Safety Analysis and Risk Control of Shore-Based Bunkering Operations for Hydrogen Powered Ships

Abstract

:1. Introduction

2. Research Background

2.1. Method Introduction

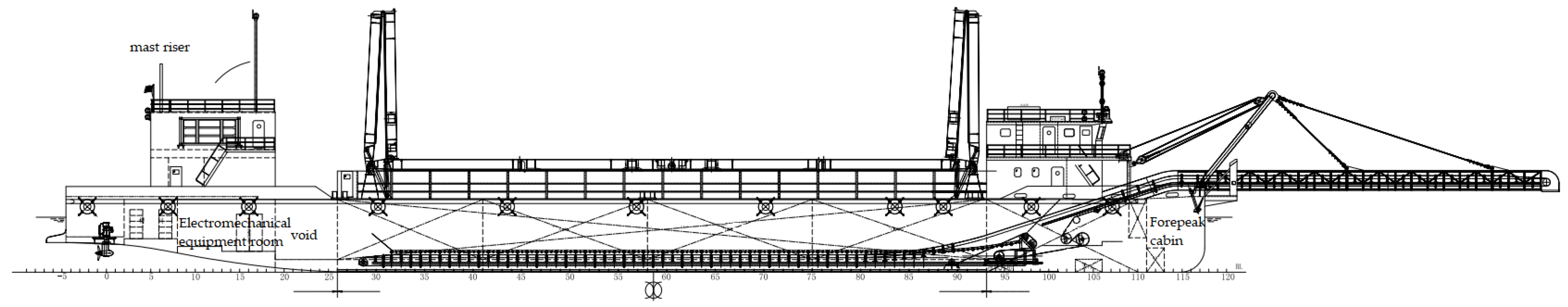

2.2. Case Overview

3. Results

3.1. Hazards Identification

3.2. Probability Analysis

3.3. Consequence Analysis

3.3.1. Mathematical Model

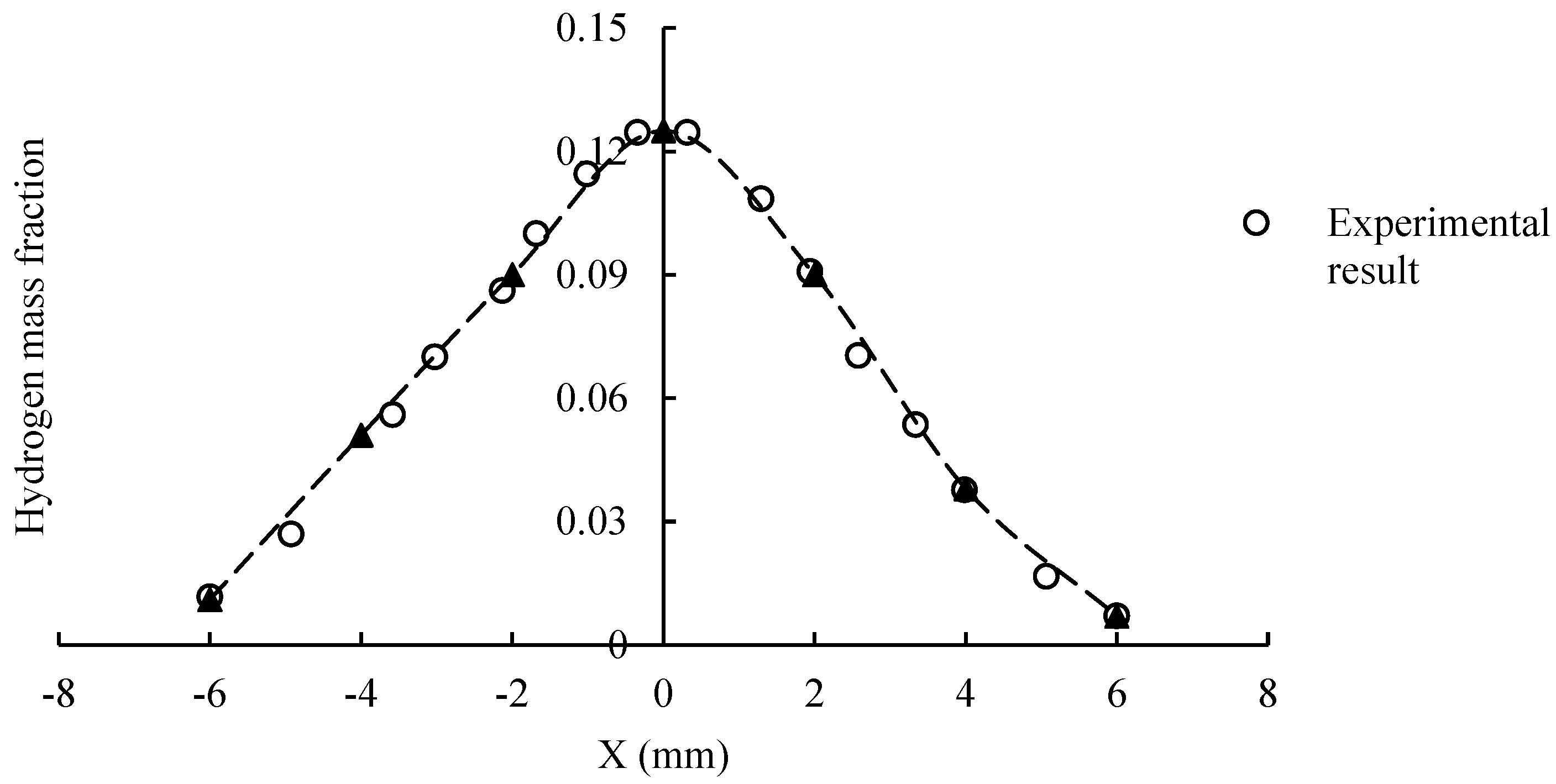

3.3.2. Comparison between the Experimental Results and the Simulation Results of Hydrogen Dispersion and Ventilation Module of FLACS Software

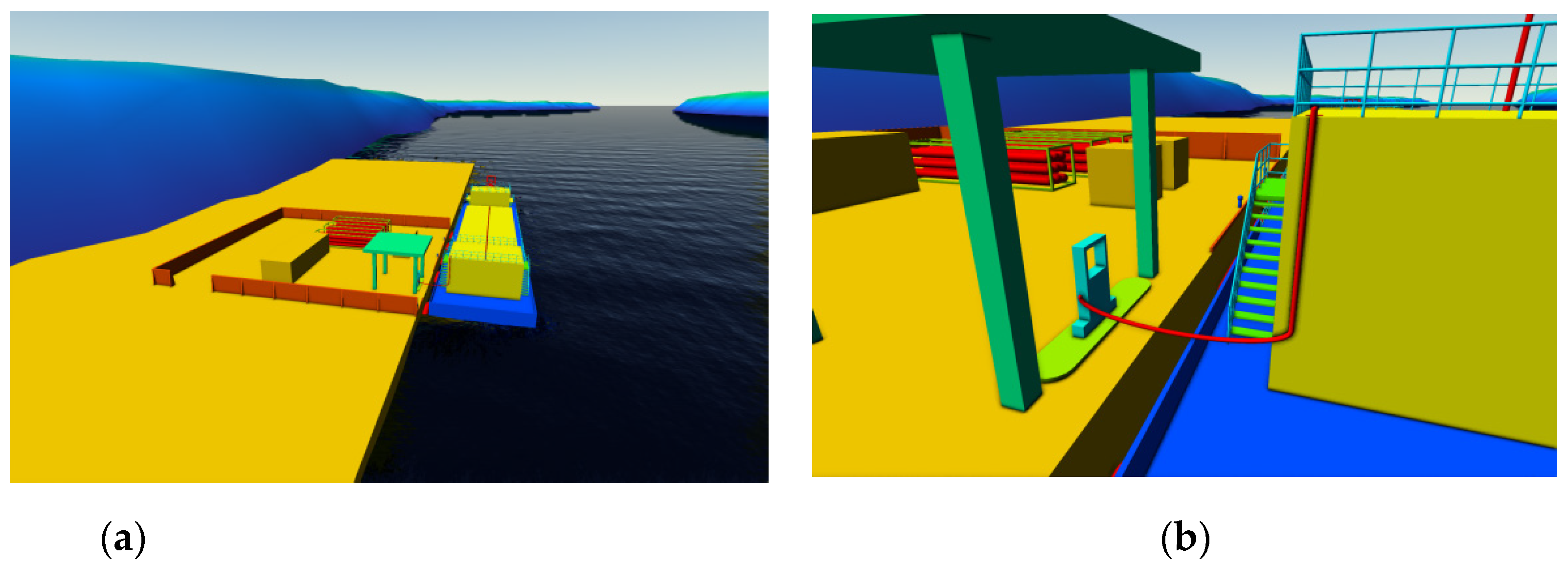

3.3.3. Simulation Model and Scene Description

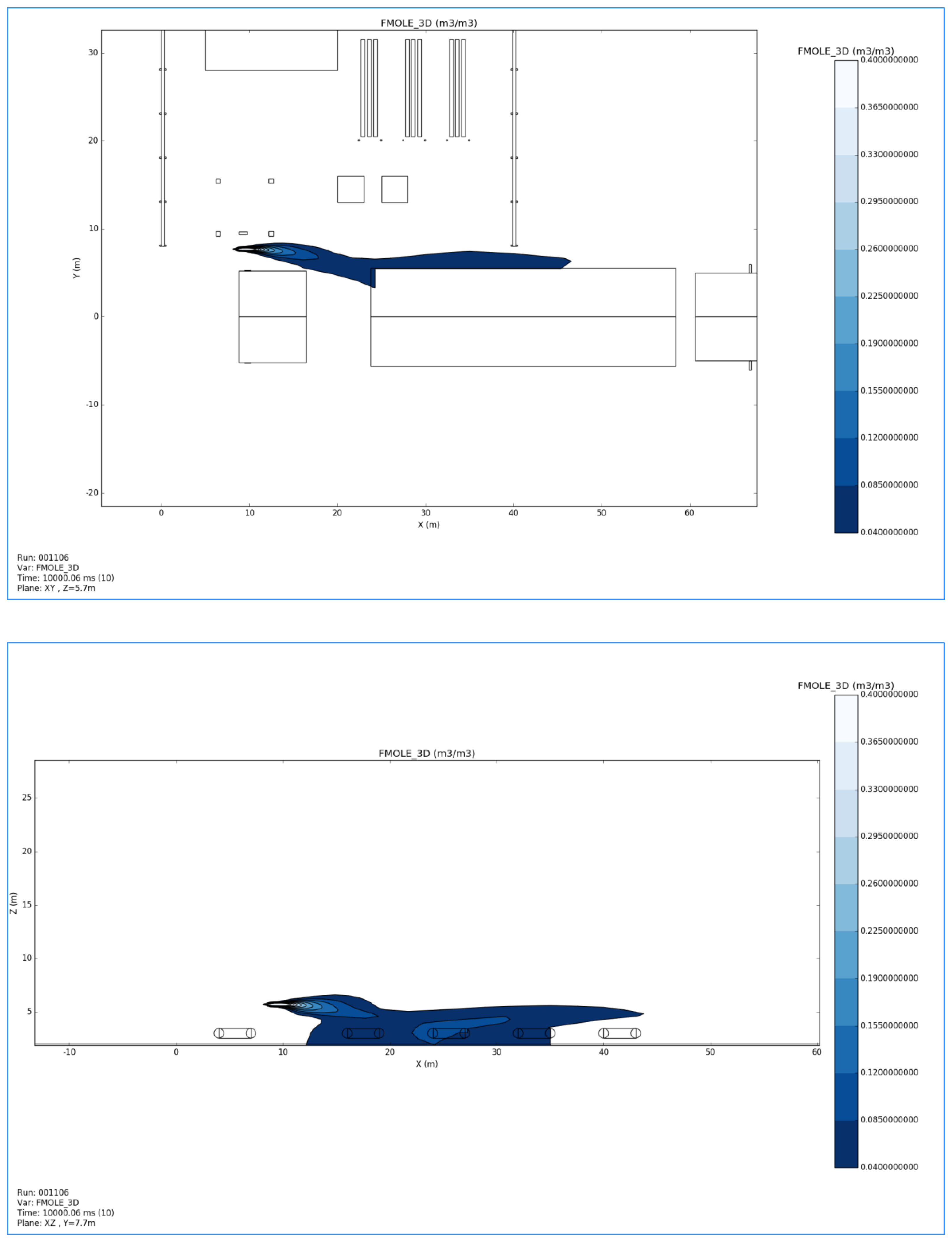

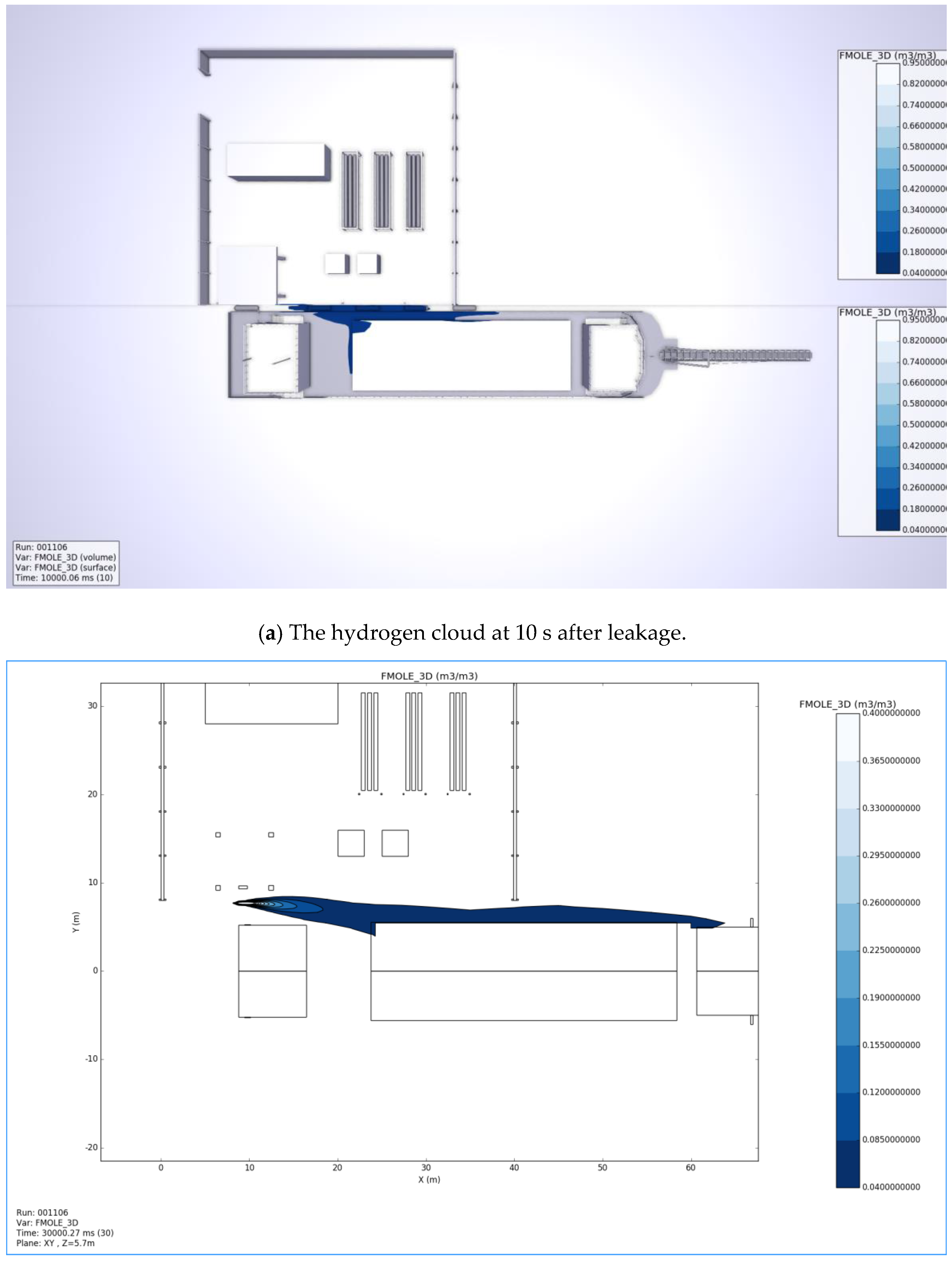

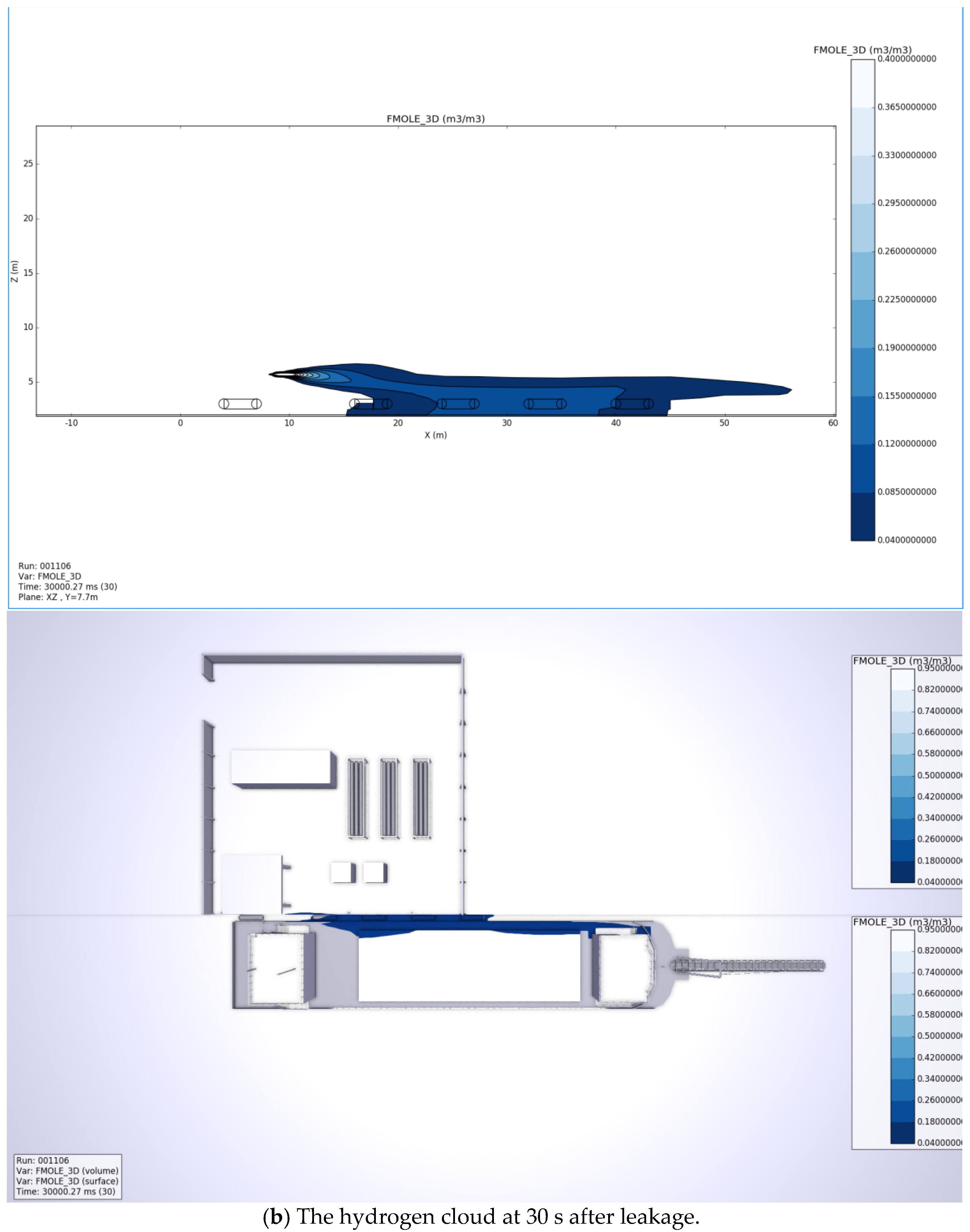

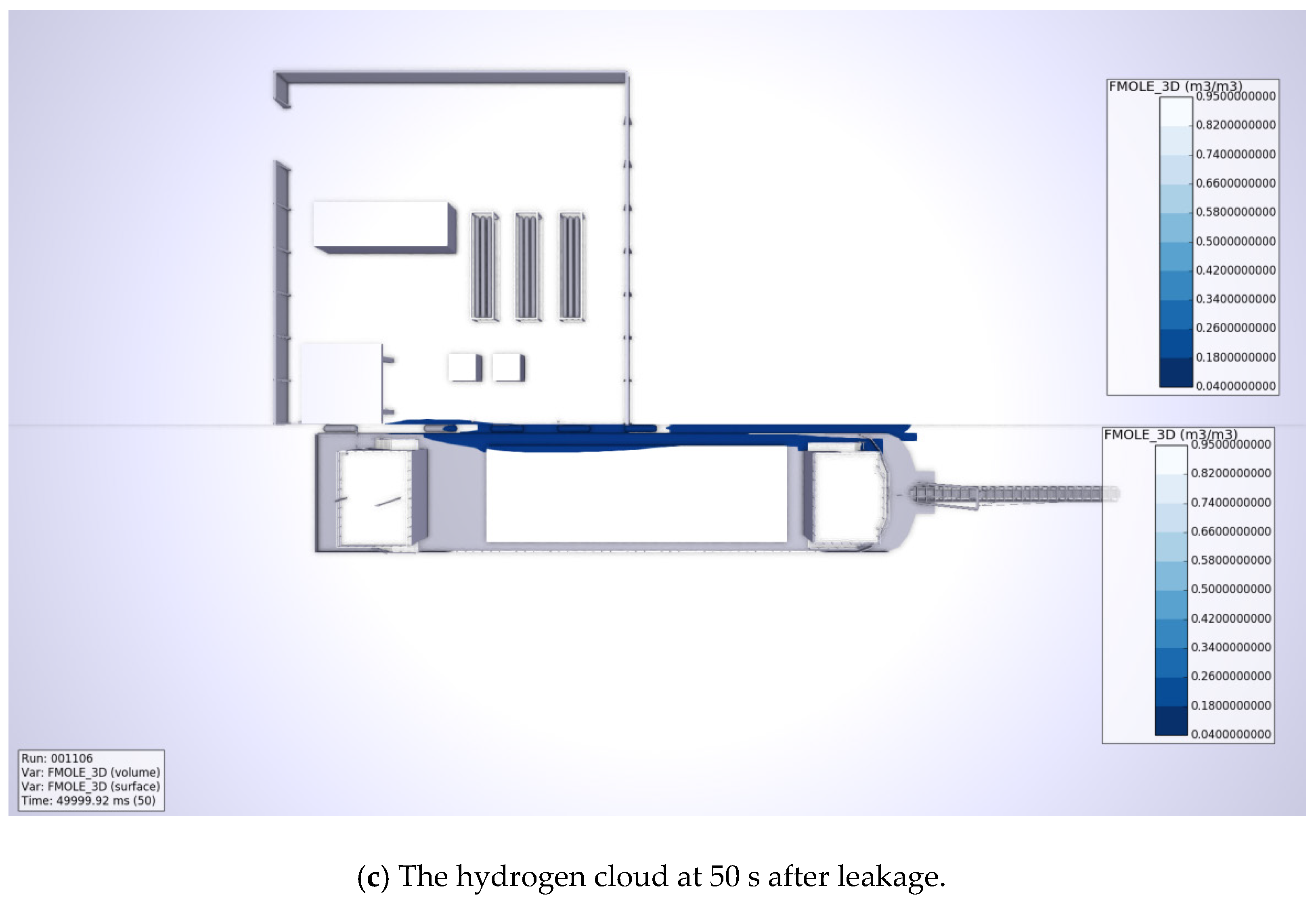

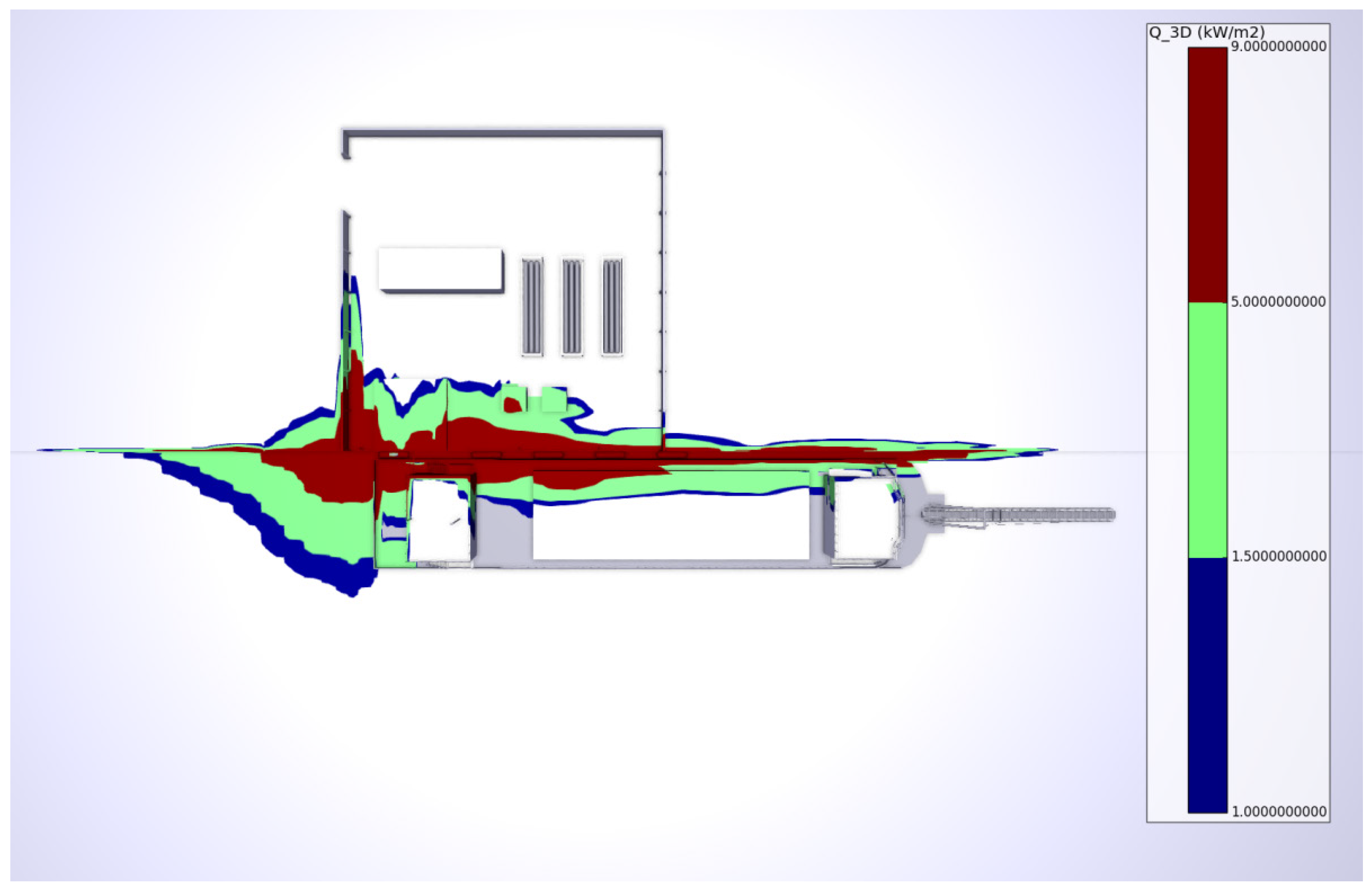

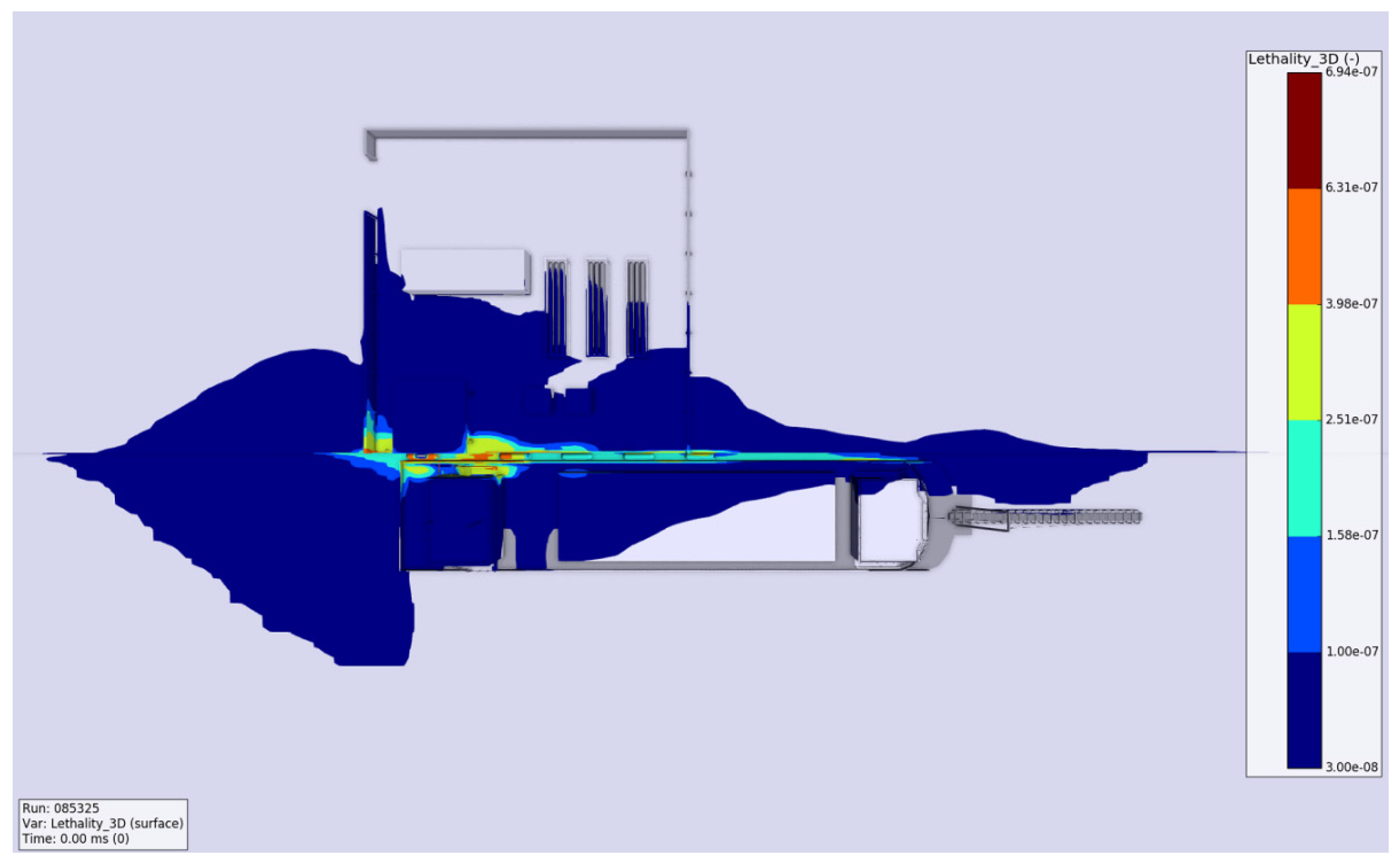

3.3.4. Consequence Simulation

3.3.5. The Determination of Safety Distance

3.4. Risk Assessment

4. Conclusions and Recommendations

4.1. Conclusions

- (1)

- Consider using the bunkering arm and hose as the hydrogen transmission channel between the ship and shore, so as to shorten the length of hose.

- (2)

- Appropriate protection measures against mechanical damage should be added to the pipes at the ship.

- (3)

- Regular maintenance of the valve and regular replacement of flange gasket.

- (4)

- A restricted area shall be set during bunkering operation, and the ignition source shall be controlled within the restricted area.

- (5)

- When the hose ruptures, the instantaneous leakage speed of hydrogen is very large, which may lead to hose swing and seriously threaten the safety of surrounding equipment and personnel. It can be considered to set up anti swing support or install energy absorbing parts on the hose fixing device to effectively realize anti swing protection.

- (1)

- The personal risk of shore-based bunkering operations for hydrogen-powered ship is acceptable, but appropriate risk control measures need to be taken to mitigate the risk as much as possible;

- (2)

- The envelope of the bunkering restriction area is 128 m along the length of the ship (from the bunkering station), 35 m along the width of the ship (from the bunker station), and 18 m in the vertical direction (from the main deck). During the hydrogen bunkering operation, irrelevant personnel are prohibited to enter the area and any form of ignition source is prohibited.

- (3)

- The shore-based hydrogen bunkering station should maintain a certain safe distance from the buildings outside the station. After risk assessment, it is recommended that the safe distance to important public buildings, railways and bridges is 150 m, and the safe distance to civil buildings is 120 m~135 m, the safe distance from the production and storage plant is 125 m~135 m.

4.2. Recommendations

- (1)

- With the deepening of the understanding of the risk of bunkering operation of hydrogen powered ships, the innovative risk assessment theory for the new-type ship still needs to be further studied.

- (2)

- There are too few real ship application cases of hydrogen powered ships in the world, and the accumulation of failure data is still insufficient. Therefore, at present, the existing mature database is mainly used for reference. After the application experience has accumulated to a certain extent, the failure probability analysis and correction for this new type ship can be considered.

- (3)

- In the consequence simulation part, this paper uses the FLACS software to simulate the leakage and diffusion during the bunkering process. In the future research, experimental methods can be considered to carry out related experimental research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ji, C.; El-Halwagi, M.M. A data-driven study of IMO compliant fuel emissions with consideration of black carbon aerosols. Ocean Eng. 2020, 218, 108241. [Google Scholar] [CrossRef]

- Offer, G.J.; Howey, D.; Contestabile, M.; Offer, G.J.; Clague, R.; Brandon, N.P. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy 2010, 38, 24–29. [Google Scholar] [CrossRef] [Green Version]

- Shi, G.; Zhang, H. Study on fuel bunkering mode of natural gas fueled power ship. Ship Sea Eng. 2013, 6, 57–60. [Google Scholar]

- Jin, Y.; Cheng, B. An intelligent replaceable on-board hydrogen tank. China: 110789333A, 14 February 2020. [Google Scholar]

- Li, F. Design of Hydrogen System and Numerical Simulation of Hydrogen Leakage of Fuel Cell Passenger Ship; Wuhan University of technology: Wuhan, China, 2018. [Google Scholar]

- Lu, L.; Liu, M.; Lu, J.; Liu, X. Study on ship shore LNG transmission speed of inland river LNG shore-based bunkering station. China Water Transp. 2019, 615, 46–47. [Google Scholar]

- Milazzo, M.F.; Bragatto, P. A framework addressing a safe ageing management in complex industrial sites: The Italian experience in «Seveso» establishments. J. Loss Prev. Process Ind. 2019, 58, 70–81. [Google Scholar] [CrossRef]

- Yacine, B.; Mébarek, D.; Hefaidh, H. Contribution to the ageing control of onshore oil and gas fields. Petroleum 2020, 6, 311–317. [Google Scholar] [CrossRef]

- Iannaccone, T.; Jeong, B.; Cozzani, V.; Zhou, P. Safety Analysis of Liquefied Natural Gas Bunkering and Simultaneous Port Operations for Passenger Ships. In ASME 2020 39th International Conference on Ocean, Proceedings of the Offshore and Arctic Engineering, Online, 3–7 August 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020. [Google Scholar]

- Yan, M. Risk Identification and Risk Analysis of LNG Filling Operation; Jiangsu University of Science and Technology: Zhenjiang, China, 2018. [Google Scholar]

- Fan, H.; Cheng, K.; Wu, S. CFD Based Simulation of LNG Release during Bunkering and Cargo Loading/Unloading Simultaneous Operations of a Containership. J. Shipp. Ocean Eng. 2017, 7, 51–58. [Google Scholar]

- Chen, L.; Dou, L. Discussion on safety management of water refueling on distribution ship. Saf. Health Environ. 2012, 12, 47–49. [Google Scholar]

- Zhu, B.; Li, C. Research on Stability Simulation of safe operation of tanker. Ship Eng. 2011, 33, 25–28. [Google Scholar]

- Wang, T.; Wu, Q.; Diaconeasa, M.A.; Yan, X.; Mosleh, A. On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment. J. Mar. Sci. Eng. 2020, 8, 485. [Google Scholar] [CrossRef]

- Parhizkar, T.; Utne, I.B.; Vinnem, J.E.; Mosleh, A. Supervised dynamic probabilistic risk assessment of complex systems, part 2: Application to risk-informed decision making, practice and results. Reliab. Eng. Syst. Saf. 2021, 208, 107392. [Google Scholar] [CrossRef]

- Zheng, K.; Chen, Y.; Jiang, Y.; Qiao, S. A SVM based ship collision risk assessment algorithm. Ocean Eng. 2020, 202, 107062. [Google Scholar] [CrossRef]

- Wang, C. Study on Environmental Safety Risk Assessment System of Hydrogenation Station; Shanghai Jiaotong University: Shanghai, China, 2016. [Google Scholar]

- Zhang, C. Research on Risk Assessment of Fuel Cell Vehicle Hydrogenation Station; Chongqing University: Chongqing, China, 2019. [Google Scholar]

- Kikukawa, S.; Mitsuhashi, H.; Miyake, A. Risk assessment for liquid hydrogen fueling stations. Int. J. Hydrog. Energy 2009, 34, 1135–1141. [Google Scholar] [CrossRef]

- Li, Z.; Xiangmin, R.; Jianxin, R. Quantitative risk assessment on a gaseous hydrogen refueling station in Shanghai. Int. J. Hydrog. Energy 2010, 35, 6822–6829. [Google Scholar]

- Antonioni, G.; Spadoni, G.; Cozzani, V. A methodology for the quantitative risk assessment of major accidents triggered by seismic events. J. Hazard. Mater. 2007, 147, 48–59. [Google Scholar] [CrossRef]

- Dian, L.I.; Tang, W.; Zhang, S. Review of risk acceptance criteria for ocean engineering. Ocean Eng. 2003, 21, 96–102. [Google Scholar]

- Antonioni, G.; Spadoni, G.; Cozzani, V. Application of domino effect quantitative risk assessment to an extended industrial area. J. Loss Prev. Process Ind. 2009, 22, 614–624. [Google Scholar] [CrossRef]

- AQT 3046-2013. Guidelines for Quantitative Risk Assessment of Chemical Enterprises; China Planning Press: Beijing, China, 2013. [Google Scholar]

- Lu, L.; Liu, M.; Shi, G. Study on risk analysis and preventive measures of LNG tanker. China Water Transp. 2019, 609, 45–47. [Google Scholar]

- Yan, M. Risk Identification of LNG Bunkering Ship and Risk Analysis of Bunkering Operation; Jiangsu University of science and technology: Nanjing, China, 2018. [Google Scholar]

- Yuan, J. Analysis of Petrochemical Tank Farm Safety Measures and Its Impact on Quantitative Risk; China University of Petroleum: Qingdao, China, 2014. [Google Scholar]

- Yu, Y.; Deng, Y. Hydrogen leakage and diffusion in high voltage chamber of fuel cell bus. J. Zhejiang Univ. (Eng. Sci.) 2020, 54, 381–387. [Google Scholar]

- Houf, W.; Schefer, R. Analytical and experimental investigation of small-scale unintended releases of hydrogen. Int. J. Hydrog. Energy 2008, 33, 1435–1444. [Google Scholar] [CrossRef]

- Schefer, R.; Houf, W.; Williams, T. Investigation of small-scale unintended releases of hydrogen: Momentum-dominated regime. Int. J. Hydrog. Energy 2008, 33, 6373–6384. [Google Scholar] [CrossRef]

- Hansen, O.R.; Gavelli, F.; Ichard, M.; Davis, S.G. Validation of FLACS against experimental data sets from the model evaluation database for LNG vapor dispersion. J. Loss Prev. Process Ind. 2010, 23, 857–877. [Google Scholar] [CrossRef]

- Wang, R.J. Establishing 3D model and Simulating explosion accident of LNG powered ship. J. Saf. Sci. Technol. 2013, 9, 73–77. [Google Scholar]

- China Classification Society. Guidelines for Ships Using Alternative Fuels; China Communications Press: Beijing, China, 2017. [Google Scholar]

- Wu, Z.; Dang, W. Research on the method of determining the external safety distance of water LNG bunkering stations. Saf. Health Environ. 2017, 17, 40–43. [Google Scholar]

- Wan, G.; Dang, W.; Wu, Z.; Lin, X. Study on determination method of safety distance of LNG filling barge. Chin. J. Saf. Sci. 2015, 25, 110–115. [Google Scholar]

- GB 50156-2012. Code for Design and Construction of Filling Station; China Planning Press: Beijing, China, 2012. [Google Scholar]

| Name | Parameter |

|---|---|

| Ship length | 70.5 m |

| Ship width | 13.9 m |

| Depth | 4.5 m |

| Draft | 3.1 m |

| Hydrogen cylinder and hydrogen storage | 36 bottles, single bottle 320 L, 35 MPa, total 280 kg |

| Bunkering pipe diameter | High pressure gas phase (outer diameter 12.7 mm, inner diameter 8.5 mm) |

| Fuel cell system | 4 × 135 kW, a total of 540 kW, PEMFC |

| Lithium battery capacity | 4 × 315 kW h, a total of 1260 kW h |

| Design speed | 13.0 km/h |

| Endurance | 140 km |

| Main Hazards | Cause | Consequence | Existing Safety Measures | Recommended Measure |

|---|---|---|---|---|

| Hose rupture |

| Hydrogen leakage and diffusion, fire and explosion in case of ignition source. |

|

|

| Rupture of hard pipe |

| Hydrogen leakage and diffusion, fire and explosion in case of ignition source |

|

|

| Valve leakage |

| Hydrogen leakage and diffusion, fire and explosion in case of ignition source |

|

|

| Names of Buildings Outside the Station | Recommended Safe Distance | |

|---|---|---|

| Major Public Buildings | 150 m | |

| Civil building protection category | Class I | 135 m |

| Class II | 125 m | |

| Class III | 120 m | |

| Class A and Class B production and storage plants | 135 m | |

| Class C, D, E production and storage plan | 125 m | |

| Outdoor distribution station | 135 m | |

| Railway | 150 m | |

| Bridge | 150 m | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Cao, J.; Zhang, Y.; Jin, D. Safety Analysis and Risk Control of Shore-Based Bunkering Operations for Hydrogen Powered Ships. World Electr. Veh. J. 2021, 12, 162. https://doi.org/10.3390/wevj12040162

Feng Y, Cao J, Zhang Y, Jin D. Safety Analysis and Risk Control of Shore-Based Bunkering Operations for Hydrogen Powered Ships. World Electric Vehicle Journal. 2021; 12(4):162. https://doi.org/10.3390/wevj12040162

Chicago/Turabian StyleFeng, Yuxiang, Jiaolong Cao, Yufeng Zhang, and Ding Jin. 2021. "Safety Analysis and Risk Control of Shore-Based Bunkering Operations for Hydrogen Powered Ships" World Electric Vehicle Journal 12, no. 4: 162. https://doi.org/10.3390/wevj12040162

APA StyleFeng, Y., Cao, J., Zhang, Y., & Jin, D. (2021). Safety Analysis and Risk Control of Shore-Based Bunkering Operations for Hydrogen Powered Ships. World Electric Vehicle Journal, 12(4), 162. https://doi.org/10.3390/wevj12040162