Digital Transformation in Maritime Ports: Defining Smart Gates through Process Improvement in a Portuguese Container Terminal

Abstract

1. Introduction

1.1. Background

1.2. Study Motivation

- Too many bureaucratic procedures;

- Lack of infrastructure and equipment;

- Lack of efficient communication mechanisms;

- Lack of integration and interoperability between systems and with stakeholders;

- Inadequate infrastructure;

- Fluctuating driver arrival times and drivers’ failure to comply with the rules;

- Lack of knowledge/training/awareness on the part of stakeholders regarding the use of technology.

- Mitigating the current challenges in terms of vehicle and goods flows;

- Promoting opportunities to improve the user experience;

- Efficient management of resources;

- Impacts on the sustainability of port operations.

1.3. Aims and Goals

- Understand the verification and authentication needs at a seaport entry gate;

- Map out the various stages of a smart gate to understand its structure and operation;

- Analyze a set of efficiency and sustainability indicators to ensure the ongoing viability of the smart gate.

2. Theoretical Background

2.1. Smart Gates

- Enhanced security: Smart gates significantly enhance security measures in maritime ports by utilizing advanced identification and verification techniques. Biometric systems, such as fingerprints, ensure that only authorized individuals have access to the terminal, mitigating the risk of unauthorized entry and potential security threats [13,22,39].

- Improved efficiency and productivity: Smart gates streamline the entry and exit processes, reducing congestion and minimizing waiting times for trucks and cargo. Through automated systems and information systems, truck drivers can preregister their information, allowing for faster verification and seamless entry into the port. This optimized flow of vehicles and cargo results in improved operational efficiency, enhancing the overall productivity of the port [22,40,41].

- Accurate data collection and analysis: Smart gates generate a wealth of data that can be collected, analyzed, and utilized for operational optimization and decision-making. By capturing information such as entry and exit times, vehicle details, and cargo manifests, ports can gain valuable insights into traffic patterns, resource allocation, and demand forecasting. This data-driven approach enables port authorities to make informed decisions, allocate resources efficiently, and proactively address potential bottlenecks or capacity constraints [14,22].

- Integration with port systems: Smart gates can be integrated into various port management systems, enabling real-time information exchange and process automation. This integration improves coordination between different stakeholders, facilitating smoother operations, accurate documentation, and faster cargo clearance processes, optimizing traffic across different transport modes [22,40].

2.1.1. Technologies Applied in Smart Gates

- Automated identification: This is performed using technologies such as RFID (radio-frequency identification) and NFC (near-field communication). Vehicles, containers, and drivers can have tags or cards equipped with these technologies, allowing for quick, contactless identification when passing through the gate. This helps to control entry and exit operations at the gate and to make the gate itself more available [12,21,22].

- Biometric recognition: Using techniques such as fingerprint reading or facial recognition, this is used to verify the identity of drivers and other individuals entering the terminal, and this information is later stored in a database using big data technology. In this way, these systems contribute to the security of the terminal [39,40,43].

- Cameras and OCR: High-resolution cameras and optical character recognition (OCR) systems are employed to capture images of vehicles, license plates, damage inspection, and other relevant information. These cameras can automatically read and interpret information, speeding up the registration and verification process. So, OCR can be used for the collection and verification of trucks and their driver information and other port users’ information [13,21,22]. (Although RFID reduces throughput time just as OCR does, the latter has the advantage that vehicles and containers do not need specific technologies to reduce this time [22].)

- Data integration: Automated gate systems are connected to different port information systems, such as the port community system (PCS) and the terminal operating system (TOS), and technologies, such as OCR and RFID, to handle the flow of cargo. This integration allows the exchange of information in real-time and the automation of processes. Also, these systems could be integrated with external parties to improve the flow of information [22].

- Data analysis and artificial intelligence: The data collected by the smart gates are analyzed using artificial intelligence and machine learning algorithms. This makes it possible to identify patterns, optimize traffic flow, predict waiting times and truck arrivals, and make informed decisions to improve operational efficiency [44,45].

2.1.2. Information Systems Applied in Smart Gates

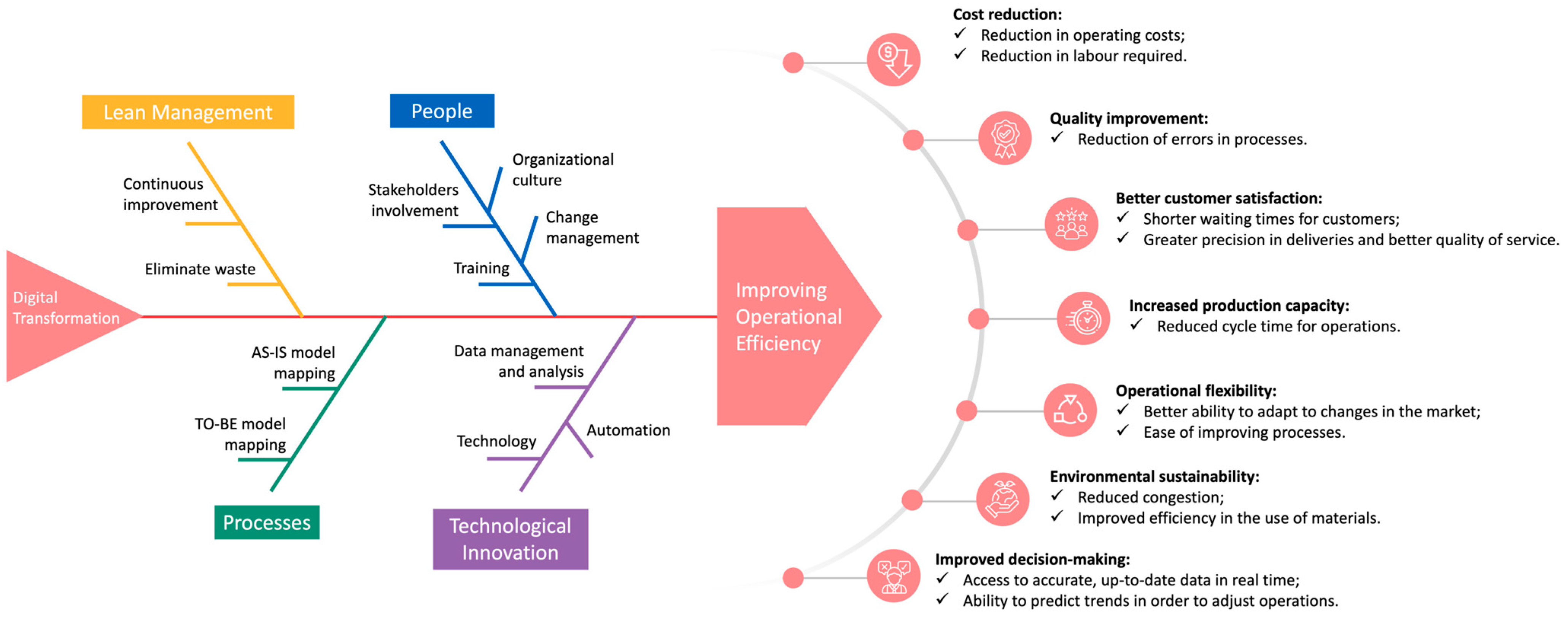

2.2. Process Management and Lean Management at Smart Gates

3. Methods

- Direct observation of current operations at the specific road terminal gate was conducted with the active participation of stakeholders, including port users, gate operators, and logistics managers. This collaborative approach allowed stakeholders to provide insights into the operational challenges they face daily, contributing to a comprehensive understanding of the current situation (AS-IS). Through these observations, critical areas needing improvement were identified based on both the researchers’ analyses and the stakeholders’ direct feedback;

- Meetings with gate operators, drivers, and other stakeholders. These sessions were designed to gather detailed information on the problems faced, requirements, and expectations of each stakeholder group. Each session included both individual and group discussions to ensure diverse perspectives were captured. Stakeholders were actively engaged throughout the entire process, from initial discussions about the digital transformation to the final validation of proposed solutions. This approach ensured that all relevant insights and feedback were integrated into the digital transformation strategy from the beginning of the digital transformation;

- Based on the feedback gathered from stakeholders during these meetings, problems were categorized into distinct groups to streamline the development of solutions. These categories included problems due to a lack of equipment/infrastructure, a lack of information and agile communication—lack of communication mechanisms; problems due to lack of knowledge/training/awareness, and problems of interoperability and systems integration.

4. Results

4.1. Critical Components and Checkpoints of a Smart Gate

4.2. Smart Gate Processes

- Collection of a particular full container;

- Collection of empty containers (if the customer has a reservation of empty containers at the terminal);

- Delivering a particular container, full or empty.

4.2.1. Checkpoint 1—Non-Stop Station for Checking Vehicle Type and Reading Truck/Container/Galley Data Automatically

- If the driver has an appointment, there will be signs directing him/her to the left-hand lanes;

- If the driver does not have an appointment, he/she goes to those on the right.

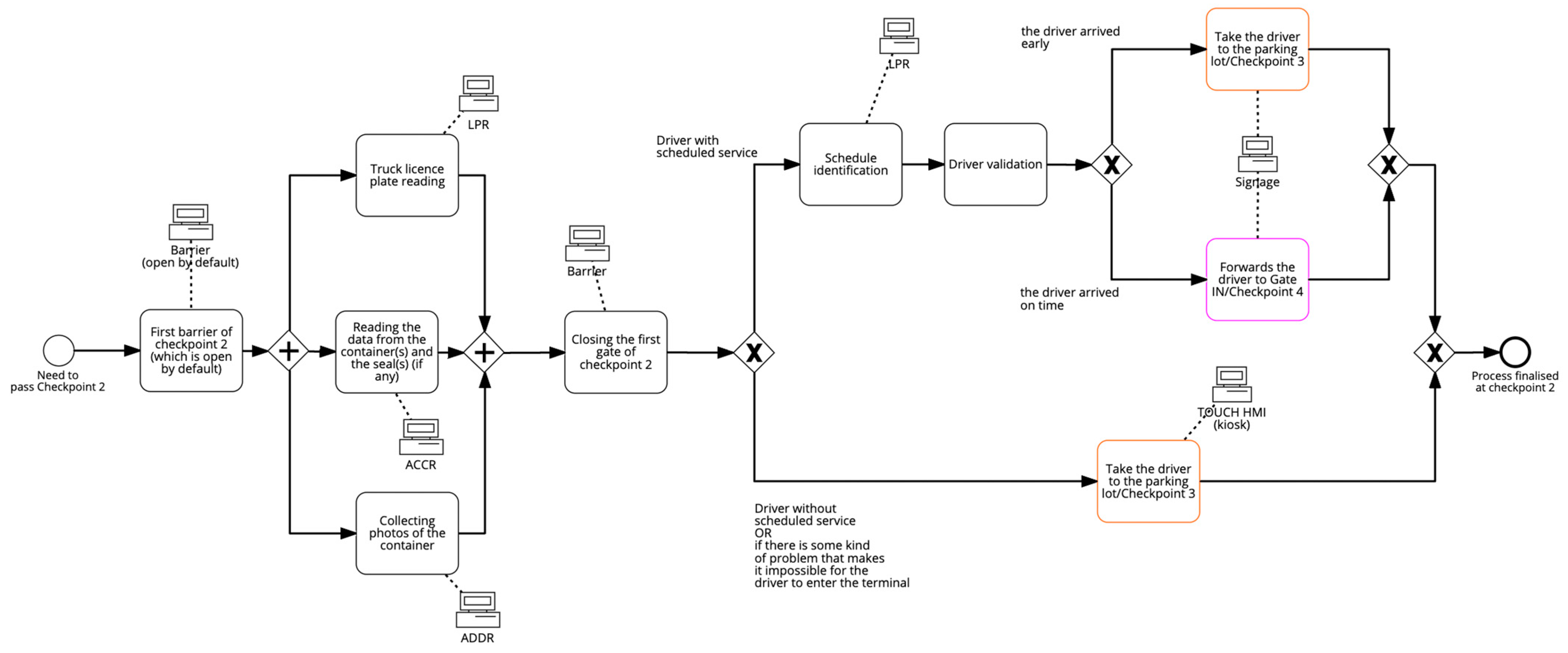

4.2.2. Checkpoint 2—Container, Vehicle, and Driver Identification

- The driver’s identification (if they have a card and a valid entry permit) using a card and biometric identification;

- Verification of the logistics service (if they have a valid prior appointment) through hardware: PIN or QR code (laser scanner);

- The confirmation of the service data by the driver;

- Weighing of the cargo (if they have not done so before going to the terminal) by means of a weighbridge);

- If necessary, the help mechanism can be activated.

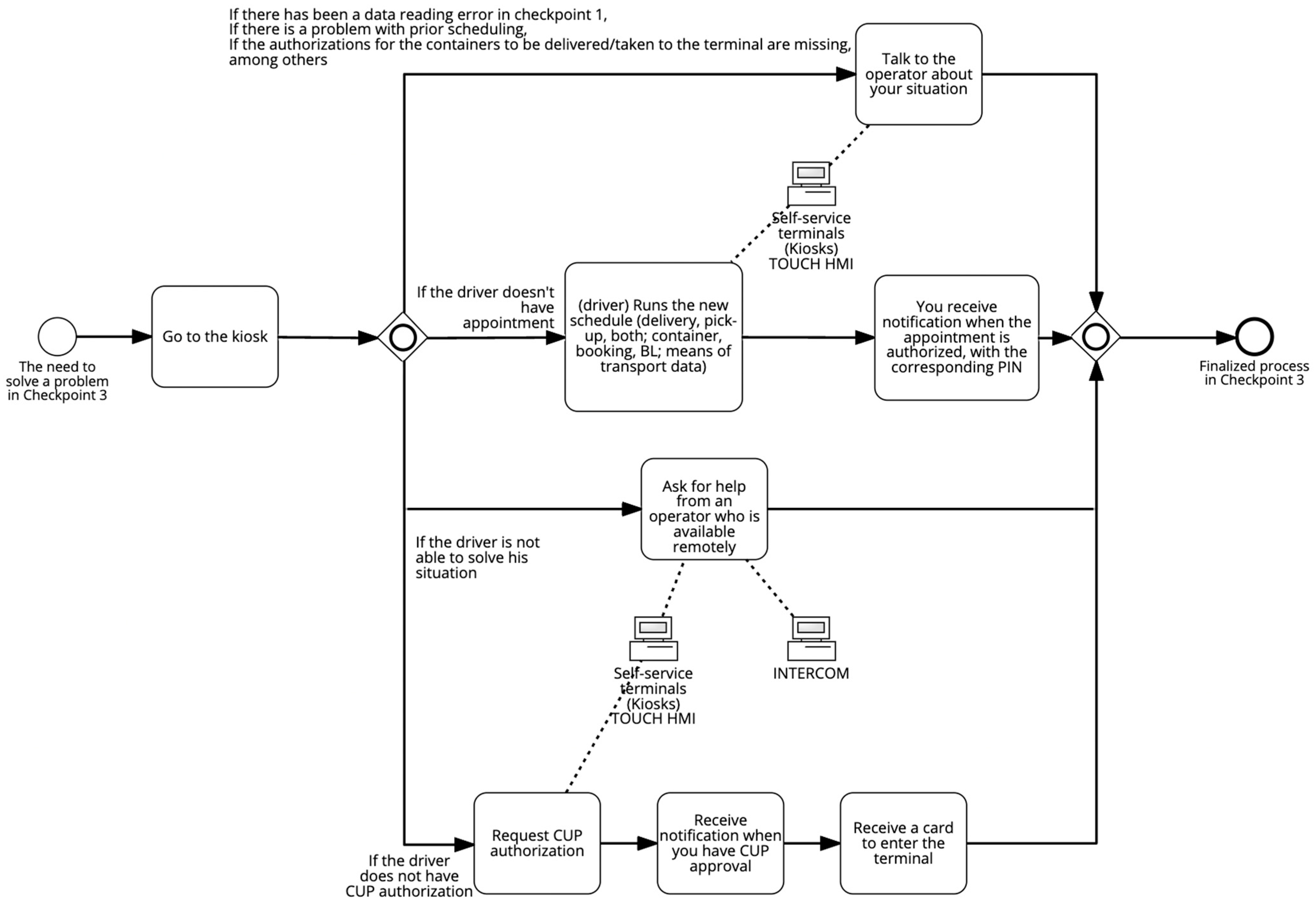

4.2.3. Checkpoint 3—Solve Anomalous Situations

- The appointment and/or authorizations (container/driver) not being complete to enter the terminal;

- The driver has an appointment but arrived early;

- Scheduling has a problem;

- There has been an error in reading the data from the truck/galley/container at checkpoint 1;

- The driver’s identification is not operational;

- The driver does not have an appointment.

4.2.4. Checkpoint 4—Ensure That Vehicles Have Permission to Enter the Terminal

4.2.5. Gate IN—Where the International Zone Starts

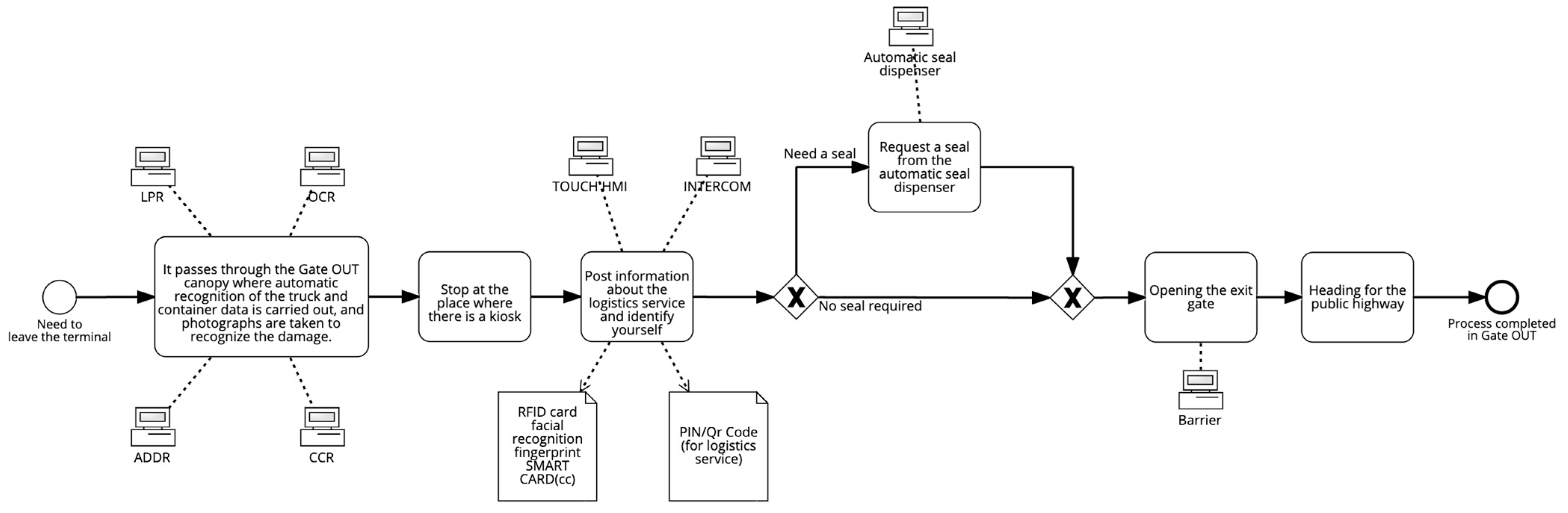

4.2.6. Gate OUT—To Leave the International Zone

4.3. Some KPIs to Measure Smart Gate Efficiency

5. Discussion

Practical Recommendations for Digital Transformation in Ports

6. Final Remarks

6.1. Conclusions

6.2. Contributions and Implications

- Practical Contributions

- Theoretical Contributions

- Policy Implications

- Global Implications

6.3. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Fatlawi, H.A.; Motlak, H.J. Design and Implementation of Smart Port Gate System Based on the Internet of Things. In Proceedings of the 2023 International Conference on Information Technology, Applied Mathematics and Statistics (ICITAMS), Dewaniyah, Iraq, 20–22 March 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 291–296. [Google Scholar] [CrossRef]

- Jović, M.; Tijan, E.; Brčić, D.; Pucihar, A. Digitalization in Maritime Transport and Seaports: Bibliometric, Content and Thematic Analysis. J. Mar. Sci. Eng. 2022, 10, 486. [Google Scholar] [CrossRef]

- Almeida, F. Challenges in the Digital Transformation of Ports. Businesses 2023, 3, 548–568. [Google Scholar] [CrossRef]

- Othman, A.; El-Gazzar, S.; Knez, M. A Framework for Adopting a Sustainable Smart Sea Port Index. Sustainability 2022, 14, 4551. [Google Scholar] [CrossRef]

- Neugebauer, J.; Heilig, L.; Voß, S. Digital Twins in the Context of Seaports and Terminal Facilities. Flex. Serv. Manuf. J. 2024, 1–97. [Google Scholar] [CrossRef]

- El Idrissi, A.; Haidine, A.; Aqqal, A.; Dahbi, A. Deployment Strategies of Mobile Networks for Internet-of-Things in Smart Maritime Ports. In Proceedings of the 2022 11th International Symposium on Signal, Image, Video and Communications (ISIVC), El Jadida, Morocco, 18–20 May 2022; pp. 5–10. [Google Scholar] [CrossRef]

- Zadeh, S.B.I.; Perez, M.D.E.; López-Gutiérrez, J.-S.; Fernández-Sánchez, G. Optimizing Smart Energy Infrastructure in Smart Ports: A Systematic Scoping Review of Carbon Footprint Reduction. J. Mar. Sci. Eng. 2023, 11, 1921. [Google Scholar] [CrossRef]

- Paraskevas, A.; Madas, M.; Zeimpekis, V.; Fouskas, K. Smart Ports in Industry 4.0: A Systematic Literature Review. Logistics 2024, 8, 28. [Google Scholar] [CrossRef]

- Basulo-Ribeiro, J.; Teixeira, L. Industry 4.0 supporting logistics towards smart ports: Benefits, challenges and trends based on a systematic literature review. J. Ind. Eng. Manag. 2024, 17, 492–515. [Google Scholar] [CrossRef]

- Kolotouchkina, O.; Barroso, C.L.; Sánchez, J.L.M. Smart cities, the digital divide, and people with disabilities. Cities 2022, 123, 103613. [Google Scholar] [CrossRef]

- Sánchez, R.J.; Perrotti, D.E.; Fort, A.G.P. Looking into the future ten years later: Big full containerships and their arrival to south American ports. J. Shipp. Trade 2021, 6, 2. [Google Scholar] [CrossRef]

- Ahmad, R.W.; Hasan, H.; Jayaraman, R.; Salah, K.; Omar, M. Blockchain applications and architectures for port operations and logistics management. Res. Transp. Bus. Manag. 2021, 41, 100620. [Google Scholar] [CrossRef]

- AlKheder, S.; Naif, D.; Musaed, D.; Al Shrekah, S.; Al Rshaid, M.; Anzi, N.A.; Baqer, I. Maritime transport management in Kuwait toward an automated port logistical city. Clean. Logist. Supply Chain 2022, 3, 100031. [Google Scholar] [CrossRef]

- Henríquez, R.; de Osés, F.X.M.; Marín, J.E.M. Technological drivers of seaports’ business model innovation: An exploratory case study on the port of Barcelona. Res. Transp. Bus. Manag. 2022, 43, 100803. [Google Scholar] [CrossRef]

- Heikkilä, M.; Saarni, J.; Saurama, A. Innovation in Smart Ports: Future Directions of Digitalization in Container Ports. J. Mar. Sci. Eng. 2022, 10, 1925. [Google Scholar] [CrossRef]

- Boullauazan, Y.; Sys, C.; Vanelslander, T. Developing and demonstrating a maturity model for smart ports. Marit. Policy Manag. 2022, 50, 447–465. [Google Scholar] [CrossRef]

- Acciaro, M.; Sys, C. Innovation in the maritime sector: Aligning strategy with outcomes. Marit. Policy Manag. 2020, 47, 1045–1063. [Google Scholar] [CrossRef]

- Rajabi, A.; Saryazdi, A.K.; Belfkih, A.; Duvallet, C. Towards Smart Port: An Application of AIS Data. In Proceedings of the 2018 IEEE 20th International Conference on High Performance Computing and Communications; IEEE 16th International Conference on Smart City; IEEE 4th International Conference on Data Science and Systems (HPCC/SmartCity/DSS), Exeter, UK, 28–30 June 2018; pp. 1414–1421. [Google Scholar] [CrossRef]

- Yau, K.-L.A.; Peng, S.; Qadir, J.; Low, Y.-C.; Ling, M.H. Towards smart port infrastructures: Enhancing port activities using information and communications technology. IEEE Access 2020, 8, 83387–83404. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Aksentijević, S.; Pucihar, A. Digital transformation in the maritime transport sector. Technol. Forecast. Soc. Chang. 2021, 170, 120879. [Google Scholar] [CrossRef]

- Neagoe, M.; Taskhiri, M.S.; Nguyen, H.O.; Turner, P. Exploring the Role of Information Systems in Mitigating Gate Con-gestion Using Simulation: Theory and Practice at a Bulk Export Terminal Gate. In Production Management for Data-Driven, Intelligent, Collaborative, and Sustainable Manufacturing. APMS 2018; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2018; Volume 535. [Google Scholar] [CrossRef]

- Heilig, L.; Voß, S. Information systems in seaports: A categorization and overview. Inf. Technol. Manag. 2016, 18, 179–201. [Google Scholar] [CrossRef]

- Paul, J.; Zhou, Y. How to build sustainable innovation capability in supply chain management. Int. J. Bus. Glob. 2017, 19, 456–476. [Google Scholar] [CrossRef]

- Rodrigue, J.-P.; Notteboom, T.; Pallis, A. Chapter 2.4—The Digital Transformation of Ports. In Port Economics, Management and Policy; Routledge: London, UK, 2022. [Google Scholar]

- Brunila, O.-P.; Kunnaala-Hyrkki, V.; Inkinen, T. Hindrances in port digitalization? Identifying problems in adoption and implementation. Eur. Transp. Res. Rev. 2021, 13, 62. [Google Scholar] [CrossRef]

- Wang, D.; Chen, S. RETRACTED: Digital Transformation and Enterprise Resilience: Evidence from China. Sustainability 2022, 14, 14218. [Google Scholar] [CrossRef]

- Min, H. Developing a smart port architecture and essential elements in the era of Industry 4. Marit. Econ. Logist. 2022, 24, 189–207. [Google Scholar] [CrossRef]

- Moszyk, K.; Deja, M.; Dobrzynski, M. Automation of the road gate operations process at the container terminal—A case study of DCT Gdańsk SA. Sustainability 2021, 13, 6291. [Google Scholar] [CrossRef]

- Rahman, R. Five Problems with Truck Congestion at Ports and How to Solve Them. Port Technology Internation. 2023. Available online: https://www.porttechnology.org/news/five-problems-with-truck-congestion-at-ports-and-how-to-solve-them/ (accessed on 31 July 2024).

- Vukić, L.; Lai, K.-H. Acute port congestion and emissions exceedances as an impact of COVID-19 outcome: The case of San Pedro Bay ports. J. Shipp. Trade 2022, 7, 25. [Google Scholar] [CrossRef]

- Nikghadam, S.; Molkenboer, K.F.; Tavasszy, L.; Rezaei, J. Information sharing to mitigate delays in port: The case of the Port of Rotterdam. Marit. Econ. Logist. 2021, 25, 576–601. [Google Scholar] [CrossRef]

- Belmoukari, B.; Audy, J.-F.; Forget, P. Smart port: A systematic literature review. Eur. Transp. Res. Rev. 2023, 15, 4. [Google Scholar] [CrossRef]

- Gui, D.; Wang, H.; Yu, M. Risk Assessment of Port Congestion Risk during the COVID-19 Pandemic. J. Mar. Sci. Eng. 2022, 10, 150. [Google Scholar] [CrossRef]

- Othman, A.; El Gazzar, S.; Knez, M. Investigating the Influences of Smart Port Practices and Technology Employment on Port Sustainable Performance: The Egypt Case. Sustainability 2022, 14, 14014. [Google Scholar] [CrossRef]

- Behdani, B. Port 4.0: A conceptual model for smart port digitalization. Transp. Res. Procedia 2023, 74, 346–353. [Google Scholar] [CrossRef]

- Reis, J.; Melão, N. Digital transformation: A meta-review and guidelines for future research. Heliyon 2023, 9, e12834. [Google Scholar] [CrossRef]

- Douaioui, K.; Fri, M.; Mabrouki, C.; Semma, E.A. Smart port: Design and perspectives. In Proceedings of the 2018 4th International Conference on Logistics Operations Management (GOL), Le Havre, France, 10–12 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.; Tsung, F. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- D’amico, G.; Szopik-Depczyńska, K.; Dembińska, I.; Ioppolo, G. Smart and sustainable logistics of Port cities: A framework for comprehending enabling factors, domains and goals. Sustain. Cities Soc. 2021, 69, 102801. [Google Scholar] [CrossRef]

- Jovic, M.; Kavran, N.; Aksentijevic, S.; Tijan, E. The transition of Croatian seaports into smart ports. In Proceedings of the 42nd International Convention on Information and Communication Technology, Electronics and Microelectronics, MIPRO 2019, Opatija, Croatia, 20–24 May 2019; pp. 1386–1390. [Google Scholar] [CrossRef]

- Jin, Z.; Lin, X.; Zang, L.; Liu, W.; Xiao, X. Lane allocation optimization in container seaport gate system considering carbon emissions. Sustainability 2021, 13, 3628. [Google Scholar] [CrossRef]

- Chen, R.; Meng, Q.; Jia, P. Container port drayage operations and management: Past and future. Transp. Res. Part E Logist. Transp. Rev. 2022, 159, 102633. [Google Scholar] [CrossRef]

- Mazzarino, M.; Braidotti, L.; Cociancich, M.; Bottin, G.; La Monaca, U.; Bertagna, S.; Marinò, A.; Bucci, V. On the Digitalisation Processes in the Adriatic Region. In Nautical and Maritime Culture, from the Past to the Future; Progress in Marine Science and Technology; IOS Press: Amsterdam, The Netherlands, 2019; Volume 3, pp. 180–190. [Google Scholar] [CrossRef]

- Hill, A.; Böse, J.W. A decision support system for improved resource planning and truck routing at logistic nodes. Inf. Technol. Manag. 2016, 18, 241–251. [Google Scholar] [CrossRef]

- E Mekkaoui, S.; Benabbou, L.; Berrado, A. A systematic literature review of machine learning applications for port’s operations. In Proceedings of the 2020 5th International Conference on Logistics Operations Management (GOL), Virtual, 28–30 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Giuliano, G.; O’brien, T. Reducing port-related truck emissions: The terminal gate appointment system at the Ports of Los Angeles and Long Beach. Transp. Res. Part D Transp. Environ. 2007, 12, 460–473. [Google Scholar] [CrossRef]

- Zhao, W.; Goodchild, A.V. The impact of truck arrival information on container terminal rehandling. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 327–343. [Google Scholar] [CrossRef]

- Kashav, V.; Garg, C.P.; Kumar, R. Ranking the strategies to overcome the barriers of the maritime supply chain (MSC) of containerized freight under fuzzy environment. Ann. Oper. Res. 2021, 324, 1223–1268. [Google Scholar] [CrossRef]

- Chinosi, M.; Trombetta, A. BPMN: An introduction to the standard. Comput. Stand. Interfaces 2012, 34, 124–134. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Paciarotti, C. Implementing lean information management: The case study of an automotive company. Prod. Plan. Control 2014, 26, 753–768. [Google Scholar] [CrossRef]

- Tripathi, V.; Chattopadhyaya, S.; Mukhopadhyay, A.K.; Sharma, S.; Li, C.; Di Bona, G. A Sustainable Methodology Using Lean and Smart Manufacturing for the Cleaner Production of Shop Floor Management in Industry 4. Mathematics 2022, 10, 347. [Google Scholar] [CrossRef]

- Marsikova, K.; Sirova, E. Optimization of selected processes in a company with the support of the lean concept. MM Sci. J. 2018, 2018, 2300–2305. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Kühl, A.; Grimm, S.; Erll, A.; Potzel, M.; Franke, J. Lean 4.0—A conceptual conjunction of lean management and Industry 4.0. Procedia CIRP 2018, 72, 622–628. [Google Scholar] [CrossRef]

- Michaud, M.; Forgues, E.-C.; Carignan, V.; Forgues, D.; Ouellet-Plamondon, C. A lean approach to optimize BIM information flow using value stream mapping. J. Inf. Technol. Constr. 2019, 24, 472–488. [Google Scholar] [CrossRef]

- Castle, A.; Harvey, R. Lean information management: The use of observational data in health care. Int. J. Prod. Perform. Manag. 2009, 58, 280–299. [Google Scholar] [CrossRef]

- Arromba, A.R.; Teixeira, L.; Xambre, A.R. Information flows improvement in production planning using lean concepts and bpmn an exploratory study in industrial context. In Proceedings of the 2019 14th Iberian Conference on Information Systems and Technologies (CISTI), Coimbra, Portugal, 19–22 June 2019; pp. 206–211. [Google Scholar] [CrossRef]

- Hölttä, V.; Mahlamäki, K.; Eisto, T.; Ström, M. Lean information management model for engineering changes. World Acad. Sci. Eng. Technol. 2010, 42, 1459–1466. [Google Scholar]

- Pschybilla, T.; Homann, A. Evaluation of end-to-end process and information flow analyses through digital transformation in mechanical engineering. Procedia CIRP 2020, 93, 298–303. [Google Scholar] [CrossRef]

- Schönig, S.; Ackermann, L.; Jablonski, S.; Ermer, A. IoT meets BPM: A bidirectional communication architecture for IoT-aware process execution. Softw. Syst. Model. 2020, 19, 1443–1459. [Google Scholar] [CrossRef]

- von Rosing, M.; Scheer, A.-W.; von Scheel, H. The Complete Business Process Handbook: Body of Knowledge from Process Modeling to BPM; Elsevier: Amsterdam, The Netherlands, 2014; Volume 1. [Google Scholar]

- Salvadorinho, J.; Teixeira, L. Organizational knowledge in the I4.0 using BPMN: A case study. Procedia Comput. Sci. 2021, 181, 981–988. [Google Scholar] [CrossRef]

- Navarro, A.M.; Sancho, M.P.L.; Garrido, J.A.M. Business process management systems in port processes: A systematic literature review. Int. J. Agil. Syst. Manag. 2020, 13, 258–278. [Google Scholar] [CrossRef]

- Rymaszewska, A. Lean implementation and a process approach—An exploratory study. Benchmarking Int. J. 2017, 24, 1122–1137. [Google Scholar] [CrossRef]

- Mehdouani, K.; Missaoui, N.; Ghannouchi, S.A. An approach for Business Process Improvement Based on Simulation Technique. Procedia Comput. Sci. 2019, 164, 225–232. [Google Scholar] [CrossRef]

- Das, B.; Venkatadri, U.; Pandey, P. Applying lean manufacturing system to improving productivity of airconditioning coil manufacturing. Int. J. Adv. Manuf. Technol. 2013, 71, 307–323. [Google Scholar] [CrossRef]

- Tiwari, P.; Sadeghi, J.K.; Eseonu, C. A sustainable lean production framework with a case implementation: Practice-based view theory. J. Clean. Prod. 2020, 277, 123078. [Google Scholar] [CrossRef]

- Maldonado, M.U.; Leusin, M.E.; Bernardes, T.C.d.A.; Vaz, C.R. Similarities and differences between business process management and lean management. Bus. Process. Manag. J. 2020, 26, 1807–1831. [Google Scholar] [CrossRef]

- Hevner, A.R. A Three Cycle View of Design Science Research. Scand. J. Inf. Syst. 2007, 19, 87–92. [Google Scholar]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Essay in Information Design Science systems. Manag. Inf. Syst. 2004, 28, 75–105. [Google Scholar] [CrossRef]

- Basulo-Ribeiro, J.; Pimentel, C.; Teixeira, L. What is known about smart ports around the world? A benchmarking study. Procedia Comput. Sci. 2024, 232, 1748–1758. [Google Scholar] [CrossRef]

| Process | Description | Limitations |

|---|---|---|

Entry process

|

|

|

Entry process

|

|

|

| Exit process |

|

|

| Critical Components | Explanation |

|---|---|

| Automatic driver identification | Use of a driver identification system, where drivers register and use ID cards or biometrics. |

| Automatic capture of data from equipment entering and leaving terminals |

|

| Schedule verification | The data collected are compared with those contained in the schedule. |

| Integration with TOS | Integration between different information systems: TOS, GAS and AGS. |

| Remote communication for routes/lanes and exception handling | People from the terminal who work remotely to support these activities. |

| # * | Checkpoint | Hardware | Explanation |

|---|---|---|---|

| 1 | Checkpoint 1—1.1. Triage | LPR (license plate recognition)—Vehicle registration number ACCR (automatic container code recognition)—Container license plate Camera context | Identification of the following:

|

| 2 | Checkpoint 1—1.2. Variable message | Information panel | According to the check carried out earlier, the panels indicate whether the driver can proceed to checkpoint 2, or whether he/she should take the public road. In the case of proceeding to checkpoint 2, the driver also receives information on which lane to take (on the left if they have an appointment, on the right if they do not). |

| 3 | Checkpoint 2—2.1. ACCR/ADDR | Information boards Barrier LPR—Front and rear ACCR/ADDR cameras Context cameras | Each lane should have a panel showing whether the lane is operational or not. In addition, each lane will have a first barrier to inhibit access to the lane if it is inoperative or if it is occupied by a vehicle in process. Collect information on the following:

|

| 4 | Checkpoint 2—2.2. Driver validation | Barrier Service kiosk with: Card reader, Biometric reader, Intercom, Touch screen. | This is where the driver is identified, and information is also given about where the driver should go, as follows:

|

| 5 | Checkpoint 3—3.1. Park entry | LPR | Car park entry record. |

| 6 | Checkpoint 3—3.2. Park exit | LPR Information panel | Registration of the vehicle leaving the car park. The vehicle leaving the car park may be travelling to the pre-gate (checkpoint 2) or to the public road. Tell the driver whether he/she can access the gate or must follow the exit route. |

| 7 | Checkpoint 3 | Kiosks | Self-service terminals support drivers in solving problems that have prevented them from entering the terminal. |

| 8 | Checkpoint 4—Access to the container terminal | LPR Barrier | Allows validation of which car is authorized to enter the terminal. |

| KPI | Explanation |

|---|---|

| No. of services not performed (due to inefficiency or unavailability of the terminal operator) | This KPI refers to the number of services that were scheduled but not performed as planned. This can happen due to various factors, such as vehicle breakdowns, delays, scheduling errors, lack of necessary documentation, lack or mismanagement of resources within the terminal, or other operational problems. This indicator is important because non-performed services can lead to delays in the supply chain, customer dissatisfaction, and operational inefficiencies. |

| Average time inside the terminal (time from entering the terminal to leaving) | This measures the average time vehicles spend inside the terminal from the moment they enter until the moment they leave. This time includes processes such as waiting, loading and unloading goods, documentation, and other administrative procedures. A low average time usually indicates an efficient flow and well-managed operations, while a high average time can indicate congestion, inefficient processes, or problems with loading/unloading operations. This KPI is crucial for understanding how to optimize operations and improve the terminal’s overall productivity. |

| No. of appointments vs. No. of no appointments | This measures the percentage of vehicles that arrive on time according to their appointment versus those that arrive without an appointment. This can help users to understand the effectiveness of training in using the scheduling system. |

| Canopy read error rate 1 | This quantifies the failure rate when reading data from the truck/container/galley, which may indicate the need for maintenance or updating of the system. |

| Average time between passing checkpoint 1 and gate IN (gate service time) | This evaluates the average time a truck takes from checkpoint 1 to gate IN, which can help identify bottlenecks and efficiency. |

| Percentage of trucks diverted to checkpoint 3 | This calculates the percentage of trucks that are diverted to checkpoint 3, which may indicate problems with pre-validation or the scheduling system. Subsequent identification of the situation that led the vehicle to checkpoint 3 (causes—software, hardware, scheduling, etc.). |

| Time to resolve contingencies in checkpoint 3 | This measures the time needed to resolve problems that make it impossible for the driver to enter the terminal. |

| Customer/driver satisfaction | This evaluates the level of satisfaction of drivers with the terminal entry process using surveys or feedback. |

| Manual intervention rate | This accounts for the frequency with which manual intervention is required due to faults in the automated system. |

| Peak capacity vs. effective utilization | This compares the maximum number of trucks the terminal can process in a period with the actual number of trucks processed. |

| Intermodal terminal throughput (volume) | This measures the number of cargo units (containers) that pass through the entry/exit gate per unit of time. |

| No. of system response failures (TOS, GOS, GAS, others) | The aim is to quantify the number of failures in information systems for a year and to categorize these failures based on their specific causes (e.g., hardware failures, software errors, network problems, human failures, security issues, etc). |

| Others | Who went out onto the public highway, what controls they went through, and how long they spent inside from checkpoint 1 to checkpoint 4; trying to identify the cause of their exit (at the limit they were validated and decided to leave…). |

| Aspect | AS-IS State | TO-BE State | Benefits of the TO-BE State |

|---|---|---|---|

| Entry process with scheduling | Manual verification of documents and information by gate operators. Limited system integration causing delays and errors. | Automated verification using OCR and integration between systems (TOS, GAS, AGS). | Reduces manual labour, decreases delays, minimizes human error, and improves overall efficiency and accuracy in data handling. |

| Entry process without scheduling | Manual process for access validation, prolonged verification time, and dependence on access cards or signals. | Drivers are directed to a specific location that does not interfere with the entry flow. This measure aims to make the process without an appointment more complex, thus emphasising the advantages of making an appointment in advance and indirectly encouraging drivers to adhere to the appointment. | Reduces delays caused by manual checks, enhances security, and allows for seamless entry without prior scheduling. |

| Exit process | Manual data entry and verification by exit operators; prone to errors and causes queues and delays. | Automated data capture and verification with minimal manual intervention. | Streamlines exit process, reduces errors, and decreases the time needed for trucks to exit, enhancing throughput and efficiency. |

| System integration | Lack of integration between critical systems leading to inconsistencies and delays. | Full integration between all relevant systems (TOS, GAS, AGS) for seamless data flow. | Ensures consistent and reliable data across systems, reducing delays and improving decision-making and operational flow. |

| Security and verification | Reliance on manual checks and signals, which are time-consuming and prone to errors. | Enhanced security with multiple automated checkpoints for driver, vehicle, and cargo validation. | Improves security and reduces unauthorized access, minimizes manual intervention, and speeds up the verification process. |

| Data handling and accuracy | High potential for errors due to manual data entry and lack of real-time data integration. | Real-time data capture and automated processing with integrated systems. | Increases data accuracy, reduces errors, and provides real-time insights for better operational management and decision-making. |

| Operational efficiency | Inefficient processes with significant delays and manual interventions leading to lower productivity. | Streamlined processes with automation at every checkpoint, reducing delays and manual interventions. | Enhances overall terminal efficiency, reduces operational costs, and increases throughput capacity and customer satisfaction. |

| Category | Strategies |

|---|---|

| Overcoming stakeholder resistance |

|

| Integration of new technologies |

|

| Practical applications and use cases |

|

| Addressing human factors |

|

| Policy and regulatory recommendations |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basulo-Ribeiro, J.; Pimentel, C.; Teixeira, L. Digital Transformation in Maritime Ports: Defining Smart Gates through Process Improvement in a Portuguese Container Terminal. Future Internet 2024, 16, 350. https://doi.org/10.3390/fi16100350

Basulo-Ribeiro J, Pimentel C, Teixeira L. Digital Transformation in Maritime Ports: Defining Smart Gates through Process Improvement in a Portuguese Container Terminal. Future Internet. 2024; 16(10):350. https://doi.org/10.3390/fi16100350

Chicago/Turabian StyleBasulo-Ribeiro, Juliana, Carina Pimentel, and Leonor Teixeira. 2024. "Digital Transformation in Maritime Ports: Defining Smart Gates through Process Improvement in a Portuguese Container Terminal" Future Internet 16, no. 10: 350. https://doi.org/10.3390/fi16100350

APA StyleBasulo-Ribeiro, J., Pimentel, C., & Teixeira, L. (2024). Digital Transformation in Maritime Ports: Defining Smart Gates through Process Improvement in a Portuguese Container Terminal. Future Internet, 16(10), 350. https://doi.org/10.3390/fi16100350