Design Technology and AI-Based Decision Making Model for Digital Twin Engineering

Abstract

:1. Introduction

- Generalization of approaches and methods for the modeling and designing of organizational and technical systems’ DT.

- Development of the system model and technology for setting up organizational and technical systems’ DT design process.

- Within the framework of DT model suggestions, development of the decision support model for diagnosing a device’s technical conditions and making decisions to eliminate its malfunctions based on artificial intelligence and fuzzy logic methods.

2. Literature Review

- The development of quantum technologies and the increase in the speed of computing systems [30,31]. If general-purpose quantum computing is ever realized, there would be a qualitative leap in the speed of hardware systems. This will make it possible to perform numerical analyses based on already existing (and more complex) models in a time acceptable for the operational interaction of a physical object and its digital copy. Today, companies are working to develop and use quantum algorithms to model complex physical processes. The transition to such technologies will speed up the solution of problems based on numerical modeling, providing for the required accuracy of algorithms under the conditions of the available computing resources (problems of multi-parameter optimization, etc.);

- The development of 5G and 6G technologies [32,33,34]. These technologies have higher throughput, lower latency, and lower battery consumption of IoT sensors. This provides an increase in the speed of signal transmissions between the physical object and its DT. The use of 5G networks will make it possible to construct virtual reality services as part of digital twins and make available the virtual verification and validation of finished products.

- The development of strong artificial intelligence technology [35,36] will make it possible to build a data center in which the role of a person in making managerial decisions will be minimized. DTs will be able to provide decision making autonomously, coordinate these decisions with other DTs, and perform self-testing and diagnostics with subsequent troubleshooting. Such decision support systems based on digital data will ensure the adoption of complex decisions in aggressive and dangerous environments without the presence of a person.

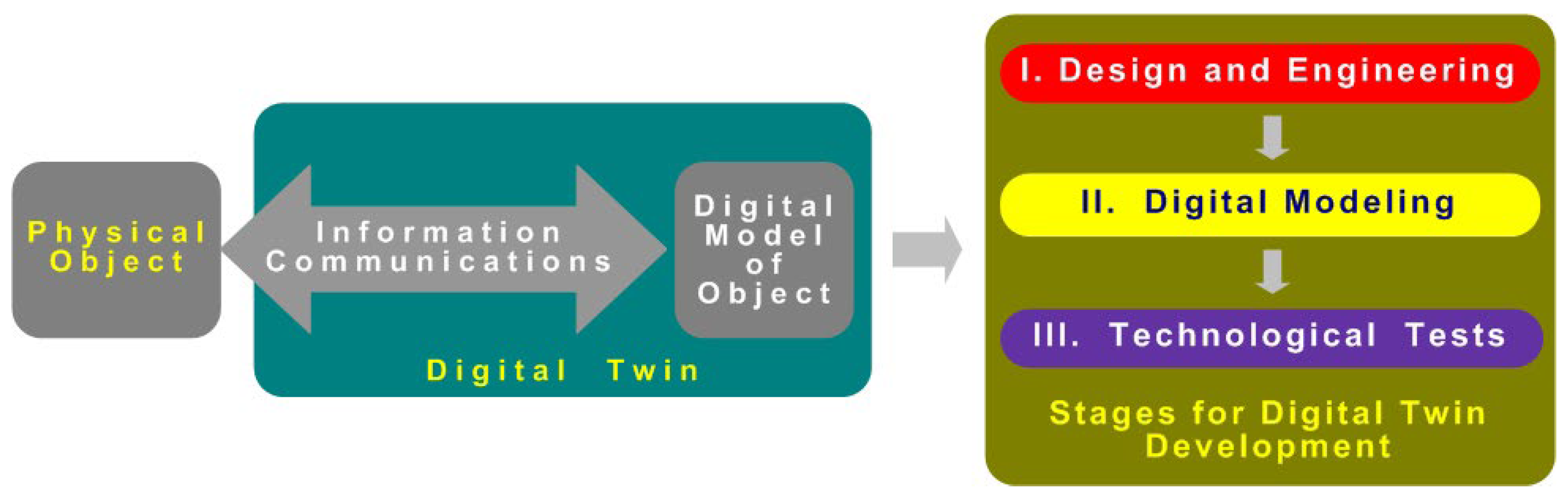

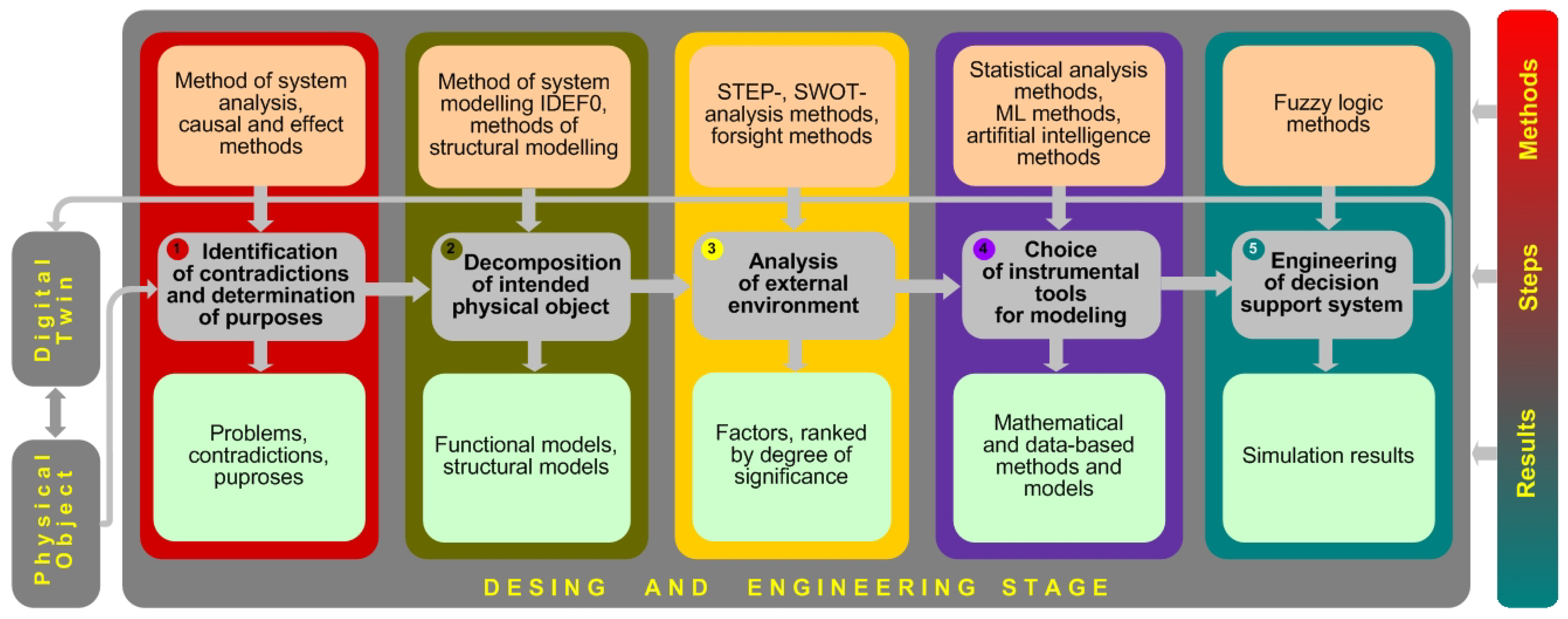

3. Methodology for Systems Engineering and Technology for Digital Twin Design

4. Empirical Results

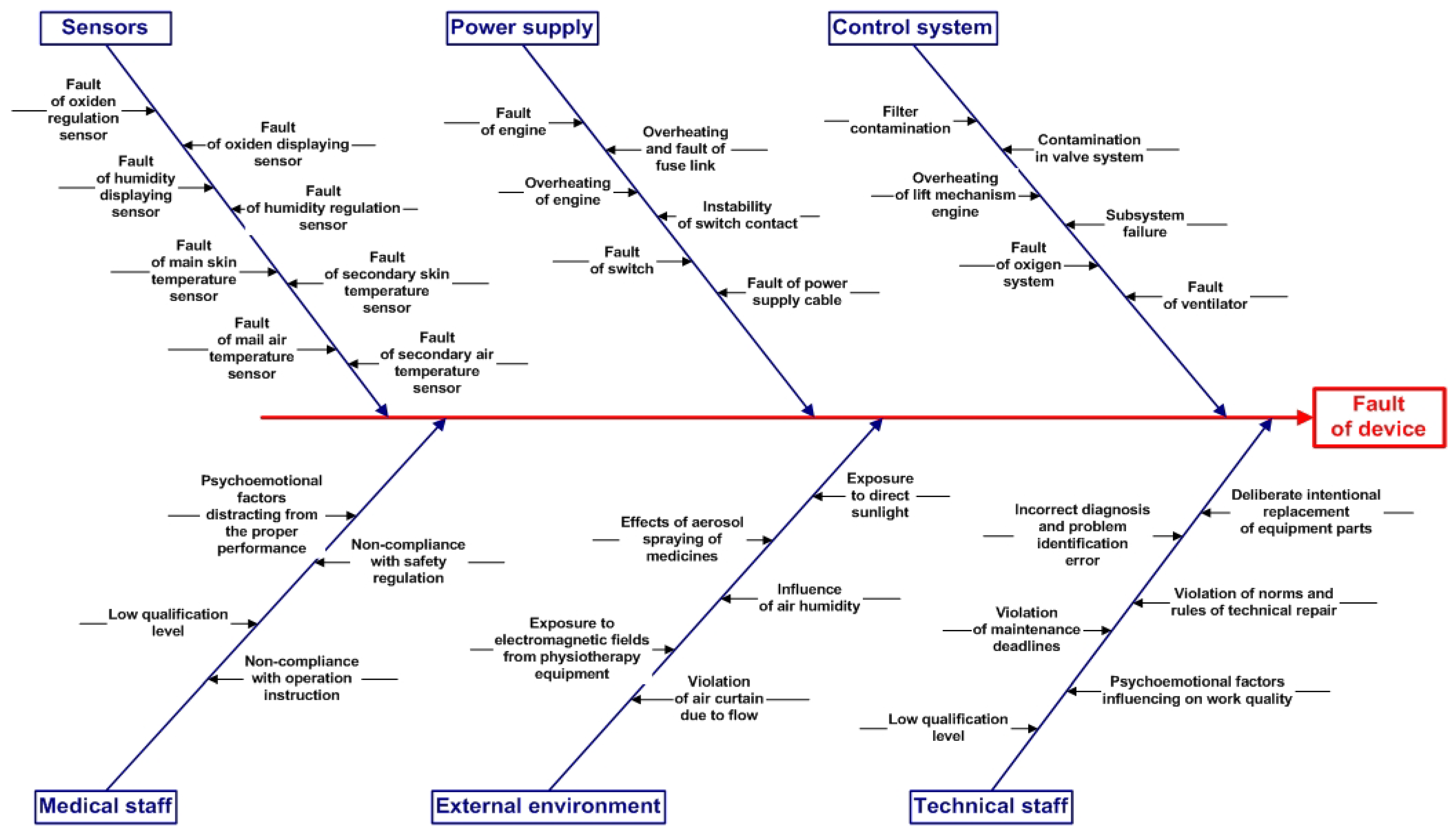

Decision Support Model for Diagnosing the Technical Condition of Equipment Based on Fuzzy Logic Methods

- If (I1 is “possible”) and (I2 is “possible”) and (I3 is “serviceable”) and (I4 is “faulty”) and (I5 is “not turn off”) then (O1 is “to repair”);

- If (I1 is “possible”) and (I2 is “possible”) and (I3 is “serviceable”) and (I4 is “serviceable”) and (I5 is “not turn off”) then (O1 is “to keep in service”);

- If (I7 is “clean) and (I9 is “present”) then (O1 is “to keep in service”);

- If (I11 is “red”) and (I13 is “2”) and (I20 is “low”) and (I21 is “serviceable”) then (O1 is “to repair”);

- If (I20 is “average”) and (I21 is “serviceable”) then (O1 is “to keep in service”);

- If (I11 is “central alarm”) and (I13 is “3”) and (I20 is “medium”) and (I22 is “faulty”) then (O1 is “to repair”);

- If (I23 is “present”) and (I24 is “non removable”) then (O1 is “to take out of service”);

- If (I23 is “missing”) and (I24 is “non recoverable”) then (O1 is “to take out of service”);

- If (I1 is “not possible”) and (I2 is “possible”) and (I3 is “overheating”) and (I4 is “correct”) and (I5 is “shutdown”) then (O1 is “to conduct additional preparation for operation”).

5. Discussion of Results

6. Conclusions

- The technology for organizing systems’ DT design has been proposed. The technology differs from others in that it combines design stages, methods and models, and provides DT accelerated engineering.

- The decision support model for diagnosing the technical condition of a technical device has been developed. The model is based on methods of situational analysis and fuzzy logic, and provides decision making under miscellaneous internal and external factors having a quantitative or qualitative nature. The model increases the accuracy and reliability of a decision support system and provides a synthesis of effective decisions in various situations and combinations of heterogeneous factors. Using observations of the object state, the model identifies, responds to changes and provides a basis for making decisions about future actions.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Erikstad, S.O. Merging Physics, Big Data Analytics and Simulation for the Next-Generation Digital Twins, High-Performance Marine Vehicles. 2017. Available online: https://www,researchgate,net/publication/320196420_Merging_Physics_Big_Data_Anlytics_and_Simulation_for_the_Next-Generation_Digital_Twins (accessed on 13 July 2022).

- Prokhorov, A.; Lysachev, M.; Borovkov, A. Digital Twin, Analysis, Trends, World Experience; LLC Alliance Print: Moscow, Russia, 2020; 401p. [Google Scholar]

- Petrov, A.V. SIMULATION AS THE BASIS OF DIGITAL TWIN TECHNOLOGY. Bull. Irkutsk State Tech. Univ. 2018, 22, 56–66. [Google Scholar]

- Makarov, V.L.; Bakhtizin, A.R.; Beklaryan, G.L. Development of digital twins for manufacturing enterprises. Bus. Inform. 2019, 13, 7–16. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Orlova, E.V. Methodology and Models for Individuals’ Creditworthiness Management Using Digital Footprint Data and Machine Learning Methods. Mathematics 2021, 9, 1820. [Google Scholar] [CrossRef]

- Orlova, E.V. Innovation in Company Labor Productivity Management: Data Science Methods Application. Appl. Syst. Innov. 2021, 4, 68. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Agrawal, A.; Fischer, M.; Singh, V. Digital Twin: From Concept to Practice. J. Manag. Eng. 2022, 38, 06022001. [Google Scholar] [CrossRef]

- AI and ML: The Brave New World of Simulation. 2021. Available online: https://www.ansys.com/blog/ai-and-ml-the-brave-new-world-of-simulation (accessed on 13 July 2022).

- Radanliev, P.; De Roure, D.; Nicolescu, R.; Huth, M.; Santos, O. Digital twins: Artificial intelligence and the IoT cyber-physical systems in Industry 4.0. Int. J. Intell. Robot. Appl. 2022, 6, 171–185. [Google Scholar] [CrossRef]

- Orlova, E.V. Decision-Making Techniques for Credit Resource Management Using Machine Learning and Optimization. Information 2020, 11, 144. [Google Scholar] [CrossRef] [Green Version]

- Orlova, E.V. Methodology and Statistical Modeling of Social Capital Influence on Employees’ Individual Innovativeness in a Company. Mathematics 2022, 10, 1809. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Bilberg, A. Virtual reality in manufacturing: Immersive and collaborative artificial-reality in design of human-robot workspace. Int. J. Comput. Integr. Manuf. 2019, 33, 22–37. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.; Percoco, G.; Urbinati, A. Building a Digital Twin for Additive Manufacturing through the Exploitation of Blockchain: A case analysis of the aircraft industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

- Korostelkin, A.A.; Klyavin, O.I.; Aleshin, M.V. Optimization of Frame Mass in Crash Testing of Off–Road Vehicles. Russ. Eng. Res. 2019, 39, 1021–1028. Available online: https://link.springer.com/article/10.3103/S1068798X19120116 (accessed on 21 June 2022). [CrossRef]

- Fonseca, Í.; Gaspar, H.; Mello, P.; Sasaki, H. A Standards-Based Digital Twin of an Experiment with a Scale Model Ship. Comput. Aided Des. 2022, 145, 103191. [Google Scholar] [CrossRef]

- Siebert, T.; Hack, E.; Labeas, G.; Patterson, E.; Splitthof, K. Uncertainty Quantification for DIC Displacement Measurements in Industrial Environments. Exp. Tech. 2021, 45, 685–694. [Google Scholar] [CrossRef]

- The Advantages of Using Digital Twin Simulations in Aerospace, Challlenge Advisory. January 2019. Available online: https://www.challenge.org/insights/digital-twin-inaerospace/ (accessed on 21 June 2022).

- Patterson, E.; Diamantakos, I.; Dvurecenska, K.; Greene, R.; Hack, E.; Labeas, G.; Lomnitz, M.; Siebert, T. Validation of a structural model of an aircraft cockpit panel: An industrial case study. J. Strain Anal. Eng. Des. 2021, 2021, 030932472110590. [Google Scholar] [CrossRef]

- Zborowski, M. Finding Meaning, Application for the Much-Discussed “Digital Twin”. J. Pet. Technol. 2018, 70, 26–32. [Google Scholar] [CrossRef]

- Digital Twins vs. Building Information Modeling (BIM). 2019. Available online: https://www.iotforall.com/digital-twin-vs-bim/ (accessed on 21 June 2022).

- Bruynseels, K.; Santoni de Sio, F.; Van Den Hoven, J. Digital Twins in Health Care: Ethical Implications of an Emerging Engineering Paradigm. Front. Genet. 2018, 9, 31. [Google Scholar] [CrossRef]

- Miskinis, C. Disrupting the Financial and Banking Services Using Digital Twins. 2021. Available online: https://www.challenge.org/insights/digital-twin-for-finance/ (accessed on 13 July 2022).

- Kümpel, M.; Mueller, C.; Beetz, M. Semantic Digital Twins for Retail Logistics. In Dynamics in Logistic; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Matyi, H.; Tamás, P. Digital Twin Technology in Logistics Literature Review. Cut. Tools Technol. Syst. 2021, 95, 13–21. [Google Scholar] [CrossRef]

- Ivanov, S.; Nikolskaia, K.; Radchenko, G.; Sokolinsky, L.; Zymbler, M. Digital Twin of City: Concept Overview. In Proceedings of the 2020 Global Smart Industry Conference (GloSIC), Virtual Event, 17–19 November 2020; pp. 178–186. [Google Scholar] [CrossRef]

- Dembski, F.; Wössner, U.; Letzgus, M.; Ruddat, M.; Yamu, C. Urban Digital Twins for Smart Cities and Citizens: The Case Study of Herrenberg, Germany. Sustainability 2020, 12, 2307. [Google Scholar] [CrossRef] [Green Version]

- Lucas, A. Ising formulations of many NP problems. Front. Phys. 2014, 2014, 5. [Google Scholar] [CrossRef] [Green Version]

- Nembrini, R.; Ferrari, D.M.; Cremonesi, P. Feature Selection for Recommender Systems with Quantum Computing. Entropy 2021, 23, 970. [Google Scholar] [CrossRef] [PubMed]

- Giordani, M.; Polese, M.; Mezzavilla, M.; Rangan, S.; Zorzi, M. Toward 6G networks: Use cases and technologies. IEEE Commun. Mag. 2020, 58, 55–61. [Google Scholar] [CrossRef]

- Allawi, Y.M.; Mohammed, A.F.Y.; Lee, J.; Choi, S.G. A Sustainable Business Model for a Neutral Host Supporting 5G and beyond (5GB) Ultra-Dense Networks: Challenges, Directions, and Architecture. Sensors 2022, 22, 5215. [Google Scholar] [CrossRef]

- Papidas, A.G.; Polyzos, G.C. Self-Organizing Networks for 5G and Beyond: A View from the Top. Future Internet 2022, 14, 95. [Google Scholar] [CrossRef]

- Martínez-García, A.N. Artificial Intelligence for Sustainable Complex Socio-Technical-Economic Ecosystems. Computation 2022, 10, 95. [Google Scholar] [CrossRef]

- Kim, D.; Jo, D. Effects on Co-Presence of a Virtual Human: A Comparison of Display and Interaction Types. Electronics 2022, 11, 367. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating Unpredictable, undesirable emergent behavior in complex systems. In Trans-Disciplinary Perspectives on System Complexity; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 85–114. [Google Scholar]

- Intensive Care Incubator for Newborns IDN-03. Operation Manual. Available online: https://www.xn--g1ajft.xn--p1ai/en/production/medicina/neonatalnaya/idn-03 (accessed on 1 August 2022).

- Zadeh, L.A. Fuzzy Sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Wenjie, J.; Wang, W.; Zhang, Z. From simple digital twin to complex digital twin Part I: A novel modeling method for multi-scale and multi-scenario digital twin. Adv. Eng. Inform. 2022, 53, 101706. [Google Scholar] [CrossRef]

- Nelles, O. Fuzzy and Neuro-Fuzzy Models. In Nonlinear System Identification; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

| Feature | Modeling Approach | ||

|---|---|---|---|

| Mathematical Modeling | Data-Based Modeling | Hybrid Modeling | |

| Object (system) description | Describes the laws of functioning of an object (process) and its connection with the external environment. The system behavior is modeled, causal relationships and patterns are identified. | It is built on the basis of available empirical data using machine learning tools. The modeling problem is reduced to model parameters selection and some function composition | It is built on the basis of the functioning regularities and is adjusted with empirical data |

| Modeling principle | White box model, cause-and-effect modeling | Black box model, correlation modeling | The gray box model |

| Simulation and design direction | Top down | Bottom up | Top down, bottom up |

| Description of information certainty | Information uncertainty is controlled by input data and accuracy of modeling. Description—deterministic, stochastic | Probabilistic description of information based on data distributions in training samples | Deterministic, stochastic |

| Modeling methods | Numerical methods, methods of operations research, methods of simulation and situational modeling | Statistical methods, extrapolation methods, machine learning methods, big data analytics methods | Interdisciplinary models |

| Predictive capability | Prediction in wide ranges of parameter values described by the model | Difficulty in predicting rare events as well as in conditions of incomplete data and noisy information, as well as outside of training samples | High predictive ability within regular/ emergency situations |

| Priority approach to decision making and management | Decision making is based on an analysis of the overall performance (efficiency) of the system. Management decisions based on the solution of inverse problems | Decision making is based on the analysis of monitoring data and diagnostics. Management decisions are based on prediction and the solving of direct problems | Solving both direct and inverse control problems |

| Type of control system | Deviation control, adaptive control | Deviation control, adaptive control | Deviation control taking into account weak environmental signals; reflective control |

| System life cycle stage | All stages | Exploitation | Growth, stability |

| Operation scheme | Numerical simulation + sensors→ Data acquisition→IIoT platform | Sensors + IIoT platform→ data collection→data analytics | Mathematical Modeling + Sensors→ Data Acquisition→ IIoT-platform→analytics |

| Tools | Matlab Simulink, ANSYS, AnyLogic, Ithink etc. | R, Python, Statictica. GPSS etc. | Interdisciplinary Platforms |

| Indicator | Description | Values |

|---|---|---|

| Input variables | ||

| I1 | Adjusting height position of the baby unit | Impossible, possible |

| I2 | Adjusting oblique position of the baby unit | Impossible, possible |

| I3 | Baby module engine | Fault, overheat, serviceable |

| I4 | Baby unit switch mechanism | Fault, correct |

| I5 | Position height mechanism of the baby module | Turns off, does not turn off |

| I6 | Air temperature under the hood | Low, normal, high |

| I7 | Filter | Dirty, clean |

| I8 | Filter installation time | More than three months, less than three months |

| I9 | Water in the tank of the humidifying system | Absent, present |

| I10 | Valve system | Dirty, clean |

| I11 | Indicator | Red, network, flicker |

| I12 | Power cable | Not attached, attached |

| I13 | Sound signal | 3, 2, intermittent, continuous |

| I14 | Fan impeller | Installed wrong, installed correctly |

| I15 | Fan | Faulty, correct |

| I16 | Display humidity sensor | Faulty, correct |

| I17 | Regulating humidity sensor | Faulty, correct |

| I18 | Main skin temperature sensor | Fault, serviceable, not connected, connected |

| I19 | Secondary skin temperature sensor | Fault, serviceable, not connected, connected |

| I20 | Air oxygen concentration | Low, medium, high |

| I21 | Oxygen connection system | Fault, correct |

| I22 | Control system | Fault, good |

| I23 | Obsolescence | Absent, present |

| I24 | Physical deterioration | Not removable, removable |

| I25 | Fusible link | Burnt out, not burned out |

| Output variable | ||

| O1 | Technical condition and operation with device | To take out of service, to repair, to conduct additional preparation for operation, to keep in service |

| Indicator | Qualitative Meaning | Range of Linguistic Values |

|---|---|---|

| I1, I2, I4, I5, I7, I8, I9, I10, I12, I14, I15, I16, I17, I21, I22, I23, I25 | “Impossible”, “Faulty”, “Not turn off”, “Dirty”, “More than 3 months old”, “Missing”, “Not connected”, “Installed incorrectly”, “Cannot be repaired” | (0; 0.35; 0.7) |

| I1, I2, I4, I5, I7, I8, I9, I10, I12, I14, I15, I16, I17, I21, I22, I23, I25 | “Possible”, “Serviceable”, “Disconnecting”, “Clean”, “Less than 3 Months”, “Present”, “Attached”, “Installed Properly”, “Retiring” | (0.4; 0.7; 1) |

| I3, I6, I11, I20. | “Low”, “Red”, “Low”, “Fault” | (0; 0.2; 0.4) |

| I3, I6, I11, I20 | “Normal”, “Network”, “Medium”, “Overheat” | (0.3; 0.5; 0.7) |

| I3, I6, I11, I20 | “Increased”, “High”, “Central alarm”, “Serviceability” | (0.6; 0.8; 1) |

| I13, I18, I19, O1 | “Take it out of service”, “Not operating” | (0; 0.175; 0.35) |

| I13, I18, I19, O1 | “Repair”, “Serviceable” | (0.2; 0.375; 0.55) |

| I13, I18, I19, O1 | “Intermittent”, “Perform additional preparation for operation”, “Not connected” | (0.4; 0.575; 0.75) |

| I13, I18, I19, O1 | “Continuous”, “Keep in service”, “Connected”, | (0.65; 0.825; 1) |

| Situation 1: If Indicator is “Network” and Sound Signal is “Continuous” and… | Input Variables | Output Variable O1 | ||||

|---|---|---|---|---|---|---|

| I11 | I13 | I12 | I25 | Others | ||

| 1-1. Power cable is “not connected” | 0.5 | 0.8 | 0.2 | 0.7 | 0.7 | 0.59 |

| 1-2. Power cable is “connected” | 0.5 | 0.8 | 0.8 | 0.8 | 0.7 | 0.92 |

| 1-3. Fusible link is “burnt out” | 0.5 | 0.8 | 0.1 | 0.35 | 0.7 | 0.376 |

| 1-4. Fusible link is “not burnt out” | 0.5 | 0.8 | 0.9 | 0.2 | 0.7 | 0.95 |

| Situation 2: If Indicator is “Flicker” and Sound Signal is “3” and… | Input Variables | Output Variable O1 | ||||

|---|---|---|---|---|---|---|

| I11 | I13 | I12 | I25 | Others | ||

| 2-1. Main skin temperature sensor is “not connected”, secondary skin temperature sensor is “connected” | 0.1 | 0.3 | 0.5 | 0.8 | 0.6 | 0.74 |

| 2-2. Main skin temperature sensor is “connected”, secondary skin temperature sensor is “not connected” | 0.1 | 0.3 | 0.9 | 0.6 | 0.6 | 0.65 |

| 2-3. Main skin temperature sensor is “not connected”, secondary skin temperature sensor is “not connected” | 0.1 | 0.3 | 0.7 | 0.55 | 0.6 | 0.574 |

| 2-4. Main skin temperature sensor is “fault”, secondary skin temperature sensor is “fault” | 0.1 | 0.3 | 0.1 | 0.2 | 0.6 | 0.454 |

| 2-5. Main skin temperature sensor is “serviceable”, secondary skin temperature sensor is “fault” | 0.1 | 0.3 | 0.35 | 0.1 | 0.6 | 0.89 |

| 2-6. Main skin temperature sensor is “fault”, secondary skin temperature sensor is “serviceable” | 0.1 | 0.3 | 0.3 | 0.4 | 0.6 | 0.95 |

| Situation 3: Baby Module Does not Function | Input Variables | Output Variable O1 | |||||

|---|---|---|---|---|---|---|---|

| I1 | I2 | I3 | I4 | I5 | Others | ||

| 3-1. Position height mechanism of the baby module is “not turn off”, baby unit switch mechanism is “fault”, baby module engine is “serviceable” | 1 | 1 | 0.7 | 0.2 | 0.4 | 0.5 | 0.464 |

| 3-2. Position height mechanism of the baby module is “not turn off”, baby unit switch mechanism is “correct”, baby module engine is “fault” | 1 | 1 | 0.1 | 0.7 | 0.3 | 0.5 | 0.52 |

| 3-3. Position height mechanism of the baby module is “not turn off”, baby unit switch mechanism is “fault”, baby module engine is “fault” | 1 | 1 | 0.3 | 0.5 | 0.2 | 0.5 | 0.34 |

| 3-4. Adjusting the height position of the baby unit is “impossible”, baby module engine is “overheat” | 0.25 | 1 | 0.5 | 0.9 | 1 | 0.5 | 0.62 |

| 3-5. Adjusting the height position of the baby unit is “impossible”, baby module engine is “fault” | 0.3 | 1 | 0.1 | 0.9 | 1 | 0.5 | 0.376 |

| 3-6. Adjusting the height position of the baby unit is “impossible”, baby module engine is “serviceable” | 0.1 | 1 | 0.8 | 0.9 | 1 | 0.5 | 0.75 |

| 3-7. Adjusting oblique position of the baby unit is “impossible”, baby module engine is “fault” | 1 | 0.5 | 0.2 | 1 | 0.8 | 0.5 | 0.45 |

| 3-8. Adjusting oblique position of the baby unit is “impossible”, baby module engine is “overheat” | 1 | 0.2 | 0.6 | 1 | 0.8 | 0.5 | 0.68 |

| 3-9. Adjusting oblique position of the baby unit is “impossible”, baby module engine is “serviceable” | 1 | 0.6 | 0.9 | 1 | 0.8 | 0.5 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orlova, E.V. Design Technology and AI-Based Decision Making Model for Digital Twin Engineering. Future Internet 2022, 14, 248. https://doi.org/10.3390/fi14090248

Orlova EV. Design Technology and AI-Based Decision Making Model for Digital Twin Engineering. Future Internet. 2022; 14(9):248. https://doi.org/10.3390/fi14090248

Chicago/Turabian StyleOrlova, Ekaterina V. 2022. "Design Technology and AI-Based Decision Making Model for Digital Twin Engineering" Future Internet 14, no. 9: 248. https://doi.org/10.3390/fi14090248

APA StyleOrlova, E. V. (2022). Design Technology and AI-Based Decision Making Model for Digital Twin Engineering. Future Internet, 14(9), 248. https://doi.org/10.3390/fi14090248