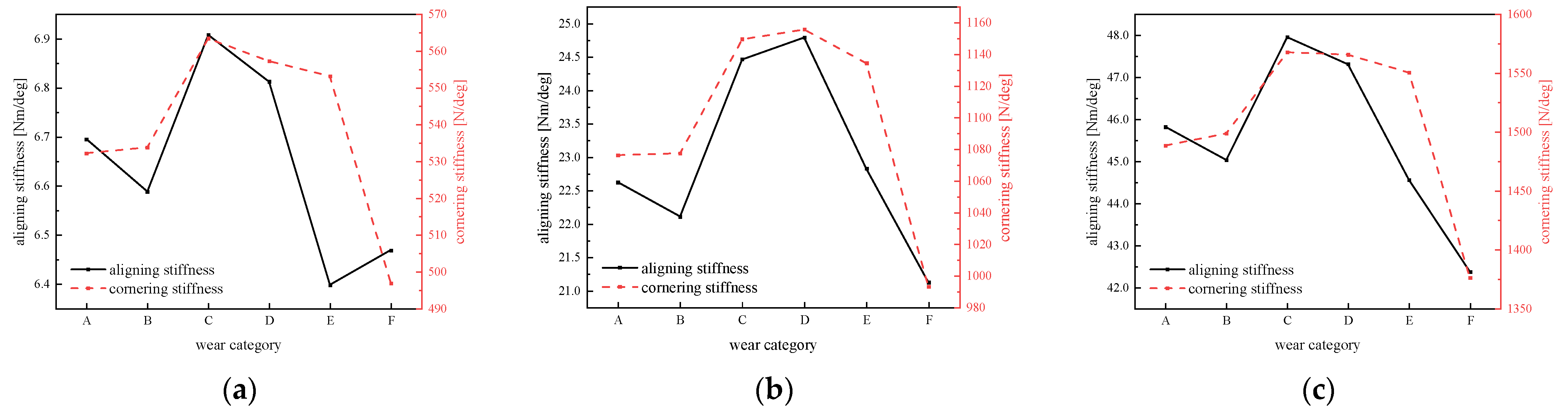

4. Cornering Characteristics of Worn Tires

5. Analysis of the Impact of Wear on Cornering Characteristics

5.1. Impact of Grounding Parameters on Cornering Characteristics

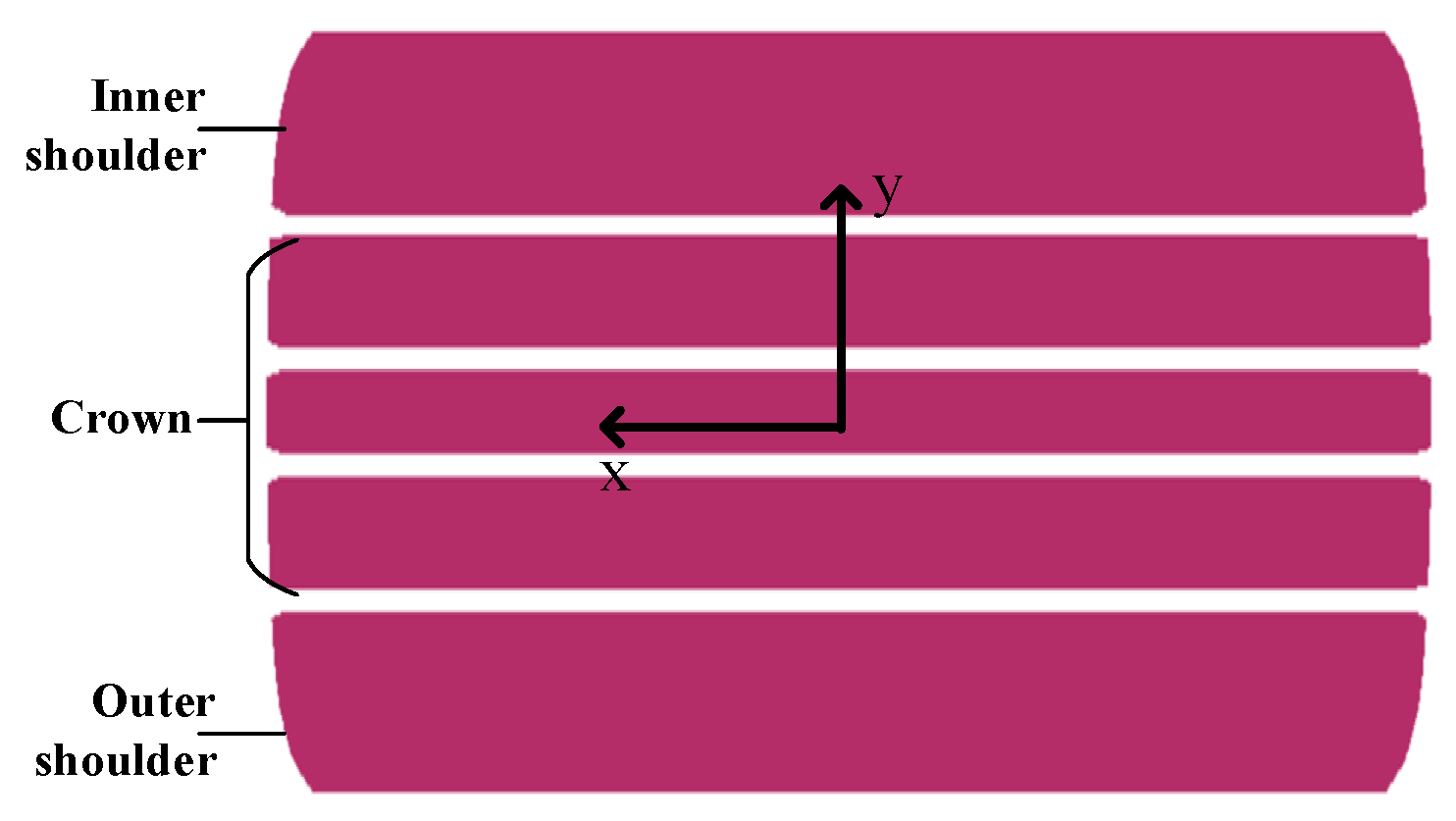

5.2. Influence of Wear on Grounding Parameters

5.2.1. Contact length

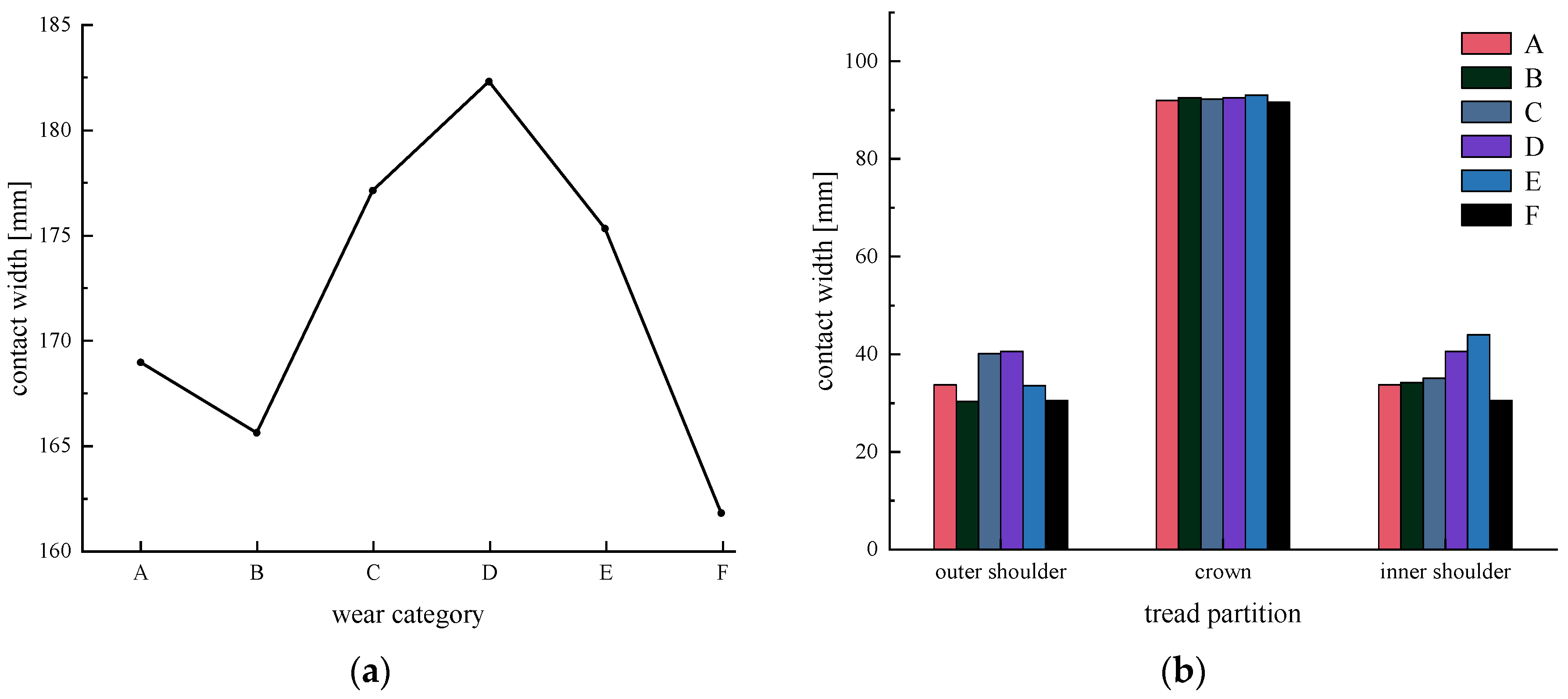

5.2.2. Contact Width

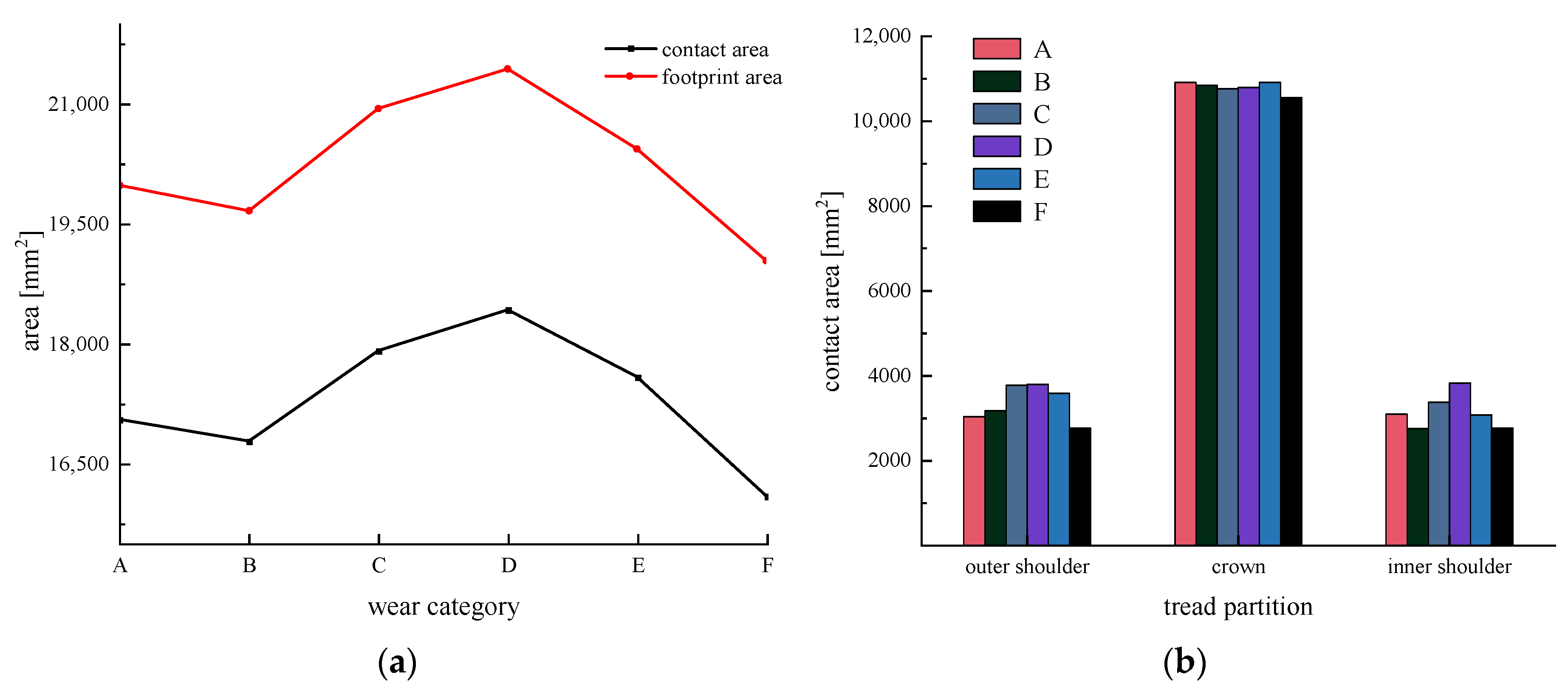

5.2.3. Contact Area

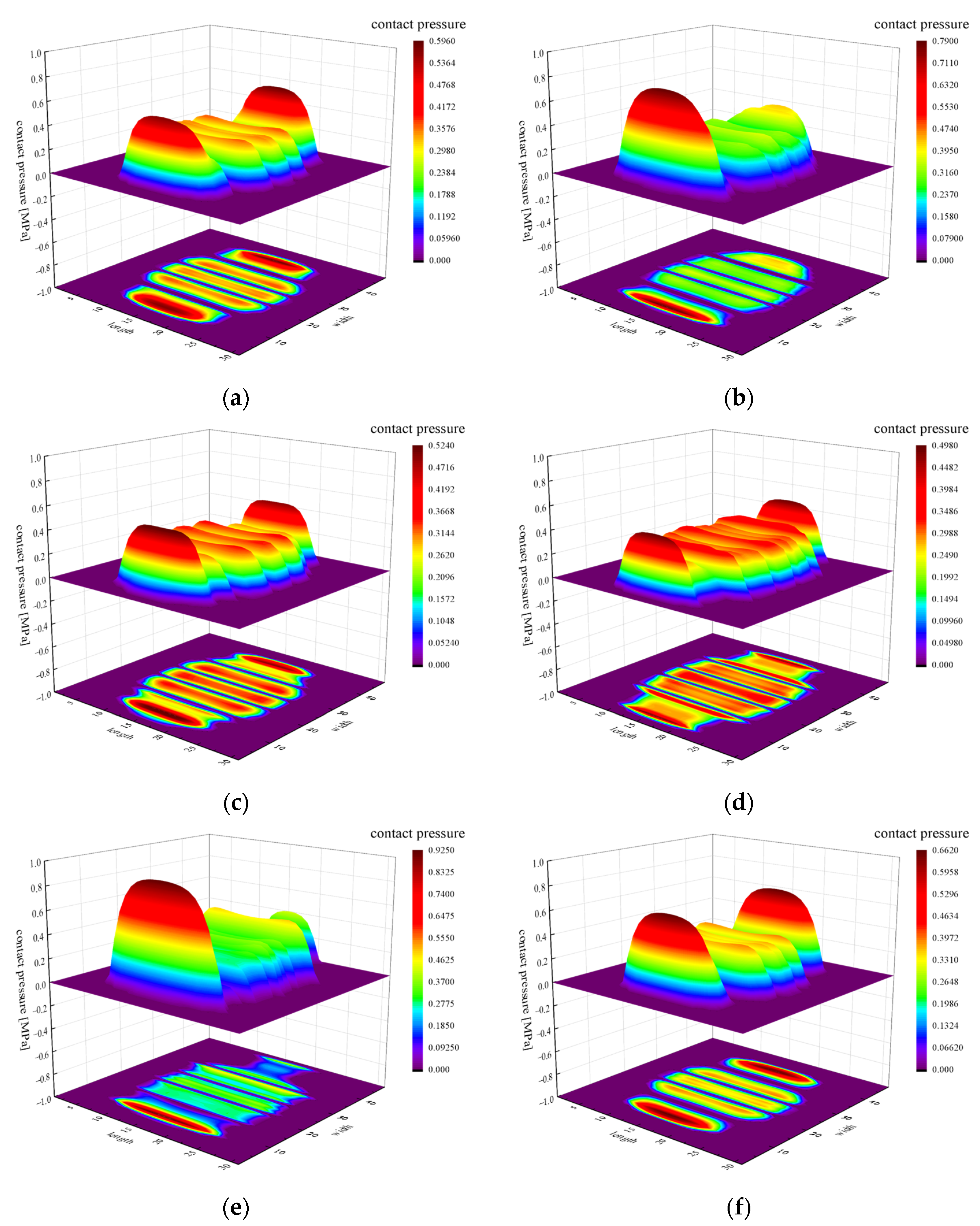

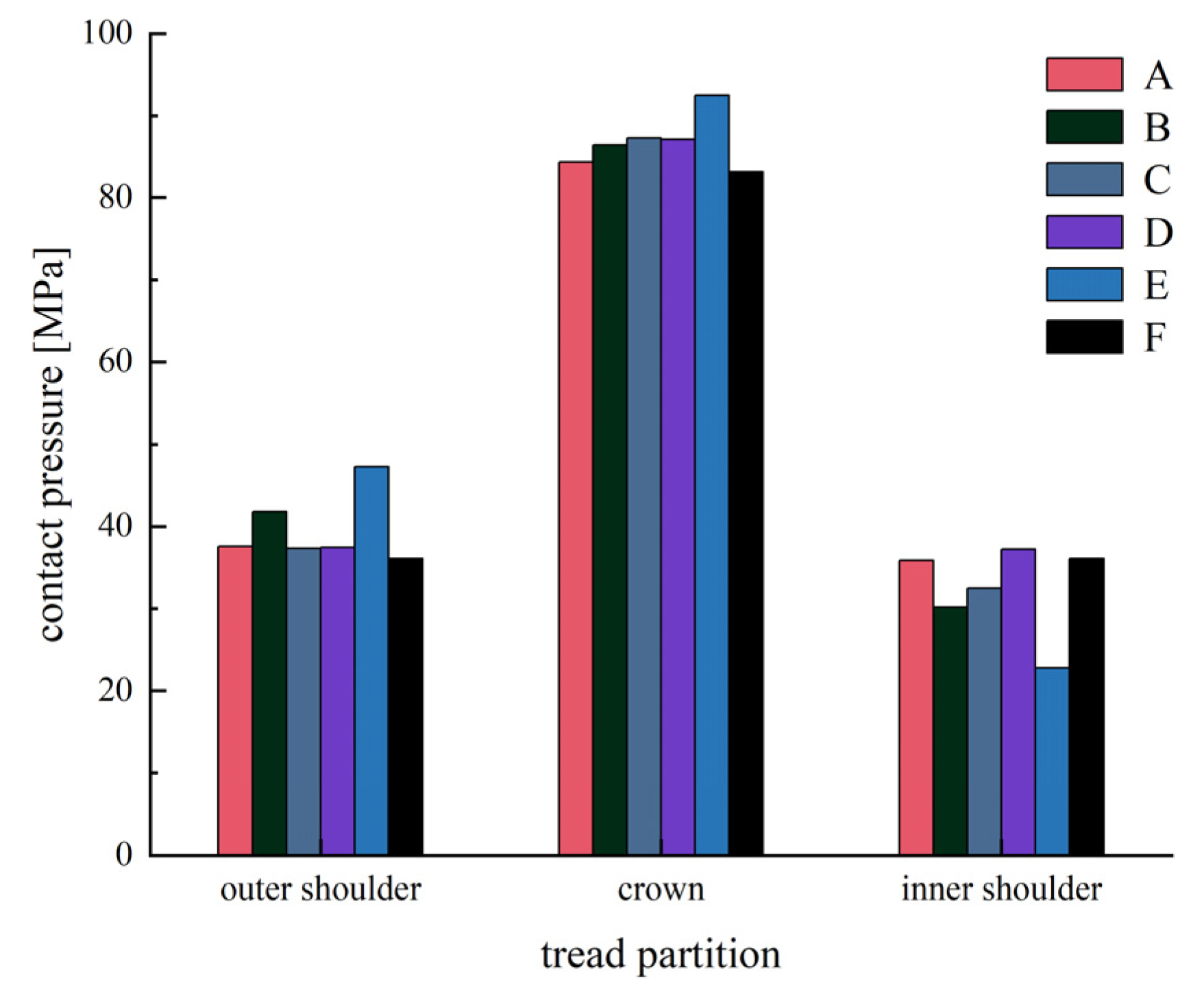

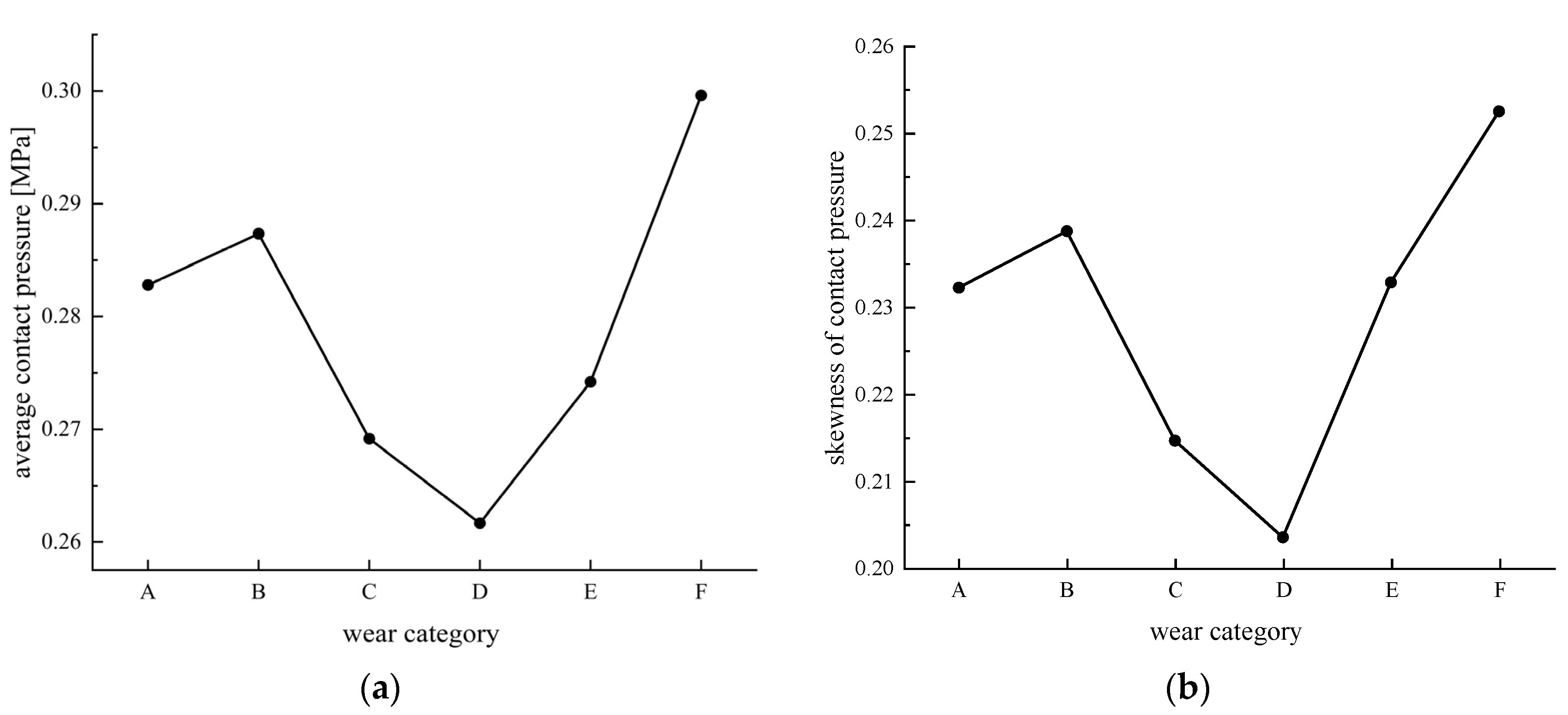

5.2.4. Distribution of Contact Pressure

6. Conclusions

- Wear can significantly affect a tire’s cornering characteristics by modifying its grounding characteristics.

- The lateral force and aligning torque are directly proportional to the overall wear amount, while the variation in tire shoulder wear minimally affects the lateral force but significantly impacts the aligning torque.

- Among the grounding parameters, five parameters including contact area exhibited a significant positive correlation with cornering stiffness. Additionally, seven parameters such as contact length displayed a significant negative correlation with cornering stiffness. Moreover, six parameters including footprint area showed a significant positive correlation with aligning stiffness. Furthermore, seven grounding characteristic parameters, such as the skewness of contact pressure, were significantly negatively correlated with aligning stiffness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Timmers, V.R.; Achten, P.A. Non-exhaust PM emissions from electric vehicles. Atmos. Environ. 2016, 134, 10–17. [Google Scholar] [CrossRef]

- Walters, M.H. Uneven Wear of Vehicle Tires. Tire Sci. Technol. 1993, 21, 202–219. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, S.; Lei, L.; Yang, X.; Wu, X. Analysis of impact factors of tire wear. J. Vib. Control 2012, 18, 833–840. [Google Scholar] [CrossRef]

- Huang, H.; Chiu, Y.; Wang, C.; Jin, X. Three-dimensional global pattern prediction for tyre tread wear. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 197–213. [Google Scholar] [CrossRef]

- Wang, C.; Huang, H.; Chen, X.; Liu, J. The influence of the contact features on the tyre wear in steady-state conditions. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 1326–1339. [Google Scholar] [CrossRef]

- Chen, X.; Xu, N.; Guo, K. Tire wear estimation based on nonlinear lateral dynamic of multi-axle steering vehicle. Int. J. Automot. Technol. 2018, 19, 63–75. [Google Scholar] [CrossRef]

- Nguyen, V.; Zheng, D.; Schmerwitz, F.; Wriggers, P. An advanced abrasion model for tire wear. Wear 2018, 396, 75–85. [Google Scholar] [CrossRef]

- Lepine, J.; Na, X.; Cebon, D. An empirical tire-wear model for heavy-goods vehicles. Tire Sci. Technol. 2022, 50, 211–229. [Google Scholar] [CrossRef]

- Nakajima, Y.; Hidano, S. Theoretical Tire Model for Wear Progress of Tires with Tread Pattern Considering Two-Dimensional Contact Patch. Tire Sci. Technol. 2022, 50, 337–369. [Google Scholar] [CrossRef]

- Sakhnevych, A. Multiphysical MF-based tyre modelling and parametrisation for vehicle setup and control strategies optimisation. Veh. Syst. Dyn. 2022, 60, 3462–3483. [Google Scholar] [CrossRef]

- Stalnaker, D.; Turner, J. Vehicle and course characterization process for indoor tire wear simulation. Tire Sci. Technol. 2002, 30, 100–121. [Google Scholar] [CrossRef]

- Runge, S.; Ignatyev, P.; Wangenheim, M.; Bederna, C.; Wies, B.; Wallaschek, J. Transient abrasion on a rubber sample due to highly dynamic contact conditions. Wear 2021, 477, 203848. [Google Scholar] [CrossRef]

- Cho, J.; Jung, B. Prediction of tread pattern wear by an explicit finite element model. Tire Sci. Technol. 2007, 35, 276–299. [Google Scholar] [CrossRef]

- Dionisio, H.; Calhabeu, A. Evaluating Tire Tread Wear and Its Dependence on Tire Working Conditions by Using the Finite Element Method and Archard’s Wear Theory. Tire Sci. Technol. 2022, 50. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Wang, Y. An integrated approach for friction and wear simulation of tire tread rubber. Part II: Wear test, characterization, and modeling. Tire Sci. Technol. 2020, 48, 146–165. [Google Scholar] [CrossRef]

- Tamada, R.; Shiraishi, M. Prediction of Uneven Tire Wear Using Wear Progress Simulation. Tire Sci. Technol. 2017, 45, 87–100. [Google Scholar] [CrossRef]

- Liang, H.; Wang, G.; Liang, C.; Zhou, H.; Li, G. Finite Element Analysis of Effect of Running Surface Width and Arc Height on Tire Uneven Wear. China Rubber Ind. 2019, 66, 207–212. [Google Scholar]

- Papaioannou, G.; Jerrelind, J.; Drugge, L. Multi-Objective Optimisation of Tyre and Suspension Parameters during Cornering for Different Road Roughness Profiles. Appl. Sci. 2021, 11, 5934. [Google Scholar] [CrossRef]

- Wang, G.; Zheng, Z.; Zhang, S. Study on reducing wear of straddle-type monorail trains’ running wheel tires. J. Mech. Eng. 2018, 54, 78–85. [Google Scholar] [CrossRef]

- Waquier, L.; Myles, B.S.; Henrard, L.; Vautard, F.; Pappas, C.M.; Feneon, B.; Delaitre, C.; Mehlem, J.J.; Khripin, C.Y. Quantitative measurement of nanoparticle release from rubber composites during fabrication and testing. J. Nanopart. Res. 2020, 22, 251. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Jerrams, S.; Hu, S.; Liu, L.; Wen, S.; Zhang, L. Constructing a fine dispersion and chemical interface based on an electrostatic self-assembly and aqueous phase compound in GO/SiO2/SBR composites to achieve high-wear resistance in eco-friendly green tires. Chem. Eng. J. 2023, 452, 139113. [Google Scholar] [CrossRef]

- Wang, X.-B.; Li, A.-J.; Ci, Q.-P.; Shi, M.; Jing, T.-L.; Zhao, W.-Z. The study on tire tread depth measurement method based on machine vision. Adv. Mech. Eng. 2019, 11, 1687814019837828. [Google Scholar] [CrossRef]

- Zhu, J.; Han, K.; Wang, S. Automobile tire life prediction based on image processing and machine learning technology. Adv. Mech. Eng. 2021, 13, 16878140211002727. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.; Zhang, Y.; Huang, X.; Dai, Y. Abrasion Status Prediction with BP Neural Network Based on an Intelligent Tire System. In Proceedings of the 2020 4th CAA International Conference on Vehicular Control and Intelligence (CVCI), Hangzhou, China, 18–20 December 2020; pp. 619–622. [Google Scholar]

- Li, B.; Quan, Z.; Bei, S.; Zhang, L.; Mao, H. An estimation algorithm for tire wear using intelligent tire concept. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2712–2725. [Google Scholar] [CrossRef]

- Todoroff, V.; Paupy, S.; Biesse, F.; Le Chenadec, Y. The mechanisms involved during the wet braking of new and worn tires. Veh. Syst. Dyn. 2019, 57, 1601–1620. [Google Scholar] [CrossRef]

- Wright, K.R.S.; Botha, T.R.; Els, P.S. Effects of age and wear on the stiffness and friction properties of an SUV tyre. J. Terramech. 2019, 84, 21–30. [Google Scholar] [CrossRef]

- Becker, C.; Els, S. Agricultural tyre stiffness change as a function of tyre wear. J. Terramech. 2022, 102, 1–15. [Google Scholar] [CrossRef]

- Nantapuk, S.; Chuepeng, S.; Tongroon, M. Influences of Aging and Inflation Pressure on Stiffness and Absorbed Energy of a Passenger Car Radial Tire. J. Ind. Technol. 2022, 18, 15–28. [Google Scholar]

- Lu, L.; Lu, D.; Wu, H.; Li, L.; Wang, W.; LYU, M. Research and modeling of tire cornering characteristics considering tread wear based on UniTire model. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 1155–1169. [Google Scholar] [CrossRef]

- Systèmes, D. SIMULIA User Assistance 2020; Abaqus: Providence, RI, USA, 2020. [Google Scholar]

- Chen, X. Research on Numerical Analysis Method and Evaluation Index of Wet Grip Performance of Tire. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Archard, J. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Wang, G.; Li, K.; Zhou, H. Abnormal wear analysis of straddle-type monorail vehicle running wheel tire. Adv. Mech. Eng. 2019, 11, 1687814019889751. [Google Scholar] [CrossRef]

- Wang, G.; Dong, Z.; Liang, C. Study on relationship between grounding characteristics and rolling resistance of radial tire. J. Mech. Eng. 2014, 50, 186–192. [Google Scholar] [CrossRef]

- Wang, G.; Qiao, L.; Zhou, H.; Qiao, H.; Liu, C. Influence of PCR tire grounding characteristics to noise and rolling resistance. J. Mech. Eng. 2019, 55, 123–131. [Google Scholar]

- Liang, C.; Wang, G.; Zhou, H.; Li, G. Experimental study of radial tire contact pressure distribution evaluation. Automob. Technol. 2013, 11, 38–42. [Google Scholar]

| Solution | FEA | Experiment | Error |

|---|---|---|---|

| contact length/mm | 144 | 147 | 2.04% |

| contact width/mm | 162 | 161 | 0.62% |

| Stiffness | FEA | Experiment | Error |

|---|---|---|---|

| radial stiffness/(N/mm) | 214.50 | 206.28 | 3.98% |

| lateral stiffness/(N/mm) | 154.06 | 148.37 | 3.84% |

| longitudinal stiffness/(N/mm) | 161.13 | 168.56 | 4.40% |

| Number | Inflation Pressure/MPa | Load/N | Velocity/km/h | Slip Angle/deg | Camber Angle/deg | Longitudinal Slip/% | Time/h |

|---|---|---|---|---|---|---|---|

| 1 | 240 | 4821 | 70 | 2 | 0 | 0 | 110 |

| 2 | 240 | 4821 | 70 | 0 | 5 | 0 | 110 |

| 3 | 240 | 4821 | 70 | 2 | 0 | 0 | 220 |

| 4 | 240 | 6000 | 70 | 0 | 0 | 60% | 220 |

| 5 | 240 | 4821 | 70 | 0 | 5 | 0 | 220 |

| Group | Wear Category | wg/mm | wc/mm | wos/mm | wis/mm | wd | wcd |

|---|---|---|---|---|---|---|---|

| Ⅰ | A | 1.1 | 1.3 | 0.9 | 1.1 | 10% | 8.33% |

| B | 1.0 | 1.3 | 0.2 | 1.6 | 77.78% | 13.04% | |

| Ⅱ | C | 2.1 | 2.4 | 1.6 | 2.2 | 15.79% | 6.67% |

| D | 2.0 | 2.4 | 1.8 | 1.8 | 0 | 9.09% | |

| E | 2.0 | 2.3 | 0.3 | 3.2 | 82.86% | 6.98% |

| Parameters | Statistics | p Value |

|---|---|---|

| cornering stiffness | 0.882 | 0.279 |

| aligning stiffness | 0.938 | 0.641 |

| contact area | 0.99 | 0.989 |

| footprint area | 0.99 | 0.989 |

| contact area ratio | 0.914 | 0.466 |

| Parameters | Cornering Stiffness | Aligning Stiffness |

|---|---|---|

| contact area | 0.961 | 0.968 |

| footprint area | 0.947 | 0.981 |

| contact area ratio | 0.924 | |

| contact length | −0.996 | −0.925 |

| contact width | 0.94 | 0.95 |

| contact length to width ratio | −0.952 | −0.95 |

| contact sea-to-land ratio | −0.925 | |

| average contact pressure | −0.97 | −0.964 |

| skewness of contact pressure | −0.869 | |

| contact area of the outer shoulder | 0.97 | 0.923 |

| contact width of the outer shoulder | 0.967 | |

| contact length to width ratio of the outer shoulder | −0.852 | |

| average contact pressure of the outer shoulder | −0.952 | |

| average contact pressure of the inner shoulder | −0.861 | |

| contact area of the inner shoulder | 0.931 | |

| contact length of the crown | −0.996 | −0.925 |

| contact length to width ratio of the crown | −0.815 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Liu, Y.; Zhou, H.; Zhang, W.; Chen, Y.; Zhu, H. Analysis of the Effect of Wear on Tire Cornering Characteristics Based on Grounding Characteristics. World Electr. Veh. J. 2023, 14, 166. https://doi.org/10.3390/wevj14070166

Zhang S, Liu Y, Zhou H, Zhang W, Chen Y, Zhu H. Analysis of the Effect of Wear on Tire Cornering Characteristics Based on Grounding Characteristics. World Electric Vehicle Journal. 2023; 14(7):166. https://doi.org/10.3390/wevj14070166

Chicago/Turabian StyleZhang, Shupei, Yue Liu, Haichao Zhou, Wei Zhang, Yixiang Chen, and Hongcheng Zhu. 2023. "Analysis of the Effect of Wear on Tire Cornering Characteristics Based on Grounding Characteristics" World Electric Vehicle Journal 14, no. 7: 166. https://doi.org/10.3390/wevj14070166

APA StyleZhang, S., Liu, Y., Zhou, H., Zhang, W., Chen, Y., & Zhu, H. (2023). Analysis of the Effect of Wear on Tire Cornering Characteristics Based on Grounding Characteristics. World Electric Vehicle Journal, 14(7), 166. https://doi.org/10.3390/wevj14070166