Review of the Charging Safety and Charging Safety Protection of Electric Vehicles

Abstract

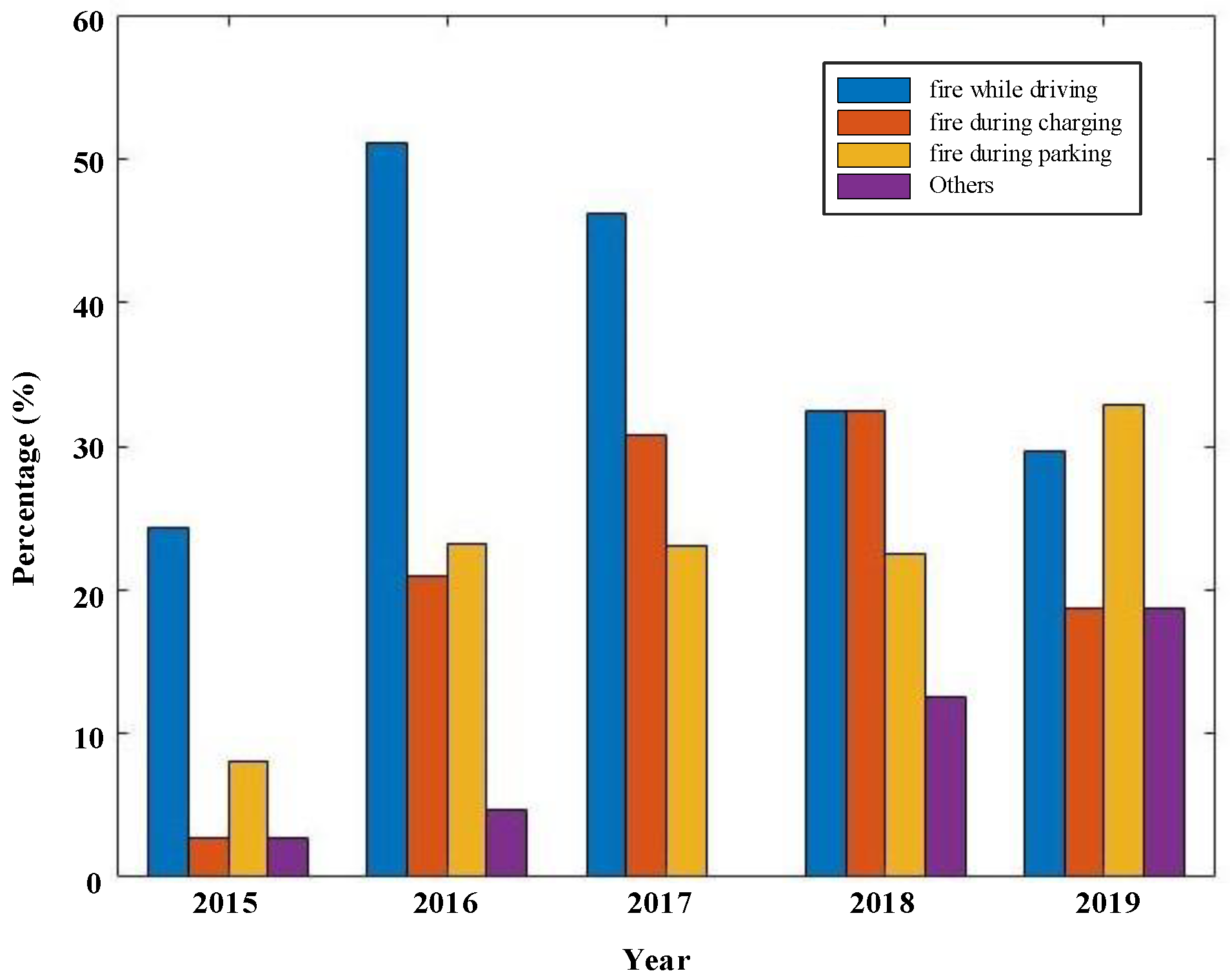

:1. Introduction

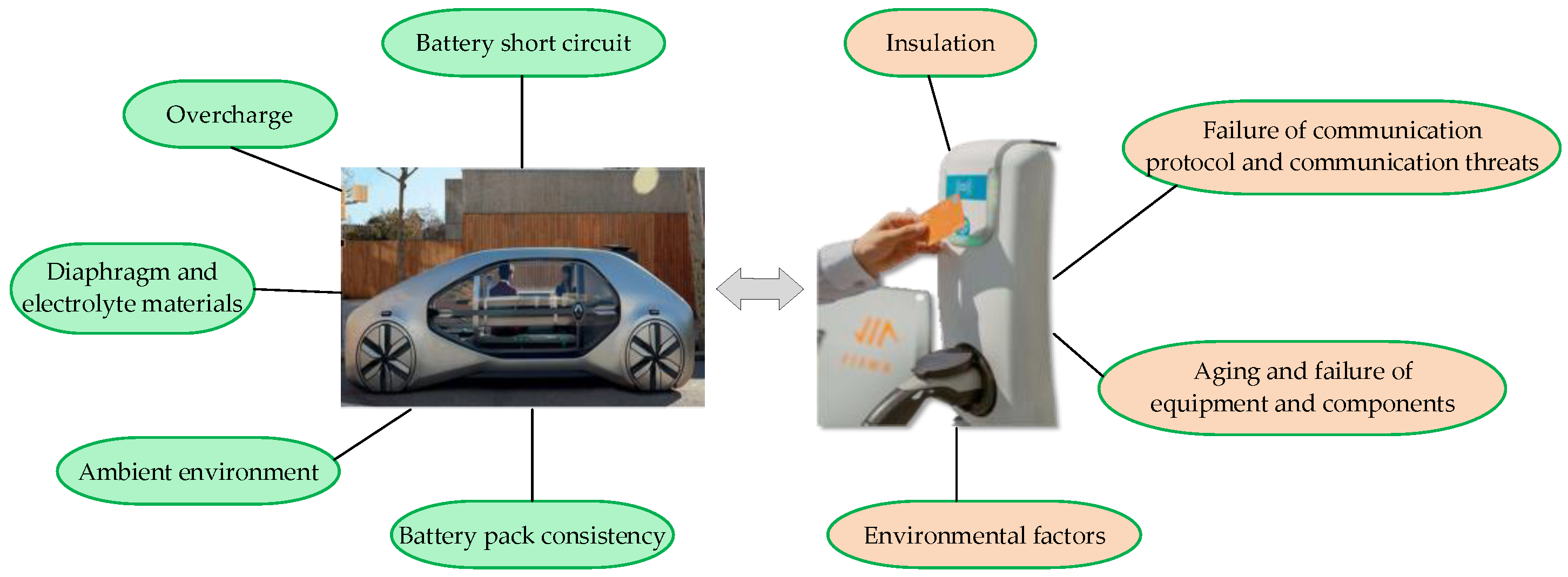

2. Analysis of the Influencing Factors of the Charging Safety of Electric Vehicles

2.1. Influencing Factors of Electric Vehicle Safety

2.1.1. Battery Short Circuit

2.1.2. Overcharge

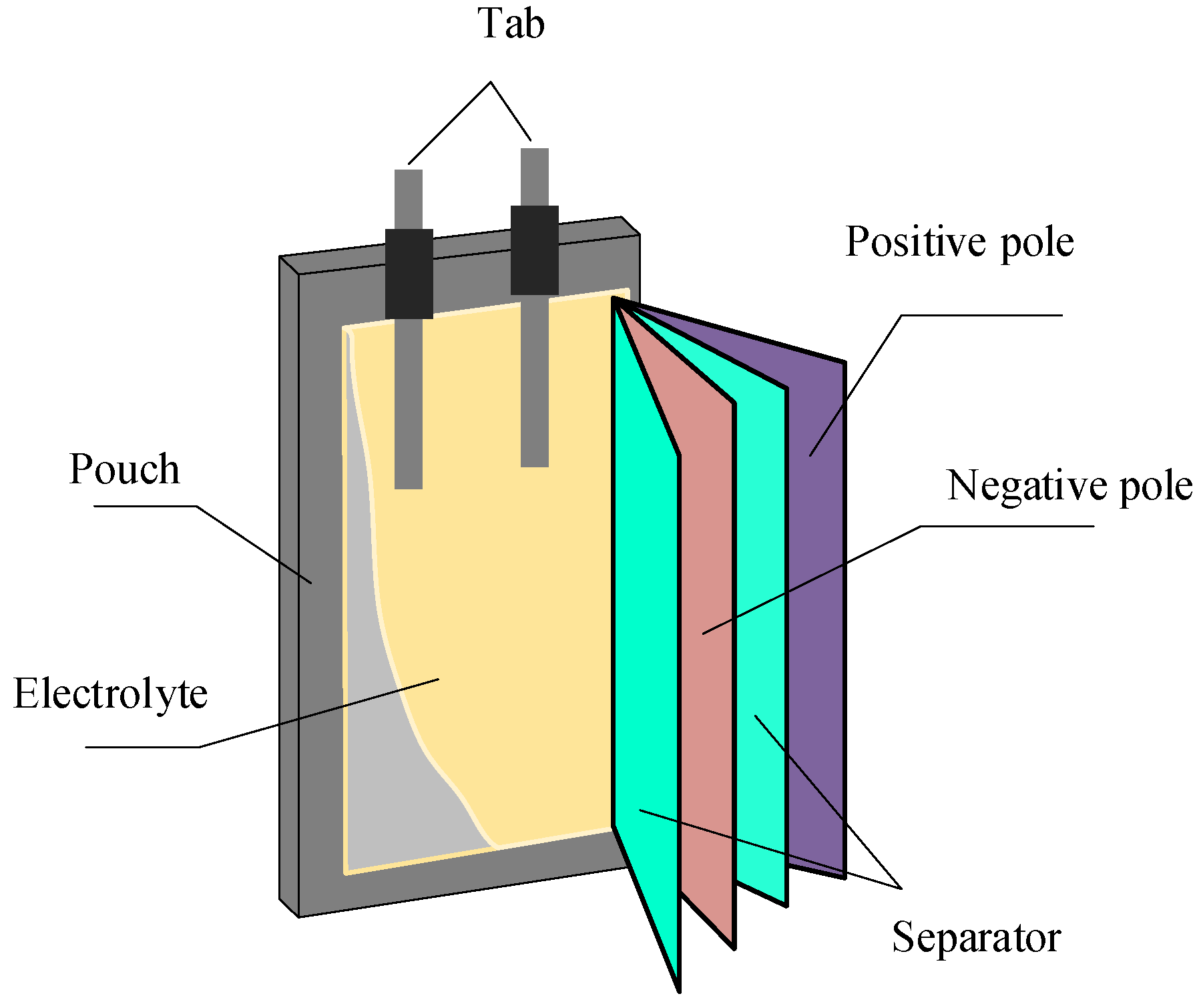

2.1.3. Diaphragm and Electrolyte

2.1.4. Battery Pack Consistency

2.1.5. Ambient Environment

2.1.6. Other Influencing Factors

2.2. Influencing Factors of Charging Pile Safety

2.2.1. Insulation

2.2.2. Failure of Communication Protocol and Communication Threats

2.2.3. Aging and Failure of Equipment and Components

2.2.4. Environmental Factors

2.2.5. Other Influencing Factors

3. Analysis of the Charging Safety Protection of Electric Vehicles

3.1. Charging Safety Protection of the Batteries of Electric Vehicles

3.1.1. Internal Short-Circuit Detection and Protection Technology

3.1.2. Battery Overcharge Mechanism Analysis and Diagnostic Protection Technology

3.1.3. Battery Pack Equalization Technology

3.1.4. Development and Application of High Stable Battery Materials

3.1.5. Battery Status Parameter Monitoring and Fault Diagnosis Method

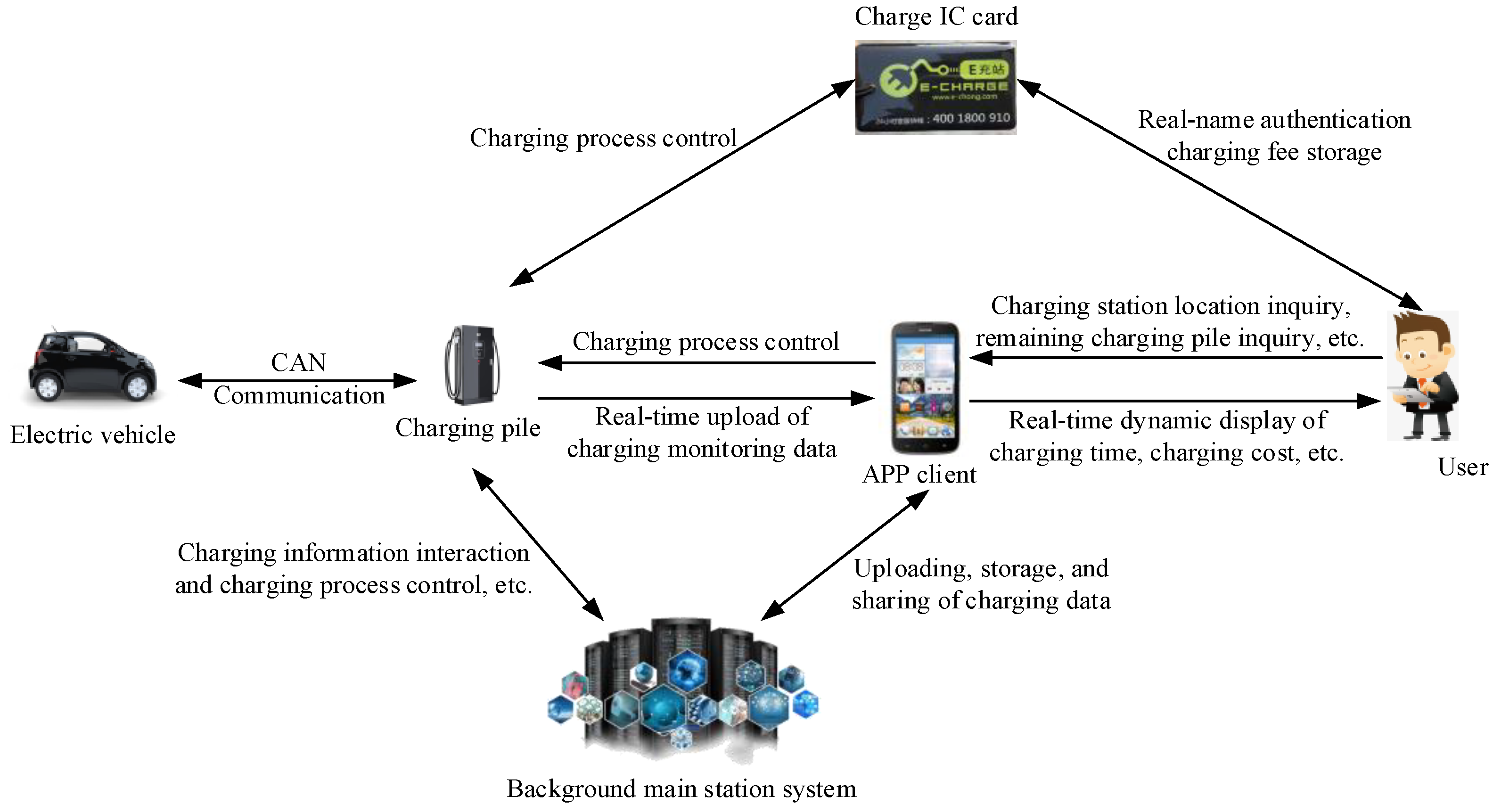

3.2. Charging Safety Protection of the Charging Equipment of Electric Vehicles

3.2.1. Insulation Protection Technology of Charging Equipment

3.2.2. Communication Safety Protection Technology of Charging Piles

3.2.3. Aging Prediction and Protection Technology of Charging Piles

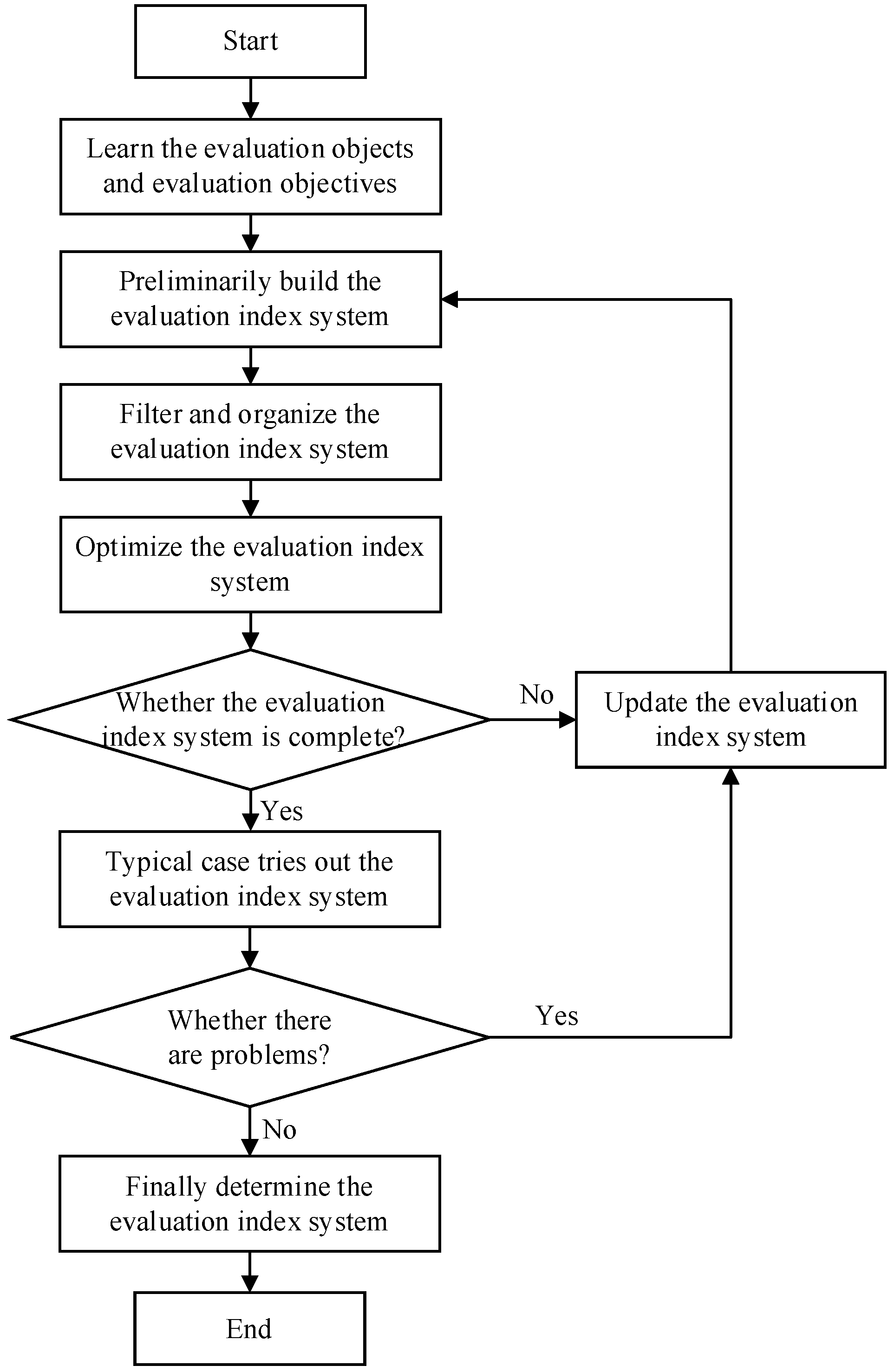

3.3. Charging Safety Evaluation Index System and Early Warning Model

4. Research Prospect

4.1. Improve the Standard System of Charging Safety of Electric Vehicles

4.2. Build a More Complete Charging Safety Database

4.3. Establish a High-Credibility Battery Fault Diagnosis Model

4.4. Establish a Sounder Dynamic Monitoring and Fault Early Warning Mechanism for Charging Equipment

4.5. Strengthen the Research on Charging Safety Protection Technology of Electricity Quality Fluctuation

4.6. Optimize the Charging Data Storage Scheme Based on Emerging Technologies Such as Blockchain

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Qiang, X.; Zhong, C.; Zhaoying, L.; Yu, L.; Yi, L. Route planning and charging navigation strategy for electric vehicles based on real-time traffic information. Proc. CSEE 2020, 40, 534–550. [Google Scholar] [CrossRef]

- Hong, L.; Jun, Y.; Shaoyun, G.; Jun, H. Dynamic response of electric vehicle and fast charging stations considering multi vehicle interaction. Proc. CSEE 2020, 40, 6455–6468. [Google Scholar]

- Gangui, Y.; Huanan, L.; Ninghui, H.; Songsong, C.; Dongmin, Y. An optimization method for location and capacity determination of charging stations considering spatial and temporal distribution of electric vehicles. Proc. CSEE 2021, 41, 6271–6284. [Google Scholar]

- Nan, L. Review on electric vehicle safety issues considering international regulations. Environ. Technol. 2020, 38, 216–223. [Google Scholar]

- Hanxiao, M. Research on safety test of electric vehicle. Sci. Technol. Innov. 2019, 29, 69–70. [Google Scholar]

- Angel, R.M.; Thomas, N. Injury surveillance and safety considerations for large- format lead-acid batteries used in mining applications. IEEE Trans. Ind. Appl. 2016, 52, 1925–1930. [Google Scholar]

- Hongxia, G.; Yuechun, Q.; Hongying, Z. The influence of over discharge on the performance of sintered Ni/MH battery. Batteries 2009, 39, 159–160. [Google Scholar]

- Spotnitz, R.; Franklin, J. Abuse behavior of high-power, lithium-ion cells. J. Power Sources 2003, 113, 81–100. [Google Scholar] [CrossRef]

- Manthiram, A. Materials Challenges and Opportunities of Lithium Ion Batteries. J. Phys. Chem. Lett. 2011, 2, 176–184. [Google Scholar] [CrossRef]

- Xuning, F. Mechanism, Modeling and Prevention of Thermal Runaway Induction and Expansion of Vehicle Li Ion Power Battery; Tsinghua University: Beijing, China, 2016. [Google Scholar]

- Ruguang, F.; Xuan, X.; Nan, J.; Hongting, W.; Jingxin, S. Design of charging safety protection system for electric bus. Mod. Manuf. Technol. Equip. 2019, 4, 104–105. [Google Scholar]

- Xiong, W. Functional Safety Analysis and Fault Diagnosis of Power Battery Charging; Xihua University: Chengdu, China, 2020. [Google Scholar]

- Zhijing, H.; Mao, L. Electric Vehicle Charging Safety Analysis and Solution Research; Shandong Industrial Technology: Jinan, China, 2017; p. 47. [Google Scholar]

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. Power Electron. IEEE 2012, 92, 50–59. [Google Scholar] [CrossRef]

- Fleischhammer, M.; Waldmann, T.; Bisle, G.; Hogg, B.-I.; Wohlfahrt-Mehrens, M. Interaction of cyclic ageing at high-rate and low temperatures and safety in lithium-ion batteries. J. Power Sources 2015, 274, 432–439. [Google Scholar] [CrossRef]

- Binghe, L.; Fucheng, Z.; Chuanyun, J. Trouble analysis and clearing of high voltage insulation fault during charging for plug-in hybrid bus. Bus Technol. Res. 2015, 37, 44–46, 61. [Google Scholar]

- Nian, L.; Bin, D. Discussion on security message of IEC 60870-5-104 telecontrol protocol. Autom. Electr. Power Syst. 2005, 29, 93–96. [Google Scholar]

- Fries, S.; Falk, R. Electric vehicle charging infrastructure-security considerations and approaches. In Proceedings of the Fourth International Conference on Evolving Internet—INTERNET 2012, Venice, Italy, 24–29 June 2012; pp. 58–64. [Google Scholar]

- FDIS 27001-2005, BS 7799-2-2005(ISO/IEC FDIS 27001-2005) Draft: Information Technology. Security Technology. Information Safety Management System. Requirements (See Item Summary for Details of Specific Offer); ISO/IEC: Geneva, Switzerland, 2005.

- GB/T 20984-2007, Information Safety Technology Information Safety Risk Assessment Specification; Standardization Administration Committee of China: Beijing, China, 2007.

- GB/Z 24364-2009, Information Safety Technology Information Safety Risk Management Guide; Standardization Administration Committee of China: Beijing, China, 2009.

- GB/T 31509-2015, Information Safety Technology Information Safety Risk Assessment Implementation Guide; Standardization Administration Committee of China: Beijing, China, 2015.

- GB/T 31722-2015, Information Technology Security Technology Information Safety Risk Management; Standardization Administration Committee of China: Beijing, China, 2015.

- Pannala, S.; Turner, J.A.; Allu, S.; Elwasif, W.R.; Kalnaus, S.; Simunovic, S.; Kumar, A.; Billings, J.J.; Wang, H.; Nanda, J. Multiscale modeling and characterization for performance and safety of lithium-ion batteries. J. Appl. Phys. 2015, 118, 072017. [Google Scholar] [CrossRef]

- Xia, B.; Shang, Y.; Nguyen, T.; Mi, C. A correlation based fault detection method for short circuits in battery packs. J. Power Sources 2017, 337, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Jing, Z.; Wei, S.; Yuanxing, Z.; Jing, Z.; Taoyong, L. Analysis of safety factors and dynamic warning during charging process of electric vehicle. Power Technol. 2019, 43, 861–863+868. [Google Scholar]

- Xia, B.; Mi, C.; Chen, Z.; Robert, B. Multiple cell lithium-ion battery system electric fault online diagnostics. In Proceedings of the 2015 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 14–17 June 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Yao, X. Design of Lithium-Ion Battery Fault Analysis and Processing System; University of Electronic Science and Technology of China: Chengdu, China, 2018. [Google Scholar]

- Longyun, S. Protection of Electric Vehicle Charging Pile Against Electric Shock. Commun. Power Supply Technol. 2020, 37, 218–219. [Google Scholar]

- Broek FV, D.; Poll, E.; Vieira, B. Securing the information infrastructure for EV charging. In Wireless and Satellite System; Springer International Publishing: Berlin, Germany, 2015; pp. 61–74. [Google Scholar]

- Weixian, W.; Jie, Z.; Heping, T.; Zhen, C.; Xiaoxi, Y. Design and implementation of information safety protection scheme of electric vehicle charging pile-background service management center. Power Constr. 2019, 40, 55–62. [Google Scholar]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Wu, C.; Zhu, C.; Ge, Y.; Zhao, Y. A Review on Fault Mechanism and Diagnosis Approach for Li-Ion Batteries. J. Nanomater. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Jin, S.; Bai, D.; Fan, Y.; Shi, H.; Fernandez, C. A critical review of improved deep learning methods for the remaining useful life prediction of lithium-ion batteries. Energy Rep. 2021, 7, 5562–5574. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, G.; Zhen, D.; Gu, F.; Ball, A. A review on online state of charge and state of health estimation for lithium-ion batteries in electric vehicles. Energy Rep. 2021, 7, 5141–5161. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review of Battery Cell Balancing Methodologies for Optimizing Battery Pack Performance in Electric Vehicles. IEEE Access 2019, 7, 129335–129352. [Google Scholar] [CrossRef]

- Kexin, W.; Qiaoyan, C. State estimation of li-ion power batteries based on adaptive unscented kalman filters. Proc. CSEE 2014, 34, 445–452. [Google Scholar]

- Gangui, Y.; Hongbo, L.; Shuangming, D.; Changxing, C.; Ying, L.; Junhui, L.; Bo, X. Energy storage battery state estimation based on model parameter identification. Proc. CSEE 2020, 40, 8145–8154, 8251. [Google Scholar]

- Ge, Z.; Xin, Z.; Guodong, L.; Zhidan, X.; Yuexin, Y. Research on vehicular lithium-ion battery system with charging and replacing technology. Power Technol. 2017, 41, 641–643. [Google Scholar]

- Alvarez, B.L.; Garcia, S.V.; Ramis, C.F. Developing an active balancing model and its Battery Management System platform for lithium-ion batteries. In Proceedings of the 2013 IEEE International Symposium on Industrial Electronics, Taipei, Taiwan, 28–31 May 2013. [Google Scholar]

- Janakeeraman, S.V.; Singh, J.; Kuitche, J.; Mallineni, J.K.; TamizhMani, G. A statistical analysis on the cell parameters responsible for power degradation of fielded PV modules in a hot-dry climate. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 3234–3238. [Google Scholar]

- Jiawang, Z.; Rong, Z.; Yongyang, Z.; Chun, L.; Guilin, L. Research on safety of lithium-ion battery for electric vehicle. Power Technol. 2018, 42, 1134–1135, 1179. [Google Scholar]

- Jiyong, C.; Xinxin, L. Analysis and Exploration on safety problems of lithium-ion batteries for new energy vehicles. Times Agric. Mach. 2019, 46, 63–64. [Google Scholar]

- Mengdi, Z. Research on Thermal Safety Response and Overheating Critical Behavior Characteristics of Agricultural Machinery Power Battery in the New Era; Jilin University: Jilin, China, 2019. [Google Scholar]

- Maleki, H.; Howard, J.N. Internal short circuit in Li-ion cells. J. Power Sources 2009, 191, 568–574. [Google Scholar] [CrossRef]

- Wei, W.; Youren, W. Review of internal short circuit of lithium-ion battery. Mach. Manuf. Autom. 2020, 49, 169–172. [Google Scholar]

- Zeyu, C.; Rui, X.; Fengchun, S. Research Status and Analysis for Battery Safety Accidents in Electric Vehicles. Chin. J. Mech. Eng. 2019, 55, 93–104, 116. [Google Scholar] [CrossRef]

- Qingsong, Z.; Ziheng, Z.; Wei, B. Thermal safety analysis of ternary lithium-ion battery under overcharge condition. Fire Sci. Technol. 2020, 39, 713–717. [Google Scholar]

- Yongxing, G. Research on Key Technology Foundation and Safety of Lithium-Ion Power Battery Manufacturing; Central South University: Changsha, China, 2010. [Google Scholar]

- Ouyang, D.; He, Y.; Chen, M.; Liu, J.; Wang, J. Experimental study on the thermal behaviors of lithium-ion batteries under discharge and overcharge conditions. J. Therm. Anal. Calorim. 2017, 132, 65–75. [Google Scholar] [CrossRef]

- Wei, S. Research on Integrated Safety Warning and Protection System of Electric Vehicle Charging; Nanjing University of Posts and Telecommunications: Nanjing, China, 2018. [Google Scholar]

- Yan, W. Study on Electrolyte Solution for Lithium-Ion Battery with Wide Temperature Range; Tianjin University: Tianjin, China, 2007. [Google Scholar]

- Minyi, C.; Ei, Z.; Jing, L.; Kangli, W.; Kai, J.; Min, Z. Review on Balancing Topology of Lithium-ion Battery Pack. Proc. CSEE 2021, 41, 5294–5311. [Google Scholar]

- Yang, L.; Caiping, Z.; Jiuchun, J.; Weige, Z.; Linjing, Z. Research on capacity difference identification method of lithium-ion battery pack. Proc. CSEE 2021, 41, 1422–1430. [Google Scholar]

- Yunlong, G.; Ziqiang, C. Inconsistency identification and state estimation of series-connected lithium-ion batteries pack based on STF&LM algorithm. Proc. CSEE 2018, 38, 4271–4280+4333. [Google Scholar]

- Shuai, W.; Zhongdong, Y.; Zhong, Z.; Yuanzhao, H.; Yinshun, W.; Yuting, Y. The influence of cell parameters inconsistency on the performance of different topological battery modules. Electr. Meas. Instrum. 2020, 57, 76–82. [Google Scholar]

- Wang; Tianfu; Qiang, L.; Zhiqiang, L. Design and implementation of charging and discharging intelligent management system for power lithium battery pack. Power Technol. 2011, 35, 1069–1071. [Google Scholar]

- Ming, G. Experimental Study on Thermal Management of Li Ion Battery Pack for Pure Electric Vehicle; Tianjin University: Tianjin, China, 2016. [Google Scholar]

- Mingyu, Z.; Gang, W.; Yinghui, W.; Guangming, S. Design and implementation of a supervisory and control system for charging facilities of electric vehicles. Autom. Electr. Power Syst. 2011, 35, 65–69+98. [Google Scholar]

- Shengguo, G.; Yunxiang, L.; Dongxue, X.; Xiangnan, F. Research on safety protection of charging system of electric vehicle. Ind. Eng. Des. 2020, 2, 121–122. [Google Scholar]

- Ping, Z.; Lin, S.; Yuejiu, Z.; Yangminggao, O.; Long, Z. Experimental study on characteristics of over-discharged Li-NCM battery. J. Automob. Saf. Energy Sav. 2017, 8, 72–78. [Google Scholar]

- Peng, Y. Research on off Board DC Charging Communication and Safety System; North China Electric Power University (Beijing): Beijing, China, 2017. [Google Scholar]

- GB/T 27930-2015, Communication Protocol between Electric Vehicle Off Board Conductive Charger and Battery Management System; Standardization Administration Committee of China: Beijing, China, 2015.

- GB/T 18487.1-2015, Conductive Charging System for Electric Vehicles Part 1: General Requirements; Standardization Administration Committee of China: Beijing, China, 2015.

- Chun, H.; Zhuo, C.; Jintao, F.; Qingwei, Y.; Xiang, L. Analysis and solutions on the safety of electric vehicle charging. Power Supply Consum. 2017, 34, 12–18, 50. [Google Scholar]

- Guoxin, H. Safety Design and Experimental Study of PHEV Power Battery System; South China University of Technology: Guangzhou, China, 2016. [Google Scholar]

- Xiang, T.; Yingfeng, C.; Xiao, X.; Bin, H.; Anping, M. Analysis on influencing factors of conductive charging safety for electric vehicles. China Automob. 2019, 12, 45–49. [Google Scholar]

- Peimin, H. Electric vehicle charging safety analysis and Solutions. Time Car 2018, 9, 71–72. [Google Scholar]

- Lei, Y. Research and Implementation of information safety Protection Technology for Distributed Electric Vehicle Charging Post. Manag. Technol. SME (Next Ten Days) 2020, 2, 165–166. [Google Scholar]

- Baojun, Z. Research and Implementation of Information Safety Protection Technology for Distributed Electric Vehicle Charging Pile; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Jun, L.; Ling, X. Aging Testing System for Rectifier Module of Electric Vehicle Charger Based on μC/OS-II Embedded System. Digit. Commun. World 2017, 7, 3–240. [Google Scholar]

- NB/T 33001-2010, Technical Specification for Off Board Conductive Charger of Electric Vehicle; China National Energy Administration: Beijing, China, 2010.

- Daoping, W.; Yaoxi, W.; Yu, T.; Xinhui, L. How to do the lightning protection work of charging station well. China Meteorological Society. In Proceedings of the 2018 16th Lightning Protection and Disaster Reduction Forum, Hefei, China, 24 October 2018; China Meteorological Society: Beijing, China, 2018; p. 3. [Google Scholar]

- Zuoqin, Z. Construction of qualified charging pile and safety firewall. Fujian Qual. Technol. Superv. 2018, 12, 35–36. [Google Scholar]

- Zuoqin, Z. Discussion on performance and safety problems of electric vehicle DC charging spot. Qual. Technol. Superv. Res. 2020, 1, 39–42. [Google Scholar]

- Hong, C. Analysis and research on charging safety of electric vehicles. Intern. Combust. Engine Parts 2017, 21, 113–114. [Google Scholar]

- Quan, W.; Miaomiao, S.; Tiange, D. On the safety of lithium-ion batteries for new energy vehicles. Mach. Manuf. 2019, 57, 55–56+93. [Google Scholar]

- Fei, G.; Yanli, Z.; Chuang, Q.; Songcen, W.; Kai, Y. Excitation source analysis of lithium-ion batteries safety accidents. Power Technol. 2019, 43, 453–457. [Google Scholar]

- Ouyang, M.; Zhang, M.; Feng, X.; Lu, L.; Li, J.; He, X.; Zheng, Y. Internal short circuit detection for battery pack using equivalent parameter and consistency method. J. Power Sources 2015, 294, 272–283. [Google Scholar] [CrossRef]

- Feng, X.; Pan, Y.; He, X.; Wang, L.; Ouyang, M. Detecting the internal short circuit in large-format lithium-ion battery using model-based fault-diagnosis algorithm. J. Energy Storage 2018, 18, 26–39. [Google Scholar] [CrossRef]

- Feng, X.; Weng, C.; Ouyang, M.; Sun, J. Online internal short circuit detection for a large format lithium ion battery. Appl. Energy 2016, 161, 168–180. [Google Scholar] [CrossRef] [Green Version]

- Kong, X.; Zheng, Y.; Ouyang, M.; Lu, L.; Li, J.; Zhang, Z. Fault diagnosis and quantitative analysis of micro-short circuits for lithium-ion batteries in battery packs. J. Power Sources 2018, 395, 358–368. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, L.; Stefanopoulou, A.; Siegel, J.; Lu, L.; He, X.; Ouyang, M. Fusing Phenomenon of Lithium-Ion Battery Internal Short Circuit. J. Electrochem. Soc. 2017, 164, A2738–A2745. [Google Scholar] [CrossRef] [Green Version]

- Seo, M.; Goh, T.; Park, M.; Koo, G.; Kim, S.W. Detection of Internal Short Circuit in Lithium Ion Battery Using Model-Based Switching Model Method. Energies 2017, 10, 76. [Google Scholar] [CrossRef]

- Fernandes, Y.; Bry, A.; de Persis, S. Identification and quantification of gases emitted during abuse tests by overcharge of a commercial Li-ion battery. J. Power Sources 2018, 389, 106–119. [Google Scholar] [CrossRef]

- Fernandes, Y.; Bry, A.; de Persis, S. Thermal degradation analyses of carbonate solvents used in Li-ion batteries. J. Power Sources 2019, 414, 250–261. [Google Scholar] [CrossRef]

- Chuang, Q.; Yanli, Z.; Fei, G.; Songcen, W.; Kai, Y.; Jianxin, N.; Qingjie, J. Thermal runaway analysis of lithium-ion battery with overcharge. J. Beijing Univ. Technol. 2017, 37, 1048–1055. [Google Scholar]

- Lin, C.T.; Cui, C.; Xu, X.T. Lithium-ion battery electro-thermal model and its application in the numerical simulation of short circuit experiment. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–22 November 2013; pp. 1–8. [Google Scholar]

- Huang, P.; Verma, A.; Robles, D.J.; Wang, Q.; Mukherjee, P.; Sun, J. Probing the cooling effectiveness of phase change materials on lithium-ion battery thermal response under overcharge condition. Appl. Therm. Eng. 2018, 132, 521–530. [Google Scholar] [CrossRef]

- Ye, J.; Chen, H.; Wang, Q.; Huang, P.; Sun, J.; Lo, S.M. Thermal behavior and failure mechanism of lithium ion cells during overcharge under adiabatic conditions. Appl. Energy 2016, 182, 464–474. [Google Scholar] [CrossRef]

- Yong, Z. Research on Overcharge and over- Discharge Fault Diagnosis of Lithium-Ion Battery; Chang’an University: Xi’an, China, 2016. [Google Scholar]

- Yanxian, S.; Zhaohua, J. Safety of overcharge test of lithiumion batteries. Power Technol. 2019, 43, 884–886. [Google Scholar]

- Xiugang, L. Research on Active Equalization Strategy in Charging Process of Power Battery Pack; Jilin University: Jilin, China, 2017. [Google Scholar]

- Minji, Z.; Yangzhou, S.; Jia, L.; Yujie, Z.; Zhibin, L. The balancing efficiency analysis of the switched-capacity method. Energy Storage Sci. Technol. 2016, 5, 222–227. [Google Scholar]

- Shibata, H.; Taniguchi, S.; Yamasaki, K. Management of serially-connected battery system using multiple switches. In Proceedings of the 4th IEEE International Conference on Power Electronics and Drive Systems, Denpasar, Indonesia, 25 October 2001; Volume 2, pp. 508–511. [Google Scholar]

- Nishijima, K.; Sakamoto, H.; Harada, K. A PWM controlled simple and high performance battery balancing system. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference, Conference Proceedings (Cat. No.00CH37018), Galway, Ireland, 23–23 June 2000; Volume 1, pp. 517–520. [Google Scholar] [CrossRef]

- Kimball, J.W.; Krein, P.T. Analysis and design of switched capacitor converters. In Proceedings of the Twentieth Annual IEEE Applied Power Electronics Conference and Exposition–APEC 2005, Austin, TX, USA, 6–10 March 2005; Volume 3, pp. 1473–1477. [Google Scholar]

- Cao, J.; Schofield, N.; Emadi, A. Battery balancing methods: A comprehensive review. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Kai, Z.; Li, S.; Shaogui, F. Research on design methodology of super capacitor balancing system based on multi-winding transformer. Power Electron. 2018, 52, 37–40. [Google Scholar]

- Cho, W.; Kim, S.-M.; Lee, K.-W.; Song, J.H.; Jo, Y.N.; Yim, T.; Kim, H.; Kim, J.-S.; Kim, Y.-J. Investigation of new manganese orthophosphate Mn3(PO4)2 coating for nickel-rich LiNi0.6Co0.2Mn0.2O2 cathode and improvement of its thermal properties. Electrochim. Acta 2016, 198, 77–83. [Google Scholar] [CrossRef]

- Baginska, M.; Blaiszik, B.J.; Merriman, R.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Automatic shutdown of lithium-ion batteries using thermoresponsive microspheres. Adv. Energy Mater. 2012, 2, 583–590. [Google Scholar] [CrossRef]

- Dianmo, Z.; Xin, C.; Hongxiang, G.; Weiwei, L. Preparation and electrochemical properties of silicon /carbon anode materials for lithium-ion batteries. Mod. Chem. Ind. 2018, 38, 118–121+123. [Google Scholar]

- Ko, Y.; Yoo, H.; Kim, J. Curable polymeric binder–ceramic composite-coated superior heat-resistant polyethylene separator for lithium ion batteries. RSC Adv. 2014, 4, 19229–19233. [Google Scholar] [CrossRef]

- Yuhong, C.; Liang, W.; He, Z.; Yawei, H. Study on TDCPP as flame retardant additive for lithium-ion battery. Mod. Chem. Ind. 2018, 38, 128–130. [Google Scholar]

- Zeng, Z.; Wu, B.; Xiao, L.; Jiang, X.; Chen, Y.; Ai, X.; Yang, H.; Cao, Y. Safer lithium ion batteries based on nonflammable electrolyte. J. Power Sources 2015, 279, 6–12. [Google Scholar] [CrossRef]

- Zeng, Z.; Murugesan, V.; Han, K.S.; Jiang, X.; Cao, Y.; Xiao, L.; Ai, X.; Yang, H.; Zhang, J.-G.; Sushko, M.L.; et al. Non-flammable electrolytes with high salt-to-solvent ratios for Li-ion and Li-metal batteries. Nat. Energy 2018, 3, 674–681. [Google Scholar] [CrossRef]

- Ziqi, Z.; Xiaoyu, J.; Ran, L.; Dingding, Y.; Xinping, A.; Hanxi, Y.; Yuliang, C. A safer sodium-ion battery based on nonflammable organic phosphate electrolyte. Adv. Sci. 2016, 3, 1600066. [Google Scholar]

- Xiaodong, H.; Shunli, L.; Yulin, L. Application advances of modified diaphragm and interlayer in lithium-sulfur batteries. Mod. Chem. Ind. 2018, 38, 30–33, 35. [Google Scholar]

- Pekala, R.; Patil, Y.; Peddini, S. Development of Separators with Inorganic Fillers for Advanced Lithium- Ion Batteries; Knowledge Foundation: New York, NY, USA, 2010; p. 155. [Google Scholar]

- Li, L.; Bo, P.; Fei, L.; Qiwei, H.; Beihu, L. Research Progress of all-solid-state lithium-ion battery. Mar. Power Technol. 2018, 38, 45–47. [Google Scholar]

- Hong, L. All solid-state lithium battery: Dream into reality. Energy Storage Sci. Technol. 2018, 7, 188–193. [Google Scholar]

- Xiong, J.; Banvait, H.; Li, L.; Chen, Y.; Xie, J.; Liu, Y.; Wu, M.; Chen, J. Failure detection for over-discharged Li-ion batteries. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Zhao, M.; Wu, J.; Zhang, W.; Gu, X.; Wu, Y. Optimal planning of AC charging piles based on constraints of time and space. Autom. Electr. Power Syst. 2016, 40, 66–70. [Google Scholar]

- Zhen, W. Research on Safety Protection Technology of Electric Vehicle Charging; Nanjing University of Technology: Nanjing, China, 2018. [Google Scholar]

- Yilmaz, M.; Krein, P.T. Review of charging power levels and infrastructure for plug-in electric and hybrid vehicles. In Proceedings of the 2012 IEEE International Electrical Vehicle Conference (IEVC’12), Greenville, SC, USA, 4–8 March 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Available online: https://www.sciencedirect.com/science/article/abs/pii/S037877531401489X (accessed on 12 August 2021).

- Lijun, Q.; Mingyu, Z.; Weiguo, Z. A method to design the security early warning model of EV charging. Power Syst. Clean Energy 2016, 32, 114–119. [Google Scholar]

- Wei, G.; Zhengzhe, L. Design and application of isolation self-checking device of charging piles. Hebei Electr. Power 2017, 36, 16–19. [Google Scholar]

- Zhu, L.; Zhang, J. A new model of jointed state of charge and health for lithium batteries. Proc. CSEE 2018, 38, 3613–3621. [Google Scholar]

- Hongyu, G.; Jiuchun, J.; Jiapeng, W.; Jiayue, W. New method of insulation detection for electric vehicle. J. Electron. Meas. Instrum. 2011, 25, 253–257. [Google Scholar]

- Xiangwen, Z.; Jin, Z.; Yong, X.; Xuanju, D.; Xiru, W.; Taiping, M.; Ming, P.; Fenghua, R. An Online Detection Circuit for Insulation Resistance of Power Battery of Pure Electric Vehicle. CN Patent CN203941235 U, 12 November 2014. [Google Scholar]

- Antoun, J.; Kabir, M.E.; Moussa, B.; Atallah, R.; Assi, C. A Detailed Security Assessment of the EV Charging Ecosystem. IEEE Netw. 2020, 34, 200–207. [Google Scholar] [CrossRef]

- Lee, S.; Park, Y.; Lim, H.; Shon, T. Study on analysis of security vulnerabilities and countermeasures in ISO /IEC 15118 based electric vehicle charging technology. In Proceedings of the 2014 International Conference on IT Convergence and Security (ICITCS), Beijing, China, 28–30 October 2014; pp. 1–4. [Google Scholar]

- Xiang, Z.; Zhihong, L.; Quming, C.; Feng, N.; Hao, Z. Data communication safety Strategy for Electric Vehicle Charging Facilities. Autom. Electr. Power Syst. 2011, 35, 92–94. [Google Scholar]

- Bing, Z.; Wei, C.; Feng, Z.; Baofeng, L. Electric vehicle charging pile control device with safety protection function. Low Volt. Electr. Appar. 2013, 16, 53–57. [Google Scholar]

- Chang, Y. Research on Comprehensive Evaluation Method for Health Status of Electric Vehicle Charging Point; Harbin University of Science and Technology: Harbin, China, 2020. [Google Scholar]

- Han, Z. Research on Health Status Analysis System of Charging Pile Based on Big Data; Xi’an Shiyou University: Xi’an, China, 2019. [Google Scholar]

- Yonggang, R.; Zhongdong, Y.; Kai, Z.; Jing, S.; Zhaoan, H.; Liqiang, W. Quantitative assessment of electrical safety protection for electric vehicle charging equipment. J. Electr. Eng. 2017, 12, 25–30, 50. [Google Scholar]

| Literature | Main Contributions |

|---|---|

| [32] | Introduces the composition of BMS and the research status of key problems such as voltage measurement and state estimation and puts forward the problems to be solved in future research. |

| [33] | Summarizes the model-based and non-model-based fault diagnosis methods and analyzes their advantages and disadvantages. |

| [34] | Reviews, classifies, and compares different adaptive mathematical models of deep learning algorithms for residual service life prediction and provides suggestions for improving the remaining battery life prediction algorithm. |

| [35] | Reviews SOC and SOH estimation technologies for electric vehicle batteries, and specifically reviews model-based and data-driven methods for SOC estimation. |

| [36] | Reviews some battery cell balancing technologies and evaluates their relationship with battery performance. |

| No. | Time | Place | Accident Description | Cause Analysis |

|---|---|---|---|---|

| 1 | April 2015 | Shenzhen, China | Smoke erupted from the battery of an electric car, then it caught fire | The electric car did not stop charging after full charging, which caused overcharging for 1.2 h, causing a short circuit inside the battery |

| 2 | January 2016 | Gjerstad, Norway | A charging Tesla electric car in a charging station burst into fire | The battery was in low-temperature for a long time and was charged in a high-rate charging mode too long, resulting in thermal runaway of the battery |

| 3 | April 2019 | Shanghai, China | A Tesla electric car suffered spontaneous combustion while charging | The single battery failed, causing a short circuit in the battery |

| 4 | June 2019 | Antwerp, Northern Belgium | A charging Tesla electric car suddenly smoked, then caught fire and was burned completely | A short circuit occurred during charging |

| 5 | October 2019 | Taegu, South Korea | A KONA electric car suddenly caught fire while charging | There were internal problems with the power battery components |

| 6 | May 2020 | Shaowu, China | A VM electric car caught fire while charging, and was burned | The core supplier mixed impurities into cores, so the power battery produced abnormal lithium plating, causing a short circuit in the battery |

| 7 | May 2020 | Dongguan, China | An electric car burst into fire while charging | A charging fault occurred to the battery pack |

| 8 | August 2020 | Guangzhou, China | A short-circuit occurred to an electric car in a charging station of Wanjiang Bus Terminal | Overcharging caused a short circuit in the battery |

| Method | Literature | Advantages and Disadvantages | Equalization Circuit Diagram |

|---|---|---|---|

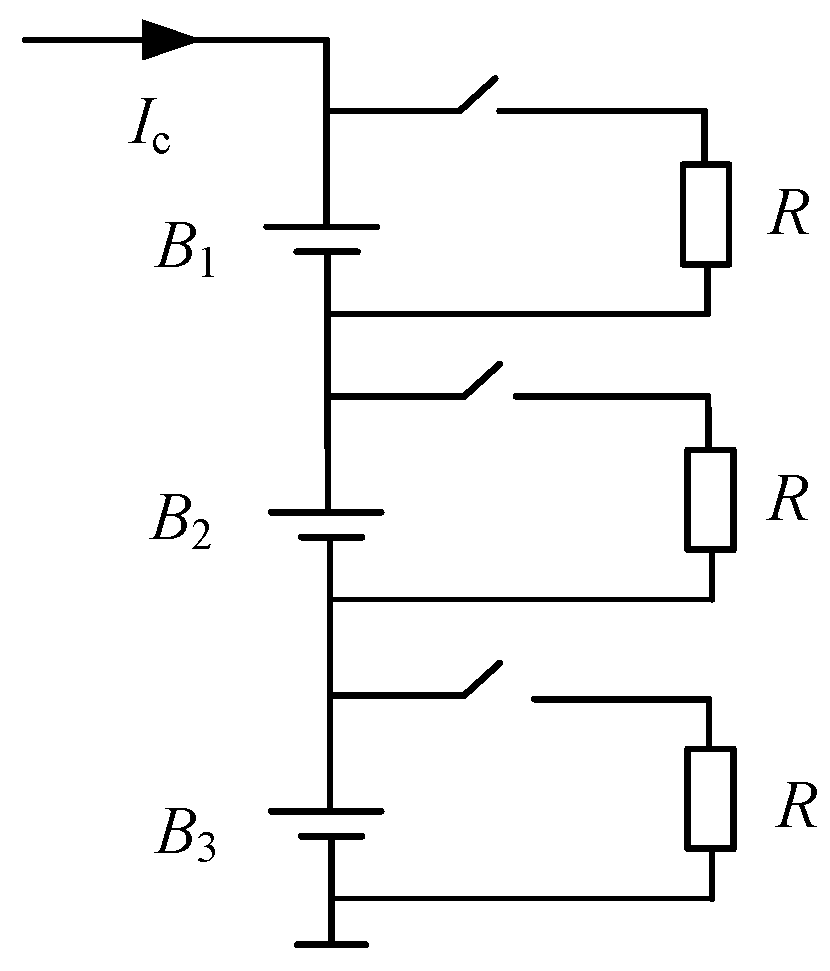

| Dissipative shunt equalization method | [94] | Advantages: low energy consumption, strong scalability, easy for modular design. Disadvantages: thermal management problems and only for small-power battery packs. | See Appendix A Figure A1 |

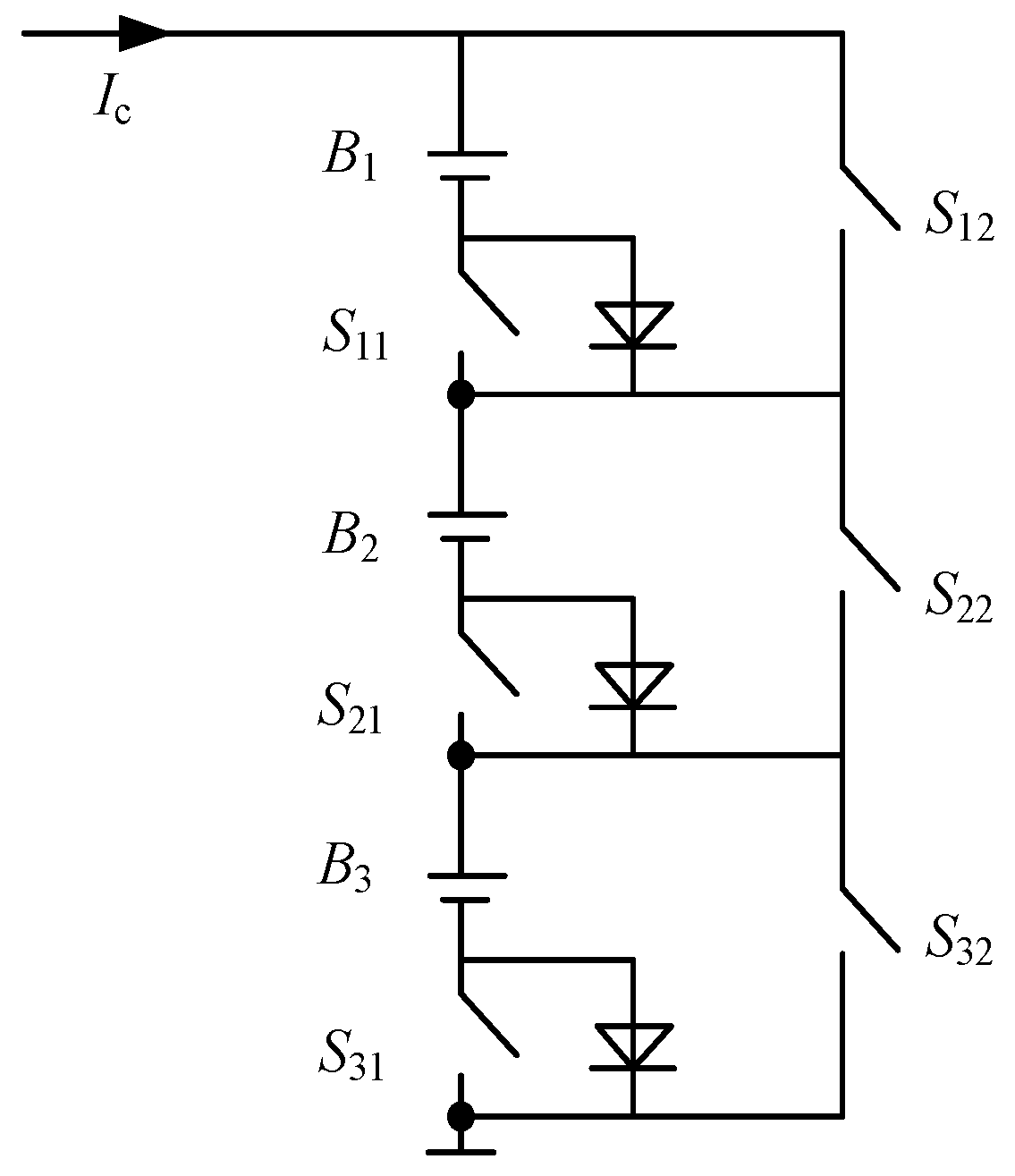

| Complete shunt equalization method | [95] | Advantages: large equalization current and fast equalization speed. Disadvantages: high cost and strict variation range of charger output voltage. | See Appendix A Figure A2 |

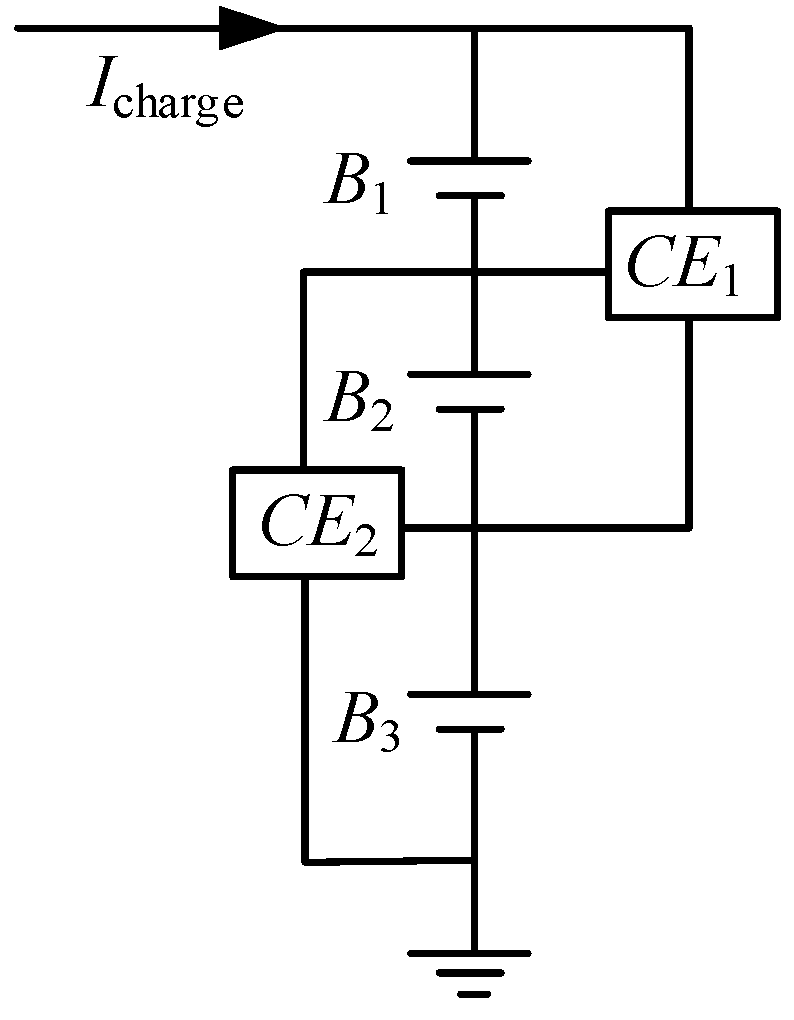

| Isomorphic CE equalization method | [96] | Advantages: can achieve the non-destructive balance between charge energy and discharge energy of battery pack. Disadvantages: strict requirements for battery voltage monitoring technology and complicated equalization circuit structure. | See Appendix A Figure A3 |

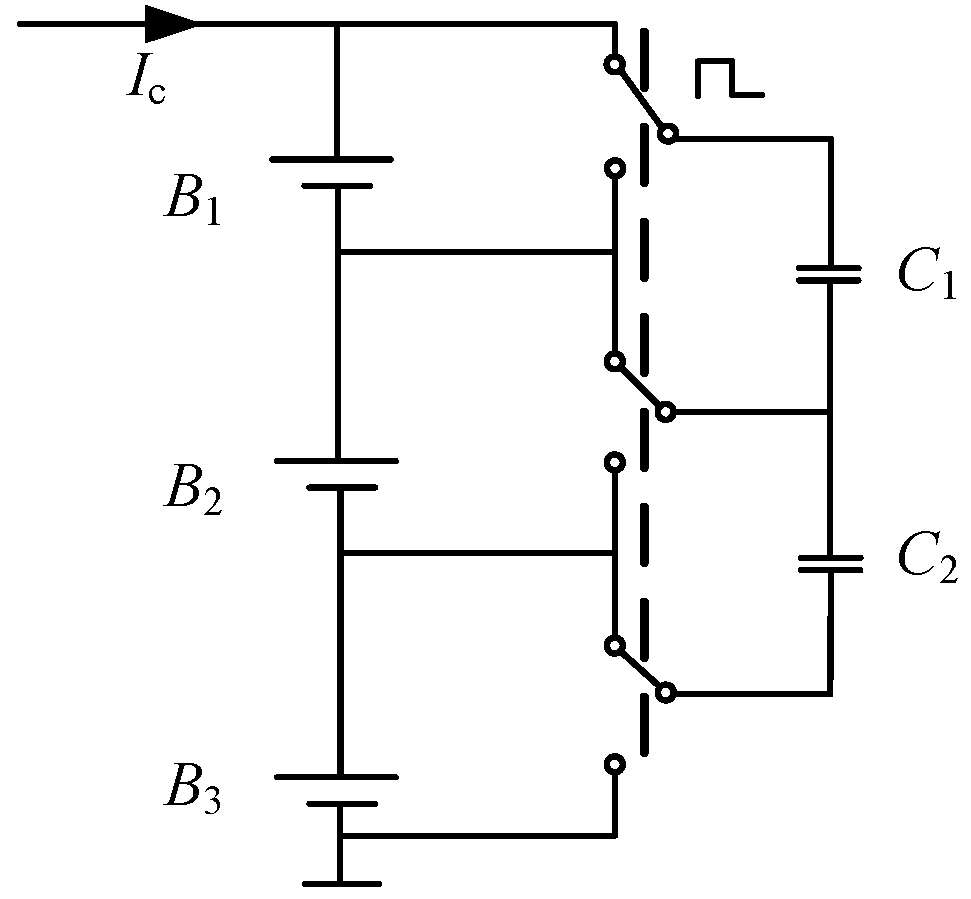

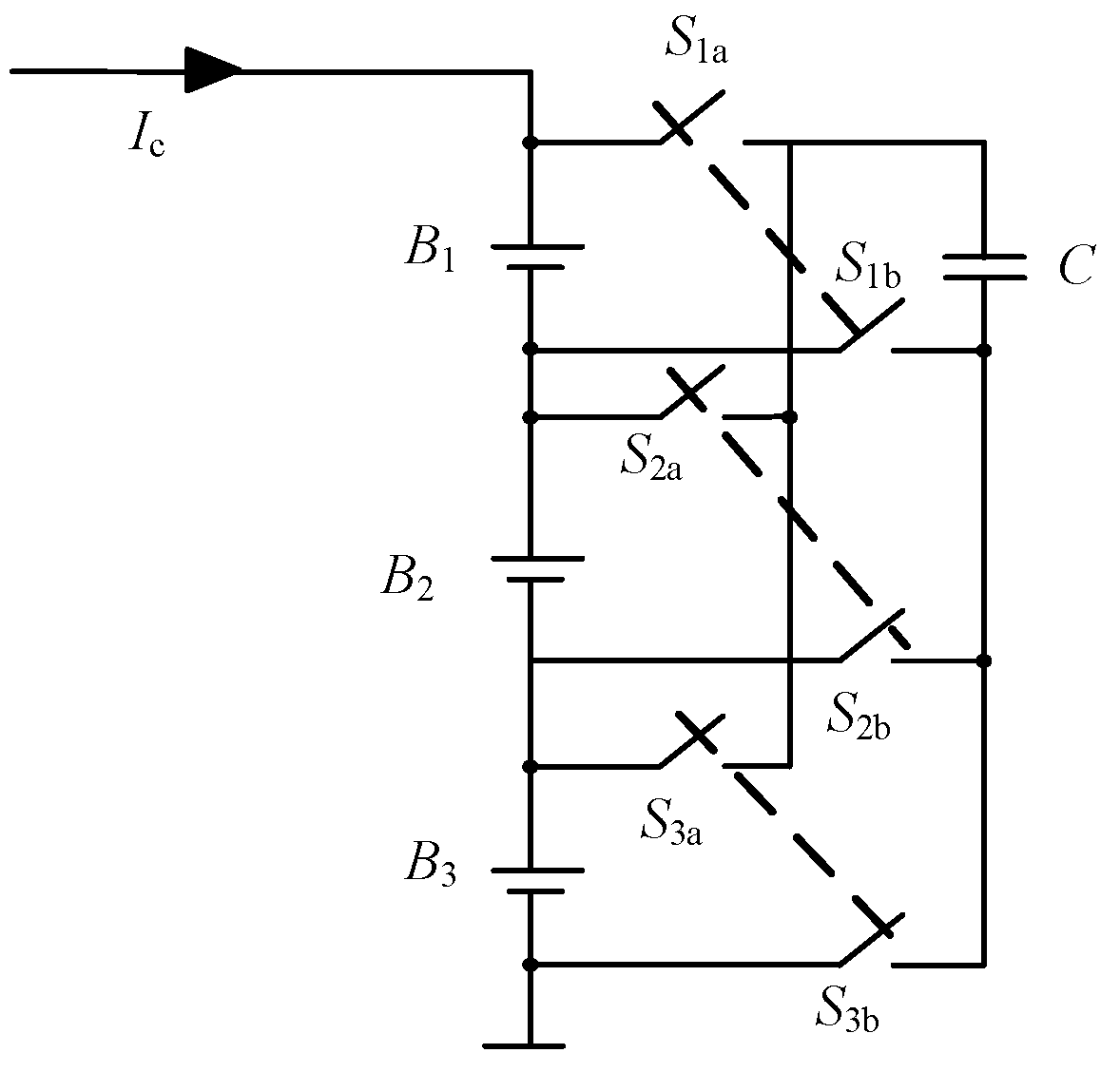

| Multiswitching capacitance method | [97] | Advantages: low requirements for the intelligence of control system, and simple circuit structure. Disadvantages: low sensitivity to voltage and low equilibrium accuracy. | See Appendix A Figure A4 |

| Single switching capacitance method | [98] | Advantages: only need a switching capacitance, good economy. Disadvantages: the equilibrium cycle is limited by the number of single batteries, slow equalization speed. | See Appendix A Figure A5 |

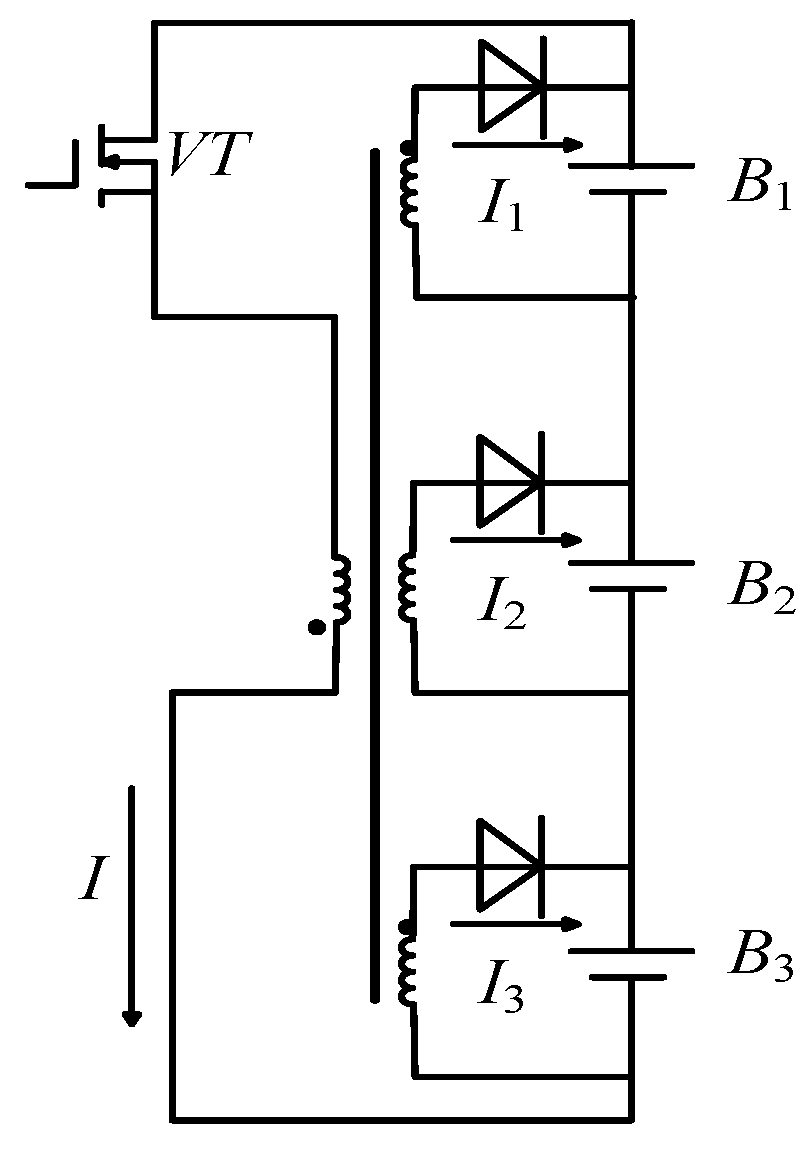

| Multi-winding transformer method | [99] | Advantages: high efficiency and no closed-loop control and voltage monitoring equipment. Disadvantages: weak scalability, general tailor ability, difficult design of a multi-winding transformer. | See Appendix A Figure A6 |

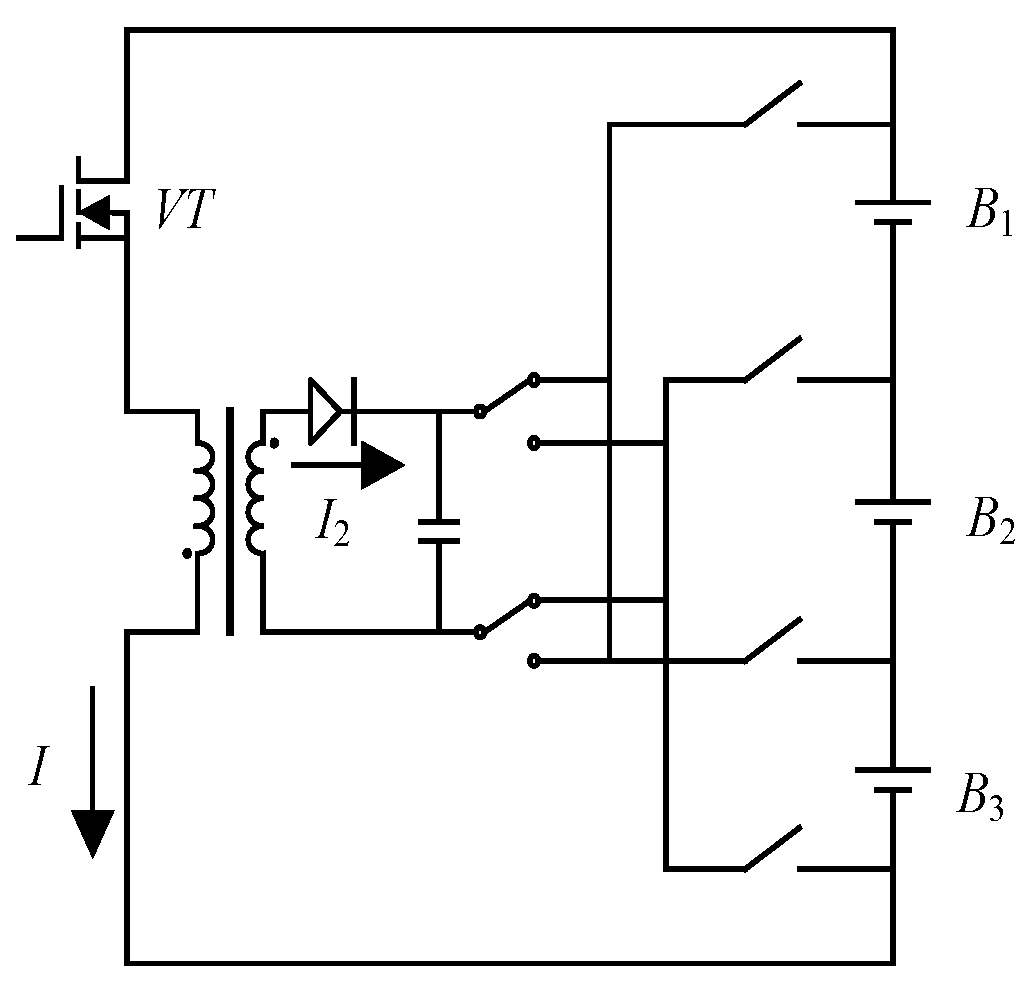

| Switching transformer method | [98] | Advantages: low cost, low circuit design difficulty. Disadvantages: large circuit loss, low equalization efficiency. | See Appendix A Figure A7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Diao, X.; Zhang, Y.; Zhang, J.; Li, T. Review of the Charging Safety and Charging Safety Protection of Electric Vehicles. World Electr. Veh. J. 2021, 12, 184. https://doi.org/10.3390/wevj12040184

Jiang L, Diao X, Zhang Y, Zhang J, Li T. Review of the Charging Safety and Charging Safety Protection of Electric Vehicles. World Electric Vehicle Journal. 2021; 12(4):184. https://doi.org/10.3390/wevj12040184

Chicago/Turabian StyleJiang, Linru, Xiaohong Diao, Yuanxing Zhang, Jing Zhang, and Taoyong Li. 2021. "Review of the Charging Safety and Charging Safety Protection of Electric Vehicles" World Electric Vehicle Journal 12, no. 4: 184. https://doi.org/10.3390/wevj12040184

APA StyleJiang, L., Diao, X., Zhang, Y., Zhang, J., & Li, T. (2021). Review of the Charging Safety and Charging Safety Protection of Electric Vehicles. World Electric Vehicle Journal, 12(4), 184. https://doi.org/10.3390/wevj12040184