Research on Collaborative Control of Differential Drive Assisted Steering and Active Front Steering for Distributed Drive Electric Vehicles

Abstract

:1. Introduction

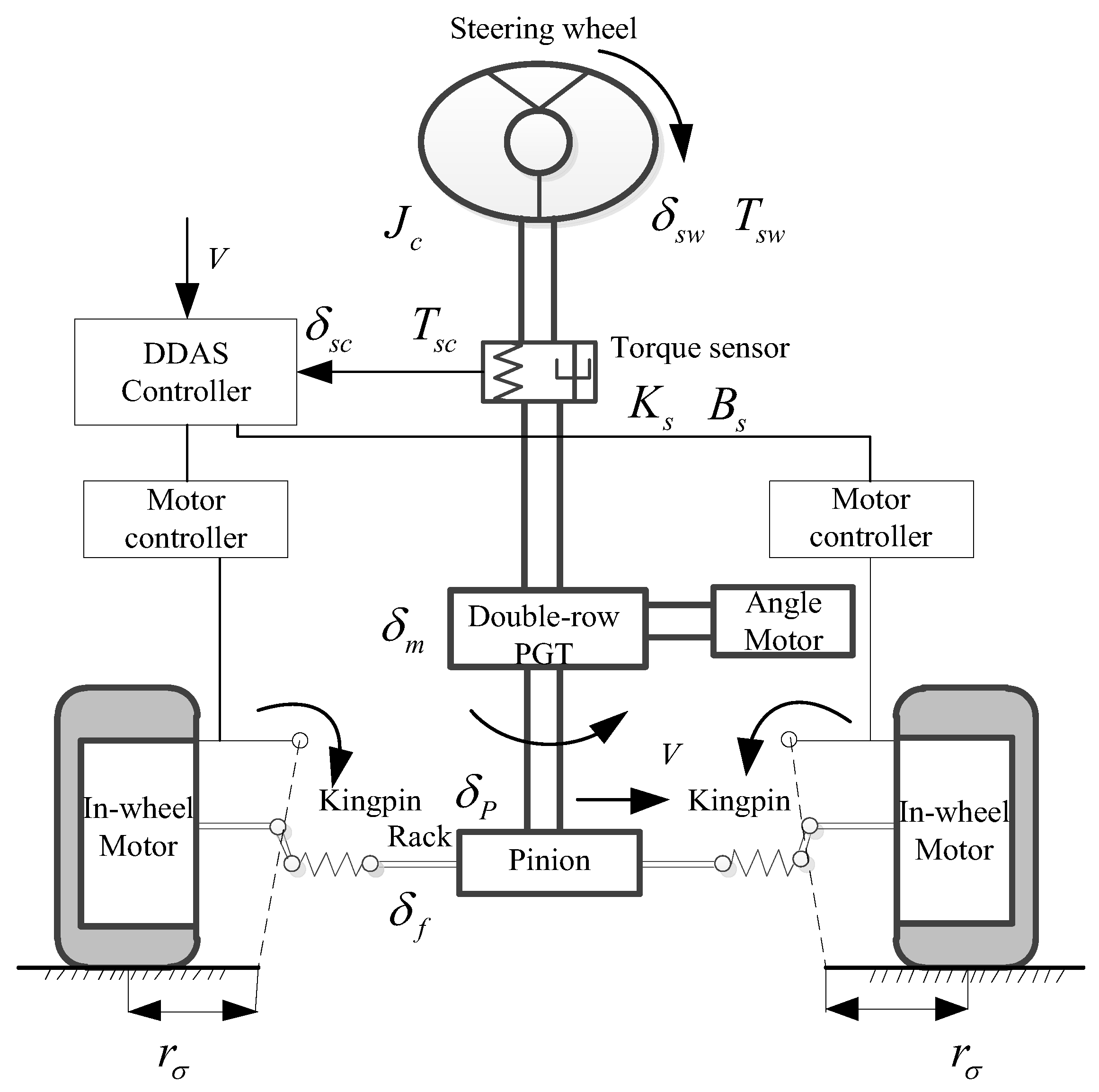

2. System Structure and Model

2.1. System Structure and Implementation Principle

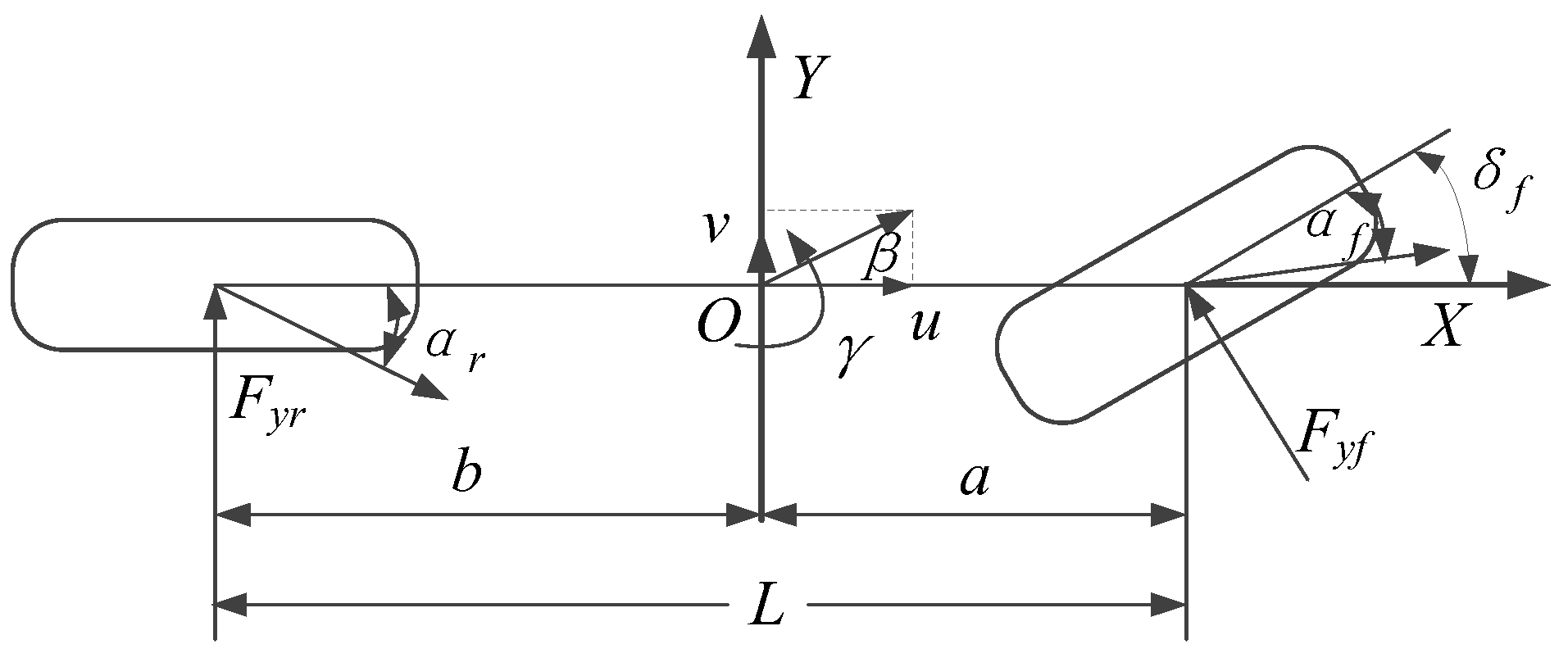

2.2. System Dynamics Model

2.3. Two Freedom Vehicle Reference Model

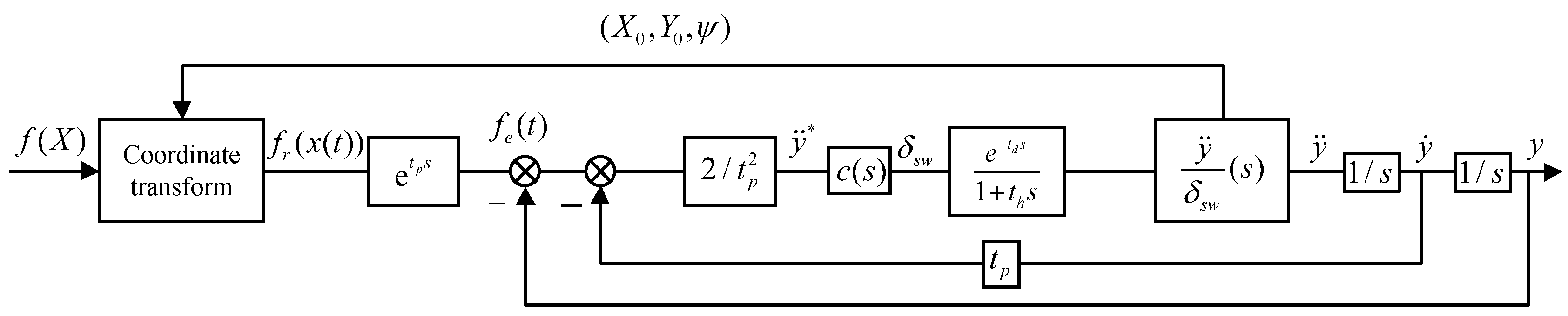

2.4. Driver Model

3. AFS System Control Strategy Based on Yaw Velocity Feedback

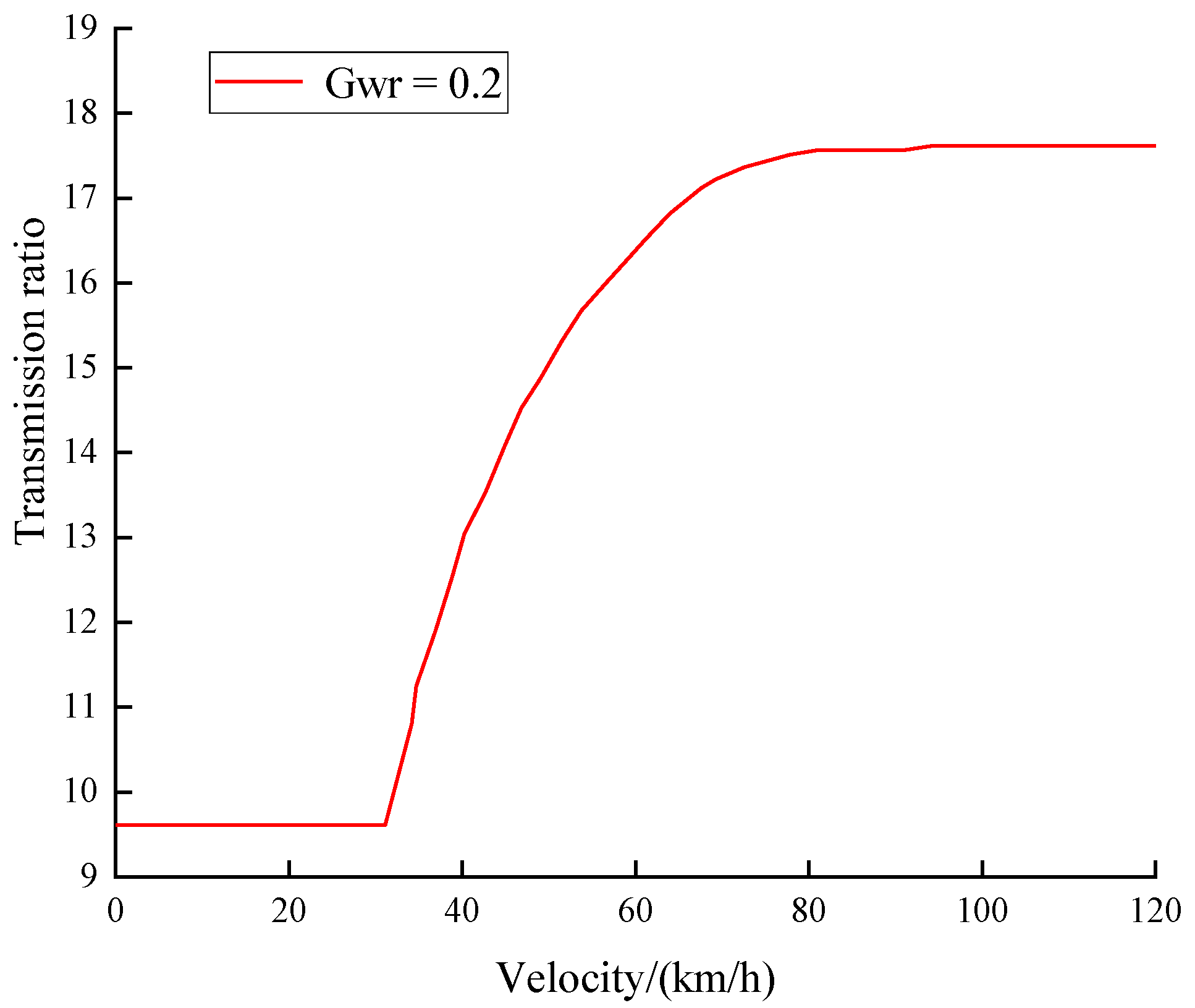

3.1. Design of Variable Transmission Ratio Curve

3.2. AFS Control Strategy

4. DDAS System Control Strategy Based on Steering Wheel Torque

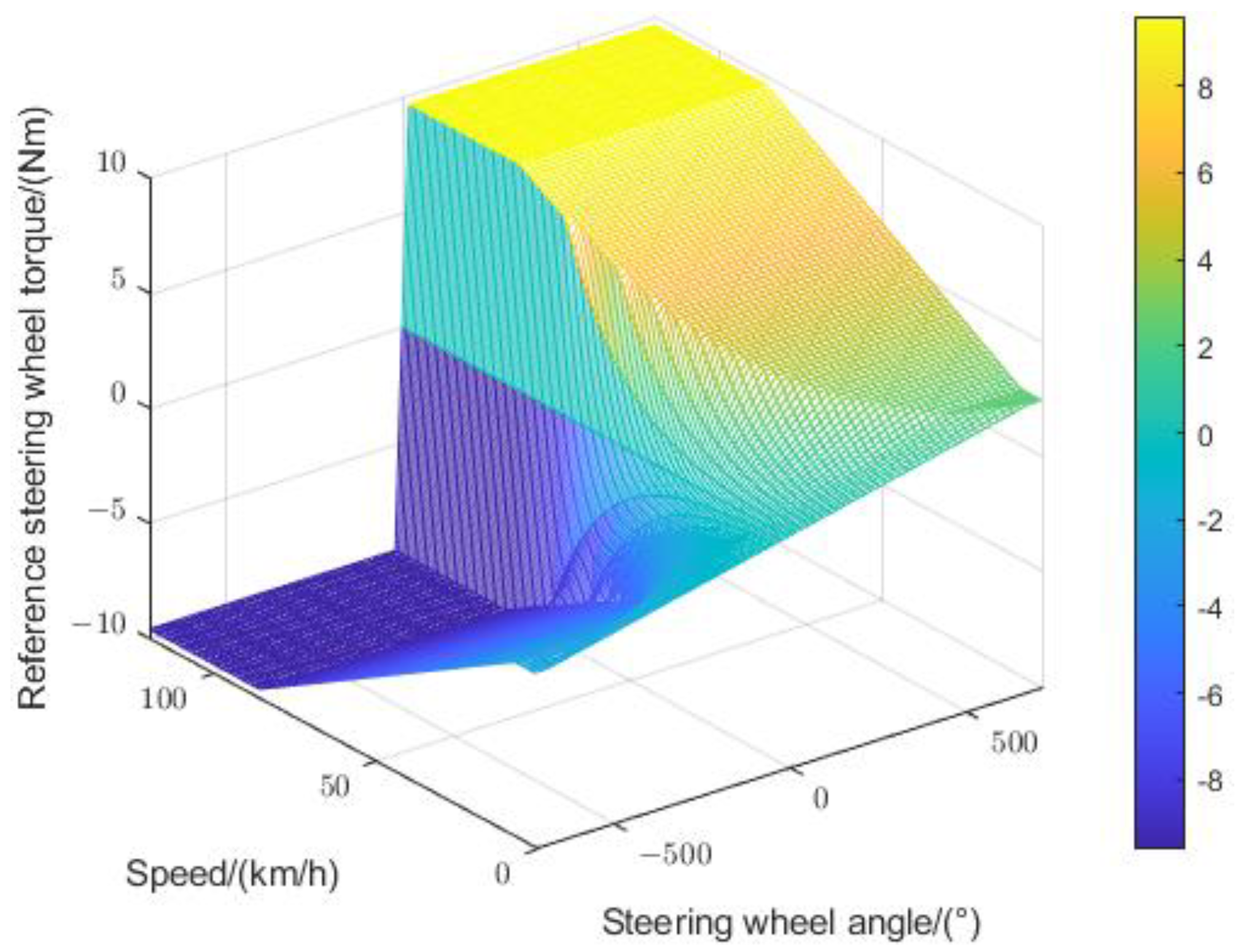

4.1. Assistance Characteristic Curve

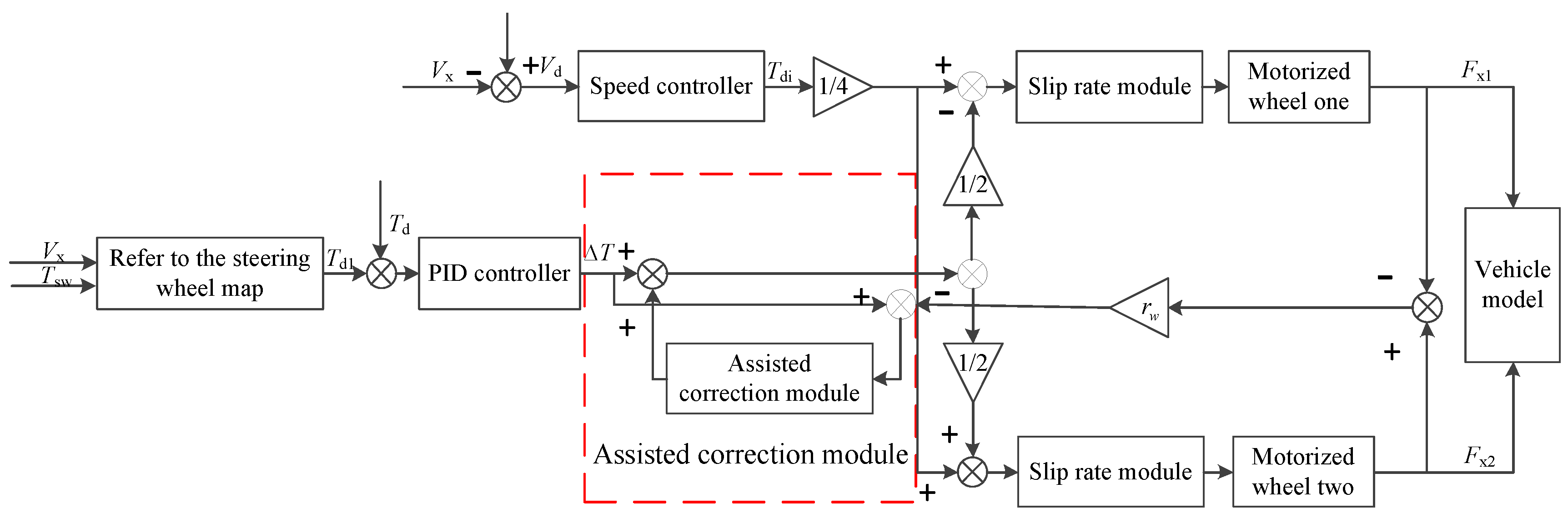

4.2. DDAS Direct Control Strategy

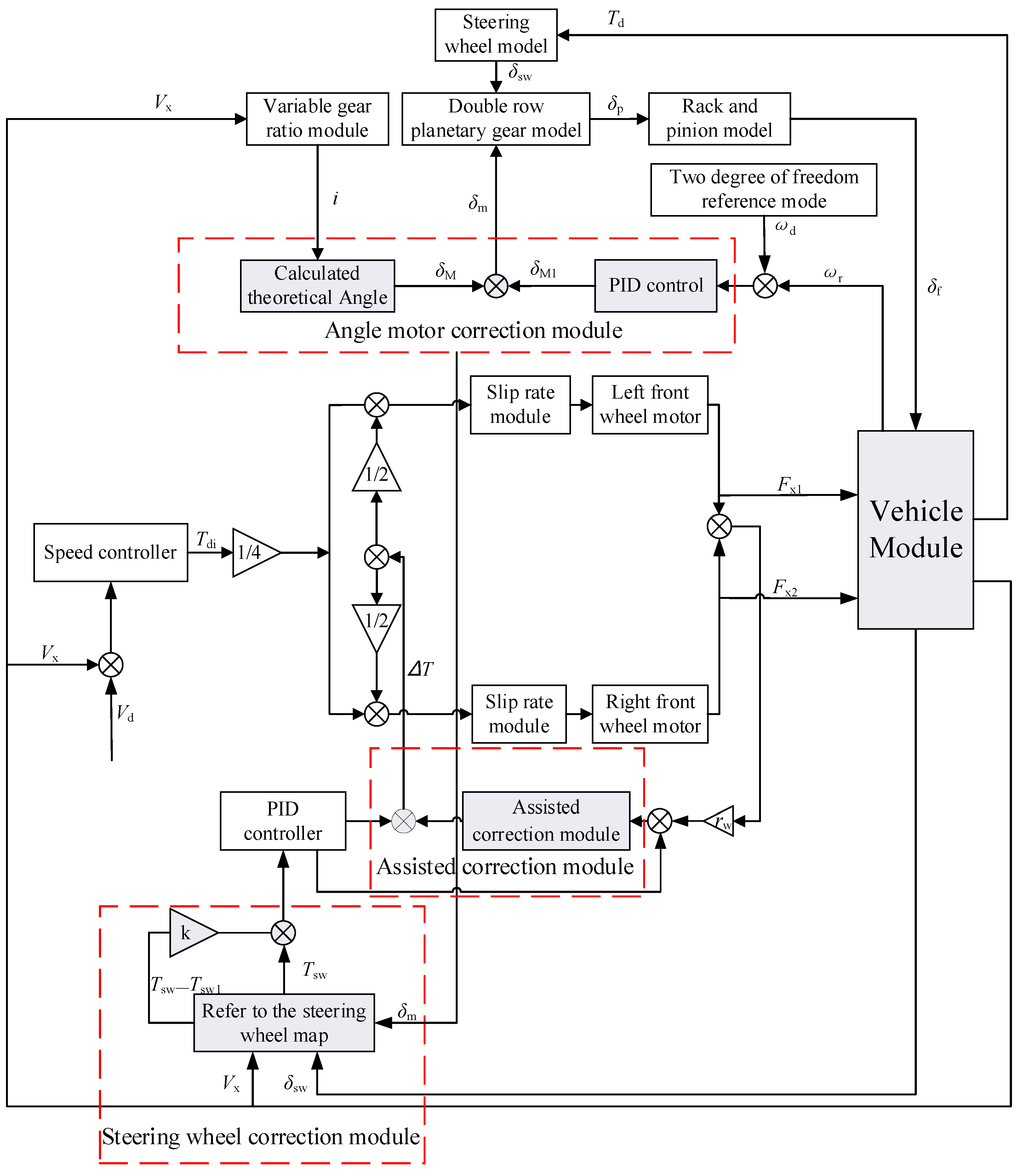

5. AFS Integrates DDAS Collaborative Control Strategy

5.1. Analysis of the Interaction Mechanism between Two Systems

5.1.1. DDAS Impact on AFS Performance

5.1.2. The Impact of AFS on DDAS

5.2. Coordinated Control Strategy Design

6. Simulation Analysis and Verification

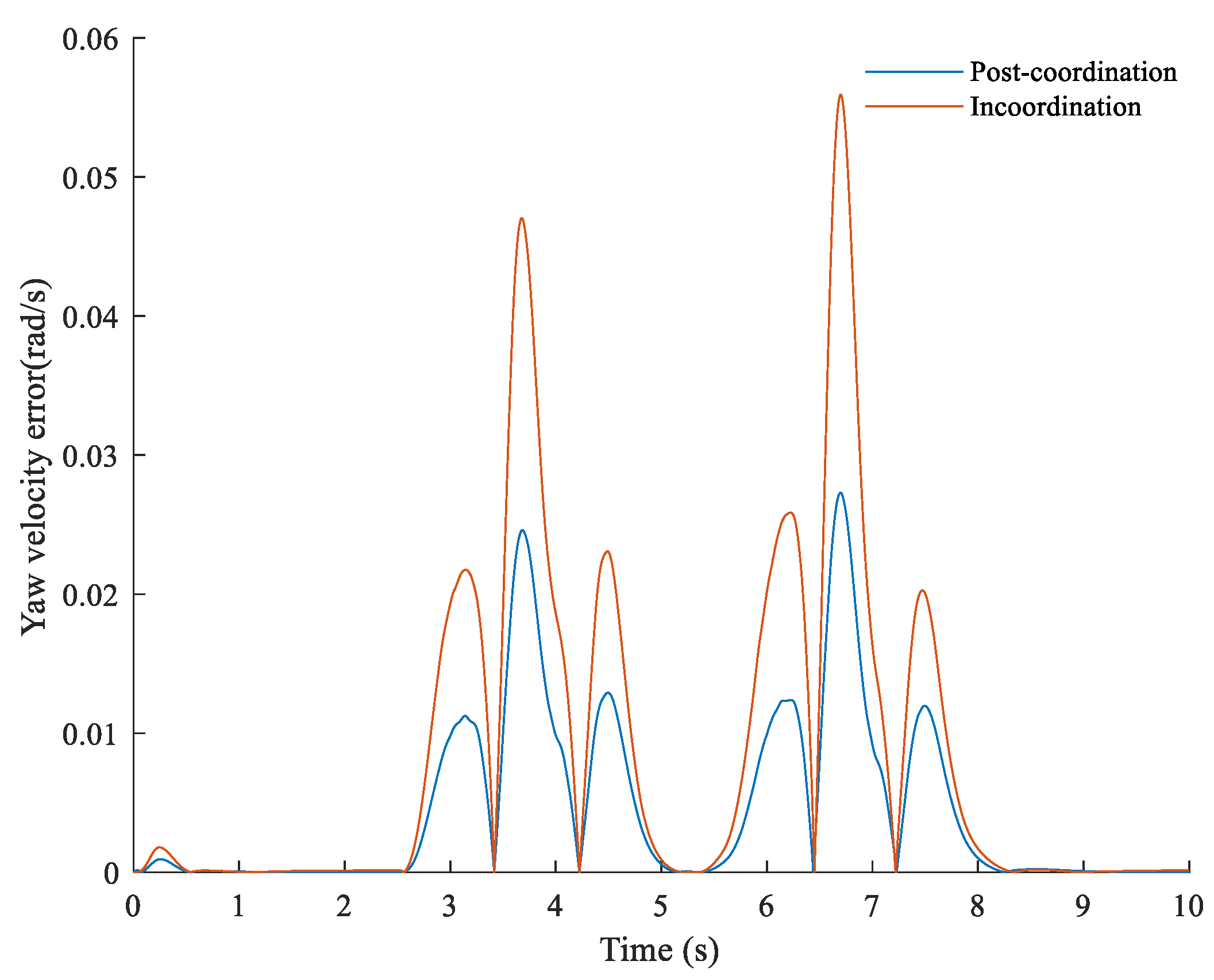

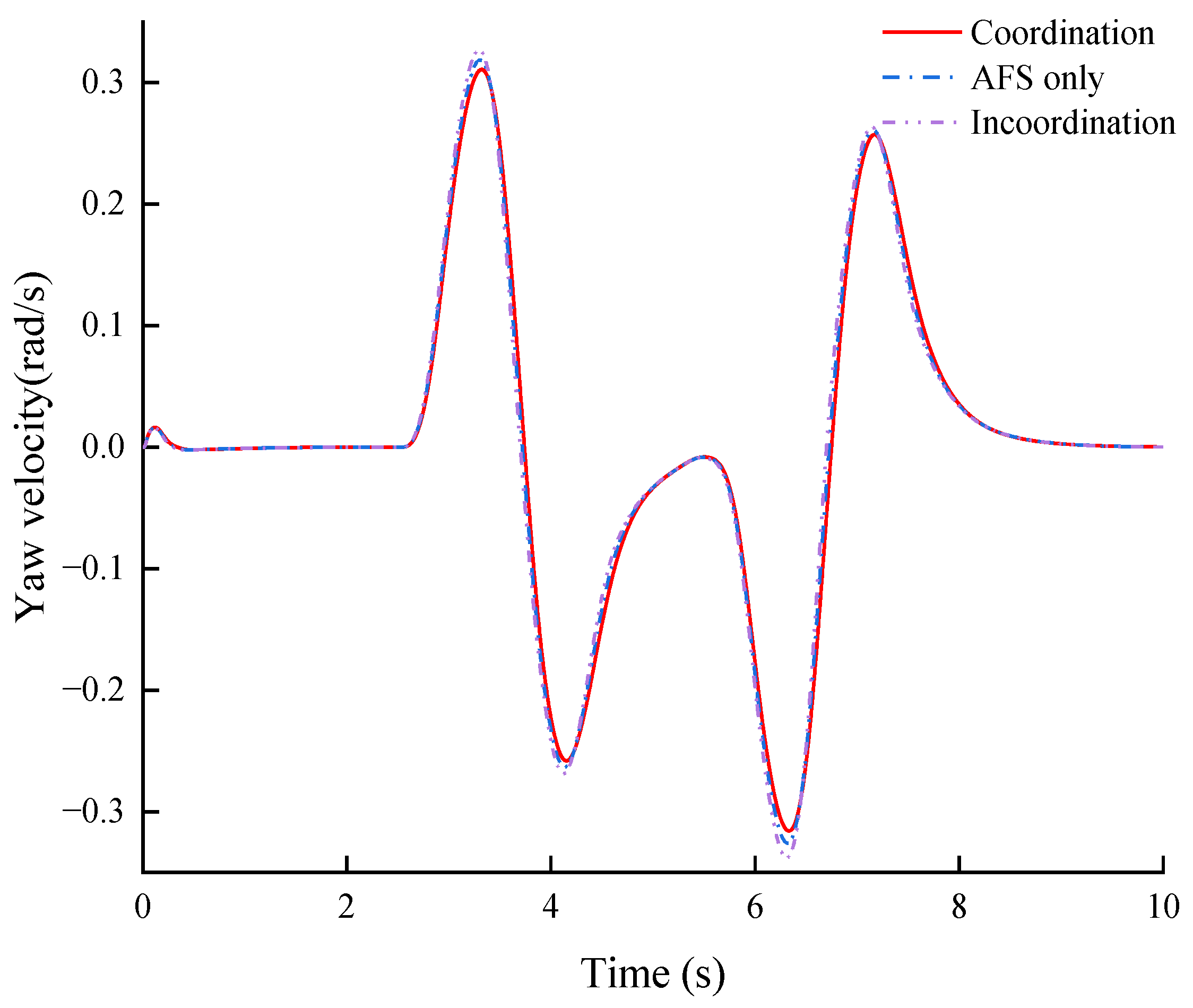

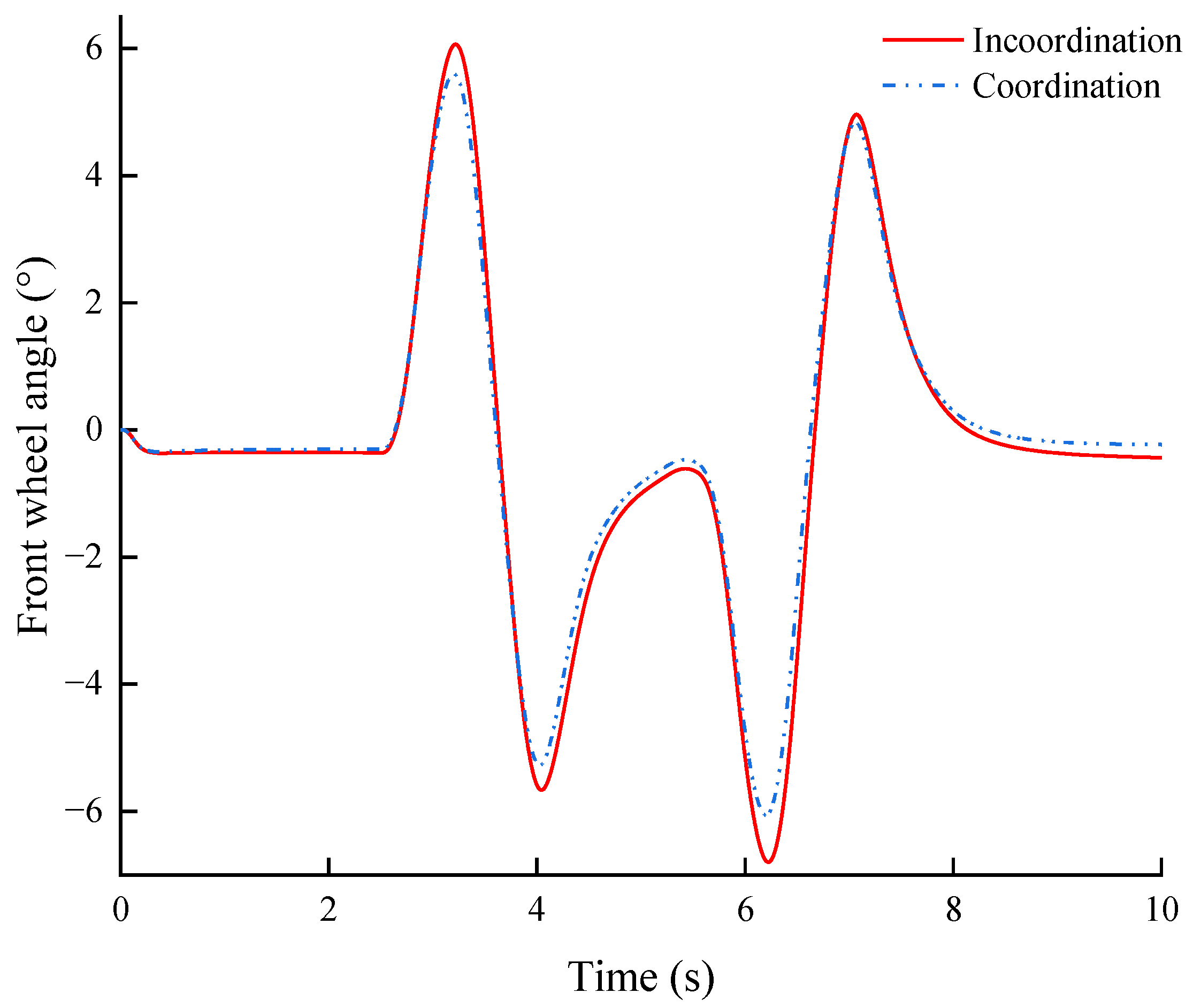

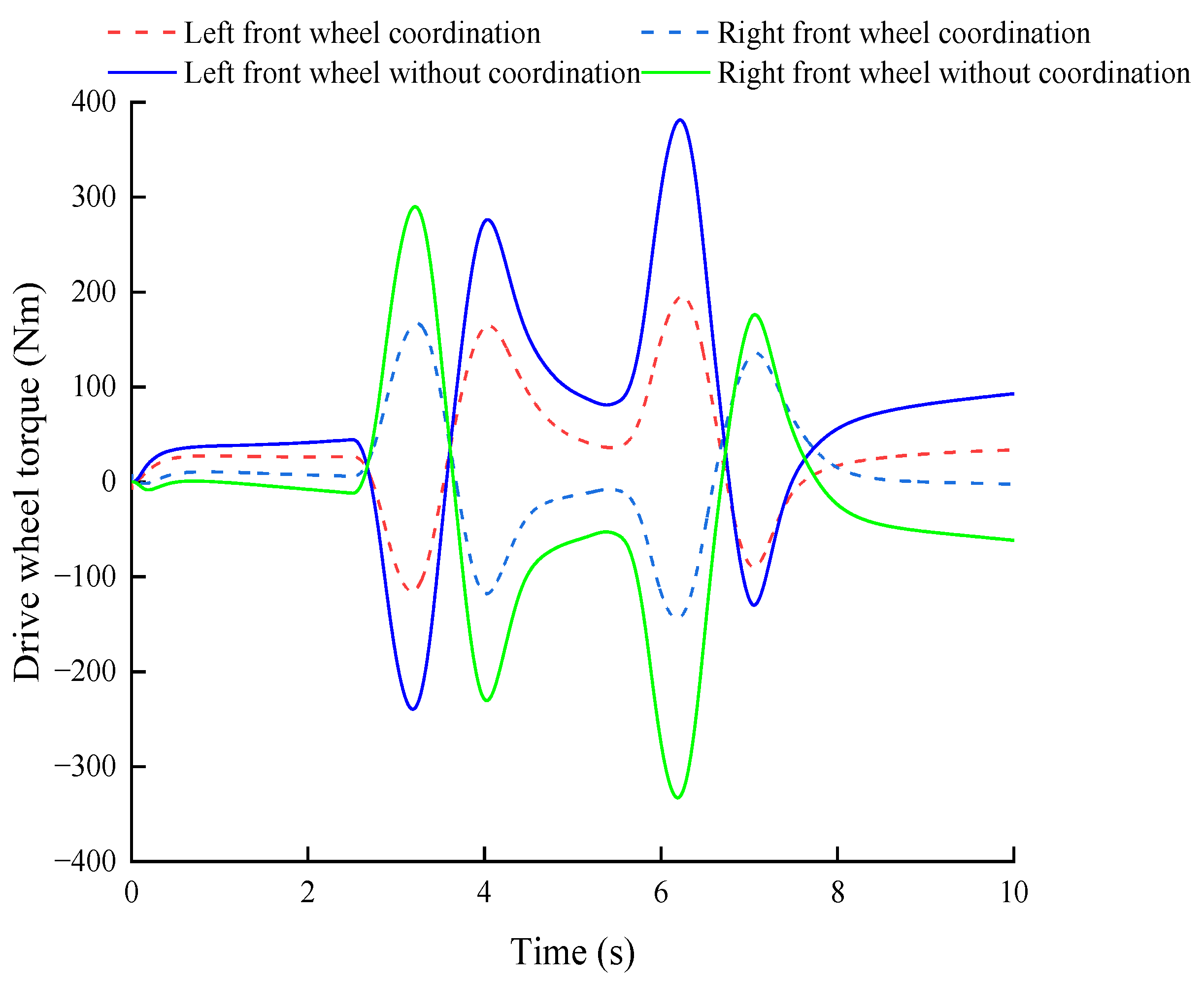

6.1. Verification of Double Lane Change

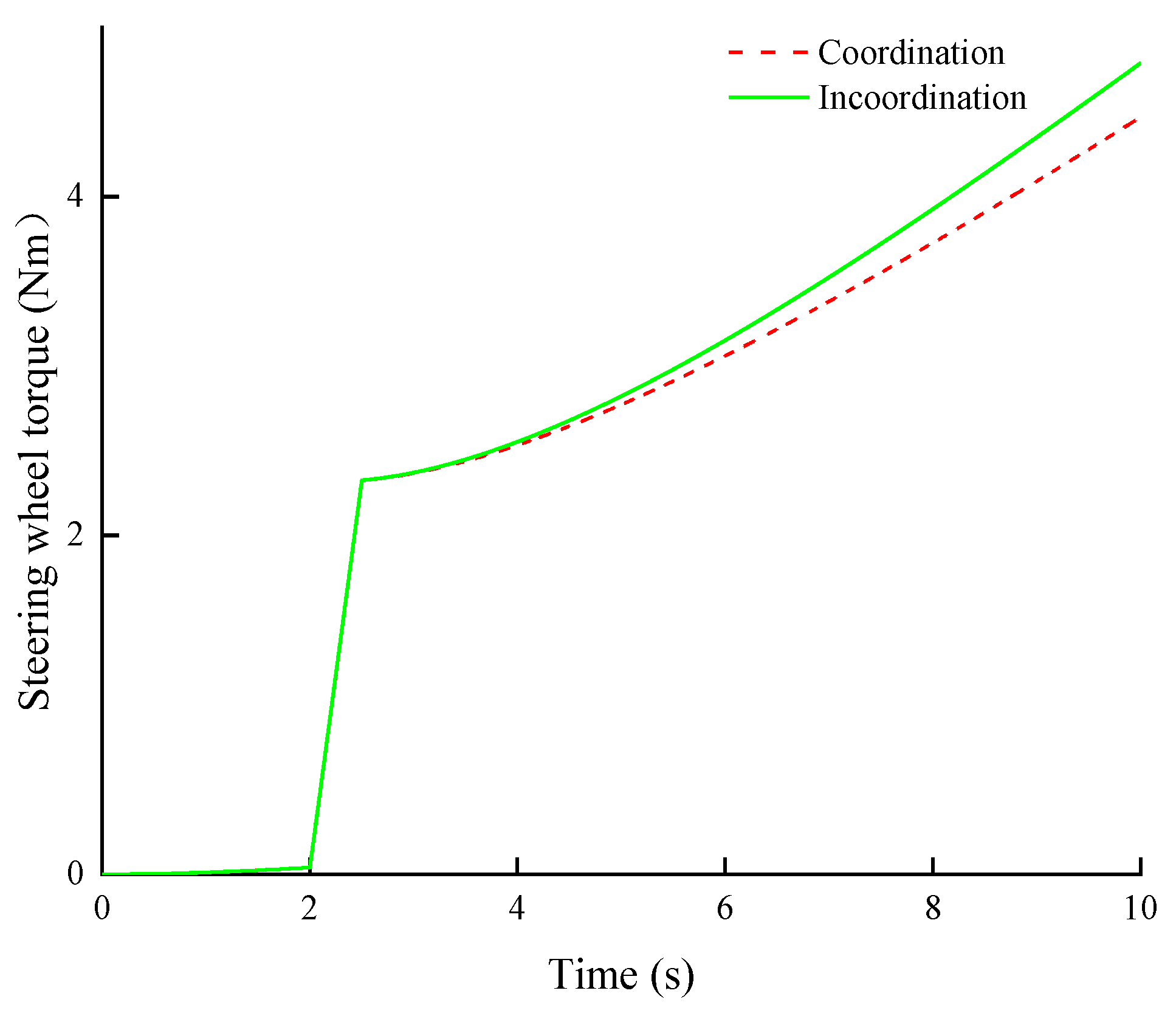

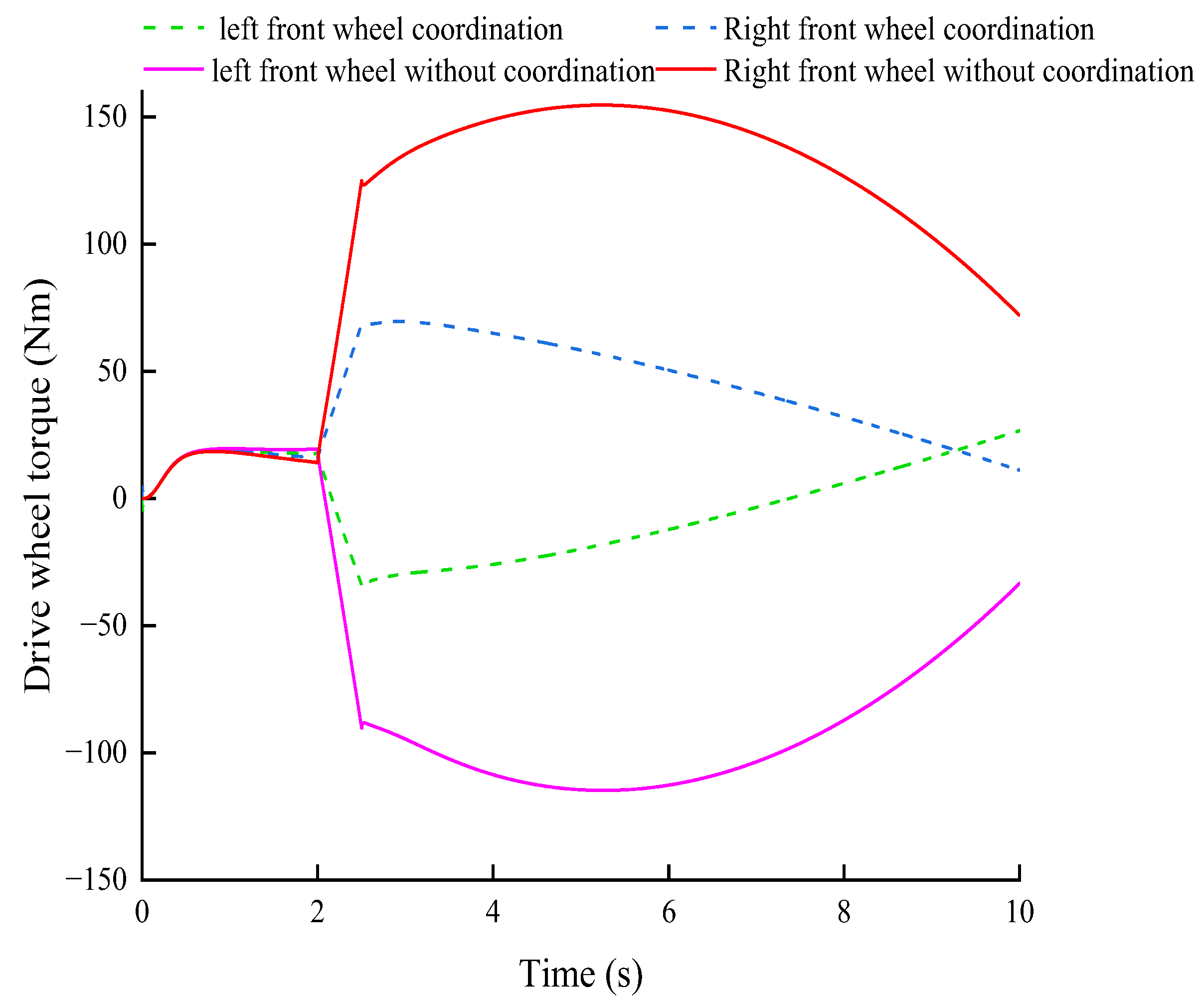

6.2. Verification of Angle Step Input

7. Conclusions

- A coupled dynamic model of the DDAS system integrating active steering function was established. On this basis, an AFS controllers based on yaw velocity feedback control and DDAS controllers based on steering wheel torque control were designed, respectively;

- The factors and causes of mutual interference between DDAS and AFS systems were analyzed, and a collaborative control strategy for DDAS and AFS was developed. A corner motor correction module was built to correct the corners to reduce the impact of the DDAS system on vehicle steering performance. A steering wheel torque correction module was established to correct the steering wheel torque to reduce the effects of AFS on the DDAS system. A power correction module has been built to enhance the collaborative control effect;

- In the co-simulation, the yaw velocity with coordinated control decreases by 4% compared with that without coordinated control under the double-shift condition. The peak value of AFS working alone is reduced by 2.4% compared to uncoordinated work. Under step operating conditions, the steering wheel torque using coordinated control is reduced by 0.32 Nm. The strategy’s effectiveness was verified under typical operating conditions, and it improved the vehicle’s handling stability and steering portability;

- This article provides a coordinated control strategy that is valuable for developing a DDAS system that integrates AFS. In future scientific research, it will be necessary to address the impact of DDAS on stability. Based on the characteristics of AFS and DYC systems, the coordinated control strategy of the system needs to be improved to prioritize ensuring the stability of vehicles during driving.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Wang, Q.; Jin, L.; Song, C. Independent wheel torque control of 4WD electric vehicle for differential drive assisted steering. Mechatronics 2011, 21, 63–76. [Google Scholar] [CrossRef]

- Jin, L.Q.; Wang, J.N.; Song, C.X.; Hu, C. Power Steering by Driving Force for Vehicle with Motorized Wheels. J. Mech. Eng. 2010, 3, 101–108. [Google Scholar] [CrossRef]

- Wang, J.N.; Wang, Q.N.; Song, C.X.; Jin, L.Q.; Hu, C.J. Co-simulation and Test of Differential Drive Assist Steering Control System for Four-wheel Electric Vehicle. J. Agric. Mach. 2010, 3, 7–13+30. [Google Scholar]

- Reinelt, W.; Klier, W.; Reimann, G.; Schuster, W.; Großheim, R. Active front steering (part 2): Safety and functionality. In Proceedings of the 2004 SAE World Congress, Detroit, MI, USA, 8–11 March 2004; pp. 1–9. [Google Scholar]

- Chen, L.; Yuan, C.Y.; Jiang, H.B.; Kai, X.; Shaohua, W. Self-adaptive Fuzzy Parameter Integrated Control of Automotive Active Suspension and Steering Systems. China Mech. Eng. 2006, 3, 2525–2528. [Google Scholar]

- Chen, W.; Xiao, H.; Jean, W. Hierarchical control of automotive electric power steering system and anti-lock brake system: Theory and experiment. Int. J. Veh. Des. 2012, 59, 23–43. [Google Scholar] [CrossRef]

- Wang, J.; Luo, Z.; Wang, Y.; Yang, B.; Assadian, F. Coordination Control of Differential Drive Assist Steering and Vehicle Stability Control for Four-Wheel-Independent-Drive EV. IEEE Trans. Veh. Technol. 2018, 67, 11453–11467. [Google Scholar] [CrossRef]

- Zhong, Z.H.; Xiao, Z.; Xiong, L.; Yang, X. Design of Differential Drive Assist Steering Controller Based on In-Wheel Motor Drive Electric Vehicle. J. Tongji Univ. Nat. Sci. 2017, 45, 47–52+104. [Google Scholar]

- Yu, Z.P.; Leng, B. Differential Drive Assisted Steering Control for Distributed Drive electric Vehicles. Automot. Eng. 2017, 3, 243–248+295. [Google Scholar]

- Lu, S.F.; Xu, X.; Chen, L.; Feng, W.; Wujie, W. Coordinated Control of Electronic Differential and Differential Drive Assisted Steering for Vehicle Driven by Hub Motor. Chin. J. Mech. Eng. 2017, 3, 78–85. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Luo, Z.; Assadian, F. Active Disturbance Rejection Control of Differential Drive Assist Steering for Electric Vehicles. Energies 2020, 13, 2647. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, T.; Li, J.; Wang, J. Coordinated Control Method for Lateral Stability and Differential Power-Assisted Steering of In-Wheel Motor Drive Electric Vehicles. World Electr. Veh. J. 2023, 14, 200. [Google Scholar] [CrossRef]

- Chen, D.L. Research on Control of Active front Steering System. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2008. [Google Scholar]

- Gao, Z.H.; Wang, J.; Wang, D.P. Dynamic Modeling and Steering Performance Analysis of Active Front Steering System. In Proceedings of the 2011 International Conference on Advanced in Control Engineering and Information Science CEIS 2011, Dali, China, 18–19 August 2011; Elsevier: Amsterdam, The Netherlands, 2011; Volume 2, pp. 1030–1035. [Google Scholar]

- Doumiati, M.; Sename, O.; Dugard, L.; Martinez-Molina, J.-J.; Gaspar, P.; Szabo, Z. Integrated vehicle dynamics control via coordination of active front steering and rear braking. Eur. J. Control 2013, 3, 121–143. [Google Scholar] [CrossRef]

- Ding, N.G.; Kang, L.; Wang, J.; Yu, G.-Z. Optimal control of active front steering for automobiles under lateral wind interference. J. Beijing Univ. Technol. 2013, 39, 161–165. [Google Scholar]

- Gao, X.J.; Yu, Z.P.; Zhang, L.J. The principle and Application of Mechanical Active Front Steering System. Automot. Eng. 2006, 3, 918–921932. [Google Scholar]

- Sang, N.; Wei, M.X. Design of ESO and N TSM controller for vehicle active front steering. J. Nanjing Univ. Aeronaut. Astronaut. 2018, 50, 521–527. [Google Scholar]

- Li, S.; Guo, K.; Chou, T.; Chen, H.; Wang, G.; Cui, G. Stability control of vehicle with active front steering under extreme conditions. Automot. Eng. 2020, 3, 191–198. [Google Scholar]

- Zhang, N.; Wang, J.; Li, Z.; Li, S.; Ding, H. Multi-Agent-Based Coordinated Control of ABS and AFS for Distributed Drive Electric Vehicles. Energies 2022, 15, 1919. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cui, T.W.; Zhao, W.Z.; Chen, J. Active front Steering Control based on Ideal Transmission Ratio. Trans. Chin. Soc. Agric. Eng. 2015, 31, 85–90. [Google Scholar]

- Zheng, H.; Li, J.; Zong, C.; Yuan, K.; Zhao, J.; Hou, J. Optimization design of vehicle yaw rate gain for steer-by-wire. J. Jilin Univ. Eng. Technol. Ed. 2012, 42, 7–12. [Google Scholar]

- Shang, G.G.; Hong, Z.; Zhang, H.D.; Luo, S.; He, R. Variable transmission ratio model of active steering system based on steady-state gain. J. Jiangsu Univ. Nat. Sci. Ed. 2010, 3, 278–282. [Google Scholar]

- Zhou, B.; Fan, L.; Lu, X.N. Design of Modified Variable Steering Ratio Curve for Active Front Steering System. China Mech. Eng. 2014, 25, 2813–2818. [Google Scholar]

- Wang, C.; Zhao, W.; Liu, S.; Sun, P. Parameter optimization of electric power steering integrated with active front steering function. Trans. Nanjing Univ. Aeronaut. Astronaut. 2012, 3, 96–102. [Google Scholar]

- Minaki, R.; Hoshino, H.; Hori, Y. Ergonomic verification of reactive torque control based on driver’s sensitivity characteristics for active front steering. In Proceedings of the Vehicle Power and Propulsion Conference 2009 VPPC 2009, Dearborn, MI, USA, 7–11 September 2009; pp. 160–164. [Google Scholar]

- Minaki, R.; Hori, Y. Experimental verification of driver-friendly reactive torque control based on driver sensitivity to active front steering. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 3077–3082. [Google Scholar]

- Zhou, B.; Xu, M.; Fan, L. AFS and EPS Integrated Control Based on EKF Tire Lateral Force Estimation. J. Vib. Shock 2015, 34, 93–98. [Google Scholar]

- Wei, J.W.; Wei, M.X.; Li, Y.F. EPS Assisted Correction Control Strategy and Evaluation for Active Steering Intervention. China Mech. Eng. 2012, 3, 1873–1876. [Google Scholar]

- Wei, J.W.; Wei, M.X. Correction strategy for sudden change of steering wheel torque in EPS System based on active steering Intervention. J. Nanjing Univ. Aeronaut. Astronaut. 2011, 3, 572–576. [Google Scholar]

- Wang, J.N.; Guo, D.D.; Yan, T.X.; Assadian; Francis; Luo, Z. Coordinated Control of DDAS and AFS in Electric Vehicles. J. Jilin Univ. Eng. Ed. 2020, 3, 776–783. [Google Scholar]

- Jilin University. Differential Collaborative Active Steering System and Its Control Method for Electric Wheel Front Axle Independent Drive Vehicles; CN201911238318.2, 6 March 2020; Jilin University: Changchun, China, 2020. [Google Scholar]

- Wei, J.; Shi, G.; Lin, Y. Design of new variable steering ratio for mechanical active steering system. In Proceedings of the 2013 IEEE International Conference on Vehicular Electronics and Safety, Dongguan, China, 28–30 July 2013; IEEE Press: New York, NY, USA, 2013; pp. 27–30. [Google Scholar]

- Yu, Z.P.; Zhao, Z.G.; Chen, H. Influence of active front steering on vehicle maneuver and stability performance. China Mech. Eng. 2005, 3, 652–657. [Google Scholar]

- Guo, K.H. Automotive Handling Dynamic; Jilin Science and Technology Press: Changchun, China, 1991. [Google Scholar]

- Xiao, B. The Research of Fuzzy Variable Transmission Ratio for Steer-by-wire System of Electric Forklift. Int. J. Intell. Syst. Appl. IJISA 2015, 7, 31–39. [Google Scholar] [CrossRef]

- Shi, G.B.; Zhao, W.Z.; Wang, C.L.; Li, Q.; Lin, Y. Influence of Variable Steering Ratio for Steering by-wire System on Vehicle Handling Stability. Trans. Beijing Inst. Technol. 2008, 28, 207–210. [Google Scholar]

- Zhang, Y.K.; Liu, B.H. Study on the Active Front Steering System with Steady Gain. In Proceedings of the FISITA 2012 World Automotive Congress, Beijing, China, 27–30 November 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 65–74. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Moment of inertia steering shaft | Jc/(kg.m2) | 0.04 |

| Steering shaft damping coefficient | Bc/(Nm.s/rad) | 0.0225 |

| Steering shaft torsional stiffness | Kc/(Nm.s/rad) | 150 |

| Pinion radius | rp/m | 0.0078 |

| Moment of inertia of reducer | Je/(kg.m2) | 0.6 |

| Damping coefficient of reducer | Be/(Nm.s/rad) | 0.02 |

| Motor moment of inertia | Jm/(kg.m2) | 0.006 |

| Motor reduction mechanism steering ratio | im | 30 |

| Forward transmission efficiency of steering gear | ηF | 0.9 |

| Reverse transmission efficiency of steering gear | ηB | 0.7 |

| Kingpin inclination angle | σ/(°) | 8 |

| Kingpin caster angle | τ/(°) | 3 |

| Lateral offset of the main pin | rσ/(°) | 0.07 |

| Parameter | Incoordination | Coordination |

|---|---|---|

| Yaw velocity/(rad) | 0.326 | 0.313 |

| Front-wheel angles/(°) | 6.062 | 5.591 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Ding, X.; Shi, Z. Research on Collaborative Control of Differential Drive Assisted Steering and Active Front Steering for Distributed Drive Electric Vehicles. World Electr. Veh. J. 2023, 14, 292. https://doi.org/10.3390/wevj14100292

Zhou Z, Ding X, Shi Z. Research on Collaborative Control of Differential Drive Assisted Steering and Active Front Steering for Distributed Drive Electric Vehicles. World Electric Vehicle Journal. 2023; 14(10):292. https://doi.org/10.3390/wevj14100292

Chicago/Turabian StyleZhou, Zhigang, Xinqing Ding, and Zhichong Shi. 2023. "Research on Collaborative Control of Differential Drive Assisted Steering and Active Front Steering for Distributed Drive Electric Vehicles" World Electric Vehicle Journal 14, no. 10: 292. https://doi.org/10.3390/wevj14100292

APA StyleZhou, Z., Ding, X., & Shi, Z. (2023). Research on Collaborative Control of Differential Drive Assisted Steering and Active Front Steering for Distributed Drive Electric Vehicles. World Electric Vehicle Journal, 14(10), 292. https://doi.org/10.3390/wevj14100292