1. Introduction

The term Forgotten Baby Syndrome (FBS) refers to the tragic yet preventable phenomenon in which a caregiver unintentionally leaves a child unattended in a vehicle, leading to fatal consequences due to heatstroke. This study explores three relevant fundamental questions: (i) What is the underlying nature of FBS? (ii) What psychological and situational mechanisms contribute to its occurrence, even among attentive and loving caregivers? (iii) To what extent can technology-based interventions mitigate the associated risks?

According to data compiled by Jan Null, from 1998 to date, at least 1011 child deaths have been recorded in the United States as a result of vehicular heatstroke [

1]. This corresponds to an average of 38 deaths per year [

1,

2]. These figures underscore the critical need for preventive solutions, such as driver alert systems. The implementation of such systems not only exemplifies the practical and socially beneficial application of Internet of Things (IoT) technologies but, most importantly, offers a lifeline that could prevent otherwise avoidable child fatalities.

As awareness of the syndrome increases, both vehicle and child seat manufacturers have increasingly expressed a willingness to integrate pre-installed alert systems. Their adoption reflects a larger movement toward improving vehicular safety standards, with the dual aim of saving lives and anticipating the upcoming regulatory frameworks [

3].

Psychologist Dr. D.M. Diamond emphasizes that this syndrome is not attributable to negligence or lack of affection but rather to specific cognitive and situational factors [

4]. His findings suggest that stress, sleep deprivation, and disruptions to daily routines can lead to the formation of false memories, causing caregivers to enter a state of “autopilot” where routine actions override conscious intentions. These conditions—combined with environmental or psychological stressors—create an optimal context for the occurrence of FBS, which can affect virtually any caregiver, regardless of background or experience [

2].

To ensure that a relevant alert system meets the stringent requirements of real-time responsiveness, environmental awareness, and child safety, in this work, a carefully selected set of sensors and actuators has been integrated with the Arduino UNO R4 WiFi platform. Design choices ranging from digital environmental sensors and photoresistors to stepper motors and tactile switches enable the system to reliably detect temperature, humidity, exposure to sunlight and user interactions. These hardware components work in unison in the presented prototype to simulate the real situation, compute the Discomfort Index (DI), and initiate safety responses such as sunshade deployment, fan activation, and alert issuance. The following sections provide a detailed overview of the individual components, their physical interconnections, and the logic driving their operation within the prototype system.

The rest of this paper is organized as follows.

Section 2 reviews the literature on FBS, emphasizing the prevalence of pediatric vehicular heatstroke, identifying current technological gaps, and comparing our approach with existing solutions.

Section 3 presents the proposed monitoring system design, highlighting IoT integration, edge computing, and the DI for thermal risk assessment, alongside software architecture and real-time visualization using Python 3.12 and vPython 7.

Section 4 details the hardware components and the final board of the system, including the Arduino UNO R4 WiFi and environmental sensors essential for system operation. Subsequent sections analyze system implementation, evaluation, and use cases demonstrating the effectiveness of timely alerts and adaptive safety measures. Finally, conclusions and future work, including car and mobile application integration, are discussed in

Section 5 and

Section 6.

2. Related Work

2.1. Forgotten Baby Syndrome

Extensive research and longitudinal data underscore the severity of pediatric vehicular heat stroke as a persistent public health issue. These incidents occur predominantly during the summer months, with a disproportionately high frequency observed in the hottest areas, e.g., the southern states of the USA, where ambient temperatures tend to reach extreme levels [

1,

5]. Statistical analyses estimate that, on average, 38 children under the age of 15 years succumb to heatstroke each year as a result of being left inside a vehicle, a figure that raises significant public health concerns. Since 1998, over 1000 such fatalities have been documented in the United States, underscoring the persistent nature of the problem. Geospatial analysis of the recorded deaths reveals a higher concentration of incidents in regions located closer to the equator, highlighting the correlation between geographic latitude and risk of heatstroke [

1].

Furthermore, according to a study by McLaren, Null, and Quinn [

6], the critical thermal maxima (CTM), the threshold temperature at which heatstroke becomes physiologically imminent, has been determined to lie between 41.6 °C and 42.0 °C. Alarmingly, such temperatures can be reached inside a closed vehicle in just 30 min after exposure to the sun, even on days when the ambient temperature does not exceed 24 °C. This reinforces the danger posed by enclosed vehicular environments and the need for preventive measures regardless of external weather conditions.

These findings emphasize that vehicular heatstroke represents a latent threat not only in extreme weather conditions but also during seemingly temperate days. Consequently, they highlight the need for continuous monitoring systems and early warning technologies capable of mitigating thermal hazards in a cost-effective manner.

2.2. Existing Technologies

Various technological interventions have been developed to help parents prevent FBS, with solutions ranging from aftermarket consumer devices to integrated automotive systems. These can be broadly categorized into three groups:

2.2.1. Existing Solutions and Their Limitations

In recent years, a variety of commercial products have emerged to address the FBS, utilizing sensor technologies, mobile applications, and alert systems. Below, we provide an overview of representative solutions and their core functionalities, followed by a comparative analysis presented in

Table 1.

Cybex Sirona S with SensorSafe is an integrated child car seat that includes the SensorSafe buckle system, which connects via Bluetooth to a dedicated mobile application. The system monitors whether a child remains buckled in the seat when the caregiver leaves the vehicle and also provides warnings related to temperature and prolonged seating. Its main advantage is that it comes pre-integrated with the seat, ensuring reliability and user convenience, although it is relatively expensive and commits the user to a specific seat model.

Bebeconfort e-Safety Smart Cushion is a smart cushion incorporating pressure sensors and communicating with a smartphone application. If the driver moves more than 20 m away from the car while the child is still seated, an alert is triggered. If no response occurs within 60 s, the child’s location is shared with pre-defined emergency contacts. While versatile and compatible with multiple seats, the system is dependent on smartphone connectivity and battery lifetime.

Doona SensAlert utilizes a cloud-based multi-layer alert system. It escalates notifications through push alerts, phone calls, and SMS messages to the caregiver and emergency contacts if a child remains in the vehicle. This redundancy enhances reliability compared to Bluetooth-only systems. However, it requires cloud access and correct app configuration and is positioned at a higher price point.

Alertino (Tecnimed) is designed according to Italian child safety regulations and does not require a smartphone. It integrates a pressure sensor in the car seat and a control unit attached to the driver’s seat belt. If the seat belt is unbuckled while a child remains seated, an immediate acoustic and visual alarm is triggered. Its simplicity and independence from apps make it highly reliable, but it cannot notify caregivers once they have exited the vehicle.

BabyMinder (Daloda) is a wireless system powered through the vehicle’s 12 V socket. A pressure sensor is placed under the car seat and activates when the engine is turned off or the seatbelt is released while a child is still detected. It emits a loud audible alarm and red light inside the vehicle. The system is straightforward and app-free but lacks remote alert capabilities.

Elepho eClip is a clip-on Bluetooth device that attaches to the seatbelt or car seat and pairs with a smartphone application. It monitors both child presence and ambient temperature. Despite being lightweight and portable, user reviews indicate potential reliability issues, as the application must be manually activated for proper operation, and Bluetooth range limitations apply.

Infalurt combines a seat pressure sensor with a wireless key fob alarm. When the caregiver moves away from the car with a child still seated, the fob emits a loud alarm. It does not require smartphones or apps, making it robust and easy to use, but it cannot notify contacts remotely and is limited in availability outside Australia, where it was developed.

BlueBeep Car Seat Guardian integrates seat and harness sensors with a dedicated application. It provides alerts if a child remains unattended and also checks for improper installation. While promising in terms of functionality, it is a newer entrant to the market with limited long-term validation.

2.2.2. Comparison with SafeCuddle

Despite the diversity of approaches, widespread adoption remains limited. Many commercially available solutions are costly, complex to install, or not standardized across vehicle manufacturers. Furthermore, user compliance and system reliability remain critical issues and include poor integration and usability and the lack of real-time data processing.

Table 2 highlights how the proposed

SafeCuddle prototype systematically addresses the main shortcomings of existing child car seat monitoring systems. The comparative analysis indicates that current commercial and research solutions are limited by technological constraints, narrow functionality, or prohibitive costs. In contrast, SafeCuddle introduces a set of integrated features that collectively strike a balance among safety, flexibility, and cost. Its advantages can be summarized as follows.

Cost-effectiveness and universality: Unlike integrated solutions (e.g., Cybex Sirona S), SafeCuddle is an aftermarket system that costs only EUR 90 and is compatible with any child car seat.

Independent and reliable operation: In contrast to app-dependent or Bluetooth-limited products (e.g., Bebeconfort e-Safety, Elepho eClip), SafeCuddle provides autonomous functionality with WiFi connectivity and local actuation, ensuring continuous monitoring without requiring manual app activation.

Enhanced safety through sensor fusion: By combining force-sensing resistors, temperature sensing, and light detection, the system minimizes false alarms and provides a more holistic assessment of the child’s condition.

Active comfort management: Beyond safety, SafeCuddle introduces unique features such as automated actuation (fan or AC activation) in overheating scenarios, and stepper motor-driven window shade adjustment under intense sunlight that no other product currently offers.

Power autonomy and resilience: Unlike BabyMinder or Alertino, which rely on vehicle power or offer only in-car alerts, SafeCuddle is equipped with a rechargeable lithium battery, enabling independent operation and remote caregiver notifications.

SafeCuddle aims to unify existing technological approaches by providing a more reliable, efficient, and real-time solution to prevent FBS. Its architecture minimizes delays and potential errors associated with cloud dependency or external services, thereby increasing the reliability of detection during critical time frames.

2.2.3. Limitations of SafeCuddle

Although SafeCuddle demonstrates strong potential as an affordable and multifunctional aftermarket solution for combating FBS, it also presents certain limitations. First, as a prototype system based on Arduino components, its long-term durability, reliability under varying environmental conditions, and compliance with automotive safety standards remain to be validated. Second, the current design increases system complexity due to the number of integrated sensors and actuators, which may raise challenges regarding power management, component wear, and user maintenance. Furthermore, SafeCuddle currently requires independent installation and calibration by the caregiver, potentially limiting its ease of adoption compared to factory-integrated solutions. Finally, while future integration with vehicle CAN networks is planned, at this stage the system relies primarily on standalone alerts, which may restrict its interoperability with existing in-vehicle safety infrastructures.

3. System Design

SafeCuddle leverages Internet of Things (IoT) technologies, utilizing the Arduino UNO R4 WiFi microcontroller as the core processing unit. A series of sensors are integrated into the system to monitor environmental conditions within the vehicle in real time. Upon acquisition, sensor data undergoes preliminary processing at the edge device to extract relevant parameters.

Subsequently, the system calculates the DI, a composite metric used to quantify the perceived level of discomfort inside the vehicle, based on temperature and humidity data. The computed results are transmitted to a Python-based desktop application that functions as the main user interface.

The desktop application employs the vPython (

https://vpython.org/ vPython3D Programming for the general public accesssed on 12 December 2023) package, which enables three-dimensional and interactive visualizations to present the data in a clear and intuitive format. The following sections provide a detailed analysis of the main hardware and software components of the system, including sensor selection, data transmission protocols, processing algorithms, and user interface functionalities.

3.1. Internet of Things

Internet of Things (IoT) consists of a vast network of interconnected physical devices embedded with sensors, actuators, and communication modules. These “smart” devices incorporate electronics, operating systems, and sensors and are often part of people’s daily lives. Especially in recent years, with the increasing emergence of cheaper and smaller wireless devices designed to serve our daily lives, more than 14 billion devices are already connected, including wireless keys or e-Pass devices [

9,

10,

11].

In the context of this study, the IoT framework serves as the foundational architecture for implementing a smart vehicle monitoring system designed to prevent FBS. Using the Arduino UNO R4 WiFi microcontroller, the system integrates various environmental and presence sensors that continuously capture data from within the vehicle. This information is processed locally and transmitted through wireless communication protocols to a centralized interface for visualization and alert generation. The decentralized and scalable nature of IoT allows flexible deployment, reduced response times, and enhanced reliability, particularly in safety-critical applications. As such, the integration of IoT technologies plays a pivotal role in delivering an efficient, low-cost, and user-friendly solution aimed at improving vehicular child safety.

3.2. Edge-Level Data Processing

The implemented system incorporates edge-level data processing to enable autonomous real-time operation without reliance on remote servers or cloud-based infrastructure. The Arduino UNO R4 WiFi microcontroller serves as the core edge device, continuously acquiring data from integrated environmental sensors, including temperature, humidity, and presence detectors. Upon acquisition, raw sensor data undergo preliminary filtering and transformation to remove anomalies and extract actionable parameters [

12].

A key computational task performed at the edge is the calculation of the DI, a composite metric that reflects the thermal conditions within the vehicle. Furthermore, embedded logic modules assess the presence of an infant in conjunction with driver exit detection, triggering immediate alerts when hazardous conditions are identified. This localized processing architecture ensures minimal latency, improves the resilience of the system, and guarantees operational continuity in scenarios with limited network connectivity. By delegating critical decision-making to the edge, the system effectively mitigates response delays, providing a timely and context-sensitive safety mechanism tailored to prevent FBS incidents [

13].

3.3. Discomfort Index (DI)

To estimate the perceived thermal discomfort within a closed vehicle without proper ventilation, this study uses one of the most widely adopted and computationally accessible metrics: the DI. Originally proposed by Thom (1959) [

14] and later refined by Besancenot (1978) [

15], the DI is an empirical thermal comfort index derived from observational climatological data. Despite its simplicity and empirical basis, it has remained a robust and widely used indicator in thermal comfort studies for more than four decades.

The

can be computed as follows.

where

is the temperature of the air, measured in degrees of calcium (°C), and

RH is the relative humidity, which is defined as the ratio of the amount of water (in the form of vapor) present in the air to the maximum water capacity that this air can hold.

This index reflects the combined effect of air temperature and humidity on the thermal sensation of the human body and is particularly relevant in confined spaces, such as the interior of a closed vehicle, where thermal stress can rapidly escalate.

Table 3 illustrates the relationship between the calculated DI value and the corresponding percentage of the population experiencing discomfort, as adapted from the relevant literature [

16]:

In summary, the DI offers a practical and efficient means of assessing thermal discomfort in enclosed environments such as unventilated or poorly ventilated vehicles. Its empirical formulation, simplicity, and long-standing use in climatological and physiological studies make it a reliable indicator of human thermal stress. By integrating air temperature and relative humidity, the DI captures the synergistic effects of environmental conditions on human perception, providing valuable insights into heat-related risks. As such, its application in this study forms a crucial component in evaluating thermal safety thresholds under extreme interior conditions.

3.4. Python and vPython

Python’s general-purpose design makes it one of the most widely used and adaptable programming languages. Unlike domain-specific alternatives, Python supports a wide array of applications across diverse fields, including education, scientific computing, data science, artificial intelligence, and software engineering. As a high-level interpreted language, it provides notable advantages such as portability, syntactic clarity, and ease of use, making it accessible to users with varying levels of programming proficiency.

Since its introduction by Guido van Rossum in 1989, Python has experienced continuous development and has become an indispensable tool in both academic and industrial settings. Its comprehensive standard library, combined with a vast ecosystem of third-party packages, facilitates the efficient implementation of complex functionalities in domains such as data analysis, data mining, and machine learning [

17,

18].

Among the specialized libraries within the Python ecosystem is vPython, which is specifically designed for the creation of interactive three-dimensional visualizations. Initially developed to support physics and engineering, vPython (visual Python) provides an intuitive programming interface that enables real-time rendering of 3D objects while abstracting the complexities of low-level graphics programming [

19].

By allowing for the rapid and dynamic visualization of spatial and physical models, vPython serves as a valuable tool in scientific simulations, educational applications, and system visualization interfaces, where enhanced spatial representation significantly contributes to user engagement and conceptual understanding.

3.5. Hardware and Software Components Graph

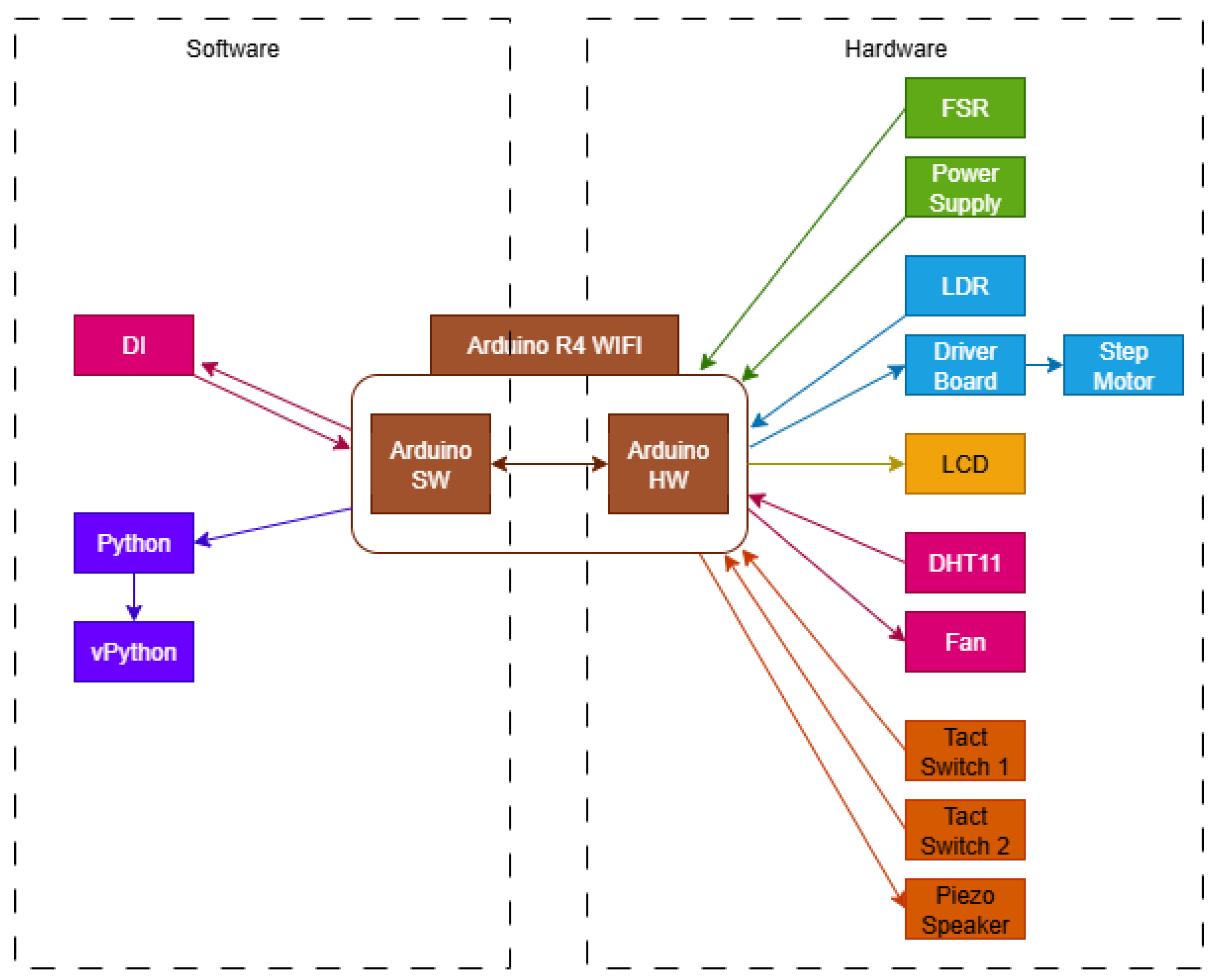

The integration of hardware and software components, as shown in

Figure 1, including IoT-enabled sensors, the Arduino UNO R4 WiFi microcontroller, and a Python-based visualization interface, forms a cohesive and scalable system for monitoring and analyzing thermal conditions within enclosed vehicle environments. Each technological element, from real-time data acquisition to 3D visualization using vPython, contributes to a comprehensive workflow that enhances both functionality and usability. This modular architecture not only enables efficient thermal risk assessment through the DI but also lays the foundation for future extensions that involve predictive analytics, user feedback integration, or deployment in broader smart mobility frameworks.

In the hardware domain, the SafeCuddle prototype integrates the FSR, LDR, and DHT11 sensors, alongside two tactile switches that serve as signal simulators to provide input data to the Arduino microcontroller. A battery unit ensures system autonomy by supplying the required power. On the output side, the system drives a stepper motor through a dedicated driver board, while additional feedback to the user is provided via an LCD screen and a piezoelectric speaker, ensuring both visual and auditory notifications.

In the software domain, the implementation extends beyond the Arduino-based programming logic. A central component is the Discomfort Index (DI) calculation, which—although executed directly on the Arduino—is highlighted as a distinct module due to its pivotal role in the overall system workflow. Complementing this, a Python-based desktop application has been developed, which receives the sensor data and renders real-time visualizations through the vPython package. This software integration not only enhances system interactivity but also provides a clear and intuitive representation of the monitored conditions.

It is important to emphasize that the Python application is not required for the correct execution of the prototype’s core functionality. All sensing, decision-making, and actuation processes can operate independently on the Arduino. However, Python is employed in the current stage of development to facilitate data reception and visualization, offering an enriched experimental environment. In future iterations of SafeCuddle, this component could be further extended into a mobile application or another user-oriented interface, thereby enhancing accessibility and practicality for real-world deployment.

4. Hardware Components

In this section, we present the sensors utilized in the system, their interconnections, and a concise description of their functional roles. Each sensor has been carefully selected to contribute to the accurate monitoring of environmental conditions within the vehicle cabin, which are critical for the reliable operation of the system.

Circuit schematics and wiring diagrams that illustrate the integration of these components with the Arduino UNO R4 WiFi microcontroller have been designed using the Tinkercad simulation environment. These diagrams provide a clear visualization of the system’s hardware architecture and serve as a reference for both implementation and educational purposes.

Each sensor is discussed with regard to its measurement principle, data output, and relevance to the detection of discomfort or safety-critical conditions within the vehicle.

4.1. Arduino UNO R4 WiFi

The Arduino UNO R4 WiFi serves as the central processing unit for the system, chosen for its balance of computational power, connectivity, and ease of integration. Based on the Renesas RA4M1 microcontroller (Renesas Electronics Corporation, Tokyo, Japan), it includes a 32-bit Arm

® Cortex

® M4 processor running at 48 MHz, significantly outperforming the traditional 8-bit AVR-based Arduino UNO in terms of memory, speed, and multitasking capability. It offers 256 KB of flash memory and 32 KB of SRAM, which allows handling more complex edge-level data processing routines and real-time sensor acquisition without the risk of memory overflow, a crucial aspect in embedded applications that involve multiple sensor nodes and time-critical alerts [

20,

21].

One of the most distinguishing features of the Arduino UNO R4 WiFi is its integrated ESP32-S3 WiFi module, which allows the device to connect to wireless networks out of the box. This dual-core ESP32 chip supports 2.4 GHz Wi-Fi, Bluetooth

® Low Energy (BLE) and additional peripherals that significantly extend the board’s capabilities for IoT applications. Through the use of this module, data collected and processed on the edge can be transmitted either to local interfaces (e.g., a Python desktop application via serial communication) or remotely (e.g., via MQTT or HTTP protocols), depending on the deployment scenario [

22].

The board also incorporates a USB-C connector, providing faster and more reliable power and data transfer, as well as a Qwiic I

2C connector, enabling rapid sensor integration through plug-and-play serial communication. These features reduce the complexity of hardware development, especially when working with a variety of digital sensors or I

2C-enabled modules. In the context of vehicular safety applications such as the one presented in this study, this modularity and extensibility allow easy adaptation to new configurations or environmental conditions [

23].

In terms of development and community support, the Arduino UNO R4 WiFi is fully compatible with the Arduino IDE 2.0 and supports over-the-air (OTA) updates, allowing firmware to be updated remotely without physical access, an essential capability for systems intended for deployment in difficult-to-reach or user-agnostic environments, such as under child seats or embedded in dashboards [

24].

To ensure robustness in mobile environments, the board includes enhanced protection circuits, including overcurrent, overvoltage, and reverse polarity protection, which makes it suitable for fluctuating power conditions common in vehicular systems. Furthermore, the availability of real-time clock (RTC) and CAN Bus support on the R4 Minima variant (for extended applications) enables future expansion into time-synchronized or vehicle-networked functionalities, which are increasingly relevant in smart mobility solutions [

25].

4.2. Sensors

Following a thorough analysis of the functional and environmental requirements of the proposed application, a set of sensors was selected to enable accurate monitoring of the conditions inside the vehicle cabin. The selection criteria included sensor reliability, response time, ease of integration, and relevance to the detection of potential risk factors associated with the Forgotten Baby Syndrome (FBS). The sensors integrated into the system are as follows:

Each sensor is described below, along with the design choices made for the SafeCuddle.

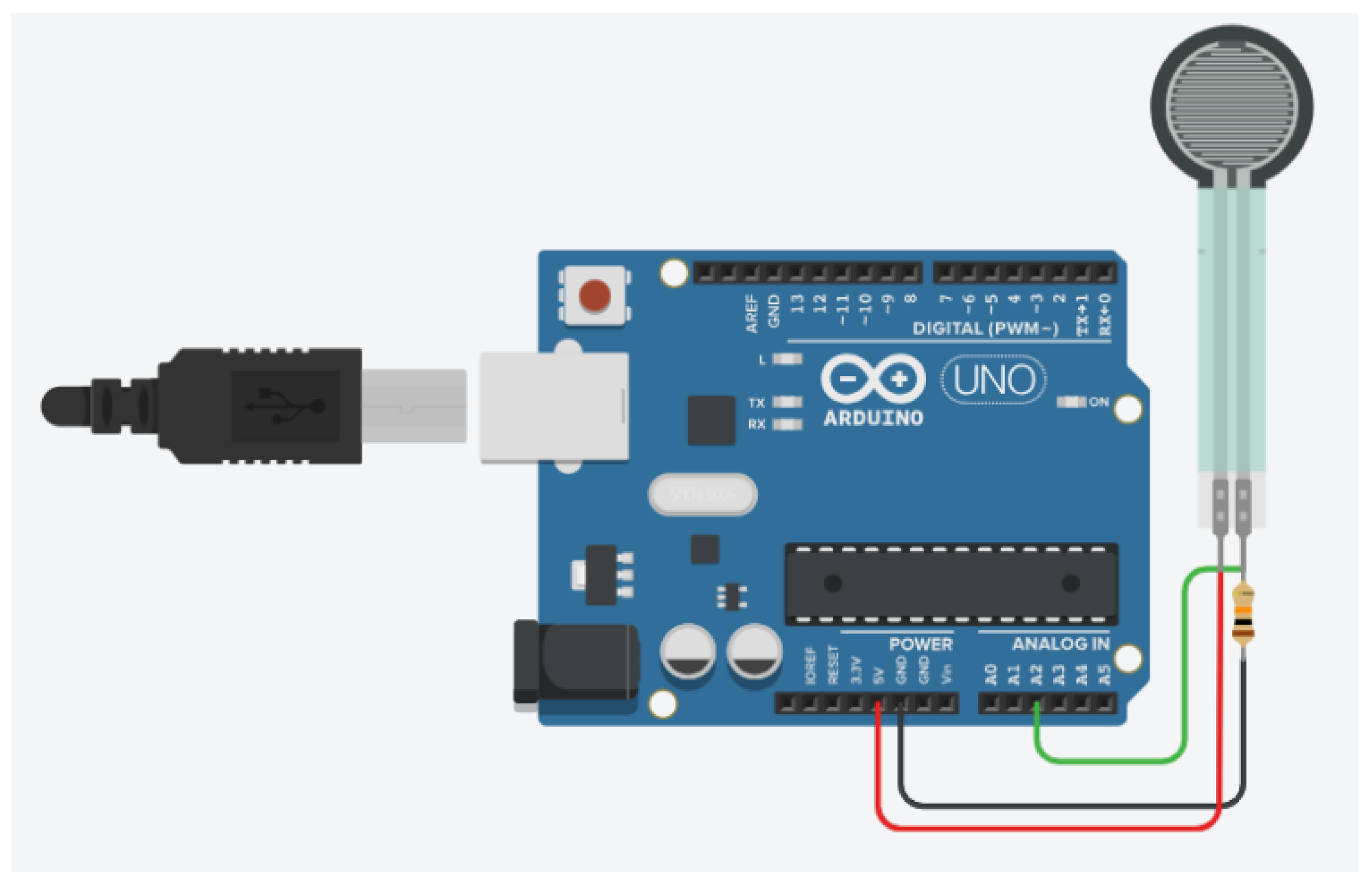

4.2.1. FSR Force Resistance

The FSR402 force-sensitive resistor is employed as a weight detection sensor in the system. Positioned beneath the child seat cushion, it serves as a trigger mechanism for the activation of the monitoring program. Specifically, the system remains in a standby state until the sensor detects a weight corresponding to the presence of a child or infant seated, at which point the program initiates operation.

The sensor exhibits a variable resistance that is inversely proportional to the applied force, the resistance of the sensor decreases as the pressure increases, reflecting an inverse proportionality. In the absence of applied force, the resistance exceeds 1 MΩ, effectively indicating no load. The operational weight detection range of the FSR402 spans approximately 100 g to 12 kg, which aligns perfectly with the typical weight range of infants and young children. For scenarios involving heavier subjects exceeding 12 kg, the system can be adapted by employing sensors with an expanded measurement range.

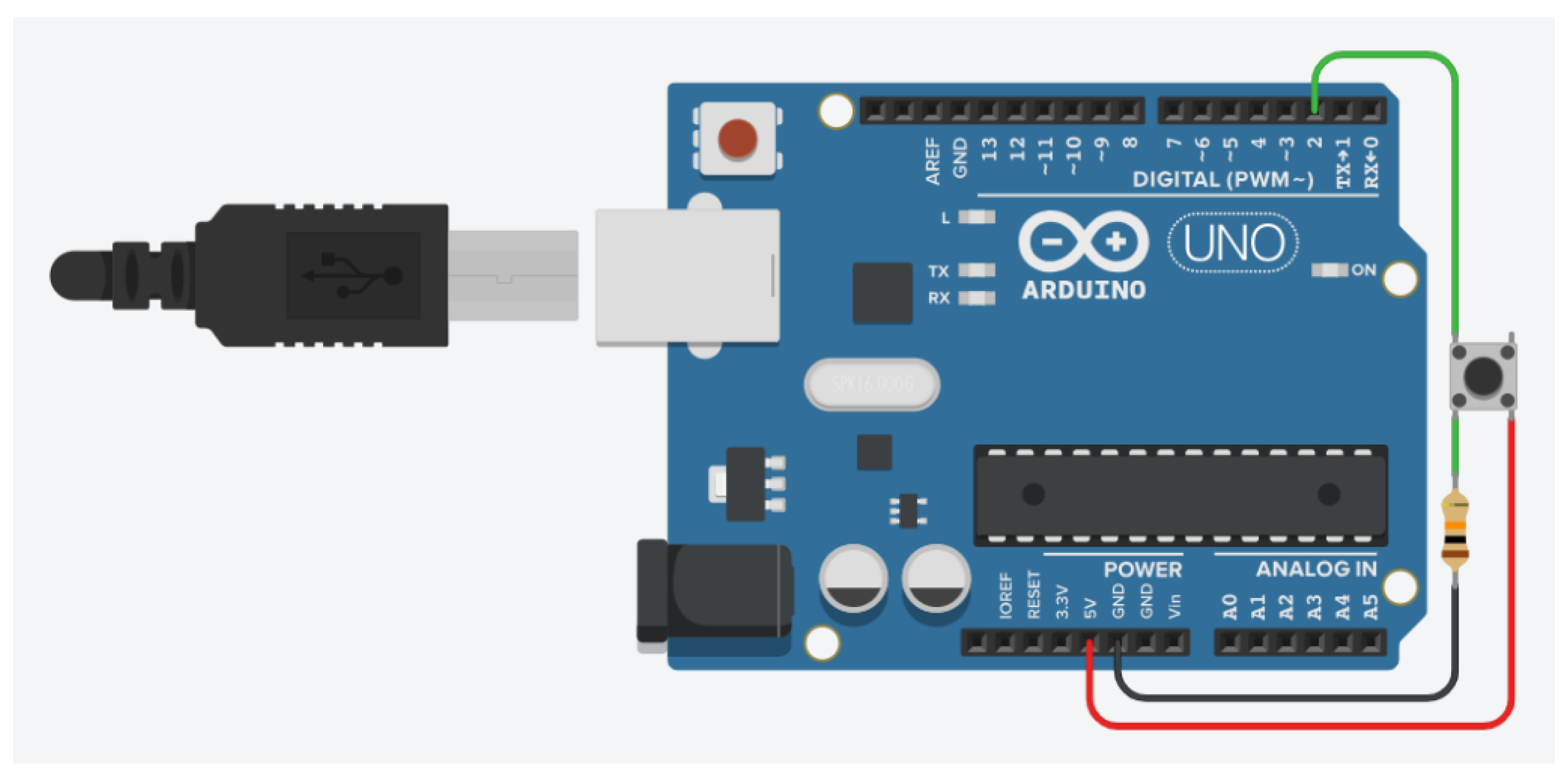

The FSR402 is interfaced with the Arduino UNO R4 WiFi via the analog input pin A2, as shown in

Figure 2. The sensor outputs an analog voltage corresponding to the resistance change and thus requires an analog-to-digital converter (ADC) input for accurate readings. Additionally, a 10 kΩ pull-down resistor is connected in series between the sensor and ground to ensure the discharge of the sensor’s capacitance after each measurement, thereby stabilizing the signal and improving the accuracy of successive readings.

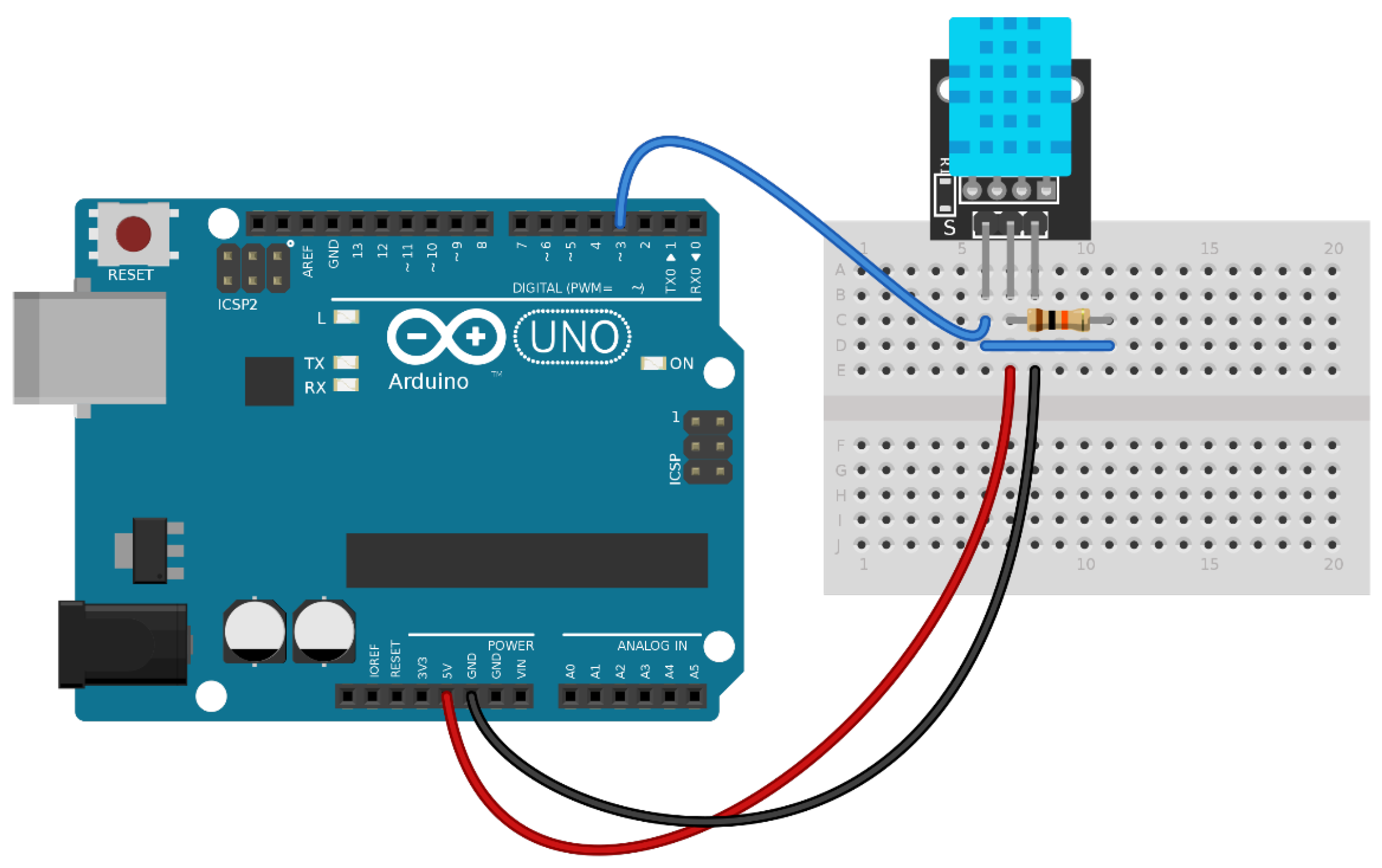

4.2.2. Temperature-Humidity DHT11

The DHT11 sensor is utilized to measure and provide digital readings of the ambient temperature and relative humidity within the vehicle cabin. The sensor operates within a humidity detection range of 20% to 80% RH and a temperature measurement range of 0 °C to 50 °C. These environmental parameters are critical inputs for the subsequent calculation of the DI, which quantifies perceived thermal stress.

To facilitate proper communication and data acquisition, the sensor interfaces with the microcontroller using a single-wire digital protocol. The DHT sensor library by Adafruit was employed to simplify sensor initialization, data reading, and error handling [

26,

27].

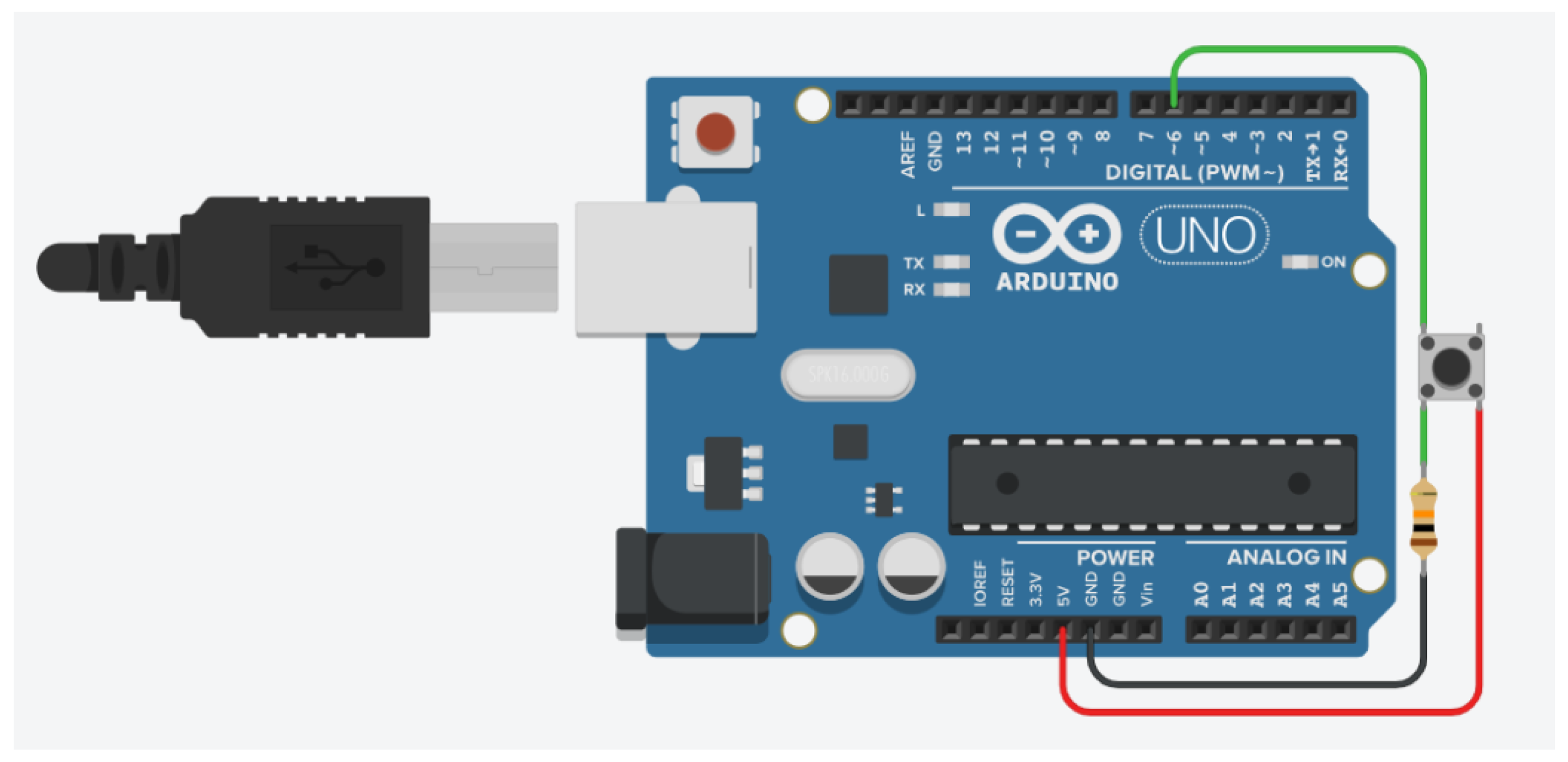

Hardware-wise, the sensor data line is connected to digital pin 3 on the Arduino UNO R4 WiFi, as shown in

Figure 3, since the sensor requires a digital I/O pin for data transmission. Furthermore, a 1 kΩ pull-up resistor is connected between the data line and the sensor’s power supply line (VCC), ensuring signal integrity and reliable communication by maintaining the data line in a defined logic state when idle.

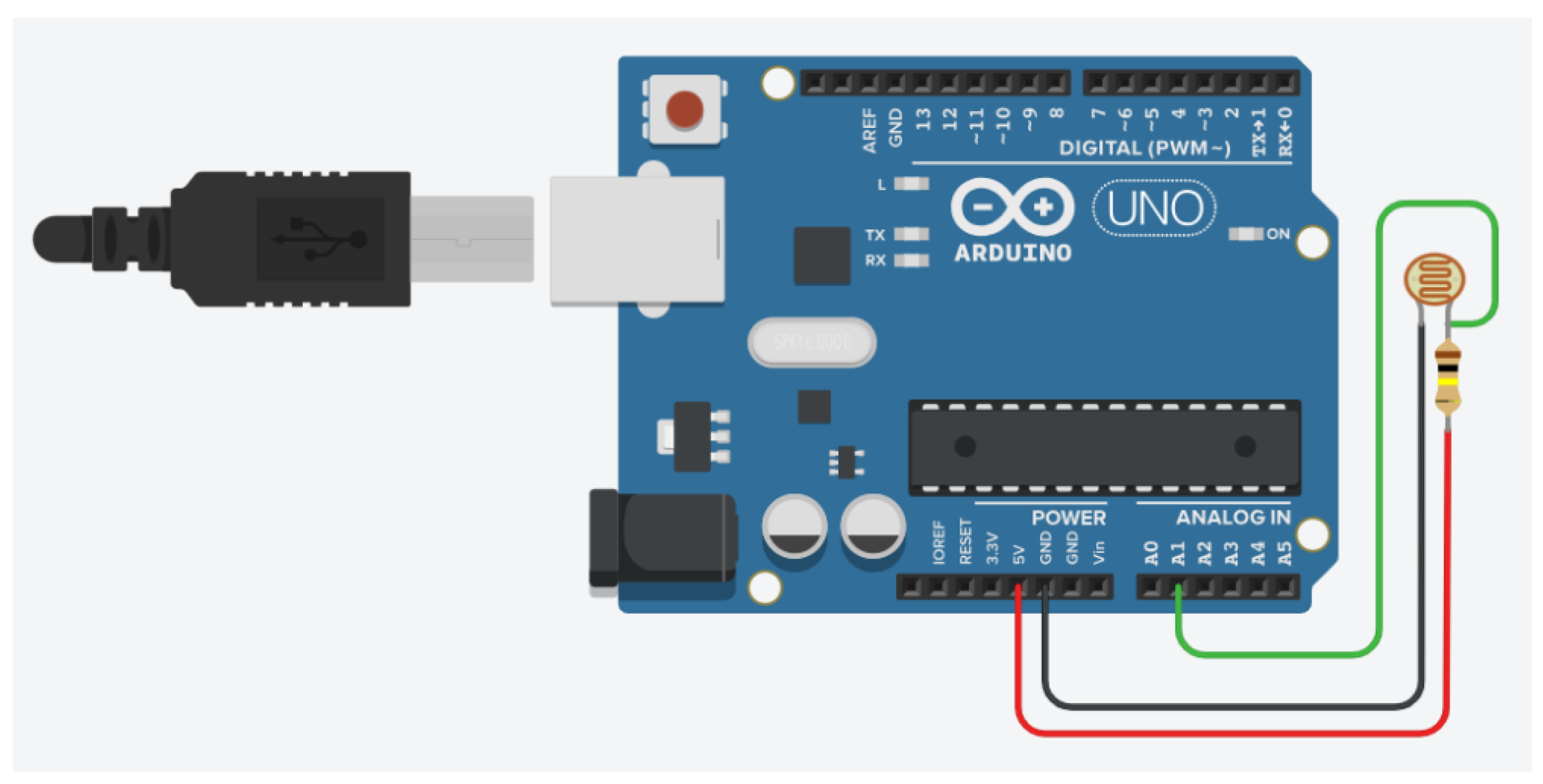

4.2.3. LDR Photoresistor

The Light-Dependent Resistor (LDR) is a simple variable resistor whose resistance inversely varies with the intensity of incident light. Within the system, it serves to monitor the exposure to sunlight inside the vehicle, providing critical input on the child’s potential exposure to direct solar radiation.

When the detected light intensity exceeds a predefined threshold—specifically, when solar radiation exceeds 70% of the sensor’s maximum sensitivity—the system alerts the user, urging them to reduce the sunshade and reduce the child’s exposure. This threshold corresponds to conditions where the child or infant may begin to experience discomfort due to excessive sunlight and heat build-up.

If the user does not respond promptly, the system automatically initiates a gradual reduction in sunshade, thereby mitigating dangerous levels of sun exposure to ensure the child’s safety and comfort.

The photoresistor is connected to the A1 analog input pin of the Arduino UNO R4 WiFi, as shown in

Figure 4, allowing continuous measurement of the intensity of ambient light. A 0.10

pull-down resistor is incorporated in the circuit to stabilize the sensor output by discharging residual capacitance and preventing signal noise.

4.3. Components

The system is completed by the following components:

4.3.1. Tact Switch

The tact switch is a simple, normally open-push button that closes the circuit when pressed, thereby sending a digital signal to the Arduino microcontroller. This component simulates various trigger events in SafeCuddle, such as seatbelt unbuckling and the driver leaving the vehicle.

For this implementation, the switch that simulates the signal of ’zone opening’ is connected to the digital pin 2 of the Arduino UNO R4 WiFi, as shown in

Figure 5. To ensure a stable and noise-free digital input, a 10 kΩ pull-down resistor is connected between the switch and ground, which prevents floating input states when the switch is open.

The second switch that simulates the exit of the driver from the vehicle is connected to digital pin 6 on the Arduino UNO R4 WiFi, as shown in

Figure 6. Similarly to the other input switch, a 10 kΩ pull-down resistor is used to ensure signal stability by preventing floating inputs when the switch is open.

In a practical implementation, this exit signal could be generated automatically through integration with an iTag device attached to car keys or through a Bluetooth connection with the driver’s mobile phone, allowing the system to detect the driver’s departure in real time without manual intervention.

4.3.2. Piezo Speaker

The system incorporates a monotone speaker, commonly referred to as a buzzer, which is widely used in electronic devices such as computers, alarm clocks, and security systems to provide audible alerts. The buzzer operates by converting electrical signals into single-frequency sound waves.

Wiring involves connecting the positive terminal of the buzzer to the designated control pin on the microcontroller, while the negative terminal is connected to ground. The buzzer operation is managed via the Arduino tone(.) and noTone(.) functions, allowing the generation and cessation of sound signals through software.

In this implementation, the buzzer is connected to digital pin 4 of the Arduino UNO R4 WiFi, as shown in

Figure 7.

4.3.3. Stepper Motor and Driver Board

The system employs a stepper motor, a type of induction motor characterized by its ability to move in precise, discrete steps. This feature facilitates accurate and controlled positioning, in contrast to conventional motors that operate continuously without fixed increments.

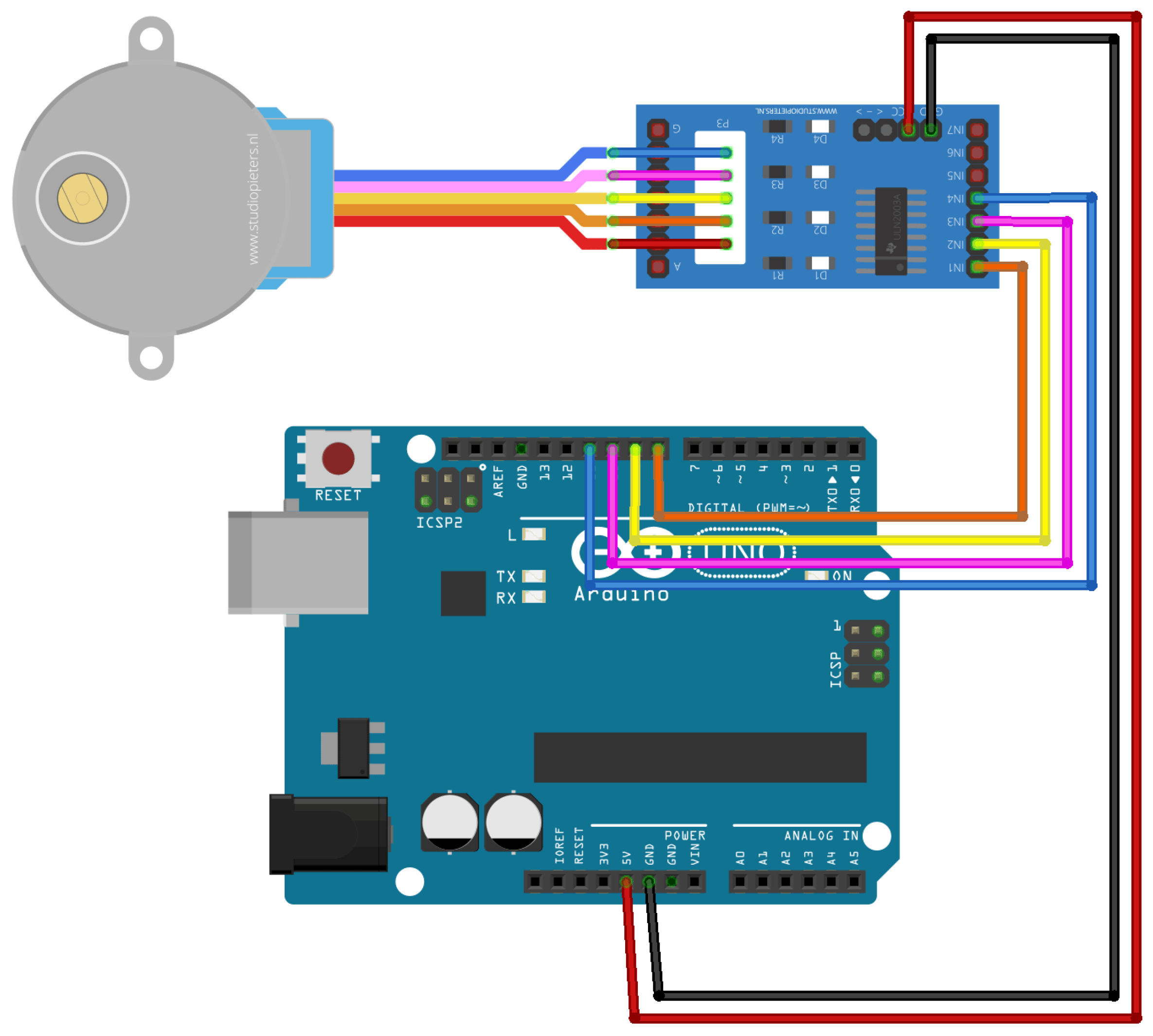

Due to its operational requirements, the stepper motor must be connected through a dedicated driver board, which supplies the necessary current and voltage levels for reliable and efficient motor function.

In this implementation, the stepper motor driver is interfaced with the Arduino UNO R4 WiFi through digital pins 8, 9, 10, and 11, which are used to send control signals that dictate the stepping sequence and motor rotation, as shown in

Figure 8.

4.3.4. LCD Display and I2C Module

For the SafeCuddle, a 16 × 2-character LCD display, which can present sixteen characters in two rows, was selected to provide visual feedback in real time to the user. The display module is interfaced with the Arduino UNO R4 WiFi through an I2C (Inter-Integrated Circuit) interface module, significantly reducing the number of microcontroller pins required.

Specifically, the I2C communication protocol requires only two signal lines: the Serial Clock Line (SCL) and the Serial Data Line (SDA). This configuration contrasts with the traditional parallel LCD interface, which requires up to seven pins, thereby conserving valuable I/O resources on the microcontroller.

The LCD module was connected directly to the dedicated SCL and SDA pins of Arduino, as shown in

Figure 9, facilitating efficient data transmission and simplified wiring.

4.3.5. Final Board of the SafeCuddle System

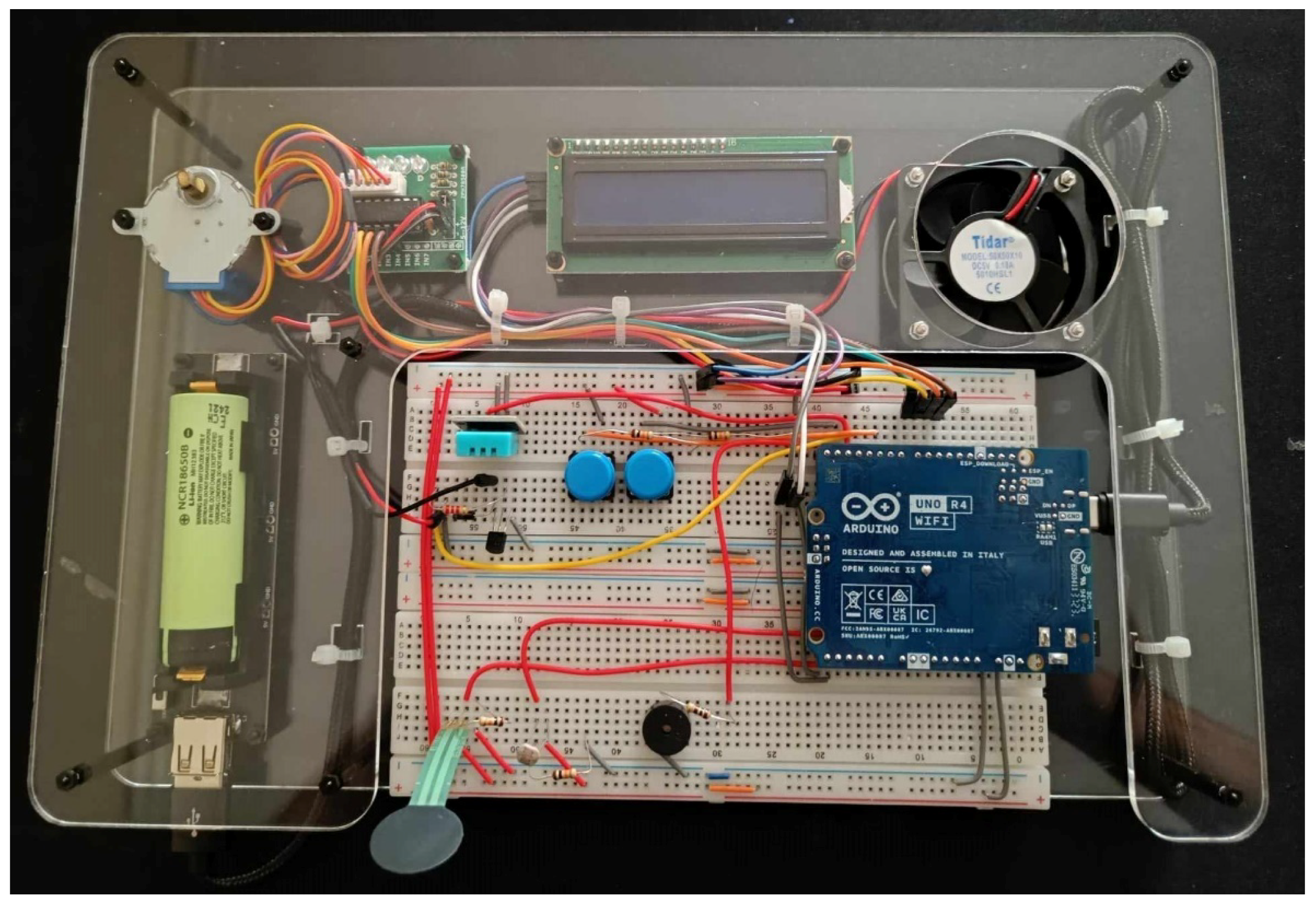

The final form of the SafeCuddle hardware is shown in

Figure 10. The prototype was assembled in a plexiglass case for protection and presentation. In future iterations, the system will be miniaturized when all components are joined to a board, leaving the sensors free so that they can be installed in each car seat as an aftermarket product.

4.4. Bill of Materials

In order to implement the proposed prototype system, a set of commercially available electronic components was selected, including the microcontroller, sensors, actuators, power supply elements and auxiliary hardware required for assembly. The total cost estimation highlights the feasibility of constructing the system with low-cost hardware while ensuring adequate functionality for the intended application.

The

Bill of Materials (BOM) used in the prototype is presented in

Table 4. The central processing unit is an

Arduino UNO R4 WiFi, which was selected due to its enhanced processing capability, integrated wireless communication, and strong support community, making it highly suitable for rapid prototyping of IoT-based vehicular applications.

For the sensing layer, a Force Sensing Resistor (FSR402) was chosen because it provides a lightweight, low-cost, and reliable method for detecting seat occupancy, with adequate sensitivity for human presence detection in automotive seating environments. The DHT11 temperature and humidity sensor was selected as it combines dual-environmental sensing in a single low-power and inexpensive unit. Although more precise sensors exist (e.g., DHT22, SHT31), the DHT11 offers sufficient accuracy for monitoring thermal conditions associated with FBS scenarios, while maintaining simplicity and cost-effectiveness. The Light-Dependent Resistor (LDR) was chosen over more advanced photodiodes because it offers fast response time, robustness under fluctuating sunlight conditions, and minimal power requirements, which are advantageous in a vehicular context where direct solar exposure must be detected reliably.

The actuation layer consists of a stepper motor, a piezoelectric buzzer, and a DC fan. These were selected for their responsiveness, low energy consumption, and robustness. The stepper motor enables controlled movement of auxiliary components (e.g., curtain or ventilation adjustment), while the piezoelectric buzzer provides a reliable low-cost audible alarm. The DC fan, powered through a Step-Up 5V conversion module, was chosen as a simple yet effective actuation component to demonstrate climate control support.

For human–machine interaction, a two-line LCD with an I2C interface was included, providing a cost-efficient and compact display solution with minimal wiring complexity while remaining legible in various lighting conditions common to automotive cabins.

The power subsystem employs a Panasonic NCR18650B lithium battery (3350 mAh) in combination with a USB charging module. This battery was selected due to its high energy density, long cycle life, and proven reliability in portable electronics, which are critical for uninterrupted operation in vehicular environments.

Finally, additional components such as breadboards, resistors, and connecting wires were selected based on their standard use in prototyping and to ensure modularity for future system extensions.

In summary, all components were carefully selected to balance accuracy, response time, reliability, cost, and suitability for in-vehicle operation, ensuring that the SafeCuddle prototype effectively addresses the target application while remaining extendable and cost-efficient.

The overall cost could be significantly reduced in the case of mass production or by designing the system directly as a printed circuit board (PCB) instead of relying on modular components. Furthermore, in the final product, an LCD display may not be necessary, as the results could be transmitted directly to a dedicated application or to the user’s mobile device. The ultimate objective is to reduce the manufacturing cost to a level that ensures competitiveness in the market.

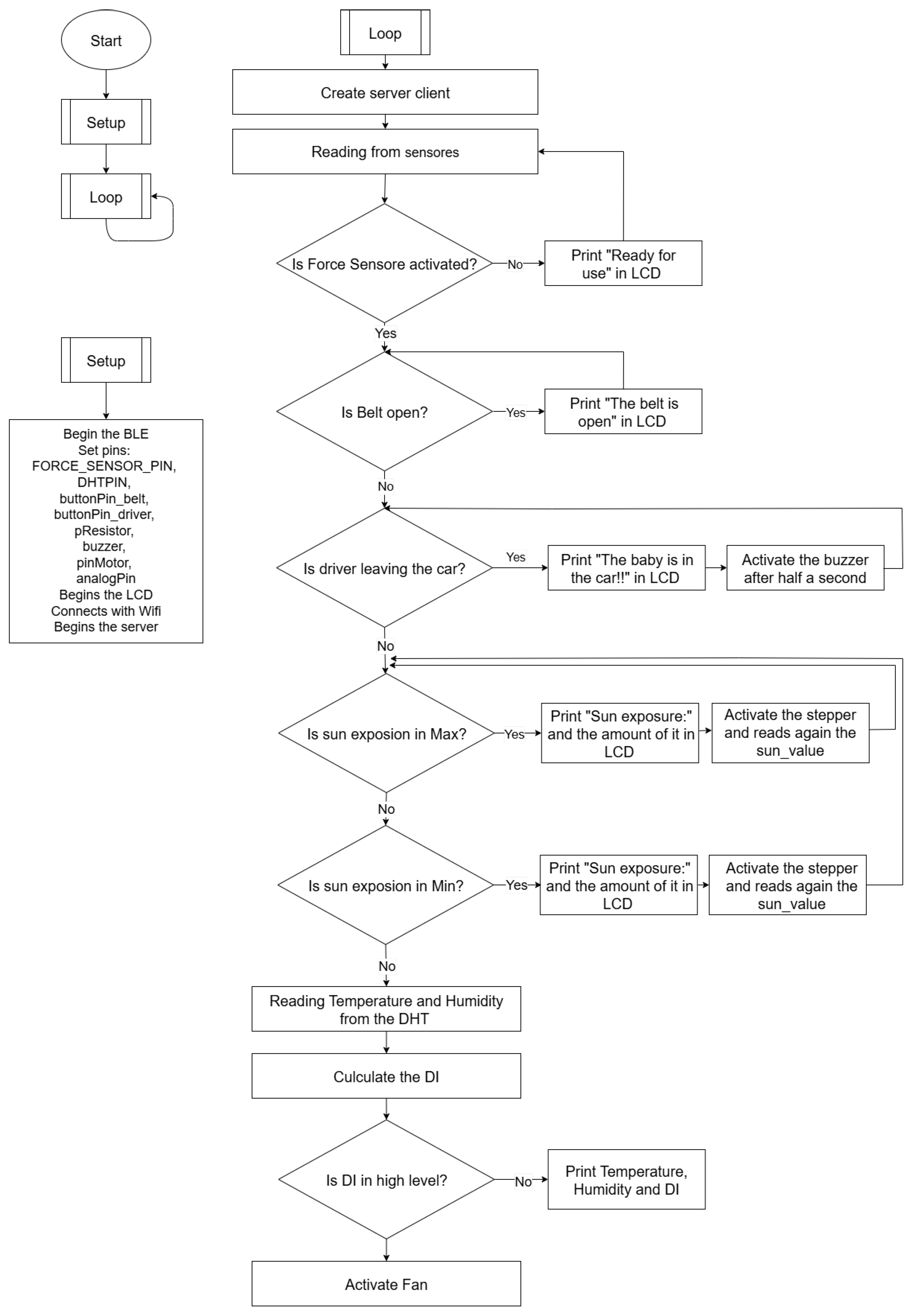

4.5. Flowchart of the SafeCuddle

Figure 11 presents the operational flowchart of the SafeCuddle system, illustrating the sequence of logical steps and decision-making processes governing its functionality. The flowchart describes the interaction between multiple sensors, actuators, and communication modules, providing an overview of how the system detects critical conditions and delivers alerts, and activates comfort-enhancing mechanisms to protect the child.

The flowchart begins with system initialization, where the Arduino-based controller sets up the pins, sensors, and connectivity modules (BLE and Wi-Fi) while establishing the server–client communication. The main loop continuously reads sensor input, including force sensors, belt status, light exposure, and environmental data from the DHT11 sensor. When the force sensor detects the presence of a child, the system verifies the belt status and provides feedback on the LCD. If the driver attempts to leave the vehicle while the child remains seated, an acoustic alarm is triggered, and a warning message is displayed. Sunlight exposure is dynamically assessed through the LDR, causing the stepper motor to adjust the window curtain for optimal comfort. At the same time, temperature and humidity are measured and a DI is calculated. If the DI exceeds a predefined threshold, the system activates the fan and reports relevant metrics on the LCD, thereby ensuring both safety and comfort. This flow demonstrates how SafeCuddle integrates multiple sensing and actuation mechanisms to address FBS while improving the child’s environment in the vehicle.

4.6. Energy Consumption and Battery Discharge Analysis

To evaluate the energy performance of the proposed prototype, both theoretical estimates and experimental discharge measurements were conducted. The system is powered by a Panasonic NCR18650B Li-ion cell (nominal 3.7 V, 3350 mAh), connected through a charger/boost converter that provides a regulated 5 V supply to the Arduino UNO R4 WiFi and all peripherals, including sensors (FSR, DHT11, LDR), actuators (piezo speaker, stepper motor, DC fan), and an LCD with an I2C interface.

4.6.1. Theoretical Estimation

The usable energy available from the battery can be approximated as

where

C is the nominal capacity,

the nominal voltage, and

the conversion efficiency of the boost regulator (assumed to be 85%).

Table 5 summarizes the estimated average current consumption of each subsystem. The total consumption of the system corresponds to a power draw of 1.57 W. This results in an estimated autonomy of

The equivalent load resistance at 5 V is, therefore,

4.6.2. Experimental Results

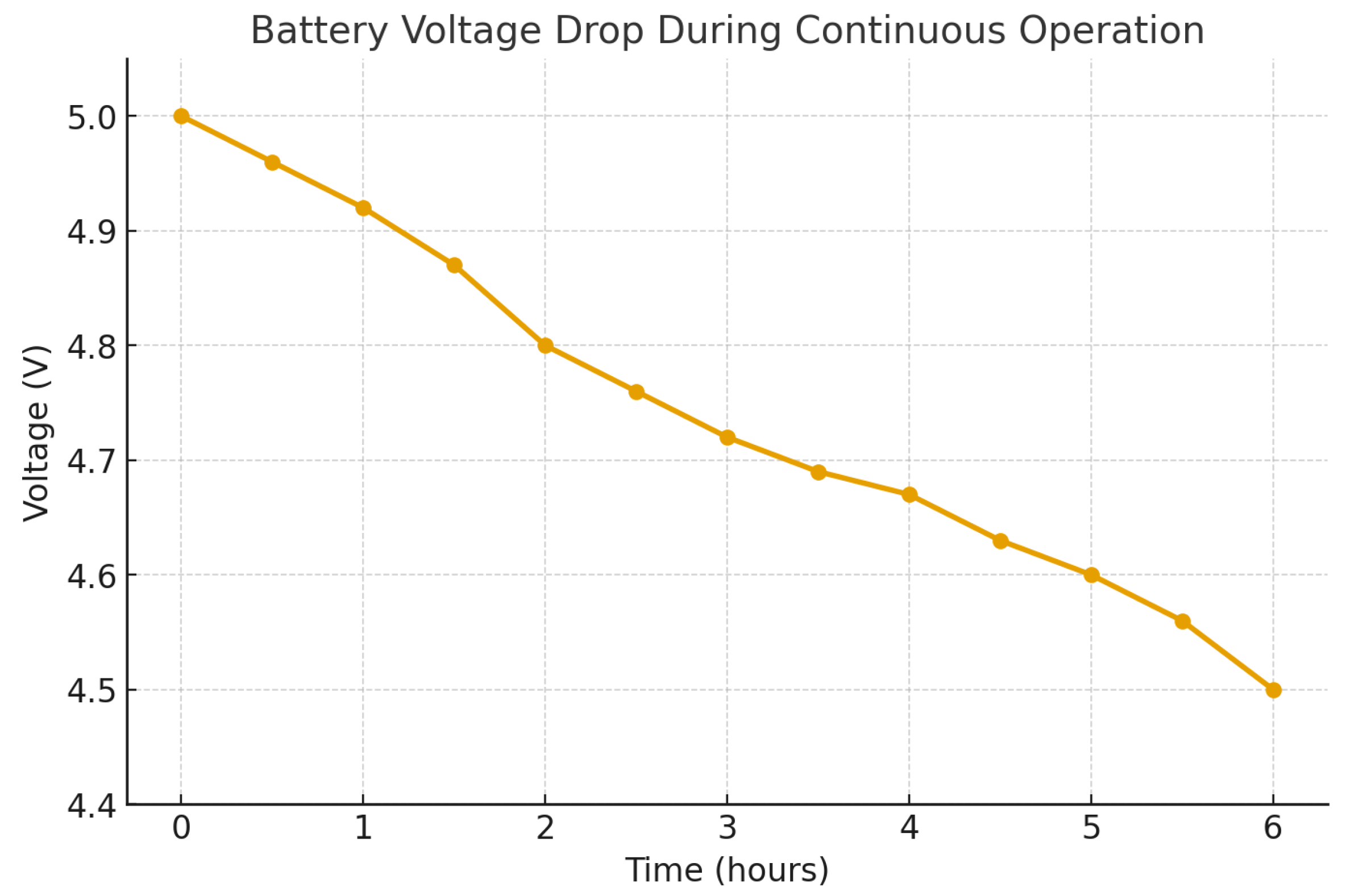

To validate the estimation, the system was tested in continuous operation for 6 h.

Table 6 shows the measured voltage drop, while

Figure 12 illustrates the discharge profile. The supply voltage decreased from 5.00 V at the beginning of the operation to 4.50 V after 6 h, corresponding to an average decline of ∼0.083 V/h.

Using the observed 6 h operating time and considering the effective usable energy after conversion (≈8.2 Wh), the average power demand of the system is:

At 5 V, this corresponds to an average current consumption of:

The energy consumption analysis and battery discharge measurements demonstrate that the proposed prototype can reliably operate on a single Panasonic NCR18650B Li-ion cell for several hours. Theoretical estimations indicated a usable energy of approximately 10.54 Wh and a corresponding autonomy of around 4.3 h based on the average current draw of all subsystems. Experimental validation under continuous operation for 6 h revealed a slightly lower effective power demand of 1.37 W, corresponding to an average current of 0.27 A and a gradual voltage drop from 5.00 V to 4.50 V. The results confirm that the system’s actual energy consumption is lower than the conservative theoretical estimate, largely due to intermittent operation of high-power components and dynamic peripheral behavior.

Overall, the prototype demonstrates sufficient energy efficiency and battery autonomy for practical applications, validating the feasibility of its design and the effectiveness of the power management approach.

4.7. Robustness of the System

The experimental evaluation of the SafeCuddle system under varying ambient temperatures demonstrates its robustness and stability.

As shown in

Table 7, the response time remains practically constant across different thermal conditions. Specifically,

At 25 °C, the system consistently responds in approximately 1120–1143 ms (average ≈ 1132 ms).

At 31 °C under shaded conditions, the response time is around 1276–1277 ms (average ≈ 1276.5 ms), representing a 12.8% increase relative to 25 °C:

At 38 °C, under direct sun exposure, the response time remains at 1276–1277 ms (average ≈ 1276.5 ms), essentially unchanged compared to 31 °C (0% increase). Compared to 25 °C, this corresponds to the same 12.8% increase.

This slight increase is largely attributable to the activation of the system’s fan as part of its protective mechanisms, which adds a negligible actuation delay. Overall, these results indicate that the system’s sensing, processing, and actuation mechanisms are minimally affected by environmental temperature variations. Consequently, SafeCuddle ensures reliable operation both in shaded and high-temperature conditions, an essential requirement for safety-critical applications such as the prevention of FBS.

5. Integration of SafeCuddle with Vehicle Networks and Context-Aware Use Cases

This section presents the potential integration of the SafeCuddle prototype with in-vehicle communication systems, specifically the Controller Area Network (CAN), to enhance its contextual awareness and decision-making capabilities. By extending the system beyond its internal environmental sensors, SafeCuddle can incorporate critical vehicular signals, such as driver departure indicators, ignition status, and Heating, Ventilation, and Air Conditioning (HVAC) operation, which are directly relevant to scenarios associated with FBS. In addition, representative use cases are examined to illustrate how CAN-based data streams complement temperature, humidity, and sunlight measurements to detect hazardous conditions. To support the analysis, a vPython-based visualization framework is used, allowing the simulation and interpretation of real-time system responses in different risk scenarios.

5.1. SafeCuddle Integration with CAN Bus

Although the SafeCuddle prototype relies primarily on environmental sensing, such as temperature, humidity, and exposure to sunlight, its safety functionality can be significantly enhanced through integration with the CAN Bus of modern vehicles. The CAN Bus represents the primary communication backbone for Electronic Control Units (ECUs), enabling access to a wide range of vehicular signals.

The SafeCuddle system, built upon the Arduino UNO R4 WiFi, can interface with the CAN Bus using a dedicated CAN controller and transceiver module (e.g., MCP2515 with TJA1050). Through the OBD-II diagnostic port, the prototype can retrieve vehicle-level signals that complement sensor measurements on-board, thereby improving situational awareness.

Relevant signals accessible via the CAN Bus include

Driver seat belt status, indicating whether the driver is preparing to leave the vehicle;

Driver door open/close events, providing contextual information about driver departure;

Ignition and engine status, identifying whether the vehicle is off and parked;

HVAC system state, reflecting whether air conditioning is active, directly influencing the evolution of the temperature in the cabin;

Parking gear and handbrake signals, confirming that the vehicle is stationary.

By integrating vehicle-level context from the CAN Bus with its environmental sensing capabilities, the SafeCuddle prototype is able to more accurately recognize conditions associated with FBS. A critical risk scenario can be inferred, for example, when the system simultaneously detects

A dangerous rise in cabin temperature;

Engine shutdown, indicating that the vehicle is no longer ventilated;

Driver seatbelt release, suggesting departure;

Driver door opening, confirming that the driver has exited the car.

The convergence of these signals provides a strong indication that a child may have been left unattended inside the vehicle under hazardous conditions. In such circumstances, the Arduino UNO R4 WiFi module embedded in SafeCuddle can promptly issue real-time alerts to the driver’s smartphone or escalate notifications to a connected safety platform. This immediate response mechanism directly addresses the chain of events leading to FBS, thereby strengthening the reliability of early warnings and increasing the likelihood of intervention before conditions become life-threatening.

Through this integration, SafeCuddle can evolve from a stand-alone monitoring seat into a context-aware vehicular IoT safety system specifically tailored to counteract the risks of FBS, contributing to both child safety innovation and the broader vision of intelligent connected vehicles.

5.2. Use Cases and vPython Visual

The use cases that will be analyzed encompass a diverse range of scenarios designed to explore the practical applications and implications of the proposed system. Each use case highlights specific challenges, requirements, and outcomes relevant to different operational contexts. By systematically examining these cases, we aim to demonstrate the versatility, effectiveness and usability of the system. The cases are as follows.

Standby mode;

Normal mode;

Maximum sun exposure;

Minimum sun exposure;

Increasing DI to discomfort levels;

Unauthorized belt opening;

The driver leaving the car while a child is in the seat.

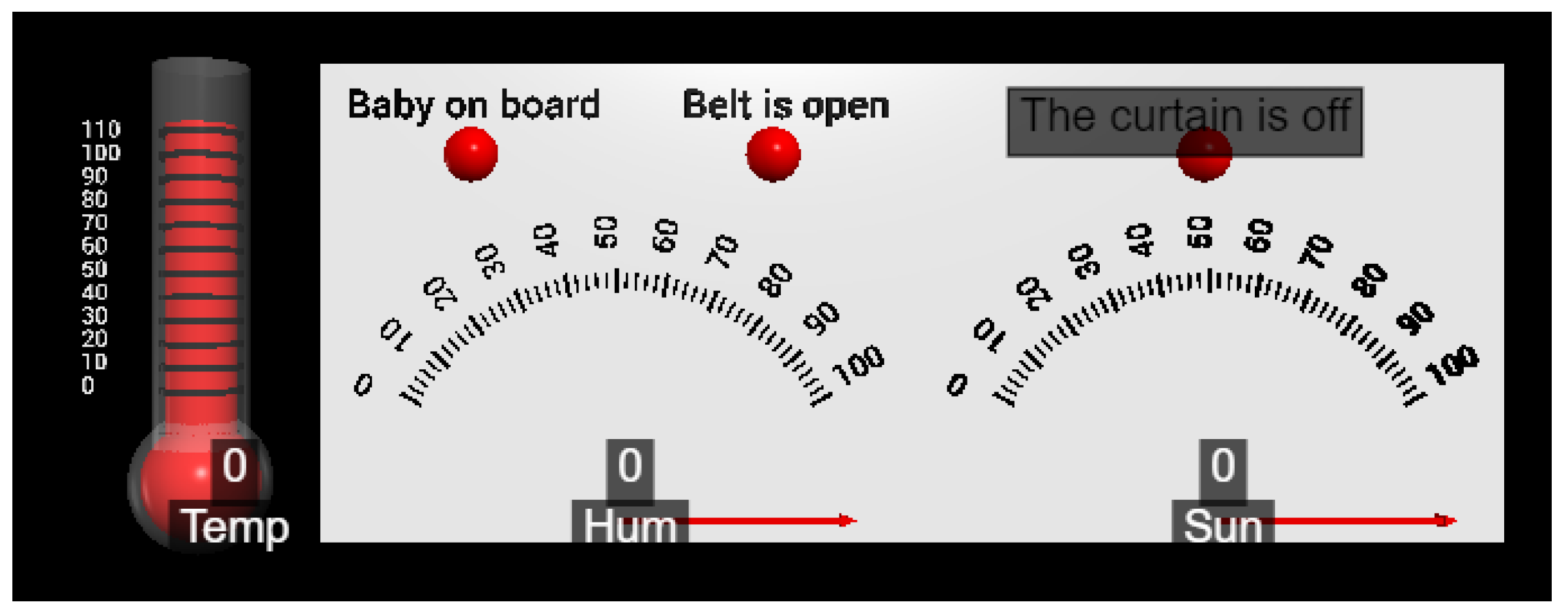

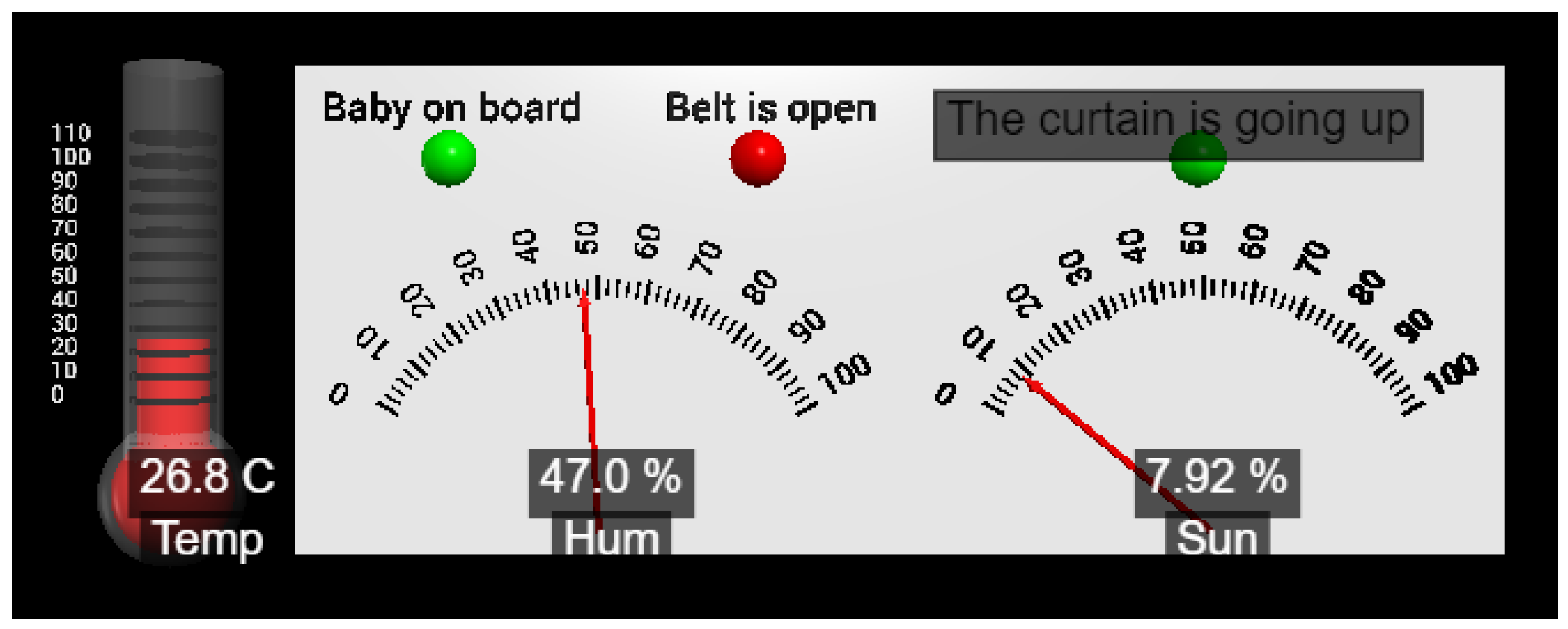

The graphic created using the vPython package is shown in

Figure 13 and contains the following:

Child presence indicator in the seat

This indicator is displayed red during standby mode, signaling that no child is detected in the seat. It switches to green in all other operational states to notify the user that a child is present.

Seat belt open indicator

The indicator remains red when no child is detected or when the seat belt is properly fastened. It changes to green when the seat belt is unbuckled. After a delay of 3 s, an audible alert via the buzzer is triggered.

Window curtain operation indicator

This indicator is red when the curtain mechanism is inactive and turns green upon activation. Additionally, an on-screen message informs the user whether the curtain is moving up or down, based on detected sun exposure levels.

Sun exposure percentage indicator

Implemented as a manometer-style gauge, this indicator dynamically reflects the current percentage of solar exposure on the child’s seat. When exposure is low, the curtain is raised if not already deployed. Conversely, under high sun exposure, the curtain gradually lowers to maintain exposure within safe limits.

Temperature display

Represented as a thermometer-shaped gauge, this element provides a real-time graphical representation of the ambient temperature in degrees Celsius.

Humidity display

Presented as a manometer-style gauge, this display continuously monitors and visualizes relative humidity changes in the vehicle environment.

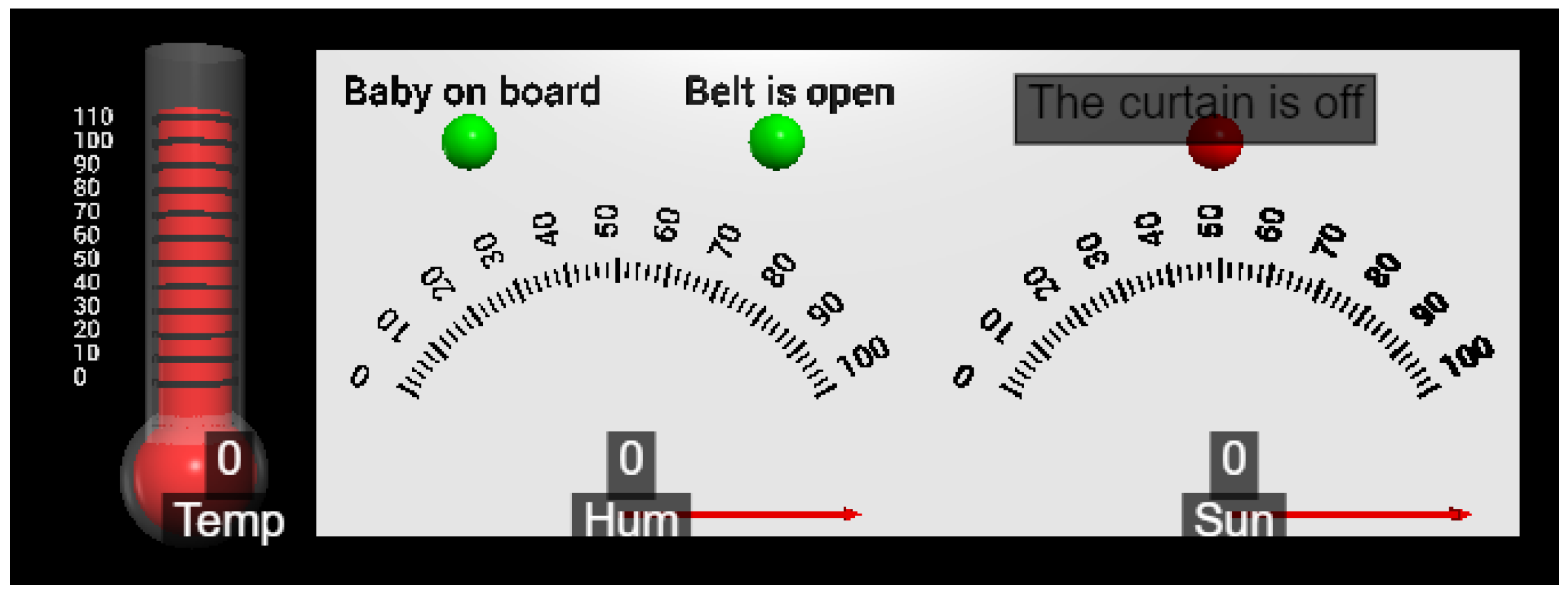

5.2.1. Standby Mode

As long as Python does not receive data, it does not display any changes in the visualization via vPython.

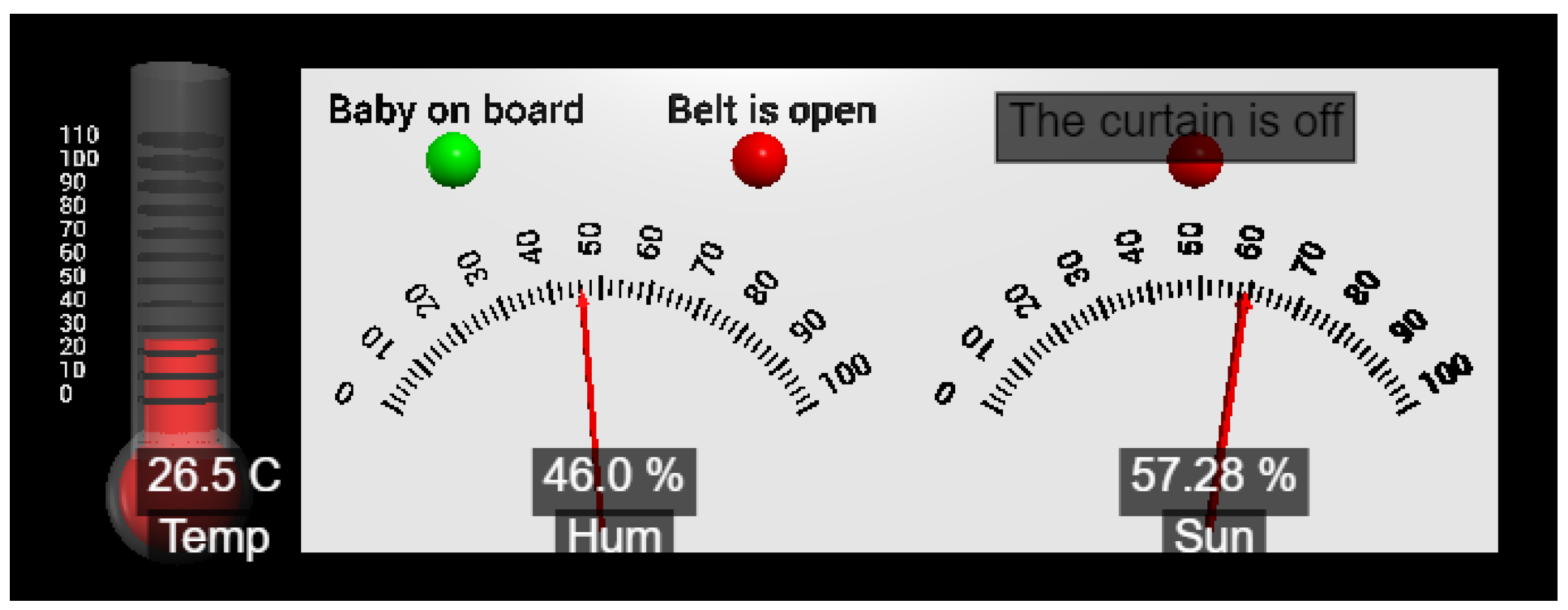

5.2.2. Normal Mode

Since the application is activated, when the child enters the seat, Python receives data and the vPython graph comes to life following the measurements it receives, which are also displayed as text, as shown in

Figure 14.

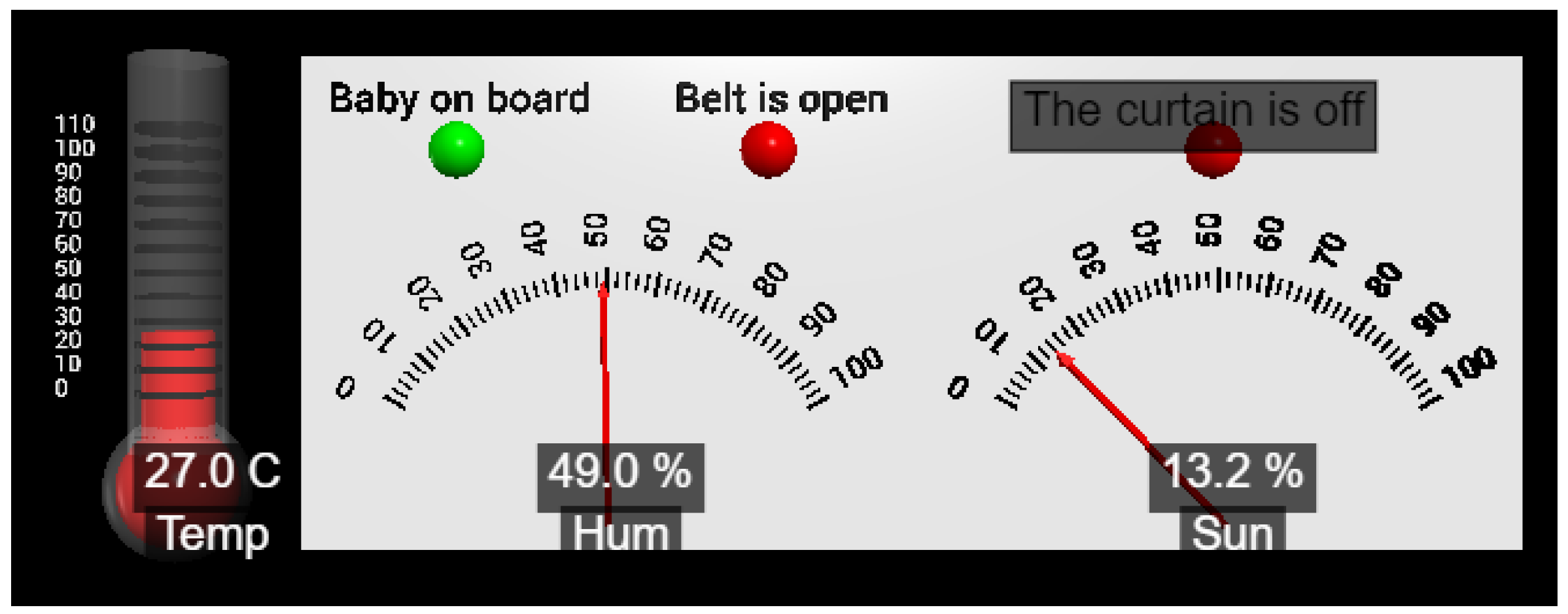

5.2.3. Maximum Sun Exposure

In the event that the seat is exposed to the sun, the curtain begins to lower until the percentage of exposure is within permissible levels. In vPython, the green indicator lights up indicating that the curtain is moving and an appropriate message informs the user that it is lowering, as shown in

Figure 15. At the same time, the LEDs on the stepper motor driver board light up, indicating that the motor has been powered up. The stepper starts taking four steps to the right, lowering the curtain, and again measures the sun exposure so that it always stops in the appropriate position.

Direct sunlight exposure is a key driver of heat build-up in closed vehicles, often leading to fatal outcomes within minutes. SafeCuddle’s light sensor captures solar intensity at the seat level. However, integration with CAN Bus signals such as window position and sunroof status offers essential context, revealing whether the cabin is ventilated or completely sealed. This additional layer of information refines the system’s ability to predict thermal escalation linked to FBS risks.

5.2.4. Minimum Sun Exposure

In the event that the seat’s exposure to the sun is minimal, the curtain begins to rise until the percentage of exposure is normal or the curtain reaches the maximum possible height. In vPython, the green indicator that the curtain is moving lights up and an appropriate message informs the user that it is rising, as shown in

Figure 16. At the same time, the LEDs on the stepper motor driver board light up, indicating that the motor has been powered up. The stepper starts taking four steps to the left, the curtain begins going up, and the system re-measures the sun exposure, so that it always stops at the appropriate position.

5.2.5. Increase in DI to Discomfort Levels

One of the most critical environmental factors of child discomfort and safety in vehicles is the rapid deterioration of cabin conditions after the car has been parked. SafeCuddle addresses this risk by continuously monitoring both temperature and humidity, two primary factors that directly influence the DI. A sudden rise in temperature can quickly elevate the DI to dangerous levels, while insufficient ventilation and humidity accumulation further exacerbate thermal stress and breathing difficulties.

When the DI rises to unacceptable levels, the fan activation process begins. The Arduino screen displays the message “The fan is on.” and the amount of DI. The fan remains active until the DI returns to acceptable levels. If needed, a variable-speed fan could also be used to adjust cooling as needed.

Through CAN Bus integration, the SafeCuddle system could augment its sensor readings with contextual vehicular signals such as ignition status, HVAC operation, ventilation mode, and recirculation settings. This combined approach will allow the system to distinguish between transient variations occurring during active driving and truly hazardous scenarios that emerge in a sealed, non-ventilated cabin after the vehicle has been turned off. By correlating environmental sensing with in-vehicle operational data, SafeCuddle will improve the accuracy of DI estimation and will strengthen its ability to predict and prevent conditions associated with the FBS.

5.2.6. Unauthorized Belt Opening

When the seat is activated, i.e., when there is a child in the seat and the belt is opened, a 3 s timer starts, which activates the buzzer to notify the user that the belt is open. The timer enables the system to distinguish whether the opening is authorized or not, i.e., whether the belt has been opened by the user with the intention of disembarking the child within 3 s. If this has been achieved, the buzzer will not be activated. However, if after 3 s the child has not disembarked and the pressure sensor continues to work, the system receives the information that the child is in the seat with an open belt. In vPython, the “Belt is open” indication is activated and the same message is displayed on the Arduino screen, as shown in

Figure 17.

5.2.7. The Driver Leaving the Car While a Child Is in the Seat

The last and most important use case is when the driver is leaving the vehicle while the child is still in the seat. This case is simulated in the model by a button that in reality could be a signal from an iTag on the car key fob. In vPython, the “Baby on board” indicator remains open and does not receive measurements since it needs to inform the user about the status, as shown in

Figure 18. This could be achieved by activating the iTag’s built-in buzzer or, preferably, by sending an SMS or placing a call to the user’s mobile phone.

In addition to the simulation based on iTag, the SafeCuddle prototype can further strengthen the detection of this scenario through direct integration with the vehicle’s CAN Bus. Critical contextual signals, such as seatbelt release by the driver, door open/close status by the driver, and engine shutdown events, provide a reliable indication that the driver has exited the vehicle. By combining these signals with seat-level monitoring of the child’s presence, the system can minimize false alarms and ensure that alerts are only triggered in situations where there is a genuine risk of a child being left unattended.

Furthermore, once the system is connected to the vehicle’s CAN Bus, it can leverage the signals of the air conditioning system to optimize the timing and criticality of alerts. Specifically, the operating status of the air conditioning can be incorporated into the decision-making process, allowing the system to differentiate between scenarios of varying risk. For example, if ventilation is turned off, the driver should be notified within a shorter delay interval (approximately 1 to 2 min), as the cabin environment can quickly become dangerous. In contrast, when the air conditioning is active and the temperature is stable, the alert can be delayed by 3 to 5 min, reflecting the lower immediate risk to the child. In the latter case, the system can classify the notification as a simple warning, in contrast to the urgent danger alert that would be triggered under adverse thermal conditions.

This integration creates a more robust detection framework compared to relying solely on external devices such as key fob tags, thereby aligning the SafeCuddle prototype more closely with the requirements of real-world vehicular safety systems targeting the prevention of FBS.

6. Future Extensions

In alignment with the rapid advancements in electronic device technology, the developed system has been designed with a modular architecture to facilitate future expansions in both hardware and software functionalities.

A primary planned extension to enhance usability, dissemination, and user engagement is the development of a mobile application. This application will enable users to receive real-time notifications and remotely control various system components, such as the ventilation fan and window curtain. Integration with the user’s smartphone will also allow for immediate push notifications, alerting the driver in case the child is inadvertently left in the vehicle.

The implementation of this extension will leverage platforms such as Arduino Cloud and IoT Remote, which provide seamless cloud-based data exchange without requiring complex network configurations like port forwarding. This architecture supports cross-network operation between transmitter and receiver devices, thereby enhancing flexibility and reliability. Additionally, Arduino Cloud offers customizable dashboards through intuitive widgets, allowing users to tailor the interface to their specific preferences and requirements.

Beyond mobile connectivity, another significant planned enhancement is the integration of the system with the vehicle’s CAN Bus. By accessing vehicular signals such as ignition status, driver seatbelt and door events, and HVAC operation, SafeCuddle can complement its environmental sensing with contextual vehicle-level data. This integration not only improves detection reliability in scenarios associated with FBS but also enables advanced functionalities, such as activating vehicle-based alarms (hazard lights or horn) when dangerous conditions are detected.

Despite these advantages, there are notable limitations to the proposed extensions, including increased operational costs and initial complexity in programming and connecting the microcontroller. While Arduino Cloud provides a free tier, it imposes restrictions on key features such as variable counts and storage capacity. Similarly, accessing and interpreting CAN Bus signals may require additional hardware interfaces and adherence to vehicle-specific protocols. Nonetheless, these extensions provide a clear pathway toward transforming SafeCuddle from a stand-alone prototype into a comprehensive vehicular IoT safety system.

In terms of future extensions, the developed Python application—currently used solely for real-time visualization of sensor data via the vPython library—can serve as the foundation for evolving the system into a comprehensive cloud-based service. Such an extension would enable remote monitoring of data and actuator control, offering enhanced functionality, scalability, and opportunities for integration with other IoT platforms.

Finally, a future development direction of the SafeCuddle prototype is its full implementation on a custom-printed circuit board (PCB). By integrating all components into a single compact board, the system can achieve a smaller form factor, simplified installation within the vehicle, and improved robustness. This transition will also enhance the product’s market readiness by resembling a commercially viable device rather than a laboratory prototype, thereby supporting the long-term goal of bringing SafeCuddle closer to real-world deployment.

7. Conclusions

The proposed SafeCuddle system demonstrates a low-cost, modular, and highly functional IoT-based solution for preventing Forgotten Baby Syndrome (FBS) incidents. By integrating the Arduino UNO R4 WiFi microcontroller with a suite of environmental and presence-detection sensors, the system enables continuous real-time monitoring of the conditions inside a vehicle and of the child’s presence in the car seat. The computation of the Discomfort Index (DI), combined with humidity, temperature, and sunlight measurements, allows early identification of adverse conditions, while edge-level data processing minimizes latency and ensures operational resilience even without cloud connectivity.

The developed Python and vPython desktop application offers dynamic, interactive visualization of sensor data, enhancing situational awareness for caregivers and facilitating future integration into mobile platforms. Beyond alerting functions, SafeCuddle introduces active comfort management features, including automated sunshade positioning and fan activation, thereby improving both safety and comfort.

A key strength of the prototype lies in its proactive alerting mechanisms. If the system detects that a driver has exited the vehicle while a child remains seated, it immediately activates an audible alarm or triggers a remote notification, serving as a fail-safe against FBS-related tragedies. The system’s modular hardware design supports easy aftermarket installation at a total cost below EUR 90, making it a competitive and accessible safety enhancement.

Experimental testing under varying ambient temperatures confirmed its robustness, with stable response times and reliable detection accuracy. Battery discharge measurements demonstrated sufficient autonomy for multi-hour operation without external power sources, further reinforcing its suitability for real-world deployment.

Future work will focus on deeper integration with vehicle CAN networks, enabling the system to leverage contextual data such as engine status, door and seatbelt signals, and HVAC operation to improve decision-making accuracy and reduce false positives. Planned developments also include mobile app support, miniaturization of components, and potential commercialization as a universal aftermarket kit.

In summary, SafeCuddle delivers a comprehensive and cost-effective IoT solution that bridges the gap between existing high-cost commercial systems and the growing demand for reliable, real-time child safety technology in vehicles.