Reliability Control of Electric Racing Car’s Accelerator and Brake Pedals

Abstract

:1. Introduction

2. Design Requirements

- Each car must use at least two independent APPSs, which means that each sensor does not share power and signal line;

- If the car uses analog sensors, the transfer function of each sensor must be different. Each sensor’s slope must be positive and either the gradients, offsets or both, should also be different to other(s);

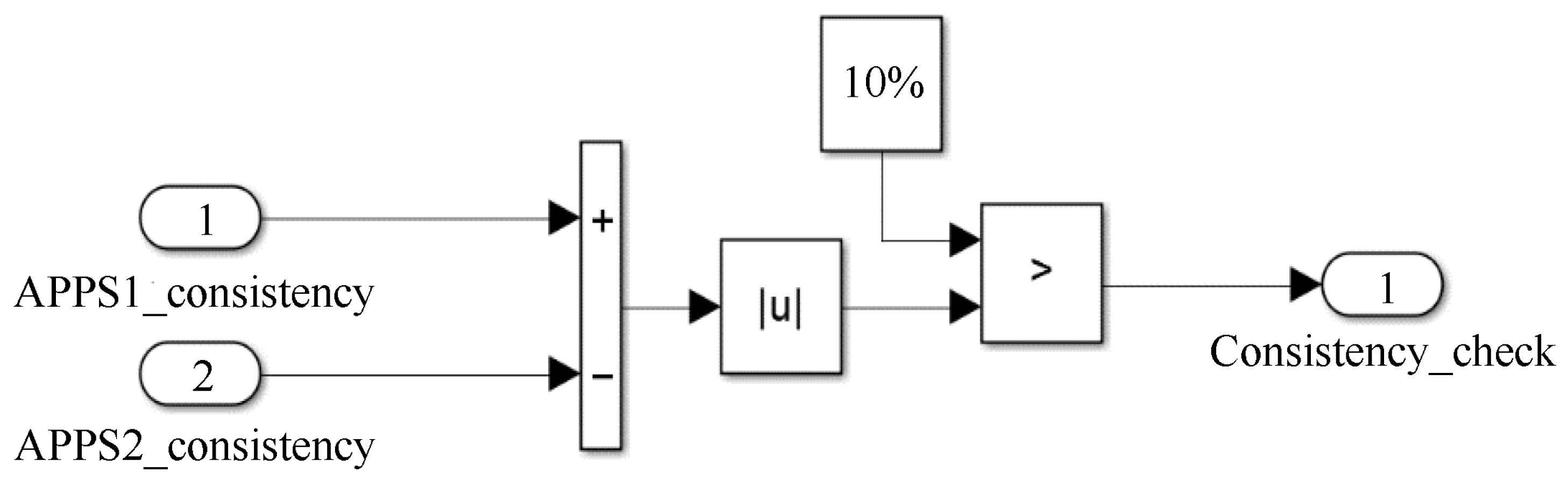

- If the difference in accelerator pedal travel between two sensors is more than 10%, the VCU must promptly cut off power to the motor(s) entirely;

- If the accelerator pedal travel is more than 25%, and at the same time the brake pedal is hardly pressed, the power to the motor(s) must be cut off immediately and completely. The power to the motor(s) must remain shut down until the accelerator pedal travel is less than 5%, whether the brakes are still actuated or not.

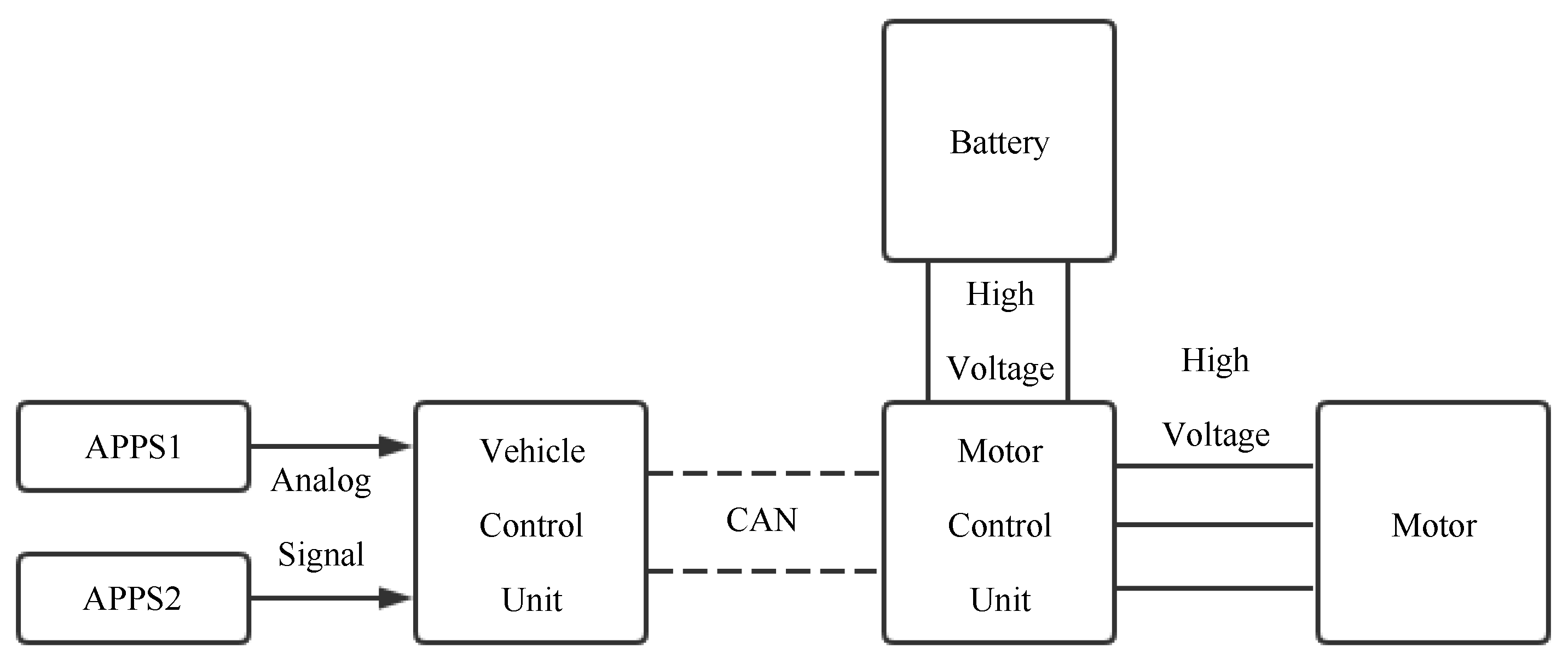

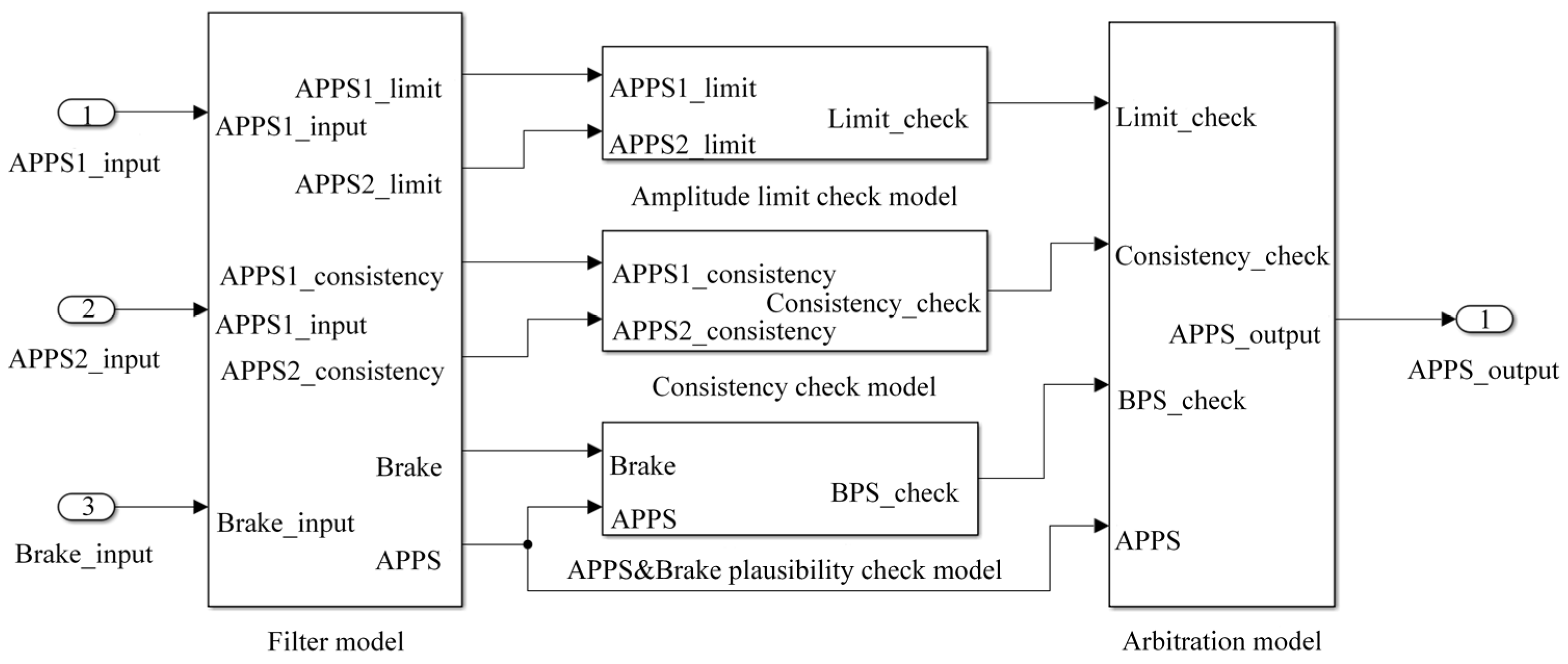

3. Pedal Reliability Model Build

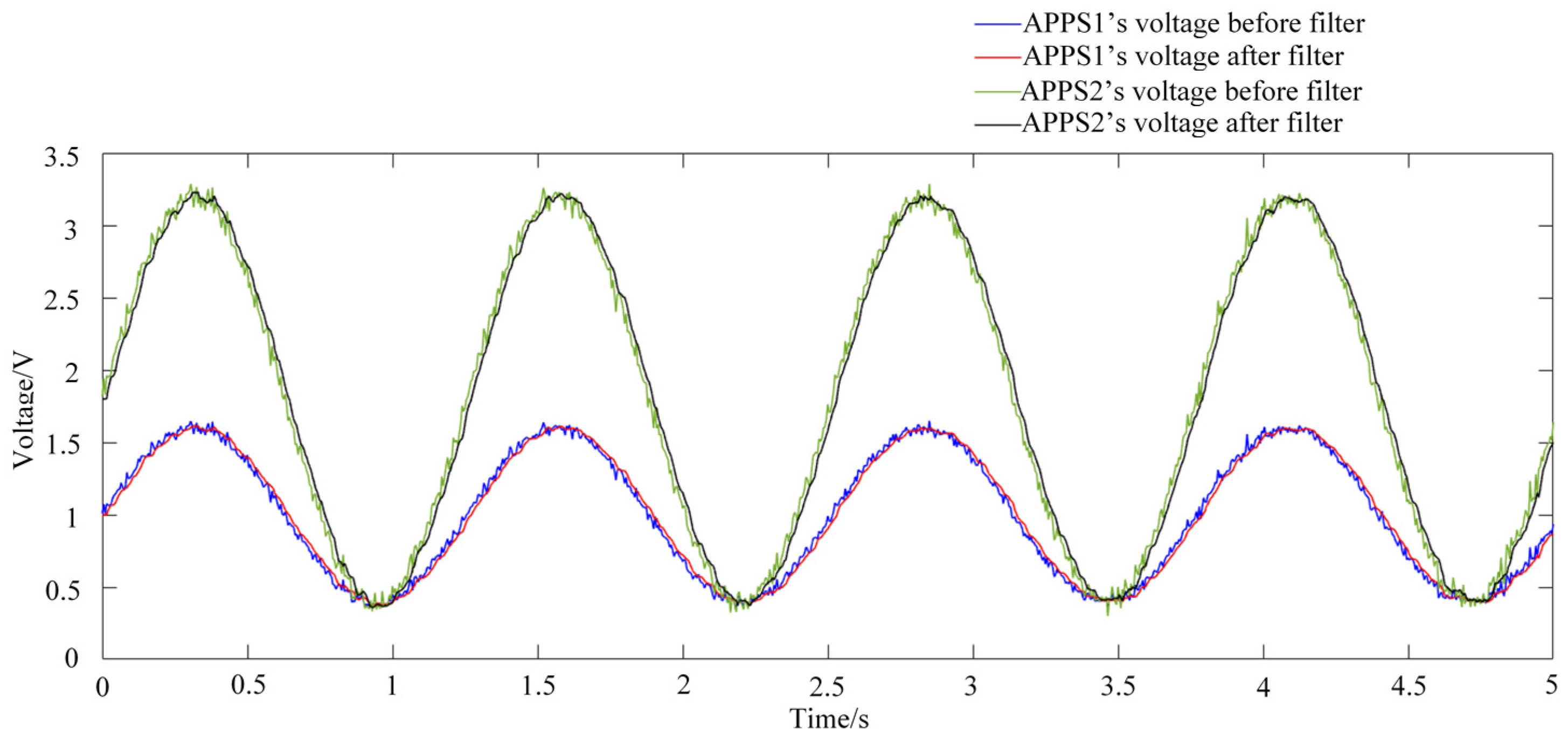

3.1. Filter

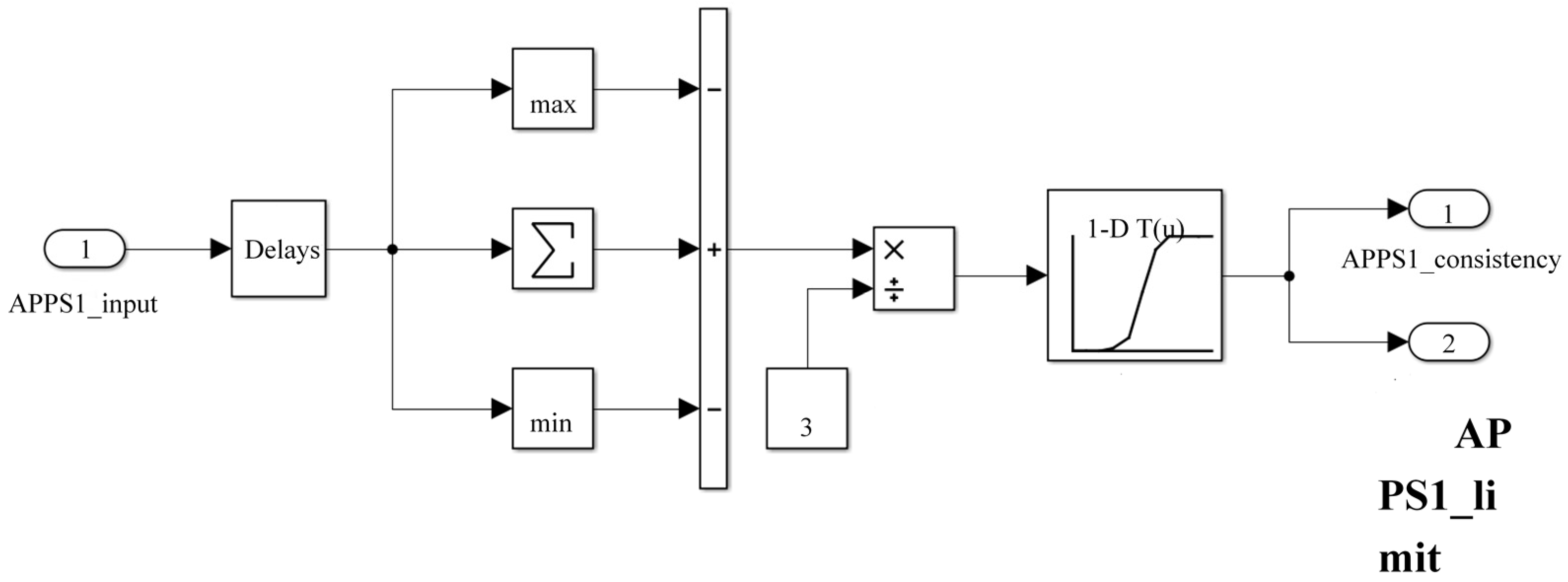

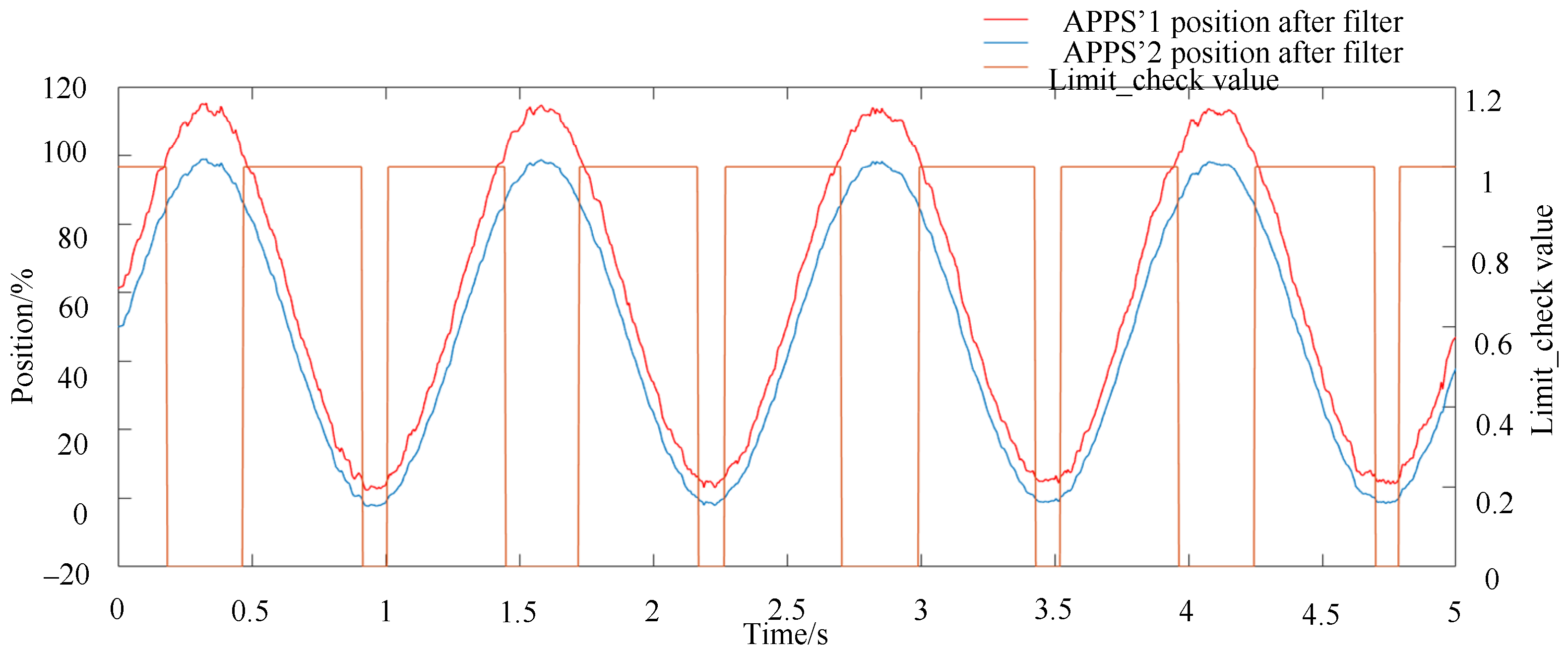

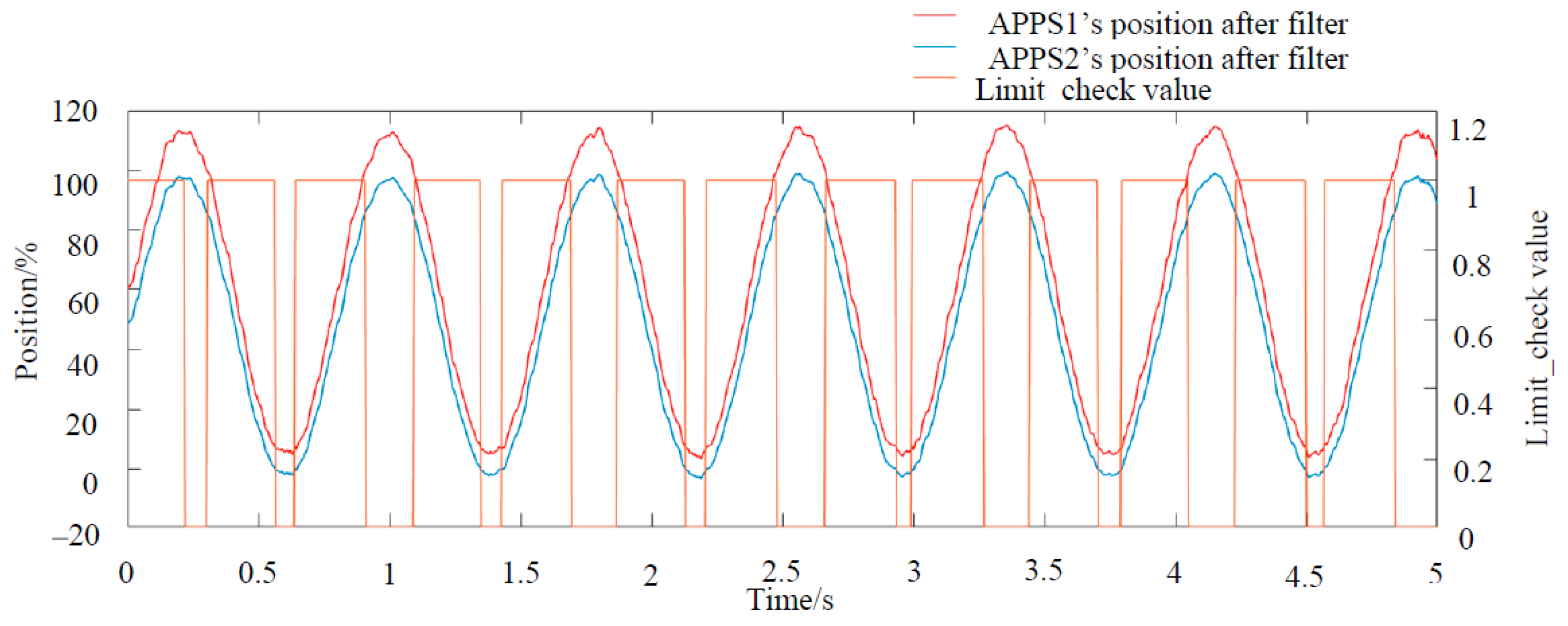

3.2. Amplitude Limit Check

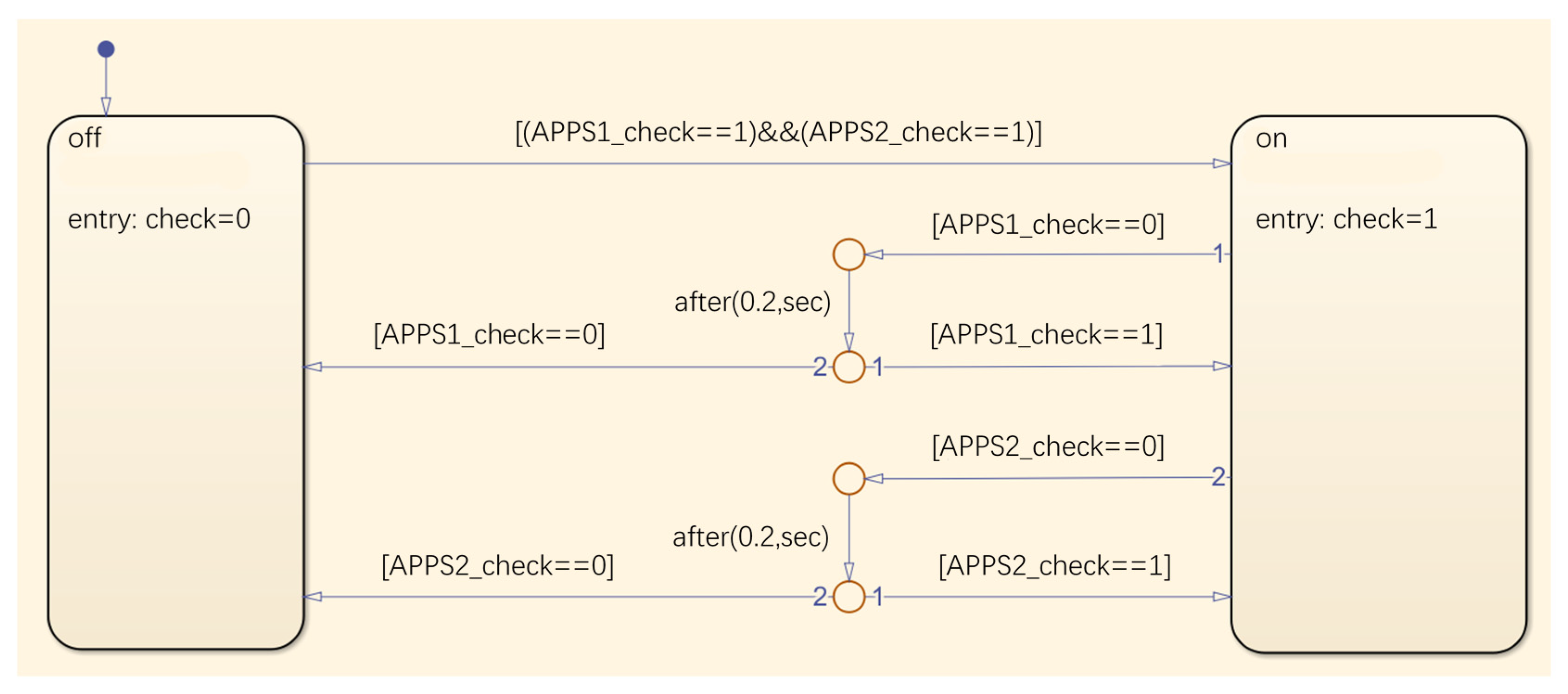

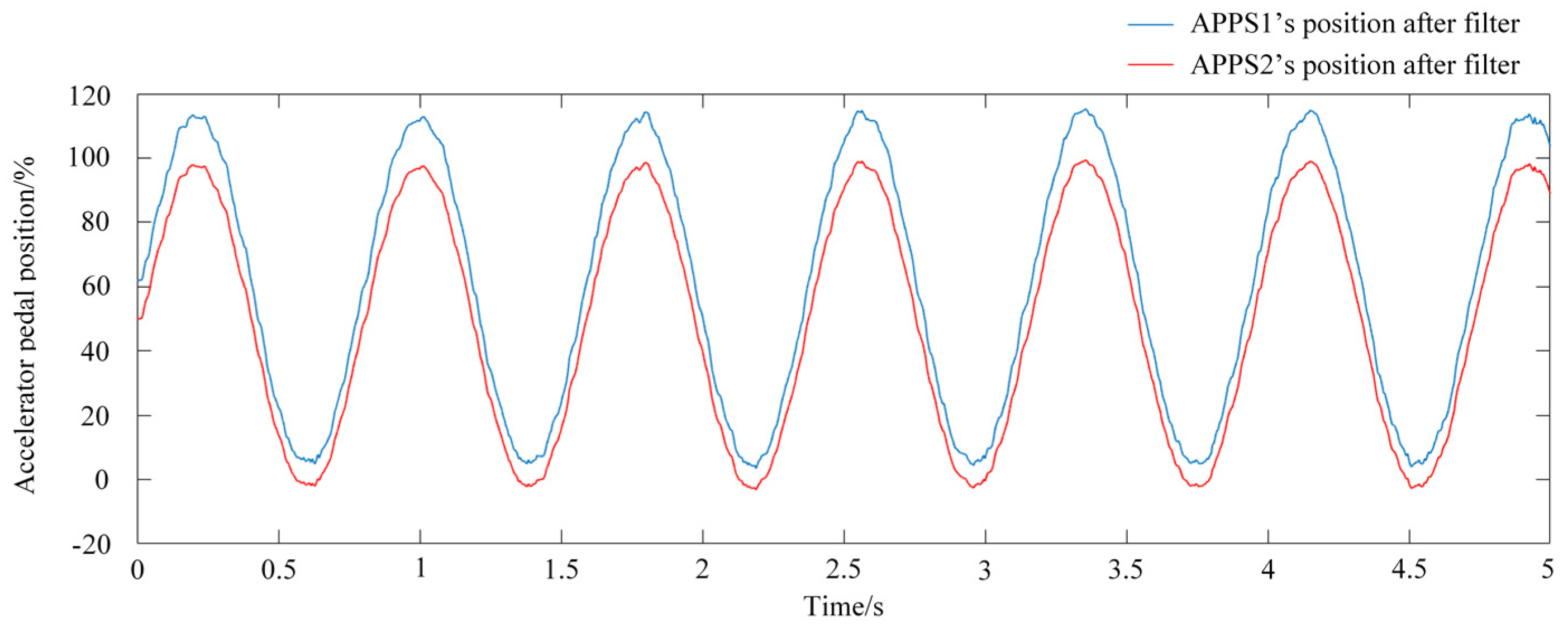

3.3. Consistency Check

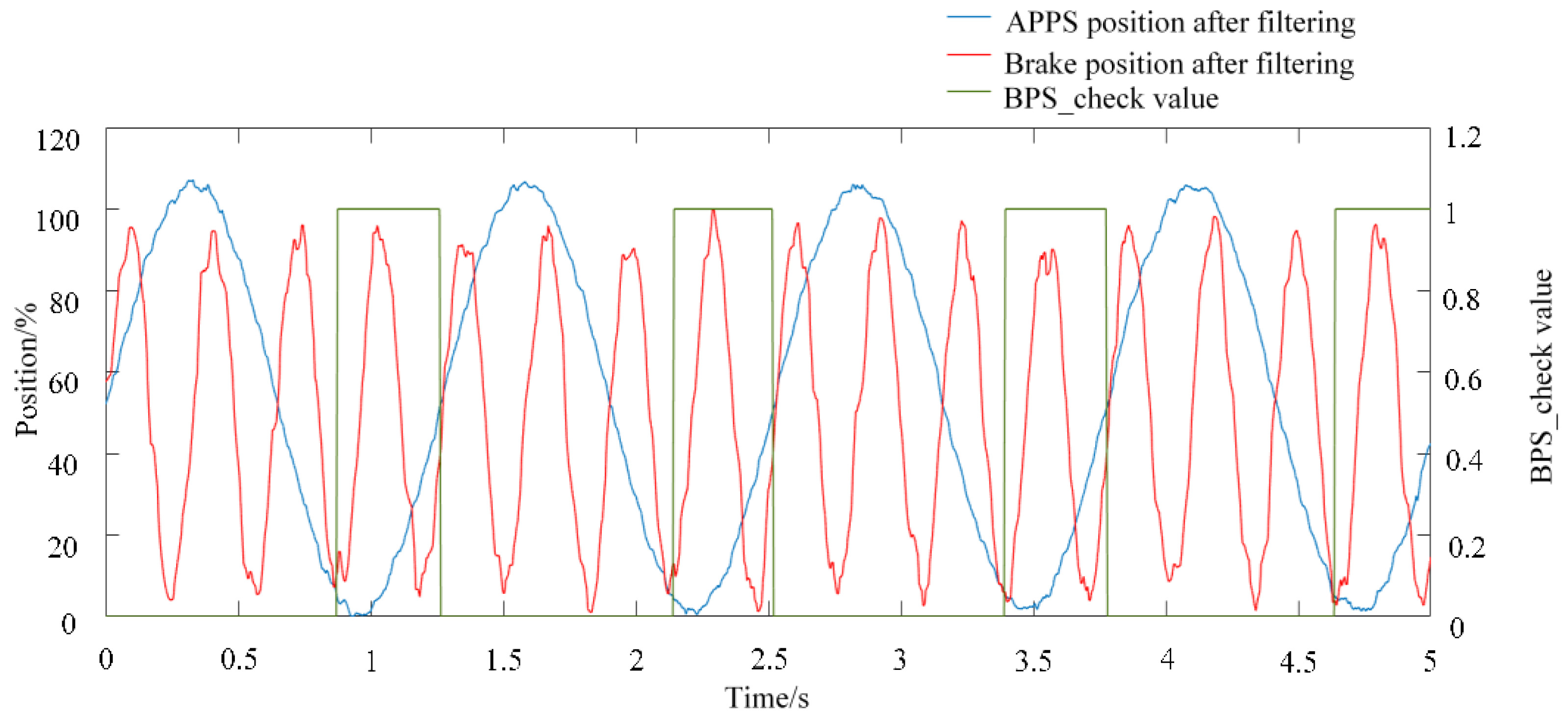

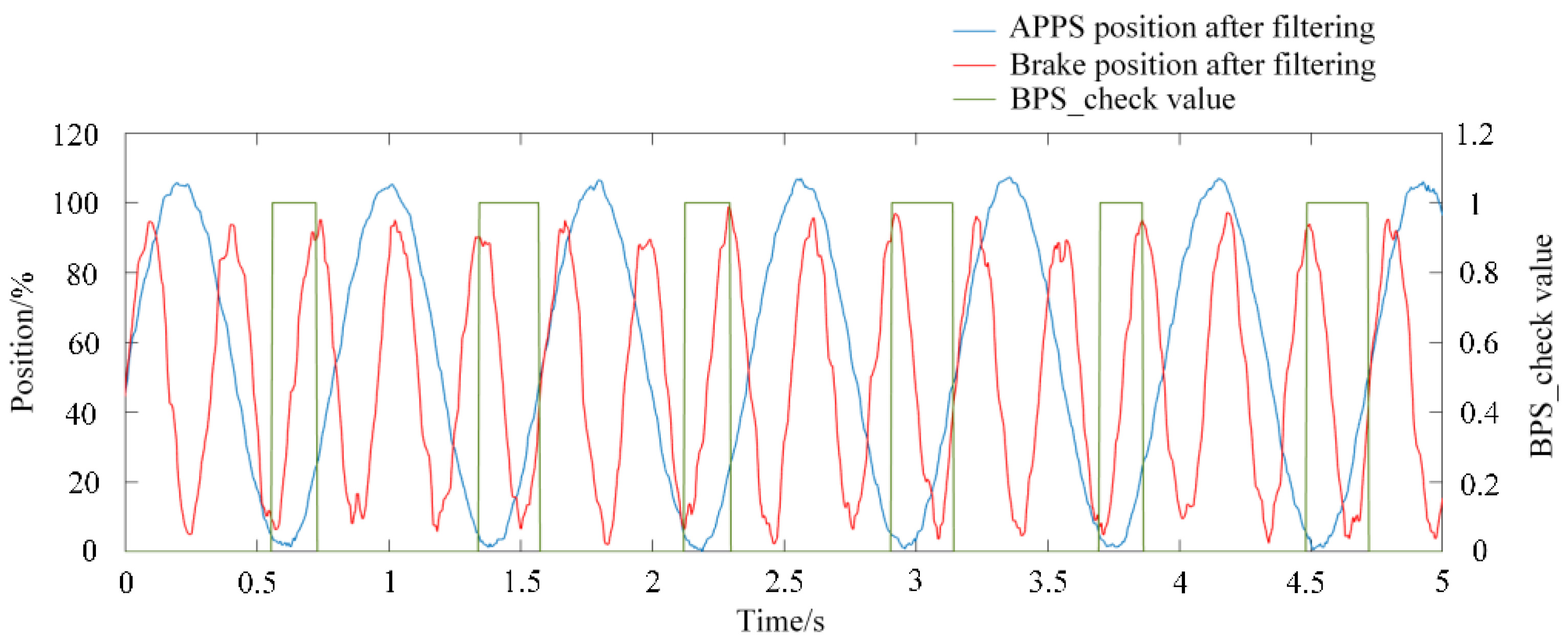

3.4. APPS/Brake Pedal Plausibility Check

4. Simulation

4.1. Projects

4.2. Simulation Results

5. Experimental Verification

5.1. Experimental Setup

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- What Is the Formula Student Germany Competition? Available online: https://www.formulastudent.de/about/concept/ (accessed on 25 September 2019).

- Mihailidis, A.; Samaras, Z.; Nerantzis, I.; Fontaras, G.; Karaoglanidis, G. The design of a Formula Student race car: A case study. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2009, 223, 805–818. [Google Scholar] [CrossRef]

- Wang, H.; Shi, L.; Man, Z.; Zheng, J.; Li, S.; Yu, M.; Jiang, C.; Kong, H.; Cao, Z. Continuous fast nonsingular terminal sliding mode control of automotive electronic throttle systems using finite-time exact observer. IEEE Trans. Ind. Electron. 2018, 65, 7160–7172. [Google Scholar] [CrossRef]

- Yang, B.; Liu, M.; Kim, H.; Cui, X. Luenberger-sliding mode observer based fuzzy double loop integral sliding mode controller for electronic throttle valve. J. Process Control 2018, 61, 36–46. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, H.; Cao, Z.; Zheng, J.; Ping, Z.; Chen, L.; Jin, X. Extreme-learning-machine-based FNTSM control strategy for electronic throttle. Neural Comput. Appl. 2020, 32, 14507–14518. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, H.; Huang, K.; Qiu, M.; Zhen, S.; Chen, Y.-H. A fuzzy approach for optimal robust control design of an automotive electronic throttle system. IEEE Trans. Fuzzy Syst. 2017, 26, 694–704. [Google Scholar] [CrossRef]

- Sun, J.-m.; Zheng, P.-t. Immune Feedback Strategy in an Electronic Throttle Control System. J. Highway Transp. Res. Dev. Engl. Ed. 2019, 13, 103–110. [Google Scholar] [CrossRef]

- Vargas, A.N.; Menegaz, H.M.; Ishihara, J.Y.; Acho, L. Unscented Kalman filters for estimating the position of an automotive electronic throttle valve. IEEE Trans. Veh. Technol. 2016, 65, 4627–4632. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, Z.-G. Fracture failure analysis of automotive accelerator pedal arms with polymer matrix composite material. Compos. Part B Eng. 2013, 53, 103–111. [Google Scholar] [CrossRef]

- Romero, J.; Queipo, N. Reliability-based and deterministic design optimization of a FSAE brake pedal: A risk allocation analysis. Struct. Multidiscip. Optim. 2017, 56, 681–695. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Tang, X.; Yang, S. A braking intention identification method based on data mining for electric vehicles. Math. Probl. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Wang, S.; Ma, J.; Yu, Q.; Gao, Q.; Yu, M. Identification of driver’s braking intention based on a hybrid model of GHMM and GGAP-RBFNN. Neural Comput. Appl. 2019, 31, 161–174. [Google Scholar] [CrossRef]

- Hao, G.; Jia, Y.; Gongxiang, C.; Chuanbao, W.U.; Ke, Z. The design of the mechanical locking device for anti-mistakenly stepped on the accelerator system with the speed threshold. J. Henan Inst. Ence Technol. Nat. Ence Ed. 2017, 45, 65–70. [Google Scholar]

- Ming-Ji, W.; He, N.; Yong, Z.; University, N.P. A design of intelligent control system for preventing mistakenly stepping on accelerator pedal of vehicle. Electron. Design Eng. 2017, 4, 14. [Google Scholar]

| Condition | Limit_Check | Consistency_Check | BPS_Check | Output |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | APPS |

| 2 | 0 | 1 | 1 | 0 |

| 3 | 1 | 0 | 1 | 0 |

| 4 | 1 | 1 | 0 | 0 |

| 5 | 0 | 0 | 1 | 0 |

| 6 | 0 | 1 | 0 | 0 |

| 7 | 1 | 0 | 0 | 0 |

| 8 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Hong, H.; D’Apolito, L. Reliability Control of Electric Racing Car’s Accelerator and Brake Pedals. World Electr. Veh. J. 2021, 12, 1. https://doi.org/10.3390/wevj12010001

Li Y, Hong H, D’Apolito L. Reliability Control of Electric Racing Car’s Accelerator and Brake Pedals. World Electric Vehicle Journal. 2021; 12(1):1. https://doi.org/10.3390/wevj12010001

Chicago/Turabian StyleLi, Yuxing, Hanchi Hong, and Luigi D’Apolito. 2021. "Reliability Control of Electric Racing Car’s Accelerator and Brake Pedals" World Electric Vehicle Journal 12, no. 1: 1. https://doi.org/10.3390/wevj12010001

APA StyleLi, Y., Hong, H., & D’Apolito, L. (2021). Reliability Control of Electric Racing Car’s Accelerator and Brake Pedals. World Electric Vehicle Journal, 12(1), 1. https://doi.org/10.3390/wevj12010001